Professional Documents

Culture Documents

Phenol Formaldehyde Resin

Phenol Formaldehyde Resin

Uploaded by

Anwesh SatapathyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phenol Formaldehyde Resin

Phenol Formaldehyde Resin

Uploaded by

Anwesh SatapathyCopyright:

Available Formats

Phenol formaldehyde resin

1

Phenol formaldehyde resin

Phenol formaldehyde resin

Identifiers

CAS number

9003-35-4

[1]

Except where noted otherwise, data are given for materials in their standard state (at 25C (77F), 100kPa)

Infoboxreferences

Phenol formaldehyde resins (PF) are synthetic polymers obtained by the reaction of phenol or substituted phenol

with formaldehyde. Phenolic resins are mainly used in the production of circuit boards. They are better known

however for the production of molded products including pool balls, laboratory countertops, and as coatings and

adhesives. In the form of Bakelite, they are the earliest commercial synthetic resin.

[2][3]

Formation and structure

Phenol-formaldehyde resins, as a group, are formed by a step-growth polymerization reaction that can be either acid-

or base-catalysed. Since formaldehyde exists predominantly in solution as a dynamic equilibrium of methylene

glycol oligomers, the concentration of the reactive form of formaldehyde depends on temperature and pH.

Phenol reacts with formaldehyde at the ortho and para sites (sites 2, 4 and 6) allowing up to 3 units of formaldehyde

to attach to the ring. The initial reaction in all cases involves the formation of a hydroxymethyl phenol:

HOC

6

H

5

+ CH

2

O HOC

6

H

4

CH

2

OH

The hydroxymethyl group is capable of reacting with either another free ortho or para site, or with another

hydroxymethyl group. The first reaction gives a methylene bridge, and the second forms an ether bridge:

HOC

6

H

4

CH

2

OH + HOC

6

H

5

(HOC

6

H

4

)

2

CH

2

+ H

2

O

The diphenol (HOC

6

H

4

)

2

CH

2

(sometimes called a "dimer") is called bisphenol F, which is an important monomer in

the production of epoxy resins. Bisphenol-F can further link generating tri- and tetra-and higher phenol oligomers.

2 HOC

6

H

4

CH

2

OH (HOC

6

H

4

CH

2

)

2

O + H

2

O

Phenol formaldehyde resin

2

Novolacs

Novolacs are phenol-formaldehyde resins with a formaldehyde to phenol molar ratio of less than one. The

polymerization is brought to completion using acid-catalysis such as oxalic acid, hydrochloric acid or sulfonate

acids. The phenol units are mainly linked by methylene and/or ether groups. Novolacs are commonly used as

photoresists. See also photolithography. The molecular weights are in the low thousands, corresponding to about

1020 phenol units.

Hexamethylenetetramine or "hexamine" is a hardener added to crosslink novolac. At a temperature >90 C, it forms

methylene and dimethylene amino bridges.

Novolac

Resoles

Base-catalysed phenol-formaldehyde resins are made with a

formaldehyde to phenol ratio of greater than one (usually around 1.5).

These resins are called resoles. Phenol, formaldehyde, water and

catalyst are mixed in the desired amount, depending on the resin to be

formed, and are then heated. The first part of the reaction, at around 70

C, forms a thick reddish-brown tacky material, which is rich in

hydroxymethyl and benzylic ether groups.

The rate of the base-catalysed reaction initially increases with pH, and reaches a maximum at about pH = 10. The

reactive species is the phenoxide anion (C

6

H

5

O

) formed by deprotonation of phenol. The negative charge is

delocalised over the aromatic ring, activating sites 2, 4 and 6, which then react with the formaldehyde.

Being thermosets, hydroxymethyl phenols will crosslink on heating to around 120 C to form methylene and methyl

ether bridges through the elimination of water molecules. At this point the resin is a 3-dimensional network, which is

typical of polymerised phenolic resins. The high crosslinking gives this type of phenolic resin its hardness, good

thermal stability, and chemical imperviousness. Resols are referred to as "one step" resins as they cure without a

cross linker unlike novolacs, a "two step" resin.

