Professional Documents

Culture Documents

Crosslinked AMH

Crosslinked AMH

Uploaded by

kreeshnuCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 7.1. Count:: Weaving Calculation & Useful FormulasDocument12 pages7.1. Count:: Weaving Calculation & Useful FormulaskreeshnuNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Corr Starch AdhesivemanDocument44 pagesCorr Starch AdhesivemankreeshnuNo ratings yet

- Science Lab Equipment Study SheetDocument2 pagesScience Lab Equipment Study Sheetapi-314843596100% (1)

- Service & Maintenance: 30e 35e N35e 40e N40e 45eDocument98 pagesService & Maintenance: 30e 35e N35e 40e N40e 45eGiancarlho RiosNo ratings yet

- MercerizationDocument141 pagesMercerizationkreeshnuNo ratings yet

- Chronicle April07Document26 pagesChronicle April07Moni Sanker100% (1)

- Changes in Fabric Handle Resulting From Different Fabric FinishingDocument6 pagesChanges in Fabric Handle Resulting From Different Fabric Finishingapi-3733260No ratings yet

- Colorants and Auxiliaries Vol 2Document455 pagesColorants and Auxiliaries Vol 2Putri Mayangsari100% (11)

- Wrinkle Free FinishingDocument4 pagesWrinkle Free FinishingkreeshnuNo ratings yet

- WWW (1) .Thefreelibrary4u.tk Lec+1-+Introduction+to+Textile+Finishing 2Document19 pagesWWW (1) .Thefreelibrary4u.tk Lec+1-+Introduction+to+Textile+Finishing 2kreeshnuNo ratings yet

- Surfactant: Etymology and DefinitionDocument9 pagesSurfactant: Etymology and DefinitionkreeshnuNo ratings yet

- Bleaching of Textiles Using PaaDocument19 pagesBleaching of Textiles Using PaakreeshnuNo ratings yet

- MERCERIZATIONDocument141 pagesMERCERIZATIONshettisanjayNo ratings yet

- Powell: Hypo Batch Controller With Temperature Indicator (Digital ORP/ORP/Temperature System) 2400 SeriesDocument5 pagesPowell: Hypo Batch Controller With Temperature Indicator (Digital ORP/ORP/Temperature System) 2400 SerieskreeshnuNo ratings yet

- Sodium Hipochlorite ManualDocument79 pagesSodium Hipochlorite Manualeduardosch100% (2)

- 03 Prednaska EngDocument19 pages03 Prednaska EngkreeshnuNo ratings yet

- Cotton Yarn Dyeing Project ReportDocument6 pagesCotton Yarn Dyeing Project ReportkreeshnuNo ratings yet

- Flexural Stress Block Development For Polypropylene Hybrid Fibre Reinforced ConcreteDocument15 pagesFlexural Stress Block Development For Polypropylene Hybrid Fibre Reinforced ConcreteAjitpal Singh0% (1)

- Nynas OilDocument2 pagesNynas OilusefiNo ratings yet

- VagogyuruDocument856 pagesVagogyurupsnmyNo ratings yet

- Cummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-UpdateDocument34 pagesCummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-Updategilar herliana putraNo ratings yet

- Taylor Power SystemsDocument4 pagesTaylor Power SystemsTeresa CarterNo ratings yet

- MAN Truck 2012 Emergency Responders GuideDocument86 pagesMAN Truck 2012 Emergency Responders GuideForum PompieriiNo ratings yet

- Ficha Técnica Cat DEO - 15W40 & 10W30Document2 pagesFicha Técnica Cat DEO - 15W40 & 10W30RhuanNo ratings yet

- NG NP Sikatop Seal 107Document3 pagesNG NP Sikatop Seal 107NourhoudaNo ratings yet

- Company ProfileDocument10 pagesCompany ProfilesamirNo ratings yet

- Cargo MT AfricaDocument72 pagesCargo MT AfricaPavel ViktorNo ratings yet

- 11.electric Motor DetailDocument3 pages11.electric Motor Detailrp63337651No ratings yet

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- Alumi Frame FormworkDocument12 pagesAlumi Frame FormworkSullam SyamsunNo ratings yet

- Dow Corning Adhesives BrochureDocument9 pagesDow Corning Adhesives BrochureHeywoodNo ratings yet

