Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

47 viewsF.254 I T

F.254 I T

Uploaded by

William John DavisonChallenge machinery provides owner's manuals on its products solely as a courtesy to its customers. Manuals include products which are non-current, unsupported or no longer produced by Challenge. Older products may not comply with current safety procedures, guidelines or regulations. All products should be used only by qualified and properly trained personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 625-011 FSN Service Manual - Issue 3Document63 pages625-011 FSN Service Manual - Issue 3William John Davison50% (2)

- DC 48SHManualDocument34 pagesDC 48SHManualWilliam John Davison100% (1)

- DC 48SHManualDocument34 pagesDC 48SHManualWilliam John Davison100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualWilliam John DavisonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Let's Get Active ! Exercise For Kidney PatientsDocument40 pagesLet's Get Active ! Exercise For Kidney PatientsWilliam John DavisonNo ratings yet

- EE-SX47/67: Global Standard Slot-Type Photomicrosensors With 50-To 100-Ma Direct Switching CapacityDocument10 pagesEE-SX47/67: Global Standard Slot-Type Photomicrosensors With 50-To 100-Ma Direct Switching CapacityWilliam John DavisonNo ratings yet

- Dc-6000 User ManualDocument77 pagesDc-6000 User ManualWilliam John DavisonNo ratings yet

- Dbm-120 Stapler FolderDocument47 pagesDbm-120 Stapler FolderWilliam John DavisonNo ratings yet

- Boss Micro BR BR-80 User ManualDocument136 pagesBoss Micro BR BR-80 User ManualMiniEscortNo ratings yet

- Acfrogcsice5objdrjomzgjpqidnljp6qfgwvb09ibvhw9b9ma0p7 Vumaicc1cm7imltfudpwluol9ssb8g-9t 4haivjoewhflyd2 GFP Ld5r8or1uyotj3wzu4Document1 pageAcfrogcsice5objdrjomzgjpqidnljp6qfgwvb09ibvhw9b9ma0p7 Vumaicc1cm7imltfudpwluol9ssb8g-9t 4haivjoewhflyd2 GFP Ld5r8or1uyotj3wzu4MelvinNo ratings yet

- Engineering EssentialsDocument36 pagesEngineering EssentialsYasser TabajaNo ratings yet

- IDMAN 5848 Edge Light ManualDocument18 pagesIDMAN 5848 Edge Light Manualhighflyer737No ratings yet

- (E. L. Wolf (Auth.) ) Applications of Graphene AnDocument87 pages(E. L. Wolf (Auth.) ) Applications of Graphene Andave chaudhuryNo ratings yet

- SM-R765A Tshoo 7Document29 pagesSM-R765A Tshoo 7Loc Nguyen Huy100% (1)

- Hds7000 Bro enDocument2 pagesHds7000 Bro enCarlos CostaNo ratings yet

- Wenzhou Hecan Electronic Equipment Co.,ltd: LED New Light Source Reflow Oven Model: T-960Document11 pagesWenzhou Hecan Electronic Equipment Co.,ltd: LED New Light Source Reflow Oven Model: T-960Fermi VázquezNo ratings yet

- UG - EC303 DSP Part-3 Fixed Point DSP Addressing Modes - PrintDocument25 pagesUG - EC303 DSP Part-3 Fixed Point DSP Addressing Modes - PrintShreyas TaterNo ratings yet

- U10 17716 Eur5 Id024Document4 pagesU10 17716 Eur5 Id024edgarzgNo ratings yet

- Embedded Systems Online TestingDocument6 pagesEmbedded Systems Online TestingPuspala ManojkumarNo ratings yet

- Tesla's Electric CarDocument5 pagesTesla's Electric CarRossen Petrov0% (1)

- All in OneDocument789 pagesAll in OneHafsa ShaukatNo ratings yet

- Rothenbuhler e Peters. Defining PhonographyDocument23 pagesRothenbuhler e Peters. Defining PhonographyCauê MartinsNo ratings yet

- 4x16 RM NyyfDocument1 page4x16 RM NyyfjamilNo ratings yet

- Incremental Encoders: Through Hollow Shaft Ø70 MM 250... 2500 Pulses Per RevolutionDocument4 pagesIncremental Encoders: Through Hollow Shaft Ø70 MM 250... 2500 Pulses Per RevolutionLarry LayeNo ratings yet

- Wideband Amplifi Cation: Ing Amplifi Er Circuits, With One or Two Transistors Per Stage. New Techniques HaveDocument88 pagesWideband Amplifi Cation: Ing Amplifi Er Circuits, With One or Two Transistors Per Stage. New Techniques HaveferbuifoNo ratings yet

- Speed Command RPM: - Inv033 - Movevelocityrpm: Inv 033 Basic Function SymbolDocument4 pagesSpeed Command RPM: - Inv033 - Movevelocityrpm: Inv 033 Basic Function SymbolRaul ArbaniesNo ratings yet

- A Presentation On Utilization of Metal Hydrides For Hydrogen Storage in Electric VehiclesDocument38 pagesA Presentation On Utilization of Metal Hydrides For Hydrogen Storage in Electric VehiclesDev AnandNo ratings yet

- CatalogDocument20 pagesCatalogDorin ȘuvariNo ratings yet

- 103 QStart Flatpack PSS PDFDocument24 pages103 QStart Flatpack PSS PDFSathish Kumar TRNo ratings yet

- Installation Instructions - F2022 - 01 - C-Bus Multi Room Audio Amplifier High Temperature Power Supply, 10385341Document2 pagesInstallation Instructions - F2022 - 01 - C-Bus Multi Room Audio Amplifier High Temperature Power Supply, 10385341DCGBNo ratings yet

- Powerware 9135 Two-in-One UPS 5000/6000 VA User's GuideDocument37 pagesPowerware 9135 Two-in-One UPS 5000/6000 VA User's Guideseemann27No ratings yet

- Service Manual: This Document Is Printed On Chlorine Free (ECF) Paper With Soy InkDocument26 pagesService Manual: This Document Is Printed On Chlorine Free (ECF) Paper With Soy Inkdwi kiaNo ratings yet

- Control Performance AnalyserDocument23 pagesControl Performance AnalyserToni SuhermanNo ratings yet

- Brosur MPDocument12 pagesBrosur MPAgus AshillaNo ratings yet

- Green-Mode PWM Controller With Frequency Trembling and Integrated ProtectionsDocument18 pagesGreen-Mode PWM Controller With Frequency Trembling and Integrated ProtectionsAndres AlegriaNo ratings yet

- NX D5 P PDFDocument27 pagesNX D5 P PDFelita04No ratings yet

- Stage 1 Bulk Charge:: Code Foe MPPT Arduino, Current and Voltage Sensor, EtcDocument7 pagesStage 1 Bulk Charge:: Code Foe MPPT Arduino, Current and Voltage Sensor, EtcxuanthamdhqnNo ratings yet

- Ba Eng LCS-XXXDDDocument3 pagesBa Eng LCS-XXXDDpecf VOLTESTNo ratings yet

F.254 I T

F.254 I T

Uploaded by

William John Davison0 ratings0% found this document useful (0 votes)

47 views139 pagesChallenge machinery provides owner's manuals on its products solely as a courtesy to its customers. Manuals include products which are non-current, unsupported or no longer produced by Challenge. Older products may not comply with current safety procedures, guidelines or regulations. All products should be used only by qualified and properly trained personnel.

Original Description:

Original Title

F.254-I-T

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentChallenge machinery provides owner's manuals on its products solely as a courtesy to its customers. Manuals include products which are non-current, unsupported or no longer produced by Challenge. Older products may not comply with current safety procedures, guidelines or regulations. All products should be used only by qualified and properly trained personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

47 views139 pagesF.254 I T

F.254 I T

Uploaded by

William John DavisonChallenge machinery provides owner's manuals on its products solely as a courtesy to its customers. Manuals include products which are non-current, unsupported or no longer produced by Challenge. Older products may not comply with current safety procedures, guidelines or regulations. All products should be used only by qualified and properly trained personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 139

The Challenge Machinery Company provides owner's

manuals on its products solely as a courtesy to its customers.

See the information below before using this manual.

These manuals are for reference only. These manuals include products which are non-

current, unsupported or no longer produced by The Challenge Machinery Company, and are

provided solely as an accomodation to our customers. By providing these manuals, The

Challenge Machinery Company makes no representation or warranty as to the products,

their current condition, or their suitability or fitness for use in any particular application, which

are the sole and independent responsibility of the product owner and user.

