Professional Documents

Culture Documents

Corrosion in Metals

Corrosion in Metals

Uploaded by

Jitendra KumarCopyright:

Available Formats

You might also like

- En 14015Document25 pagesEn 14015CITRIX100% (2)

- 7 Forms of Corrosion IDocument39 pages7 Forms of Corrosion IJesus De la RosaNo ratings yet

- Temper EmbrittlementDocument13 pagesTemper EmbrittlementAnonymous 5odj1Ic100% (1)

- Thermit Australia Product Catalogue 2012Document20 pagesThermit Australia Product Catalogue 2012Rey Luis Teh0% (1)

- Corrosion in MetalsDocument5 pagesCorrosion in MetalsPratama ZetoNo ratings yet

- Chemistry Project 2Document19 pagesChemistry Project 2JohnNo ratings yet

- Chloride Attack On Stainless SteelDocument9 pagesChloride Attack On Stainless SteelAnand GuptaNo ratings yet

- IGA/ EGP Het FractureDocument3 pagesIGA/ EGP Het Fractureitzme_sdNo ratings yet

- CORROSION Uniform CorrosionDocument101 pagesCORROSION Uniform Corrosionhal_nasik_planning5657100% (11)

- Condenser Tube LifeDocument12 pagesCondenser Tube LifeAlvinmorNo ratings yet

- Shell and Tube Heat ExchangerDocument54 pagesShell and Tube Heat ExchangerQOBITNo ratings yet

- Corrodium MarineDocument2 pagesCorrodium Marinekelvinc256No ratings yet

- Galvanic Corrosion - WikipediaDocument40 pagesGalvanic Corrosion - WikipediaAhmed Hashem AbdelmohsenNo ratings yet

- 1 CorrosionDocument18 pages1 CorrosionMelvin VargheseNo ratings yet

- Stainless SteelsDocument16 pagesStainless SteelsGnobelNo ratings yet

- Galvanic CorrosionDocument8 pagesGalvanic Corrosionravi8373No ratings yet

- To Study The Effect of Metal Coupling On Rate of CorrosionDocument13 pagesTo Study The Effect of Metal Coupling On Rate of CorrosionHimanshu58% (12)

- Chloride Attack On Stainless SteelDocument10 pagesChloride Attack On Stainless SteelgovimanoNo ratings yet

- Corrosion and Its PreventionDocument28 pagesCorrosion and Its PreventionMehul Neha Bisht100% (2)

- Remember TheseDocument34 pagesRemember Thesem_alodat6144No ratings yet

- Chloride Attack On Stainless SteelDocument7 pagesChloride Attack On Stainless Steelpravin_koyyanaNo ratings yet

- Etc.) - The Number of Grades Is Therefore Seemingly Infinite, With A Large NumberDocument16 pagesEtc.) - The Number of Grades Is Therefore Seemingly Infinite, With A Large Numberandres16012008No ratings yet

- Galvanic CorrosionDocument9 pagesGalvanic Corrosionesakkibabu19870% (1)

- Galvanic Corrosion WikipediaDocument7 pagesGalvanic Corrosion WikipediaCharles HernandezNo ratings yet

- Corrosion and Corrosion Theory 1.: Q 1.0.1 What Is Corrosion. or Define CorrosionDocument8 pagesCorrosion and Corrosion Theory 1.: Q 1.0.1 What Is Corrosion. or Define CorrosionmudassarNo ratings yet

- Corrosion Problems Associated With Stainless SteelDocument11 pagesCorrosion Problems Associated With Stainless SteelVivek RathodNo ratings yet

- 4PREVENTIONDocument44 pages4PREVENTIONaddoNo ratings yet

- Uniform, or General Attack. Galvanic, or Two-Metal Corrosion. Crevice Corrosion. PittingDocument49 pagesUniform, or General Attack. Galvanic, or Two-Metal Corrosion. Crevice Corrosion. PittingalaialiNo ratings yet

- Leaflet Corrosion of Arcelor MittalDocument6 pagesLeaflet Corrosion of Arcelor MittalKaushik PatelNo ratings yet

