Professional Documents

Culture Documents

Turbine Blade Fir Tree FEA

Turbine Blade Fir Tree FEA

Uploaded by

shilton19890 ratings0% found this document useful (0 votes)

83 views15 pagesThis document discusses optimizing the design of turbine blade fir-tree roots through intelligent CAD and finite element analysis. It presents an optimization framework that uses a knowledge-based intelligent CAD system and finite element analysis to automatically optimize the shape of fir-tree roots against geometric and mechanical constraints. Key aspects discussed include using the intelligent CAD system to parametrically model variations in dimensions and topology, analyzing how geometric features affect stress distribution using finite element analysis, and incorporating this process into an optimization loop to automatically find the best solution.

Original Description:

analysis of a turbine fir tree

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses optimizing the design of turbine blade fir-tree roots through intelligent CAD and finite element analysis. It presents an optimization framework that uses a knowledge-based intelligent CAD system and finite element analysis to automatically optimize the shape of fir-tree roots against geometric and mechanical constraints. Key aspects discussed include using the intelligent CAD system to parametrically model variations in dimensions and topology, analyzing how geometric features affect stress distribution using finite element analysis, and incorporating this process into an optimization loop to automatically find the best solution.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

83 views15 pagesTurbine Blade Fir Tree FEA

Turbine Blade Fir Tree FEA

Uploaded by

shilton1989This document discusses optimizing the design of turbine blade fir-tree roots through intelligent CAD and finite element analysis. It presents an optimization framework that uses a knowledge-based intelligent CAD system and finite element analysis to automatically optimize the shape of fir-tree roots against geometric and mechanical constraints. Key aspects discussed include using the intelligent CAD system to parametrically model variations in dimensions and topology, analyzing how geometric features affect stress distribution using finite element analysis, and incorporating this process into an optimization loop to automatically find the best solution.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 15

Turbine blade r-tree root design optimisation using

intelligent CAD and nite element analysis

Wenbin Song

a,

*

, Andy Keane

a

, Janet Rees

b

, Atul Bhaskar

a

, Steven Bagnall

b

a

Department of Mechanical Engineering, University of Southampton, Higheld, Southampton, SO17 1BJ, UK

b

Rolls-Royce Plc., Bristol, BS34 7QE, UK

Received 16 January 2001; accepted 26 May 2002

Abstract

This paper is concerned with automation and optimisation of the design of a turbine blade r-tree root by incor-

porating a knowledge based intelligent computer-aided design system (ICAD

) and nite element analysis. Various

optimisation algorithms have been applied in an eort to optimise the shape against a large number of geometric and

mechanical constraints drawn from industrial experience in the development of such a structure. Attention is devoted to

examining the eects of critical geometric features on the stress distribution at the interface between the blade and disk

using a feature-based geometry modelling tool and the optimisation techniques. Various aspects of this problem are

presented: (1) geometry representation using ICAD

and transfer of the geometry to a nite element analysis code, (2)

application of boundary conditions/loads and retrieval of analysis results, (3) exploration of various optimisation

methods and strategies including gradient-based and modern stochastic methods. A product model from Rolls-Royce

is used as a base design in the optimisation.

2002 Elsevier Science Ltd. All rights reserved.

Keywords: Intelligent CAD; Design optimisation; Finite element analysis; Genetic algorithms

1. Introduction

Over the last several decades, the engineering design

world has been transformed by the introduction of

massive computational power. Computers are now the

principal tools for conceptual design, analysis, mock-up,

and manufacture. CAD, analysis, mock-up and assem-

bly checking are now completely carried out in a virtual

environment and this process is being continuously up-

dated [1]. In the engineering design community, the most

notable changes lie in two aspects: CAD and analysis.

Most companies use CAD and analysis software to de-

liver more reliable products in increasingly reduced time

scales, but the pursuit of lower cost and shorter devel-

opment time never stops because of the competitive

world market.

The design process is a recursive one in which changes

are often required during the later stages due to various

factors arising as the design progresses, and design re-

quirements often not only involve structure and func-

tionality, but also cost, manufacture and environmental

aspects. Traditional design processes typically treat these

areas using dierent models and requirements are often

described in dierent formats and dierent documents.

The use of nite element analysis has long become a

common practice during the product development pro-

cess, especially in the aerospace industry, where a large

number of FE codes, including commercial packages

and in-house codes are currently in use. The capability

covers stress analysis, thermal and vibration analysis, as

well as fatigue life estimates. Although most of these

tools have user-friendly interfaces and powerful pre- and

post-processing capabilities, the successful use of such

tools requires experience in the eld. These tools are now

used at all stages of the design process from concept to

detailed design.

Computers and Structures 80 (2002) 18531867

www.elsevier.com/locate/compstruc

*

Corresponding author. Fax: +44-23-8059-4813.

E-mail address: w.song@soton.ac.uk (W. Song).

0045-7949/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved.

PII: S0045- 7949( 02) 00225- 0

The study and development of computer programs

on mathematical optimisation algorithms has been a

long term eort since the early 1960s and a large number

of numerical algorithms are now available in the form of

standard function library APIs together with some de-

sign exploration systems with built-in algorithms. OP-

TIONS [2] is such a system which provides a exible

framework for incorporating user codes ranging from

very simple ones to complicated external software pack-

ages as well as more than 40 search algorithms and can

be used either interactively or in batch mode.

The optimisation process typically starts with the

parameterisation of the model and is then followed by a

search process using dierent algorithms and strategies

based on the evaluation of a measure of merit. Basically,

there are three dierent types of parameterisation ap-

proach currently being developed for design optimisa-

tion in the engineering community [3]. The rst is based

on using the coordinates of the boundary grid points in

a discretised domain as design variables, which is rela-

tively easy to implement but makes it dicult to main-

tain a smooth geometry and the resulting optimised

designs may be impractical for manufacture. The second

is based on using a CAD system. Although the advan-

tages of using a CAD system is obvious: smooth ge-

ometry, relatively small number of design variables, etc.,

it is dicult for traditional CAD systems to handle the

variations of topology due to large perturbations in

some dimensions. In addition, the underlying parame-

ters describing the geometry are not normally available

to calculate the sensitivities analytically. The third ap-

proach is similar to the morphing techniques used in

computer sciences, and is termed free-form deformation,

which is based on the idea of modelling the deformation

rather than the base geometry. In this work, the second

approach is adopted but the parametric modelling is

performed using the design automation tool ICAD

from KTI [4]. The dierence between ICAD and tradi-

tional CAD systems is that it can be used to generate

parametric models based on various geometric features.

Furthermore, non-geometric information can also be

integrated into the model and used in the following

analysis stages. The underlying geometric modelling

engine used by ICAD makes possible the smooth

transfer of geometry to analysis codes. The incorpora-

tion of ICAD and nite element codes into the search

process gives the ability to carry out search based on

high delity analysis results and to explore dierent

geometric features using a relatively small set of pa-

rameters.

