Professional Documents

Culture Documents

Technical Manual 1 Slide Rail System

Technical Manual 1 Slide Rail System

Uploaded by

Lalaine23Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Manual 1 Slide Rail System

Technical Manual 1 Slide Rail System

Uploaded by

Lalaine23Copyright:

Available Formats

1 E+S Trench shoring systems....................................

2

1.1 Sliding rail systems............................................2

Single slide rail system Linear shoring..............2

Double slide rail system Linear shoring.............8

Deep Linear shoring........................................13

Single slide rail innercity shoring.....................16

Double slide rail innercity shoring....................19

Single slide rail system corner post.................22

Double slide rail for corner post......................25

Head shoring with sheet piles.........................28

End-of-trench shoring with slide-rail panels.....31

2 Krings Trench shoring systems..............................33

2.1 Sliding rail systems..........................................33

Single slide rail system, parallel shoring, EG

PV....................................................................33

Double slide rail system, parallel shoring, DG

PV....................................................................37

Single slide-rail inner-city parallel shoring.......40

Corner post EG Eck / DG Eck.........................43

Slide rail panels Krings sliding rail systems.....46

Imprint.........................................................................48

1

Table of contents

Single-rail linear shoring with U-type and rectangular roller unit

2,13 m - 6,38 m Module length

4,13 m Length slide rail

1,32 m / 2,32 m Panel height

variable Pipe culvert height

Linear shoring - no comparison

With Linear shoring the soil on either side of the trench

remains untouched, while there are no adverse effects on

building foundations, not even if they are in the immediate

vicinity of the excavation. No impairment of traffic flow,

not even it if is moving right alongside the trench. Until

the invention of Linear shoring such feats were considered

unattainable.

Linear shoring combines tried-and-tested functional

principles with unconventional, innovative ideas to create

a revolutionary new shoring system. A feature of the Linear

shoring system is the replacement of the permanently

positioned hinged spreaders, due to the ingeneous use

of rigid boogie cars that act on the shoring panels in such

way that the trench width is completely uniform troughout

all stages of the installation.

Vertically mobile, horizontally adjustable.

The boogie cars mounted in the supports of the shoring

system can be adjusted in height to match the increasing

depth of the trench. The width of the frame is adapted by

the spreader system to the desired trench width.

A right to right angles.

The mobile frame accurately ensures right angles in the

trench. Everything is linearly aligned, always at exactly

the same distance from the opposite side. In all phases

of construction. That is the key to success. Because this

means you can work more efficiently, faster and to a

higher standard of quality whilst at the same time cutting

costs appreciably.

2 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Single slide rail system Linear shoring

1

Pipe culvert length l

c

Linear shoring support I

Shoring / trench width b Boogie car II

Inner width b

c

Base panel III

Pipe culvert height h

c

Top panel IV

Thickness t

pl

Module length l

M

Single-rail linear shoring with U-type or rectangular roller unit

(All dimensions in mm. The details of length of pipe opening l

c

refer to the rectangular roller unit.)

3 1.1 Sliding rail systems

Single slide rail system Linear shoring

1

Linear shoring support

G [kg] l [m] Short description Art. No.

715,0 4,13 Linear shoring support, single slide rail 820 935

Linear shoring boogie car

G [kg] l [m] Short description Art. No.

420,0 2,00 Rectangular roller unit 832 200

550,0 2,00 Linear shoring U-type boogie car 832 205

Base panels -inside- (height 2.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

176,00 4,38 516,0 1,89 0,11 2,13 1,89 821 120

90,00 6,03 650,0 2,60 0,11 2,84 2,60 821 160

65,50 7,05 730,0 3,04 0,11 3,28 3,04 821 250

45,20 8,44 840,0 3,64 0,11 3,88 3,64 821 610

39,40 9,02 965,0 3,89 0,11 4,13 3,89 821 850

81,00 9,58 1.185,0 4,14 0,15 4,38 4,14 821 855

58,10 11,34 1.505,0 4,89 0,15 5,13 4,89 821 860

36,60 14,22 1.880,0 6,13 0,15 6,38 6,13 821 861

Top panels -inside- (height 1.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

176,00 2,49 355,0 1,89 0,11 2,13 1,89 822 060

90,00 3,43 445,0 2,60 0,11 2,84 2,60 821 180

65,50 4,01 500,0 3,04 0,11 3,28 3,04 822 120

45,20 4,80 570,0 3,64 0,11 3,88 3,64 822 620

39,40 5,13 635,0 3,89 0,11 4,13 3,89 822 760

81,00 5,45 870,0 4,14 0,15 4,38 4,14 822 783

58,10 6,45 1.090,0 4,89 0,15 5,13 4,89 822 800

36,60 8,09 1.370,0 6,13 0,15 6,38 6,13 822 801

Top panels -inside- (height 2.30 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

176,00 4,35 530,0 1,89 0,11 2,13 1,89 822 065

90,00 5,98 660,0 2,60 0,11 2,84 2,60 822 155

65,50 6,99 740,0 3,04 0,11 3,28 3,04 822 180

45,20 8,37 845,0 3,64 0,11 3,88 3,64 822 680

39,40 8,95 975,0 3,89 0,11 4,13 3,89 822 780

81,00 9,50 1.409,0 4,14 0,15 4,38 4,14 822 785

Base panels -inside- with injection pipe (height 2.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

63,00 7,05 810,0 3,04 0,12 3,28 3,04 821 251

43,50 8,44 890,0 3,64 0,12 3,88 3,64 821 615 A

43,90 9,02 980,0 3,89 0,12 4,13 3,89 821 827 A

Top panels -inside- with injection pipe (height 1.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

63,00 4,01 572,0 3,04 0,12 3,28 3,04 822 130

43,50 4,80 670,0 3,64 0,12 3,88 3,64 822 660

(The details of length of pipe opening l

c

refer to the rectangular roller unit.)

4 1.1 Sliding rail systems

Single slide rail system Linear shoring

1

Combinations of height

The shoring wall height can be adapted to the necessary trench depth with different panel combinations. Please note that, up to the

maximum height, reduced shoring depths can be obtained by overlapping the inner and outer panels.

Extension bars for rectangular roller unit

G [kg] l [m] Short description Art. No.

38,0 0,140 Extension bar HEB 220 830 005

50,0 0,275 Extension bar HEB 220 830 010

55,0 0,350 Extension bar HEB 220 830 011

57,0 0,375 Extension bar HEB 220 830 012

60,0 0,412 Extension bar HEB 220 830 015

70,0 0,550 Extension bar HEB 220 830 020

110,0 1,100 Extension bar HEB 220 830 030

152,0 1,650 Extension bar HEB 220 830 075

192,0 2,200 Extension bar HEB 220 830 125

278,0 3,300 Extension bar HEB 220 830 300

358,0 4,400 Extension bar HEB 220 830 305

Extension bars for U-type roller unit

G [kg] l [m] Short description Art. No.

77,0 0,140 Extension bar HEA 450 831 503

95,0 0,275 Extension bar HEA 450 831 500

115,0 0,375 Extension bar HEA 450 831 507

130,0 0,550 Extension bar HEA 450 831 510

207,0 1,100 Extension bar HEA 450 831 520

286,0 1,650 Extension bar HEA 450 831 530

362,0 2,200 Extension bar HEA 450 831 540

Area A Length l

Weight G Module length l

M

Weight per shoring panel G / VP Pipe culvert length l

c

Diameter d Shoring / trench width b

Earth pressure max. eh Inner width b

c

Thickness t

pl

5 1.1 Sliding rail systems

Single slide rail system Linear shoring

1

Trench widths

b b

c

Length extension bar

[m] [m] [m]

1,280 0,900 without extension bar

1,420 1,040 0,140

1,555 1,175 0,275

1,630 1,250 0,350

1,655 1,275 0,375

1,692 1,312 0,412

1,830 1,450 0,550

2,380 2,000 1,100

2,930 2,550 1,650

3,480 3,100 2,200

4,580 4,200 3,300

5,680 5,300 4,400

Other trench widths possible by combining different extension bar lengths.

Larger trench widths available on request.

Accessories / Spares

Standard d [m] G [kg] l [m] Short description Art. No.