Resols are major polymeric resin materials widely used for gluing and bonding building materials. Exterior plywood,

oriented strand boards (OSB), engineered laminated composite lumber (LCL) are typical applications.

Crosslinking and the phenol/formaldehyde ratio

When the molar ratio of formaldehyde:phenol reaches one, in theory every phenol is linked together via methylene

bridges, generating one single molecule, and the system is entirely crosslinked. This is why novolacs (F:P <1) do not

harden without the addition of a crosslinking agent, and why resols with the formula F:P >1 will.

Applications

Phenolic resins are found in myriad industrial products. Phenolic laminates are made by impregnating one or more

layers of a base material such as paper, fiberglass or cotton with phenolic resin and laminating the resin-saturated

base material under heat and pressure. The resin fully polymerizes (cures) during this process. The base material

choice depends on the intended application of the finished product. Paper phenolics are used in manufacturing

electrical components such as punch-through boards and household laminates. Glass phenolics are particularly well

suited for use in the high speed bearing market. Phenolic micro-balloons are used for density control. Snooker balls

as well as balls from many table-based ball games are also made from phenol formaldehyde resin. The binding agent

in normal (organic) brake pads, brake shoes and clutch disks are phenolic resin. Synthetic resin bonded paper, made

from phenolic resin and paper, is used to make countertops.

Phenol formaldehyde resin

3

Phenolic resins are also used for making exterior plywood commonly known as WBP (Weather & boil proof)

Plywood because Phenolic resins have no melting point but only a decomposing point in the temperature zone of 220

degree Celsius & above.

Phenolic resin is used as a binder in loudspeaker driver suspension components which are made of cloth.

Sometimes people select phenolic resin parts because their coefficient of thermal expansion closely matches that of

the aluminum used for other parts of a system, as in early computer systems

[4]

and Duramold.

The Dutch forger Han van Meegeren mixed phenol formaldehyde with his oil paints before baking the finished

canvas in order to fake the drying out of the paint over the centuries.

Trade names

Maritex Aquarius is a very high performance bearing material made using novolac resin, fibre reinforcement and

added lubricants for momentary dry run situations. It is also used dry at slow speeds and high pressures, showing

very low wear rates of shaft or bearing.

Tufnol plate

Bakelite is made from phenolic resin and wood flour.

Novotext is cotton fibre-reinforced phenolic, using randomly

oriented fibres.

Oasis is "an open-celled phenolic foam that readily absorbs water

and is used as a base for flower arrangements."

Biodegradation

Phenol-formaldehyde is degraded by the white rot fungus

Phanerochaete chrysosporium

References

[1] http:/ / www. commonchemistry.org/ ChemicalDetail.aspx?ref=9003-35-4

[2] [2] A. Gardziella, L.A. Pilato, A. Knop, Phenolic Resins: Chemistry, Applications, Standardization, Safety and Ecology, 2nd edition, Springer,

2000

[3] [3] Wolfgang Hesse "Phenolic Resins" in Ullmann's Encyclopedia of Industrial Chemistry, 2002, Wiley-VCH, Weinheim. .

[4] J. G. Ferguson, W. E. Grutzner, D. C. Koehler, R. S. Skinner, M. T. Skubiak, and D. H. Wetherell. "No. 1 ESS Apparatus and Equipment"

(http:/ / www3. alcatel-lucent.com/ bstj/ vol43-1964/ articles/ bstj43-5-2355. pdf). The Bell System Technical Journal. 1964. p. 2417.

External links

No longer available from the previously linked source.