2. Overview

A r-tree joint may be used in turbine structures to

attach a blade to the rotating disk. Mechanical loads are

transferred through the joint from the blade to the disk

[5]. The overall aim of r-tree structure optimisation

program is to enable the designer to explore dierent

candidate geometries at the preliminary stage, ranging

from relatively simple designs to rather complex ones, at

a reduced cost compared to using previous manual

methods (such costs have often prevented the explora-

tion of more complex proles and dierent size and

shape teeth). This process involves the use of feature-

based parametric geometry construction tools such as

ICAD and large-scale structural nite analysis packages,

along with an optimisation program implementing var-

ious search strategies. Although this problem is basically

a structural analysis problem, the strategy employed

here is rather dierent. The use of the ICAD system and

nite element analysis software together gives it the ca-

pability to model the variations parametrically both for

dimensions and in the topology used, and to analyse the

eect of geometric features on the stress distribution

based on the nite element analysis results. Further-

more, the above process may be incorporated into a

search loop to automatically nd the best solution

against pre-dened constraints. As considered here, this

is a 2D problem nested in the overall 3D blade/disc

optimisation procedure and uses well established 2D

criteria modied from 3D analysis.

The overall architecture of the ICAD based design

optimisation used is illustrated in Fig. 1. In this struc-

ture, ICAD is used to generate the model denition

based on rules which may be stored in a knowledge

database. The model is dened in a descriptive form

using the ICAD design language which is a derivation of

and extension to common LISP, aimed at geometric

modelling capabilities. This model is used to produce

geometry and related information. The geometry is then

passed to the analysis code along with any geometry

dependent properties to evaluate the design perfor-

mance. The optimiser is used to nd the best solution for

a particular set of design parameters. Parallel processing

can be achieved by using facilities provided by the

OPTIONS search systems.

3. Geometry representation using ICAD

The product design process normally begins with the

denition of requirements based on customer demands

and goes from the conceptual design stage to the de-

tailed design stage. Once the design specication is de-

termined, the conceptual design stage starts with the

implementation of the design in a computer environ-

ment followed by analysis to explore the feasibilities of

candidates. Analysis plays an important role in investi-

gating various design alternatives to determine the best

design. It is, however, very dicult, for traditional CAD

systems to capture design intent and to describe the

1854 W. Song et al. / Computers and Structures 80 (2002) 18531867

functional relationships between thousands of entities in

a complex product model [6,7]. What is produced by this

kind of CAD system is the nal results of design, not the

modelling and analysis process, which is often docu-

mented separately. Whenever the designer would like to

review the design or rebuild the modelling process with

some even minor modications this usually takes a long

time. This kind of knowledge is documented or retained

as the experience of the designers which is dicult to

utilise during subsequent iterations by other designers.

Expert system and knowledge-based approaches have

made some progress in this regard. The intelligent CAD

system (ICAD) from Knowledge Technologies Interna-

tional is a combination of knowledge-based engineering

(KBE) and CAD technology and its generative model-

ling capability can be used to provide exible and robust

geometry for subsequent analysis.

ICAD is a knowledge-based computer-aided design

tool. Although geometry is the main object of manipu-

lation, the most interesting feature is that it can be used

to capture a corporate knowledge base along with best

practice and performance, manufacturing and cost cri-

teria into a complete product model, known as a gen-

erative model. The dierence between using KBE tools

and using conventional CAD lies in the following as-

pects: KBE is knowledge oriented, while CAD is ge-

ometry oriented; CAD works from the bottom up with

detailed dimensions while KBE works on conceptual

level and can harness all the design specications in-

cluding physical laws, material criteria, manufacturing

constraints, and even non-technical aspects. KBE uses

rule-based model generation methods in conjunction

with a CAD modelling engine supporting solid model-

ling techniques. The rules which are used to describe the

geometric relationships can be expressed in various

forms, such as equalities or inequalities using mathe-

matical and logical relationships. It can further make

some decisions about design on the basis of the rules

supplied to it. This will give the model some kind of

intelligence. It should be noted that there are other

CAD/CAE tools such as Pro/Engineer [8], which also

oers feature-based parametric solid modelling capa-

bilities. Moreover, most CAD/CAE tools also provide

their own macro languages that form the basis for the

extension of their functionality. The choice of ICAD in

this study is based on the exibility oered by incorpo-

rating the LISP language into the IDL that is used in

model construction.

Analysis based optimisation has been identied as

being able to play a signicant part in the process of

producing high quality designs against known con-

straints. However the embedding of optimisation in the

design process requires the parameterisation of the de-

sign and automatic updating of the model used in the

analyses. ICAD can be used to implement this capability

because of its object-oriented, descriptive geometry

modelling approach. This allows engineers to quickly

and accurately explore and test multiple what ifs

against all known constraints. This makes it possible

to optimise the design in a reduced time scale.

Here, the design of the r-tree geometry is carried out

using ICAD. The basic procedure of the geometry de-

sign falls into two steps: rst to identication of the

features and rules used to dene the geometry and sec-

ondly the breaking down of the whole model into several

modules, each of which becomes a building block in a

hierarchical structure. In ICAD, each of these basic

blocks is described using the ICAD design language

(IDL) as a generic denition which can be implemented

in the ICAD browser using a specic set of parameter

values. Thus the model is dened parametrically: dif-

ferent sets of parameter values will result in dierent

Fig. 1. Overall system architecture.

W. Song et al. / Computers and Structures 80 (2002) 18531867 1855

designs from the same template. In addition, multi-

modality and backward compatibility can be achieved

by incorporating dierent behaviours into one model

with a single interface while only the internal imple-

mentation is modied.

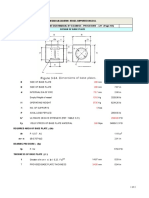

A single basic tooth geometry is illustrated in Fig. 2,

which is dened in such a way as to allow the designer to

explicitly control the non-contact clearance and to avoid

duplicate entities in the model. This latter feature eases

the application of boundary conditions and loads during

analysis.

The acceptability of any r-tree geometry needs to be

checked since some particular combination of parame-

ters may result in unacceptable features such as inter-

sections between entities or the collapse of very short

entities. The handling of unacceptable features is im-

portant to the optimisation process as well as to the

analysis code. Using ICAD, geometry features can be

checked within the modelling process, as part of the

whole model and appropriate actions can then be taken

using preset default values, while signalling which pa-

rameter is causing the problem. Taking the modelling of

the base tooth as an example, in every step in the

modelling process acceptability is checked to make sure

an acceptable geometry can be produced, otherwise, a

geometry failure is signalled to the optimiser to cancel

the analysis. An example of unacceptable base tooth

geometry, in which two circular arcs are intersected, is

also illustrated in Fig. 2.

Here, the blade root and disc head geometry are

dened in the same way as the basic tooth, with further

parameters and rules being needed. Details are covered

in the following sections. Some of the quantities used in

the denition are not expected to change and are thus

held constant during an optimisation run, while others

which are identied as being more inuential to the

design will be varied by the optimiser in the optimisation

loop and are known as design variables.