47,0 Adapter for DKU piling frame, corner shoring, h = 0.50 m KDIV 842 758

55,0 Adapter for DKU piling frame, corner shoring, h = 0.50 m KDVI 842 752

94,0 Adapter for DKU piling frame, corner shoring, h = 1.00 m KDVI 842 753

45,0 Adapter for DKU piling frame, h = 0.50 m KDVI (single slide rail, E+S) 842 749

40,0 Adapter for DKU piling frame, h = 1.00 m KDIV (single slide rail, E+S) 842 759

75,5 Adapter for DKU piling frame, h = 1.00 m KDVI (single slide rail) 842 751

105,0 Adapter for EGS / DGS (LV) 834 080

40,0 Bearing claw for DKU piling frame element 336 960

6,9 Connector 862 200

7,9 0,750 Cover panel for in-situ concrete DG -base panel- 834 100

9,9 1,000 Cover plate for in-situ concrete DG -top plate- 834 110

105,0 2,27 DKU piling frame guide frame 842 099

175,0 3,81 DKU piling frame guide frame 842 100

DIN 934 0,1 Nut M 24 IA 0150F

DIN 934 0,4 Nut M 36 IA 0210F

0,035 1,4 0,150 Pin 832 230

0,035 0,8 0,110 Pin (for connector) 862 100

0,05 4,6 0,300 Pin for roller unit (deep Linear shoring) 832 246

0,04 3,2 0,300 Pin, Linear shoring (double slide rail) 832 245

2,5 Pin, Linear shoring (single slide rail) 850 720

425,0 4,60 Pressure beam (boxes, slide rail) 861 075

525,0 5,80 Pressure beam (boxes, slide rail) 861 085

175,5 1,60 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 076

236,0 2,35 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 074

271,0 2,80 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 070

318,0 3,40 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 071

12,4 Pressure plate for boogie car 834 015

43,6 Pull adapter double slide rail 834 060

30,8 Pull adapter single slide rail 834 057

DIN 933 0,4 Screw M 24 x 80 IB 0470F

DIN 933 1,0 Screw M 36 x 80 IB 0614F

DIN 11024 0,006 0,03 Spring cotter 6 mm HE 0050 F

DIN 11024 0,008 0,1 Spring cotter 8 mm HE 0060F

6 1.1 Sliding rail systems

Single slide rail system Linear shoring

1

Accessories / Spares (contd.)

Standard d [m] G [kg] l [m] Short description Art. No.

25,7 5,000 Suspension chain KL-13-8 821 100

300,0 2,60 Waling for DKU piling frame, module length 2.84 m (single slide rail,

E+S)

842 704

402,0 3,64 Waling for DKU piling frame, module length 3.88 m (single slide rail,

E+S)

842 705

420,0 3,89 Waling for DKU piling frame, module length 4.13 m (single slide rail,

E+S)

842 710

445,0 4,14 Waling for DKU piling frame, module length 4.38 m (single slide rail,

E+S)

842 711

7 1.1 Sliding rail systems

Single slide rail system Linear shoring

1

Double slide rail system Linear shoring with U-type boogie car

2,25 m - 6,50 m Module length

5,13 m - 9,13 m Length slide rail

1,32 m / 2,32 m Panel height

variabel Pipe culvert height

Linear shoring - no comparison

With Linear shoring the soil outside the trench remains

untouched no adverse effects on buildings and traffic

flow. Instead of permanently positioned hinged spreaders,

the non-bending roller units of the linear shoring system

hold the supports and thus keep the shoring panels in the

trench apart. This way, the trench width remains com-

pletely uniform throughout all stages of the project. With

the optional E+S U boogie car, even larger vertical pipe

clearances can be achieved.

Vertically mobile, horizontally adjustable.

The boogie cars mounted in the supports of the shoring

system can be adjusted in height to match the increasing

depth of the trench. The width of the roller frame is adap-

ted by the spreader system to the desired trench width.

Linear shoring is suitable for cast-in-place concrete and

can thus be flexibly used in all construction projects.

Tall panels can now be fitted in spite of overhead

cables.

With other systems the panels have to be inserted in a

complicated procedure from above. For the first time ever

it is now possible to swing shoring panels into position

from the sides. Because the shoring panels are swung at

ground level from the side into the supports and not

lowered from a great height, overhead cables such as

tram contact lines are no longer an obstacle. This repres-

ents a huge step forward in many inner-city applications.

Advantages that count.

Linear shoring yields extremely good soil compaction

values during extraction. The overall efficiency of the

system particularly in deep trenches is enhanced even

further by the fact that the forces released during extrac-

tion are considerably lower than on most other shoring

systems. And that is an assurance of a high overall pipe-

laying rate.

8 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Double slide rail system Linear shoring

1

Pipe culvert length l

c

Linear shoring support I

Shoring / trench width b Boogie car II

Inner width b

c

Base panel III

Pipe culvert height h

c

Top panel IV

Thickness t

pl

Module length l

M

Overlapping linear shoring with U-type or rectangular roller unit

(All dimensions in mm. The details of length of pipe opening l

c

refer to the rectangular roller unit.)

9 1.1 Sliding rail systems

Double slide rail system Linear shoring

1

Linear shoring support

G [kg] l [m] Art. No.

995,0 5,13 820 912

1.200,0 6,13 820 915

1.410,0 7,13 820 920

1.865,0 8,13 820 924

2.348,0 9,13 820 929

Linear shoring support with injection pipe

G [kg] l [m] Art. No.

1.111,3 5,13 820 913

1.265,0 6,13 820 916

1.522,5 7,13 820 921

1.575,0 7,63 820 922

1.775,4 8,13 820 926

Linear shoring boogie car

G [kg] l [m] Short description Art. No.

420,0 2,00 Rectangular roller unit 832 200

465,0 2,20 Linear shoring rectangular roller unit 832 215

550,0 2,00 Linear shoring U-type boogie car 832 205

Base panel -outside- (Height 2,32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

149,00 4,64 540,0 2,00 0,11 2,25 2,00 821 150

80,00 6,29 670,0 2,71 0,11 2,96 2,71 821 170

59,00 7,31 755,0 3,15 0,11 3,40 3,15 821 310

49,00 8,70 865,0 3,75 0,11 4,00 3,75 821 770

41,40 9,28 985,0 4,00 0,11 4,25 4,00 821 910

75,00 9,86 1.225,0 4,25 0,15 4,50 4,25 821 913

54,50 11,60 1.545,0 5,00 0,15 5,25 5,00 821 912

34,70 14,50 1.910,0 6,25 0,15 6,50 6,25 821 916

Top panel -outside- (Height 1,32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

149,00 2,64 365,0 2,00 0,11 2,25 2,00 822 075

80,00 3,58 450,0 2,71 0,11 2,96 2,71 821 190

59,00 4,16 510,0 3,15 0,11 3,40 3,15 822 310

49,00 4,95 580,0 3,75 0,11 4,00 3,75 822 710

41,40 5,28 640,0 4,00 0,11 4,25 4,00 822 810

75,00 5,61 900,0 4,25 0,15 4,50 4,25 822 813

54,50 6,60 1.130,0 5,00 0,15 5,25 5,00 822 815

34,70 8,25 1.400,0 6,25 0,15 6,50 6,25 822 830

Top panel -outside- (Height 2,30 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

54,50 11,50 1.700,0 5,00 0,15 5,25 5,00 822 820

Base panels -inside- (height 2.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

176,00 4,38 516,0 2,00 0,11 2,25 1,89 821 120

90,00 6,03 650,0 2,71 0,11 2,96 2,60 821 160

65,50 7,05 730,0 3,15 0,11 3,40 3,04 821 250

45,20 8,44 840,0 3,75 0,11 4,00 3,64 821 610

39,40 9,02 965,0 4,00 0,11 4,25 3,89 821 850

81,00 9,58 1.185,0 4,25 0,15 4,50 4,14 821 855

10 1.1 Sliding rail systems

Double slide rail system Linear shoring

1

Base panels -inside- (height 2.32 m) (contd.)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

58,10 11,34 1.505,0 5,00 0,15 5,25 4,89 821 860

36,60 14,22 1.880,0 6,25 0,15 6,50 6,13 821 861

The details of length of pipe opening l

c

refer to the rectangular roller unit.

Top panels -inside- (height 1.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

176,00 2,49 355,0 2,00 0,11 2,25 1,89 822 060

90,00 3,43 445,0 2,71 0,11 2,96 2,60 821 180

65,50 4,01 500,0 3,15 0,11 3,40 3,04 822 120

45,20 4,80 570,0 3,75 0,11 4,00 3,64 822 620

39,40 5,13 635,0 4,00 0,11 4,25 3,89 822 760

81,00 5,45 870,0 4,25 0,15 4,50 4,14 822 783

58,10 6,45 1.090,0 5,00 0,15 5,25 4,89 822 800

36,60 8,09 1.370,0 6,25 0,15 6,50 6,13 822 801

Top panels -inside- (height 2.30 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

176,00 4,35 530,0 2,00 0,11 2,25 1,89 822 065

90,00 5,98 660,0 2,71 0,11 2,96 2,60 822 155

65,50 6,99 740,0 3,15 0,11 3,40 3,04 822 180

45,20 8,37 845,0 3,75 0,11 4,00 3,64 822 680

39,40 8,95 975,0 4,00 0,11 4,25 3,89 822 780

81,00 9,50 1.409,0 4,25 0,15 4,50 4,14 822 785

Base panels -inside-, reinforced (height 2.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

154,40 7,05 982,0 3,15 0,15 3,40 3,04 821 249

106,50 8,44 1.125,0 3,75 0,15 4,00 3,64 821 248

Top panels, inner, reinforced (height 2.30 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

154,40 6,99 1.080,0 3,15 0,15 3,40 3,04 822 181

106,50 8,37 1.220,0 3,75 0,15 4,00 3,64 822 182

Base panels -inside- with injection pipe (height 2.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

63,00 7,05 810,0 3,15 0,12 3,40 3,04 821 251

43,50 8,44 890,0 3,75 0,12 4,00 3,64 821 615 A

43,90 9,02 980,0 4,00 0,12 4,25 3,89 821 827 A

Top panels -inside- with injection pipe (height 1.32 m)

eh [kN/m] A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

63,00 4,01 572,0 3,15 0,12 3,40 3,04 822 130

43,50 4,80 670,0 3,75 0,12 4,00 3,64 822 660

The details of length of pipe opening l

c

refer to the rectangular roller unit.

