Professional Documents

Culture Documents

Best Practices in HSE

Best Practices in HSE

Uploaded by

Jonathan GonzalesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Best Practices in HSE

Best Practices in HSE

Uploaded by

Jonathan GonzalesCopyright:

Available Formats

Best Practices Branch

Prevention Division

in workplace

health &

safety

Sharing

best practices

in workplace

health &

safety

Sharing

best practices

June 1999

5033A (10/01)

Sharing best practices in workplace health and safety is the theme of this

workbook. The Workplace Safety and Insurance Board (WSIB) has

prepared this workbook to achieve three goals.

commitment of top management to excellence in health

and safety performance. The trunk of the tree what holds

everything else up is a system for managing health and

safety for setting goals and making sure that everyone

knows their responsibilities and is accountable for them.

The branches of the tree are the functions that ensure

employee participation and effective communications and

training, and that recognise and motivate good health and

safety performance. The leaves are the activities performed

in the workplace to anticipate, recognise, assess and

control health and safety hazards, and to manage disability

if injury and illness do occur.

When all these elements are in place and functioning

well, a workplace will be successful in creating safe and

healthy tasks, workplaces and behaviours. And the tree

will bear fruitfruit that includes healthy and safe

workers, good employee morale, lower costs, and a

successful business.

We want your feedback on both the vision and those

elements of the health and safety program that your

experience shows are critical to effective and continuously

improving health and safety performance.

Companies who have benchmarked their health and

safety programs have consistently identified many of these

elements identified on the prevention tree as essential to

the implementation of their health and safety system. The

workbook can help you benchmark your own health and

safety processes or participate in a benchmarking initiative

with other firms. If interested, you may participate in this

initiative by working with partner organisations to

benchmark the practices of members' workplaces.

Benchmarking will help guide us toward those activities

that deserve to be considered best practices. We will

compile benchmarks into a database available to all Ontario

employers and workers.

The Best Practices Branch, Prevention Division, of the

WSIB can help benchmarking groups get started. See back

page for details on how to contact us.

Goal 1) Learning from the best

We want to learn about companies recognised as leaders in

health and safety. This will help us gain a clearer and more

complete understanding of how leaders have achieved

success in preventing injuries and illness. We want to

know why leaders take action and "walk the talk". Our aim

is to ensure that this knowledge is shared with all workers

and employers (the "workplace parties") so that others can

learn successful prevention strategies.

Goal 2) Communicating and

disseminating best practices

We also want to share our work-in-progress and our

approach to benchmarking and best practices.

Benchmarking can be described as

the search for successful occupational health and

safety practices so that workplaces may identify

opportunities for improving their organisation's

performance.

One thing we have learned from those who have used

benchmarking techniques is that it helps to have a

framework to classify the types of practices that you are

interested in. Based on our review of the literature and our

talks with workplace representatives, we have proposed a

framework that is based on the analogy of a tree.

The prevention tree represents our current vision of a

good workplace health and safety program. Using the

analogy of the tree, we can describe the essential elements

of a health and safety program. A tree may have many

leaves but it will not thrive unless it has a healthy root

system, trunk and branches. The roots of a successful

program are leadership and commitment by top

management in the workplace, and workplace culture and

values that reinforce health and safety in all operations. At

the base of the tree is a health and safety policy, which lays

the foundation for the program by expressing the

in workplace

health & safety

sharing

best practices

1

Thanks!

We want to thank you for your participation. By sharing best practices in health and safety we

can build towards the development of a model of a successful health and safety program and

a set of leading indicators of workplace health and safety. This model will ultimately be the

framework for our best practices programs, our research and development, as well as a practi-

cal guide that we can share with Ontarios workplace parties.

A word about best practices

This workbook describes a variety of practices that some

workplaces have used successfully. That doesn't mean that

they will work in all situations, or that they are the only

way to achieve success. By searching for best practices

we are trying to come up with a menu of approaches that

may work for some firms. One thing we have learned,

however, is that a best practice is not a magic bullet.

Any practice can only be successful when it is appropriate

to the situation and implemented with commitment.

Goal 3) Giving you an information tool

Although the ideas we share in this workbook will also

continuously improve as a result of feedback from lead-

ing workplaces, we have designed the workbook to be

used by any workplace for stimulating thought about

health and safety programs and processes. The workbook

can also be used to gather information from other work-

places on processes that you are interested in and to help

you think about your own programs and processes.

2

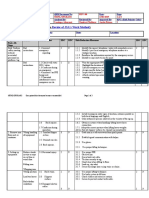

Health and safety program elements

Based on our initial research we have identified some of the key elements required for a health and safety program. In the

future, we may expand the workbook to include more of the sub-elements identified below.

Foundation of Leadership, Commitment, Culture,

and Values.

Health and Safety Policy

Occupational Health and Safety Management System

Roles, Responsibilities and Involvement

Continuous Improvement Process

Goals and Expectation Setting

Accountability and Performance Tracking

System Evaluation and Audits: Qualitative and

Quantitative

Hazard Anticipation, Recognition and Assessment

Inspection

Investigation and Reporting

Record-keeping

Job/task Analysis

Job, Equipment, and Workplace Design

Change Management

Purchasing

Employee Participation

Joint Health and Safety Committees

Safety Teams

The Health and Safety Program Elements and Sub-elements

Hazard Control

Contractor Safety

Operating Procedures

Ergonomics Programs

Hygiene Programs

Emergency Response

Personal Protective Equipment

Preventive Maintenance

Infection Control

Training

Compliance

Train-the-trainer

New Employee Orientation

Job Specific

Communications

Messages

Feedback

Methods

Response to Employee Concerns

Recognition and Motivation

Awards

Disability Management

Return to Work Program

How to use this workbook

This workbook describes a number of elements that correspond with the health and safety essentials depicted by the

prevention tree and listed below. Each element in the workbook contains three parts. The first part includes examples of

practices documented in case studies, health and safety journals, and implemented by top industry performers. The

second part includes a series of questions about your firms practices on that element. The third part asks a few questions

about your continuous improvement efforts.

The workbook is designed for flexibility; browse it in whatever sequence interests you. Complete any or all of the

elements. Do it in short sittings, use it for workshop material, do it all at once, divide among staff and share responses

whatever suits your pace and style.