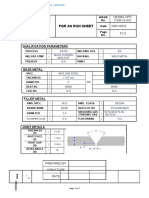

The rst r-tree geometry tackled is a simplied

version of an existing r-tree model, which is composed

of straight lines and circular arcs only. The complete

geometry is described by approximately 20 quantities, as

shown in Table 1. The resultant blade/disc geometry is

illustrated in Fig. 3. Some of these quantities are iden-

tied as playing an important role in the stress distri-

bution and thus will be optimised against known

constraints. Others will be kept at constant values based

on previous experience.

Every entity within the ICAD model can have addi-

tional non-geometric properties which will ease the use

of the geometry in other applications such as analysis

and manufacture. This object-oriented feature enables

various information related to a product design to be

integrated into a single model. For example, to apply

boundary conditions and loads to entities during the

analysis stage, it is desirable to name the entities with

unique labels which can then be referenced later. Using

unique tag names on each entity in the geometry enables

the boundary conditions, load properties and mesh

parameters to be specied in batch mode.

Geometric quantities such as the minimum thickness

of the blade root, the distance between the centre of the

contact face of the tooth on each side, etc., are calcu-

lated in the ICAD model based on a mathematical

representation of the geometry. Some of these are trea-

ted as constraints in the optimisation problem and some

are used to generate the FE model or to retrieve analysis

results. For example, point coordinates are normally

required to get the stress values at those points. The full

details of the geometric constraints used are covered in

Section 5.

4. Finite element analysis

The r-tree joint used to hold a blade in place in a

turbine structure is usually identied as a critical com-

ponent which is subject to high mechanical loads. Most

often the attachment is a multi-lobe construction used to

transfer loads from blade to disk. It is generally assumed

that there are two forms of loading which act on the

blade, the primary radial centrifugal tensile load result-

ing from the rotation of the disk, and bending of the

blade as a cantilever which is produced by the action of

the gas pressure on the airfoil and forces due to tilting of

the airfoil. The resulting stress distribution in the root

attachment area is a function of geometry, material and

loading conditions (which are of course related to the

speed of rotation). It is known that some critical ge-

ometry features exist for the stress distribution in the

bladedisk interface.

Many studies into the stress state of the blade root

attachment have been reported, originally using photo-

Fig. 2. Base tooth geometry parameters and an example of

unacceptable geometry with xed end point.

1856 W. Song et al. / Computers and Structures 80 (2002) 18531867

elastic methods [9,10], now mainly using nite element

analysis [1113]. Modern nite element codes already

have the capability of dealing with thermalmechanical

coupling and contact analysis between blade root and

disk head. It is now relatively easy to obtain the stress

distribution in the attachment area using commercial FE

codes. Also many in-house FE codes exist to handle

corporate-specic problems (these have some advanta-

ges over commercial tools among which the most no-

table is complete control over the source code).

Although there are many kinds of code available, the

general procedure of nite element analysis is almost

always as follows:

(1) create the geometry, or import the geometry from

another CAD system;

(2) apply the boundary conditions and loads;

(3) mesh the geometry;

(4) solve the problem and retrieve the results.

Most FE codes support batch running of the analysis

and this allows the analysis to be embedded into the

overall optimisation loop. To smoothly couple the

modelling process and analysis, however, is not an easy

task. It involves the transfer of the geometry itself and

related geometry dependent properties to the analysis

code, in this case, the nite element software.

It has been shown from previous preliminary opti-

misation work that it is possible to reduce the number of

teeth in a r-tree joint. From aerodynamics, a constant

space/chord ratio ensures a constant lift coecient, and

it is thus possible to trade blade number for blade chord.

Consequently a reduction in blade number will cause an

increase of centrifugal load transferring to the r-tree

Table 1

Blade root/disk head geometry parameters

Variable Name Type

Skew (b) () Root skew angle Variable

Nteeth Number of teeth Variable

Rwa () Root wedge angle Variable

Alor (L) (mm) Axial length of root Variable

Snw (mm) Shank neck width Variable

Fsw (mm) Fir-tree shoulder width Variable

Rcrest (mm) Fir-tree tooth crest radius Variable

Rtrough (mm) Fir-tree tooth trough radius Variable

Bp 1, 2 (mm) Blade tooth pitch Variable

Btcr (mm) Bottom tooth crest radius Variable

Cpw (mm) Cooling passage width Variable

Bglr (R1) (mm) Bucket groove lower radius Variable

Bgur (R2) (mm) Bucket groove upper radius Variable

Dtp 1, 2 (mm) Disk tooth pitch Variable

Fcrest (mm) Disk tooth crest radius Variable

Ftrough (mm) Disk tooth trough radius Variable

Nblades Number of blades Parameter

Drad (mm) Disk radius Parameter

Ninc Number of blades inclusive Parameter

Rtsn (mm) Radius to shank neck Parameter

Nblades Number of blades Parameter

Drad (mm) Disk radius Parameter

Snfr (R) (mm) Shank neck llet radius Parameter

Tfa (/) () Top ank angle Parameter

Ufa (c) () Under ank angle Parameter

Ncfc (mm) Non-contact face clearance Parameter

Bac (Ca) (mm) Blade axial chord Parameter

Cpa (mm

2

) Cooling passage area Parameter

Tfa (/) () Top ank angle Parameter

Ufa (c) () Under ank angle Parameter

Fdcr (mm) First disk crest radius Parameter

Inr (mm) Inner radius Parameter

Dhnw (D) (mm) Disk head neck width Derived

Bga (mm

2

) Bucket groove area Derived

Bch (H) (mm) Bottom-to-contact height Derived

Bl (mm) Bedding length Derived

Fh (mm) Fir-tree height Derived

W. Song et al. / Computers and Structures 80 (2002) 18531867 1857

root. The root will have to be redesigned to cope with

the larger load. At the same time, a reduced number of

blades leaves more disc material between adjacent r-

tree root slots, and the wider disc post thus allows a

bigger tooth design and this makes a further reduction

of r-tree teeth numbers viable. The reduced number of

teeth will bring further cost savings.

The loading on the root is mainly due to centrifugal

load which is dependent on the mass of the whole blade.

The design of the r-tree root involves an iterative

process of controlling the blade mass, which incorpo-

rates the root mass. Also some key features, such as the

llet radius, play very important roles in the stress dis-

tribution in notch regions. Thus a set of competitive

constraints ranging from geometrical, mechanical,

cooling requirements, etc., is established for use in ex-

ploration of various design candidates for the r-tree

root. Finite element analysis is then utilised to obtain the

resulting stress distributions. This further complicates

the situation. A traditional manual method is now

too slow for this process and thus automation is re-

quired. Four types of constraints are used to check the

design:

Crushing stress describes the direct tensile stress on

the teeth: bedding width is the main factor aecting

the stress.

Unzipping can occur after a blade release: the disc

post on either side of the released blade are then sub-

ject to high tensile and bending stresses. The disc post

must be able to withstand these stresses in order to

avoid a progressive unzipping and release of all

the blades.

Disc neck creep: the disc posts are subject to direct

tensile stress which causes material creep. Too much

creep, combined with low cycle fatigue, can dramat-

ically reduce the component life.