- Corrosion 4preventionسخةDocument45 pagesCorrosion 4preventionسخةali AbbasNo ratings yet

- Corrosion of Copper and Copper Alloys: Ahmed JabirDocument14 pagesCorrosion of Copper and Copper Alloys: Ahmed JabirAhmed JabirNo ratings yet

- Corrosion of Carbon SteelDocument3 pagesCorrosion of Carbon Steelvandanak_mechNo ratings yet

- Corrosion: Corrosion Is A Natural Process That Converts A Refined Metal Into ADocument15 pagesCorrosion: Corrosion Is A Natural Process That Converts A Refined Metal Into AWaqas LuckyNo ratings yet

- Corrosion, Stainless SteelDocument7 pagesCorrosion, Stainless Steelcsteimel47591No ratings yet

- Galvanic SeriesDocument11 pagesGalvanic SeriesblakasNo ratings yet

- Aluminum OxidationDocument9 pagesAluminum OxidationTarkan OdabasiNo ratings yet

- Durability Durability of of Steel Steel Structures StructuresDocument21 pagesDurability Durability of of Steel Steel Structures StructuresKris d100% (1)

- Corrosion of Aluminum and Its AlloysDocument5 pagesCorrosion of Aluminum and Its AlloysPyae PhyoaungNo ratings yet

- Corrosion of Aluminum and Its Alloys Forms of CorrosionDocument6 pagesCorrosion of Aluminum and Its Alloys Forms of Corrosionsyz4426No ratings yet

- Corrosion in Elec ApplicationsDocument6 pagesCorrosion in Elec Applicationsmohamadsadegh kamaliNo ratings yet

- The Phenomenon of Damage Due To Corrosion of Metals and The Choice of Stainless Steels For Counteracting This PhenomenonDocument3 pagesThe Phenomenon of Damage Due To Corrosion of Metals and The Choice of Stainless Steels For Counteracting This PhenomenonMatheus VillaNo ratings yet

- Galvanic Corrosion When Carbon and Steel Are Bonded Together.Document5 pagesGalvanic Corrosion When Carbon and Steel Are Bonded Together.chris_996No ratings yet

- Inter Granular CorrosionDocument25 pagesInter Granular CorrosionErsin AydınNo ratings yet

- Numeraical Simulations For Advancment in TechnologyDocument13 pagesNumeraical Simulations For Advancment in Technologysharan31No ratings yet

- Corrosion Testing of Metals - Is It Needed?: Presented atDocument21 pagesCorrosion Testing of Metals - Is It Needed?: Presented atandrea assanelliNo ratings yet

- Oxidation: Rusting by Taruvinga H.CDocument7 pagesOxidation: Rusting by Taruvinga H.CEmmanuel MukweshaNo ratings yet

- Aluminium and CorrosionDocument6 pagesAluminium and Corrosionfazyroshan100% (1)

- SUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Document11 pagesSUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Mufleh IdrisNo ratings yet

- Corrosion Types Encountered With Power Cables: ContentDocument5 pagesCorrosion Types Encountered With Power Cables: ContentVasudev AgrawalNo ratings yet

- CH 06 - Corrosion & ErosionDocument22 pagesCH 06 - Corrosion & ErosionvegaronNo ratings yet

- Corrosion Is The Gradual Destruction of Materials (Usually: MetalsDocument4 pagesCorrosion Is The Gradual Destruction of Materials (Usually: MetalsJonathan KingNo ratings yet

- Aluminium's Corrosion Resistance - Aluminium DesignDocument7 pagesAluminium's Corrosion Resistance - Aluminium DesignCarlos LuNo ratings yet

- Corrosion PreventionDocument41 pagesCorrosion Preventionali AbbasNo ratings yet

- Performance of Galvanized Steel ProductsDocument16 pagesPerformance of Galvanized Steel ProductsAndy ChongNo ratings yet

- Boiler Corrosion PDFDocument12 pagesBoiler Corrosion PDFWasif MalikNo ratings yet