3

Your reaction

We hope you will reflect on the example practices and identify the ones that you have used successfully, the ones that

you tried and found effective, and the ones you find intriguing and worth a try. Please mark up the list any way you

wish we want to hear your reaction. Our questions are to probe for your thoughts about your health and safety

program, and the critical elements and activities that in your opinion have resulted in your successful health and safety

performance. Under each element we have asked whether you would be willing to share your practices with us. If you

have agreed we will be contacting you to follow-up or you may contact us directly. See back page for details on how to

contact us.

Some initial questions about your workplace health & safety program

If you have undertaken a program to improve health and safety in your firm within the last 10 years, what

were the best things you did? Which are the most important for firms just starting to improve their health and

safety program?

Which of the above elements do you think are most responsible for your firm's success? Which do you think

your firm particularly excelled at?

4

Health and Safety Program Elements Workbook Pages

Health and Safety Policy.......................................................................................................................6-7

Occupational Health and Safety Management Systems ...........................................................................8-11

Hazard Anticipation, Recognition, and Assessment ...............................................................................12-15

Investigation and Reporting ..............................................................................................................16-19

Employee Participation .....................................................................................................................20-23

Hazard Control ...............................................................................................................................24-25

Contractor Safety.............................................................................................................................26-27

Training ..........................................................................................................................................28-31

Communication About Safety.............................................................................................................32-35

Recognition and Motivation ...............................................................................................................36-37

Measurements for Health and Safety Systems ..........................................................................................38

5

H

e

a

l

t

h

a

n

d

S

a

f

e

t

y

P

o

l

i

c

y

The development and implementation of a written health and safety policy is the

necessary foundation for an effective health and safety program. A health and safety

policy is communicated to all employees in the organization to help them

understand senior managements commitment to health and safety and enlist their

co-operation and participation

6

About your firm

Do you have a written health and safety policy? Yes No

Who has signed the policy? Position___________________________________________________

How frequently is the policy re-issued (changing date, circulating, with or without change of content)?

Did input to the policy document came directly from:

Board level President/VP level

Middle management level Union or worker representatives

Outside sources, e.g. model policies, trade groups

How is the policy communicated to employees and first line supervision?

When was the health and safety policy last revised/updated?

What are the major goals and objectives identified in the policy?

Examples of Health and Safety Policy Practices

The health and safety of workers is a company

priority and is written into the policy statement

The purpose and intent of the safety program is

clearly defined in the policy

The company health and safety policy is

communicated to all employees and is written

clearly so it can be understood by all employees

The policy clarifies the health and safety

responsibility and accountability of management

and staff

Employees have an opportunity to discuss the

policy and ask questions. Employees can provide

valuable feedback about the written policy

Reinforcing employees understanding of the

policy occurs when employees observe managers,

supervisors and co-workers setting examples to

ensure that the workplace is safe and hazard free.

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

Continuous improvement

How would you rate your firms health and safety policy?

Do not have a policy Needs improvement Satisfactory A model program

To what do you attribute the success of your health and safety policy?

I would be willing to share the specifics of my company practices in this area.

See back page for details on how to contact us.

What would you tell others are the benefits of implementing a health and safety policy?

How much does your health and safety policy contribute to your overall health and safety performance?

Have you evaluated your firms health and safety policy? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms development or implementation

of health and safety policy.

If you were looking for a company your

own firm could learn from, what

companies do you think of as having an

exemplary health and safety policy?

H

e

a

l

t

h

a

n

d

S

a

f

e

t

y

P

o

l

i

c

y

7

8 O

c

c

u

p

a

t

i

o

n

a

l

H

e

a

l

t

h

a

n

d

S

a

f

e

t

y

M

a

n

a

g

e

m

e

n

t

S

y

s

t

e

m

Health and safety goals and supporting objectives

are communicated company-wide and are signed

off and endorsed by the company Chief Executive

Officer and labour representatives.

Health and safety objectives are based on a

recent, comprehensive program evaluation, risk

assessments, and hazard identification. Objectives

are measurable and are understood by those who

are to accomplish them

The health and safety responsibility and

accountability of management and staff is clarified

in the health and safety policy.

Someone at the most senior management level is

responsible for health and safety and ensures that

the management system is properly implemented

at all levels of the company. Senior management

allocates sufficient resources to provide a safe and

healthy work environment and assigns sufficient

authority to those who maintain it.

Health safety is on the agenda of all senior

management meetings.

Work teams draw up their own health and safety

program and report progress to the health and

safety committee.

Operations staff are process owners, responsible

for maintaining a list of hazards and risks in all

parts of the process. Staff are required to keep

everyone updated.

The company provides expert advisors to help

staff and supervisors identify hazards and control

measures.

Health and safety requirements for each job are

written out and shared with employees. The safe

practices and safe conditions specifically related to

each job are documented, and provided to each

employee. Depending on the job type, the

information may include descriptions of proper

attire, personal protective equipment and its use,

safe work practices, controls related to hazardous

materials and physical hazards. The employee and

manager sign the document. The document is

reviewed if changes to the job are made or an

incident occurs.

Responsibility for record keeping and

documentation necessary to support the program

is assigned.

All planned and unplanned facility, equipment,

process and procedure changes are accompanied

by review of health and safety systems.

Health and safety evaluations are used to rate job

performance. Outcome of evaluations affect pay

and/or promotion or disciplinary actions.

A good health and safety management system is as important as good technical

safety and industrial hygiene knowledge and skills. The concept of a management

system is not new. This concept has been integral in many organizations efforts to

achieve total quality in products and services.

Other sections of this workbook present activities to reduce hazards, prevent injury and illness, and communicate.

Improvements in workplace health and safety should result from implementing programs in these areas. However,

an occupational health and safety management system is needed to ensure that they do: that good intentions and

earnest efforts really do achieve prevention in the workplace. Without a management system in place, a workplace

may fail to notice that compliance with a procedure declines after the novelty wears off, or that one departments

procedure is not quite practical because it overlooks the needs of a related department.

Implementation of a health and safety management system ensures that the intended prevention activities as set

out on the prevention tree are carried out and that they achieve the intended benefits by:

definition of measurable goals and assignment of responsibility for goals to people who will be accountable

for achieving them.

Performing evaluations and audits, to maintain standards and achieve continuous improvement.

Examples of Occupational Health and Safety Management System Practices in

setting goals and ensuring accountability

9 O

c

c

u

p

a

t

i

o

n

a

l

H

e

a

l

t

h

a

n

d

S

a

f

e

t

y

M

a

n

a

g

e

m

e

n

t

S

y

s

t

e

m

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

The supervisor continuously monitors to ensure

good housekeeping practices, proper task

procedure, adequate staff assigned to risky

procedures, and that all areas, equipment, and

tools are maintained for healthy operations.

