Professional Documents

Culture Documents

5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0

5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0

Uploaded by

Nicholas Richardson0 ratings0% found this document useful (0 votes)

34 views8 pagesThis document provides specifications for a 5.0mm diameter full color LED lamp. It includes dimensions, materials, electrical and optical characteristics, and testing conditions. The LED uses red, green, and blue chips to produce full color light. It lists maximum ratings, forward voltage, wavelength, and luminous intensity parameters. Guidelines are provided for soldering, mounting, and handling to prevent damage to the LED.

Original Description:

Original Title

RGB CC 5mm

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for a 5.0mm diameter full color LED lamp. It includes dimensions, materials, electrical and optical characteristics, and testing conditions. The LED uses red, green, and blue chips to produce full color light. It lists maximum ratings, forward voltage, wavelength, and luminous intensity parameters. Guidelines are provided for soldering, mounting, and handling to prevent damage to the LED.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

34 views8 pages5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0

5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0

Uploaded by

Nicholas RichardsonThis document provides specifications for a 5.0mm diameter full color LED lamp. It includes dimensions, materials, electrical and optical characteristics, and testing conditions. The LED uses red, green, and blue chips to produce full color light. It lists maximum ratings, forward voltage, wavelength, and luminous intensity parameters. Guidelines are provided for soldering, mounting, and handling to prevent damage to the LED.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

5.

0 mm DIA LED LAMP

540R2GBC-CC

REV:A / 0

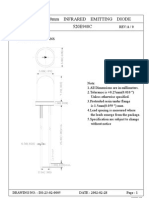

PACKAGE DIMENSIONS

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 1

HD-R/RD013

Note:

1.All Dimensions are in millimeters.

2.Tolerance is 0.25mm(0.010 ")

Unless otherwise specified.

3.Protruded resin under flange

is 1.5mm(0.059 ") max.

4.Lead spacing is measured where

the leads emerge from the package.

5.Specification are subject to change

without notice

6.highlight <-500V the led can

withstand the max static level when

assembling or operation.

5.0 mm DIA LED LAMP

540R2GBC-CC

REV:A / 0

FEATURES

* 5.0mm DIA LED LAMP

* LOW POWER CONSUMPTION.

* I.C. COMPATIBLE.

* THREE CHIPS ARE MATCHED FOR UNIFORM LIGHT OUTPUT.

* LONG LIFE-SOLIDSTATE RELIABILITY.

* FULL COLOR AND HIGH CONTRAST LAMP

CHIP MATERIALS

* Dice Material : AlGaInP/GaAs & GaInN/GaN & GaInN/GaN

* Light Color : FULL COLOR(SUPER RED & ULTRA PURE GREEN & ULTRA

BLUE)

* Lens Color : WATER CLEAR

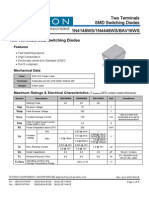

ABSOLUTE MAXIMUM RATING:(Ta25C)

SYMBOL DESCRIPTION

ULTRA

RED

ULTRA

PURE

GREEN

ULTRA

BLUE

UNIT

PAD Power Dissipation Per Chip 80 130 120 mW

VR Reverse Voltage Per Chip 5 5 5 V

IF Average Forward Current Per Chip 30 30 30 mA

IPF Peak Forward Current Per Chip (Duty=0.1,1KHZ) 60 120 70 mA

- Derating Linear From 25C Per Chip 0.4 0.4 0.4 mA/C

Topr Operating Temperature Range -25C to 85C

Tstg Storage Temperature Range -40C to 85C

Lead Soldering Temperature1.6mm(0.063 inch) From Body260C5C For 5 Seconds

ELECTRO-OPTICAL CHARACTERISTICS:(Ta=25C)