- ADMIX - RotosolverDocument2 pagesADMIX - RotosolverRaul DiazNo ratings yet

- (Solid Mechanics and Its Applications 218) David Wagg, Simon Neild (Auth.) - Nonlinear Vibration With Control - For Flexible and Adaptive Structures-Springer International Publishing (2015)Document461 pages(Solid Mechanics and Its Applications 218) David Wagg, Simon Neild (Auth.) - Nonlinear Vibration With Control - For Flexible and Adaptive Structures-Springer International Publishing (2015)oscar201140No ratings yet

- (A3) Cementitious Waterproofing Applicator ListDocument1 page(A3) Cementitious Waterproofing Applicator ListjimdabrondNo ratings yet

- Commissioning ChecklistDocument20 pagesCommissioning ChecklistRPM28XINo ratings yet

- g5 Fuse Relays PDFDocument17 pagesg5 Fuse Relays PDFVukasin TaskovicNo ratings yet

- TD CTC 997 PuDocument2 pagesTD CTC 997 PuMeliany SariNo ratings yet

- Hot CrackingDocument3 pagesHot CrackingFsNo ratings yet

- CFRP System - Horse ConstructionDocument37 pagesCFRP System - Horse ConstructionAyman ElMawardyNo ratings yet

- LGA775 Socket: Mechanical Design GuideDocument25 pagesLGA775 Socket: Mechanical Design GuideFernando DislaNo ratings yet

- Diy Sls 3d PrinterDocument32 pagesDiy Sls 3d PrinterTF Escritório MGNo ratings yet

- Schott Borofloat Technical Data Sheet EnglishDocument1 pageSchott Borofloat Technical Data Sheet Englishlilian.agenaisNo ratings yet

- Outdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1Document48 pagesOutdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1Muhidin KozicaNo ratings yet

- LAOAC Solid WasteDocument5 pagesLAOAC Solid WasteMark Roed Onofre LuceroNo ratings yet

- CAT76A-AA Metric Accessories GDocument25 pagesCAT76A-AA Metric Accessories GM. GUNERNo ratings yet

Crosslinked AMH

Crosslinked AMH

Uploaded by

kreeshnuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosslinked AMH

Crosslinked AMH

Uploaded by

kreeshnuCopyright:

Available Formats

Revue Roumaine de Chimie, 2007, 52(11), 10711076

SYNTHESIS OF POLYACRYLAMIDE - BASED HYDROGELS

BY SIMULTANEOUS POLYMERIZATION/CROSSLINKING

Camelia MIHILESCU,

a *

Anca DUMITRESCU,

b

Bogdan C. SIMIONESCU

a

and Victor BULACOVSCHI

a

a

Department of Macromolecules, Chemical Engineering Faculty, Gh. Asachi Technical University, 71A, Bd. D. Mangeron,

700050 Iasi, Roumania

b

Institute of Macromolecular Chemistry P. Poni, Aleea Grigore Ghica Voda 41A, 700487 Iasi, Roumania

Received January 15, 2007

A simultaneous polymerization/crosslinking method for preparing polyacrylamide based hydrogels is proposed. The

influence of different experimental parameters (chemical nature of the crosslinking agent, pH, monomer and initiator

concentration, temperature and reaction time) on crosslinked polymer yield and its swelling behavior was studied. Both

polymer yield and network structure as reflected by its swelling capacity depend on synthesis conditions and

mainly on monomer concentration in the initial monomer solution.

INTRODUCTION

A large variety of hydrogels were obtained

from many suitable monomers. Their properties

depend on the chemical nature of the starting

compounds and the crosslinking degree of the

resulting polymeric networks. They satisfy the

requirements imposed by different applications in

food industry, cosmetics, agriculture, medicine,

pharmacy, technical and electronic instrumentation,

photography etc.

The main property of hydrogels stands in their

capacity to absorb large amounts of water. This

characteristic depends on network structure,

determined by the experimental conditions used for

their preparation of polymer gels.

1

Earlier investigations were concerned with the

hydrophilic nature and the swelling ability of

hydrogels. Gradually, the investigation area was

extended and mechanical, diffusion and absorption

properties became of real interest since they confer

these materials the capacity to mime living tissues.

Last years, many papers reported the preparation

and swelling behavior of polyacrylamide (PAAm)

based hydrogels, which are of both theoretical and

practical interest.

2-9

Usually, these materials are

obtained by copolymerization of acrylamide (AAm)

with a bifunctional monomer, or by free radical

Corresponding author: cmihail@ch.tuiasi.ro

polymerization of AAm followed by crosslinking of

the resulted homopolymer.