Where a malfunction, near-miss, or accident has

occurred, the supervisor seeks to determine what

may have been overlooked in established

procedure or monitoring, and makes appropriate

revisions.

Retrospective performance measures include

injuries, diseases, other absence, reports of

discomfort, near-misses, product quality rates.

Prospective performance indicators include

observation of working environment and work

methods, verification of permits to work,

condition of emergency equipment and medical

facilities, etc.

Hazard control is analysed by examining history

of work orders generated from audits, inspections,

health and safety consultations, investigations,

and safety committee reports.

A reliable safety management audit process with

clear measurable objectives is established. Both

qualitative and quantitative goals may be

included. Goals are tailored to the needs of the

organisation. Audits are performed by competent

auditors who are as independent as possible from

the activity being audited. Audits are

implemented at the departmental and company-

wide levels, and include both scheduled and

unannounced audits.

An observational sampling program is used.

Targets are objectively measurable and clearly

communicated, and all training and equipment

required to meet targets is supplied. The sampling

program includes observations by employees and

feedback is given to employees.

Sample practices in monitoring goal achievement

10 O

c

c

u

p

a

t

i

o

n

a

l

H

e

a

l

t

h

a

n

d

S

a

f

e

t

y

M

a

n

a

g

e

m

e

n

t

S

y

s

t

e

m

Continuous improvement

How would you rate your firms health and safety management system?

No activity Needs improvement Satisfactory A model program

To what do you attribute the success of your health and safety management system?

I would be willing to share the specifics of my company practices in this area.

For details on how to contact us see back page.

What would you tell others are the benefits of implementing a health and safety management system?

How much does your health and safety management system contribute to your overall health and safety

performance?

About your firm

Do you use a management systems audit to monitor how you are managing health and safety ?

Yes No

If yes, what elements do you include in the audit?

Have you evaluated your firms health and safety management system? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms development or implementation

of your health and safety management system.

If you were looking for a company your own firm could learn from, what companies do you think of as

having an exemplary health and safety management system?

O

c

c

u

p

a

t

i

o

n

a

l

H

e

a

l

t

h

a

n

d

S

a

f

e

t

y

M

a

n

a

g

e

m

e

n

t

S

y

s

t

e

m

11

H

a

z

a

r

d

A

n

t

i

c

i

p

a

t

i

o

n

,

R

e

c

o

g

n

i

t

i

o

n

a

n

d

A

s

s

e

s

s

m

e

n

t

About your firm

How are hazards detected in your firm? Please list the five most common ways hazards are detected.

(Most common =1)

1.

2.

3.

4.

5.

How often are work areas inspected in your firm, by whom, how formally?

Who inspects, what area?

Frequency of the inspection Written record kept Action items identified

When management and your union/worker representatives jointly perform inspection and hazard

recognition or inspection practices:

Are inspection reports completed? Yes No

If yes, are they reviewed by management? Yes No

What is the process when someone recognises a hazard?

What is the time-frame for corrective action?

Inspections and audits are important components of hazard anticipation, recognition

and assessment activities.

Senior line managers participate in corporate

health and safety audits.

In response to internal audit results, a safety

action plan is developed and is approved by senior

management. Safety action teams, continuous

improvement teams, and joint health and safety

teams implement the plan.

Frequent audits (random and scheduled) are

conducted by workers, managers and safety

professionals. Audit findings are used for hazard

identification and risk analysis and eliminating

sources of risk of injury/illness.

Audit criteria

Include observable items for which there are

regulations.

Include factors identified in past accidents and

illnesses.

Are explicit and unambiguous.

Are phrased in positive form.

Include both conditions and practices.

Audit performance scores are reported to the

workforce.

Each department strives to improve its own

performance scores.

The workplace (or portions thereof) are inspected

every month by members of the joint health and

safety committee. Staff are asked for concerns and

recommendations on job safety.

Systematic self-assessments are linked to overall

requirements and expectations.

Supervisors and middle managers are expected to

continuously inspect and make immediate

remedy to restore the safety level designed into

the operations. As a result, inspections and

accident investigations should find no hazardous

conditions or practices that a supervisor could

have remedied.

Through regular audits, inspection and hazard

recognition, all employees know that

identification of hazardous conditions is

acceptable and encouraged, and feel empowered

to take initiative when hazards arise.

Examples of Hazard Inspection and Recognition Practices

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

12

13

H

a

z

a

r

d

A

n

t

i

c

i

p

a

t

i

o

n

,

R

e

c

o

g

n

i

t

i

o

n

a

n

d

A

s

s

e

s

s

m

e

n

t

Do you use a formal audit system?

No Proprietary system _____________________ Developed our own

How often is a full or partial audit performed?

How often is the same part of the firm re-audited?

On your inspections, do you audit/observe:

behaviours/practices

conditions

both

Where there are sub-contractors involved on the site, is there a requirement for them to conduct formal

inspections of their areas of responsibility? Yes No

If yes, a) how often? ______________________

b) how do they show that they meet the requirement? (produce minutes etc.)

c) or does the companys own committee inspect contractors work areas?

14

H

a

z

a

r

d

A

n

t

i

c

i

p

a

t

i

o

n

,

R

e

c

o

g

n

i

t

i

o

n

a

n

d

A

s

s

e

s

s

m

e

n

t

Continuous improvement

How would you rate your firms inspection and hazard recognition?

No activity Needs improvement Satisfactory A model program

To what do you attribute the success in hazard recognition?

I would be willing to share the specifics of my company practices in this area.

See back page for further details on how to contact us.

What would you tell others are the benefits of inspection and hazard recognition?

How much does your inspection and hazard recognition contribute to your overall health and safety

performance?

Have you undertaken to evaluate how your firm inspects and recognizes hazards? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms inspection and hazard

recognition.

If you were looking for a company your own firm could learn from, what companies do you think of as

having an exemplary health and safety inspection and hazard recognition program?

H

a

z

a

r

d

A

n

t

i

c

i

p

a

t

i

o

n

,

R

e

c

o

g

n

i

t

i

o

n

a

n

d

A

s

s

e

s

s

m

e

n

t

15

I

n

v

e

s

t

i

g

a

t

i

o

n

a

n

d

R

e

p

o

r

t

i

n

g

About your firm

What is the minimum injury or disease severity for which your firm requires a written accident report

form?

What is the source of your firms accident report form?