Peak stresses: peak stresses occur at the inner llet ra-

dii of both the blade and the disc. If the llet radii are

too small and produce unacceptable peak stresses,

some bedding width has to be sacriced to make

them bigger.

Apart from the above constraints, which are used to

check the candidate designs, some others are used to

check the optimised result. These include vibration

limits, neck stress, etc. From a preliminary blade num-

ber optimisation, these criteria are not deemed a sig-

nicant constraint here.

As the r-tree geometry is constant along the root

centre line, it is possible to think of the stresses as 2D.

However, the loading applied along the root centre line

is not uniform, so strictly speaking, the distribution of

stresses will be 3D. Nonetheless, it is still possible to

assume that each section behaves essentially as a 2D

problem with dierent loadings applied to it. The dif-

ference of loading on each section is aected by the ex-

istence of skew angle which will increase the peak

stresses in the obtuse corners of the blade root and the

acute corners of the disk head. From previous root

analysis research, it is feasible and convenient to use

a factor to estimate the peak stresses at each notch of

the blade and disc, and this factor takes dierent values

for dierent teeth.

Also, it is known from previous work using photo-

elastic and nite element methods, that the distribution

of centrifugal load between the teeth is very non-uni-

form and the top tooth may take a signicant portion of

the load. This feature allows the possibility of using

dierent tooth sizes. The system implemented here also

allows designers to explore the eect of varying the

number of teeth, but this may cause diculties when

gradient-based methods are used for optimisation.

Both a one sector model and a three sector model are

considered when estimating the mechanical constraints,

the one sector model for the estimation of maximum

notch point stresses, crushing stresses and blade/disk

neck mean stresses and the three sector model for the

estimation of unzipping stresses. Typical FE results are

illustrated in Fig. 4a and b, for the one sector model and

three sector model, respectively. In general, nite ele-

ment analysis is computationally expensive, thus a

compromise between accuracy and computation cost

should always be made to obtain acceptable results as

quickly as possible when this is embedded in an opti-

misation run. This compromise is made by an appro-

priate choice of mesh density.

Fig. 3. Geometry denition of a (a) typical blade root and (b)

typical disk head.

1858 W. Song et al. / Computers and Structures 80 (2002) 18531867

The whole process from the importing of geometry,

application of boundary conditions and loading, to re-

sults retrieval is implemented here as a SC03 Plugin,

which is a facility provided by the RR in-house FEA

code SC03 to extend the capability of its core func-

tionality. A command le is used by SC03 to carry out

jobs ranging from importing geometry from IGES les,

applying boundary conditions and loads, to retrieving

stress results.

5. Optimisation

Here two dierent optimisation problems were

tackled using population based genetic algorithms (GAs)

and gradient-based methods. One was to minimise the

area outside of the last continuous radius of the turbine

disc for the 2D case, which is proportional to the rim

load by virtue of the constant axial length. This quantity

is referred to as the r-tree frontal area in the following

Fig. 4. Typical stress eld for (a) single blade and (b) three blades with the middle out.

W. Song et al. / Computers and Structures 80 (2002) 18531867 1859

sections. The number of teeth is treated as a design

variable in this problem and the number of constraints is

dependent on the number of teeth. The other was to nd

the optimum tooth prole to minimise the maximum

notch stress. The design variables (Table 2) and con-

straints (Table 3) used in the second problem are a

subset of those dened in the rst problem (which has 14

design variables and up to 53 constraints for a three-

tooth design) although the goals are dierent.

The constraints are divided into two categories,

geometric and mechanical, which are summarized in

Table 4 along with the normalized values for the initial

design. For the meaning of symbols used in this section,

please see Fig. 3a and b. The normalization adopted

here is described as follows for upper and lower limits u

and l, respectively:

a. constraints with upper bounds only:

y

norm

y=u; u 6 0

y; u 0

;

b. constraints with lower bounds only:

y

norm

l=y; y 6 0; l > 0

y=l; l < 0 or y 0

y; l 0

;

8

<

:

c. constraints with both upper and lower bounds:

y

norm

2

y l

u l

1:

These dierent formula will make it possible for all

normalized constraints to have consistent behaviour

when the design is moving from an infeasible region

towards feasibility, and to have the values of )1 or 1 at

the boundary of the constraints.

5.1. Mesh density parameters

As mentioned earlier, it is necessary to establish the

appropriate values for mesh control parameters. The

purpose is to nd a compromise between the high

computational costs that are incurred for very ne me-

shes and the accuracy required to capture the maximum

stresses in the notch area. Therefore, the local and global

Table 2

Denition of optimisation problems

Variables Number of vari-

ables

6 14

Tooth prole parameters

Root wedge angle () 2040 2040

Tooth pitch (mm) 2.04.0 2.04.0

Blade crest radius (mm) 0.21.0 0.21.0

Blade trough radius (mm) 0.21.0 0.21.0

Disk crest radius (mm) 0.21.0 0.21.0

Disk trough radius (mm) 0.21.0 0.21.0

Fir-tree root/disk head parameters

Skew angle () [15]

a

1020

Axial length of root (mm) [20] 1525

Shank neck width (mm) [6.7615] 6.57.5

Fir-tree shoulder width (mm) [9.8943] 812

Bottom tooth crest radius (mm) [1.0668] 0.81.2

Cooling passage width (mm) [1.3455] 1.21.5

Bucket groove lower radius (mm) [3.5] 3.04.0

Bucket groove upper radius (mm) [2.2] 1.52.5

a

[ ] indicates value when not used in optimisation.

Table 3

Constraints and objective function applied in the optimisation problems

Number Constraints Number of variables

6 14

1 R1=R2

2 H=D

3 DP=F

45 min < DP < max

6 Lca

7 RSA

8 Minimum serration pitch

9 Bottom neck width > pitch

10 Minimum wall thickness

11 Bucket groove area > cooling passage area

1223 Notch stresses

2435 Section stresses

3643 Crushing stresses

4445 Bucket groove stresses

4653 Unzipping stresses

Objective function Maximum notch stress Fir-tree frontal area

1860 W. Song et al. / Computers and Structures 80 (2002) 18531867

eects of mesh density must be studied. Following the

set-up of the system, a series of systematic evaluations

has been carried out to establish appropriate mesh

density parameter values and to gain experience on the

eects of design variables changes. These were per-

formed by varying the mesh density control parameters

while holding all others constant. Two mesh control

parameters, the global and local edge node spacing were

chosen. Reducing the notch edge node spacing increases

the mesh density and therefore reduces the perturba-

tions in maximum notch stress. These studies resulted

in the use of 0.001 mm for both global and local edge

node spacing. The parameter study also revealed the

eect of dierent geometric features on the stress dis-

tribution within the structure which are summarized

in Table 5. It can be also seen from the parameter

study results that the notch stress on the second tooth

takes the largest value, as already implied from previ-

ous work [10]: this aspect makes it desirable to design

each tooth using dierent values of tooth prole pa-

rameters.