Older products may not comply with current safety procedures, guidelines or regulations,

and it is the product owner's and user's responsibility to evaluate the suitability and fitness of

the products in their current use and application. The Challenge Machinery Company makes

no representation, warranty or recommendation regarding any modifications which may be

required on non-current or unsupported products. The Challenge Machinery Company

assumes no liability for any modification or alteration to any Challenge product, and any such

modification or alteration to any Challenge product is not authorized by The Challenge

Machinery Company. The availability of these manuals is solely for the purpose of providing

reference information for the products.

This manual may not be complete in all aspects of product maintenance and repair. All

products should be used only by qualified and properly trained personnel, following proper

safety procedures. All products should be regularly inspected and maintained, and their condition,

application and use should be periodically evaluated by qualified personnel. Only qualified and

properly trained technicians should perform maintenance, repair and replacement

procedures. Attempting these procedures without proper training may cause machine

damage or operator injury!

Products may be unsupported by The Challenge Machinery Company due to age or the

unavailability of parts from their original manufacturer. No parts or product support will be

available to repair or maintain unsupported products. Older products may not be UL listed (if

the product does not have a UL label it is not a listed product), and may not comply with

applicable installation or other regulations or requirements if relocated to a new facility.

Many municipalities require a product to be UL listed before an electrician will connect power

to them. Often the cost of updating an older product to comply with current safety regulations is

greater than the value of the product.

F.254-I-T

Feb 2011

CH A M PION 3 0 5

PA PER CU T T IN G

M A CH IN E

M o d els X , X G, X T

Sold and Serviced by

The Challenge Machinery Company

6125 Norton Center Drive

Norton Shores, MI 49441-6081 USA

ChallengeMachinery.com

Serial Numbers 07X1360 & Up

T ECH N ICA L

M A N U A L

1.0 Introduction

2

1.0 Introduction

This manual is designed to help you get the most from your Challenge equipment. Keep this manual

in a safe, convenient place for quick reference by operators and service personnel.

SAFETY ALERT! This symbol means CAUTION: Personal safety in-

structions! Pay special attention to the instructions in bold type. Personal injury may result if the

precautions are not read and followed.

READ THIS MANUAL BEFORE OPERATING! Follow the precautions and instructions given. If af-

ter reading the manual questions still remain, contact your Authorized Challenge Dealer.

FOR PARTS AND SERVICE, contact the Authorized Challenge Dealer from whom you purchased

the machine. Use the illustrations and parts lists at the back of this manual to identify the correct

parts needed. Always give the SERIAL NUMBER and MODEL of your machine to insure the correct

parts are sent as soon as possible.

RECORD YOUR MACHINE SERIAL NUMBER in the space provided on the front cover of this man-

ual. Fill out the warranty card accompanying your machine and return it DIRECTLY TO CHAL-

LENGE.

If you bought a used machine, it is important to have the following information on record at Challenge.

Copy this page, fill in the information and send it care of The Challenge Service Department, 6125

Norton Center Drive Norton Shores MI 49441.

CHALLENGE MODEL SERIAL NUMBER

ATTN COMPANY

ADDRESS

CITY STATE/PROVINCE ZIP

PHONE DATE INSTALLED

DEALER NAME & CITY

* WARRANTY INFORMATION *

It is very important that you read and understand the conditions outlined in the Warranty Information

Sheet attached to the outside of the shipping container of your machine.

The Warranty Information Sheet must be filled out completely and returned to THE CHALLENGE

MACHINERY COMPANY in order for the warranty to be issued for this machine.

Challenge is a registered trademark of

The Challenge Machinery Company 6125 Norton Center Drive Norton Shores MI 49417

Copyright 1997-2012 by The Challenge Machinery Company. All rights reserved. Printed in the U.S.A

1.0 Introduction

3

TABLE OF CONTENTS

1.0 Introduction................................................................................................................................. 2

2.0 Safety ......................................................................................................................................... 5

2.1 Precautions............................................................................................................................. 5

2.2 Power Lockout Procedure....................................................................................................... 5

2.3 Warning Label Definitions........................................................................................................ 6

3.0 Maintenance Guide..................................................................................................................... 8

3.1 Maintenance Adjustments....................................................................................................... 9

3.1.1 Centering the Backgauge Control Knob............................................................................ 9

3.1.2 Squaring the Backgauge.................................................................................................. 9

3.1.3 Proximity Switches......................................................................................................... 10

3.1.4 Hydraulic Valve Adjustments.......................................................................................... 13

3.1.5 Clamp Cylinder .............................................................................................................. 17

3.1.6 Clamp Parallel Rod........................................................................................................ 18

3.1.7 Backgauge Gibs............................................................................................................. 19

3.1.8 Lead Screw Adjustment Nuts ......................................................................................... 20

3.1.9 Backgauge Drive Belt Adjustment .................................................................................. 21

3.1.10 Knife Bar Gibs.............................................................................................................. 21

3.2 Repair and Replacement....................................................................................................... 23

3.2.1 Fuses............................................................................................................................. 23

3.2.2 Knife Bar Cylinder .......................................................................................................... 23

3.2.3 Pilot Check Valve........................................................................................................... 25

3.2.4 Clamp Return Speed Adjustment ................................................................................... 26

3.2.5 Table Maintenance ........................................................................................................ 26

4.0 Troubleshooting ........................................................................................................................ 28

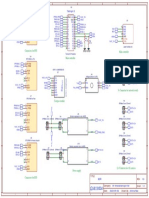

5.0 Schematics & Parts Lists........................................................................................................... 32

5.1 Main Assembly Front View................................................................................................. 32

5.2 Main Assembly Side View.................................................................................................. 36

5.3 Main Assembly Top View.................................................................................................... 38

5.4 Main Assembly Rear View.................................................................................................. 40

5.5 Main Assembly X Model Tables.......................................................................................... 44

5.6 Main Assembly XG/XT Model Table................................................................................... 46

5.7 Main Assembly - Air Table Assembly..................................................................................... 48

5.8 Main Assembly - Power Panel Wiring XG/XT - 1 Phase....................................................... 50

5.9 Main Asm. Front View (Rough)........................................................................................... 52

5.10 Main Assembly- Electric Eyes ............................................................................................. 56

5.11 Main Assembly- Electric Eyes ............................................................................................. 58

5.12 Main Assembly Electric Eyes (X, XG, XT)......................................................................... 60

5.13 Main Assembly - Wiring X Model 1ph............................................................................ 61

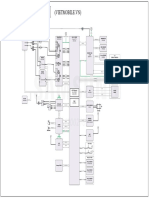

5.14 Basic Machine Schematic XG/XT Models........................................................................ 62

5.15 Basic Machine Schematic X Models................................................................................. 64

5.16 Power Panel Assembly 305X ........................................................................................... 66

5.17 Power Panel Asm. 305X (Blower Opt. Wiring) .................................................................. 70

5.18 Power Panel Assembly 305X XG/XT Models................................................................. 72

5.19 Interconnection Diagram 305X XG/XT Models.............................................................. 78

5.20 Interconnection Diagram 305X ......................................................................................... 80

5.21 Control Console Assembly - 305XG Model .......................................................................... 80

5.22 Control Console Assembly - 305X....................................................................................... 80

5.23 Control Console Assembly - XT Model - Color LCD............................................................. 80

5.24 Cut Button Assembly (Obsolete).......................................................................................... 80

5.25 Cut Button Assembly (Current)......................................................................................... 80

5.26 Kit Ergonomic Touch Switch (Cut Button Option).............................................................. 80

5.27 Line Light Assembly............................................................................................................ 80

5.28 Air Table Blower Assembly Single Phase ......................................................................... 80

1.0 Introduction

4

5.29 Compressor Assembly.........................................................................................................80

5.30 Backgauge Control Assembly ..............................................................................................80

5.31 X/XG/XT Troubleshooting ....................................................................................................80

5.32 Description of Error Messages .............................................................................................80

5.33 Sensor Data Abbreviations...................................................................................................80

5.34 Encoder Cable Assembly 305X - X Models .......................................................................80

5.35 Encoder Cable Assembly 305X XG/XT Models...............................................................80

5.36 Knife Latch Assembly...........................................................................................................80

5.37 Bell-Crank Assembly Clamp..............................................................................................80

5.38 Hydraulic Manifold Assembly ...............................................................................................80

5.39 Hydraulic Power Unit Assembly ...........................................................................................80

5.40 Hydraulic Manifold ...............................................................................................................80

5.41 Manifold Assembly...............................................................................................................80

5.42 Fuse Charts.........................................................................................................................80

5.43 XG/XT Models Label Power Panel Connection Procedure.................................................80

5.44 305 X Model Label Power Panel Conn. Procedure. ...........................................................80

5.45 Warning Label......................................................................................................................80

5.46 Paper Deflector (Kit Option) .................................................................................................80

5.47 Paper Deflector Assembly....................................................................................................80

5.48 Extension Tables - 24 x 36 - (Kit Option)............................................................................80

5.49 Extension Air Tables - 24 x 36 (Kit Option).........................................................................80

5.50 Back Gauge Tape Kit...........................................................................................................80

5.51 Electric Eye Kit Instructions (Obsolete)..............................................................................80

5.52 Electric Eye Kit Instructions (Current) ................................................................................80

5.53 Jogging Aid Construction Guide...........................................................................................80

5.54 Converting 305X Series from Three Phase to Single Phase. ................................................80

5.55 Knife Lifter Assembly ...........................................................................................................80

6.0 Safety System Tests ..................................................................................................................80

2.0 Safety

5

2.0 Safety

2.1 Precautions

This machine is designed for one-person operation. Never operate the machine with more than

one person.