SYMBOL PARAMETER TEST CONDITION MIN. TYP. MAX. UNIT

Ultra Red 2.0 2.6 V

Ultra Pure Green 3.5 4.0 V VF

Forward Voltage

IF=20mA

Ultra Blue 3.5 4.0 V

Ultra Red 100 A

Ultra Pure Green 100 A IR Reverse Current VR=5V

Ultra Blue 100 A

Ultra Red 625 nm

Ultra Pure Green 525 nm D Dominant Wavelength IF=20mA

Ultra Blue 460 nm

Ultra Red 20 nm

Ultra Pure Green 22 nm Spectral Line Half-Width IF=20mA

Ultra Blue 30 nm

Ultra Red 40 deg

Ultra Pure Green 40 deg 21/2 Half Intensity Angle IF=20mA

Ultra Blue 40 deg

Ultra Red 1500 2100mcd

Ultra Pure Green 4200 5800mcd IV Luminous Intensity IF=20mA

Ultra Blue 1100 1500mcd

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 2

HD-R/RD014

5.0 mm DIA LED LAMP

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 3

540R2GBC-CC

REV:A / 0

5.0 mm DIA LED LAMP

540R2GBC-CC

REV:A / 0

SOLDERING

METHOD SOLDERING CONDITIONS REMARK

DIP

SOLDERING

Bath temperature: 2605

Immersion time: with 5 sec

Solder no closer than 3mm

from the base of the package

Using soldering flux, RESIN FLUX

is recommended.

SOLDERING

IRON

Soldering iron: 30W or smaller

Temperature at tip of iron: 260 or lower

Soldering time: within 5 sec.

During soldering, take care not to

press the tip of iron against the

lead.

(To prevent heat from being

transferred directly to the lead, hold

the lead with a pair of tweezers

while soldering

1) When soldering the lead of LED in a condition that the package is fixed with a panel (See Fig.1),

be careful not to stress the leads with iron tip.

2) When soldering wire to the lead, work with a Fig (See Fig.2) to avoid stressing the package.

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 4

Panel

(Fig.1)

Lead wries

Leave a slight

clearance

Lead wries

( Fig. 2)

5.0 mm DIA LED LAMP

540R2GBC-CC

REV:A / 0

3) Similarly, when a jig is used to solder the LED to PC board, take care as much as possible to

avoid steering the leads (See Fig.3).

4) Repositioning after soldering should be avoided as much as possible. If inevitable, be sure to

preserve the soldering conditions with irons stated above: select a best-suited method that

assures the least stress to the LED.

5) Lead cutting after soldering should be performed only after the LED temperature has returned to

normal temperature.

LED MOUNTING METHOD

1) When mounting the LED by using a case, as shown Fig.4, ensure that the mounting holds on

the PC board match the pitch of the leads correctly-tolerance of dimensions of the respective

components including the LED should be taken into account especially when designing the

case, PC board, etc. to prevent pitch misalignment between the leads and board holes, the

diameter of the board holes should be slightly larger than the size of the lead. Alternatively, the

shape of the holes should be made oval. (See Fig.4)

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 5

PC board

ig.3 F

jig

Fig.4

case

pc board

5.0 mm DIA LED LAMP

540R2GBC-CC

REV:A / 0

2) Use LEDs with stand-off (Fig.5) or the tube or spacer made of resin (Fig.6) to position the LEDs.

FORMED LEAD

1) The lead should be bent at a point located at least 2mm away from the package. Bending

should be performed with base fixed means of a jig or pliers (Fig.7)

2) Forming lead should be carried our prior to soldering and never during or after soldering.

3) Form the lead to ensure alignment between the leads and the hole on board, so that stress

against the LED is prevented. (Fig.8)

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 6

Stand-off

Fig.5 Fig.6

Tube

2

m

m

Fig.7

5.0 mm DIA LED LAMP

540R2GBC-CC

REV:A / 0

LEAD STRENGTH

1) Bend strength

Do not bend the lead more than twice. (Fig.9)

2) Tensile strength (@Room Temperature)

If the force is 1kg or less, there will be no problem. (Fig.10)

HANDLING PRECAUTIONS

Although rigid against vibration, the LEDs may damaged or scratched if dropped. So take care

when handling.

CHEMICAL RESISTANCE

1) Avoid exposure to chemicals as it may attack the LED surface and cause discoloration.

2) When washing is required, refer to the following table for the proper chemical to be sued.

(Immersion time: within 3 minutes at room temperature.)

SOLVENT ADAPTABILITY

Freon TE

Chlorothene

Isopropyl Alcohol

Thinner

Acetone

Trichloroethylene

--Usable --Do not use.

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 7

Fig.9

OK

Fig.10

1Kg

NOTE: Influences of ultrasonic cleaning of

the LED resin body differ depending

on such factors as the oscillator

output, size of the PC board and the

way in which the LED is mounted.

