Professional Documents

Culture Documents

Electro-Pneumatic Positioner EPL Series: Instruction Manual

Electro-Pneumatic Positioner EPL Series: Instruction Manual

Uploaded by

Simbu ArasanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electro-Pneumatic Positioner EPL Series: Instruction Manual

Electro-Pneumatic Positioner EPL Series: Instruction Manual

Uploaded by

Simbu ArasanCopyright:

Available Formats

99.66.

02-C

GB

Electro-Pneumatic Positioner EPL Series

Instruction Manual

Clorius Controls A/S 2

Electro-Pneumatic Positioner EPL Series

1. Read all safety instructions in this manual carefully before using this EPL positioner. All

work should be done by staff with the necessary training and experience.

2. The air filter regulator should be installed before this EPL positioner.

3. The EPL positioned approved for ATEX Eex md IIB T5 must be connected to a fuse with

the following ratings:

- Max 125mA, breaking capacity 35A

- Suitable 1/2 PF threaded, certified EEx d cable glands and plugs must be used.

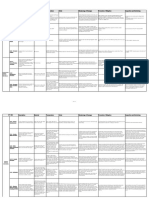

1. Part Number System

EPL

Protection

Class

Feedback

Lever

Pressure

Gauge

(SUP.

OUT)

Pilot

Valve

Orifice

Position

Feedback

Connection

Threads

High

Temp

Mounting

Bracket

Description Code Description Code

Protection

Class:

Feedback

Lever:

Pressure

Gauge:

Pilot Valve

Orifice:

F: Flameproof Ex md IIB T6

D: Flameproof Ex md IIC T6

A: Flameproof

Eex md IIB T5 ATEX

I: Intrinsic safety (Ex ia IIB T6)

W: Weatherproof to IP66

A: stroke (10~40mm)

B: stroke (10~80mm)

C: stroke (80~150mm)

1: 6 bar (90 psi)

2: 10 bar (150 psi)

S: Standard

(actuator volume over 180)

M: Small orifice (1.0 or 0.7)

(actuator volume 90~180 )

Position

Feedback:

(only for

weatherproof

type)

Connection

Threads:

(pneumatic

electrical)

High

Temperature:

(only for

weatherproof

type)

Mounting

Bracket:

N: None (standard)

O: Position transmitter

(4~20mA output signal)

3: PT 1/4 PT 1/2 (standard)

4: NPT 1/4 NPT 1/2

5: PT 1/4 M20 x 1.5

T: 70 (standard)

H: 120

(without position feedback option)

85

(with position feedback option)

N: None

L: For DIN / IEC 534

2. Specifications

EPL

Linear Type (Lever Feedback)

Single Double

Input Signal 4~20mA DC (Note. 1)

Input Resistance 235 15

Air Supply Max. 7.0bar (100psi) free of oil, water, and moisture

Standard Stroke 10~80mm (Note. 2)

Pneumatic Connections Rc 1/4 (NPT 1/4)

Electrical Connections Rc 1/2 (NPT 1/2)

Protection Class

Ex md IIB T6, Ex md IIC(H2) T6, IP66, Ex ia IIB T6

Eex md IIB T5 ATEX

Ambient Temperature -20~70

Clorius Controls A/S 3

Electro-Pneumatic Positioner EPL Series

Pressure Gauge Stainless Steel

Output Characteristics Linear

Linearity Within 1.0 % F.S Within 1.5 % F.S

Sensitivity Within 0.2 % F.S Within 0.5 % F.S

Hysteresis Within 1.0 % F.S

Repeatability Within 0.5 % F.S

Air Consumption 5 LPM (Sup. 1.4kgf/)

Flow Capacity 80 LPM (Sup. 1.4kgf/)

Material Aluminum Die-cast

Weight 2.9 kg (with terminal box)

Note: 1) 1/2 spilt range is available for 4-12mA input signal or 12-20mA input signal.

2) Operating stroke can be extended up to 80~150mm.

3. Mounting and Selecting RA (reverse acting) or DA (direct

acting)

CAUTION: To reduce the risk of ignition of hazardous atmospheres, disconnect the device

from the supply circuit before opening. Keep assembly tightly closed during

operation.

A. Mounting and Attaching Feedback Lever

_ Mount the EPL positioner to the control valve as shown

to the right.