- EngineerDocument38 pagesEngineerHumayun Rashid KhanNo ratings yet

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksFrom EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Selenium cells: The construction, care and use of selenium cells with special reference to the Fritts cellFrom EverandSelenium cells: The construction, care and use of selenium cells with special reference to the Fritts cellNo ratings yet

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarNo ratings yet

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarNo ratings yet

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarNo ratings yet

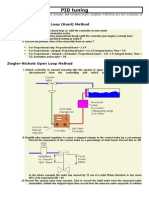

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarNo ratings yet

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarNo ratings yet

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarNo ratings yet

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarNo ratings yet

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- LiftingDocument5 pagesLiftingJitendra KumarNo ratings yet

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarNo ratings yet

- Halon 1301 Bromotrichlhoromethane CF3BrDocument2 pagesHalon 1301 Bromotrichlhoromethane CF3BrJitendra Kumar0% (1)

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarNo ratings yet

- Hydraulic SystemsDocument4 pagesHydraulic SystemsJitendra KumarNo ratings yet

- Hull ConstructionDocument4 pagesHull ConstructionJitendra KumarNo ratings yet

- Holding Down ArrangementsDocument3 pagesHolding Down ArrangementsJitendra KumarNo ratings yet

- Hydraulic GovernorsDocument6 pagesHydraulic GovernorsJitendra KumarNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Bucket Teeth CASEDocument9 pagesBucket Teeth CASEnemez1zNo ratings yet

- Parafusos InglesDocument58 pagesParafusos InglesheitormartNo ratings yet

- Brown and Sharpe Handbook Young MachinistsDocument326 pagesBrown and Sharpe Handbook Young Machinistscegur23100% (1)

- 01 - Different Types of Metal Joining ProcessesDocument44 pages01 - Different Types of Metal Joining ProcessesMetwally NaserNo ratings yet

- Astm A490Document20 pagesAstm A490cesardario90No ratings yet

- Key-Hole Plasma Arc Welding of 8 MM Thick Maraging Steel - A Comparison With Multi-Pass GtawDocument7 pagesKey-Hole Plasma Arc Welding of 8 MM Thick Maraging Steel - A Comparison With Multi-Pass Gtawkeep smileNo ratings yet

- Busbar TightnessDocument11 pagesBusbar Tightnesssanjeev267No ratings yet

- Super Abrasive CatalogueDocument8 pagesSuper Abrasive CatalogueBorisNo ratings yet

- Maintenance Free EARTHING1Document4 pagesMaintenance Free EARTHING1Akshay GatkalNo ratings yet

- Anaconda SS 304 Standard Fittings and Locknuts PDFDocument4 pagesAnaconda SS 304 Standard Fittings and Locknuts PDFBoiaflinNo ratings yet

- Low Carbon SteelsDocument6 pagesLow Carbon SteelsJimNo ratings yet

- Steel Requirements in Civil ConstructionDocument8 pagesSteel Requirements in Civil ConstructionRisa Dwi ParamithaNo ratings yet

- Zinc Alloy Coated Steel Wire With High Corrosion Resistance: Nippon Steel Technical Report No. 96 July 2007Document5 pagesZinc Alloy Coated Steel Wire With High Corrosion Resistance: Nippon Steel Technical Report No. 96 July 2007José SierraNo ratings yet

- ASTM A802!A802M - 95 (Reapproved 2010) - STD Practice For Steel Castings Surface Acceptance STD & Visual ExaminationDocument3 pagesASTM A802!A802M - 95 (Reapproved 2010) - STD Practice For Steel Castings Surface Acceptance STD & Visual ExaminationJoe ScopeliteNo ratings yet

- Astm F436M PDFDocument5 pagesAstm F436M PDFEnrique AntonioNo ratings yet

- ASTM A36/A36M Standard Specification For Carbon Structural SteelDocument4 pagesASTM A36/A36M Standard Specification For Carbon Structural SteeliuliamicutNo ratings yet

- Classification of Steel Welding and NDTDocument4 pagesClassification of Steel Welding and NDTALFA ENGINEERING0% (1)