WSIB Form 7 Safe Workplace Association model form

Proprietary system _________________ Company developed system

Does your firm investigate reported accidents? Who does the investigation? When?

How severe does an accident have to be to warrant an investigation? Please give an example.

Which of the following non-critical events would you investigate?

paper cut eyestrain nausea clothing torn on doorknob back pain

How much time is required to completely report an injury, from the moment of injury to the conclusion of

first aid and all the paperwork (excluding any meetings on following dates, or medical appointments off-

site)?

What percentage of your firms total reportable injuries would you say are actually reported? ______%

Do you report or investigate illnesses/diseases differently from injuries? If so, how?

Investigation of accidents and near-misses can capture data on hazards and

oversights in safety management.

Examples of Investigation and Reporting Practices

A near miss reporting system is established. Staff

report near-miss accidents and are asked to

provide recommendations for avoiding repetition

with full consequences.

Supervisors investigate near misses and

recommend ways of preventing similar

occurrences.

Detailed injury questionnaires are administered.

Recording of accidents is used to build up an

accident performance profile.

Careful record keeping and detailed analysis of

health and safety data is maintained.

Investigations refrain from inferring any causal

mechanisms beyond available evidence.

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

16

17

I

n

v

e

s

t

i

g

a

t

i

o

n

a

n

d

R

e

p

o

r

t

i

n

g

What are the roles of the following in reporting injuries/diseases?

Write/add Provide information Review/see Approve/amend

Injured worker

Supervisor

Union or worker representative

Middle management

Executive management

Safety specialist

Witness(s)

Nurse/doctor

Under your firms policies, are near-miss (no injury, no illness) events:

Always required to be reported. Yes No

Reportable under certain conditions, e.g. potential severity of outcome (describe conditions).

Reportable during periodic campaigns.

How closely does actual practice follow policy for near-miss reporting?

What information about accidental injury, occupational diseases, and near-misses is communicated to the

Board/President/VP level in your firm? Please mention regularly scheduled reports and any events which

would be required to be reported to them immediately.

Do you use a standardized approach to accident investigation?

No, other than common sense

Company developed system

Proprietary system _____________

How do you determine when an investigation is done and you have determined the cause? What signs

indicate that you have enough information and do not need more?

What standards are used against which to assess information collected?

Do you determine preventive measures based on an accident investigation, and if so, how?

Do you follow through on findings from investigations? If so, how?

18

I

n

v

e

s

t

i

g

a

t

i

o

n

a

n

d

R

e

p

o

r

t

i

n

g

Continuous improvement

How would you rate your firms reporting and investigation?

No activity Needs improvement Satisfactory A model program

To what do you attribute your success in reporting and investigation?

I would be willing to share the specifics of my company practices in this area.

For further details on how to contact us see back page.

What would you tell others are the benefits of investigation and reporting of injuries?

How much does your reporting and investigation contribute to your overall health and safety

performance?

Have you evaluated how your firm reports and investigates injuries and near-misses?

Yes No If yes, what indicators or measures did you use?

What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms reporting and investigation.

If you were looking for a company your own firm could learn from, what companies do you think of as

having an exemplary investigation and reporting program?

I

n

v

e

s

t

i

g

a

t

i

o

n

a

n

d

R

e

p

o

r

t

i

n

g

19

E

m

p

l

o

y

e

e

P

a

r

t

i

c

i

p

a

t

i

o

n

About your firm

How does your firm involve employees in the development and implementation of your health and safety

program?

What role do employees play and what authority do they have? For example:

Suggest needs

Review proposals

Approve purchases

Develop materials

Deliver programs

Monitor performance

Which types of health and safety-related decisions or actions can not proceed without employee

involvement? Please give a couple of examples of this.

People work more safely when they participate in decision-making processes. This

means that employees are given the opportunity to communicate their thoughts to

management and receive feedback.

Examples of Employee Participation Practices

Employees have an active role in management of

health and safety through on site health and

safety committees with representatives from

labour and management working co-operatively

to plan and implement safety activities.

Employees are provided with a forum to discuss

safety concerns and report unsafe work

conditions.

Employees participate in five minute pre-shift

safety talks.

Confidential surveys of safety climate are

administered by a qualified analyst and results are

reported and interpreted to management;

management remedies sources of perceived risk.

Staff play a key role in the development and

implementation of health and safety programs.

Safety is a key focus of discussion at all periodic

staff meetings.

Work teams draw up their own health and safety

program and report progress to the health and

safety committee.

Employee task forces are used to analyse special

health and safety problems.

Employee and contractor representatives meet to

discuss health and safety issues. Key issues are

identified and solutions are developed. The results

are then shared with the company. Plant teams

are developed to study and review common

issued raised by the joint committee and then

modified to meet their own health and safety

needs.

Employees meet with staff from award winning

companies to discuss and learn more about

excellent health and safety practices. Employees

are required to return and share and make

recommendations for change based on new

information acquired.

An information technology system is

implemented to enable employees to raise health

and safety questions/concerns to management.

Management is required to respond to all

questions.

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

20

21

E

m

p

l

o

y

e

e

P

a

r

t

i

c

i

p

a

t

i

o

n

JOINT HEALTH AND SAFETY COMMITTEES

The Ontario Occupational Health and Safety Act provides that almost every workplace will have employee

involvement through the Joint Health and Safety Committee (JHSC) or health and safety representative.

What role does the JHSC or health and safety representative play in your firm in addition to their legal

requirements: inspections, investigations, and recommendations.

What do you believe makes employees feel comfortable enough to participate honestly and openly in your

firm?

What resources are available to employees to help them participate in the health and safety program?

What are the top three benefits you see as a result of employee involvement in health and safety?

1.

2.

3.

Provide some examples.

22

E

m

p

l

o

y

e

e

P

a

r

t

i

c

i

p

a

t

i

o

n

Continuous improvement

How would you rate your firms employee involvement in health and safety?

No activity Needs improvement Satisfactory A model program

To what do you attribute your success in employee involvement in health and safety??

I would be willing to share the specifics of my company practices in this area.

For further details on how to contact us see back page.

What would you tell others are the benefits of employee involvement in the health and safety program?

How much does your employee involvement contribute to your overall health and safety performance?

Have you evaluated how employees in your firm are involved in your health and safety efforts?

Yes No

If yes, what indicators or measures did you use?

What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms employee involvement in health

and safety.

If you were looking for a company your own firm could learn from, what companies do you think of as

having exemplary employee involvement?