_ Fix the EPL positioner and the feedback lever to the control

valve stem at position where the angle between the valve

stem is settled to 90 degrees as shown below when the input

signal is set to 12mA (50%). Be sure that the elimination

spring should be installed.

_ The feedback lever A is for stroke 1040mm and the

feedback lever B is for stroke 10~80mm. For up to stroke

150mm, please connect a feedback lever A and a feedback

ever B with each other. The operation angle of the EPL

positioner is minimum 10 q and maximum 30 q .

Connect the feedback lever and the enclosed additional feedback lever with each other for a

stroke extension of over 80mm.

[Elimination Spring Installation]

B. Position of Span Adjuster According to Actuator Type (RA or DA)

Span adjuster is set to RA (reverse acting) as a standard factory setting. But it is necessary to re-set its position

for DA (direct acting) as shown below.

WARNING: When adjusting or replacing a span adjuster, be sure to shut off air supply to

the EPL positioner. Otherwise, the EPL positioner might react suddenly and

cause damage or injury.

Direct Acting (DA) Reverse Acting (RA)

Clorius Controls A/S 4

Electro-Pneumatic Positioner EPL Series

4. Air Connections

5. Internal View

Never move the seat adjuster. It was already set at the factory precisely.

Output pressure gauge

Zero adjusting screw

Supply pressure gauge

Terminal box

Torque motor Case

Feedback lever

Nozzle

Span adjusting screw

Pilot valve

Seat adjuster

Stopper screw

Auto/Manual screw

Clorius Controls A/S 5

Electro-Pneumatic Positioner EPL Series

6. Span and Zero Adjustment

_ Check the proper installation of the EPL positioner and the feedback lever.

_ Check the proper position of a span adjuster according to the actuator type (direct acting or reverse acting).

_ Connect all air connections.

_ Supply air and set the input signal to 4mA. Turn the zero adjusting screw clockwise or counter clockwise to set the

zero position.

_ Check the stroke of the control valve by setting the input signal to 20mA. If the stroke does not meet 100%, turn the

span adjusting screw clockwise or counter clockwise until 100% is reached.

_ Set the input signal back to 4mA and adjust the zero adjusting screw until the zero point is reached.

_ Repeat the process of _ to _ until the desired set points are reached.

_ If the strokes of the control valve perfectly meet 0% and 100%, each setting point of 8, 12, and 16mA is

automatically reached.

NOTE: Due to variations in circuitry and environmental effects, often 0% is set at 4.5mA and

100% at 19.5mA to make sure that at the end points the valve will be fully open or

fully closed.

7. Wire Diagrams

CAUTION: Always check that the electrical load is within the range stated on the nameplate.

Failure to remain within electrical ratings may result in damage to or premature

failure of the electrical switches, sensors or transmitter electronics.

NOTE: For the ATEX-approved product, please connect a fuse with the ratings of Max.

125mA, breaking capacity 35A and suitable 1/2 PF threaded certified EEx d cable

glands and plugs must be used.

Clorius Controls A/S 6

Electro-Pneumatic Positioner EPL Series

B. Specifications

Power Supply Rating 5.5~30V DC loop-powered

Recommended Power Supply 24V DC

Output Signal 4~20mA

Operating Temperature -20 to 70

Load Impedance 0~600 ohms

Max. Output 30mA DC

Linearity 1.0 %

Hysteresis 1.0 % of full scale

Repeatability 0.5 % of full scale

Adjustment Zero and Span in terminal box

C. With mA loop calibrator D. With multimeter tester

E. Span and Zero Adjustment

_ Select RA or DA on a board in the terminal box. For reference, RA (reverse acting) is a standard factory setting.

_ Supply 4mA input signal and turn the zero adjusting screw on a board clockwise or counter clockwise until output signal

becomes 4mA.

_ Supply 20mA input signal and turn the span adjusting screw on a board clockwise or counter clockwise until output

signal becomes 20mA.

_ Repeat the process of _ to _ until output signal approaches input signal.

1. Be sure that Span and Zero of the EPL positioner should be exactly set before

setting Span and Zero of the position transmitter.

2. Be sure that 5.5 - 30VDC should be supplied in case of using the mA tester

(multimeter tester).