11 1.1 Sliding rail systems

Double slide rail system Linear shoring

1

Combinations of height

The shoring wall height can be adapted to the necessary trench depth with different panel combinations. Please note that, up to the

maximum height, reduced shoring depths can be obtained by overlapping the inner and outer panels.

Extension bars for rectangular roller unit

see Single slide rail system Linear shoring (page 5)

Extension bars for U-type roller unit

see Single slide rail system Linear shoring (page 5)

Trench widths

b b

c

Length extension bar

[m] [m] [m]

1,540 0,900 without extension bar

1,680 1,040 0,140

1,815 1,175 0,275

1,890 1,250 0,350

1,915 1,275 0,375

1,952 1,312 0,412

2,090 1,450 0,550

2,640 2,000 1,100

3,190 2,550 1,650

3,740 3,100 2,200

4,840 4,200 3,300

5,940 5,300 4,400

Other trench widths possible by combining different extension bar lengths.

Larger trench widths available on request.

12 1.1 Sliding rail systems

Double slide rail system Linear shoring

1

Deep Linear shoring

2,25 m - 6,50 m Module length

variabel Length slide rail

1,32 m / 2,32 m Panel height

variabel Pipe culvert height

The deep linear shoring is a further development of the

known powerful linear shoring where two units of linear

trench support are connected with each other. When fi-

nally installed, the two supporting modules, the compon-

ents of which are of the same length, complement each

other, dealing independently with the pressure of the soil,

while ensuring the required enormous excavation of

around 14 m which can be reached using this method.

Due to its high performance, this new method constitutes

a really big step forward in shoring technology.

The scope of application of this new shoring method are

deeper building pits for sewer line construction, shafts

and press pits up to a depth of 14 m, depending on the

surface properties. With extremely poor, cohesive and

sticky grounds with great friction forces to be overcome

between the individual shoring elements and the ascend-

ing ground, application of this newly developed deeper

linear shoring can be economic already for depths ranging

from 7 to 10 m since, here, deployment of a traditional

linear shoring especially its demolition can be exhaust-

ing and time-consuming due to the high friction forces

involved.

13 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Deep Linear shoring

1

Shoring / trench width (outer rail) b

A

Linear shoring support I

Shoring / trench width (inner rail) b

I

Linear shoring boogie car II

Inner width b

c

Base panel III

Pipe culvert height h

c

Top panel IV

Thickness t

pl

Module length l

M

Pipe culvert length l

c

Deep Linear shoring

(All dimensions in mm)

14 1.1 Sliding rail systems

Deep Linear shoring

1

Linear shoring support -outside-

G [kg] l [m] Short description Art. No.

1.265,0 5,13 Linear shoring support -outside- 820 951

1.265,0 6,13 Linear shoring support -outside- 820 947

1.475,0 7,13 Linear shoring support -outside- 820 953

Linear shoring support -inside-

G [kg] l [m] Short description Art. No.

1.195,0 5,13 Linear shoring support -inside- 820 952

1.300,0 6,13 Linear shoring support -inside- 820 948

1.550,0 7,13 Linear shoring support -inside- 820 954

Linear shoring boogie car

G [kg] l [m] Short description Art. No.

505,0 2,20 Linear shoring boogie car (Deep linear shoring) 832 224

Shoring panels

see Double slide rail innercity linear shoring (page 10)

Extension bars for deep Linear shoring roller unit

see Single slide rail system Linear shoring (page 5)

Extension bars

G [kg] l [m] Short description Art. No.

75,0 0,640 Extension bar HEB 220 830 026

156,0 0,412 - 0,530 Extension bar HEB 220, TLV, hydraulically adjustable 830 310

Trench widths

b

A

b

I

b

c

Length of extension bar

[m] [m] [m] [m]

2,180 1,540 0,900 without extension bar

2,455 1,815 1,175 0,275

2,730 2,090 1,450 0,550

3,280 2,640 2,000 1,100

3,830 3,190 2,550 1,650

4,380 3,740 3,100 2,200

Other trench widths possible by combining different extension bar lengths.

Larger trench widths available on request.

Accessories / Spares

see Single slide rail system Linear shoring (page 6)

Inner width b

c

Length l

Weight G Shoring / trench width (outer rail) b

A

Shoring / trench width (inner rail) b

I

15 1.1 Sliding rail systems

Deep Linear shoring

1

Single slide rail innercity shoring

2,84 m / 4,38 m Module length

4,13 m Length slide rail

1,00 m Height sheet pile element

variable Length sheet piles (KD VI/8)

Pipelines inside, traffic outside.

During inner-city trenching operations, attention has to

be paid to the numerous supply lines crossing the trench.

At the same time it is essential that no vibrations are

transmitted to the soil outside the trench because of

housing close by and roads and rails often running

alongside the trench.

Large-area support prevented by small supply lines.

Large-area support systems are out of the question - in

spite of their other advantages - for use in trench sections

crossed by numerous supply lines, if only for functional

reasons.

Unlimited combinations.

The new inner-city linear shoring piling frame system can

be combined with the components of the linear shoring

system from E+S - with supports, boogie cars and large

support panels. Consequently, the advantages of inner-

city linear shoring can be combined with those on a single

site. This offers you totally new scope for cost estimation

and efficiency.

16 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Single slide rail innercity shoring

1

Module length l

M

Linear shoring support I

Pipe culvert length l

c

Boogie car II

Shoring / trench width b Base panel III

Inner width b

c

Top panel IV

Pipe culvert height h

c

Sheet pile element DKU V

Thickness t

pl

Sheet pile VI

Waling VII

Single-rail inner-city linear shoring with U-type or rectangular roller unit

(All dimensions in mm. The details of length of pipe opening l

c

refer to the rectangular roller unit.)

17 1.1 Sliding rail systems

Single slide rail innercity shoring

1

Linear shoring support

G [kg] l [m] Short description Art. No.

715,0 4,13 Linear shoring support, single slide rail 820 935

Linear shoring boogie car

G [kg] l [m] Short description Art. No.

420,0 2,00 Rectangular roller unit 832 200

550,0 2,00 Linear shoring U-type boogie car 832 205

Universal DKU piling frame element (height 1.00 m)

G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Short description Art. No.

510,0 1,75 0,31 2,84 2,27 Universal DKU piling frame element 842 671

785,0 3,29 0,31 4,38 3,81 Universal DKU piling frame element 842 674

You can find further piling frame elements in lengths 3.64 m and 3.89 m at our website www.es-verbau.com

Shoring panels

see Single slide rail system Linear shoring (page 4)

Waling

G [kg] l

M

[m] l [m] Short description Art. No.

300,0 2,84 2,60 Waling for DKU piling frame, module length 2.84 m (single slide rail, E+S) 842 704

445,0 4,38 4,14 Waling for DKU piling frame, module length 4.38 m (single slide rail, E+S) 842 711

Extension bars

see Single slide rail system Linear shoring (page 5)

Trench widths

see Single slide rail system Linear shoring (page 6)

Accessories / Spares

see Single slide rail system Linear shoring (page 6)

Area A Length l

Weight G Module length l

M

Weight per shoring panel G / VP Pipe culvert length l

c

Thickness t

pl

The details of length of pipe opening l

c

refer to the rectangular roller unit.

18 1.1 Sliding rail systems

Single slide rail innercity shoring

1

Double slide rail innercity shoring

3,70 m Module length

5,13 m - 9,13 m Length slide rail

1,00 m Height sheet pile element

variable Length sheet piles (KD VI/8)

The first overlapping inner-city slide-rail shoring.

Progress through innovation.

As one of the world's leading specialists in high-perform-

ance steel-shoring systems, E+S has addressed itself to

the problem of high-depth inner-city shoring. The solution,

overlapping inner-city linear shoring, is another milestone

in an impressive series of innovative system developments

from E+S.

Depths up to 7 m in the centre of towns.

This E+S innovation makes inroads into a new perform-

ance dimension. For the first time, inner-city trench shor-

ing with numerous transversing pipelines is possible up

to a depth of 7 m without any vibration or impact force.

The surrounding ground remains unaffected.

Shoring is installed and removed entirely without vibration.

Even right next to the trench, there are no significant ad-

verse effects on the soil, residential buildings or the road

system. There is no horizontal soil displacement with our

special overlapping inner-city shoring system.