Safe use of this machine is the responsibility of the operator. Use good judgment and common

sense when working with and around this machine.

Read and understand all instructions thoroughly before using the machine. If questions remain,

contact the dealer from which you purchased this machine. Failure to understand the operating

instructions may result in personal injury.

Only trained and authorized people should operate this machine.

Do not alter safety guards or devices. They are for your protection. Severe personal injury may

result.

Disconnect power before cleaning or performing maintenance. See Section 2.2 Power Lockout

Procedure.

Observe all caution labels and plates on this machine.

Be sure the cutter is properly grounded.

Be sure there is sufficient power to operate the cutter properly.

Keep foreign objects off the table and away from cutter blade.

BE EXTREMELY CAREFUL when handling and changing the cutter knife. Severe lacerations or

dismemberment could result from careless handling procedures.

Keep the floor around the cutter free of trim, debris, oil and grease.

When replacing hydraulic parts, loosen the connections slowly to release pressure. Never loosen

connections with the machine running.

If the cutter sounds unusual or operates abnormally, turn it off and consult the troubleshooting

section of this manual. If the problem cannot be corrected, have it checked by a qualified service

person.

CRUSH HAZARD, keep hands and fingers from under the clamp while clamping. Use Jogging

Aid to load paper, and use the backgauge to push paper out before unloading. DO NOT REACH

UNDER THE KNIFE AND CLAMP AREA!

2.2 Power Lockout Procedure

For maximum safety when making adjustments or repairs to your machine, be sure to lock out the

main power control switch to which the machine is connected. The switch should be moved to the

OFF position and a padlock placed in the loop. The person servicing the machine should hold the

key.

Figure 1

2.0 Safety

6

2.3 Warning Label Definitions

The following warning labels are found at various locations on your machine. Read and understand

the meaning of each symbol. If a label is lost from the machine, it should be replaced. The item

number and location of each label can be found in Section 17.0, Schematics and Parts List.

HAZARDOUS AREA

Disconnect power before cleaning, servicing, or making adjustments not requiring

power. Do not alter safety guards or devices; they are for your protection. Replace

all guards. Do not operate with any guards removed.

SHOCK HAZARD

Disconnect power before removing cover. Replace cover before operation.

SHOCK HAZARD

Disconnect power before removing cover. Replace cover before operation.

SINGLE OPERATOR

Do not operate with more than one person.

2.0 Safety

7

!OJO!

This Este simbolo de alerta de seguridad significa OJO ! - IN-

STRUCCIONES DE SEGURIDADPERSONAL. Lea las instrucciones porque se refieren a su

seguridad personal. Fall de obedecer las instrucciones que siguen podria resultar en lesiones

corporales.

Esta maquina, junto con sus mecanismos de seguridad, esta disenada para ser manejada por

UNA SOLA PERSONA a la vez. Jamas debe ser manejada por mas de una persona al mismo

tiempo.

La seguridad es la responsabilidad del operario que usa esta maquina.

LEA DETENIDAMENTE el manual de instrucciones y las PRECAUCIONES DE SEGURIDAD

antes de poner a funcionar la cortadora. Pidale a su supervisor una copia.

El manejo de la guillotina debe estar exclusivamente a cargo de personal entrenado y autorizado

para ello.

NO MODIFIQUE LOS MECANISMOS DE SEGURIDAD, estan ahi para su proteccion no deben

ni modificarse ni quitarse.

DESCONECTE LA CORRIENTE ELECTRICA antes de proceder a hacerle servicio de limpieza,

engrasar, o de hacer adjustes que no requieren corriente. Trabe el interruptor en la posicion

OFF (apagado); vea Procedimiento para cortar la corriente electrica al pie de esta pagina.

Eche llave a la guillotina y quite la llave cuando la maquina no esta en operacion; vea Corriente

electrica.

Asegurese de que la guillotina este debidamente a tierra. Vea Conexion de la fuerza electrica.

Verifique el voltaje y asegurese de que este sea suficiente para el debido funcionamiento de la

guillotina.

Preste atencion a todas las placas con advertencias instaladas en esta guillotina.

No permita que objetos estranos esten en la mesa o cerca de la cuchilla cortadora.

TENGA SUMO CUIDADO al tocar y cambiar la cuchilla. Heridas severas y hasta desmem-

bramiento pueden resultar del manejo sin cuidado o negligente.

El suelo alrededor de la guillotina debe mantenerse despejado y libre de recortes, desperdicios,

aceite y grasa.

Al haber la necesidad de reemplazar partes hidraulicas, afloje todas las conexiones poco a poco

para dejar escapar la presion. Jamas debe aflojarse conexiones mientras la maquina este

andando.

Si la guillotina empezara a sonar o trabajar diferentemente a lo acostumbrado, desconectela y

consulte la seccion Troubleshooting (Reparador) de este manual. Si no es posible corregir el

problema, llame a su servicio autorizado para que le examinen la maquina.

PELIGRO DE MACHUQUE - Mantenga manos y dedos fuera de la agarradera mientras sujeta el

papel. Use el calibrador trasero y su rueda de mano para empujar el papel cortado. NO PONGA

SUS MANOS BAJOLA CUCHILLA O AREA DE LA AGARRADERA.

NO OPERE SIN LAS GUARDAS PROTECTORAS!

OJO ! PRECAUCION - Como proceder para desconectar

la corriente el ectrica.

Para maxima seguridad durante ajustes y reparaciones de su maquina, verifique bien que el interruptor principal

de control de corriente al cual la maquina esta conectada, este desconectado. El interruptor deba ser puesto en

la posicion OFF (desconectado) y se debe poner un candado en la anilla. La llave del candado debe ser guar-

dada por la persona que estara efectuando los trabajos de servicio o de reparacion en la guillotina.

Desconecte la corriente electrica antes de proceder a hacer cualquier ajuste o reparacion o de efectuar el en-

grase en cualquier maquina.

3.0 Maintenance Guide

8

3.0 Maintenance Guide

NOTICE

The instructions on the following

pages are for the use of trained

service personnel onl y!

Attempting to perform repair and

replacement procedures without

proper training may cause ma-

chine damage or operator injury!

PARTS CUSTOMERS: Parts with the express understanding that they are to replace parts

found missing or no longer serviceable on equipment designed and/or manufactured at

Challenge. The Challenge Machinery Company assumes no liability for any modification or

alteration to any Challenge products, and any such modification or alteration to any Chal-

lenge product is not authorized by The Challenge Machinery Company. Any modification or

alteration of any Challenge product will void any remaining warranty.

3.0 Maintenance Guide

9

3.1 Maintenance Adjustments

3.1.1 Centering the Backgauge Control Knob

The Backgauge Control Knob is coupled with a potentiometer. If the Control Knob is misadjusted, the

backgauge may wander forward or backward.

To adjust the Control Knob, turn the power off and then on and immediately enter Sensor Data Mode.

Hold the rubber coupling in the Control Knob Assembly while turning the knob. Adjust the knob until

.512 is displayed on the screen. Turn the power of and then on once again.

Figure 2

3.1.2 Squaring the Backgauge

To test the backgauge for squareness, place a small lift of paper against the left side of the back-

gauge (but not against the side guide) and make a cut.

Figure 3

Now, leave the backgauge in the same position, flip the lift over and against the right side of the back-

gauge (but not against the side guide). Make another cut to see if any of the stock will trim off. Run

two checks, one starting on the left and moving to the right, the other, moving from the right to the left.

Trim in either sequence indicates the backgauge is out of square.

1. As machine wears, make sure the backgauge gibs are set properly first (see Backgauge

Gibs), then follow steps 2 through 5.

NOTE: Gib adjustment is not necessary on initial machine setup because they have been ad-

justed at the factory.

