Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

165 viewsFiducial Marks Characteristics - Paper

Fiducial Marks Characteristics - Paper

Uploaded by

PeZeroPeAFiducial marks are printed features on circuit boards that provide common measurable points to allow automated assembly machines to accurately locate and place components. They are necessary because boards can clamp slightly differently in machines, causing variances of tenths of a millimeter that could ruin the board. Fiducial marks come in different types for different uses, but generally involve a filled copper circle and are used by machines to measure their positions and compute any offsets needed for accurate placement of parts.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Volvo A30d Articulated Dump PDFDocument15 pagesVolvo A30d Articulated Dump PDFHamid Essarbouti100% (1)

- SMT Manufacturability Design GuidelinesDocument25 pagesSMT Manufacturability Design GuidelinespcbppcNo ratings yet

- SOP For Duct Leak TestingDocument8 pagesSOP For Duct Leak TestingSubodh Murkewar67% (3)

- Supply Chain Management ProjectDocument70 pagesSupply Chain Management ProjectTahseen Raza100% (1)

- FiducialDocument2 pagesFiducialRavi MeharwadeNo ratings yet

- Smema Fiducial Mark Standard Standard 3.1 1.0Document4 pagesSmema Fiducial Mark Standard Standard 3.1 1.0F1No ratings yet

- 04.Pcb Fiducial Mark Design Guidelines (0.04 MB)Document4 pages04.Pcb Fiducial Mark Design Guidelines (0.04 MB)essen999No ratings yet

- Why Do We Need PCB Fiducials and How To Use ItDocument12 pagesWhy Do We Need PCB Fiducials and How To Use ItjackNo ratings yet

- PCB Layout NotesDocument3 pagesPCB Layout NotesMehmet KibarNo ratings yet

- PCB Design Review ChecklistDocument4 pagesPCB Design Review Checklistraphael.souzaNo ratings yet

- IC Planning and Implementation (Physical Design) : FloorplanningDocument29 pagesIC Planning and Implementation (Physical Design) : FloorplanningVakeel Mohammad AnsariNo ratings yet

- SMT Seminar ReportDocument26 pagesSMT Seminar ReportShruthi Uppar100% (1)

- Lab Heet 10Document5 pagesLab Heet 10prashantNo ratings yet

- SMT Placement EquipmentDocument4 pagesSMT Placement EquipmentAjayChandrakarNo ratings yet

- PD ReferenceDocument69 pagesPD ReferenceAgnathavasiNo ratings yet

- In Order To Avoid The Change in Time Period or Duty Cycle of The Clock Signal Which in Turn Changes The Operating Frequency of A DesignDocument7 pagesIn Order To Avoid The Change in Time Period or Duty Cycle of The Clock Signal Which in Turn Changes The Operating Frequency of A DesignRajesh PerlaNo ratings yet

- Short Answer QuestionsDocument8 pagesShort Answer QuestionsRajyalakshmi MNo ratings yet

- Module 3 - 2Document49 pagesModule 3 - 2Biswajit LME016No ratings yet

- DFM GuidelinesDocument10 pagesDFM GuidelinesThe HoangNo ratings yet

- Seminar Report On SMTDocument12 pagesSeminar Report On SMTYashasvi Mittal100% (2)

- Vlsi Unit 3Document35 pagesVlsi Unit 3Mukesh Kamar kamatNo ratings yet

- What Is SMT FootprintDocument9 pagesWhat Is SMT FootprintjackNo ratings yet

- 09 PlacementDocument48 pages09 PlacementSujit Kumar100% (1)

- BudMesh2D TreadMesh3Document10 pagesBudMesh2D TreadMesh3Etienne JankovichNo ratings yet

- Setting OutDocument8 pagesSetting OutSuranga Gayan100% (1)

- SMT Manufacturability Design GuidelinesDocument25 pagesSMT Manufacturability Design Guidelinesizzati_2607100% (1)

- 1.1 Definition: Surface Mount TechnologyDocument17 pages1.1 Definition: Surface Mount TechnologySri LathaNo ratings yet

- Additive Manufacturing MaterialDocument60 pagesAdditive Manufacturing MaterialPRATIK JADHAVNo ratings yet

- Design For AssemblyDocument19 pagesDesign For AssemblyJavierNo ratings yet

- Floor Plan (Questions)Document6 pagesFloor Plan (Questions)ArunNo ratings yet

- 13 - Computer Aided Design I & II BDocument21 pages13 - Computer Aided Design I & II BJuan SilvaNo ratings yet

- Printed Circuit Board Manufacturing ProcessDocument2 pagesPrinted Circuit Board Manufacturing ProcessDipesh AggarwalNo ratings yet

- Me 8381 Lab ManualDocument36 pagesMe 8381 Lab ManualMohanraj SubramaniNo ratings yet