Underground overlap

In terms of function, overlapping inner-city linear shoring

is comparable to modern overlapping large-area shoring.

The short piles are guided in overlapping pile frames. The

pile frames are held in special supports that are already

in successful use in E+S linear shoring. The result is two

overlapping walls of piling that can be pulled independ-

ently of one another.

19 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Double slide rail innercity shoring

1

Waling (outside belt) IX Linear shoring support I

Waling (inside belt) X Boogie car II

Module length l

M

Base panel III

Pipe culvert length l

c

Top panel IV

Shoring / trench width b Sheet pile element (outside belt) V

Inner width b

c

Sheet pile element (inside belt) VI

Pipe culvert height h

c

Sheet piles (outside belt) VII

Thickness t

pl

Sheet piles (inside belt) VIII

Overlapping inner-city linear shoring with U-type or rectangular roller unit

(All dimensions in mm. The details of length of pipe opening l

c

refer to the rectangular roller unit.)

20 1.1 Sliding rail systems

Double slide rail innercity shoring

1

Linear shoring support

G [kg] l [m] Art. No.

995,0 5,13 820 912

1.200,0 6,13 820 915

1.410,0 7,13 820 920

1.865,0 8,13 820 924

2.348,0 9,13 820 929

Linear shoring boogie car

G [kg] l [m] Short description Art. No.

420,0 2,00 Rectangular roller unit 832 200

465,0 2,20 Linear shoring rectangular roller unit 832 215

550,0 2,00 Linear shoring U-type boogie car 832 205

Sheet pile elements -outer belt- (height 1.00 m)

G [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

1.330,0 3,45 0,30 3,70 3,45 820 980

Sheet pile elements -inner belt- (height 1.00 m)

G [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

1.217,0 3,45 0,30 3,70 3,34 821 000

Base panel -outside- (Height 2,32 m)

A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

8,00 805,0 3,45 0,11 3,70 3,45 821 320

Top panel -outside- (Height 1,32 m)

A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

4,55 560,0 3,45 0,11 3,70 3,45 822 410

Base panels -inside- (height 2.32 m)

A [m] G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Art. No.

7,75 785,0 3,45 0,11 3,70 3,34 821 255

Top panel -inside-

A [m] G / VP [kg] l

c

[m] t

pl

[m] h [m] l

M

[m] l [m] Art. No.

4,41 550,0 3,45 0,11 1,32 3,70 3,34 822 140

7,68 795,0 3,45 0,11 2,30 3,70 3,34 822 145

The details of length of pipe opening l

c

refer to the rectangular roller unit.

Waling (piling frame element, double slide rail

G [kg] l

M

[m] l [m] Short description Art. No.

254,0 3,70 3,30 Waling -inside- (double slide rail, E+S) 821 002

374,0 3,70 3,46 Waling -outside- (double slide rail, E+S) 821 003

Extension bars / trench widths / accessories / spares

For extension bars, see single-rail Linear shoring (p. 5)

For trench widths, see overlapping Linear shoring (p. 12)

For accessories/spares, see single-rail Linear shoring (p. 6)

21 1.1 Sliding rail systems

Double slide rail innercity shoring

1

Single slide rail system corner post

2,13 m - 6,38 m Module length

4,13 m Length slide rail

1,32 m / 2,32 m Panel height

1,75 m - 6,00 m Shoring width

Corner rail shoring is a special shoring solution for shaft

structures. It usually consists of 4 slide-rail panels and 4

corner rail supports. It does without special bracing sys-

tems. All forces are discharged by the shoring panels.

Corner rail shoring can take the form of single-rail or

overlapping shoring, depending on the supports em-

ployed.

Since the panels of various lengths are used in pairs,

rectangular pits of different sizes are possible. Because

of the particular design of this system, its use depends

essentially on the soil conditions.

22 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Single slide rail system corner post

1

Shoring / trench width b Corner post I

Inner width b

c

Base panel II

Pipe culvert height h

c

Top panel III

Length extension bar L

ZwSt

Module length l

M

Pipe culvert length l

c

Single slide rail system corner post

(All dimensions in mm)

23 1.1 Sliding rail systems

Single slide rail system corner post

1

Corner post

G [kg] l [m] Short description Art. No.

170,0 2,30 Corner post 835 129

357,5 4,13 Corner post 835 130

Shoring panels

see Single slide rail system Linear shoring (page 4)

Ways of installation

Example:

Trench-end shoring module length = 3.28 m

-> Required extension bar combination for roller unit in linear shoring bay: 2000 mm

Panel length l

pl

Length l

Inner width b

c

Module length l

M

Weight G Pipe culvert length l

c

24 1.1 Sliding rail systems

Single slide rail system corner post

1

Double slide rail for corner post

2,25 m - 6,50 m Module length

5,13 m / 6,13 m Length slide rail

1,32 m / 2,32 m Panel height

1,89 m - 6,14 m Shoring width

Corner rail shoring is a special shoring solution for shaft

structures. It usually consists of 4 slide-rail panels and 4

corner rail supports. It does without special bracing sys-

tems. All forces are discharged by the shoring panels.

Corner rail shoring can take the form of single-rail or

overlapping shoring, depending on the supports em-

ployed.

Since the panels of various lengths are used in pairs,

rectangular pits of different sizes are possible. Because

of the particular design of this system, its use depends

essentially on the soil conditions.

25 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Double slide rail for corner post

1

Shoring / trench width b Corner post I

Inner width b

c

Base panel II

Pipe culvert height h

c

Top panel III

Length extension bar l

ZwSt

Module length l

M

Pipe culvert length l

c

Double slide rail for corner post

(All dimensions in mm)

26 1.1 Sliding rail systems

Double slide rail for corner post

1

Corner post

G [kg] l [m] Short description Art. No.

720,0 5,13 Corner post 835 100

900,0 6,13 Corner post 835 120

Shoring panels

see Double slide rail innercity linear shoring (page 10)

Ways of installation

Example:

Trench-end shoring module length = 3.40 m

-> Required extension bar combination for roller unit in linear shoring bay: 2140 mm

Inner panel length l

Ipl

Length l

Inner width b

c

Module length l

M

Weight G Pipe culvert length l

c

Outer panel length l

Apl

27 1.1 Sliding rail systems

Double slide rail for corner post

1

Head shoring with sheet piles

This end-of-trench shoring is necessary if the width of the

shored pipe trench will no longer accommodate any

standard end-of-trench panels.

Since the piles must never be supported by the spreader

system of our shoring, the loads of the placed / driven

sheet piles are discharged with special extendable cross

girders mounted in the vertical shoring rail. This end-of-

trench shoring is recommended particularly in pressing

pits. The sheet piles serve here as the abutments for the

driving machine and also create an opening for the inser-

tion of the pipe.

28 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

Head shoring with sheet piles

1

Inner width b

c

Adapter for head shoring I

Thickness sheet pile d

KD

Extension bar II

Shoring / trench width b

Head shoring with sheet piles

(All dimensions in mm)

29 1.1 Sliding rail systems

Head shoring with sheet piles

1

Adapter for end shoring

G [kg] l [m] Art. No.

132,0 0,45 899 994

Extension bars for end shoring

G [kg] b

c

[m] l [m] Short description Art. No.

65,0 1,040 0,140 Extension bar HEA 360 830 801

85,0 1,175 0,275 Extension bar HEA 360 830 802

95,0 1,275 0,375 Extension bar HEA 360 830 803

100,0 1,315 0,415 Extension bar HEA 360 830 804

114,0 1,450 0,550 Extension bar HEA 360 830 800

175,0 2,000 1,100 Extension bar HEA 360 830 806

240,0 2,550 1,650 Extension bar HEA 360 830 810

304,0 3,100 2,200 Extension bar HEA 360 830 830

340,0 3,375 2,475 Extension bar HEA 360 830 833

412,0 4,000 3,100 Extension bar HEA 360 830 835

420,0 4,062 3,162 Extension bar HEA 360 830 834

436,0 4,200 3,300 Extension bar HEA 360 830 836

447,0 4,300 3,400 Extension bar HEA 360 830 837

468,0 4,475 3,575 Extension bar HEA 360 830 840

485,0 4,615 3,715 Extension bar HEA 360 830 843

500,0 4,750 3,850 Extension bar HEA 360 830 845

561,0 5,300 4,400 Extension bar HEA 360 830 850

626,0 5,850 4,950 Extension bar HEA 360 830 855

693,0 6,400 5,500 Extension bar HEA 360 830 857

758,0 6,950 6,050 Extension bar HEA 360 830 860

948,0 8,600 7,700 Extension bar HEA 360 830 880

Accessories / Spares

see Single slide rail system Linear shoring (page 6)

Inner width b

c

Length l

Weight G Shoring / trench width b

30 1.1 Sliding rail systems

Head shoring with sheet piles

1

End-of-trench shoring with slide-rail panels

This is end-of-trench shoring made of standard sliding

rail panels which, in accordance with the existing cone

of slope, are employed as late as possible with the

placement and lowering method. The panels are braced

against the vertical shoring rail and are guided in the

transverse direction by the bulb of the outer panels.