PAPER

3.0 Maintenance Guide

10

2. Loosen backgauge locking screw (smaller head). Loosen the jam nuts on the backgauge

squaring screws.

Figure 4

3. Back off the squaring screw on the side that the trim occurred and tighten the other.

4. With the squaring screws tight, make another test. Continue to adjust and test until no trim

occurs when testing in either sequence.

5. Tighten the jam nuts and lock screw.

3.1.3 Proximity Switches

These tests require the machine to be operational for checking and adjust-

ing. Be very careful that tools and other people are clear of moving parts and that the cutter is not

accidentally operated while adjustments are being made.

Challenge Champion cutters incorporate proximity switches to detect stages of operation. These

types of limit switches have no moving parts and are more reliable than the old style of contact

switches.

NOTE: Adjust the switches in the following order:

1. Knife Up/Down Limit Switches

2. Hydraulic Up Limit Switch

3. Clamp Up Limit Switch

4. False Clamp Sheath Limit Switch

Locking

Screw

Squaring Screws

3.0 Maintenance Guide

11

CRUSH HAZARD! When the limit switch is actuated, the clamp will return

to the up position. Keep hands and tools clear.

1. Knife Up/Down Proximity Switches

Figure 5

The Knife Up and Knife Down Proximity switches are mounted to a bracket that is attached to the

Knife Cylinder (Figure 5). With the power off, set the collar between the proximity switches and then

turn on power. Press cut buttons once to turn on the hydraulic motor. The knife will move to the ab-

solute top of its stroke. Move the collar to the top proximity switch until LED turns on, then move it an

additional 1/4 higher and tighten its setscrew. An indicator light on the switch body comes on when

the switch is actuated (proximity switches must be within 1/8 (3.2mm) to actuate). Check the Knife

Down Proximity switch by going into the Maintenance screen to Knife Adjust and lock the knife in the

down position. Check the distance between the proximity switch and the actuator.

2. Hydraulic Up Proximity Switch

This switch is mounted on the left, rear leg of the base casting (Figure 6 on page 12). An indicator

light on the switch body comes on when the switch is actuated (proximity switches must be within 1/8

(3.2mm) to actuate). The switch senses the extension of the clamp cylinder at the top of its stroke.

This stops hydraulic power to the clamp and knife. If the switch is not properly set, the knife and

clamp cylinders will be under constant load (indicated by excessive heat and noise).

To adjust:

a. Loosen the bottom lock nut and turn the top lock nut down to raise the switch.

b. Turn on the machine and press the cut buttons once to start the hydraulic motor.

c. The knife and clamp will move to the extreme up position and a load will remain on the

hydraulics.

d. When the cylinder has stopped moving, pass a metal object in front of the switch to actu-

ate it and take the load off the hydraulics. Keeping pressure on the switch to hold it

against its mounting bracket, turn the lock nut up to lower the switch until the indicator

light in the switch comes on. Tighten the lower jam nut.

e. Press the cut buttons to cycle the clamp and check clamp position.

3.0 Maintenance Guide

12

Figure 6

3. Clamp Up Proximity Switch

This switch is mounted inside the rear of the arch casting, Figure 7. It is tripped by the clamp when

the clamp is in the up position. This switch prevents backgauge movement if the clamp is not up. On

machines equipped with the air table option, it also diverts the air from the table when the clamp is

down to prevent the stock from moving during a cut. This switch is tripped by a actuator on the top of

the clamp and must be adjusted to within 1/8 (3.2mm) of the face of the switch.

Figure 7

4. False Clamp Sheath Limit Switch

This switch is mounted on the false clamp sheath on the right side of the machine, Figure 7. It is

tripped when the false clamp plate is in the sheath. This switch prevents the backgauge from getting

any closer then 2 to the clamp if the false clamp plate is not in the sheath. If the switch is actuated

(the false clamp plate is in the sheath) then the minimum cut size is 3/4. To check the switch slide

the false clamp plate into the sheath and check that the light on the switch is on. If the switch needs

to be adjusted, move the switch to within 1/8 (3.2mm) from the face of the switch to the metal false

clamp plate.

Hyd. Up Prox-

imity Switch

3.0 Maintenance Guide

13

Figure 8

3.1.4 Hydraulic Valve Adjustments

Several of the following tests require the machine to be operational for

checking and adjusting. Be very careful that tools and other people are clear of moving parts and that

the cutter is not accidentally operated while adjustments are being made. Disconnect the power and

lock it out, see Safety Precautions, page 8, whenever working on the machine unless the directions

specifically require the machine to be powered.

For initial setup, adjust the valves in the following order:

1. Main System Relief Valve- 1800 psi

2. Knife down sequence valve- 1600 psi

3. Clamp up relief valve- 400-600 psi

4. Pressure reducer valve (X only)- 1400max/400min psi

5. Electronic Clamp Pressure- 1400max/400min psi

NOTE: Pressure settings fluctuate with oil temperature. Set pressures when the oil is hot.

3.0 Maintenance Guide

14

Figure 9

1. Main System Relief Valve (Figure 9)

This valve maintains the overall hydraulic pressure for the entire system. Factory setting: 1800 psi.

Check Procedure:

a. Open the left access door on front of the cutter.

b. Turn the power on and make a cut to hold the knife down on the cutting stick. Read the

pressure off the main system pressure gauge (front gauge) while the knife is down. If the

gauge does not read 1800 psi, an adjustment is needed. You may need to send knife

down in maintenance mode to read the gauge more easily.

To Adjust:

Loosen the lock nut on the relief valve. Use an Allen wrench to turn the adjusting screw.

Turn clockwise to increase pressure, counter-clockwise, to decrease pressure.

a. Make a cut and hold the buttons in. Or go to knife down adjustment in maintenance

mode to cycle the hydraulics. Adjust the valve screw until you have the correct pressure.

b. Tighten the lock nut while holding the hex wrench in place.

c. Proceed to readjust the other valves.

2. Knife Down Sequence Valve (Figure 9)

This valve controls the clamp and knife sequence. It keeps the knife up until after the clamp has

made contact. It is the upper right valve on the front of the manifold. Factory Setting: 1600 psi.

NOTE: Main System Pressure must be set at 1800 psi before making this adjustment.

Check Procedure:

a. Open the left access door on front of the cutter.

b. Press the cut buttons while reading the pressure on the main system pressure gauge

(front gauge). The gauge should read approximately 1600 psi as the knife is moving

down (when bottomed, the gauge will jump to 1800 psi showing the Main System Re-

lief Pressure previously set).

c. If correct, proceed to check the Pressure Reducer.

Main

System

Gauge

Electronic

Clamp Valve

Main System

Relief Valve

Knife Down

Sequence

Clamp Up

Sequence

3.0 Maintenance Guide

15

To adjust:

a. Loosen the lock nut.

b. Make a cut and hold the buttons in. While reading the main system gauge, adjust the

valve until you have the correct pressure. Clockwise to increase, counter-clockwise to

decrease.

c. Tighten the lock nut while holding the hex wrench in place.

d. Proceed to readjust the other valves.

3. Clamp Up Sequence Valve (Figure 9 on page 14)

This valve maintains clamp pressure so the clamp remains down until the knife has stopped in

the up position. Factory setting: 400-600 psi.

Check Procedure:

a. Open the left access door of the cutter.

b. Press the cut buttons, and while reading the pressure on the main gauge (front

gauge), release them. The gauge should read between 400-600 psi as the clamp is

going up. There should be no clamp movement until the knife is stopped in the up

position.

c. If correct, proceed to check the Pressure Reducer.

To Adjust:

a. Remove the protective cap and loosen the lock nut on the clamp up sequence valve.

b. Make a cut, then release the buttons. Read the main gauge as the clamp is return-

ing. Adjust the valve for a reading of 400-600 psi.

c. Tighten the lock nut while holding the hex wrench in place and replace the protective

cap.

d. Proceed to readjust other valves.

4. Manual Pressure Reducer Valve- (X only)

This valve, Figure 10 on page 16, limits the amount of pressure to the clamp system. Factory setting:

1000 psi (1400max/400min).

To Check:

With the hydraulic access door open, activate the cut buttons and read the pressure off

the clamp gauge (rear gauge). It should read 750 psi for average cutting purposes.

To Adjust:

1. Loosen the lock knob. There are two knobs, one behind the other. The outer is the adjusting

knob. The inner is the lock knob.

2. Push the cut buttons and check the reading on the clamp gauge (rear gauge) when the clamp

is on the table and the knife is coming down.