5.2. Optimisation

The optimisation is performed here using the OP-

TIONS software package [2] which provides designers

with a exible structure for incorporating problem spe-

cic code as well as more than 40 optimisation algo-

rithms. The critical parameters to be optimised, known

as design variables, are stored in a design database,

which also includes the objective, constraints and limits.

The design variables are transferred to ICAD by means

of a property list le which contains a series of pairs with

alternating names and values. This le is updated during

the process of optimisation and reects the current

conguration. The geometry le produced by ICAD is

then passed to the FE code SC03 which is executed by a

command le. The analysis results are written out to

another le, which is read in by the optimisation code.

The design variables are then modied according to the

optimisation strategy in use until convergence or a

specied number of loops has been executed. The pro-

gram structure is illustrated in Fig. 5.

Due to the presence of a discrete design variable (the

number of teeth), most gradient based optimisa-

tion techniques will not work directly here. Therefore a

two-stage strategy of combining a GAs with gradient

search was used in this problem. A typical GA (as dis-

cussed by Goldberg [14]) is rst employed in an attempt

to give a fairly even coverage on the search space, and

then gradient based search methods are applied on

promising individuals with the number of teeth xed.

Table 4

Normalized constraint vector for the base design

Number Name of constraint Numeric values

Lower bound Value Upper bound

1 Ratio of R1 to R2 R1=R2 )1.0 )0.8642

2 Ratio of H to D H=D )1.0 )0.8955

3 Ratio of R1 to disk trough R1=Ftrough )1.0 )0.5268

4 Maximum ratio of tooth pitch to disk trough

DP=Ftroughmax

1.4779 1.0

5 Minimum ratio of tooth pitch to disk trough

DP=Ftroughmin

)1.0 )0.5467

6 Ratio of axial length to blade axial chord [LCA] )1.0 )0.4961

7 Root stagger angle [RSA] 0.7499 1.0

8 Ratio of blade/disk serration pitch [PMIN] )1.0 )0.4540

9 Ration of blade bottom neck width to tooth pitch

[BNP]

)1.0 )1.1474

10 Minimum wall thickness of bottom blade notch

[BNMIN]

)1.0 )1.3038

11 Ratio of bucket groove region area to cooling passage

area [AR]

)1.0 )1.0900

1219 Maximum blade notch stress [NBL(R)(2

a

)]

b

)1.0 0.9270 1.0

2023 Maximum disk notch stress [NDL(R)(3)] )1.0 0.9948 1.0

2429 Maximum blade section stress [SB(1)] )1.0 0.6931 1.0

2935 Maximum disk section stress [SD(4)] )1.0 0.5623 1.0

3643 Maximum crushing stress [CS(1)] )1.0 0.6514 1.0

4445 Maximum bucket groove stress )1.0 0.9023 1.0

4653 Maximum unzipping stress [UZP(1)] )1.0 0.3688 1.0

a

The numbers in bracket indicate the number of the tooth or the section where the maximum stress occurs.

b

For the purpose of compactness, only the maximum stresses are shown in the table.

W. Song et al. / Computers and Structures 80 (2002) 18531867 1861

One of the considerations here is that GAs are capable

of dealing with discrete design variables. Another con-

sideration is that as the GA proceeds, the population

tends to saturate with designs close to all the likely op-

tima including sub-optimal and globally optimum de-

signs, while gradient based methods are more suited to

Table 5

Eect on stress distribution of design variables for the base design

Geometry features Unzip stress Notch stress Section stress Crushing

stress

Blade Disk Blade Disk

Skew angle 1; rest

Shank neck width ) 1; rest 1, 4); rest

Blade shoulder width ) 2,3; rest ) 1; rest )

Bottom tooth crest radius 2; rest) ) 4; rest

Cooling passage width 1,2; rest ) 1); 2, 3 1, 2; 3, 4)

Bucket groove lower radius

Bucket groove upper radius

Tooth pitch )

Blade crest radius 1); rest )

Blade trough radius ) ) 1, 2); 3, 4

Disk crest radius 1); rest ) ) )

Disk trough radius ) ) 4); rest

indicates increase, ) indicates decrease, means no signicant eect when variable increases, number indicates the tooth number in

top-down order.

Fig. 5. Optimisation program structure.

1862 W. Song et al. / Computers and Structures 80 (2002) 18531867

locating the exact position of individual optimum

given suitable starting points. Here the GA is used to

give good starting points for the gradient search meth-

ods.

An initial analysis on the base design revealed that

several geometric and mechanic constraints were vio-

lated. These include geometric constraints 4, 9, 10 and

11, and the disk notch stress constraints. Table 4

shows the resulting normalized constraint values for

the base design. Note that this means that the GA must

rst locate feasible designs before it can begin optimi-

zation.

5.3. Optimisation results

5.3.1. Results for minimising the r-tree frontal area

GAs often require large number of evaluations of the

objective function and constraints. The computational

cost involved can soon become prohibitively high when

computationally intensive nite element analysis is used

to calculate the stresses in the structure. In this problem

each evaluation takes about 56 min to nish, and not

surprisingly, most of this time is engaged in nite ele-

ment analysis. This means that it takes about 80 h to

nish a 10 generation GA search with a population size

of 100 using serial processing. (Note that for some spe-

cic sets of parameters, there is no viable geometry that

can be constructed, and when this occurs SC03 is simply

signalled to cancel the analysis.)

Because of the large number of design variables, the

optimisation trace may only be simply plotted on con-

tour maps of any two variables if these maps are as these

maps are necessarily produced while holding all the

other variables constant. Furthermore, if only a small

number of quantities are chosen as design variables,

there may be no feasible designs at all. For an infeasible

starting design, it is easier for the optimiser to nd a

feasible region if a large number of quantities are left as

design variables and broad exploratory searches meth-

ods are used.

A contour map for two design variables has been

generated using results from the GA search (Fig. 6).

Infeasible geometries and possible analysis failures are

also illustrated in the gure. It is noted that identica-

tion of this type of failure is useful for identifying any

problems with the implementation of the system

(sometimes calculations fail simply because of delays

due to overloading of the network), but this is not a

concern for optimisation as long as appropriate mea-

sures are employed to avoid misleading the optimiser.

This is important especially when approximations such

as response surfaces are introduced to improve run

speeds. A gradient based search is illustrated in Fig. 7a.

It can be seen that better starting points do not always

converge to better results, depending on the location

in the design space. This justies the use of the whole

nal population of the GA results instead of just the

best one as starting points for gradient search. A com-

parison between this simple two-stage strategy and a

direct gradient-based search is provided in Fig. 7b,

which shows that this two-stage strategy, although

simple, works better than a direct gradient search as

the initial GA search oers a better chance of steer-

ing the optimiser towards global optima, while a direct

Fig. 6. Contour map of r-tree frontal area for root wedge angle and tooth-pitch based on GA results. : Geometry or analysis

failure infeasible points; : minimum as shown.

W. Song et al. / Computers and Structures 80 (2002) 18531867 1863

gradient-based search will more likely get stuck in a to

local optimum.