Article Sources and Contributors

4

Article Sources and Contributors

Phenol formaldehyde resin Source: http://en.wikipedia.org/w/index.php?oldid=617644983 Contributors: @pple, Almcmillan, Altenmann, Andy Dingley, Asterladybug, Benbest, Biscuittin,

Bjohns86, Brigade Piron, CensoredScribe, ChemGardener, Ciaccona, Cmsnead, Darrien, DavidCary, ECHOOooo, Edward, EvilFlyingMonkey, Femto, Gaius Cornelius, Iain99, Isnow, Jbusenitz,

Jcuadros, Jorge Stolfi, Joris Gillis, KJS77, Leyo, LilHelpa, Mark.hamid, Marknagel, Michel Awkal, Nikevich, Ost316, Paal.foyn, Plasmic Physics, Polychrome, Pratyya Ghosh, Pro crast in a tor,

RichiH, Rojypala, Rossami, SDasey, Sandcherry, Shaddack, Smokefoot, Souptikb, SpareHeadOne, TheBendster, Tony1, V8rik, Zureks, 72 anonymous edits

Image Sources, Licenses and Contributors

File:3-D_Structure_of_Bakelite.png Source: http://en.wikipedia.org/w/index.php?title=File:3-D_Structure_of_Bakelite.png License: GNU Free Documentation License Contributors:

JohnSRoberts99

File:Novolac.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Novolac.jpg License: Creative Commons Attribution-Sharealike 3.0 Contributors: User:Souptikb

File:Textolite.jpg Source: http://en.wikipedia.org/w/index.php?title=File:Textolite.jpg License: Creative Commons Zero Contributors: Zureks

License

Creative Commons Attribution-Share Alike 3.0

//creativecommons.org/licenses/by-sa/3.0/

You might also like

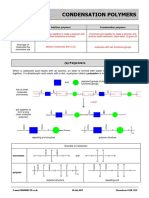

- Chemsheets GCSE 1237 Condensation Polymers ANS Mn74Document4 pagesChemsheets GCSE 1237 Condensation Polymers ANS Mn74lolNo ratings yet

- VuHaiNam - Assignment 7Document4 pagesVuHaiNam - Assignment 7Nam VuNo ratings yet

- Epoxy Resins - Manufacturing Process of Epoxy ResinsDocument1 pageEpoxy Resins - Manufacturing Process of Epoxy ResinsChirag Thakur0% (1)

- Preparation of PhenolDocument2 pagesPreparation of PhenolAwad SaidNo ratings yet

- Phenol Formaldehyde Resin. BakeliteDocument4 pagesPhenol Formaldehyde Resin. BakeliteRIMA AMIRA DARMAWANTI -100% (1)

- Synhetic Rubber Mnufcturing: By: Syed Mehran FaridDocument17 pagesSynhetic Rubber Mnufcturing: By: Syed Mehran FaridHarish YadavNo ratings yet

- Solution Polymerisation of StyreneDocument4 pagesSolution Polymerisation of StyreneMatthew Ong80% (5)

- Phthalocyanines 10.1002@14356007.a20 - 213Document34 pagesPhthalocyanines 10.1002@14356007.a20 - 213Ana VicoveanuNo ratings yet

- Bulk Polymerization of Styrene With AIBN PDFDocument1 pageBulk Polymerization of Styrene With AIBN PDFJenYerroNo ratings yet

- Styrene BulkPolymerizationDocument2 pagesStyrene BulkPolymerizationNitin Hansalia100% (1)

- Zone MeltingDocument4 pagesZone MeltingAnwesh SatapathyNo ratings yet

- And Then There Were NoneDocument312 pagesAnd Then There Were NoneAnwesh Satapathy100% (27)

- Types of Resist: Kuldeep Singh U11ec145Document5 pagesTypes of Resist: Kuldeep Singh U11ec145u11ee079No ratings yet

- Lecture Notes Polymer BasicsDocument218 pagesLecture Notes Polymer BasicsSanjay Kumar100% (1)

- Phenol FormaldehydeDocument4 pagesPhenol FormaldehydeyigitilgazNo ratings yet

- Phenol Formaldehyde ResinDocument3 pagesPhenol Formaldehyde ResinaliffNo ratings yet

- Phenol Formaldehyde Resin. BakeliteDocument7 pagesPhenol Formaldehyde Resin. BakeliteSO R ANNo ratings yet

