Professional Documents

Culture Documents

Indian Standard: Specification For Door Spring Rat-Tail Type (

Indian Standard: Specification For Door Spring Rat-Tail Type (

Uploaded by

ssaurav89Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indian Standard: Specification For Door Spring Rat-Tail Type (

Indian Standard: Specification For Door Spring Rat-Tail Type (

Uploaded by

ssaurav89Copyright:

Available Formats

I S : 452 - 1973

Gr 3

Indian Standard

SPECIFICATION FOR

DOOR SPRING RAT-TAIL TYPE

( Second Revision )

Second Reprint FEBRUARY 1989

uclc 663.372.4

BUREAU OF INDIAN STANDARDS

hlANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

October 1973

-_B

( Reaffirmed 1996 )

ls:432-1973

I ndian Standard

SPECIFICATION FOR

DOOR SPRING RAT-TAIL TYPE

( Second Revision )

Builders Hardware Sectional Committee, BDC 15

Chaiman

SHIU Yusm MOWJXE

Members

R@resaating

M. C. Mowjee & Company,

Hardware Industries

Calcutta

Calcuttq; and Builders

Associatron of India,

SHRl SAHIB SINGH ( AkYUZt# t0

Shri Yusuf Mowjee )

SHRI D. R. BAHL

SHRI P. K. SETH! ( Altemafc )

SHRI J. P. BAJAJ

SKI A. K. BHIMANI

SHRI H. C. SAMPAT ( Alternate)

&RI R. M. CHAUDHARI

SHRI J. K. ANAND ( Alterke )

CONTROLLER OP STORES. EASTERN

RAILWAY

Engineer-in-Chiefs Branch, Army Headquarters

Institution of Engineers ( India ), Calcutta

Vertex Manufacturing Company Ltd, Bombay

Indian Aluminium Company Ltd, Calcutta

Railway Board ( Ministry of Railways )

SHRI P. K. DE

SHRI K. L. GEHLOTE

SHRI K. P. JAIN

SHRI V. S. KAMBOJ

SHRI J. R. KANSARA

SHRI V. S. KAMBOJ ( Altcmafe )

SHRI S. C. KAPOOR

Des Lock Industries, Calcutta

Indian Institute of Architects, Bombay

Engineering Association of India, Calcutta

Jayna Trading Corporation, Delhi

Arvind Industries, Jamnagar, Gujarat

SHRI S. D. MAJUMDER

SHRI AJOYBNDU PAUL

DR A. V. R. RAO

SURVEYOR OF WORKS ( I )

SHRI D. AJITHA SI MHA,

Directorate General of Supplies &

( Ministry of Supply )

Disposals

National Test House, Calcutta

Govindo Sheet Metal Works & Foundry Calcutta

National Buildings Organisation, New Delhi

Central Public Works Department, New Delhi

Director General, IS1 ( Ex-o$cio Member )

Director ( Civ Engg )

stcrrtu~

SHIU S. P. MAGGU

Senior Technical Assistant ( Civ Engg ), IS1

( Conlinurd on page 2 )

@ CopVrighf 1973

BUREAU OF INDIAN STANDARDS

This publication is protected under the In&m Copyright Act ( XIV of 1957 ) and

reproduction in whole or in part by any means exce

publisher shall be damed to be an infringement o

P

t with written permission Of the

copyright under the raid Act.

IS : 452 - 1973

( Continusdfrom page 1)

Door and Window Fittings Subcommittee, BDC 15 : 1

Convener ReDresenting

!&RI YUSUF MOWJEE M. C. Mowjee & Company, Calcutta

Members

SWRI SAHm SINoH ( Alternate to

Shri Yusuf Mowjee )

SHRI A. K. BHIMANI

SHRI H. C. SAMPAT ( Akrnaf6 )