31 1.1 Sliding rail systems

E+S Trench shoring systems / Sliding rail systems

End-of-trench shoring with slide-rail panels

1

Shoring / trench width b Base panel I

Inner width b

c

Top panel II

Thickness outside panel t

Apl

Panel length l

pl

Kopfverbau mit Gleitschienenplatten

(All dimensions in mm)

Shoring panels

see Double slide rail innercity linear shoring (page 10)

Trench widths

Extension bar combinations max. b

c

Extension bar combinations min. b

c

l

M

l

pl

Art. No.

[mm] [m] [mm] [m] [m] [m]

275 / 550 1,725 2*20 / 550 1,490 2,25 2,00 821 150

412 / 1100 2,412 2*20 / 140 / 1100 2,180 2,96 2,71 821 170

275 / 1650 2,825 140 / 1650 2,690 3,40 3,15 821 310

375 / 2200 3,475 140 / 2200 3,240 4,00 3,75 821 770

275 / 375 / 2200 3,750 375 / 2200 3,475 4,25 4,00 821 910

275 / 550 / 2200 3,925 140 / 550 / 2200 3,790 4,50 4,25 821 913

412 / 1100 / 2200 4,612 275 / 1100 / 2200 4,475 5,25 5,00 821 912

32 1.1 Sliding rail systems

End-of-trench shoring with slide-rail panels

1

Single slide rail system, parallel shoring, EG PV

max. 4,00 m Shoring depth

variable Pipe culvert height

32,70 - 125,00 kN Earth pressure max.

2,00 m - 7,00 m Panel length

2,32 m Height base panel

1,30 m Height top panel

Parallel shoring is the logical refinement of the famous

KRINGS slide rail system and is able to guarantee optim-

um performance and reliability, even in the most difficult

of ground conditions. Cracking and soil substinence are

both dramatically reduced.

High strength, system flexibility and user friendliness are

the main features and instead of the fixed in position

threaded spindels the double and triple parallel slide rails

are connected by a heavy duty sliding frame, that slides

up and down within the slide rails. This design has the

advantage of increased system strength and a dramatic

reduction of soil subsidence which could otherwise cause

damage to roads and nearby structures.

33 2.1 Sliding rail systems

Krings Trench shoring systems / Sliding rail systems

Single slide rail system, parallel shoring, EG PV

2

Pipe culvert length l

c

Slide rail I

Shoring / trench width b Boogie car II

Inner width b

c

Base panel III

Pipe culvert height h

c

Top panel IV

Thickness t

pl

Module length l

M

Single slide-rail, parallel shoring, EG PV with U-type or rectangular roller unit

(All dimensions in mm. The details of length of pipe opening l

c

refer to the rectangular roller unit.)

34 2.1 Sliding rail systems

Single slide rail system, parallel shoring, EG PV

2

Slide rail

G [kg] l [m] Short description Art. No.

489,0 4,00 Single slide rail system, parallel shoring, EG PV 156 060

Boogie car

G [kg] Short description Art. No.

171,4 Rectangular roller unit 159 280

450,0 U-type boogie car 832 204

Extension bars for rectangular roller unit, parallel shoring, 2112 x 260 mm

G [kg] l [m] Short description Art. No.

24,9 0,500 Extension bar HEB 240 159 810

52,0 1,000 Extension bar HEB 240 159 570

72,0 1,500 Extension bar HEB 240 159 575

78,0 2,000 Extension bar HEB 240 159 690

Extension bars are available in all lengths on request and can be combined.

Extension bars for U-type roller unit, parallel shoring, 1700 x 450 mm

G [kg] l [m] Short description Art. No.

95,0 0,275 Extension bar HEA 450 831 500

130,0 0,550 Extension bar HEA 450 831 510

207,0 1,100 Extension bar HEA 450 831 520

286,0 1,650 Extension bar HEA 450 831 530

362,0 2,200 Extension bar HEA 450 831 540

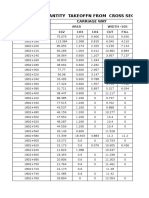

Shoring widths for rectangular roller unit, parallel shoring, 2112 x 260 mm

Shoring panel

KRA 6,00 - 7,00

Shoring panel

KRI 6,00 - 7,00

Shoring panel

KRU 4,00 - 5,00

Shoring panel

KRI 4,00 - 5,00

Shoring panel

KRU 2,00 - 3,50

Shoring panel

KRI 2,00 - 3,50

Length

extension bar

b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] [m]

0,820 0,520 0,705 0,405 0,685 0,435 0,790 0,540 0,685 0,465 0,760 0,540 without extension bar

1,320 1,020 1,205 0,905 1,185 0,935 1,290 1,040 1,185 0,965 1,260 1,040 0,500

1,820 1,520 1,705 1,405 1,685 1,435 1,790 1,540 1,685 1,465 1,760 1,540 1,000

2,320 2,020 2,205 1,905 2,185 1,935 2,290 2,040 2,185 1,965 2,260 2,040 1,500

2,820 2,520 2,705 2,405 2,685 2,435 2,790 2,540 2,685 2,465 2,760 2,540 2,000

Shoring widths for U-type roller unit, parallel shoring, 1700 x 450 mm

Shoring panel

KRA 6,00 - 7,00

Shoring panel

KRI 6,00 - 7,00

Shoring panel

KRU 4,00 - 5,00

Shoring panel

KRI 4,00 - 5,00

Shoring panel

KRU 2,00 - 3,50

Shoring panel

KRI 2,00 - 3,50

Lenth

extension bar

b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] [m]

1,275 0,975 1,165 0,865 1,145 0,895 1,245 0,995 1,145 0,925 1,215 0,995 without extension bar

1,550 1,250 1,440 1,140 1,420 1,170 1,520 1,270 1,420 1,200 1,490 1,270 0,275

1,825 1,525 1,715 1,415 1,695 1,445 1,795 1,545 1,695 1,475 1,765 1,545 0,550

2,375 2,075 2,265 1,965 2,245 1,995 2,345 2,095 2,245 2,025 2,315 2,095 1,100

2,925 2,625 2,815 2,515 2,795 2,545 2,895 2,645 2,795 2,575 2,865 2,645 1,650

3,475 3,175 3,365 3,065 3,345 3,095 3,445 3,195 3,345 3,125 3,415 3,195 2,200

35 2.1 Sliding rail systems

Single slide rail system, parallel shoring, EG PV

2

Accessories / Spares

Standard d [m] G [kg] l [m] Short description Art. No.

55,0 Adapter for DKU piling frame, corner shoring, h = 0.50 m KDVI 842 752

94,0 Adapter for DKU piling frame, corner shoring, h = 1.00 m KDVI 842 753

38,0 Adapter for DKU piling frame, h = 0.50 m KDIV (single slide rail, Krings) 842 760

30,0 Adapter for DKU piling frame, h = 0.50 m KDVI (single slide rail, Krings) 842 757

60,0 Adapter for DKU piling frame, h = 1.00 m KDVI (single slide rail, Krings) 842 754

40,0 Bearing claw for DKU piling frame element 336 960

105,0 2,27 DKU piling frame guide frame 842 099

175,0 3,81 DKU piling frame guide frame 842 100

DIN 6915 0,1 Nut M 16 139 045

DIN 934 0,1 Nut M 24 IA 0150F

DIN 934 0,4 Nut M 36 IA 0210F

0,080 2,6 0,110 Pin (single/double slide rail) 159 030

0,043 1,1 0,125 Pin d = 50, connector (slide rail) 159 050

425,0 4,60 Pressure beam (boxes, slide rail) 861 075

525,0 5,80 Pressure beam (boxes, slide rail) 861 085

175,5 1,60 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 076

236,0 2,35 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 074

271,0 2,80 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 070

318,0 3,40 Pressure beam (Medium, Magnum shoring, KS 100, GLS) 861 071

6,0 Pulling lug 170 x 150 100 950

DIN 6914 0,1 Screw M 16 x 70 139 035

DIN 933 0,4 Screw M 24 x 80 IB 0470F

DIN 933 1,0 Screw M 36 x 80 IB 0614F

0,006 0,1 0,042 Spring cotter 42 x 6 159 160

25,7 5,000 Suspension chain KL-13-8 821 100

209,0 2,524 Waling for DKU piling frame, module length 2.77 m (single slide rail,

Krings)

842 712

355,0 3,524 Waling for DKU piling frame, module length 3.77 m (single slide rail,

Krings)

842 713

400,0 4,024 Waling for DKU piling frame, module length 4.27 m (single slide rail,

Krings)

842 714

40,0 1,80 Wire rope 4-legs, 1800 x 20 139 110

46,0 2,80 Wire rope 4-legs, 2800 x 20 139 120

Inner width b

c

Length l

Weight G Module length l

M

Diameter d Pipe culvert length l

c

Shoring / trench width b

36 2.1 Sliding rail systems

Single slide rail system, parallel shoring, EG PV

2

Double slide rail system, parallel shoring, DG PV

max. 7,00 m Shoring depth

variable Pipe culvert height

32,70 - 125,00 kN/m Earth pressure max.