3. Check a loop power if the output power indicating lamp is not on.

9. Optional Restricted Pilot Valve Orifice

WARNING: Before removing the pilot valve, be sure to

disconnect the EPL positioner from the signal and

compressed air source

For improved control using smaller actuators, a restricted pilot valve orifice kit is

included with the EPL positioner. To install, the pilot valve must be removed from the

EPL positioner. Remove four screws holding the pilot valve to the EPl positioner

body. As you remove the pilot valve, be sure to hold the compensation spring in

place. Flip the valve so the bottom faces you. Remove the o-rings from the out 1

and out 2 ports (as shown in the diagram at right). Place the orifice plates in their

place with new O-rings above them, and re-install the pilot valve, making sure the

compensation spring is back in place. The EPL positioner is now set up for smaller actuators.

8. Position Transmitter (420mA output signal)

A. Board View

Clorius Controls A/S 7

Electro-Pneumatic Positioner EPL Series

There happens a hunting with a

small pneumatic actuator

Install two orifices at the bottom of the pilot valve as instructed in 12.

Optional Restricted Pilot Valve Orifice

The valve always opens

regardless of input signal.

The orifice of the Auto/Manual screw on the pilot valve is clogged.

Disconnect supply air and clean the orifice with a wire attached inside of

the EPL positioner cover as shown below.

Never move the seat adjuster. It was already set at the factory

precisely.

The valve always opens or

closes with input signal

The air connections are not made properly. Check again if the pneumatic

actuator type is RA (reverse acting) or DA (direct acting) and make the

proper air connections. See 7. Air Connections.

Linearity is very poor Re-set Zero and Span.

Hysteresis is very poor Tighten a mounting bracket.

11. Dimensions

10. Troubleshooting Tips

Troubles Solutions

Clorius Controls A/S

Tempovej 27

DK-2750 Ballerup

Denmark

Tel.: +45 77 32 31 30

Fax: +45 77 32 31 31

www.cloriuscontrols.com

Clorius Controls A/S

Tempovej 27

DK-2750 Ballerup

Denmark

Tel.: +45 77 32 31 30

Fax: +45 77 32 31 31

www.cloriuscontrols.com

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- NR 13 EnglishDocument37 pagesNR 13 Englishjeffreymacasero100% (1)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- PG42CB00E Rev 001Document191 pagesPG42CB00E Rev 001al100% (2)

- Electric Motor Maintenance and Troubleshooting, 2nd EditionFrom EverandElectric Motor Maintenance and Troubleshooting, 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Installation Instructions - 4.5" Murphy LevelGaugeDocument4 pagesInstallation Instructions - 4.5" Murphy LevelGaugebmdickeyNo ratings yet

- 2008CoxPaper - The Benefits of Online DGA Tap Changer MonitoringDocument6 pages2008CoxPaper - The Benefits of Online DGA Tap Changer Monitoringlbk50No ratings yet

- TIAPortalOpennessenUS en USDocument278 pagesTIAPortalOpennessenUS en USrmorenodx4587No ratings yet

- Part XIDocument47 pagesPart XIDr. S.No ratings yet

- Application Guide Safe BarrierDocument19 pagesApplication Guide Safe BarriernoljacNo ratings yet

- Melcor - Thermoelectric HandbookDocument16 pagesMelcor - Thermoelectric Handbookmelfer60% (5)

- Chapter 14 Sucker Rod Pumping - 1987 - Developments in Petroleum ScienceDocument104 pagesChapter 14 Sucker Rod Pumping - 1987 - Developments in Petroleum ScienceFalokid Rabo100% (1)

- Ecas 4 PDFDocument66 pagesEcas 4 PDFCarolina83% (6)

- A16 A17 CylinderDocument7 pagesA16 A17 Cylinderjaneesh RNo ratings yet

- Designed For Use With ILP, IHP Automatic Suppression Unit: Pressure SwitchesDocument2 pagesDesigned For Use With ILP, IHP Automatic Suppression Unit: Pressure SwitchesJohan Villarreal100% (1)

- MEMOBUS/Modbus Communications: YASKAWA ELECTRIC SIEP C710606 10A YASKAWA AC Drive - V1000 PRELIM. Programming Manual 259Document26 pagesMEMOBUS/Modbus Communications: YASKAWA ELECTRIC SIEP C710606 10A YASKAWA AC Drive - V1000 PRELIM. Programming Manual 259papal_leguasNo ratings yet