Vertex Manufacturing Company Ltd, Bombay

SHRI P. Boss C. K. Sirkar & Company, Calcutta

SHRI G. S. CHOwlXiURY Builders Hardware Industries Association of India,

Calcutta

SHRI J. P. JAIN Indian Hardware Industries Limited, New Delhi

SHRI V. S. KAMBOJ

Jayna Trading Corporation, Delhi

SHRI BIPXN KUHARIA

Chemi Chrome Industries Private Limited, Kanpur

SHRI L. S. KUMAWAT Engineer-in-Chiefs Branch, Army Headquarters

. Sum S . BALAKRIBHNAN ( Alternate )

SHRI S. K. LAHXRI Lahiris Architectural Industries Private Limited,

Calcutta

SHRI A. K. LAHIRI. ( Alternate )

SHRI AJOYENDU PAUL Gobindo Sheet Metal Works & Foundry, Calcutta

SIXRI N. V. SHA~TRI Railway Board ( Ministry of Railways )

SURVEYOR OF WORKS ( I )

Central Public Works Department, New Delhi

2

IS : 452 - 1973

I ndian Standard

SPECIFICATION FOR

DOOR SPRING RAT-TAIL TYPE

( Second Revision )

0, FOREWORD

0.1 This Indian Standard ( Second Revision) was adopted by the Indian

Standards Institution on 22 March 1973, after the draft finalized by the

Builders Hardware Sectional Committee had been approved by the Civil

Engineering Division Council.

0.2 This standard was published in 1953 and subsequently revised in 1963.

A second revision of the standard has been issued to make improvements

in the same in the light of the experience gained by the manufacturers and

users since 1963. The second revision also makes reference to the recent

Indian Standards on materials of construction.

0.3 This standard contains clause 7.2 which permits the purchaser to use

his option for selection to suit his requirements.

0.4 While issuing this standard, the Sectional Committee took note of the

acute scarcity of non-ferrous materials like copper, zinc and other alloys in

the country and the need for conservation of the same in the national

interest.

However, in view of the demand for hardware items made

of these materials in overseas markets, the Sectional Committee has

retained them specifically to meet the requirements of export trade. For

all indigenous use, it is recommended that hardware items made out

of these materials should not be used.

0.5 In the formulation of this standard due weightage has been given to

international co-ordination among the standards and practices prevailing

in different countries in addition to relating it to the practicesin the field in

this country.

0.6 This standard is one of a series of Indian Standards on builders

hardware,

3

IS I 452 - 1973

0.7 For the purpose of deciding whether a particular requirement of this

standard is complied with, the final value, observed or calculated, express-

ing the result of a test or analysis, shall be rounded off in accordance with

IS : Z-1960*. The number of significant places retained in the rounded off

value should be the same as that of the speci&d value in this standard.

1. SCOPE

1.1 This standard lays down the requirements for materials, dimensions,

manufacture, finish and tests for door springs, rat-tail type commonly used

in building construction.

2. TYPES

2.1 Door springs, rat-tail type, shall be of the following two types accord-

ing to the materral used:

a) Mild steel door springs, and

b) Brass door springs.

3. MATERIAL

3.1 Mild Steel Sheets -

Mild steel sheets and plates used in the manu-

facture of mild steel door springs, rat-tail type shall conform to Grade 0 of

IS : 1079- 1968t and shall satisfy the following bend test:

Suitable test pieces when cold shall withstand without fracture,

being doubled over, either by pressure or by blows from a hammer,

until the internal diameter is equal to twice the thickness of the

test piece and the sides become parallel.

3.2 Mild Steel Rods - Mild steel rods used shall conform to Grade

St-42-S of IS : 226-1969:.

3.3 Brass Rods -Brass rods used in the manufacture of door springs

shall have copper content not less than 60 percent and tensile strength

40 kgf/mmz and shall conform to IS : 319-1968s.

.

3.4 Rivets -

Rivets used shall be of mild steel and shall conform to

IS : 2998-196511.

*Rules for rounding off numerical values ( rcuiscd ) .

tSpecification for hot rolled carbon steel sheet and atrip ( second revision).

$Specification for structural ateel ( standard quality) (fourth ~&&WI ).

@pecification for free cutting brass rods and sections ( second recisMn ).