E

m

p

l

o

y

e

e

P

a

r

t

i

c

i

p

a

t

i

o

n

23

24

H

a

z

a

r

d

C

o

n

t

r

o

l

About your firm

What proportion of work tasks in your company have had a job safety analysis, ergonomic assessment,

and/or risk assessment conducted that identifies potential risks of the job and resulted in risk reduction

measures and/or documents the administrative controls for minimising those risks?

What percentage of the time does your firm obtain and act on health and safety design reviews (e.g.

ergonomics, job safety analysis) by experts or internal committees at the following process stages?

Committee review (%) Expert advice (%) Acton (%)

Facility planning (pre-design) .............................................................______ ______ ______

Facility detail design development .....................................................______ ______ ______

Facility detail design approval ............................................................______ ______ ______

Facility renovation design development .............................................______ ______ ______

Facility renovation design approval ....................................................______ ______ ______

Equipment purchaseneeds assessment and criteria development .....______ ______ ______

Equipment purchaseselection / purchase order ...............................______ ______ ______

Equipment purchasemodify task procedures for new equipment .....______ ______ ______

Prevent recurrence after injury ..........................................................______ ______ ______

Prevent recurrence after multiple injuries ..........................................______ ______ ______

Employee health and safety concern..................................................______ ______ ______

other..................................................................................................______ ______ ______

What are the qualifications of the people who perform job safety analyses in your firm?

What are the qualifications of the people who perform ergonomic assessments in your firm?

What sources do you consult for design assessments to determine if jobs are within acceptable limits:

Health and safety regulations _________________________________________________________________________

Ergonomic guidelines _______________________________________________________________________________

Reference materials (e.g. texts, handbooks) ______________________________________________________________

Foreign source ergonomic regulations and guidelines_______________________________________________________

Other ___________________________________________________________________________________________

The company implements systematic job safety

analysis. Once an analysis is complete, job

procedures can be written or revised to remove

hazards and reflect the way the job will be

performed.

Ergonomics is included in the engineering design

An ergonomic analysis of each job is undertaken

and a database is maintained. Based on the results

of the analysis the company implements

recommended ergonomic changes to reduce risk

of biomechanical injury and human error.

Control measures are implemented for all jobs

where ergonomic risk has been determined.

Prior to the introduction of new operations or

process changes, process and ergonomic risk

factors are evaluated and corrections are made if

the risk level is unacceptable.

Safety committees review renovation and

construction plans and safety equipment

purchases to foresee health and safety

implications and intercept any decisions likely to

result in unacceptable risks. Reviews consider

effects in the immediate work unit and

implications for other units.

Examples of Safe Job Design Practices

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

The first opportunity for prevention and/or control of a potential hazard is at the design

stage of the facility, equipment or process. Job safety analysis identifies ways in which

processes may deviate from normal and result in harm, and ways in which this is

prevented. Ergonomics incorporates knowledge of human capabilities and limitations to

identify risks of musculoskeletal injury and human error. Risk assessment evaluates

probabilities of hazard states, size of exposed population, and consequences, to

determine the need for risk reduction measures.

Continuous improvement

How would you rate your firms safety planning and design?

No activity Needs improvement Satisfactory A model program

To what do you attribute the success in safety planning and design?

I would be willing to share the specifics of my company practices in this area.

For further details on how to contact us see back page.

What would you tell others are the benefits of safety planning and design activities?

How much does your safety planning and design contribute to your overall health and safety performance?

Have you evaluated your firms health and safety policy? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms development or implementation

of safety planning and design.

If you were looking for a company your own firm could

learn from, what companies do you think of as having

an exemplary safety planning and design activities

program?

H

a

z

a

r

d

C

o

n

t

r

o

l

25

C

o

n

t

r

a

c

t

o

r

S

a

f

e

t

y

About your firm

Do you have a program related to contractor safety? Yes No

How do the requirement(s) apply?

Please check as many as applicable.

Contractor selection

Onsite work practices

Offsite work practices

Termination of work as penalty

Payment withheld as penalty

What requirements are imposed on contractors?

How do you verify compliance with each of those requirements? Who does it?

How do you acquaint contractors with your requirements?

What consequences have you actually imposed for failure to comply with your requirements?

Contractor safety is an integrated element of good health and safety programs.

A contractor safety program defines expected

safety performance by detailing how contractors

are to be selected, trained, and educated to

ensure safety performance is at expected

company standards.

Bid pre-qualification and selection process

includes a review of the contractors injury data

for several years and submission of a written

health and safety plan. Pre-qualified contractors

are required to have good safety performance as a

contract condition.

Contractors are given site safety manuals, subject

to the same rules as other employees. They

participate in safety committees and in accident

investigation teams.

Contractors must complete health and safety

orientation before they are allowed to perform

work on the site.

Safety evaluations are conducted at the

completion of the project.

The contractor is subject to inspections and

required to attend safety meetings.

Examples of Contractor Safety Practices

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

26

27

Continuous improvement

How would you rate your firms program for contractor safety?

No activity Needs improvement Satisfactory A model program

To what do you attribute the success in contractor health and safety?

I would be willing to share the specifics of my company practices in this area.

For further details on how to contact us see back page.

What would you tell others are the benefits of implementing a contractor health and safety program?

How much does your contractor health and safety program contribute to your overall health and safety

performance?

Have you evaluated your firms contractor health and safety program? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms development or implementation

of contractor safety.

If you were looking for a company your own firm could learn from, what companies do you think of as

having an exemplary contractor health and safety program?

C

o

n

t

r

a

c

t

o

r

S

a

f

e

t

y

T

r

a

i

n

i

n

g

About your firm

Do you have a written health and safety training program? Yes No

training topic/issue

who delivers

who receives

delivery method

How soon after hire or reassignment do employees receive general health and safety training?

As soon as possible Specific limit ___________ Before permitted to work

How soon after hire or reassignment do employees receive task-specific health and safety training?

As soon as possible Specific limit ___________ Before permitted to work

How soon after installation of new equipment do employees receive training in safe operation?

As soon as possible Specific limit ___________ Before permitted to work

Where do you obtain the instructional material to use in health and safety training programs?

Who develops task specific and new equipment training?

Training has a direct influence on developing and molding the safety knowledge,

skills, and attitudes that all employees need to prevent injuries and illness.

New employees receive introduction and

orientation training. This introduction training

includes orientation to the health and safety

policy manual. New employees receive a one day

orientation session to the company safety program

and spend time with a mentor in order to

perform the job safely and correctly. New

employees continue to train until the

trainer/mentor is satisfied that the new employee

can work alone.