9-11

The present paper

proposes the synthesis of PAAm based gels by a

simultaneous polymerization/ crosslinking method in

presence of aliphatic aldehydes as crosslinking

agents. The influence of experimental parameters on

both polymerization yield and swelling behavior of

hydrogels are discussed.

RESULTS AND DISCUSSION

The reaction of AAm with formaldehyde in

basic media is well known and largely used

in practice.

12

It forms methylol-acrylamide which,

in certain conditions, tourns in N,N-

methylenebis(acrylamide), usually used as

crosslinking agent in polymerization reactions.

It is worth mentioning that the methylolation

can be carried out, also, in polymer analogous

reactions between pre-synthesized PAAm and

formaldehyde in alkaline media. The obtained

products are expected to crosslink in proper

conditions, forming a gel structure.

Based on these considerations it was interesting

to undergo the preparation of PAAm - based gels

by a simultaneous polymerization/crosslinking

procedure of AAm in the presence of aldehydes

(Scheme I).

1072 Camelia Mihilescu et al.

Scheme 1 Schematic representation of the simultaneous polymerization/crosslinking of AAm.

Formaldehyde, butyraldehyde and 2,4-

dihydroxybenzaldehyde were tested as crosslinking

agents, at two pH values (a low acid, pH = 5.5 6

and a low basic, pH = 9.5) realized with Na

2

CO

3

buffer. The progress of the reaction was followed

determining the polymer yields and swelling

degrees. Reasonable polymer yields were obtained

with formaldehyde in basic conditions (Table 1);

this compound is more reactive as compared to the

other aliphatic or aromatic aldehydes in forming

methylolic intermediates. The high swelling degree

of the products obtained in the presence of

formaldehyde denote that the crosslinking has

occurred to a lesser extent.

The polymerization of AAm in presence of

butyraldehyde in basic media yields water- soluble

PAAm, which might suggest that no crosslinking

occurs. At the same time, 2,4-dihydroxybenzalde-

hyde forms low swelling capacity products, unable

to be used in hydrogel specific applications.

The evolution of the polymerization/

crosslinking reaction in presence of formaldehyde

is strongly influenced by pH. In basic conditions

the polymer yield reaches 50 %, the obtained gel

presenting a swelling degree of about 400 %. In

slight acid media the prepared hydrogels swell up

to 9.000%. One has to consider the formation, in acid

media, of low amounts of methylenebis(acrylamide),

able to copolymerize with AAm in a less structured

tridimensional network.

Polyacrylamidebased hydrogels 1073

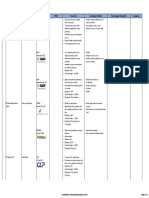

Table 1

Influence of crosslinking agent, at acid and basic pH values, on crosslinked polymer yield

No. Aldehyde pH Crosslinked polymer yield (%)

1 5.5 6.0 35.13

2

CH

2

O

9.5* 52.16

3 5.5 6.0 11.63

4

C

3

H

7

-CHO

9.5* ---

5 5.5 6.0 11.14

6

C

6

H

3

(OH)

2

CHO

9.5* 8.25

[AAm] = 3 (mol/L), [K

2

S

2

O

8

]/[AAm] (mol/mol) = 0.055, [aldehyde]/[AAm] (mol /mol) = 3/1, temperature = 50

o

C, reaction time = 5 h,

*buffer = Na

2

CO

3

( 0.53 %)

Normally, pH modification shouldn't affect the

tridimensional network structure obtained through

the polymerization/crosslinking process. No matter

the chemical nature of the intermediate compounds

and no matter the succession of elementary

reactions, the hydrogels structure should be the

same (Scheme 1).

The experimental data on the influence of

monomer and initiator concentrations, temperature

and reaction time reveal that polymer yields do not

overpass 50 % (Figs. 1 4). This is probably due

to the formation of a mixture of linear PAAm and

crosslinked product, during the polymerization/

crosslinking process, from which the former one is

eliminated through successive extractions during

the hydrogel purification.

Monomer concentration is the parameter that

affects the polymer synthesis. Both polymer yield

and network structure depend on initial monomer

concentration (Table 2), as previously observed in

different papers.

8,9

The modification of initiator concentration

([I

2

] = 0.094 0.85 %), even in large limits, of

temperature (T = 33 61

o

C) and polymerization

duration (t = 1 7 hs), determine minor changes in

polymer yield (Figs. 2 4). Also, initiator

concentration has no relevant influence on the

swelling behavior of the hydrogels (Table 3).