IlSpecification for cold forged steel rivets for cold closing.

fSr452-1973

3.5 Steel Wire -Steel wire for springs shall conform to Grade 1 or

Grade 2 of IS : 4454-1967..

3.6 Phosphor Bronze Wire - Phosphor bronze wire for springs shall

conform to grade PCu Sn4 of IS : 1385-1968t.

3.7 Cast Brass- Cast brass used in the manufacture of brass door

springs shall conform to Grade 3 of IS : 292-1961:.

3.8 Brass Sheets -Brass sheets used in the manufacture of brass door

springs shall conform to alloy designation CuZu 40 of IS : 410-l 9678.

4. SIZES

4.1 Door spring of rat-tail type shall be of the following sizes:

300 mm and 375 mm

NOTE -The size of the door spring shall be denoted by the distance from the centre

of the spindle to the centre of the roller.

5. DIMENSIONS

5.1 The leading dimensions of door springs shall conform to those specified

in Fig. 1.

6. MANUFACTURE

6.1 Mild Steel Door Springs - The cylindrical casing shall be made

either from mild steel sheet of I.60 mm thickness, lap-jointed, welded,

brazed or riveted; or made from steel tube of not less than I.25 mm thick-

ness. The casing shall be fitted at both ends with pressed mild steel caps

with a round hole of 9.5 mm to pass the spindle. The spindle shall be of mild

steel and 8 mm square in section. It shall be face-fitted at both ends into

the spindle holders made from 2.00 mm thick mild steel sheet riveted to

the base plate of 2.50 mm thickness as shown in Fig. 1. One end of the

spring shall be securely fitted to the inside of the casing and the other end

to the spindle. The tail rod shall be of mild steel and 10 mm in diameter.

One end of the tail rod shall be forged, welded or riveted to the cylinder

as shown in Fig. 1. To the other end of the tail rod a mild steel roller of

22 mm diameter shall be fitted as shown in Fig. 1. The rotation of the

rod shall be smooth and square. The roller shall rotate freely without

appreciable friction. The bearing portion of the roller and the roller plate

shall be reasonably smooth.

The roller plate shall be of mild steel sheet

l-60 mm in thickness.

*Specification for steel wires for cold formed springs.

tSpecification for phosphor bronze rods and bars, sheet and strip, and wire

( /;rst r&&n ) .

$3pecification for brass ingots and castings ( revised ).

ispecification for rolled brass plate, sheet, strip and foil ( second revision ).

5

ls:4!i2-1973

6.2 Brass Door Springs - The cylindrical casing shall be made either

from brass sheet of 1.60 mm thickness or from seamless brass tube of

1.25 mm thickness. The casing shall be fitted at both ends with cast brass

caps with a round hole of 9.5 mm diameter to pass the spindle. The tail

rod shall be of rolled brass and shall be 10 mm in diameter. The base

plate shall be made from brass sheet of 2.50 mm thickness and roller plate

from brass sheet of 1.60 mm thickness. In all other respects brass door

springs shall conform to the requirements specified for mild steel door

springs.

7. FINISH

7.1 In the case of mild steel door springs, casing, tail rod, spindle cap and

base plate shall be stove enamelled black or copper oxidized. Spindle,

roller plate and roller shall be bright finished and the spring if made of

steel wire shall be copper oxidized or electro galvanized.

7.2 In the case of brass door springs, casing, tail rod, spindle cap and base

plate shall be bright finished or copper oxidized as required by the purcha-

SW. Spindle, roller plate and roller shall be bright finished and the

spring if made of mild steel wire shall be copper oxidized or electro-

galvanized.

8. PERFORMANCE TESTS

8.1 Each door spring shall withstand the following tests which shall be

carried out after fitting the spring to the door frame:

a) The tail rod when pushed through to the maximum possible limit

and released 100 times in quick succession the spring shall show

no sign of damage or any permanent set during or on completion

of the test.

b) The torque required to push open the door through 90 shall not

exceed 4 kg m.

9. MARRING

9.1 Each door spring shall have clearly and permanently marked- on its

casing name or trade-mark of the manufacturer and the size of door springs.

9.1.1 The door spring may also be marked with the IS1 Certification

Mark.