- Effects of Prep On CreepDocument11 pagesEffects of Prep On CreepFlo RenceNo ratings yet

- Uni MechDocument2 pagesUni MechSAMPATHUNo ratings yet

- Ferrous & Non Ferrous Material PropertiesDocument6 pagesFerrous & Non Ferrous Material PropertiesTusharNo ratings yet

- Ammonium NH: List of Common IonsDocument2 pagesAmmonium NH: List of Common IonsCrispy ChickenNo ratings yet

- Bayer Process PDFDocument2 pagesBayer Process PDFFrandi CahyaNo ratings yet

- Phase DiagramsDocument80 pagesPhase DiagramsWilliams AkandiNo ratings yet

- SttaptiteDocument6 pagesSttaptiteSean YangNo ratings yet

- Gating System Design and Optimization in Sand MoldDocument19 pagesGating System Design and Optimization in Sand MoldĐinh Nguyễn Thành TrungNo ratings yet

- (2023) Extraction of Scandium From Bauxite Residue by High-Pressure (Icp)Document11 pages(2023) Extraction of Scandium From Bauxite Residue by High-Pressure (Icp)Mincen RevaNo ratings yet

Corrosion in Metals

Corrosion in Metals

Uploaded by

Jitendra KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrosion in Metals

Corrosion in Metals

Uploaded by

Jitendra KumarCopyright:

Available Formats

Corrosion in metals

Galvanic Action

Corrosion within cooling systems can occur if the coolant, i.e. water, has not been properly treated. The

corrosion can take the form of acid attack with resultant loss of metal from a large area of the exposed

surface, or by Oxygen attack characterised by pitting. A primary motive force for this corrosion is Galvanic

action

The Galvanic Series.

Or lectromotive series for metals

Cathode

Gold and !latinum

Titanium

"ilver

"ilver solder

Chromium#$ickel#%ron &!assive'

Chromium#%ron &!assive'

"tainless "teel &!assive'

Copper

(onel

)*+,* Cupro#$ickel

-)#,, $ickel#Copper

.ydrogen

lead

Tin

/#0 Tin lead "older

1ron2es

1rasses

$ickel

"tainless#"teel 03#3 &Active'

"tainless "teel 03#3#, &Active'

Chromium %ron &Active'

Chromium#$ickel#%ron &Active'

Cadmium

%ron

"teel

Cast %ron

Chromium

4inc

Aluminium

Aluminium Alloys

(agnesium

Anode

The metals closer to the anodic end of the list corrode with preference to the metals towards

the cathode end.

A galvanic cell can occur within an apparently .omogeneous material due to several processes

on of which is differential aeration where one area is exposed to more oxygen than another. The area with

less oxygen becomes anodic and will corrode.

Galvanic action within metal

Galvanic action due to temperature gradient

This situation can exist in cooling water systems with complex layout of heat exchangers and

passage ways within the diesel engine. "ystems containing readily corrodible metals such as 2inc, tin and

lead alloys can complicate and intensify problems by causing deposit formations.

Differential Aeration

#5here only a single metal exists within a system corrosion can still take place if the oxygen content of

the electrolyte is not homogenous. "uch a situation can occur readily in a 6acket water system as regions

of stagnant flow soon have the oxygen level reduced by the oxidation of local metal. The metal ad6acent

to water with reduced levels of oxygen become anodic to metals with higher oxygen content electrolyte in

contact with it. Generally, the anodic metal is small in comparison the cathode i.e. the area of stagnant

flow is small compared to the area of normal flow of electrolyte, and high rates of corrosion can exist. One

clear case of this is the generation of deep pits below rust scabs.

Corrosion of Metals

Steel (Fe)

5ill readily corrode by the reaction with oxygen in the water primarily by galvanic action.

The %ron reduces to %ron ions at anode, the oxygen is reduced by combining with water and

electrons passed from the anode &by iron changing to ions' to hydroxyl ions. Temperature, p. and the

concentration of oxygen all affect the rate of corrosion.