Table 2

Influence of initial monomer concentration on polymer swelling behaviour

No. [AAm]

(mol/l)

Swelling degree

( % )

Swelling rate constant

(min

1

)

1 0.56 3880 2.08

.

10

-4

2 1.40 4870 7.178

.

10

-5

3 2.24 9100 6.028

.

10

-5

[K

2

S

2

O

8

], 0.5 %; [CH

2

O] = 12.33 mol/L, pH = 5,5 6; temperature = 50

o

C; reaction duration =4 h

0 0.5 1 1.5 2 2.5

0

10

20

30

40

Y

i

e

l

d

(

%

)

[AAm] (mol/l)

Fig. 1 Influence of monomer concentration on

polymer yield. Temperature, 50

o

C; reaction duration,

4 h; [I

2

], 0.5 %; [CH

2

O] = 12.33 mol/L.

1074 Camelia Mihilescu et al.

0 20 40 60 80

0

20

40

60

Y

i

e

l

d

(

%

)

o

Temp ( C)

0 2 4 6 8

0

20

40

60

Y

i

e

l

d

(

%

)

Time (h)

Fig. 2 Influence of initiator concentration on

polymer yield. [AAm], 3 mol/L; [Aldehyde]/[AAm],

3/1 mol/mol; [I

2

], K

2

S

2

O

8

; temperature, 50

o

C;

reaction duration, 5 h.

Fig. 3 Influence of reaction temperature on

polymer yield. [AAm], 3 mol/L; [I

2

], 0.28%;

[Aldehyde]/[AAm], 5/1 mol/mol; reaction time, 4 h.

Fig. 4 Influence of polymerization duration on

polymer yield. [AAm], 3 mol/L; [I

2

], 0.28%;

temperature, 50

o

C; [CH

2

O]/[AAm], 5/1 mol/mol.

Polyacrylamidebased hydrogels 1075

Table 3

Influence of initiator concentration on polymer swelling behaviour

No. [I

2

]

(%)

Swelling degree

(%)

Swelling rate constant

(min

1

)

1 0.094 1100 4.4

.

10

-4

2 0.470 930 2.7

.

10

-4

3 0.850 1020 1.3

.

10

-4

[AAm], 3 mol/L; [Aldehyde]/[AAm], 3/1 mol/mol; [I

2

], K

2

S

2

O

8

; temperature, 50

o

C; reaction duration, 5 h; pH = 5,5 6.

The processing of the experimental swelling data yielded curves having shapes as presented in figure 5.

The resulting data, obtained from representation of this type, are given in Tables 2 and 3.

0 5000 1

.

10

4

1.5

.

10

4

2

.

10

4

0

1000

2000

3000

4000

S

w

e

l

l

i

n

g

d

e

g

r

e

e

(

%

)

Time (min)

0 2000 4000 6000 8000 1

.

10

4

2.5

2

1.5

1

0.5

0

ln

max

max

k 2.08 10

4

=

min

-1

Time ( min)

Fig. 5 Typical swelling kinetic curves (sample No. 1, Table 2).

EXPERIMENTAL

Materials

Acrylamide (Merck) was recrystallized from acetone/

methanol mixture (7/3 v/v) and dried in vacuum.

Formaldehyde, 37% solution (Chemical Company, Roumania),

butyraldehyde (B.D.H. Laboratory, Chemicals Division,

England) and 2,4-dihydroxybenzaldehyde (Fluka), all pure

chemical reagents, were used as delivered.

Potassium peroxodisulfate was purified just before use by

the usual method.

Procedure

The preparation of PAAm-based hydrogels was achieved

by an original polymerization/crosslinking procedure.

The reactions were carried out in a three-bottomed flask in

water, under nitrogen, at pre-established temperature, duration

and monomer, initiator and crosslinking agent concentrations.

The temperature was maintained with an accuracy of 0.5C.

At the end of the reaction the product was extracted in water,

to remove the non-reacted monomer and the homopolymer.

Subsequently, water in the polymer network was replaced with

methanol and the product dried to constant weight at 40

o

C.

The polymer yield was determined gravimetrically, the same

technique being used to follow the evolution of the

polymerization process. Several experiments were performed

to check the accuracy/reproducibility of the experimental data.

Swelling

The swelling of PAAm-based materials in water was

studied with a Dogatkin type apparatus, at room temperature.

The swelling degree () was determined according to

= (W

w

/W

p

) x 100

where W

w

represents the weight of absorbed water and W

p

the weight of the dry polymer.