NOTE - The use of the IS1 Certification Mark is governed by the provisions of the

Indian Standards Institution ( Certification Marks) Act and the Rules and Regufa-

tions made thereunder. The IS1 Mark on products covered by an Indian Standard

conveys the assurance that they have been produced to comply with the requirements of

that standard under a well-defined system of inspection, testing and quality control

which is devised and supervised by IS1 and operated by the producer. IS1 marked

products are also continuously checked by IS1 for conformity to that standard as a

further safeguard. Details of conditions under which a licence for the use of the IS1

Certification Mark may be granted to manufacturers or processors, may be obtained

from the Indian Standards Institution.

6

IS : 452 - 1973

3.55mm 9 SPRING, ONE

END RIVETED TO THE CYLINDER AN0

THE OTHER EN0 INSERTED INSIDE

THE SPI,NDLE

CAP FOR CYLINDER

2*5Dmm BASE PLATE

SPINDLE HOLDER RIVETED TO

BASE PLATE .

--I

LMACHINED MS

3 mm # PIN, SNAPPED

ROLLER 3 mm THICK

AT BOTH ENOS

TOP FITTED

OF SPINOLE

SECTION YY

All dimensions in millimetrcs.

Fm. 1 TYPICAL DESIGN OF RAT-TAIL TYPE DOQR SPRING

7

As in the Original Standard, this Page is Intentionally Left Blank

10. PACKING

10.1 Door spring shall be wrapped in strong kraft, paper and packed

in carton or other approved packing, each* containing six door springs.

When packed in wooden boxes,

each box shall contain twelve door

springs.

10.2 Each package shall be labelled with the name or trade-mark of the

manufacturer, particulars of the quantity, description of the contents and

size of door springs.

11. SAMPLING AND CRITERION FOR CONFORMITY

11.1 The scale of sampling and criterion for conformity, for door spring

rat-tail type shall be as given in Appendix A.

APPENDIX A

( Clause 11.1 )

SAMPLING AND CRITERION FOR CONFORMITY

A-l. LOT

A-l.1 In any consignment, all the door springs of the same type and

size and manufactured at the same time shall be grouped together

to constitute a lot.

A-2. SAMPLE SIZE

A-2.1 The number of door springs to be selected from the lot shall depend

upon the size of the lot and shall be in accordance with co1 1 and

2 of Table 1.

A-2.1.1 Door springs shall be selected at random from at least 10

percent of the packages subject to a minimum of 3, equal number of

springs being selected from each package.

A-3. TESTS

A-3.1 All door springs selected as in A-2.1 shall be checked for dimen-

sional requirements (see 5 ), manufacturing defects ( see 6 ) and finish

( see 7 ). Any spring which fails to satisfy the requirements of any one 01

more of the characteristics shall be considered as a defective spring.

9

Is:432-1973

TABLE 1 SCALE OF SAMPLING AND CRITERION FOR CONFORMPL7Z

( Clauses A-2.1 and A-4.1 )

LOT SIZE SAMPLE SIZE PERMISSIBLE No. OF

DEFECTIVE DOOR

SPRINGS

(1) (2: (3)

up to 200 15 0

201

1,

300 20 1

301

,9

500 30 2

501 3, 800 40 2

801 and above 55 3

NOTE

-The sampling plan given here is such that lots with l-5 percent or lesr

defectives will be accepted most of the times.

A-4. CRITERION FOR CONFORMITY

A-4.1 The lot shall be considered as conforming to the requirements

pf this standard if the number of defective springs among those inspected

does not exceed the corresponding number given in co1 3 of Table 1; other-

wise it shall be considered as not conforming to the requirements of this

standard.

For conformity to the requirements of the material, the

manufacturer shall provide a certificate of compliance to the requirements

of the corresponding Indian Standards ( see 3 ).