2,00 m - 7,00 m Panel length

2,32 m Height base panel

1,33 m Height top panel

Parallel shoring is the logical refinement of the famous

KRINGS slide rail system and is able to guarantee optim-

um performance and reliability, even in the most difficult

of ground conditions. Cracking and soil substinence are

both dramatically reduced.

High strength, system flexibility and user friendliness are

the main features and instead of the fixed in position

threaded spindels the double and triple parallel slide rails

are connected by a heavy duty sliding frame, that slides

up and down within the slide rails. This design has the

advantage of increased system strength and a dramatic

reduction of soil subsidence which could otherwise cause

damage to roads and nearby structures.

37 2.1 Sliding rail systems

Krings Trench shoring systems / Sliding rail systems

Double slide rail system, parallel shoring, DG PV

2

Pipe culvert length l

c

Slide rail I

Shoring / trench width b Boogie car II

Inner width b

c

Base panel III

Pipe culvert height h

c

Top panel IV

Thickness t

pl

Module length l

M

Double slide-rail, parallel shoring, DG PV with U-type or rectangular roller unit

(All dimensions in mm. The details of length of pipe opening l

c

refer to the rectangular roller unit.)

38 2.1 Sliding rail systems

Double slide rail system, parallel shoring, DG PV

2

Slide rail

G [kg] l [m] Short description Art. No.

980,0 4,80 Double slide rail system, parallel shoring, DG PV 157 130

1.235,0 6,00 Double slide rail system, parallel shoring, DG PV 157 150

1.475,0 7,00 Double slide rail system, parallel shoring, DG PV 157 155

Boogie car

G [kg] Short description Art. No.

346,0 Rectangular roller unit 159 310

392,0 Rectangular roller unit 159 320

450,0 U-type boogie car 832 204

Extension bars for rectangular roller unit, parallel shoring, 2510 / 3310 x 405 mm

G [kg] l [m] Short description Art. No.

64,9 0,50 Extension bar HEB 240, L=500x305 mm 159 820

106,5 1,00 Extension bar HEB 240, L=1000x305 mm 159 580

148,0 1,50 Extension bar HEB 240, L=1500x305 mm 159 660

190,0 2,00 Extension bar HEB 240, L=2000x305 mm 159 700

Extension bars are available in all lengths on request and can be combined.

Extension bars for U-type roller unit, parallel shoring, 1700 x 450

see Single slide rail system EG PV (page 35)

Shoring widths for rectangular roller unit, parallel shoring, 2510 / 3310 x 405 mm

Shoring panel

KR 6,00 - 7,00

Shoring panel

KRU 4,00 - 5,00

Shoring panel

KRI 4,00 - 5,00

Shoring panel

KRU 2,00 - 3,50

Shoring panel

KRI 2,00 - 3,50

Length

extension bar

b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] [m]

1,410 0,695 1,275 0,725 1,380 0,825 1,275 0,755 1,350 0,825 without extension bar

1,910 1,195 1,775 1,225 1,880 1,325 1,775 1,255 1,850 1,325 0,500

2,410 1,695 2,275 1,725 2,380 1,825 2,275 1,755 2,350 1,825 1,000

2,910 2,195 2,775 2,225 2,880 2,325 2,775 2,255 2,850 2,325 1,500

3,410 2,695 3,275 2,725 3,380 2,825 3,275 2,755 3,350 2,825 2,000

Shoring widths for U-type roller unit, parallel shoring, 1700 x 450 mm

Shoring panel

KR 6,00 - 7,00

Shoring panel

KRU 4,00 - 5,00

Shoring panel

KRI 4,00 - 5,00

Shoring panel

KRU 2,00 - 3,50

Shoring panel

KRI 2,00 - 3,50

Length

extension bar

b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] b [m] b

c

[m] [m]

1,580 0,865 1,445 0,895 1,550 0,995 1,445 0,925 1,520 0,995 without extension bar

1,855 1,140 1,720 1,170 1,825 1,270 1,720 1,200 1,795 1,270 0,275

2,130 1,415 1,995 1,445 2,100 1,545 1,995 1,475 2,070 1,545 0,550

2,680 1,965 2,545 1,995 2,650 2,095 2,545 2,025 2,620 2,095 1,100

3,230 2,515 3,095 2,545 3,200 2,645 3,095 2,575 3,170 2,645 1,650

3,780 3,065 3,645 3,095 3,750 3,195 3,645 3,125 3,720 3,195 2,200

Accessories / Spares

see Single slide rail system EG PV (page 36)

39 2.1 Sliding rail systems

Double slide rail system, parallel shoring, DG PV

2

Single slide-rail inner-city parallel shoring

2,77 m / 4,27 m Module length

4,00 m Length slide rail

1,00 m Height sheet pile element

variable Length sheet piles (KD VI/8)

Pipelines inside, traffic outside.

During inner-city trenching operations, attention has to

be paid to the numerous supply lines crossing the trench.

At the same time it is essential that no vibrations are

transmitted to the soil outside the trench because of

housing close by and roads and rails often running

alongside the trench.

Large-area support prevented by small supply lines.

Large-area support systems are out of the question - in

spite of their other advantages - for use in trench sections

crossed by numerous supply lines, if only for functional

reasons.

Unlimited combinations.

The new inner-city linear shoring piling frame system can

be combined with the components of the linear shoring

system from E+S - with supports, boogie cars and large

support panels. Consequently, the advantages of inner-

city linear shoring can be combined with those on a single

site. This offers you totally new scope for cost estimation

and efficiency.

40 2.1 Sliding rail systems

Krings Trench shoring systems / Sliding rail systems

Single slide-rail inner-city parallel shoring

2

Module length l

M

Linear shoring support I

Pipe culvert length l

c

Boogie car II

Shoring / trench width b Base panel III

Inner width b

c

Top panel IV

Pipe culvert height h

c

Sheet pile element DKU V

Thickness t

pl

Sheet pile VI

Waling VII

Single slide-rail inner-city parallel shoring with U-type or rectangular roller unit

(All dimensions in mm. The details of length of pipe opening l

c

refer to the rectangular roller unit.)

41 2.1 Sliding rail systems

Single slide-rail inner-city parallel shoring

2

Slide rail

G [kg] l [m] Short description Art. No.

489,0 4,00 Single slide rail system, parallel shoring, EG PV 156 060

Parallel shoring roller unit

G [kg] Description Short description Art. No.

171,4 SL PV R 2112 x 260 Rectangular roller unit 159 280

450,0 SL PV U 1700 x 450 U-type boogie car 832 204

Universal DKU piling frame element (height 1.00 m)

G / VP [kg] l

c

[m] t

pl

[m] l

M

[m] l [m] Short description Art. No.

510,0 2,61 0,31 2,77 2,27 Universal DKU piling frame element 842 671

785,0 4,11 0,31 4,27 3,81 Universal DKU piling frame element 842 674

You can find further piling frame elements at our website www.es-verbau.com

The details of length of pipe opening l

c

refer to the rectangular roller unit.

Waling

G [kg] l

M

[m] l [m] Short description Art. No.

209,0 2,77 2,524 Waling for DKU piling frame, module length 2.77 m (single slide rail, Krings) 842 712

400,0 4,27 4,024 Waling for DKU piling frame, module length 4.27 m (single slide rail, Krings) 842 714

Extension bars

see Single slide rail system EG PV (page 35)

Trench widths

see Single slide rail system EG PV (page 35)

Accessories / Spares

see Single slide rail system EG PV (page 36)

Thickness t

pl

Length l

Weight G Module length l

M

Pipe culvert length l

c

42 2.1 Sliding rail systems

Single slide-rail inner-city parallel shoring

2

Corner post EG Eck / DG Eck

max. 5,50 m Shoring depth

32,70 - 125,00 kN/m Earth pressure max.

2,00 m - 7,00 m Panel length

2,32 m Height base panel

1,33 m Height top panel

The KRINGS corner slide rail system is the proven time

and labor saving method of shoring all types of pit and

shaft excavations. Suitable for depths up to 26.4' / 8.00 m

the KRINGS corner slide rails together with the standard

trench shoring products are ideal for applications such

as tank installations, repair shaft, launching and receiving

shafts for pipejacking, thrustboring and microtunneling

works, retaining walls and manhole pits.

Corner slide rails can be custom made for any required

angle. For jacking, boring and microtunneling shafts

KRINGS provides the perfect solution. Special corner rails

are available upon request and many variations and pos-

sibilities are possible with this system.

43 2.1 Sliding rail systems

Krings Trench shoring systems / Sliding rail systems

Corner post EG Eck / DG Eck

2

Shoring / pit width b Corner post I

Inner width b

c

Base panel -outside- II

Base panel -inside- III

Corner post EG Eck / DG Eck

(All dimensions in mm)

44 2.1 Sliding rail systems

Corner post EG Eck / DG Eck

2

Slide rail

G [kg] l [m] Description Short description Art. No.