3.0 Maintenance Guide

16

3. Turn the Pressure adjusting knob clockwise for MORE pressure, counter-clockwise for LESS.

DO NOT set the clamp pressure below 400 psi. Severe lacerations or dis-

memberment could result! The knife and clamp system will lose sequence settings below 400 psi

and the knife could come down before the clamp.

4. Make another cut and check the pressure gauge. Adjust the pressure to your cutting applica-

tion (See Operator Tips or Knives sections).

5. Tighten the locking knob.

Figure 10

1. Electronic Clamp Control Valve- (XG)

The electronic clamping control allows the convenience of changing the clamp pressure at the control

console. The pressure is controlled by use of the up and down arrow keys, 0 being the lowest, 15 the

highest; and is indicated in the upper right hand corner of the display. See below:

Adjustment of the Electronic Valve:

a. To adjust the pressure range, enter the Maintenance Mode and choose Diagnostic.

b. To adjust the pressure, select Clamp Adjust. See the next screen on page 86:

c. Setting the Maximum Pressure: Perform a cut cycle, after the clamp has contacted

the table and while the knife bar is coming down, read the pressure on the right hand

pressure gauge. It should be set at 1400 p.s.i. If not, correct by using the up and

Clamp

Gauge

Pressure Adjust

Knob

Lock

Knob

5.000 in

DIAGNOSTIC

Error Code

Sensor Data

Clear Memory

Clamp Adjust

Select & press enter

A) Maint C) Send

B) Job D) Exit

3.0 Maintenance Guide

17

down arrow keys. When finished, choose D), to exit and go to the minimum pressure

set up seen shown below:

d. Setting the Minimum Pressure: Perform a cut cycle, after the clamp has contacted

the table and while the knife bar is coming down, read the pressure on the right hand

pressure gauge. It should be set at 400 p.s.i. If not, correct by using the up and

down arrow keys. When finished, choose C), to return to the Send mode, or D) Exit to

return to Diagnostics.

3.1.5 Clamp Cylinder

If the clamp piston bottoms in the cylinder before the clamp makes contact with the table, or if the

clamp does not make full travel on the up stroke, the clamp cylinder may need adjustment. The

clamp cylinder is located inside the left base casting leg behind the left front door (Figure 11, on page

18).

5.000

Set Maximum

>

Press /\ to Increase

Press \/ to Decrease

A) Main C) Send

B) Job D) Exit

5.000

Set Minimum

>

Press /\ to Increase

Press \/ to Decrease

A) Main C) Send

B) Job D) Exit

Clamp

Cylinder

3.0 Maintenance Guide

18

Figure 11

To adjust:

1. Turn on machine. Start the hydraulic motor by pressing both cut buttons simultaneously.

Turn off the machine.

2. DISCONNECT THE POWER AND LOCK IT OUT! (See Power Lockout procedure, page 5).

3. Loosen the jam nut.

4. Use the flats on the clamp cylinder shaft to turn the shaft into or out of the clevis as required,

(Figure 8). (In decreases, out increases height.) The clamp should be set to 4 above the

table.

Figure 8

5. Retighten the jam nut securely.

3.1.6 Clamp Parallel Rod

If the clamp is not parallel with the table:

1. DISCONNECT THE POWER AND LOCK IT OUT! (See Power Lockout procedure, page 5.)

2. Loosen the jam nuts on each end of the clamp connecting rod, (Figure 9 & Figure 14). (Note:

the left jam nut has left hand threads.)

Figure 9 & Figure 10 LH & RH End of Rod

Jam

Nut

Jam

Nut

Clevis

Jam Nut

Wrench Flat

3.0 Maintenance Guide

19

3. Using the flats on the end exposed below the base casting, (Figure 9 & 14), turn the connect-

ing rod and align the clamp with the table. Place a long strip of paper under each end of the

clamp. Push the cut buttons and when the clamp contacts the table, attempt to pull the strips

out. The clamp should be adjusted so neither strip pulls out.

4. Retighten the jam nuts securely.

3.1.7 Backgauge Gibs

If you are having trouble keeping the back-gauge square, check for backgauge side play. Position

the backgauge approximately 2 (50-55mm) from the rear of the table and turn off power.

Remove the rear table cover. From the back, hold each end of the backgauge and try pulling one

end while pushing the other to rock it side to side. If there is noticeable side-to-side play in the back-

gauge, the gibs will need adjusting. Check for play at various positions on the table, (Figure 11).

Note: there will be some front to rear movement between the backgauge nut and screw.

Figure 11

The backgauge has two gibs that ride on an iron rail underneath the table, (Figure 12). These are ad-

justed with setscrews, which are held in position with jam nuts.

Figure 12

To adjust:

1. Run the backgauge back to 23 (600mm) and disconnect the power.

2. Always adjust the side gib first. Loosen all jam nuts and adjusting screws then tighten the

front and rear screws.

3. Pull each end of the backgauge and try to rock it side to side as before to check for play.

4. Continue to adjust these two screws until there is no play and the hand-wheel still turns easily

(X only).

Set Screws

& Jam Nuts

Rail

3.0 Maintenance Guide

20

5. Lock the screws in place with the jam nuts.

6. Snug up the middle two screws and lock in place with the jam nuts.

7. Snug up the bottom gib adjusting screws finger tight and lock in place with the jam nuts.

8. Run the backgauge back and forth to make sure it does not bind. Readjust if necessary.

9. Replace the rear table cover.

10. Check the backgauge squareness.

3.1.8 Lead Screw Adjustment Nuts

If play is noted in the forward pillow block and thrust bearings, take up the play in the adjustment nuts

by:

1. Loosening the lead screw jam nuts, Figure 13 (X) & Figure 14 (XT/XG) on page 20.

2. Snug up the inner nut to eliminate any play.

3. Tighten the nuts against each other.

4. Check the socket head bolts in the pillow block to make sure they are also tight.

Figure 13 X Model Jam Nut Location

Figure 14 XG Model Jam Nut Location

3.0 Maintenance Guide

21

3.1.9 Backgauge Drive Belt Adjustment

If the backgauge motor runs but the backgauge does not move or slips, the belt may need adjust-

ment, Figure 15.

Figure 15

To adjust the belt:

1. Turn off the machine, DISCONNECT THE POWER AND LOCK IT OUT! (See Power Lock-

out procedure, page 5.)

2. Remove the drive belt cover guard at the rear of the table.

3. Loosen the four socket head screws holding the motor to the mounting plate.

4. Slide the motor down to put more tension on the belt, or lift it up to reduce tension for remov-

ing belt.

5. If belt cannot be tightened, replace with a new belt.

6. Adjust the tension of the belt so that there is a 1/2-3/4 (10mm) flex remaining and tighten

the mounting plate socket screws.

7. Replace the belt guard cover.

8. Reconnect the power to the machine.

3.1.10 Knife Bar Gibs

The knife bar gibs are two steel backed UHMW plates on either side of the arch that guide and hold

the knife as it cuts. If adjusted too tight the knife may not come down, or scoring could damage the

gibs and knife bar. If too loose, you could get uneven or inaccurate cuts.

WARNING: Knives are heavy and very sharp (even after use). Severe

lacerations could result. Follow all safety precautions and knife changing instructions from

the Knives section of this manual.

3.0 Maintenance Guide

22

There are three, socket set screws with jam nuts on each side of the arch that adjust the gibs, (Figure

20). These should be adjusted only with the knife bar directly behind the screws being tightened.

Figure 20

To adjust:

1. Start the machine and make a cut. When the knife is half way down, have someone press

the stop button. The knife bar should be stopped half way across the gibs.

2. Loosen all (6) jam nuts on the gib adjusting screws and back the screws out 1/2 turn.

3. Adjust center (2) screws until snug - not tight to eliminate the air gap between the knife bar

and gib. Tighten those (2) jam nuts.

4. Place the machine into knife down adjustment mode. See Operating instructions for your

machines model.

5. Adjust the bottom two screws the same way the middle screws were adjusted. Tighten the

jam nuts.

6. Start the machine. The knife should return to the up position. Shut the machine off.

7. Adjust the upper (2) gib adjusting screws and tighten the jam nuts.

8. Turn the power back on and cycle the knife several times. Recheck the gibs (repeat steps 2-6

as necessary).

9. Dont over-tighten the gibs.

10. If the knife bar and gibs get scored, remove only the burrs by scraping and then sanding

smooth.

3.0 Maintenance Guide

23

3.2 Repair and Replacement

3.2.1 Fuses

FIRE HAZARD. Replace only with same type and rating fuse.