10

BUREAU OF INDIAN STANDARDS

Headquarters :

Manak Bhavan, 9 Bahadur Shah Zafar Marg, NEW DELHI 110002

Telephones : 3 31 01 31, 3 31 13 75 Telegrams : Manaksanstha

( Common to all Offices )

Regional Offices : Telephone

*Western ; Manakalaya, E9 MIDC, Marol, Andheri ( East ), 6 32 92 95

BOMBAY 400093

tEastern : l/l4 C. I. T. Scheme VII M, V. I. P. Road,

Maniktola, CALCUTTA 700054

Northern : SC0 445-446, Sector 35-C

CHANDIGARH 160036

Southern : C. I. T. Campus, MADRAS 600113

Branch Offices :

36 24 99

{

2 18 43

3 1641

l

41 24 42

41 25 19

C41 29 16

Pushpak, Nurmohamed Shaikh Marg, Khanpur,

4HMADABAD 380001

F Block, Unity Bldg, Narasimharaja Square,

BANGALORE 560002

{

2 63 48

2 63 49

22 48 05

Gangotri Complex, 5th Floor, Bhadbhada Road, T. T. Nagar, 6 27 16

BHOPAL 462003

Plot No. 82/83. Lewis Road, BHUBANESHWAR 751002

5 36 27

53/5 Ward No. 29, R. G. Barua Road,

5th Byelane. GUWAHATI 781003

-

5-8-56C L N. Gupta Marg. (Nampally Station Road),

22 10 83

HYDERABAD 500001

R14 Yudhister Marg. C Scheme, JAIPUR 302005

{

6 34 71

6 98 32

117/418B Sarvodaya Nagar. KANPUR 208005

Patliputra Industrial Estate, PATNA 800013

Hantex Bldg ( 2nd Floor ), Rly Station Road,

TRIVANDRUM 695001

{

2: :: 9:

6 23 05

52 27

lnspecfion Office ( With Sale Point ):

Institution of Engineers ( India ) Building, 1332 Shivaji Nagar, 5 24 35

PUNE 410005

*Sales Office in Bombay is at Novelty Chambers. Grant Road,

Bombay 400007

89 66 28

tSdes Office in Calcutta is at 5 Chowringher Approach, P. 0. Princrp

27 68 00

Street, Calcutta 700072

Reprography Unit, BIS, New Delhi, India

You might also like

- Manual 1 - The Fundamentals of Road Construction PDFDocument42 pagesManual 1 - The Fundamentals of Road Construction PDFssaurav89100% (2)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Is 1019Document16 pagesIs 1019dnageshm4n244No ratings yet

- 226Document16 pages226Abhijeet Vardhe100% (5)

- 804-Rectangular Steel TanksDocument24 pages804-Rectangular Steel Tanksjun005100% (4)

- 655 RDocument12 pages655 R9810482818No ratings yet

- I S 816 - 1969Document29 pagesI S 816 - 1969Hariprasad gantyalaNo ratings yet

- Indian Standard: Specification For Floor Door Stoppers (Document12 pagesIndian Standard: Specification For Floor Door Stoppers (ssaurav89No ratings yet

- Is 280-1978Document13 pagesIs 280-1978Johnson Sunder100% (1)

- 733 AluminiumDocument17 pages733 Aluminiumdhoops1988No ratings yet

- Specification For Cold-Rolled Steel Strips For Springs (First RecisionDocument20 pagesSpecification For Cold-Rolled Steel Strips For Springs (First Recisiontopazamp123No ratings yet

- 9295Document14 pages9295Rathish ViswanathanNo ratings yet

- 2209Document20 pages2209ssaurav89No ratings yet

- Is 1852Document28 pagesIs 1852kbasawaNo ratings yet

- Is 8081 Specification For Slotted SectionsDocument16 pagesIs 8081 Specification For Slotted Sectionsbantyrock9671No ratings yet

- Reaffirmed 1996Document9 pagesReaffirmed 1996ssaurav89No ratings yet

- Is 2751 Code of Practice For Welding of Mild Steel Plain And.183134444Document38 pagesIs 2751 Code of Practice For Welding of Mild Steel Plain And.183134444Vivek KalaNo ratings yet

- Is - 816Document30 pagesIs - 816mmkatta100% (1)