Therefore, ultrasonic cleaning should only be

performed after confirming there is no problem by

5.0 mm DIA LED LAMP

540R2GBC-CC

REV:A / 0

Experiment Item:

Test Condition

Item

Lamp & IR

Reference Standard

OPERATION LIFE

Ta 255

IF= 20mA RH=60%RH

DYNAMIC:100mA 1ms 1/10 duty

STATIC STATE: IF20mA

TEST TIME:

168HRS-24HRS+24HRS

500HRS-24HRS+24HRS

1000HRS-24HRS+72HRS

MIL-STD-7501026

MIL-STD-8831005

JIS C 7021B-1

HIGH

TEMPERATURE

HIGH HUMIDITY

STORAGE

Ta 655

RH 9095%RH

TEST TIME240HRS2HRS

MIL-STD-202103B

JIS C 7021 B-1

TEMPERATURE

CYCLING

10525-5525

30min 5min 30min 5min

10CYCLES

MIL-STD-202107D

MIL-STD-7501051

MIL-STD-8831010

JIS C 7021 A-4

THERMAL SHOCK

1055-555

10min 10min

10CYCLES

MIL-STD-202107D

MIL-STD-7501051

MIL-SYD-8831011

SOLDER

RESISTANCE

Tsol2605

DWELL TIME10lsec

MIL-STD-202210A

MIL-STD-750-2031

JIS C 7021A-1

SOLDERABILITY

Tsol2305

DWELL TIME5lsec

MIL-STD-202208D

MIL-STD-7502026

MIL-STD-8832003

JIS C 7021 A-2

DRAWING NO. : DS-35-04-0636 DATE : 2005-10-19 Page : 8

You might also like

- Fujifilm Finepix S1000fd Service ManualDocument112 pagesFujifilm Finepix S1000fd Service ManualAstronom SuceavaNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Unit 1 - IoT Web TechnologyDocument39 pagesUnit 1 - IoT Web Technologytrupti.kodinariya981094% (17)

- 5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Document8 pages5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Alexandru OleinicNo ratings yet

- LC4341-11 Datasheet, Pinout, Application Circuits SINGLE DIGIT DISPLAY LEDDocument6 pagesLC4341-11 Datasheet, Pinout, Application Circuits SINGLE DIGIT DISPLAY LEDordenador90No ratings yet

- Data Sheet: HLMP-RL20, HLMP-SL20Document9 pagesData Sheet: HLMP-RL20, HLMP-SL20Anonymous pMVR77x1No ratings yet

- 7 Segment LA5622-S2 DatasheetDocument6 pages7 Segment LA5622-S2 Datasheetcris_itdNo ratings yet

- DC363GDocument10 pagesDC363GpepenitoNo ratings yet

- Data Sheet: Tel: 025-84107685 Fax: 025-84107684Document10 pagesData Sheet: Tel: 025-84107685 Fax: 025-84107684angelNo ratings yet

- Led 5mm yDocument6 pagesLed 5mm yMarcos PainenahuelNo ratings yet

- D+led-Ld5rDocument6 pagesD+led-Ld5rJulia EchazarretaNo ratings yet

- Specification LR770D: SSC CustomerDocument12 pagesSpecification LR770D: SSC CustomerMangesh GaikwadNo ratings yet

- Especificacion Tecnica LEDDocument10 pagesEspecificacion Tecnica LEDJorge Herrero GarcíaNo ratings yet

- Stla-2835db Ver.ADocument20 pagesStla-2835db Ver.AjayveeNo ratings yet

- KDF71Document6 pagesKDF71ADANo ratings yet

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDocument2 pagesData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaNo ratings yet

- Product Specification: PLBT3-WDRG2613Document6 pagesProduct Specification: PLBT3-WDRG2613api-62031994No ratings yet

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290StuxnetNo ratings yet

- Nichia NF2L757DRT V1 DatasheetDocument20 pagesNichia NF2L757DRT V1 DatasheetJoseph NiksaNo ratings yet

- Vishay Bccomponents: FeaturesDocument16 pagesVishay Bccomponents: FeaturesPetrutStefanVartolomeiNo ratings yet