- Proe ReferenceDocument90 pagesProe ReferencesrinivaskayalaNo ratings yet

- EMP Chapter2Document24 pagesEMP Chapter2rushildhamandeNo ratings yet

- How To Design Step Groove PCB in Altium DesignerDocument5 pagesHow To Design Step Groove PCB in Altium DesignerjackNo ratings yet

- 35.2 Preliminaries and Basic Definitions: The Concept of TrackDocument4 pages35.2 Preliminaries and Basic Definitions: The Concept of TrackEr SarbeshNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- DFM Assembly Guidelines1 PDFDocument25 pagesDFM Assembly Guidelines1 PDFselvakumarNo ratings yet

- Digital read outDocument3 pagesDigital read outsjsuv82No ratings yet

- Electra AutorouterDocument9 pagesElectra Autoroutersnobic9379No ratings yet

- UltiboardDocument6 pagesUltiboardSwathy NairNo ratings yet

- Mass Manufacturing: Mechanical Roll No:16,17,18,23,94Document43 pagesMass Manufacturing: Mechanical Roll No:16,17,18,23,946016 RishithaNo ratings yet

- The Accuracy of Angle EncodersDocument9 pagesThe Accuracy of Angle EncodersatulNo ratings yet

- Stick Diagrams and LayoutsDocument17 pagesStick Diagrams and LayoutsPraneetha InumarthiNo ratings yet

- Machine Drawing PDFDocument50 pagesMachine Drawing PDFbrian Decker100% (1)

- MSA - 7 8 Prospekt ENDocument16 pagesMSA - 7 8 Prospekt ENChang Jun LeeNo ratings yet

- IC Design Process, BEOL, FEOLDocument6 pagesIC Design Process, BEOL, FEOLsrijaNo ratings yet

- VLSI Answer KeyDocument15 pagesVLSI Answer Keyrendezvous2k23No ratings yet

- Concepts and Terminology Used in Printed Circuit Boards (PCB)Document9 pagesConcepts and Terminology Used in Printed Circuit Boards (PCB)sonu24meNo ratings yet

- Printed Circuit BoardDocument16 pagesPrinted Circuit BoardAjayChandrakarNo ratings yet

- Total Station Interface ManualDocument21 pagesTotal Station Interface Manualsathisiva20100% (3)

- Geometric Dimensioning and Tolerancing (G.D.T)Document6 pagesGeometric Dimensioning and Tolerancing (G.D.T)harsharg6_8No ratings yet

- What Is PCB Fiducial Mark Used ForDocument9 pagesWhat Is PCB Fiducial Mark Used ForjackNo ratings yet

- 220 MHZ All-Mode Transverter PDFDocument6 pages220 MHZ All-Mode Transverter PDFvu2ttp0% (1)

- ProtaStructure Design Guide - Flat Slab and Raft Design With Slab Patch PanelsDocument15 pagesProtaStructure Design Guide - Flat Slab and Raft Design With Slab Patch PanelsCivil EngineerNo ratings yet

- Cadence Virtuso Layout EditorDocument18 pagesCadence Virtuso Layout EditorKrishna ChaitanyaNo ratings yet

- Placement: Key FeaturesDocument7 pagesPlacement: Key FeaturesNaveen Silveri100% (1)

- GD&T PDFDocument34 pagesGD&T PDFShruti SethNo ratings yet

- Hidden Surface Determination: Unveiling the Secrets of Computer VisionFrom EverandHidden Surface Determination: Unveiling the Secrets of Computer VisionNo ratings yet

- Polygon Computer Graphics: Exploring the Intersection of Polygon Computer Graphics and Computer VisionFrom EverandPolygon Computer Graphics: Exploring the Intersection of Polygon Computer Graphics and Computer VisionNo ratings yet

- Scanline Rendering: Exploring Visual Realism Through Scanline Rendering TechniquesFrom EverandScanline Rendering: Exploring Visual Realism Through Scanline Rendering TechniquesNo ratings yet

- Shader: Exploring Visual Realms with Shader: A Journey into Computer VisionFrom EverandShader: Exploring Visual Realms with Shader: A Journey into Computer VisionNo ratings yet

- Masterroc MF 701: High-Performance Backfill AdmixtureDocument3 pagesMasterroc MF 701: High-Performance Backfill AdmixtureAlireza DehghanNo ratings yet

- Curriculum Vitae: Personal DetailDocument3 pagesCurriculum Vitae: Personal DetailArdiansah EkoNo ratings yet

- SPCC Specification For SteelDocument2 pagesSPCC Specification For SteelHikmah SusantiNo ratings yet

- SS490Document1 pageSS490Md. Abu Baker SiddikNo ratings yet

- Structural ConnectionsDocument205 pagesStructural ConnectionsbsitlerNo ratings yet