- Indian StandardDocument12 pagesIndian StandardBilal AhmadNo ratings yet

- Disclosure To Promote The Right To InformationDocument17 pagesDisclosure To Promote The Right To Informationsarath6725No ratings yet

- Is 2016Document13 pagesIs 2016Sumit Shyamal100% (1)

- Is 1239 BookDocument34 pagesIs 1239 Booknagaraj108No ratings yet

- Is 3502 2009 PDFDocument10 pagesIs 3502 2009 PDFRajashekar.PNo ratings yet

- Is - 6132-Part1Document13 pagesIs - 6132-Part1Rajendran NairNo ratings yet

- 2633 - 1986 - R2006 - Method of Testing Uniformity of Coating On Zinc Coated Articles PDFDocument12 pages2633 - 1986 - R2006 - Method of Testing Uniformity of Coating On Zinc Coated Articles PDFManoj Kumar BarikNo ratings yet

- Is 3815Document15 pagesIs 3815mishra_198250% (2)

- Is-1566-1982 (2000)Document16 pagesIs-1566-1982 (2000)hhr2412No ratings yet

- Is-1566-1982 (2000)Document15 pagesIs-1566-1982 (2000)hhr2412100% (1)

- Specificationfor Coldformedlightgaugestructural SteelsectionsDocument31 pagesSpecificationfor Coldformedlightgaugestructural SteelsectionsprasenjitsayantanNo ratings yet

- 277 - Galvanised Steel SheetsDocument10 pages277 - Galvanised Steel SheetsKaushik SenguptaNo ratings yet

- Reaffirmed 1996Document9 pagesReaffirmed 1996ssaurav89No ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationCristian WalkerNo ratings yet

- Is 15911 2010Document13 pagesIs 15911 2010Pankita BistNo ratings yet

- 1278 - Filler Rods For Gas WeldingDocument20 pages1278 - Filler Rods For Gas WeldingKaushik SenguptaNo ratings yet

- Is 2830 1992Document9 pagesIs 2830 1992Sunny SaparNo ratings yet

- Reaffirmed 2006Document9 pagesReaffirmed 2006Kaushik SenguptaNo ratings yet

- Irc 024-1967Document87 pagesIrc 024-1967harivennelaNo ratings yet

- Is 801Document39 pagesIs 801Shashi TapsiNo ratings yet

- Is 7215 Tolerances For Fabrication of Steel Structures R0.183135154Document24 pagesIs 7215 Tolerances For Fabrication of Steel Structures R0.183135154rikumohan100% (1)

- 10742Document10 pages10742satish3393No ratings yet

- 6916 Welding FabricationDocument33 pages6916 Welding FabricationvikasgahlyanNo ratings yet

- Is 6392 1971Document62 pagesIs 6392 1971Chandra SekharNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- The Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenFrom EverandThe Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Housing: HOSTELS-Under ConstructionDocument29 pagesHousing: HOSTELS-Under Constructionssaurav89No ratings yet

- Reaffirmed 1996Document9 pagesReaffirmed 1996ssaurav89No ratings yet

- Reaffirmed 1996Document18 pagesReaffirmed 1996ssaurav89No ratings yet

- Welded Steel Wire Fabric For General Use - Specification: Indian StandardDocument8 pagesWelded Steel Wire Fabric For General Use - Specification: Indian Standardssaurav89No ratings yet

- Reaffirmed 1996Document14 pagesReaffirmed 1996ssaurav89No ratings yet

- OP AMPS HughesDocument8 pagesOP AMPS Hughesmarkos_mylonas4152No ratings yet

- JAMB English Language Past Questions and Answers 2010 - 2018Document84 pagesJAMB English Language Past Questions and Answers 2010 - 2018Joel Adams100% (6)

- CEFIC Quantis Report FinalDocument24 pagesCEFIC Quantis Report FinalJayanth KumarNo ratings yet

- Bernard Stanley Hoyes: RAG DrawingsDocument29 pagesBernard Stanley Hoyes: RAG Drawingsapi-258238272No ratings yet

- Sony PCM-7040 1st EdDocument81 pagesSony PCM-7040 1st EdnicureddogsfloNo ratings yet