Specific health and safety training is given to

supervisors on legislative responsibilities, how to

conduct periodic safety audits, identification of

hazards, and how to respond to safety problems.

All employees receive mandatory safety training

and are provided with retraining on a regular

basis. Training courses are offered on-site.

Training in work techniques for quality and

productivity includes safe work practices.

A training database that tracks training and re-

training for all employees is maintained.

Supervisors and Joint Health and Safety

Committee (JHSC) representatives are provided

with specialised training. JHSC representatives

undertake the same in-house training provided to

all management.

Safety training is direct and relevant and has

application for real work settings. For example,

training utilises video re-enactments of incidents

starring the employee involved and the group

team leader. The safety team makes a video-tape

after the incident investigation. The actors re-

enact the incident to describe what happened.

Root causes of the incident and suggested ways

that the incident could have been avoided are

discussed in training. Corrective action is taken

and shared amongst the employees.

Training effectiveness is measured through

improvement in quality and operational

performance, as well as comprehension and

application of predefined learning goals.

Examples of Training Practices

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

28

29

T

r

a

i

n

i

n

g

Is on-the-job training conducted to help ensure that workers perform all tasks safely and without risk to

their health?

What are the top three messages in your health and safety training programs?

1.

2.

3.

If nothing has changed in an employees equipment or job duties, how often on average does he or she

receive health and safety training after initial hire?

Please describe a few typical health and safety training programs including the topic, presenter, and

delivery method (movies, discussions, demonstrations, buddy-system, etc.) Which are the most effective?

Which does training include:?

company policies and procedures

specific job hazards

safety precautions

health precautions

job responsibilities

regulatory requirements

company enforcement policy

worker right to know

worker right to refuse unsafe work

What type of evaluation do you use to check the achievement of the learners and the effectiveness of the

programs?

What do you think are the most important elements of your health and safety training program?

Other topics?

30

T

r

a

i

n

i

n

g

Continuous improvement

How would you rate your firms health and safety training program?

No activity Needs improvement Satisfactory A model program

To what do you attribute the success of your health and safety training?

I would be willing to share the specifics of my company practices in this area.

For details on how to contact us see back page.

What would you tell others are the benefits of implementing a health and safety policy?

How much does your health and safety training contribute to your overall health and safety performance?

Have you evaluated your firms health and safety training program? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms development or implementation

of health and safety training.

If you were looking for a company your own firm could learn from, what companies do you think of as

having exemplary health and safety training?

T

r

a

i

n

i

n

g

31

C

o

m

m

u

n

i

c

a

t

i

o

n

A

b

o

u

t

S

a

f

e

t

y

About your firm

What is the most important health and safety message that top management communicates to employees?

Why?

How are health and safety messages developed?

What is the most frequently communicated health and safety message from top management to

employees?

What is the most important health and safety message employees communicate to top management?

What is the most frequently communicated health and safety message from employees to top

management?

Communications is a critical function in achieving the organizations health and

safety goals and objectives, and cascading the health and safety message throughout

the organization.

The CEO communicates expectations for health

and safety performance throughout the company.

The companys health and safety goals, objectives

and expectations are communicated to all

employees through the use of newsletters,

orientation sessions, and other measures such as:

monthly safety meetings

monthly safety themes set out in the

company calendar

Corporate annual report

E-mail bulletins on safety incidents

Updating of daily notice boards to spread

health and safety information.

Posting results of inspections, surveys, and

audits on bulletin boards.

Safety teams are used to ensure that all levels

within the organization can communicate

regularly on safety issues. Communication efforts

are integrated with the safety department,

engineering, and training.

Top management/executives ask questions about

health and safety when visiting shop floor areas.

Preparation of relevant questions in advance of

the visit enables non-technical managers to show

interest and support of health and safety working

conditions.

A safety communication program is developed to

heighten awareness among employees.

Campaigns are developed and include recognition

of individuals, groups or departments with

outstanding safety performance. Symbols and

slogans are used to build a communications

campaign. For example, the plant safety slogan is

located on the front entrance of the building, in

meeting rooms, calendars, and pay cheque

stuffers.

The company allocates a special room where

employees find current information about the

companys health and safety goals, accident

statistics, etc.

Examples of Communication Practices

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

32

33

C

o

m

m

u

n

i

c

a

t

i

o

n

A

b

o

u

t

S

a

f

e

t

y

For what health and safety messages would you use each of the following forms of communication?

Meetings/discussions ______________________________________________________________

Lectures/presentations _____________________________________________________________

Posters/signs/displays______________________________________________________________

Email/payroll stuffers ______________________________________________________________

Posted memos and reports __________________________________________________________

Communicate through managers _____________________________________________________

Peer communication _______________________________________________________________

Other___________________________________________________________________________

How do employees communicate health and safety concerns to senior management?

How often does the average employee have this opportunity?

How does the organization respond to employee concerns? (By whom, what response time standard?)

How is an employee notified of the outcome of his/her concern?

What role do slogans and campaign-type communication play in the success of your health and safety

program?

34

C

o

m

m

u

n

i

c

a

t

i

o

n

A

b

o

u

t

S

a

f

e

t

y

Continuous improvement

How would you rate your firms health and safety communications?

No activity Needs improvement Satisfactory A model program

To what do you attribute the success of your health and safety communications?

I would be willing to share the specifics of my company practices in this area.

For details on how to contact us see back page.

What would you tell others are the benefits of communications health and safety throughout the

organization?

How much does your health and safety communication contribute to your overall health and safety

performance?

Have you evaluated your firms health and safety communication program? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms development or implementation

of health and safety communication.

If you were looking for a company your own firm could learn from, what companies do you think of as

having an exemplary health and safety communications?

C

o

m

m

u

n

i

c

a

t

i

o

n

A

b

o

u

t

S

a

f

e

t

y

35

R

e

c

o

g

n

i

t

i

o

n

a

n

d

M

o

t

i

v

a

t

i

o

n

About your firm

Do you use incentives, recognition, and awards in your health and safety program?

When do you use negative consequences?

For what violations or failures?

What is a typical penalty for this violation?

When do you use positive rewards?

For what achievements?

What is a typical reward for this achievement?

Who might receive a reward or penalty?

The worker

A specialist such as safety specialist, nurse, or designer

A whole work team, department, etc.