Figure 16

The Champions each have a set of fuses. The fuses are located inside the main power box, (Figure

16). Check the label inside the cover for correct ratings for these fuses. Labels are reproduced with

the drawings at the back of this manual in case those on the cover may be damaged or illegible. (See

pages 80, 80, & 80.)

3.2.2 Knife Bar Cylinder

Replacing the Knife Bar Cylinder:

1. Remove the knife from the cutter (see Knife, Installation and Set Up).

2. Place a 3 (60mm) lift of paper under the clamp only to hold it up and out of the way of the

knife bar. Then place a 3 (1 meter) long 2x4 board flat side down under the right end of the

knife bar. This will be used for leverage on the knife bar when removing and reinstalling the

knife bar pin.

3. Lock the clamp and knife down by following instructions in the Operator Controls section for

your particular model of machine.

4. Turn off the main power disconnect switch. DISCONNECT POWER AND LOCK IT OUT!

See page 5.

Loosen connections slowly to bleed off any trapped pressure!

5. Place a pan underneath the cylinder and gradually loosen and remove the hydraulic connec-

tions. Loosen the connections slowly to bleed off any trapped pressure.

3.0 Maintenance Guide

24

Figure 22

6. Remove the clevis pin. E-style retaining rings on each side of the pin can be removed

through the access panel in the side of the arch casting. The pin has a 1/4-20 tapped hole in

it to aid removal and a clearance hole in the front of the arch provides access to knock the pin

out of the knife bar, (pg. 95, fig. 65). Use the board to block up the knife bar and to release

pressure from the pin to make it easier to remove.

7. Now, remove the pin retainer and the Tru-arc retaining ring from the lower mounting pin hold-

ing the cylinder to the base.

8. Remove the old cylinder. With the shaft of the old cylinder bottomed out, note the dimension

between the top of the cylinder body and the bottom of the cylinder clevis. Also note the ap-

proximate position of the proximity switch actuator. Transfer the proximity switch actuator,

the clevis lock nut, and the clevis onto the new cylinder and insert it into position on the cut-

ter.

9. Reinstall the base pin, Tru-Arc retainers, and the pin retainer.

10. Install the upper pin to connect the cylinder to the knife bar and replace the retaining rings.

11. The cylinder shaft can be threaded into the clevis to adjust the position of the knife bar.

When properly adjusted, the distance from the top of the knife bar recess to the table with the

knife in the down position should measure 4-1/8 (103mm), (Figure 18).

Figure 17

12. Lock the jam nut securely in place.

13. Reconnect the hydraulic hoses.

Clevis

Jam

Nut

-20 Tapped Hole E-Ring

Clevis

3.0 Maintenance Guide

25

CRUSH HAZARD! Knife and clamp will return to the up position when

the key is turned on and the cut buttons are pressed for the first time. Keep hands and tools

away.

Figure 18

14. Reconnect the power to the cutter and turn main power on.

15. Adjust the Knife up proximity switch actuator. Press the cut buttons once to turn on the hy-

draulic motor and raise the knife and clamp. Allow machine to run for a few minutes to work

the air out of the system.

16. See Knife Installation and Set up for reinstalling the knife.

3.2.3 Pilot Check Valve

The Pilot Check Valve on the knife cylinder (Figure 19) helps to hold the knife in the up position. If it

becomes stuck or plugged, the clamp will come down but the knife will remain in the up position.

Figure 19

To check:

1. Follow the knife changing procedures to remove the knife blade and then block the knife bar

in the up position.

Clamp

Knife

Bar

Arch

Table

4-1/8

Pilot Check

Valve

3.0 Maintenance Guide

26

2. Turn the main-power disconnect switch to the off position, DISCONNECT THE POWER AND

LOCK IT OUT! (See Power Lockout Procedure, page 5.)

3. Place a pan underneath the valve and slowly loosen the pilot valve connections to bleed off

any pressure.

4. Remove the check valve and hoses from the knife cylinder. Replace the hose fitting attached

to the cylinder with the two 90

0

fittings on the check valve. (The smaller fitting goes on the

top port.) Reconnect the hoses.

5. Reconnect the power and run the machine.

6. If the knife cycles without the valve in line, replace with a new check valve.

3.2.4 Clamp Return Speed Adjustment

The clamp return speed can be adjusted if it becomes too sluggish or too fast. This adjustment is

made on the air cylinder that brings the clamp down. To make this adjustment, remove the rear arch

cover. Turn the lower flow control on the air cylinder clockwise to decrease the return speed of the

clamp. Turn the flow control counter-clockwise to increase the return speed of the clamp. The clamp

should be adjusted such that it returns fast but does not bounce at the top of the stroke.

The clamp down speed can be adjusted to personal preference. Adjust the clamp down speed using

the upper flow control valve on the upper end of the cylinder (rod end).

3.2.5 Table Maintenance

The table of a paper cutter requires periodic maintenance to remove surface oxidation. Polishing is

also required to provide a smooth surface for paper to move freely. The frequency of this mainte-

nance will be determined by a number of factors. Among these are the humidity, environmental dust,

handprints, liquid spills, and type of paper stock. We recommend the use of the Challenge Cutter

Care Kit P/N 16077 for of your table care needs.

To prepare a new machines table, use the following instructions.

1. Remove the rust-protective coating from the table with a solvent.

2. Remove all solvent residues from the table with a dry cloth. Continue until the cloth shows no

sign of residue.

3. Apply a light coating of an SAE 10-weight non-detergent motor oil or equivalent to the table and

allow it to penetrate for at least one hour.

4. Remove all excess oil from the table with paper toweling (not cloth) until the paper towel you are

using shows no sign of oil.

5. Apply a paste wax (Challenge P/N 16078) to the table to seal the pores of the metal.

Note: Do not use a wax that contains a cleaning compound on the table. The cleaner contains mi-

croscopic abrasive particles that will cause wear between the table and the bottom of the backgauge.

A silicone spray (Challenge P/N 16079) will show the same type of wear as the cleaner if the excess

silicone is not removed. If the excess is not removed, the silicone spray has a substance that holds

the silicone to the surface it is sprayed on that causes a black, gummy build-up under the backgauge.

If a silicone spray is used, paper toweling must be used to remove the excess to prevent this wear

and build-up.

To clean surface oxidation from a table, follow the procedure below:

3.0 Maintenance Guide

27

1. Spray Rust-B-Gone (Challenge P/N 16080) on the table and allow it to dissolve the rust. Then

remove it with paper toweling. Or, pour a small quantity of SAE 10-weight motor oil onto the ta-

ble. Using a Scotch-Brite Pad or a 400 grit sand paper, polish the table following the grain of

the metal until all oxidation is removed to your satisfaction.

2. Remove all of the oil from the table until the cloth you are using shows no sign of residue.

3. Apply a light coating of an SAE 10-weight non-detergent motor oil or equivalent to the table and

allow it to penetrate for at least one hour.

4. Remove all excess oil from the table with paper toweling (not cloth) until the paper towel you are

using shows no sign of oil.

5. Apply a paste wax (Challenge P/N 16078) to the table to seal the pores of the metal.

Note: Do not use a wax that contains a cleaning compound on the table. The cleaner contains mi-

croscopic abrasive particles that will cause wear between the table and the bottom of the backgauge.

A silicone spray (Challenge P/N 16079) will show the same type of wear as the cleaner if the excess

silicone is not removed. If the excess is not removed, the silicone spray has a substance that holds

the silicone to the surface it is sprayed on that causes a black, gummy build-up under the backgauge.

If a silicone spray is used, paper toweling must be used to remove the excess to prevent this wear

and build-up.

4.0 Troubleshooting

28

4.0 Troubleshooting

Never work on this machine with the power on unless the instruc-

tions say the machine power must be on. Lock the power off at the wall disconnect switch.

See Power Lockout Procedure, page 5.

WONT START

1. Fuse blown 4. Cut button defective

2. Starter is defective 5. Check error codes

3. Loose plug or wire

CUT BUTTONS PUSHED- MACHINE SHUTS OFF

1. Knife and clamp are out of sequence. Turn off power and turn back on.

2. Check clamp and knife up limit switches.

3. When cutting a full pile, the clamp up limit switch does not break contact, either adjust limit switch

or cut down on pile height.