- Year - End Yes-O Accomplishment Report 2023Document8 pagesYear - End Yes-O Accomplishment Report 2023NELDANo ratings yet

- About StetterDocument9 pagesAbout Stettergsm.nkl6049No ratings yet

- FRM SMRDocument8 pagesFRM SMRAnonymous 8HnV4CAo100% (1)

- All About Polyester FinishesDocument16 pagesAll About Polyester FinishessegbukNo ratings yet

- A Flock PrintingDocument34 pagesA Flock Printingaqsa imranNo ratings yet

- Geo NotesDocument7 pagesGeo NotesFaria KhanNo ratings yet

- Basic Calculations For A Power Plant-Calculating The Coal QuantityDocument9 pagesBasic Calculations For A Power Plant-Calculating The Coal QuantityRama KrishnaNo ratings yet

- Technical Data Sheet: Crompton Greaves Consumer Electricals LimitedDocument2 pagesTechnical Data Sheet: Crompton Greaves Consumer Electricals LimitedAniNo ratings yet

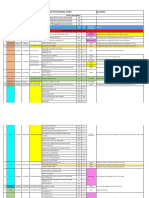

- All PR's Daily Report 25-Nov-2023Document44 pagesAll PR's Daily Report 25-Nov-2023adnanmushtaqpa00416No ratings yet

- Ndd010-Mcs Type B - Rev.j Mcs33Document4 pagesNdd010-Mcs Type B - Rev.j Mcs33edgarpatoNo ratings yet

- Zanussi Zdi 200 Users Manual 205681 PDFDocument32 pagesZanussi Zdi 200 Users Manual 205681 PDFLuisMi Gonzalez JimenezNo ratings yet

- Hard Hats With Higher Electrical Resistance ProtectionDocument3 pagesHard Hats With Higher Electrical Resistance ProtectionartmalemitNo ratings yet

- H3-206E Shaft Arc Furnace PDFDocument8 pagesH3-206E Shaft Arc Furnace PDFRizky ArisandiNo ratings yet

- Amercoat: Amerlock 400AL/AL WNDocument4 pagesAmercoat: Amerlock 400AL/AL WNCad AutocadNo ratings yet

- United States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GDocument9 pagesUnited States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GFebrian Dimas Adi NugrahaNo ratings yet

- BHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134Document3 pagesBHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134pradhankruhsnaNo ratings yet

- PLC Lab 1Document2 pagesPLC Lab 1abhinandNo ratings yet

- MATRIX ODE Installation Manual v1.0Document12 pagesMATRIX ODE Installation Manual v1.0Aizul Zakaria Bin HamzahNo ratings yet

- Yorfk ZF 180 To 300Document7 pagesYorfk ZF 180 To 300Martin BourgonNo ratings yet

- Alternatives To Cfcs and Their Characteristics: Mse-Tot-Alternative Refrigerants - Final-Dec01.Ppt 1Document22 pagesAlternatives To Cfcs and Their Characteristics: Mse-Tot-Alternative Refrigerants - Final-Dec01.Ppt 1Kevin PiocNo ratings yet

- 2007 ColetDocument2 pages2007 ColetJost VielmetterNo ratings yet

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document24 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)aliihsan3461No ratings yet

Fiducial Marks Characteristics - Paper

Fiducial Marks Characteristics - Paper

Uploaded by

PeZeroPeA0 ratings0% found this document useful (0 votes)

165 views4 pagesFiducial marks are printed features on circuit boards that provide common measurable points to allow automated assembly machines to accurately locate and place components. They are necessary because boards can clamp slightly differently in machines, causing variances of tenths of a millimeter that could ruin the board. Fiducial marks come in different types for different uses, but generally involve a filled copper circle and are used by machines to measure their positions and compute any offsets needed for accurate placement of parts.

Original Description:

e: Fiducial marks characteristics - Paper.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFiducial marks are printed features on circuit boards that provide common measurable points to allow automated assembly machines to accurately locate and place components. They are necessary because boards can clamp slightly differently in machines, causing variances of tenths of a millimeter that could ruin the board. Fiducial marks come in different types for different uses, but generally involve a filled copper circle and are used by machines to measure their positions and compute any offsets needed for accurate placement of parts.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

165 views4 pagesFiducial Marks Characteristics - Paper

Fiducial Marks Characteristics - Paper

Uploaded by

PeZeroPeAFiducial marks are printed features on circuit boards that provide common measurable points to allow automated assembly machines to accurately locate and place components. They are necessary because boards can clamp slightly differently in machines, causing variances of tenths of a millimeter that could ruin the board. Fiducial marks come in different types for different uses, but generally involve a filled copper circle and are used by machines to measure their positions and compute any offsets needed for accurate placement of parts.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

Fiducial marks characteristics

Popa Marian - Bogdan

Advanced electronics technologies in automotive industry

Politehnica University, Faculty of Electronics, Telecommunications and Information Technology

Bucharest, Romania

popa.marianbogdan@gmail.com

Abstract - Most placement devices are fed boards for assembly by

a rail conveyor, with the board being clamped down in the assembly

area of the machine. Each board will clamp slightly differently than

the others, and the variance which will generally be only tenths of a

millimeter is sufficient to ruin a board without proper calibration.