195,0 3,50 EG ECK - 3500 Single corner rail 156 030

517,0 4,50 DG ECK - 4500 Double corner slide rail 157 050

575,0 5,00 DG ECK - 5000 Double corner slide rail 157 060

624,0 5,50 DG ECK - 5500 Double corner slide rail 157 070

244,0 2,00 DG A ECK - 2000 Double corner extension rail 157 010

Shoring widths for DG corner

KRI KRU Shoring panel

b [m] b

c

[m] b [m] b

c

[m] Length [m]

2,685 2,175 2,620 2,110 2,00

3,185 2,675 3,120 2,610 2,50

3,685 3,175 3,620 3,110 3,00

4,185 3,675 4,120 3,610 3,50

4,725 4,175 4,660 4,110 4,00

5,225 4,675 5,160 4,610 4,50

5,725 5,175 5,660 5,110 5,00

6,730 6,015 6,630 6,015 6,00

7,730 7,015 7,630 7,015 7,00

Accessories / Spares

see Single slide rail system EG PV (page 36)

Inner width b

c

Length l

Weight G Shoring / trench width b

45 2.1 Sliding rail systems

Corner post EG Eck / DG Eck

2

Base panel KRI (height 2.32 m)

eh [kN/m] A [m] G / VP [kg] t

pl

[m] l

M

DG PV [m] l

M

EG PV [m] l [m] Art. No.

141,00 4,64 530,0 0,110 2,32 2,27 2,00 151 096

90,50 5,80 620,0 0,110 2,82 2,77 2,50 151 101

62,90 6,96 710,0 0,110 3,32 3,27 3,00 151 106

46,20 8,12 805,0 0,110 3,82 3,77 3,50 151 111

50,60 9,28 1.025,0 0,125 4,32 4,27 4,00 151 121

40,00 10,44 1.140,0 0,125 4,82 4,77 4,50 151 126

32,40 11,60 1.250,0 0,125 5,32 5,27 5,00 151 131

Base panel KRU (height 2.32 m)

eh [kN/m] A [m] G / VP [kg] t

pl

[m] l

M

DG PV [m] l

M

EG PV [m] l [m] Art. No.

141,00 4,64 530,0 0,110 2,32 2,27 2,00 151 256

90,50 5,80 620,0 0,110 2,82 2,77 2,50 151 261

62,90 6,96 710,0 0,110 3,32 3,27 3,00 151 267

46,20 8,12 805,0 0,110 3,82 3,77 3,50 151 273

50,60 9,28 1.025,0 0,125 4,32 4,27 4,00 151 276

40,00 10,44 1.140,0 0,125 4,82 4,77 4,50 151 286

32,40 11,60 1.250,0 0,125 5,32 5,27 5,00 151 291

Top panel KRI (height 1.30 m)

eh [kN/m] A [m] G / VP [kg] t

pl

[m] l

M

DG PV [m] l

M

EG PV [m] l [m] Art. No.

141,00 2,60 364,0 0,110 2,32 2,27 2,00 151 015

90,50 3,25 426,0 0,110 2,82 2,77 2,50 151 020

62,90 3,90 491,0 0,110 3,32 3,27 3,00 151 025

46,20 4,55 554,0 0,110 3,82 3,77 3,50 151 030

50,60 5,20 678,0 0,125 4,32 4,27 4,00 151 040

40,00 5,85 754,0 0,125 4,82 4,77 4,50 151 045

32,40 6,50 825,0 0,125 5,82 5,27 5,00 151 050

Top panel KRU (height 1.30 m)

eh [kN/m] A [m] G / VP [kg] t

pl

[m] l

M

DG PV [m] l

M

EG PV [m] l [m] Art. No.

141,00 2,60 364,0 0,110 2,32 2,27 2,00 151 175

90,50 3,25 426,0 0,110 2,82 2,77 2,50 151 180

62,90 3,90 491,0 0,110 3,32 3,27 3,00 151 185

46,20 4,55 554,0 0,110 3,82 3,77 3,50 151 190

50,60 5,20 678,0 0,125 4,32 4,27 4,00 151 200

40,00 5,85 754,0 0,125 4,82 4,77 4,50 151 205

32,40 6,50 825,0 0,125 5,32 5,27 5,00 151 210

Base panel KR -outside- (height 2.30 m)

eh [kN/m] A [m] G / VP [kg] t

pl

[m] l

M

DG PV [m] l

M

EG PV [m] l [m] Art. No.

37,80 13,80 1.840,0 0,150 6,30 6,25 6,00 151 133

27,70 16,10 2.180,0 0,150 7,30 7,25 7,00 151 134

46 2.1 Sliding rail systems

Krings Trench shoring systems / Sliding rail systems

Slide rail panels Krings sliding rail systems

2

Base panel KR -inside- (height 2.30 m)

eh [kN/m] A [m] G / VP [kg] t

pl

[m] l

M

DG PV [m] l

M

EG PV [m] l [m] Art. No.

37,80 13,80 1.840,0 0,150 6,30 6,25 6,00 151 293

27,70 16,10 2.180,0 0,150 7,30 7,25 7,00 151 294

Top panel KR -outside- and -inside- (height 1.35 m)

eh [kN/m] A [m] G / VP [kg] t

pl

[m] l

M

DG PV [m] l

M

EG PV [m] l [m] Art. No.

37,80 8,10 1.380,0 0,150 6,30 6,25 6,00 151 053

27,70 9,45 1.650,0 0,150 7,30 7,25 7,00 151 054

Difference between KRI and KRU panel

Weight per shoring panel G / VP Length l

Diameter d Height h

Earth pressure max. eh Thickness t

pl

Single slide rail system EG PV Area A

Double slide rail system DG PV Weight G

47 2.1 Sliding rail systems

Slide rail panels Krings sliding rail systems

2

Imprint

Editor

ThyssenKrupp Bauservice GmbH

Division Emunds + Staudinger / Krings

Ottostrae 30

41836 Hckelhoven-Baal

GERMANY

Phone: +49 2433 453-0

Fax: +49 2433 453-100

E-mail: ES-Krings@thyssenkrupp.com

www.es-verbau.com

Composition and Production

visaplan GmbH

www.visaplan.com

indivis GbR

www.indivis.de

Technical contents are subject to change.

www.es-verbau.com

.

48

You might also like

- STB5100 Electric Wiring DiagramDocument10 pagesSTB5100 Electric Wiring Diagramsea13100% (2)

- Boq For BeamsDocument22 pagesBoq For BeamsgopaltryNo ratings yet

- Slab Design - Roof: Ca CBDocument26 pagesSlab Design - Roof: Ca CBAnissah ManialaNo ratings yet

- Beam PropertiesDocument14 pagesBeam PropertiesaudiihussainNo ratings yet

- Column 1: Made by DateDocument12 pagesColumn 1: Made by DateHafiz KamarudinNo ratings yet

- Aashto LRFDDocument43 pagesAashto LRFDchabaloonNo ratings yet

- Project Job Ref. Section Sheet No./rev. Calc. by Date CHK'D by Date App'd by DateDocument3 pagesProject Job Ref. Section Sheet No./rev. Calc. by Date CHK'D by Date App'd by DateAmanda SmithNo ratings yet

- Project and Operation Management: Project Scheduling With Uncertain Activity TimesDocument41 pagesProject and Operation Management: Project Scheduling With Uncertain Activity TimesNur SyahidaNo ratings yet

- CH 12 - Simple - Circular - CurveDocument38 pagesCH 12 - Simple - Circular - CurveAbdirahman Waasuge100% (1)

- T - Sections Half H.E.A.: X XB XT X X y y y M T / 2 2 4 3 3 4 3 - 2 2 / 2 / WebDocument1 pageT - Sections Half H.E.A.: X XB XT X X y y y M T / 2 2 4 3 3 4 3 - 2 2 / 2 / WebAlden CayagaNo ratings yet

- UC - British Universal Colums - 152x152x30Document1 pageUC - British Universal Colums - 152x152x30mljaininsulationNo ratings yet

- Mild Steel Sheets, Plates and Floor PlatesDocument4 pagesMild Steel Sheets, Plates and Floor PlatesrockykrishNo ratings yet

- Column DesignDocument19 pagesColumn DesignPraful Patil100% (1)

- Boqs For STC Containers P2 S1/S2/Rev: Sr. No. Description Size Unit P 2 S1 P2 S2 Rev Total Weight (KG) RemarksDocument3 pagesBoqs For STC Containers P2 S1/S2/Rev: Sr. No. Description Size Unit P 2 S1 P2 S2 Rev Total Weight (KG) Remarksmc160403810 Usman AliNo ratings yet

- Treatment Plant HeaderDocument3 pagesTreatment Plant HeaderShamen AmarasekaraNo ratings yet