The oxygen reacts with the 7e

/8

to form .ematite &7e/O,' . This is a reddish brown loose

deposit. 5ith reduced oxygen content the formation of (agnetite &7e, O9' will occur. This is a more

tenacious layer and forms a protective boundary on the metal preventing further corrosion. This layer may

be removed in low p. or high p. conditions.

"cabs and tubercles of 7erric oxides and 7erric hydroxides form over an active pit.

Stainless Steels

These are alloys of steel with high chromium content &around 00:'. The alloying process results in a

material with excellent corrosion resistance. Oxygen combines with the chromium and iron to form a

tenacious self healing oxide layer.

The disadvantage of stainless steel is that in low oxygen environments, such as boil feed, the

corrosion resistance is actually reduced. %n addition stress corrosion cracking and pitting can occur when

in the presence of chlorine ions. %n this way stainless steel is not recommended in situations were

stagnant sea water might exists at it could perforate ;uicker than mild steel. The chlorine ions are the

correct right si2e to enter the atomic matrix of the metal and their concentration accelerates corrosion by

the propogation of cracks. Catastrophic failure can occur.

Copper(Cu) and Copper allos

<sed in heat exchangers due to there high heat conductivity. Copper corrosion in oxygenated water is

slow due to the time taken for oxygen to diffuse throught the oxide layer.

As copper is a relatively soft metal water velocities must be kept low. %ts presence can lead to

heavy pitting if deposited in steel systems. Ammonia in the water can remove the oxide layer and

promote rapid corrosion

Aluminium (Al)

%s essentially inert in neutral water up to about 03*=C. %t is ampoteric meaning it will corrode rapidly in

high and low p. conditions. %n the presence of "odium Carbonate or sodium hydroxide at p. above > this

corrosion is particularly severe. These conditions may exist were boiling occurs concentrating hydroxyl

ions.

!inc (!n)

%s anodic to steel and is often used as a protective coating on steel in a process called galvanising. %t is

ampoteric, corrosion increases in high and low p. conditions.

Note! At temperatures above 60'C the anodic/cathodic relationship with steel is reversed. This is of

particular importance in engine cooling sstems. The author has !oined a vessel were the third

engineer was merril fitting anodes to the clinder heads of a daihatsu generator engine. The fact

that the engine was fresh water cooled with inhibitor treatment also was ignored

%f galvanised pipes are to be fitted in a cooling circuit the coating must first be removed by

controlled acid washing.

Factors affecting corrosion rates

Temperature

As a rule of thumb for each 0*=C rise in temperature doubles the rate of corrosion.

The rate of oxygen diffusion increases in an open system with temperature up to around 3*=C.

A rapid tailing off then occurs due to the solubility of oxygen. 7or this reason open system feed tanks seen

on many vessels have heating coils which maintain the temeprature at 3?=C or higher.. %n a closed system

there is no such tail off as the oxygen cannot escape

p"#Al$alinit

The electrochemical nature of the metal will determine its corrosion rate with respect to p.. The corrosion

rate of iron reduces as the p. increases to about 0, due to the reduced solubility of the 7e ions.

Aluminium and 2inc, being ampoteric, have rates of corrosion that increases with p. higher or lower than

neutral

You might also like

- En 14015Document25 pagesEn 14015CITRIX100% (2)

- 7 Forms of Corrosion IDocument39 pages7 Forms of Corrosion IJesus De la RosaNo ratings yet

- Temper EmbrittlementDocument13 pagesTemper EmbrittlementAnonymous 5odj1Ic100% (1)

- Thermit Australia Product Catalogue 2012Document20 pagesThermit Australia Product Catalogue 2012Rey Luis Teh0% (1)

- Corrosion in MetalsDocument5 pagesCorrosion in MetalsPratama ZetoNo ratings yet

- Chemistry Project 2Document19 pagesChemistry Project 2JohnNo ratings yet

- Chloride Attack On Stainless SteelDocument9 pagesChloride Attack On Stainless SteelAnand GuptaNo ratings yet

- IGA/ EGP Het FractureDocument3 pagesIGA/ EGP Het Fractureitzme_sdNo ratings yet