Several steepest descent search methods have been

applied to the problem after the initial GA search: these

include the Hooke and Jeeves direct search method plus

various other methods discussed in Schwefels book [15].

The rst method is very fast when the number of design

variables is small, as shown in Fig. 8, in which only 6

variables are chosen as design variables, while (the full

scale problem contains 14 design variables). Although

the complexity of this problem is only modest, the

computational cost in terms of the thousands of evalu-

ations required for some search techniques is still an

obstacle for a detailed search. It can be seen from the

contour maps that the objective function is rather

smooth, and this may justify the use of approximation

techniques alongside the accurate nite element model.

This will be the focus of further research.

A 20% reduction in the objective function was

achieved using the above methods while satisfying all the

Fig. 7. (a) Schwefel library method: repeated lagrangian interpolation (LAGR) on GA results and (b) comparison of search results

using dierent search strategies.

1864 W. Song et al. / Computers and Structures 80 (2002) 18531867

geometric and mechanic constraints. By looking at the

trace data of the search process, it can be seen that

the three geometric constraints and the disk notch

stresses (identied earlier) remain the major factors af-

fecting the optimisation results. Note that the primary

changes to geometry occurred during the GA search and

are as illustrated in Fig. 9. These are a decrease in tooth

pitch, an increase in shank neck width and a decrease in

three of the four llet radii. In addition, the root wedge

angle is slightly increased.

5.3.2. Results for minimising the maximum notch stress

local shape tuning

Although minimising the frontal area, and thus the

rim-load will reduce overall weight, the life of blade/disc

is highly dependent on the notch stresses, and therefore

the notch stress may be ultimately minimised for the to

achieve required life targets. Therefore, following the

search on the full scale problem, a second optimisation

problem to minimise the maximum notch stress has been

carried out, starting from the best design found in the by

previous search. It is expected that this search will drive

the geometry in a dierent direction given the changed

goal. The result is shown in Fig. 10. In this case only the

six tooth prole parameters were chosen as design

variables. It can be seen that although a 25% reduction

in the maximum notch stress can be achieved, the r-tree

area is now increased by approximately 11%. Also note

that the root wedge angle has dropped signicantly

while the pitch and all the radii have risen. Clearly, the

choice of objective function has signicant impact on the

nal design.

6. Concluding remarks

The generative modelling facility provided by the

ICAD system enables the rapid evaluation of dierent

design alternatives in an engineering environment. In-

corporating such capabilities into a FEA-based struc-

tural optimisation process has been shown to be an

eective way to reduce design time scales and at the

Fig. 8. Contour map of r-tree frontal area and Hooke and Jeeves search terrace.

Fig. 9. Comparison of geometry between the base design and

the best of the GA search results.

W. Song et al. / Computers and Structures 80 (2002) 18531867 1865

same time improve the quality of the end product. Other

information such as a cost evaluation model or a man-

ufacturing requirements model could be further included

without sacricing the compatibility of the existing

model. A complete and consistent product model could

then be achieved to be set-up for evaluation in the design

optimisation process.

The system implemented has been used to carry out

r-tree root optimisation using a two-stage hybrid

strategy combining gradient-based methods and GAs. It

is now clear that without a large number of evaluations,

it is not easy to explore the eects of dierent geometric

parameters and nd the best possible solutions using

direct searches. Such large numbers of nite element

analyses are computationally expensive even for a model

of modest complexity. Further research on the con-

struction of approximation models and strategies on

how to use them will be required to achieve further ef-

ciency gains as well as and most benet from the in-

tegration and automation oered by the use of ICAD

modelling.

Acknowledgements

This work was funded by the EPSRC under grant

reference GR/M53158 and the University Technology

Partnership for Design, which is a collaboration between

Rolls-Royce, BAE SYSTEMS and the Universities of

Cambridge, Sheeld and Southampton.

References

[1] Biedron RT, Mehrotra T, Nelson ML, Preston FS, Rehder

JJ, et al. Compute as fast as the engineers can think!

NASA/TM-1999-209715.

[2] Keane AJ. The OPTIONS design exploration system,

Reference Manual and User Guide Version B3.0, Febru-

ary, 2000.

[3] Samareh JA. Status and future of geometry modelling

and grid generation for design and optimisation. J Aircraft

1999;36(1).

[4] Knowledge Technologies International, http://www.

ktiworld.com.

[5] Theory and design. Sawyers gas turbine engineering

handbook, vol. I. Gas Turbine Publications; 1976.

[6] Samareh JA. Use of CAD geometry in MDO, AIAA-96-

3991. In: 6th AIAA/USAF/NASA/ISSMO Symposium on

Multidisciplinary Analysis and Optimisation, 46 Septem-

ber, 1996, Bellevue, WA.

[7] Townsend JC, Samareh JA, Weston RP, Zorumski WE.

Integration of a CAD system into an MDO Framework,

NASA/TM-1998-207672.

[8] Pro/Engineer, http://www.ptc.com, 2002.

Fig. 10. Tooth prole after frontal area minimisation (left) and notch stress minimisation (rightas shown in column ). Note:

indicates number of evaluations.

1866 W. Song et al. / Computers and Structures 80 (2002) 18531867

[9] Durelli AJ, Dally JW, Riley WF. Stress and strength studies

on turbine blade attachments. Proc. SESA 1958;16(1):171

82.

[10] Shaw H. An improved blade root design for axial ow

compressors (and turbines). Aeronaut J Royal Aeronaut

Soc 1970;74.

[11] Boddington PH, Chen K, Ruiz C. The numerical analysis

of dovetail joints. Comput Struct 1985;20(4):7315.

[12] Gontarovskii PP, Kirkach BN. Investigation of the stress

strain state of turbine blade root attachments by the nite

element method. Strength Mater 1982;14(8):103741,

Translated from Problemy Prochnosti 1982;8:3740 .

[13] Papanikos P, Maguid SA, Stjepanovic Z. Three-dimen-

sional nonlinear nite element analysis of dovetail joints in

aeroengine discs. Finite Elem Anal Des 1998;29:17386.

[14] Goldberg DE. Genetic algorithms in search, optimisation

and machine leaning. Reading, MA: Addison-Wesley;

1989.

[15] Schwefel HP. Optimal engineering design: principles and

application. New York: Marcel Dekker; 1982.