- Devive Function NumbersDocument10 pagesDevive Function NumbersSherleanne PintoNo ratings yet

- Simply ModbusDocument5 pagesSimply Modbuskanna22sg100% (1)

- Control Devices PDFDocument24 pagesControl Devices PDFjonnymarin23No ratings yet

- DC MotorsDocument216 pagesDC Motorsdin_thorpe3248No ratings yet

- Wago LinuxDocument248 pagesWago LinuxBOsy Ying LoNo ratings yet

- 1756 ControlLogix SystemDocument40 pages1756 ControlLogix Systemlucasengcps100% (1)

- Norgren Catalouge PDFDocument22 pagesNorgren Catalouge PDFjaydee45No ratings yet

- Sub ControlDocument4 pagesSub ControlAndres CavazosNo ratings yet

- Cpd1702f10s1 Servo Drive Berger Lahr ManualDocument8 pagesCpd1702f10s1 Servo Drive Berger Lahr Manual1piotr1No ratings yet

- MicroLogix 1400 Programmable Controllers PDFDocument42 pagesMicroLogix 1400 Programmable Controllers PDFPablo ToscanoNo ratings yet

- Unit 35 Portfolio Answer 2018Document22 pagesUnit 35 Portfolio Answer 2018Hatem HusseinNo ratings yet

- Gxworks 2 Simple ProjectDocument106 pagesGxworks 2 Simple ProjectRobinson Velasco NavalesNo ratings yet

- Operation and Application of PLC With Ladder DiagramDocument9 pagesOperation and Application of PLC With Ladder DiagramYuva Raj50% (2)

- Logo System Manual en-US en-USDocument344 pagesLogo System Manual en-US en-USglanchezNo ratings yet

- AC Motor Control Circuits - WorksheetDocument22 pagesAC Motor Control Circuits - WorksheetAbhishek RoyNo ratings yet

- P-Link Module PE-link Module: User'S ManualDocument61 pagesP-Link Module PE-link Module: User'S ManualNgọc Nguyễn ThanhNo ratings yet

- LVDT Displacement SensorsDocument8 pagesLVDT Displacement SensorslelixNo ratings yet

- Three Phase DIN-Rail Digital Energy Meter Model:SDE430-C 1000ADocument3 pagesThree Phase DIN-Rail Digital Energy Meter Model:SDE430-C 1000AOmar Farhat100% (1)

- 5 PLC PDFDocument31 pages5 PLC PDFshihabNo ratings yet

- ELFA SiemensDocument23 pagesELFA SiemensHERNANDO A BECERRA100% (1)

- Delta B Drive Short Manual PDFDocument32 pagesDelta B Drive Short Manual PDFAshok SahuNo ratings yet

- Variable Speed Drive - IntroductionDocument6 pagesVariable Speed Drive - Introductionawhk2006No ratings yet

- PLC Based Inspection, Packaging and Storing of MaterialsDocument5 pagesPLC Based Inspection, Packaging and Storing of MaterialsAlauddin khanNo ratings yet

- Ac Crane ControlDocument28 pagesAc Crane ControlErc Nunez VNo ratings yet

- Vacon NX OPTC2 C8 Modbus N2 Board User Manual DPD0Document42 pagesVacon NX OPTC2 C8 Modbus N2 Board User Manual DPD0TanuTiganuNo ratings yet

- HB2 - HB4 Generator ManualDocument28 pagesHB2 - HB4 Generator ManualVladimir Illich Pinzon BallenNo ratings yet

- News Eplan en UsDocument208 pagesNews Eplan en UsNguyen Duc TrungNo ratings yet

- 3G3JXDocument8 pages3G3JXrwciriloNo ratings yet

- Panasonic FPWIN ManualDocument317 pagesPanasonic FPWIN Manualelkin mezaNo ratings yet

- Utilization of Repetitive Surge Oscillograph (RSO)Document27 pagesUtilization of Repetitive Surge Oscillograph (RSO)Aitzaz HussainNo ratings yet

- Electrical Safety OffshoreDocument2 pagesElectrical Safety Offshorerw992049No ratings yet

- Mechanical Drives 1 Lap 2Document81 pagesMechanical Drives 1 Lap 2j.bbarnesNo ratings yet