Fiducial marks allow automated assembly equipment to accurately

locate and place parts on boards. These devices locate the circuit

pattern by providing common measurable points. By measuring the

location of the fids relative to the board plan stored in the machine's

memory, the machine can reliably compute the degree to which parts

must be moved relative to the plan, called offset, to ensure accurate

placement.

What is a fiducial mark?

FiducialMark - A printed board artwork feature (or

features) that is created in the same process as the printed

circuit board conductive pattern and that provides a common

measurable point for component mounting with respect to a

land pattern or land patterns.

In printed circuit board (PCB) design, fiducial marks,

also known as circuit pattern recognition marks or simply

"fids," allow automated assembly equipment to accurately

locate and place parts on boards. These devices locate the

circuit pattern by providing common measurable points. They

are usually made by leaving a circular area of the board bare

from solder-stop coating (similar to clearcoat), in which a

filled copper circle is placed. This center metallic disc can be

solder-coated, gold-plated or otherwise treated, although bare

copper is most common as it is not a current-carrying contact.

Why use fiducial marks?

Most placement devices are fed boards for assembly

by a rail conveyor, with the board being clamped down in the

assembly area of the machine. Each board will clamp slightly

differently than the others, and the variance which will

generally be only tenths of a millimeter is sufficient to ruin a

board without proper calibration. Consequently, a typical PCB

will have three fids to allow placement robots to precisely

determine the board's orientation. By measuring the location

of the fids relative to the board plan stored in the machine's

memory, the machine can reliably compute the degree to

which parts must be moved relative to the plan, called offset,

to ensure accurate placement.

Using three fids enables the machine to determine

offset in both the X and Y axes, as well as to determine if the

board has rotated during clamping, allowing the machine to

rotate parts to be placed to match. Parts requiring a very high

degree of placement precision, such as integrated circuit chip

packages with many fine leads, may have subsidiary fiducial

marks near the package placement area of the board to further

fine-tune the targeting.

Conversely, low end, low-precision boards may only

have two fiducials, or use fiducials applied as part of the

screen printing process applied to most circuit boards. Some

very low-end boards may use the plated mounting screw holes

as ersatz fiducials, although this yields very low accuracy.

For prototyping and small batch production runs, the

use of a fiducial camera can greatly improve the process of

board fabrication. By automatically locating fiducial markers,

the camera automates board alignment. This helps with front

to back and multilayer applications, eliminating the need for

set pins.

Fiducial marks design

Fiducial Marks are a feature of the printed circuit

board artwork, created in the same process as the circuit

artwork. The circuit pattern and fiducial should be etched at

the same step. Fiducial Marks provide common measurable

points for all steps in the assembly process. This allows all

automated assembly equipment to accurately locate the circuit

pattern. Fiducial Marks are generally categorized in: global,

local, panel, image fiducials.

Global Fiducials: fiducial marks used to locate the

position of all features on an individual printed circuit board.

When multiple boards are processed as a panel, the global

fiducials may also be referred to as panel fiducials if used to

locate the circuits from the panel datum.

Image Fiducials - Global fiducial marks on a multiple

printed circuit board fabrication panel that are located within

the perimeter of an end-product printed circuit board.

Local Fiducial - A fiducial mark (or marks) used to

locate the position of an individual land pattern on a printed

circuit board. Three local fiducial marks should be provided

when it is necessary to provide the most accurate correction

for both translational and rotational offsets. For these

applications the three local fiducial marks should be in a

triangular pattern and should be located as far apart as possible

within the perimeter of the land pattern.

Panel Fiducials - Global fiducial marks on a multiple

printed circuit board fabrication panel that are located outside

the perimeters of the end-product printed circuit boards.

Global and/or panel fiducials should ideally be

located on a three point grid based system, with the lower left

fiducial located at the 0,0 datum point and the other two

fiducials located in the positive X and Y directions.

Global fiducials should be located on all PCB layers

that contain components to be mounted with automated

equipment. This is true even if the circuit design contains no

fine pitch (<= .020 pitch) components, as most modern

assembly equipment uses vision recognition for PCB

alignment. While other circuit objects (via-holes, etc.) can be

used, this can compromise accurate component placement.

Requirements

The use and design of fiducial marks shall be in

accordance with the following requirements.

Global Fiducials.

Offsets - A minimum of two global fiducial marks

shall be provided when it is necessary to correct for

translational (X- and Y-position) and rotational offsets (theta-

position). These global fiducial marks should be located

diagonally opposite one another and as far apart as possible on

the printed circuit board or fabrication panel.