- EBP 216 Exp 2Document15 pagesEBP 216 Exp 2Kelvin LimNo ratings yet

- History: Phenol Formaldehyde Resins or Phenolic Resins Are Synthetic Polymers Obtained by The ReactionDocument6 pagesHistory: Phenol Formaldehyde Resins or Phenolic Resins Are Synthetic Polymers Obtained by The ReactionIBIZANo ratings yet

- CT Lab Phenol FormaldehydeDocument6 pagesCT Lab Phenol FormaldehydeprasoonNo ratings yet

- Phenolic Resin AdhesivesDocument32 pagesPhenolic Resin AdhesivesDeepak BNo ratings yet

- Phenolic ResinDocument4 pagesPhenolic ResinVasu DevanNo ratings yet

- Phenyl Formaldehyde Resins Manufacture - DisasterDocument13 pagesPhenyl Formaldehyde Resins Manufacture - DisasterIndrajeet PaNo ratings yet

- MP DiolDocument6 pagesMP DiolJijo T GeorgeNo ratings yet

- Epoxy Resin ManufactureDocument17 pagesEpoxy Resin Manufactureradhika khannaNo ratings yet

- Inhibitors For Unsaturated Polyester Resines. Parker 1963Document4 pagesInhibitors For Unsaturated Polyester Resines. Parker 1963Guz UchihaNo ratings yet

- PolymersDocument13 pagesPolymersVaibhav ShrivastavaNo ratings yet

- Solvent Cement As Thermoplastic AdhesiveDocument18 pagesSolvent Cement As Thermoplastic AdhesiveShivam PanchalNo ratings yet

- Research of PhthalocyaninesDocument167 pagesResearch of PhthalocyaninesKristin PittmanNo ratings yet

- 2006, Production of Alkyd Resin - Effect of CatalystDocument5 pages2006, Production of Alkyd Resin - Effect of CatalystNhu TranNo ratings yet

- Manufacturing and Mass Balance of Copper Phthalocyanine (CPC) Blue and Green PigmentsDocument6 pagesManufacturing and Mass Balance of Copper Phthalocyanine (CPC) Blue and Green PigmentsAdvanced Research PublicationsNo ratings yet

- 06 - Chapter 1 PDFDocument42 pages06 - Chapter 1 PDFOmNo ratings yet

- Polymer Additives: Fillers & ReinforcementsDocument5 pagesPolymer Additives: Fillers & ReinforcementsHina Ibrahim100% (1)

- Flame Retardant Epoxy Resin Based On Bisphenol A Epoxy ResinDocument7 pagesFlame Retardant Epoxy Resin Based On Bisphenol A Epoxy ResinGajaraj GajapathiNo ratings yet

- Presentation of ALKYDDocument25 pagesPresentation of ALKYDthe0me100% (1)

- Paints and Pigments PDFDocument33 pagesPaints and Pigments PDFASWIN KUMAR100% (1)

- AdditivsDocument40 pagesAdditivsMohsin MalikNo ratings yet

- Alkyd Resin ManufacturingDocument6 pagesAlkyd Resin ManufacturingAmr Abdelmegid abdelsalam hussein100% (1)

- Resins and Resin CombinationDocument14 pagesResins and Resin CombinationAbdul qadeerNo ratings yet

- BRB Silanes Presentation PDFDocument48 pagesBRB Silanes Presentation PDFgokhanyaparNo ratings yet

- The Essential Ingredients in A PVC Formulation AreDocument7 pagesThe Essential Ingredients in A PVC Formulation AreRicky DavisNo ratings yet

- Activated Chemicals of Cementitious Capillary Crystalline WaterproofingDocument10 pagesActivated Chemicals of Cementitious Capillary Crystalline Waterproofingshahriz amriNo ratings yet

- Emulsion Polymers and Emulsion Polymerization (PDFDrive)Document596 pagesEmulsion Polymers and Emulsion Polymerization (PDFDrive)WALTER KLISSMANNo ratings yet