- Study of Variable Frequency Drive Using Pulse Width ModulationDocument3 pagesStudy of Variable Frequency Drive Using Pulse Width ModulationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 0702 Pnuematic Component Symbols - ASCO PDFDocument2 pages0702 Pnuematic Component Symbols - ASCO PDFShilpa Kamath100% (1)

- 5030 Legacy Pid ControllerDocument2 pages5030 Legacy Pid ControllerVikrant1No ratings yet

- Advanced Instrumentation Solutions Crafted With Highest PrecisionDocument6 pagesAdvanced Instrumentation Solutions Crafted With Highest PrecisionSandeep K Tiwari0% (1)

- AC Motor Control PDFDocument4 pagesAC Motor Control PDFkryptNo ratings yet

- Design of VFD Drive For AC MotorDocument8 pagesDesign of VFD Drive For AC MotorralphholingsheadNo ratings yet

- Programmable Logic Controllers A Complete Guide - 2020 EditionFrom EverandProgrammable Logic Controllers A Complete Guide - 2020 EditionNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- PLC programmable logic controller A Clear and Concise ReferenceFrom EverandPLC programmable logic controller A Clear and Concise ReferenceNo ratings yet

- OPES2024 Brochure V7Document12 pagesOPES2024 Brochure V7Simbu ArasanNo ratings yet

- PDO Bus TemplateDocument3 pagesPDO Bus TemplateSimbu ArasanNo ratings yet

- 003 - Standard Procedure For Coating and WrappingDocument6 pages003 - Standard Procedure For Coating and WrappingSimbu ArasanNo ratings yet

- DN-1672-PO-029298 (SLA 4) - 04 NOS (With 28 Days Report)Document1 pageDN-1672-PO-029298 (SLA 4) - 04 NOS (With 28 Days Report)Simbu ArasanNo ratings yet

- Mitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateDocument4 pagesMitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateSimbu ArasanNo ratings yet

- TWI Welding Training 4Document36 pagesTWI Welding Training 4Simbu Arasan100% (1)

- My Desk: Time Is GoldDocument22 pagesMy Desk: Time Is GoldSimbu ArasanNo ratings yet

- 004 - Standard Procedure For Surface Preparation and PaintingDocument9 pages004 - Standard Procedure For Surface Preparation and PaintingSimbu ArasanNo ratings yet

- 571 SummaryDocument3 pages571 SummarySimbu Arasan100% (1)

- 001 - Standard Procedure For Hydrostatic Pressure Test of PipingDocument8 pages001 - Standard Procedure For Hydrostatic Pressure Test of PipingSimbu Arasan0% (1)

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- BHEL Earthing SystemDocument8 pagesBHEL Earthing SystemSimbu ArasanNo ratings yet

- TATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Document4 pagesTATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Simbu ArasanNo ratings yet

- CR QapDocument2 pagesCR QapSimbu ArasanNo ratings yet

- UF NF Dispatch Master Data 04-11-15Document47 pagesUF NF Dispatch Master Data 04-11-15Simbu ArasanNo ratings yet

- DO's & Dont'sDocument5 pagesDO's & Dont'sSimbu ArasanNo ratings yet

- Uf 500 LPHDocument6 pagesUf 500 LPHSimbu ArasanNo ratings yet

- SWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtyDocument2 pagesSWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtySimbu ArasanNo ratings yet

- Structural Tank Instructions 11967-ADocument22 pagesStructural Tank Instructions 11967-Aiftikhar_khalid_1No ratings yet

- TPL-US-QMD-002 - Surface Preparation and Painting ProcedureDocument4 pagesTPL-US-QMD-002 - Surface Preparation and Painting ProcedureSimbu ArasanNo ratings yet

- 006 CBCRDT Tata ProjectsDocument3 pages006 CBCRDT Tata ProjectsSimbu ArasanNo ratings yet

- WPPDC-QMD-001-Material Control and Werehousing ProcedureDocument5 pagesWPPDC-QMD-001-Material Control and Werehousing ProcedureSimbu ArasanNo ratings yet

- Standard BOQ-UF 1000LPH-Single MembraneDocument9 pagesStandard BOQ-UF 1000LPH-Single MembraneSimbu ArasanNo ratings yet

- Standerd 1000LPH BOM-SS PipeDocument10 pagesStanderd 1000LPH BOM-SS PipeSimbu ArasanNo ratings yet