- C.H. Robinson Contract Addendum and Carrier Load Confirmation - #349533259Document3 pagesC.H. Robinson Contract Addendum and Carrier Load Confirmation - #349533259terry72imlNo ratings yet

- Io TDocument39 pagesIo TECESPLNo ratings yet

- UNIT-4 Key Distribution & ManagementDocument53 pagesUNIT-4 Key Distribution & ManagementBharath Kumar T VNo ratings yet

- Apache Kafka Quick Start GuideDocument180 pagesApache Kafka Quick Start GuidesleepercodeNo ratings yet

- Expt. No: 1111: Determination of Total Hardness of Water by Complexometric Titration (EDTA Method)Document3 pagesExpt. No: 1111: Determination of Total Hardness of Water by Complexometric Titration (EDTA Method)Nael NomanNo ratings yet

- CalendarDocument1 pageCalendarfattyfeet5No ratings yet

- Invenia ABUS 2.0 Release Notes - UM - 4700-0044-00 - 4Document24 pagesInvenia ABUS 2.0 Release Notes - UM - 4700-0044-00 - 4Jawad SandhuNo ratings yet

- Carbohydrates Discussion Questions and AnswersDocument2 pagesCarbohydrates Discussion Questions and AnswerslolstudentNo ratings yet

- General Physics 1 Reviewer PDFDocument29 pagesGeneral Physics 1 Reviewer PDFJhon Robert ClavoNo ratings yet

- Looking Back and Looking ForwardDocument6 pagesLooking Back and Looking ForwardJotham SederstromNo ratings yet

- CL336: Advanced Transport Phenomena: Written Quiz - 1Document2 pagesCL336: Advanced Transport Phenomena: Written Quiz - 1LikhithNo ratings yet

- Operation Manual Hydraulic Drifter ED-100: ISO 9001:ISO 14001 CertifiedDocument55 pagesOperation Manual Hydraulic Drifter ED-100: ISO 9001:ISO 14001 CertifiedDaniel F Barros100% (2)

- 1454665129905-MNRE Empanelled Agency-All India PDFDocument25 pages1454665129905-MNRE Empanelled Agency-All India PDFAurobindo SaxenaNo ratings yet

- NY CREATES IBM Board PacketDocument2 pagesNY CREATES IBM Board PacketSean MickeyNo ratings yet

- Pollack Cells Gels Engines LifeDocument320 pagesPollack Cells Gels Engines LifeAlfonso Lema100% (3)

- Lec 3Document32 pagesLec 3wjeelaniNo ratings yet

- Peripheral Testosterone MetabolismDocument8 pagesPeripheral Testosterone MetabolismAgung SentosaNo ratings yet

- Purchase Order NO: 1010849367: VendorDocument2 pagesPurchase Order NO: 1010849367: VendorErian Adhi Nur PersadaNo ratings yet

- Valuecent Profile PDFDocument9 pagesValuecent Profile PDFAP Advisory BVNo ratings yet

- Celebrity's Self-Disclosure On Twitter and Parasocial Relationships (Mediating Soc Presence)Document8 pagesCelebrity's Self-Disclosure On Twitter and Parasocial Relationships (Mediating Soc Presence)RIZKINo ratings yet

- DrupalDocument344 pagesDrupalMike Nall100% (4)

- Configuring Resilient Ethernet Protocol: Information About Configuring REPDocument12 pagesConfiguring Resilient Ethernet Protocol: Information About Configuring REPGabi Si Florin JalencuNo ratings yet

- Embediment LengthDocument6 pagesEmbediment LengthkelvinNo ratings yet

- Political Cycle - Alberto AlesinaDocument3 pagesPolitical Cycle - Alberto AlesinayumicintaNo ratings yet

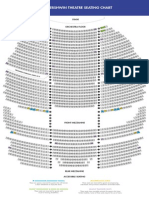

- The Gershwin Theatre Seating Chart: StageDocument1 pageThe Gershwin Theatre Seating Chart: StageCharles DavidsonNo ratings yet