- Types of PolymerizationDocument27 pagesTypes of PolymerizationMizanul IslamNo ratings yet

- PolyetheretherkeytoneDocument4 pagesPolyetheretherkeytoneGriffin BeemillerNo ratings yet

- Polychloroprene ContDocument10 pagesPolychloroprene ContGilberto Monteiro100% (1)

- 2.synthetic Rubber TRG DR - JACOB K VARKEYDocument40 pages2.synthetic Rubber TRG DR - JACOB K VARKEYbodekizNo ratings yet

- Silicones - Preparation, Properties and PerformanceDocument14 pagesSilicones - Preparation, Properties and PerformanceMohit JoshiNo ratings yet

- CM17214 Project Report PolystyreneDocument60 pagesCM17214 Project Report Polystyrenemridul bhawaNo ratings yet

- Production of Melamine Fortified Urea-FormaldehydeDocument7 pagesProduction of Melamine Fortified Urea-FormaldehydeJaqueline MaraNo ratings yet

- Progresses in Synthesis of Pol PDFDocument15 pagesProgresses in Synthesis of Pol PDFKevin ChumánNo ratings yet

- Epoxy Resin CrystallisationDocument2 pagesEpoxy Resin CrystallisationabthakurNo ratings yet

- Aniket Dharanakar ReportDocument82 pagesAniket Dharanakar ReportAKSHAY JEDHENo ratings yet

- Melamineformaldehyde-Resin (MF-MUF Resins)Document13 pagesMelamineformaldehyde-Resin (MF-MUF Resins)Ivan Fisgativa VillarragaNo ratings yet

- Synthesis of PMMADocument5 pagesSynthesis of PMMATe-greg MillerNo ratings yet

- C Colours-Merged PDFDocument90 pagesC Colours-Merged PDFvinodhiniNo ratings yet

- Additives: Fully CompoundedDocument4 pagesAdditives: Fully CompoundedVy ThoaiNo ratings yet

- Market SurveyDocument4 pagesMarket SurveyGenesis LowNo ratings yet

- Styrene MonomerDocument13 pagesStyrene MonomerSerkan Gecim100% (2)

- PMMADocument17 pagesPMMAAnurag KhandelwalNo ratings yet

- Seminar On "Flame Retardent Synthetic Fibres": By: Raghav Mehra Mtech 1 YearDocument49 pagesSeminar On "Flame Retardent Synthetic Fibres": By: Raghav Mehra Mtech 1 YearRaghav MehraNo ratings yet

- Types of EpoxyDocument5 pagesTypes of EpoxybalsamNo ratings yet

- Moulding Powder TypeDocument12 pagesMoulding Powder TypendsramNo ratings yet

- The Plenco DifferenceDocument13 pagesThe Plenco DifferenceTaofik NurdiansahNo ratings yet

- Phenol FormaldehydeDocument22 pagesPhenol FormaldehydeRajput RudraNo ratings yet

- 1005 Syn LabDocument7 pages1005 Syn LabMuhammad Ubaid Ur RehmanNo ratings yet

- Urea FormaldehydeDocument5 pagesUrea FormaldehydeAnwesh SatapathyNo ratings yet

- Parting ProcesssDocument8 pagesParting ProcesssAnwesh SatapathyNo ratings yet

- Solvent Extraction and DewaxingDocument21 pagesSolvent Extraction and DewaxingAnwesh SatapathyNo ratings yet

- PolyurethaneDocument13 pagesPolyurethaneAnwesh SatapathyNo ratings yet

- Iodine ValueDocument3 pagesIodine ValueAnwesh SatapathyNo ratings yet

- IIIT BH Faculty Profile 2015 BatchDocument12 pagesIIIT BH Faculty Profile 2015 BatchAnwesh SatapathyNo ratings yet

- Acid ValueDocument3 pagesAcid ValueChaiwatTippuwananNo ratings yet

- Polymer Properties and ApplicationDocument9 pagesPolymer Properties and Applicationওয়াসিমNo ratings yet