W. Song et al. / Computers and Structures 80 (2002) 18531867 1867

You might also like

- Being Happy - Andrew MatthewsDocument242 pagesBeing Happy - Andrew MatthewsLioe Stanley100% (4)

- Interchangeability PDFDocument16 pagesInterchangeability PDFMaulikNo ratings yet

- Leg Support Calculation PDFDocument2 pagesLeg Support Calculation PDFSanjay MoreNo ratings yet

- Christu Jyothi Institute of Technology & Science YeshwanthapurDocument46 pagesChristu Jyothi Institute of Technology & Science YeshwanthapurMani MannNo ratings yet

- Escodisc: AvailabilitiesDocument10 pagesEscodisc: AvailabilitiesEmerson IpialesNo ratings yet

- H60 STSH 2011 PDFDocument2 pagesH60 STSH 2011 PDFthritaNo ratings yet

- Optimization of A Highly Stressed Radial Compressor Impeller OptislangDocument42 pagesOptimization of A Highly Stressed Radial Compressor Impeller OptislangticklinNo ratings yet

- EX18195003 - 001-6901-01 Rev 0 OBSDocument2 pagesEX18195003 - 001-6901-01 Rev 0 OBSRichardNo ratings yet

- 2 1 01 Auxiliary Gear BoxDocument30 pages2 1 01 Auxiliary Gear BoxHeryanto SyamNo ratings yet

- Analysis of A Compessor Rotor Using Finite Element AnalysisDocument21 pagesAnalysis of A Compessor Rotor Using Finite Element Analysisinam vfNo ratings yet

- Turbocare Gas Turbine Symposium 18/19 April 2005 Dallas TXDocument19 pagesTurbocare Gas Turbine Symposium 18/19 April 2005 Dallas TXteedee1No ratings yet

- Sellos de LaberintoDocument320 pagesSellos de LaberintoJavierNo ratings yet

- Gas Turbine Heat Transfer Ten Remaining Hot Gas Path ChallengesDocument9 pagesGas Turbine Heat Transfer Ten Remaining Hot Gas Path Challengeseankibo100% (2)

- Propulsion System: Faculty of Aeronautical Engineering 1Document106 pagesPropulsion System: Faculty of Aeronautical Engineering 1Nandha Kumar100% (1)

- MODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion System PDFDocument43 pagesMODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion System PDFantonNo ratings yet

- Axial Flow Compressor 2Document11 pagesAxial Flow Compressor 2ram kishor singh100% (1)

- '' Turbine - Nozzle - Diffuser - Compressor ''Document15 pages'' Turbine - Nozzle - Diffuser - Compressor ''Eng-Ahmed Salama100% (1)

- Kurzke Turbine Map ExtensionpdfDocument14 pagesKurzke Turbine Map ExtensionpdfzzzNo ratings yet

- Study of Manufacturing of Gas TurbineDocument33 pagesStudy of Manufacturing of Gas TurbineSalman MohammedNo ratings yet

- Environmental Considerations For Gas Turbine Clean Energy SystemsDocument45 pagesEnvironmental Considerations For Gas Turbine Clean Energy SystemsMehulkumar PatelNo ratings yet

- Heat Transfer: (Meng 3121)Document52 pagesHeat Transfer: (Meng 3121)HASSAN ARSHADNo ratings yet

- Introduction and Overview: Fundamentals of Thermal-Fluid SciencesDocument23 pagesIntroduction and Overview: Fundamentals of Thermal-Fluid SciencesJoelle KharratNo ratings yet

- GT2019 90177Document11 pagesGT2019 90177Hiwa Khaledi100% (1)

- PGI2003 FastStartup&DesignForCyclingDocument20 pagesPGI2003 FastStartup&DesignForCyclingscarrion80100% (1)

- Performance of Industrial GasturbinesDocument28 pagesPerformance of Industrial Gasturbinessomporn duangbuntaoNo ratings yet

- The Modernization of A 1965, MS New Life For An Old 5001, Gas Turbine: UnitDocument8 pagesThe Modernization of A 1965, MS New Life For An Old 5001, Gas Turbine: UnitRozy AlriadiNo ratings yet

- Com Bust orDocument9 pagesCom Bust orDanishAmanNo ratings yet

- Humidified Gas Turbines, by EderDocument66 pagesHumidified Gas Turbines, by EderDomingo Pinto100% (1)

- CH 07Document60 pagesCH 07Lucais KwonNo ratings yet

- Development of Gas Turbine Combustors For Fuel Flexibility 2 PDFDocument31 pagesDevelopment of Gas Turbine Combustors For Fuel Flexibility 2 PDFJohn Kelly100% (2)

- Turbinas Franco Tossi FTM GeneraleDocument55 pagesTurbinas Franco Tossi FTM GeneralePedro Victor Cobeñas CajusolNo ratings yet

- CFX Turbosystem 18.2 WS10 TG Centrif Compr SplitterDocument19 pagesCFX Turbosystem 18.2 WS10 TG Centrif Compr SplitterSai Santhosh ManepallyNo ratings yet

- Lava Final ReportDocument69 pagesLava Final ReportUma MaheshNo ratings yet

- Compressor Brochure A4 - SpreadsDocument27 pagesCompressor Brochure A4 - SpreadsIwan AbdurahmanNo ratings yet

- GEA18457ADocument20 pagesGEA18457AEdGouramiNo ratings yet

- Introduction To Off Design SimulationsDocument26 pagesIntroduction To Off Design SimulationsHalil İbrahim KüplüNo ratings yet

- Highlights of Roy Smith's Career at General Electric: C. C. KochDocument5 pagesHighlights of Roy Smith's Career at General Electric: C. C. KochupsasaNo ratings yet

- Compressor Modeling With Inlet DistortionDocument25 pagesCompressor Modeling With Inlet Distortionsainath_84No ratings yet

- Man Diesel Gas Turbines PDFDocument6 pagesMan Diesel Gas Turbines PDFnebojsabraticNo ratings yet

- WB Brush Seals Labyrinth - A4Document2 pagesWB Brush Seals Labyrinth - A4triplbingaziNo ratings yet

- Air SystemDocument12 pagesAir Systemmahmouddiaa554No ratings yet

- WRViT580 Product-Spec-Sheet v3B LRDocument1 pageWRViT580 Product-Spec-Sheet v3B LRLuis ReyesNo ratings yet

- Gas Turbine CombustionDocument38 pagesGas Turbine CombustionSiva Subramaniyan100% (2)

- Introduction of Gas Turbine Air Intake Cooling SystemDocument12 pagesIntroduction of Gas Turbine Air Intake Cooling SystemAndry Kurnia100% (1)

- GT Fuel Nozzle RefurbishmentDocument3 pagesGT Fuel Nozzle Refurbishmentnabil160874No ratings yet

- SulzerDocument32 pagesSulzerYeti Candra Dwi AnggrainiNo ratings yet

- E&M Combustion Presentation EnglishDocument24 pagesE&M Combustion Presentation EnglishGurcharan Singh100% (1)

- Axial Comp On OffDocument4 pagesAxial Comp On OffMohamed OmarNo ratings yet

- Turbines 1Document64 pagesTurbines 1deepak2755No ratings yet

- Auto Conference Turbochargers 2012 Holmes Hutchinson1 PDFDocument86 pagesAuto Conference Turbochargers 2012 Holmes Hutchinson1 PDFashwynvinay_90182279No ratings yet

- Introduction To CombustionDocument21 pagesIntroduction To CombustionAravindhan RameshNo ratings yet

- Ar001Document124 pagesAr001Sriram ChNo ratings yet

- Asme GT2005-68799 PDFDocument9 pagesAsme GT2005-68799 PDFJeeEianYannNo ratings yet