The swelling rate constant was evaluated from the semi-

logarithmic plots of the swelling degree vs. time, by using the

Math Cad 7 Professional program.

CONCLUSIONS

A simultaneous polymerization/crosslinking

method to prepare PAAm-based hydrogels is

proposed. The obtained stable networks were

1076 Camelia Mihilescu et al.

characterized determining the swelling degrees that

are placed in the range of those specific to super

absorbent hydrogels.

Both polymer yield and swelling behavior

depend on chemical structure of the aldehyde

crosslinking agent and on medium pH.

The hydrogels crosslinking degree, as reflected

by their swelling ability, depends on synthesis

conditions. The most important parameter affecting

the swelling behavior was found to be the initial

concentration of the monomer.

REFERENCES

1. K. Dusek, Developments in polymerization, Haward

RN (Eds.), London: Applied Science, 1982, vol. 3, p. 143.

2. L. J. Puig, J. C. Sanchez-Diaz, M. Villacampa,

E. Mendizabal, J. E. Puig, A. Aguiar and I. Katime,

J. Colloid Interface Sci., 2001, 235, 278-282.

3. E. C. Muniz and G. Geuskens, J. Mat. Sci., Mat. Med.,

2001, 12, 879-881.

4. F. Di Benedetto, A. Biasco, D. Pisignano and R. Cingolani,

Nanotechnology, 2005, 16, S165-S170.

5. D. Melekaslan, N. Gundogan and O. Okay, Polymer

Bulletin, 2003, 50, 287-294.

6. N. Orakdogen and O. Okay, Polymer Bulletin, 2006, 57,

631-641.

7. N. Orakdogen, M. Y. Kizilay and O. Okay, Polymer,

2005, 46, 11407-11415.

8. J. P. Baker, L. H. Hong, H. W. Blanch and J. M. Prausnitz,

Macromolecules, 1994, 27, 1446-1454.

9. H. J. Naghash, A. Massah and A. Erfan, Eur. Polym. J.,

2002, 38, 147-150.

10. T. Tripathy, S. R. Pandey, N. C. Karmakar, R. P. Bhagat,

and R. P. Singh, Eur. Polym. J., 1999, 35, 2057-2072.

11. N. Bicak, D. C. Sherrington and B. F. Senkal, React.

Funct. Polym, 1999, 41, 69-76.

12. M. Dimonie, C. Boghina, C. Cincu, N. Marinescu and

M. Marinescu, Acrilamida, Seria Polimeri, Ed. Tehnic,

Bucureti, 1986.

13. H. Ghandehari, P. Kopeckova and J. Kopecek, Biomaterials,

1997, 18, 861-872.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 7.1. Count:: Weaving Calculation & Useful FormulasDocument12 pages7.1. Count:: Weaving Calculation & Useful FormulaskreeshnuNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Corr Starch AdhesivemanDocument44 pagesCorr Starch AdhesivemankreeshnuNo ratings yet

- Science Lab Equipment Study SheetDocument2 pagesScience Lab Equipment Study Sheetapi-314843596100% (1)

- Service & Maintenance: 30e 35e N35e 40e N40e 45eDocument98 pagesService & Maintenance: 30e 35e N35e 40e N40e 45eGiancarlho RiosNo ratings yet

- MercerizationDocument141 pagesMercerizationkreeshnuNo ratings yet

- Chronicle April07Document26 pagesChronicle April07Moni Sanker100% (1)

- Changes in Fabric Handle Resulting From Different Fabric FinishingDocument6 pagesChanges in Fabric Handle Resulting From Different Fabric Finishingapi-3733260No ratings yet

- Colorants and Auxiliaries Vol 2Document455 pagesColorants and Auxiliaries Vol 2Putri Mayangsari100% (11)

- Wrinkle Free FinishingDocument4 pagesWrinkle Free FinishingkreeshnuNo ratings yet

- WWW (1) .Thefreelibrary4u.tk Lec+1-+Introduction+to+Textile+Finishing 2Document19 pagesWWW (1) .Thefreelibrary4u.tk Lec+1-+Introduction+to+Textile+Finishing 2kreeshnuNo ratings yet

- Surfactant: Etymology and DefinitionDocument9 pagesSurfactant: Etymology and DefinitionkreeshnuNo ratings yet

- Bleaching of Textiles Using PaaDocument19 pagesBleaching of Textiles Using PaakreeshnuNo ratings yet