Nonlinear Distortions - A minimum of three global

fiducial marks shall be provided when it is necessary to

correct for nonlinear distortions, such as scaling, stretch and

twist. These global fiducials should be located in a triangular

pattern and should be located as far apart as possible on the

printed circuit board or fabrication panel.

Local Fiducials.

Translational Offsets - One or more local fiducial

marks shall be provided when it is necessary to correct for

translational (X- and Y-position). These local fiducial marks

shall be located inside the perimeter of the land pattern,

preferably at the center of the land pattern.

Translational and Rotational Offsets - A minimum of

two local fiducial marks shall be provided when it is necessary

to correct for both translational (X-and Y-position) and

rotational offsets (theta-position). These local fiducial marks

should be located either diagonally opposite one another

inside the perimeter of the land pattern or one should be

located in accordance with the requirements of global fiducials

requirements and the other located on the conductive pattern

of the printed circuit board.

If space is limited, a minimum of one local fiducial

mark may be used to correct translational offsets (x and y

position). The single fiducial should be located in the center of

the land pattern.

It is good practice to keep all fiducial marks the same

size as some assembly equipment is less flexible in its ability

to recognize different size marks on the same printed circuit

board.

Fiducial marks characteristics

Some general characteristics of fiducials are:

Shape. Choosing an optimal fiducial mark for a

specific application depends on the requirement. For instance,

the crosshair-shape that is easy for a human to employ may

not be appropriate for a machine vision approach capable of

edge detection. Some fiducials contain a combination of

features, which allows the same unit to work well with

different detection methods. For example, the bow-tie shape

has two rounded edges on the outside to generate a circle, as

well as a crosshair in the middle for manual alignment.

Figure 3. Commonly used fiducials

Clearly, any visual feature can be used as a fiducial if

its location is known (or can be computed) and it can be

automatically identified. Indeed, tracking systems designed for

use in unprepared environments have been proposed that use

regions, lines, and other natural environmental features.

However, most applications for fiducial images assume a

prepared space with specific images placed in the

environment, with the assumption that the relative

transformation between a camera frame and frames indicated

by the fiducials needs to be determined. In tracking

terminology, the position and orientation (six degrees of

freedom) of the frame marked by fiducials needs to be

identified relative to the camera. This problem is also

commonly referred to as pose estimation.

Determination of position and orientation of a

physical object relative to a camera frame requires the

correspondence of at least four non-linear points. As an

example, estimating the pose of a camera relative to a physical

environment will require the identification of four 2D points

in the camera image and knowledge of their 3D coordinates in

the world coordinate system. It is possible to compute pose

from only three points. However, the result is ambiguous,

generally emitting two, and often three or four, solutions.

Hence, any ideal fiducial solution supporting 6DOF pose

estimation should always provide a minimum of four points.

Additional points can be used to compute least-square

solutions that can average out errors and increase the

estimate's accuracy. Many fiducial methods utilize a single,

typically very simple, fiducial image such as a ring or disk

with the requirement that multiple fiducials must be

simultaneously tracked. Since the location of fiducials in

camera images will always be permuted by noise and

quantization error, there is a clear advantage to tracking

additional points, so fiducials that emit multiple tracking

points seem advantageous. Also, many applications require

tracking of styli, independent marked locations, or multiple

users, where placement of a large number of fiducial images is

prohibitive.

We reach the conclusion that an ideal fiducial image

should emit at least four points. Beyond that, it is clear that the

points should approximate a square. The size of the fiducial

equates to resolution in the capture image. Four points not in

the form of a square will result in some elements of the image

presenting a lesser resolution to the camera than others,

thereby decreasing tracking accuracy in corresponding

orientations.

This does not necessarily imply that the fiducial

image itself must be square. Any image that can emit four

points would suffice. However, there are clear computational

advantages to simplicity, and a square fiducial image is the

simplest possible fiducial emitting four points. The straight

edges of a square can be used to compute best-fit lines

allowing corners to be computed with greater, potentially sub-

pixel, accuracy.

Size. Smaller and crisper fiducials provide better

alignment. Minimum diameter is determined by the optical

system and the resolution of the motion hardware. Maximum

size is determined by the field of view of the imaging system.

Fiducial marks located on the same part should not vary in

size by more than a few percentage points.

Figure 4. Typical size of fiducials

Clearance. A clear area, devoid of any other circuit

features or markings, should be maintained around the fiducial

mark. The size of the clear area should be, minimally, equal to

the radius of the fiducial mark. When possible, the amount of

clearance around the mark should equal the marks diameter.

Figure 5. Fiducial mark diameter

Edge Clearance. A fiducial mark should be located

no closer to the edge than 7.62mm (0.300"), per Surface

Mount Equipment Manufacturers Association Standard

Transport Clearance.