- CORROSION Uniform CorrosionDocument101 pagesCORROSION Uniform Corrosionhal_nasik_planning5657100% (11)

- Condenser Tube LifeDocument12 pagesCondenser Tube LifeAlvinmorNo ratings yet

- Shell and Tube Heat ExchangerDocument54 pagesShell and Tube Heat ExchangerQOBITNo ratings yet

- Corrodium MarineDocument2 pagesCorrodium Marinekelvinc256No ratings yet

- Galvanic Corrosion - WikipediaDocument40 pagesGalvanic Corrosion - WikipediaAhmed Hashem AbdelmohsenNo ratings yet

- 1 CorrosionDocument18 pages1 CorrosionMelvin VargheseNo ratings yet

- Stainless SteelsDocument16 pagesStainless SteelsGnobelNo ratings yet

- Galvanic CorrosionDocument8 pagesGalvanic Corrosionravi8373No ratings yet

- To Study The Effect of Metal Coupling On Rate of CorrosionDocument13 pagesTo Study The Effect of Metal Coupling On Rate of CorrosionHimanshu58% (12)

- Chloride Attack On Stainless SteelDocument10 pagesChloride Attack On Stainless SteelgovimanoNo ratings yet

- Corrosion and Its PreventionDocument28 pagesCorrosion and Its PreventionMehul Neha Bisht100% (2)

- Remember TheseDocument34 pagesRemember Thesem_alodat6144No ratings yet

- Chloride Attack On Stainless SteelDocument7 pagesChloride Attack On Stainless Steelpravin_koyyanaNo ratings yet

- Etc.) - The Number of Grades Is Therefore Seemingly Infinite, With A Large NumberDocument16 pagesEtc.) - The Number of Grades Is Therefore Seemingly Infinite, With A Large Numberandres16012008No ratings yet

- Galvanic CorrosionDocument9 pagesGalvanic Corrosionesakkibabu19870% (1)

- Galvanic Corrosion WikipediaDocument7 pagesGalvanic Corrosion WikipediaCharles HernandezNo ratings yet

- Corrosion and Corrosion Theory 1.: Q 1.0.1 What Is Corrosion. or Define CorrosionDocument8 pagesCorrosion and Corrosion Theory 1.: Q 1.0.1 What Is Corrosion. or Define CorrosionmudassarNo ratings yet

- Corrosion Problems Associated With Stainless SteelDocument11 pagesCorrosion Problems Associated With Stainless SteelVivek RathodNo ratings yet

- 4PREVENTIONDocument44 pages4PREVENTIONaddoNo ratings yet

- Uniform, or General Attack. Galvanic, or Two-Metal Corrosion. Crevice Corrosion. PittingDocument49 pagesUniform, or General Attack. Galvanic, or Two-Metal Corrosion. Crevice Corrosion. PittingalaialiNo ratings yet

- Leaflet Corrosion of Arcelor MittalDocument6 pagesLeaflet Corrosion of Arcelor MittalKaushik PatelNo ratings yet

- Corrosion 4preventionسخةDocument45 pagesCorrosion 4preventionسخةali AbbasNo ratings yet

- Corrosion of Copper and Copper Alloys: Ahmed JabirDocument14 pagesCorrosion of Copper and Copper Alloys: Ahmed JabirAhmed JabirNo ratings yet

- Corrosion of Carbon SteelDocument3 pagesCorrosion of Carbon Steelvandanak_mechNo ratings yet

- Corrosion: Corrosion Is A Natural Process That Converts A Refined Metal Into ADocument15 pagesCorrosion: Corrosion Is A Natural Process That Converts A Refined Metal Into AWaqas LuckyNo ratings yet

- Corrosion, Stainless SteelDocument7 pagesCorrosion, Stainless Steelcsteimel47591No ratings yet

- Galvanic SeriesDocument11 pagesGalvanic SeriesblakasNo ratings yet

- Aluminum OxidationDocument9 pagesAluminum OxidationTarkan OdabasiNo ratings yet