4. Defective circuit board

CUT BUTTONS ACTIVATED- WONT CUT

1. A cut button is defective.

2. Motor wired wrong, going in opposite direction of the arrow sticker on the motor

3. Pilot check on the knife cylinder is defective

4. Sequence valve pressure is set too high

5. Either down solenoid in valves inoperative

6. Knife up limit switch is not properly adjusted

7. Defective circuit board

ERRATIC OPERATION- POWER LOSS

1. Low hydraulic oil level

2. Debris in relief valve

3. Defective pump

4. Oil bypassing clamp cylinder seals

CLAMP WONT OPERATE

1. Bind in linkage or gibs

2. Clamp pressure reducer valve set too low

3. High pressure solenoid defective

4. Relief valve defective

5. Clamp return spring defective

CLAMP WONT HOLD PRESSURE

1. Clamp cylinder seals worn

2. Pressure valve setting too low

3. Clamp not parallel to table

CLAMP WONT BOTTOM

1. Clamp cylinder out of adjustment

2. Clamp return spring broken or out of adjustment

CLAMP NOT PARALLEL TO TABLE

1. The clamp connecting rod is out of adjustment.

4.0 Troubleshooting

29

CONCAVE CUTTING- ENDS WIDE, CENTER NARROW

1. Excessive moisture at edges of paper

2. More ink on edges of lift

CONCAVE CUTTING- VARIATION OF TOP AND BOTTOM

1. Soft stock not firmly clamped

2. Knife is dull or ground incorrectly

3. Knife bar gibs loose

4. Air in stock when clamped, pulls away from backgauge

5. Clamp not parallel to table

INCONSISTENT STOPPING OF KINFE IN UP POSITION

1. Bind in knife linkage or gibs

2. Up sequence valve not properly adjusted

3. Knife links worn

HESITATION OF KNIFE

1. Dull knife

2. Seals worn in knife or clamp cylinder

3. Defective pilot check on knife cylinder

4. Knife links worn

KNIFE WONT RETURN

1. Defective high pressure valve

2. Directional valve(s) stuck in

3. Up sequence pressure too low

CLAMP WONT RETURN

1. Up sequence pressure too high

2. Bind in clamp linkage or gibs

3. Clamp not parallel to table

4. Clamp return spring defective

KNIFE DRIFTS DOWN

1. Knife bar gibs out of adjustment

2. Defective pilot check on knife cylinder

3. Defective seals in knife cylinder

4. Knife latch out of adjustment

KNIFE STOPS IN STOCK

1. Knife dull

2. Relief valve defective

3. Pressure control valve clogged or defective

4. Knife cylinder seals worn

5. Clamp cylinder seals worn

6. Motor stalling due to low voltage or too small wire to machine

NOISY AND SLUGGISH HYDRAULIC SYSTEM

1. Cylinder seals worn on clamp or knife

2. Low on hydraulic fluid

3. Worn spline coupling in motor/pump

INACCURATE CUTTING

1. Backgauge not square

2. Knife bar has play- tighten gibs

3. Backgauge gibs loose

4.0 Troubleshooting

30

4. Dull knife

5. Clamp not parallel to table

6. Accuracy not set correctly

BACKGAUGE SPEED ERRATIC

1. Oil on pulley belt

2. Belt/pulley loose

BACKGAUGE MOVEMENT ERRATIC

1. Backgauge gibs loose or binding on table way (rail under table)

2. Backgauge nut binding on leadscrew, screw bent or dirty

3. Problem with electrical drive component

4. Defective circuit board

DRAWING OF STOCK

1. Dull knife

2. Low clamp pressure

3. Hydraulic fluid low

4. Air in lift- reduce pile height

5. Clamp not parallel to table

SLOW KNIFE

1. Defective seals in clamp cylinder

2. Defective pilot check valve on knife cylinder

3. Pump not achieving full pressure

4. Main system or clamp pressure reducer is by-passing fluid

4.0 Troubleshooting

31

NOTES

5.0 Schematics & Parts Lists

32

5.0 Schematics & Parts Lists

5.1 Main Assembly Front View

47500 Sht. 1 of 16, Rev. X

5.0 Schematics & Parts Lists

33

Main Assembly Front View

47500 Sht. 1 of 16, Rev. X

NO. PART NO. DESCRIPTION OF ACCESSORIES QTY

1 S-1781-116 LABEL- WARNING (XD/XG/XT ONLY) 1

2 4506 STUD - CLAMP 2

3 47097 DOOR ASM. - R.H. FRONT 1

4 47033-3 ENCLOSURE - FRONT 1

5 47163 GASKET 6

6 H-465-1 MANIFOLD ASSEMBLY REF.

7 S-1781-11 LABEL - CAUTION (NON-EURO ONLY) 1

7 S-1781-35 LABEL - CAUTION (EURO MACH. ONLY) 1

8 47101 LATCH - FRONT ENCLOSURE 2

9 EE-2149-9 TABLE LIGHT ASSEMBLY- ON/OFF SWITCH 1

10 S-1781-16 LABEL - CAUTION 1

11 8815 WASHER - KNIFE SCREWS 6

12 47507 KNIFE 2

13 4171 CUT STICK 1

14 A-9121 CUT PLATE 2

15 4503-3 LINK - KNIFE BAR 2

16 E-2196 PLUG - HOLE 3

17 4518 PIN - KNIFE LINK 2

18 S-845 LIGHT - TABLE 1

19 S-1781-11A LABEL - CAUTION (NON-EURO ONLY) 2

19 S-1781-35 LABEL - CAUTION (EURO MACH. ONLY) 2

20 EE-2832-1 SWITCH ASSEMBLY- CUT BUTTON 1

21 4449 KNIFE ADJUSTING SCREW 2

22 S-1193-75 "E" RING - 3/4 2

23 S-1087-1 PIN - ROD END 1

24 EE-2830 SWITCH ASSEMBLY- MAIN DISCONNECT 1

25 4501-4 KNIFE BAR ASSEMBLY- 305 1

26 E-2196-11 PLUG - HOLE 2

27 S-1694 TYRAP 3

28 S-1781-25 LABEL - INSTRUCTION 1

29 47173-1 DOOR ASM. - L.H. FRONT 1

30 H-437 CHECK VALVE ASSEMBLY REF.

31 H-433-1 TUBE ASSEMBLY - KNIFE CYL. PILOT REF.

32 H-435 TEE - MALE RUN 1

33 S-1350-2 BUSHING - CABLE STRAIN RELIEF 1

34 11145-1 RIVET - 3/16 4

35 EE-2823-1 CONTROL CONSOLE- SPACER "XG" 1

35 EE-2850-1 CONTROL CONSOLE- SPACER "X" 1

35 EE-2998-4 CONTROL CONSOLE- SPACER "XT" 1

36 47502 BRACKET- CONSOLE 2

37 4505 GIB - KNIFE BAR 2

38 S-1864-2 CAPTIVE RET. DEVICE- #10 2

39 EE-2882 ELECTRICAL PANEL - SPACER 1

39 EE-3170 ELECTRICAL PANEL - NON-SPACER "X" 1

5.0 Schematics & Parts Lists

34

Main Assembly Front View

47500 Sht. 1 of 16, Rev. X

NO. PART NO. DESCRIPTION OF ACCESSORIES QTY

40 S-1781-52 LABEL - POWER CONN. PROC. - SPACER 1

40 S-1781-161 LABEL - POWER CONN. PROC. - "X" 1

41 47252 FIBER BOARD - KNIFE SLIDE 1

42 47645-1 CLAMP COMPRESSOR ASSEMBLY 1

43 S-1781-34 DECAL - EXTENSION TABLES 2

44 H-504 KIT- HYDRAULIC MANIFOLD 1

45 H-203-33 VALVE- PRESSURE REDUCING, ELEC. (SPACER) REF.