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetNo ratings yet

- DS-0035 3W PM2L-3LLx-SD v1.6Document13 pagesDS-0035 3W PM2L-3LLx-SD v1.6Pavan KumarNo ratings yet

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocument2 pagesHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNo ratings yet

- MCD288 DVD Micro Theatre: /all VersionsDocument39 pagesMCD288 DVD Micro Theatre: /all VersionsLeonelHernandezNo ratings yet

- Tdoct2014b EngDocument2 pagesTdoct2014b Engmahmoud abuelmgdNo ratings yet

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDocument6 pagesLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaNo ratings yet

- SMP1320 Series: Low Resistance, Low Capacitance, Plastic Packaged PIN DiodesDocument11 pagesSMP1320 Series: Low Resistance, Low Capacitance, Plastic Packaged PIN DiodesAnonymous CGk2roNo ratings yet

- Technical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2Document8 pagesTechnical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2StuxnetNo ratings yet

- A561E 7 SegmentosDocument5 pagesA561E 7 SegmentosRaulJoseRainieriNo ratings yet

- XZWR25X109FSNADocument8 pagesXZWR25X109FSNAMaik GonzalezNo ratings yet

- Sony Dsr-pd175 - pd177 - pd198 Service ManualDocument249 pagesSony Dsr-pd175 - pd177 - pd198 Service ManualPrime Lens100% (4)

- Piraña3plechipDocument5 pagesPiraña3plechipAdrianRamiroNo ratings yet

- TDA2008Document10 pagesTDA2008miusayNo ratings yet

- Ecm-Dm5p v1.1 PDFDocument4 pagesEcm-Dm5p v1.1 PDFginkgosvNo ratings yet

- AVAGO Proximity SensorDocument13 pagesAVAGO Proximity SensorshiroshkNo ratings yet

- Property of Lite-On Only FeaturesDocument11 pagesProperty of Lite-On Only FeaturesBLUEE009No ratings yet

- Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)Document2 pagesHobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)RodrigoNo ratings yet

- Service Manual: Digital Video Camera RecorderDocument174 pagesService Manual: Digital Video Camera RecorderBogdan BancilaNo ratings yet

- E 2209 AcdcDocument2 pagesE 2209 AcdcLuis Alejandro Gonzalez SantanaNo ratings yet

- Flyback Transformers: SchematicsDocument2 pagesFlyback Transformers: Schematicscatsoithahuong84No ratings yet

- Blanco Frío - LED-LD5WDocument7 pagesBlanco Frío - LED-LD5WLalo Sucasaca PampaNo ratings yet

- Varistor 222k.6kvDocument5 pagesVaristor 222k.6kvJess AJNo ratings yet

- Illustrated Assembly Manual k2543Document12 pagesIllustrated Assembly Manual k2543Herik Anahue CatuntaNo ratings yet

- Sony HCD-GNX60Document76 pagesSony HCD-GNX60kalentoneschatNo ratings yet

- Service Manual Incl. Parts KV-S3105C - KV-S3085Document274 pagesService Manual Incl. Parts KV-S3105C - KV-S3085smang1050% (2)

- 1N4148WS (SMD) PDFDocument5 pages1N4148WS (SMD) PDFRobmixNo ratings yet

- 5.0Mm Infrared Emitting Diode 520E940CDocument4 pages5.0Mm Infrared Emitting Diode 520E940CRonald TucumanNo ratings yet

- Elektro KomponenDocument150 pagesElektro KomponenRiky HidayatNo ratings yet

- To Customer P/N Ude P/N Description RV3-ZZ-0079 RJ45 1X1 Vertical Through HoleDocument11 pagesTo Customer P/N Ude P/N Description RV3-ZZ-0079 RJ45 1X1 Vertical Through HoleJackson ChanNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerNo ratings yet

- Illustrated Assembly Manual - Velleman K8042 Symmetric 1A Power SupplyDocument12 pagesIllustrated Assembly Manual - Velleman K8042 Symmetric 1A Power Supplymr_sharkNo ratings yet

- 1N5221B - 1N5267B: 500Mw Epitaxial Zener DiodeDocument2 pages1N5221B - 1N5267B: 500Mw Epitaxial Zener DiodeErickCortezAldacoNo ratings yet

- DCRHC30 - Sony ManualDocument73 pagesDCRHC30 - Sony ManualjunkmailboxforyourspamNo ratings yet