- Durability Durability of of Steel Steel Structures StructuresDocument21 pagesDurability Durability of of Steel Steel Structures StructuresKris d100% (1)

- Corrosion of Aluminum and Its AlloysDocument5 pagesCorrosion of Aluminum and Its AlloysPyae PhyoaungNo ratings yet

- Corrosion of Aluminum and Its Alloys Forms of CorrosionDocument6 pagesCorrosion of Aluminum and Its Alloys Forms of Corrosionsyz4426No ratings yet

- Corrosion in Elec ApplicationsDocument6 pagesCorrosion in Elec Applicationsmohamadsadegh kamaliNo ratings yet

- The Phenomenon of Damage Due To Corrosion of Metals and The Choice of Stainless Steels For Counteracting This PhenomenonDocument3 pagesThe Phenomenon of Damage Due To Corrosion of Metals and The Choice of Stainless Steels For Counteracting This PhenomenonMatheus VillaNo ratings yet

- Galvanic Corrosion When Carbon and Steel Are Bonded Together.Document5 pagesGalvanic Corrosion When Carbon and Steel Are Bonded Together.chris_996No ratings yet

- Inter Granular CorrosionDocument25 pagesInter Granular CorrosionErsin AydınNo ratings yet

- Numeraical Simulations For Advancment in TechnologyDocument13 pagesNumeraical Simulations For Advancment in Technologysharan31No ratings yet

- Corrosion Testing of Metals - Is It Needed?: Presented atDocument21 pagesCorrosion Testing of Metals - Is It Needed?: Presented atandrea assanelliNo ratings yet

- Oxidation: Rusting by Taruvinga H.CDocument7 pagesOxidation: Rusting by Taruvinga H.CEmmanuel MukweshaNo ratings yet

- Aluminium and CorrosionDocument6 pagesAluminium and Corrosionfazyroshan100% (1)

- SUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Document11 pagesSUBJECT: Corrossion Problems Associated With Stainless Steel 4-1Mufleh IdrisNo ratings yet

- Corrosion Types Encountered With Power Cables: ContentDocument5 pagesCorrosion Types Encountered With Power Cables: ContentVasudev AgrawalNo ratings yet

- CH 06 - Corrosion & ErosionDocument22 pagesCH 06 - Corrosion & ErosionvegaronNo ratings yet

- Corrosion Is The Gradual Destruction of Materials (Usually: MetalsDocument4 pagesCorrosion Is The Gradual Destruction of Materials (Usually: MetalsJonathan KingNo ratings yet

- Aluminium's Corrosion Resistance - Aluminium DesignDocument7 pagesAluminium's Corrosion Resistance - Aluminium DesignCarlos LuNo ratings yet

- Corrosion PreventionDocument41 pagesCorrosion Preventionali AbbasNo ratings yet

- Performance of Galvanized Steel ProductsDocument16 pagesPerformance of Galvanized Steel ProductsAndy ChongNo ratings yet

- Boiler Corrosion PDFDocument12 pagesBoiler Corrosion PDFWasif MalikNo ratings yet

- EngineerDocument38 pagesEngineerHumayun Rashid KhanNo ratings yet

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksFrom EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Selenium cells: The construction, care and use of selenium cells with special reference to the Fritts cellFrom EverandSelenium cells: The construction, care and use of selenium cells with special reference to the Fritts cellNo ratings yet

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarNo ratings yet

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarNo ratings yet

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarNo ratings yet

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarNo ratings yet

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarNo ratings yet

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarNo ratings yet

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarNo ratings yet

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- LiftingDocument5 pagesLiftingJitendra KumarNo ratings yet

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarNo ratings yet

- Halon 1301 Bromotrichlhoromethane CF3BrDocument2 pagesHalon 1301 Bromotrichlhoromethane CF3BrJitendra Kumar0% (1)

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarNo ratings yet

- Hydraulic SystemsDocument4 pagesHydraulic SystemsJitendra KumarNo ratings yet

- Hull ConstructionDocument4 pagesHull ConstructionJitendra KumarNo ratings yet

- Holding Down ArrangementsDocument3 pagesHolding Down ArrangementsJitendra KumarNo ratings yet