45 5136 VALVE- PRESSURE REDUCING, MANUAL (X) 1

46 47568-1 ASSEMBLY- KNIFE LATCH 1

47 47504 BRACKET- KNIFE BAR KEEPER 1

48 E-2196-17 PLUG- HOLE 4

49 40016-8 VIBRATION ABSORBER 4

50

51 H-6940-416 SCREW - 1/4-20 X 1" FT. PT. SET 8

52 H-6975-404 SCREW - 1/4-20 X 1/2 NYLOK CUP PT. SS 2

53 H-6918-608 SCREW - 3/8-16 X 1" SOC. HD. 6

54 H-6910-102406 SCREW - #10-24 X 3/4 BUTT. HD. 2

55 H-6913-606 SCREW - 3/8-16 X 3/4 HEX 4

56 H-6953-856 SCREW - 1/2-13 X 3-1/2 OVAL PT. SOC. SET 6

57 H-6910-102404 SCREW - #10-24 X 1/2 BUTT. HD. 15

58 H-6910-102408 SCREW - #10-24 X 1" BUTT. HD. 2

59 H-6910-83204 SCREW - #8-32 X 1/2 BUTT. HD. 2

60 H-6897-102403 SCREW - #10-24 X 3/8 NYLOK FL HD.SOC.CAP 2

61 H-7324-8 WASHER - 1/4 INT. TOOTH 14

62 H-7324-#10 WASHER - #10 INT. TOOTH 15

63 H-7324-#8 WASHER - #8 INT. TOOTH 2

64 H-7327-12 WASHER - 3/8 MED. LOCK 8

65 H-6910-102403 SCREW - #10-24 X 3/8 BUTT. HD. 10

66 H-6424-4 NUT - 1/4-20 HEX 12

67 H-6424-6 NUT - 3/8-16 HEX JAM 2

68 E-2883 ANCHOR - TIE WRAP 3

69 H-7002-8 NUT - 1/2-13 HEX JAM (BLACK) 6

70 H-6423-#8 NUT - #8-32 HEX 2

71 H 6910-405 1/4-20 X 5/8 BUTT. HD. 2

72 H-6913-605 SCREW- 3/8-16 X 5/8 HEX HD. 2

73 H-6923-44012 SCREW- #4-40 X 3/4 RD. HD. 2

74 H-7324-#4 WASHER- #4 INT. TOOTH 3

75 H-6423-#4 NUT- #4-40 HEX 2

76 S-1781-11 LABEL- CAUTION 1

77 K-47548 TOOL KIT- 305 X 1

77 K-47547 TOOL KIT- 305 XD/XG 1

78 H-7321-#10 WASHER-#10 SAE FLT. PLT'D 4

79 H-7321-6 WASHER-3/8 SAE FLT. 4

5.0 Schematics & Parts Lists

35

Main Assembly Front View

47500 Sht. 1 of 16, Rev. X

NO. PART NO. DESCRIPTION OF ACCESSORIES QTY

80

81 H-6910-504 SCREW- 5/16-18 X 1/2 BUT HD 4

82 E-2196-24 HOLE PLUG - 3/8 SHORTY 3

83 47617 FALSE CLAMP PLATE SHEATH ASM. 1

84 H-7324-10 WASHER-5/16 INTERNAL TOOTH 4

85 H-7321-5 WASHER-5/16 SAE FLT. 4

86 H-7327-10 WASHER-5/16 MEDIUM LOCK 4

87 H-6417-5 NUT- 5/16-18 HEX 4

88 H-6910-404 SCREW- 1/4-20 X 1/2 BUT HD 1

89 H-6423-4 NUT- 1/4-20 HEX KEP 1

90 S-1781-42 LABEL- GROUND 1

91 EE-3210 CABLE ASM- COMPRESSOR POWER REF.

92 49249 BACKGAUGE CONTROL ASSEMBLY 1

93 H-6910-604 SCREW- 3/8-16 X 1/2 BHC 2

5.0 Schematics & Parts Lists

36

5.2 Main Assembly Side View

47500 Sht. 2 of 16, Rev. L

5.0 Schematics & Parts Lists

37

Main Assembly Side View

47500 Sht. 2 of 16, Rev. L

5.0 Schematics & Parts Lists

38

5.3 Main Assembly Top View

47500 Sht. 3 of 16

5.0 Schematics & Parts Lists

39

Main Assembly- Top View

47500 Sht. 3 of 16

5.0 Schematics & Parts Lists

40

5.4 Main Assembly Rear View

47500 Sht. 4 of 16, Rev. N

5.0 Schematics & Parts Lists

41

Main Assembly Rear View Parts List

47500 Sht. 4 of 16, Rev. N

NO. PART NO. DESCRIPTION OF ACCESSORIES QTY

1 47519 BRACKET - KNIFE PROX. 1

2 S-1781-15 LABEL - "HAZARDOUS MOVING PARTS" 1

3 EE-2848 CABLE ASM.- LCD BACK LITE 1

4 7032-M TRIM- PLASTIC (9 FT. & 37.5" LONG) 1

5 S-1350-16 BUSHING 4

6 S-1694-2 TYRAP- #10 1

7 EE-2839-2 CABLE ASM.- LINE LIGHT 1

8 47552 COVER- REAR BASE, L.H. 1

9 47050 COVER- BASE, R.H. REAR 1

10

11 47570 COVER- REAR BASE, MAIN 1

12 47171 BRACKET- CLAMP PROX. SWITCH 1

13 47006-2 PLATE ASM.- FALSE CLAMP 1

14 S-1244 PIN- LOCK 2

15 S-1861 SHIM 2

16 4509-1 BAR CLAMP GUIDE 2

17 47001 COVER- REAR ARCH 1

18 47557-1 AIR CYLINDER ASSEMBLY 1

19 47522 CLAMP 1

20 47267 BRACKET- HYDRAULIC DAMPER 1

21 EE-2834 CABLE ASM.- JUNCTION BOX REF.

22 H-230-6 ELBOW- 90%%D "O" RING TO TUBE 2

23 E-1152-35 SPACER- STAND OFF 1

24 E-1152-36 SPACER- STAND OFF 5

25 47571 BRACKET- REAR COVER 4

26

27 47268 PIN- HYDRAULIC DAMPER 1

28 4508 CLAMP- GUIDE BAR 2

29 4507-1 PIN- KNIFE BAR LINK 2

30 E-2626-6 TERMINAL BLOCK- 6 POLE 1

31 P-303 1/4 VINYL TUBING 58"

32 E-2883 ANCHOR- TYRAP 1

33 S-1694 TYRAP 1

34 47195 BRACKET- ARCH JUNCTION 1

35 S-1864-2 CAPTIVE RETAINING DEVICE 4

36 S-1864-3 CAPTIVE RETAINING DEVICE 6

37 47019-1 GUIDE- REAR, R.H. 1

38 47020-1 GUIDE- REAR, L.H. 1

5.0 Schematics & Parts Lists

42

Main Assembly Rear View Parts List

47500 Sht. 4 of 16, Rev. N

NO. PART NO. DESCRIPTION OF ACCESSORIES QTY

39 4441-1 PAPER GUIDE 1

40

41 E-2186-7 CLAMP- WIRE HARNESS (PROGRAMMABLE ONLY) 2

42 S-1694-2 TIE- CABLE (#10) 1

43 S-1781-61 LABEL - KNDN 1

44 S-1781-62 LABEL - KNUP 1

45 H-6417-6 NUT- 3/8-16 HEX (USE AS SPACERS) 2

46 S-1781-63 LABEL - CLDN 1

47 S-1781-64 LABEL - CLUP 1

48 47528 LIMIT SWITCH ACTUATOR- CLAMP "UP" 1

72 H-7327-12 WASHER- 3/8 LOCK 8

73

74

75 H-7324-#10 WASHER- #10 INT. TOOTH 14

76 S-1193-25 "E" RING- 1/4 2

77 H-7324-#4 WASHER- #4 INT. TOOTH 2

78 H-6922-44012 SCREW- #4-40 X 3/4 FLAT HD. 2

79 H-6423-#4 NUT- #4-40 HEX 2

80

81

82

H-6910-

102403 SCREW- #10-24 X 3/8 BUTT. HD. 12

83 H-6951-406 SCREW- 1/4-20 X 3/8 S.S. NYLOC 3

84 H-6910-403 SCREW- 1/4-20 X 3/8 BUT HD 7

85 H-7324-8 WASHER- 1/4 INT. TOOTH 2

89 H-6910-404 SCREW- 1/4-20 X 1/2 BUTT. HD. 6

90

H-6910-

102404 SCREW- #10-24 X 1/2 BUTT. HD. 16

91

H-6910-

102406 SCREW- #10-24 X 3/4 BUTT. HD. 2

92 E-2743 WIRE - #18 GA. GRN/YEL EURO MTW 5" LONG 1

93 E-1214-8 CONNECTOR - #10 INS. RING (16-22 GA.) 1

94 H-6918-608 SCREW- 3/8-16 X 1" SOC. HD. 20

95 H-6918-606 SCREW- 3/8-16 X 3/4 SOC. HD. 2

96 H-6910-408 SCREW- 1/4-20 X 1" BUTT. HD. 1

97

H-6903-

102404 SCREW- #10-24 X 1/2 BUTT. HD., NYLOC 2

98 S-1781-16 LABEL- CRUSH HAZARD 1

99

H-21S-375-

1000 ROLL PIN- 3/8 X 1" 1

100 S-1781-12 LABEL- SHOCK HAZARD, ELECTRICAL 1

5.0 Schematics & Parts Lists

43

Notes

5.0 Schematics & Parts Lists

44

5.5 Main Assembly X Model Tables

47500 Sht. 5 of 16 Rev. D

5.0 Schematics & Parts Lists

45

Main Assembly X Model Tables

47500 Sht. 5 of 16 Rev. D

5.0 Schematics & Parts Lists

46