- MERCERIZATIONDocument141 pagesMERCERIZATIONshettisanjayNo ratings yet

- Powell: Hypo Batch Controller With Temperature Indicator (Digital ORP/ORP/Temperature System) 2400 SeriesDocument5 pagesPowell: Hypo Batch Controller With Temperature Indicator (Digital ORP/ORP/Temperature System) 2400 SerieskreeshnuNo ratings yet

- Sodium Hipochlorite ManualDocument79 pagesSodium Hipochlorite Manualeduardosch100% (2)

- 03 Prednaska EngDocument19 pages03 Prednaska EngkreeshnuNo ratings yet

- Cotton Yarn Dyeing Project ReportDocument6 pagesCotton Yarn Dyeing Project ReportkreeshnuNo ratings yet

- Flexural Stress Block Development For Polypropylene Hybrid Fibre Reinforced ConcreteDocument15 pagesFlexural Stress Block Development For Polypropylene Hybrid Fibre Reinforced ConcreteAjitpal Singh0% (1)

- Nynas OilDocument2 pagesNynas OilusefiNo ratings yet

- VagogyuruDocument856 pagesVagogyurupsnmyNo ratings yet

- Cummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-UpdateDocument34 pagesCummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-Updategilar herliana putraNo ratings yet

- Taylor Power SystemsDocument4 pagesTaylor Power SystemsTeresa CarterNo ratings yet

- MAN Truck 2012 Emergency Responders GuideDocument86 pagesMAN Truck 2012 Emergency Responders GuideForum PompieriiNo ratings yet

- Ficha Técnica Cat DEO - 15W40 & 10W30Document2 pagesFicha Técnica Cat DEO - 15W40 & 10W30RhuanNo ratings yet

- NG NP Sikatop Seal 107Document3 pagesNG NP Sikatop Seal 107NourhoudaNo ratings yet

- Company ProfileDocument10 pagesCompany ProfilesamirNo ratings yet

- Cargo MT AfricaDocument72 pagesCargo MT AfricaPavel ViktorNo ratings yet

- 11.electric Motor DetailDocument3 pages11.electric Motor Detailrp63337651No ratings yet

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- Alumi Frame FormworkDocument12 pagesAlumi Frame FormworkSullam SyamsunNo ratings yet

- Dow Corning Adhesives BrochureDocument9 pagesDow Corning Adhesives BrochureHeywoodNo ratings yet

- ADMIX - RotosolverDocument2 pagesADMIX - RotosolverRaul DiazNo ratings yet

- (Solid Mechanics and Its Applications 218) David Wagg, Simon Neild (Auth.) - Nonlinear Vibration With Control - For Flexible and Adaptive Structures-Springer International Publishing (2015)Document461 pages(Solid Mechanics and Its Applications 218) David Wagg, Simon Neild (Auth.) - Nonlinear Vibration With Control - For Flexible and Adaptive Structures-Springer International Publishing (2015)oscar201140No ratings yet

- (A3) Cementitious Waterproofing Applicator ListDocument1 page(A3) Cementitious Waterproofing Applicator ListjimdabrondNo ratings yet

- Commissioning ChecklistDocument20 pagesCommissioning ChecklistRPM28XINo ratings yet

- g5 Fuse Relays PDFDocument17 pagesg5 Fuse Relays PDFVukasin TaskovicNo ratings yet

- TD CTC 997 PuDocument2 pagesTD CTC 997 PuMeliany SariNo ratings yet

- Hot CrackingDocument3 pagesHot CrackingFsNo ratings yet

- CFRP System - Horse ConstructionDocument37 pagesCFRP System - Horse ConstructionAyman ElMawardyNo ratings yet

- LGA775 Socket: Mechanical Design GuideDocument25 pagesLGA775 Socket: Mechanical Design GuideFernando DislaNo ratings yet

- Diy Sls 3d PrinterDocument32 pagesDiy Sls 3d PrinterTF Escritório MGNo ratings yet

- Schott Borofloat Technical Data Sheet EnglishDocument1 pageSchott Borofloat Technical Data Sheet Englishlilian.agenaisNo ratings yet

- Outdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1Document48 pagesOutdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1Muhidin KozicaNo ratings yet

- LAOAC Solid WasteDocument5 pagesLAOAC Solid WasteMark Roed Onofre LuceroNo ratings yet

- CAT76A-AA Metric Accessories GDocument25 pagesCAT76A-AA Metric Accessories GM. GUNERNo ratings yet