Material. The material will be dictated by the part,

but etched metals, organics and raw ceramics are common.

The main points are mark resolution, permanence and

contrast. The fiducial mark should be bare or covered copper.

For optimum performance, there should be a high degree of

contrast between the surface of the fiducial mark and the

adjacent printed circuit board base material.

Contrast. Most machine vision recognition systems

perform best when a consistent high contrast is present

between the fiducial mark and the base material.

Coverings. The covering may be a clear anti-

oxidation coating, nickel plating, tin plating, or a hot-air

leveled solder coating.

Plating and coating Thickness. When used, the

thickness for the bare-copper fiducial mark plating or coating

should be from 0.005 to 0.01 0 mm [0.0002 to 0.0004 inch].

The thickness of a solder coating should never exceed 0.025

mm [0.001 inch].

Flatness. The flatness of the fiducial surface should

be 15m (0.0006") or flatter.

Land Patterns. The fiducial marks should be used in

conjunction with land patterns that have been designed in

accordance with the requirements of IPC-SM-782 (Surface

Mount Land Patterns (Configurations and Design Rules).

Conclusion

If specific panel components require high processing

accuracy, it may be best to use more local fiducials. However,

this also increases cycle time, as there are more alignments per

panel.

All the fiducial marks on a PCB must be identically

constructed.

It is important to respect all the standards defined

above for a good alignment with the pick and place machine.

Fiducial marks are presented in CAD documentation. There

we must find the origin of every circuit that makes up the

panel together with orientation in space. In the gerber

documentation fiducial marks are not represented in solder

paste layers, but the coordinates of fiducials are given in pick

and place documents.

REFERENCES

http://www.cepdinc.com/presentations/PcbLayoutGuidelines_files/fr

ame.htm,PCB Layout Checklist

http://airborn.com.au/method/doc.html,PCB Design Documentation

http://www.alternatezone.com/electronics/files/PCBDesignTutorialR

evA.pdf, PCB Design Layout Rules Recommendation

http://www.latticesemi.com/lit/docs/package/tn1074.pdf, PCB

Layout Recommendations

You might also like

- Volvo A30d Articulated Dump PDFDocument15 pagesVolvo A30d Articulated Dump PDFHamid Essarbouti100% (1)

- SMT Manufacturability Design GuidelinesDocument25 pagesSMT Manufacturability Design GuidelinespcbppcNo ratings yet

- SOP For Duct Leak TestingDocument8 pagesSOP For Duct Leak TestingSubodh Murkewar67% (3)

- Supply Chain Management ProjectDocument70 pagesSupply Chain Management ProjectTahseen Raza100% (1)

- FiducialDocument2 pagesFiducialRavi MeharwadeNo ratings yet

- Smema Fiducial Mark Standard Standard 3.1 1.0Document4 pagesSmema Fiducial Mark Standard Standard 3.1 1.0F1No ratings yet

- 04.Pcb Fiducial Mark Design Guidelines (0.04 MB)Document4 pages04.Pcb Fiducial Mark Design Guidelines (0.04 MB)essen999No ratings yet

- Why Do We Need PCB Fiducials and How To Use ItDocument12 pagesWhy Do We Need PCB Fiducials and How To Use ItjackNo ratings yet

- PCB Layout NotesDocument3 pagesPCB Layout NotesMehmet KibarNo ratings yet

- PCB Design Review ChecklistDocument4 pagesPCB Design Review Checklistraphael.souzaNo ratings yet

- IC Planning and Implementation (Physical Design) : FloorplanningDocument29 pagesIC Planning and Implementation (Physical Design) : FloorplanningVakeel Mohammad AnsariNo ratings yet

- SMT Seminar ReportDocument26 pagesSMT Seminar ReportShruthi Uppar100% (1)

- Lab Heet 10Document5 pagesLab Heet 10prashantNo ratings yet

- SMT Placement EquipmentDocument4 pagesSMT Placement EquipmentAjayChandrakarNo ratings yet

- PD ReferenceDocument69 pagesPD ReferenceAgnathavasiNo ratings yet

- In Order To Avoid The Change in Time Period or Duty Cycle of The Clock Signal Which in Turn Changes The Operating Frequency of A DesignDocument7 pagesIn Order To Avoid The Change in Time Period or Duty Cycle of The Clock Signal Which in Turn Changes The Operating Frequency of A DesignRajesh PerlaNo ratings yet

- Short Answer QuestionsDocument8 pagesShort Answer QuestionsRajyalakshmi MNo ratings yet

- Module 3 - 2Document49 pagesModule 3 - 2Biswajit LME016No ratings yet

- DFM GuidelinesDocument10 pagesDFM GuidelinesThe HoangNo ratings yet

- Seminar Report On SMTDocument12 pagesSeminar Report On SMTYashasvi Mittal100% (2)