- Turbine Off-Frequency Operation: GE Power SystemsDocument4 pagesTurbine Off-Frequency Operation: GE Power Systemskcirrenwod100% (1)

- Advanced (Gas) Turbine System - Conceptual Design (Final RPT) - ABB (2000)Document319 pagesAdvanced (Gas) Turbine System - Conceptual Design (Final RPT) - ABB (2000)B Bala Venkata GaneshNo ratings yet

- KBE Approach To Automotive StructureDocument10 pagesKBE Approach To Automotive StructureuratmerihNo ratings yet

- A Knowledge-Based Master Modeling Approach To System Analysis and DesignDocument10 pagesA Knowledge-Based Master Modeling Approach To System Analysis and DesignHeribertoNo ratings yet

- CAD-centric Creation and Optimization of A Gas Turbine Flowpath Module With Multiple ParameterizationsDocument10 pagesCAD-centric Creation and Optimization of A Gas Turbine Flowpath Module With Multiple ParameterizationsKomal KumarNo ratings yet

- Two Dimensional Airfoil Optimisation Using CFD in A Grid Computing EnvironmentDocument8 pagesTwo Dimensional Airfoil Optimisation Using CFD in A Grid Computing Environmentananth9660No ratings yet

- CAD-Based Parametric Cross-Section Designer For Gas Turbine Engine MDO ApplicationsDocument10 pagesCAD-Based Parametric Cross-Section Designer For Gas Turbine Engine MDO ApplicationsValiyakattel NilsNo ratings yet

- The Application of Pro Engineer in CADCAMDocument9 pagesThe Application of Pro Engineer in CADCAMHafiezul HassanNo ratings yet

- Geometric Modeling: Exploring Geometric Modeling in Computer VisionFrom EverandGeometric Modeling: Exploring Geometric Modeling in Computer VisionNo ratings yet

- Analytic Solutions For Tapered Column Buckling PDFDocument6 pagesAnalytic Solutions For Tapered Column Buckling PDFshilton1989No ratings yet

- RPM To Linear Velocity Calculator - EndMemoDocument1 pageRPM To Linear Velocity Calculator - EndMemoshilton1989No ratings yet

- STEP Files - ProcedureDocument1 pageSTEP Files - Procedureshilton1989No ratings yet

- 1Document9 pages1shilton1989No ratings yet

- Goyen HardwareDocument3 pagesGoyen Hardwareshilton1989No ratings yet

- Preface: John Moalli Menlo Park. CaliforniaDocument1 pagePreface: John Moalli Menlo Park. Californiashilton1989No ratings yet

- OF Of: of P. P. 2091, An of P. On On ofDocument5 pagesOF Of: of P. P. 2091, An of P. On On ofshilton1989No ratings yet

- T A B L E 23O.-Characterlstlcs A Number of Plastics'6Document2 pagesT A B L E 23O.-Characterlstlcs A Number of Plastics'6shilton1989No ratings yet

- Document Change Notice DCN Number 5070: Old Revision New Revision Logistics Review (Y/N)Document1 pageDocument Change Notice DCN Number 5070: Old Revision New Revision Logistics Review (Y/N)shilton1989No ratings yet

- Document Change Notice DCN Number 5098: Old Revision New Revision Logistics Review (Y/N)Document1 pageDocument Change Notice DCN Number 5098: Old Revision New Revision Logistics Review (Y/N)shilton1989No ratings yet

- S900 Inverter User Manualv1.5 PDFDocument86 pagesS900 Inverter User Manualv1.5 PDFOmar ShadyNo ratings yet

- Scavenger Hunt 2019Document2 pagesScavenger Hunt 2019Rahul AdhikariNo ratings yet

- ToR For Fiberglass Biogas Plants Installation - EOI PDFDocument4 pagesToR For Fiberglass Biogas Plants Installation - EOI PDFmy09No ratings yet

- ASTM GradesDocument4 pagesASTM GradesSaurabh MundheNo ratings yet

- OHara PDFDocument17 pagesOHara PDFTomás HidalgoNo ratings yet

- The Evolution of Video Streaming and Digital Content DeliveryDocument8 pagesThe Evolution of Video Streaming and Digital Content DeliveryBrookings InstitutionNo ratings yet

- CESCCommunityProjectPlan Brgy - MacarioDaconDocument6 pagesCESCCommunityProjectPlan Brgy - MacarioDaconKennedy BalmoriNo ratings yet

- PQR As Run SheetDocument2 pagesPQR As Run SheetAhmed ElsharkawNo ratings yet

- MGje 6 Fix GX PK Yp RBJ LBRDocument9 pagesMGje 6 Fix GX PK Yp RBJ LBRBANOTH KUMARNo ratings yet

- FlapDocument100 pagesFlapRicha Agrawal100% (2)

- LECLANCHE Cell Datasheet GL60 GNMC 60ahDocument2 pagesLECLANCHE Cell Datasheet GL60 GNMC 60ahChaitanyaNo ratings yet

- Research Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisDocument17 pagesResearch Progress of The Arti Ficial Intelligence Application in Wastewater Treatment During 2012 - 2022: A Bibliometric AnalysisjinxiaohuibabaNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- Biology Investigatory Project: Malaria: Its Effects and CausesDocument17 pagesBiology Investigatory Project: Malaria: Its Effects and CausesRishi KeshavNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- MEP MyanmarDocument27 pagesMEP Myanmarempty87No ratings yet

- Catalogo ColonneDocument140 pagesCatalogo Colonneapi-18378576No ratings yet

- CR Unit 1 &11 (Part A &B)Document12 pagesCR Unit 1 &11 (Part A &B)durai muruganNo ratings yet

- Background of Philippine Art and Literature in Romantic RealismDocument2 pagesBackground of Philippine Art and Literature in Romantic RealismRaldz CoyocaNo ratings yet

- Da0bl7mb6d0 Rev DDocument44 pagesDa0bl7mb6d0 Rev DFerreira da CunhaNo ratings yet

- Open-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsDocument24 pagesOpen-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsSHAIK MUSTHAFANo ratings yet

- Urinalysis - Fatin AinaDocument14 pagesUrinalysis - Fatin AinaAl- ImanuddinNo ratings yet

- The Efects of Tree Characteristics On Rainfall Interception in UrbanDocument8 pagesThe Efects of Tree Characteristics On Rainfall Interception in UrbanGuilherme SantanaNo ratings yet

- Spider-81 Hardware Spec 7.7Document7 pagesSpider-81 Hardware Spec 7.7KonradNo ratings yet

- As 1729-1994 Timber - Handles For ToolsDocument7 pagesAs 1729-1994 Timber - Handles For ToolsSAI Global - APACNo ratings yet

- Neisseria Gonorrhoeae and Neisseria MeningitidesDocument3 pagesNeisseria Gonorrhoeae and Neisseria MeningitidesAmador Gielas0% (1)

- Bigbang PDFDocument772 pagesBigbang PDFLeanne Haddock100% (1)

- 11 Chemistry Module 2Document19 pages11 Chemistry Module 2SpongeBob SquarePants Fidget ToysNo ratings yet