- C Purlins IIDocument2 pagesC Purlins IIson_goukoNo ratings yet

- Water Tank Slab 1. Ground Floor Slab: 2 - WAY SLAB Design To BS 8110 (With Corner Restraints) ProjectDocument2 pagesWater Tank Slab 1. Ground Floor Slab: 2 - WAY SLAB Design To BS 8110 (With Corner Restraints) ProjectAh Leng LauNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument12 pagesSpreadsheets To BS 8110: The Concrete CentreAnil kumar RNo ratings yet

- Plastic Bending of SteelDocument12 pagesPlastic Bending of SteelJohn Diete-Koki100% (1)

- StaadDocument10 pagesStaadAgrawalAnuragNo ratings yet

- Conveyor Truss Connections Calcs - 11Document4 pagesConveyor Truss Connections Calcs - 11René Mella CidNo ratings yet

- Beam DesignDocument6 pagesBeam DesignSHEETHALNo ratings yet

- Rebar TableDocument4 pagesRebar TableyadavniranjanNo ratings yet

- RISA-3D Report DataDocument4 pagesRISA-3D Report DatagertkroonNo ratings yet

- Footing ComputationDocument13 pagesFooting ComputationPoppy MooreNo ratings yet

- Column Design Name of Work:-: PK - Nandwana@yahoo - Co.inDocument27 pagesColumn Design Name of Work:-: PK - Nandwana@yahoo - Co.innsureshbabu0% (1)

- Prepared BY Dr. Mohammed Kadhum FekheraldinDocument55 pagesPrepared BY Dr. Mohammed Kadhum Fekheraldinhemantkle2uNo ratings yet

- The Excel Sheet For Reinforced Flat Slab DesignDocument2 pagesThe Excel Sheet For Reinforced Flat Slab DesignVaibhav Gupta0% (1)

- Crane 5TANDocument11 pagesCrane 5TANAnh Do VoNo ratings yet

- Spreadsheets To BS 8110Document12 pagesSpreadsheets To BS 8110Ahmed AliNo ratings yet

- Link BeamDocument8 pagesLink BeamNeil SonNo ratings yet

- Concrete Continuous Footing Quantity Take-Off WorksheetDocument17 pagesConcrete Continuous Footing Quantity Take-Off WorksheetxtianNo ratings yet

- BoefDocument6 pagesBoefmetroroadNo ratings yet

- Hipped Plate RoofDocument7 pagesHipped Plate RoofgvgbabuNo ratings yet

- Column Base Design:: Input DataDocument3 pagesColumn Base Design:: Input DataEng HatemNo ratings yet

- Sesmic Load at Floor LevelDocument14 pagesSesmic Load at Floor LevelJennifer PearsonNo ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- Proposed Riprap AlongDocument9 pagesProposed Riprap AlongMark Allan RojoNo ratings yet

- Project Arch - Portfolio - Vinay - CompressedDocument24 pagesProject Arch - Portfolio - Vinay - CompressedTadiVinayKumarNo ratings yet

- Hss Round Steel Section Tables 080307 PDFDocument3 pagesHss Round Steel Section Tables 080307 PDFDimas Hanggara PutraNo ratings yet

- Steel BookDocument246 pagesSteel BookHuma Baig100% (1)

- Weld StressDocument9 pagesWeld StressArvindNo ratings yet

- AISC DG11 ExamplesDocument7 pagesAISC DG11 ExamplesMarcel Toruño MendezNo ratings yet

- Office Container Mob & ErectionDocument20 pagesOffice Container Mob & ErectionRachel FloresNo ratings yet

- Concrete Frame Multi Storey Cost EstimateDocument2 pagesConcrete Frame Multi Storey Cost Estimateaddrien danielNo ratings yet

- What Is The Difference Between Screw Pitch and LeadDocument6 pagesWhat Is The Difference Between Screw Pitch and LeadnagarajNo ratings yet

- Takeoff Quantity RCDG Dec172015Document54 pagesTakeoff Quantity RCDG Dec172015Shadz SalahuddinNo ratings yet

- Multistoreyed Building-3Document24 pagesMultistoreyed Building-3V.m. RajanNo ratings yet

- Lifting Hook DesignDocument7 pagesLifting Hook DesignAji V0% (1)

- Column DesignDocument8 pagesColumn DesignValentin CirlescuNo ratings yet

- Anchoring To ConcreteDocument13 pagesAnchoring To ConcreteRoberto HernandezNo ratings yet

- Shear Stud Anchor DesignDocument4 pagesShear Stud Anchor DesignVarun ShastryNo ratings yet

- 08 Reinforced Concrete ColumnsDocument36 pages08 Reinforced Concrete ColumnsGerhard vd WesthuizenNo ratings yet

- ES TechnischesHandbuch en-GB Part1 Ebook 01Document48 pagesES TechnischesHandbuch en-GB Part1 Ebook 01xyzhynNo ratings yet

- DSI ALWAG-Systems Pantex Lattice Girders EDocument8 pagesDSI ALWAG-Systems Pantex Lattice Girders Epramods_8No ratings yet

- 160Kmph Found Detail AUG 2Document14 pages160Kmph Found Detail AUG 2Mahesh MishraNo ratings yet

- CAOIMPEX Drilling ToolsDocument42 pagesCAOIMPEX Drilling ToolsDrilling TechNo ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- Bemo Rail General ManualDocument19 pagesBemo Rail General ManualTh NattapongNo ratings yet

- Lintech Metric Components SpecheetDocument4 pagesLintech Metric Components SpecheetElectromateNo ratings yet

- Post TensionDocument56 pagesPost TensionanoopsurendranNo ratings yet

- Containers and Container Terminal BrajdicaDocument4 pagesContainers and Container Terminal BrajdicaMihael LisakNo ratings yet

- Sugar Crane Harvester BrosureDocument20 pagesSugar Crane Harvester BrosurenightfurryifyNo ratings yet

- Sibson, 1977 PDFDocument26 pagesSibson, 1977 PDFSibylline ConsultsNo ratings yet

- Failure Cause Value MappingDocument54 pagesFailure Cause Value MappingHuỳnh Thanh Tuấn0% (1)

- 6.project Implementation Approach - DR .HasliDocument44 pages6.project Implementation Approach - DR .HasliNoordin Abdul MajidNo ratings yet

- App Builder Host PiDocument414 pagesApp Builder Host PiSadot Enrique Castillo GalanNo ratings yet

- Design of Prestressed Concrete Piles For Seismic Loads Adds A NewDocument3 pagesDesign of Prestressed Concrete Piles For Seismic Loads Adds A NewMahindaNo ratings yet

- Complete Catalogue 2017Document280 pagesComplete Catalogue 2017daniiely4643No ratings yet

- SeparatorsDigest 1999 1 enDocument28 pagesSeparatorsDigest 1999 1 enRicardo LopezNo ratings yet

- 10 - Imperfection in Solids Point Defects in MetalsDocument12 pages10 - Imperfection in Solids Point Defects in MetalshussainNo ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- Matlab Module 3Document21 pagesMatlab Module 3Kaustubh GandhiNo ratings yet

- Luminous 3 en LRDocument52 pagesLuminous 3 en LRraphyjoseph100% (1)

- Euronorm 2-80Document16 pagesEuronorm 2-80Phung Tuan AnhNo ratings yet

- Breviar de Calcul - Cos C.R.Document63 pagesBreviar de Calcul - Cos C.R.tulvyNo ratings yet

- Eg Unit 5 QPDocument3 pagesEg Unit 5 QPMICHEL RAJ MechNo ratings yet

- Dewa Asset ManagemntDocument7 pagesDewa Asset ManagemntDC VashistNo ratings yet

- Rittal Enclosure and Process CoolingDocument98 pagesRittal Enclosure and Process CoolingVadivelu DhanakotiNo ratings yet

- Content: 1 Install The SoftDocument34 pagesContent: 1 Install The SoftAkhtar KhanNo ratings yet

- Discover Media PQ Gen.2 April - 2018 - enDocument5 pagesDiscover Media PQ Gen.2 April - 2018 - enMir MihailescuNo ratings yet

- PP6a.gpio InterruptsDocument10 pagesPP6a.gpio InterruptsSunheang TyNo ratings yet

- Koln VRS Tickets Prices Railway NetworkDocument2 pagesKoln VRS Tickets Prices Railway NetworkAndrei BarbuNo ratings yet

- Clarifying ObjectivesDocument12 pagesClarifying Objectives383860No ratings yet

- Environmental Degradation PDFDocument10 pagesEnvironmental Degradation PDFMuhammad UsmanNo ratings yet

- CNC Job 2Document12 pagesCNC Job 2AnshorNo ratings yet

- Profiled Metal Roofing DesignDocument32 pagesProfiled Metal Roofing DesignEJourDNo ratings yet

- Python L1 Assignments Topgear Hima 284446Document10 pagesPython L1 Assignments Topgear Hima 284446subhani shaik100% (1)

- Slack AdjusterDocument2 pagesSlack AdjusterMathappan SNo ratings yet

- S1100 Ventilator Machine: Adult PediatricDocument4 pagesS1100 Ventilator Machine: Adult PediatricRay FNNo ratings yet