- PEEK - Wikipedia, The Free EncyclopediaDocument2 pagesPEEK - Wikipedia, The Free EncyclopediasanjayrajeNo ratings yet

- Test 2 CHM572 June 2024Document3 pagesTest 2 CHM572 June 2024NUR AINA SYAHMINA MOHD AMRANNo ratings yet

- Polymer Basic 2 DKDocument6 pagesPolymer Basic 2 DKvanbanbinhdinhNo ratings yet

- Polyester ReportDocument25 pagesPolyester ReportTamilarasan PachiappenNo ratings yet

- Rapid #: - 22003388Document60 pagesRapid #: - 22003388Jayaramudu TippabattiniNo ratings yet

- USP Codigo Columnas PDFDocument2 pagesUSP Codigo Columnas PDFleslieNo ratings yet

- PVCDocument18 pagesPVCCemal KayaNo ratings yet

- Identification of PolymersDocument5 pagesIdentification of Polymersnithansa100% (1)

- Superabsorbent Polymers and Superabsorbent Polymer CompositesDocument5 pagesSuperabsorbent Polymers and Superabsorbent Polymer CompositesmutazsalihNo ratings yet

- Comparative Study Regarding Friction Coefficient For Three Epoxy ResinsDocument5 pagesComparative Study Regarding Friction Coefficient For Three Epoxy ResinsEdgar Arturo Gomez MeiselNo ratings yet

- Exelene Hdpe 5100MDocument1 pageExelene Hdpe 5100MAndres Quiroga JuarezNo ratings yet

- Synthetic Fibres2Document78 pagesSynthetic Fibres2nitishkohliNo ratings yet

- Chapter 1. The Sceince of Large MoleculesDocument27 pagesChapter 1. The Sceince of Large MoleculesSamsulNo ratings yet

- Plastics: Why Is Widely Used? Definition of TermsDocument9 pagesPlastics: Why Is Widely Used? Definition of TermsrenaNo ratings yet

- PPS-34 - Effect of Nucleating Agent Incorporation On Mechanical, Morphological, and Rheological Propoerties of in Situ Copolymer PP and PPH POE BlendsDocument5 pagesPPS-34 - Effect of Nucleating Agent Incorporation On Mechanical, Morphological, and Rheological Propoerties of in Situ Copolymer PP and PPH POE BlendsmansourotaibiNo ratings yet

- Lec 9-Compatibility of Polymer BlendsDocument7 pagesLec 9-Compatibility of Polymer BlendsMua ban linh tinh100% (1)

- Hyperbranched Polymers For Hardcoat With Superior PerformancesDocument5 pagesHyperbranched Polymers For Hardcoat With Superior PerformancesBernard HassonNo ratings yet

- 3rd and 4thDocument16 pages3rd and 4thmohsinNo ratings yet

- Pead Bimodal Sibur Pe HD03580SBDocument2 pagesPead Bimodal Sibur Pe HD03580SBvinicius SouzaNo ratings yet

- Polyurea Spray Elastomers An Overview of Current TechnologyDocument25 pagesPolyurea Spray Elastomers An Overview of Current TechnologyA MahmoodNo ratings yet

- Synthetic Fibres and Plastics: Unit Ii: Chemicals and MaterialsDocument32 pagesSynthetic Fibres and Plastics: Unit Ii: Chemicals and MaterialsAzra BaigNo ratings yet

- An Engineers Guide To Specify The Right ThermoplasticDocument63 pagesAn Engineers Guide To Specify The Right ThermoplasticChithiran CullenNo ratings yet

- Addition Polymerisation: PolymersDocument12 pagesAddition Polymerisation: PolymersTajmar JamesNo ratings yet

- Classification of PolymersDocument11 pagesClassification of Polymerssayon.ghosh1001No ratings yet

- Abdurachma Dan Malik - Indonesia - Full PaperDocument12 pagesAbdurachma Dan Malik - Indonesia - Full PaperJamaludin MalikNo ratings yet