- Hydraulic GovernorsDocument6 pagesHydraulic GovernorsJitendra KumarNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Bucket Teeth CASEDocument9 pagesBucket Teeth CASEnemez1zNo ratings yet

- Parafusos InglesDocument58 pagesParafusos InglesheitormartNo ratings yet

- Brown and Sharpe Handbook Young MachinistsDocument326 pagesBrown and Sharpe Handbook Young Machinistscegur23100% (1)

- 01 - Different Types of Metal Joining ProcessesDocument44 pages01 - Different Types of Metal Joining ProcessesMetwally NaserNo ratings yet

- Astm A490Document20 pagesAstm A490cesardario90No ratings yet

- Key-Hole Plasma Arc Welding of 8 MM Thick Maraging Steel - A Comparison With Multi-Pass GtawDocument7 pagesKey-Hole Plasma Arc Welding of 8 MM Thick Maraging Steel - A Comparison With Multi-Pass Gtawkeep smileNo ratings yet

- Busbar TightnessDocument11 pagesBusbar Tightnesssanjeev267No ratings yet

- Super Abrasive CatalogueDocument8 pagesSuper Abrasive CatalogueBorisNo ratings yet

- Maintenance Free EARTHING1Document4 pagesMaintenance Free EARTHING1Akshay GatkalNo ratings yet

- Anaconda SS 304 Standard Fittings and Locknuts PDFDocument4 pagesAnaconda SS 304 Standard Fittings and Locknuts PDFBoiaflinNo ratings yet

- Low Carbon SteelsDocument6 pagesLow Carbon SteelsJimNo ratings yet

- Steel Requirements in Civil ConstructionDocument8 pagesSteel Requirements in Civil ConstructionRisa Dwi ParamithaNo ratings yet

- Zinc Alloy Coated Steel Wire With High Corrosion Resistance: Nippon Steel Technical Report No. 96 July 2007Document5 pagesZinc Alloy Coated Steel Wire With High Corrosion Resistance: Nippon Steel Technical Report No. 96 July 2007José SierraNo ratings yet

- ASTM A802!A802M - 95 (Reapproved 2010) - STD Practice For Steel Castings Surface Acceptance STD & Visual ExaminationDocument3 pagesASTM A802!A802M - 95 (Reapproved 2010) - STD Practice For Steel Castings Surface Acceptance STD & Visual ExaminationJoe ScopeliteNo ratings yet

- Astm F436M PDFDocument5 pagesAstm F436M PDFEnrique AntonioNo ratings yet

- ASTM A36/A36M Standard Specification For Carbon Structural SteelDocument4 pagesASTM A36/A36M Standard Specification For Carbon Structural SteeliuliamicutNo ratings yet

- Classification of Steel Welding and NDTDocument4 pagesClassification of Steel Welding and NDTALFA ENGINEERING0% (1)

- Effects of Prep On CreepDocument11 pagesEffects of Prep On CreepFlo RenceNo ratings yet

- Uni MechDocument2 pagesUni MechSAMPATHUNo ratings yet

- Ferrous & Non Ferrous Material PropertiesDocument6 pagesFerrous & Non Ferrous Material PropertiesTusharNo ratings yet

- Ammonium NH: List of Common IonsDocument2 pagesAmmonium NH: List of Common IonsCrispy ChickenNo ratings yet

- Bayer Process PDFDocument2 pagesBayer Process PDFFrandi CahyaNo ratings yet

- Phase DiagramsDocument80 pagesPhase DiagramsWilliams AkandiNo ratings yet

- SttaptiteDocument6 pagesSttaptiteSean YangNo ratings yet

- Gating System Design and Optimization in Sand MoldDocument19 pagesGating System Design and Optimization in Sand MoldĐinh Nguyễn Thành TrungNo ratings yet

- (2023) Extraction of Scandium From Bauxite Residue by High-Pressure (Icp)Document11 pages(2023) Extraction of Scandium From Bauxite Residue by High-Pressure (Icp)Mincen RevaNo ratings yet