The whole staff of the facility

The workers supervisor

How are recognition awards determined?

on a periodic schedule when a good thing occurs both

Does the rest of the organization know when a reward/penalty has been given? How?

Who actually administers a penalty?

Who actually delivers a reward?

Do departments compete for rewards?

Yes No If yes, what measurement is used to tally their scores?

Recognition can be used to enhance management commitment, improve attitudes

and motivation, and sustain desired performance

Pay increases and bonuses are related to the

employees health and safety performance.

Contractors are eligible to win safety prizes.

Awards are given for safe and healthy working

conditions and practices, not merely avoidance of

lost time claims.

To encourage employee participation in decision-

making, staff are encouraged to make suggestions

for improvements in health and safety by entering

suggestion/ideas for continuous improvement.

Each suggestion is eligible to win a prize at the

end of the contest period. For example, a name is

randomly selected and the winner receives a gift

certificate or a periodic luncheon is held for

everyone who puts in a suggestion, or an annual

prize is awarded for the most innovative

suggestion. Management is required to explore

the merits/benefits of the suggestions made by

staff.

Employee bonuses are affected by the company's

overall health and safety performance.

Examples of Recognition and Motivation Practices

Your Reaction

Have you used or tried any of the above practices? Yes No

If yes, which ones did you find effective and why?

36

Continuous improvement

How would you rate your firms health and safety recognition system?

No activity Needs improvement Satisfactory A model program

To what do you attribute the success of your health and safety recognition system?

I would be willing to share the specifics of my company practices in this area.

For details on how to contact us see back page.

What would you tell others are the benefits of implementing a recognition system?

How much do your health and safety recognition practices contribute to your overall health and safety

performance?

Have you evaluated your firms recognition/motivation program? Yes No

If yes, what indicators or measures did you use? What were the results of the evaluation?

How did you use the results?

Please share an example or two of specific actions or events in your firms health and safety incentives.

If you were looking for a company your own firm could learn from, what companies do you think of as

having an exemplary recognition and motivation program?

R

e

c

o

g

n

i

t

i

o

n

a

n

d

M

o

t

i

v

a

t

i

o

n

37

38

Measuring Health & Safety

What measurement(s) does your firm use to evaluate your overall health and safety performance?

Please rank to indicate which you consider most meaningful as a measure of health and safety and which

your firm relies most upon (1=most). (Please add any measures that you use that are not listed here.)

Meaningful Reliance

Frequency rate ______ ______

Compensation cost ______ ______

Severity rate ______ ______

Total number of injuries ______ ______

Regulatory violations ______ ______

Union health and safety grievances ______ ______

Worker feedback about unresolved concerns ______ ______

Indirect costs, e.g. loss replacement, sales lost ______ ______

Results of hazard inspections or audits ______ ______

Observations of safe work practices ______ ______

Others (please specify) _______________________________________________

_________________________________________________________________

_________________________________________________________________

How would you rate your firms performance measurement system?

No activity Needs improvement Satisfactory A model program

I would be willing to share the specifics of my company practices in this area. For further details on

how to contact us see back page.

How often do you compute the calculated performance scores (if used)?

Other than health and safety performance measures listed above, what criteria and sources of information

do you think determine top managements health and safety expectations?

More important than quantitative health and safety performance measures

Less important than quantitative health and safety performance measures

C

o

u

n

t

i

n

g

t

h

e

r

i

n

g

s

:

H

o

w

d

o

y

o

u

m

e

a

s

u

r

e

h

e

a

l

t

h

a

n

d

s

a

f

e

t

y

?

COMPANY PROFILE:

Company_______________________________________________________________________________________

Location _______________________________________________________________________________________

Contact(s) ______________________________________________________________________________________

Telephone _____________________________________________________ Fax ____________________________

E-mail address __________________________________________________________________________________

Company Demographics:

Industry Sector __________________________________________________________________________________

% of Workers Employed in Office _____________________________ % Non-office____________________________

Number of employees in your workplace ________________ In firm, Ontario-wide____________________________

Employee Characteristics:

% of Female ____________________________________________________________________________________

% of Male ______________________________________________________________________________________

Average Educational Level _________________________________________________________________________

Average Age ____________________________________________________________________________________

Unionized

Yes No

Predominant Language(s) Spoken ___________________________________________________________________

Average Length of Service _________________________________________________________________________

New Hires Per Year _______________________________________________________________________________

% of Shiftworkers ________________________________________________________________________________

Title of person completing workbook _________________________________________________________________

Title of person you report to ________________________________________________________________________

If you would like to share information with us related to your interest in benchmarking, discussing the workbook or your

model program in any of the health and safety elements, please contact Kathy Zoras, Senior Research/Policy Analyst at

416-344-4347 or fax at 416-344-4919 or e-mail: kathy_zoras@wsib.on.ca

Thank you for your participation.

39

You might also like

- JSA For HDPE Liner Fusion Welding PDFDocument4 pagesJSA For HDPE Liner Fusion Welding PDFHaleemUrRashidBangash67% (3)

- CHST Complete GuideDocument24 pagesCHST Complete GuideAshraf EL Wardagy67% (3)

- JSA SplicingDocument3 pagesJSA Splicingluis100% (4)

- Health & Safety - NEBOSH National General Certificate in Occupational Health & SafetyDocument8 pagesHealth & Safety - NEBOSH National General Certificate in Occupational Health & SafetyIuliana BodaNo ratings yet

- 006 Field Instrument InstallationDocument8 pages006 Field Instrument InstallationMohamed KasemNo ratings yet

- Concrete Surface Coating JSA-027Document5 pagesConcrete Surface Coating JSA-027shivgovind pal100% (1)

- Chevron Hazard Analysis Guidelines 2012Document10 pagesChevron Hazard Analysis Guidelines 2012valdivijNo ratings yet

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- Construction Job Safety AnalysisDocument8 pagesConstruction Job Safety AnalysisMohd Yazid Mohamad Yunus100% (1)

- Behaviour Based SafetyDocument26 pagesBehaviour Based SafetyTarun Kakkar0% (1)

- Boc India Limited: Induction ProgrammeDocument83 pagesBoc India Limited: Induction ProgrammeAyah'e BhinoNo ratings yet

- Health and Safety Assignment One - 2012-1Document4 pagesHealth and Safety Assignment One - 2012-1hkhan95No ratings yet

- Engineering ControlsDocument13 pagesEngineering Controlsmakmak9100% (1)

- Initial & Re-CertificationDocument107 pagesInitial & Re-CertificationSatya PrabhatNo ratings yet