- Vlsi Unit 3Document35 pagesVlsi Unit 3Mukesh Kamar kamatNo ratings yet

- What Is SMT FootprintDocument9 pagesWhat Is SMT FootprintjackNo ratings yet

- 09 PlacementDocument48 pages09 PlacementSujit Kumar100% (1)

- BudMesh2D TreadMesh3Document10 pagesBudMesh2D TreadMesh3Etienne JankovichNo ratings yet

- Setting OutDocument8 pagesSetting OutSuranga Gayan100% (1)

- SMT Manufacturability Design GuidelinesDocument25 pagesSMT Manufacturability Design Guidelinesizzati_2607100% (1)

- 1.1 Definition: Surface Mount TechnologyDocument17 pages1.1 Definition: Surface Mount TechnologySri LathaNo ratings yet

- Additive Manufacturing MaterialDocument60 pagesAdditive Manufacturing MaterialPRATIK JADHAVNo ratings yet

- Design For AssemblyDocument19 pagesDesign For AssemblyJavierNo ratings yet

- Floor Plan (Questions)Document6 pagesFloor Plan (Questions)ArunNo ratings yet

- 13 - Computer Aided Design I & II BDocument21 pages13 - Computer Aided Design I & II BJuan SilvaNo ratings yet

- Printed Circuit Board Manufacturing ProcessDocument2 pagesPrinted Circuit Board Manufacturing ProcessDipesh AggarwalNo ratings yet

- Me 8381 Lab ManualDocument36 pagesMe 8381 Lab ManualMohanraj SubramaniNo ratings yet

- Proe ReferenceDocument90 pagesProe ReferencesrinivaskayalaNo ratings yet

- EMP Chapter2Document24 pagesEMP Chapter2rushildhamandeNo ratings yet

- How To Design Step Groove PCB in Altium DesignerDocument5 pagesHow To Design Step Groove PCB in Altium DesignerjackNo ratings yet

- 35.2 Preliminaries and Basic Definitions: The Concept of TrackDocument4 pages35.2 Preliminaries and Basic Definitions: The Concept of TrackEr SarbeshNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- DFM Assembly Guidelines1 PDFDocument25 pagesDFM Assembly Guidelines1 PDFselvakumarNo ratings yet

- Digital read outDocument3 pagesDigital read outsjsuv82No ratings yet

- Electra AutorouterDocument9 pagesElectra Autoroutersnobic9379No ratings yet

- UltiboardDocument6 pagesUltiboardSwathy NairNo ratings yet

- Mass Manufacturing: Mechanical Roll No:16,17,18,23,94Document43 pagesMass Manufacturing: Mechanical Roll No:16,17,18,23,946016 RishithaNo ratings yet

- The Accuracy of Angle EncodersDocument9 pagesThe Accuracy of Angle EncodersatulNo ratings yet

- Stick Diagrams and LayoutsDocument17 pagesStick Diagrams and LayoutsPraneetha InumarthiNo ratings yet

- Machine Drawing PDFDocument50 pagesMachine Drawing PDFbrian Decker100% (1)

- MSA - 7 8 Prospekt ENDocument16 pagesMSA - 7 8 Prospekt ENChang Jun LeeNo ratings yet

- IC Design Process, BEOL, FEOLDocument6 pagesIC Design Process, BEOL, FEOLsrijaNo ratings yet

- VLSI Answer KeyDocument15 pagesVLSI Answer Keyrendezvous2k23No ratings yet

- Concepts and Terminology Used in Printed Circuit Boards (PCB)Document9 pagesConcepts and Terminology Used in Printed Circuit Boards (PCB)sonu24meNo ratings yet

- Printed Circuit BoardDocument16 pagesPrinted Circuit BoardAjayChandrakarNo ratings yet

- Total Station Interface ManualDocument21 pagesTotal Station Interface Manualsathisiva20100% (3)

- Geometric Dimensioning and Tolerancing (G.D.T)Document6 pagesGeometric Dimensioning and Tolerancing (G.D.T)harsharg6_8No ratings yet

- What Is PCB Fiducial Mark Used ForDocument9 pagesWhat Is PCB Fiducial Mark Used ForjackNo ratings yet

- 220 MHZ All-Mode Transverter PDFDocument6 pages220 MHZ All-Mode Transverter PDFvu2ttp0% (1)

- ProtaStructure Design Guide - Flat Slab and Raft Design With Slab Patch PanelsDocument15 pagesProtaStructure Design Guide - Flat Slab and Raft Design With Slab Patch PanelsCivil EngineerNo ratings yet

- Cadence Virtuso Layout EditorDocument18 pagesCadence Virtuso Layout EditorKrishna ChaitanyaNo ratings yet

- Placement: Key FeaturesDocument7 pagesPlacement: Key FeaturesNaveen Silveri100% (1)