- P521Document3 pagesP521ge_bdNo ratings yet

- S 5800Document114 pagesS 5800elenoremailNo ratings yet

- 10.2Mm (0.4inch) Three Digit Numeric Dis-PlayDocument6 pages10.2Mm (0.4inch) Three Digit Numeric Dis-Playmolotov007No ratings yet

- Fa e Ka 3 GBDocument6 pagesFa e Ka 3 GBGabrielito PachacamaNo ratings yet

- Compact Sub Station BrochureDocument8 pagesCompact Sub Station BrochureAnimesh SahaNo ratings yet

- Kerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDocument5 pagesKerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDr.Thrivikramji.K.P.No ratings yet

- Poster RT 01Document1 pagePoster RT 01RuiFPTNo ratings yet

- Sanyo PLC-XP57 SM PDFDocument122 pagesSanyo PLC-XP57 SM PDFapex6744No ratings yet

- Alfa Laval Cooling Insulation Che00153enDocument2 pagesAlfa Laval Cooling Insulation Che00153enSuprabho IslamNo ratings yet

- Pavement Analysis and Design: OverviewDocument16 pagesPavement Analysis and Design: OverviewGerald SoberanoNo ratings yet

- CSC 452 SyllabusDocument2 pagesCSC 452 SyllabusCorey EllisNo ratings yet

- AE1102 Structures Slides 3Document26 pagesAE1102 Structures Slides 3SaraNo ratings yet

- Deck MachineryDocument10 pagesDeck Machineryaman kumarNo ratings yet

- Light System and Design Calculations ExampleDocument9 pagesLight System and Design Calculations ExampleMark Anthony GarciaNo ratings yet

- Philips 43pus7303Document20 pagesPhilips 43pus7303Vladimir ShestNo ratings yet

- Aire Acondicionado AttomDocument24 pagesAire Acondicionado AttomCecilia Ixtchel Zapata SanchezNo ratings yet

- Voet Chapt 11Document112 pagesVoet Chapt 11Sandhya KanetkarNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- Api 671Document6 pagesApi 671ecsuperalNo ratings yet

- Sigunit L54-45 AFDocument2 pagesSigunit L54-45 AFDudee DaryanNo ratings yet

- Hobart Hood Type DishwasherDocument24 pagesHobart Hood Type DishwasherneelkamalNo ratings yet

- Roll PinsDocument8 pagesRoll Pinshemanth337No ratings yet

- Faculty of Civil Engineering and Built Environment: Full ReportDocument36 pagesFaculty of Civil Engineering and Built Environment: Full ReportAndreas LarssonNo ratings yet

- Ametek 0Document19 pagesAmetek 0senthilrsenthilNo ratings yet

- 10774A ENU Beta TrainerHandbook Part1Document262 pages10774A ENU Beta TrainerHandbook Part1Engine Tuning UpNo ratings yet

- Doppler Sonar - Model DS30Document4 pagesDoppler Sonar - Model DS30Israel Moises Pareja CarriònNo ratings yet

- Evaluation of Blended Learning in Higher Education A Case StudyDocument9 pagesEvaluation of Blended Learning in Higher Education A Case StudyGlobal Research and Development ServicesNo ratings yet

- PMP Exam Brain Dump Sheet PM Lessons Learned GroupDocument15 pagesPMP Exam Brain Dump Sheet PM Lessons Learned GroupHany EldakakNo ratings yet

- Philips EnduraLED T8 Tube LED Light Installation GuideDocument3 pagesPhilips EnduraLED T8 Tube LED Light Installation GuideGreen SupplyNo ratings yet

- Curriculum Vitae: Personal Details Name: Address: Email: Phone: D.O.B Nationality VisasDocument5 pagesCurriculum Vitae: Personal Details Name: Address: Email: Phone: D.O.B Nationality VisasMick ThompsonNo ratings yet

- Gipam2200 Catalog e 0802Document36 pagesGipam2200 Catalog e 0802Tu CongVanNo ratings yet

- Release Note For Local Loading Tool (LLT) 4.5.3: Reference: ICO-OPE-00119 V04Document9 pagesRelease Note For Local Loading Tool (LLT) 4.5.3: Reference: ICO-OPE-00119 V04AleksandarNo ratings yet