- Near Miss Examples in The WorkplaceDocument2 pagesNear Miss Examples in The WorkplacefmitranoNo ratings yet

- Health and Safety Executive UK 2005 PDFDocument53 pagesHealth and Safety Executive UK 2005 PDFrnrmmanphdNo ratings yet

- What Is An Occupational Health and Safety (OH&S) Program?Document18 pagesWhat Is An Occupational Health and Safety (OH&S) Program?Varsha SinghNo ratings yet

- PDF HSA Ireland Best Practices in Safety GuideDocument19 pagesPDF HSA Ireland Best Practices in Safety GuidemanuelNo ratings yet

- Tripod Beta - Sledge Hammer - Final Final-2Document1 pageTripod Beta - Sledge Hammer - Final Final-2satrio aryo100% (1)

- Introduction To Behaviour Based SafetyDocument6 pagesIntroduction To Behaviour Based SafetyXindy Imey PratiwiNo ratings yet

- GE EHS SummaryDocument8 pagesGE EHS Summaryvivekshete0% (1)

- HSE PresentationDocument46 pagesHSE Presentationshan123455555555No ratings yet

- The Importance of Near Miss Reporting - What You Need To KnowDocument6 pagesThe Importance of Near Miss Reporting - What You Need To KnowaneethavilsNo ratings yet

- Near Miss ReportingDocument14 pagesNear Miss ReportingMuflihMuhammadNo ratings yet

- Accident CausationDocument4 pagesAccident CausationJoe Mark Costan AvilaNo ratings yet

- Learn From AccidentDocument43 pagesLearn From AccidentgkmlalNo ratings yet

- (I) GC2 Element 2 Transport v7 October 2015 RevisionDocument42 pages(I) GC2 Element 2 Transport v7 October 2015 RevisionMuhammad Ramzan100% (1)

- LOTO OshaDocument36 pagesLOTO OshaYoga PradanaNo ratings yet

- VP EHS Chief Sustainability Officer in ST Louis MO Resume Tom JanicikDocument2 pagesVP EHS Chief Sustainability Officer in ST Louis MO Resume Tom JanicikTom JanicikNo ratings yet

- Near MissDocument2 pagesNear MissHafidz Asy'ari AkbarNo ratings yet

- How Near Miss Reporting Can Stop AccidentsDocument9 pagesHow Near Miss Reporting Can Stop AccidentsaneethavilsNo ratings yet

- IOSH Managing SafelyDocument3 pagesIOSH Managing Safelyhsecouncil100% (1)

- Effective Safety Management Systems: by George RobothamDocument33 pagesEffective Safety Management Systems: by George RobothamLoganathan DharmarNo ratings yet

- Problems With Safety Observation Reporting - A Construction Industry Case StudyDocument34 pagesProblems With Safety Observation Reporting - A Construction Industry Case StudyRadger Teddy ManuelNo ratings yet

- OshaDocument14 pagesOsha12035safyaabdulmalik100% (2)

- Incident Causation Theory PDFDocument32 pagesIncident Causation Theory PDFironbutterfly13100% (2)

- ILO RecommedationsDocument10 pagesILO RecommedationsAmin UllahNo ratings yet

- Behaviour Based Safety: Presented byDocument14 pagesBehaviour Based Safety: Presented bynasrul draco100% (1)

- Safety ReportDocument99 pagesSafety ReportHorace Prophetic Davis100% (1)

- Zero HarmDocument2 pagesZero Harmtnsv222No ratings yet

- ISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFDocument5 pagesISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFpurva02No ratings yet

- Implementation of Behaviour Based SafetyDocument11 pagesImplementation of Behaviour Based SafetyAnoop NairNo ratings yet

- Case Study 1 - Health and Safety Policy - Final Draft - August 2018Document76 pagesCase Study 1 - Health and Safety Policy - Final Draft - August 2018lonnyNo ratings yet

- BS ISO 45001 Occupational Health and Safety Management SystemsDocument1 pageBS ISO 45001 Occupational Health and Safety Management SystemsvikNo ratings yet

- Ppe Matrix - SampleDocument36 pagesPpe Matrix - SampleTHANH ĐÔNG DinhNo ratings yet

- HSE New Hire OrientationDocument118 pagesHSE New Hire OrientationAbdullah AnarNo ratings yet

- Safe Work ProceduresDocument6 pagesSafe Work ProceduresZafar IqbalNo ratings yet

- Near Miss ReportDocument2 pagesNear Miss ReportPraveen KumarNo ratings yet

- Near Miss: Bureau of Workers' Compensation PA Training For Health & Safety (Paths)Document28 pagesNear Miss: Bureau of Workers' Compensation PA Training For Health & Safety (Paths)Wahyu ArdaniNo ratings yet

- Safety Talk - Leading and Lagging IndicatorsDocument2 pagesSafety Talk - Leading and Lagging IndicatorsmineprincessNo ratings yet

- Hazard Identification Reporting and Workplace Inspections - Group Safety Standard 11Document7 pagesHazard Identification Reporting and Workplace Inspections - Group Safety Standard 11reneth davidNo ratings yet

- Leading Indicators GN Feb14 PDFDocument78 pagesLeading Indicators GN Feb14 PDFPippo TopolinoNo ratings yet

- Work Place InspectionDocument24 pagesWork Place InspectionMayom MabuongNo ratings yet

- SOP 1 SOP For Consultation and Participation of WorkersDocument7 pagesSOP 1 SOP For Consultation and Participation of WorkersRASHA534No ratings yet

- Improving The Safety Culture in The Organization by Implementing Behaviour Based Safety (BBS)Document12 pagesImproving The Safety Culture in The Organization by Implementing Behaviour Based Safety (BBS)IJRASETPublicationsNo ratings yet

- Safe Operating Procedures GuideDocument12 pagesSafe Operating Procedures GuideRahul100% (2)

- Construction Safety: Working at HeightsDocument6 pagesConstruction Safety: Working at Heightsakb2853No ratings yet

- NEBOSH Examiner Reports January 2005Document10 pagesNEBOSH Examiner Reports January 2005Kay56No ratings yet

- Behavior-Based Safety and Occupational Risk Management - Scott Geller 2005Document24 pagesBehavior-Based Safety and Occupational Risk Management - Scott Geller 2005Jimmy LumanauwNo ratings yet

- Qualities of A Great HSE ProfessionalDocument3 pagesQualities of A Great HSE ProfessionalInnocent BhaikwaNo ratings yet