- GD&T PDFDocument34 pagesGD&T PDFShruti SethNo ratings yet

- Hidden Surface Determination: Unveiling the Secrets of Computer VisionFrom EverandHidden Surface Determination: Unveiling the Secrets of Computer VisionNo ratings yet

- Polygon Computer Graphics: Exploring the Intersection of Polygon Computer Graphics and Computer VisionFrom EverandPolygon Computer Graphics: Exploring the Intersection of Polygon Computer Graphics and Computer VisionNo ratings yet

- Scanline Rendering: Exploring Visual Realism Through Scanline Rendering TechniquesFrom EverandScanline Rendering: Exploring Visual Realism Through Scanline Rendering TechniquesNo ratings yet

- Shader: Exploring Visual Realms with Shader: A Journey into Computer VisionFrom EverandShader: Exploring Visual Realms with Shader: A Journey into Computer VisionNo ratings yet

- Masterroc MF 701: High-Performance Backfill AdmixtureDocument3 pagesMasterroc MF 701: High-Performance Backfill AdmixtureAlireza DehghanNo ratings yet

- Curriculum Vitae: Personal DetailDocument3 pagesCurriculum Vitae: Personal DetailArdiansah EkoNo ratings yet

- SPCC Specification For SteelDocument2 pagesSPCC Specification For SteelHikmah SusantiNo ratings yet

- SS490Document1 pageSS490Md. Abu Baker SiddikNo ratings yet

- Structural ConnectionsDocument205 pagesStructural ConnectionsbsitlerNo ratings yet

- Year - End Yes-O Accomplishment Report 2023Document8 pagesYear - End Yes-O Accomplishment Report 2023NELDANo ratings yet

- About StetterDocument9 pagesAbout Stettergsm.nkl6049No ratings yet

- FRM SMRDocument8 pagesFRM SMRAnonymous 8HnV4CAo100% (1)

- All About Polyester FinishesDocument16 pagesAll About Polyester FinishessegbukNo ratings yet

- A Flock PrintingDocument34 pagesA Flock Printingaqsa imranNo ratings yet

- Geo NotesDocument7 pagesGeo NotesFaria KhanNo ratings yet

- Basic Calculations For A Power Plant-Calculating The Coal QuantityDocument9 pagesBasic Calculations For A Power Plant-Calculating The Coal QuantityRama KrishnaNo ratings yet

- Technical Data Sheet: Crompton Greaves Consumer Electricals LimitedDocument2 pagesTechnical Data Sheet: Crompton Greaves Consumer Electricals LimitedAniNo ratings yet

- All PR's Daily Report 25-Nov-2023Document44 pagesAll PR's Daily Report 25-Nov-2023adnanmushtaqpa00416No ratings yet

- Ndd010-Mcs Type B - Rev.j Mcs33Document4 pagesNdd010-Mcs Type B - Rev.j Mcs33edgarpatoNo ratings yet

- Zanussi Zdi 200 Users Manual 205681 PDFDocument32 pagesZanussi Zdi 200 Users Manual 205681 PDFLuisMi Gonzalez JimenezNo ratings yet

- Hard Hats With Higher Electrical Resistance ProtectionDocument3 pagesHard Hats With Higher Electrical Resistance ProtectionartmalemitNo ratings yet

- H3-206E Shaft Arc Furnace PDFDocument8 pagesH3-206E Shaft Arc Furnace PDFRizky ArisandiNo ratings yet

- Amercoat: Amerlock 400AL/AL WNDocument4 pagesAmercoat: Amerlock 400AL/AL WNCad AutocadNo ratings yet

- United States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GDocument9 pagesUnited States Patent (19) : Im, Naperville, Both of Ill. Attorney, Agent, or Firm-William C. Clarke Arthur GFebrian Dimas Adi NugrahaNo ratings yet

- BHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134Document3 pagesBHEL Creep-Testing-Requirements-As-Per-Ibr-1526376134pradhankruhsnaNo ratings yet

- PLC Lab 1Document2 pagesPLC Lab 1abhinandNo ratings yet

- MATRIX ODE Installation Manual v1.0Document12 pagesMATRIX ODE Installation Manual v1.0Aizul Zakaria Bin HamzahNo ratings yet

- Yorfk ZF 180 To 300Document7 pagesYorfk ZF 180 To 300Martin BourgonNo ratings yet

- Alternatives To Cfcs and Their Characteristics: Mse-Tot-Alternative Refrigerants - Final-Dec01.Ppt 1Document22 pagesAlternatives To Cfcs and Their Characteristics: Mse-Tot-Alternative Refrigerants - Final-Dec01.Ppt 1Kevin PiocNo ratings yet

- 2007 ColetDocument2 pages2007 ColetJost VielmetterNo ratings yet

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document24 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)aliihsan3461No ratings yet