- Nano Membrane Status SheetDocument3 pagesNano Membrane Status SheetSimbu ArasanNo ratings yet

- Study of Instrumentation Symbols As Per ISA StandardsDocument54 pagesStudy of Instrumentation Symbols As Per ISA Standardspra578100% (1)

- Tractor and Trailer Brake ValvesDocument2 pagesTractor and Trailer Brake ValvesAhmad RopaiNo ratings yet

- CoC Oral Exam Preparation - (Part - 15) - Fire & Safety - Marine StudyDocument12 pagesCoC Oral Exam Preparation - (Part - 15) - Fire & Safety - Marine StudyShaip SankarNo ratings yet

- General Twin Seal 06Document24 pagesGeneral Twin Seal 06Gk GaneshNo ratings yet

- Portable Systems & Parts Book: General Table of ContentsDocument97 pagesPortable Systems & Parts Book: General Table of ContentsJose RafaelNo ratings yet

- Tabela Completa Especificacao de TubulacaoDocument251 pagesTabela Completa Especificacao de TubulacaoAlessandre OliveiraNo ratings yet

- BERMAD Fire Protection CatalogueDocument274 pagesBERMAD Fire Protection Cataloguepjanic79100% (1)

- Storage TankDocument10 pagesStorage TankJacekNo ratings yet

- AcculoadDocument47 pagesAcculoadEnrique Arellano HidalgoNo ratings yet

- Submersible+Borehole+Pumps 60+HzDocument114 pagesSubmersible+Borehole+Pumps 60+HzNong Noc100% (1)

- AirValves 2013Document268 pagesAirValves 2013Peter Toralva YauriNo ratings yet

- ASME B16.34 - Valves - Flanged, Threaded and Welding EndsDocument190 pagesASME B16.34 - Valves - Flanged, Threaded and Welding EndsAvik Bhai100% (2)

- Pilatus Aircraft LTD PC 12 MMOPDocument72 pagesPilatus Aircraft LTD PC 12 MMOPLysterNo ratings yet

- Airsmart Controller User'S Manual (Compressor Application) : 13-17-600 October 2, 2009Document89 pagesAirsmart Controller User'S Manual (Compressor Application) : 13-17-600 October 2, 2009sebastian100% (4)

- ME Manual Vol.1Document650 pagesME Manual Vol.1Georgi Galev100% (1)

- VARCO October 2013Document48 pagesVARCO October 2013Pumper MagazineNo ratings yet

- Kimray 45015 PVDocument14 pagesKimray 45015 PVwlidhaaa100% (3)

- Operating Manual: For Swing Sink Clamping ElementDocument20 pagesOperating Manual: For Swing Sink Clamping Elementmedi38No ratings yet

- Pressure Reducing: Model 129FcDocument6 pagesPressure Reducing: Model 129Fcjames alfarasNo ratings yet

- 6.0 GERAND Flow Meter G-1000-6Document5 pages6.0 GERAND Flow Meter G-1000-6Piyarat SuwannakhaNo ratings yet

- 924G 924Gz Wheel Loader RBB00001-UP (MACHINE) POWERED BY 3056E Engine (SEBP3526 - 79) - Sistemas y Componentes ElectricoDocument5 pages924G 924Gz Wheel Loader RBB00001-UP (MACHINE) POWERED BY 3056E Engine (SEBP3526 - 79) - Sistemas y Componentes Electricoubaldo caraballoNo ratings yet

- Presostat - BRIODocument2 pagesPresostat - BRIOFlorin_RNo ratings yet

- Newco Cast Steel Angle Stop Checks 150-600Document5 pagesNewco Cast Steel Angle Stop Checks 150-600Oscar Alvitez DominguezNo ratings yet

- ASCO Solenoid Valve Troubleshooting GuideDocument2 pagesASCO Solenoid Valve Troubleshooting GuideNeeraj JangidNo ratings yet

- Boletim Tecnico - JF016 - Re0f10dDocument9 pagesBoletim Tecnico - JF016 - Re0f10dautomaticosbrasilNo ratings yet

- Flow Control ValvesDocument24 pagesFlow Control Valvesmk_chandru100% (1)

- Data Sheet U53Document2 pagesData Sheet U53edwinmenaNo ratings yet