Professional Documents

Culture Documents

Standard Commissioning Procedure For Daylighting Controls

Standard Commissioning Procedure For Daylighting Controls

Uploaded by

Carolina HernándezCopyright:

Available Formats

You might also like

- SM JCB 3CX 4CX 328739808-9803-3280-9 PDFDocument1,212 pagesSM JCB 3CX 4CX 328739808-9803-3280-9 PDFСергей Ганкевич97% (33)

- 1.1.3.11 Lab - Draw A Process DiagramDocument4 pages1.1.3.11 Lab - Draw A Process DiagramJoshua ManalotoNo ratings yet

- Heat Transfer Phenomena and ApplicationsDocument382 pagesHeat Transfer Phenomena and ApplicationsSchreiber_DiesesNo ratings yet

- Procedures or Subprograms: ObjectivesDocument65 pagesProcedures or Subprograms: ObjectivesFebwin VillaceranNo ratings yet

- Lesson Plan in Mathematics 7Document6 pagesLesson Plan in Mathematics 7Pomendia PaulrolandNo ratings yet

- Daylight Sensor Design and App Guide SGDocument24 pagesDaylight Sensor Design and App Guide SGniti860No ratings yet

- THE KAZAKHSTAN’S ARCHITECTURE of the Nineteenth century (THE FORMS SUMMATION) / Research paper by Konstantin I.SAMOILOV. – the Thematic brochures series: STYLES OF THE KAZAKHSTAN’S ARCHITECTURE. – Almaty, 2016. – 42 p.Document43 pagesTHE KAZAKHSTAN’S ARCHITECTURE of the Nineteenth century (THE FORMS SUMMATION) / Research paper by Konstantin I.SAMOILOV. – the Thematic brochures series: STYLES OF THE KAZAKHSTAN’S ARCHITECTURE. – Almaty, 2016. – 42 p.Konstantin SamoilovNo ratings yet

- The Almaty Lawn-And-Park Ensemble "Promenade": EntertainmentDocument52 pagesThe Almaty Lawn-And-Park Ensemble "Promenade": EntertainmentKonstantin SamoilovNo ratings yet

- January 2012Document84 pagesJanuary 2012yawarmiNo ratings yet

- Automatic Time Switches:: 09 Attachment 3 - ECM Functional Test Instructions, P. 13Document4 pagesAutomatic Time Switches:: 09 Attachment 3 - ECM Functional Test Instructions, P. 13iman2222No ratings yet

- 1881 and 1949 Earthquakes at The Chios-Cesme Strait (Aegean Sea)Document9 pages1881 and 1949 Earthquakes at The Chios-Cesme Strait (Aegean Sea)Stauros StephanidesNo ratings yet

- Prefunctional Test Checklist - Exhaust - AirportDocument7 pagesPrefunctional Test Checklist - Exhaust - Airportlong minn2No ratings yet

- Delta Times: of Climate ChangeDocument68 pagesDelta Times: of Climate ChangeDaisyNo ratings yet

- SimAUD2018 Proceedings LoResDocument400 pagesSimAUD2018 Proceedings LoResSofea14No ratings yet

- OE Watch - Foreign Military Studies OfficeDocument53 pagesOE Watch - Foreign Military Studies Officecondorblack2001No ratings yet

- Prefunctional Test Checklist - PipingDocument7 pagesPrefunctional Test Checklist - Pipinglong minn2No ratings yet

- LR HorizonsDocument21 pagesLR HorizonsIrina MaltopolNo ratings yet

- A Review of Seismic Design and Behavior of Gali-Zakho Tunnel Lining PDFDocument9 pagesA Review of Seismic Design and Behavior of Gali-Zakho Tunnel Lining PDFwaimaungNo ratings yet

- Energy ConservationDocument250 pagesEnergy ConservationSchreiber_DiesesNo ratings yet

- Horizons, Issue 34, May 2012Document31 pagesHorizons, Issue 34, May 2012silidiriNo ratings yet

- Acoustic Performance ANSI S12.60-2002Document6 pagesAcoustic Performance ANSI S12.60-2002yomama3No ratings yet

- The New Sharing EconomyDocument13 pagesThe New Sharing EconomyDaisy100% (4)

- Daylight Booklet 3 Nov 2017 Med Single PagesDocument48 pagesDaylight Booklet 3 Nov 2017 Med Single PagesNipun GeorgeNo ratings yet

- Prefunctional Test Checklist-11 - Fan Supply AirDocument7 pagesPrefunctional Test Checklist-11 - Fan Supply Airlong minn2No ratings yet

- Moscow Defense Brief 1-2006Document32 pagesMoscow Defense Brief 1-2006yawarmiNo ratings yet

- Moscow Defense Brief 1-2007Document28 pagesMoscow Defense Brief 1-2007yawarmiNo ratings yet

- Probabilistic Seismic Hazard Assessment For Albania, Macedonia and SerbiaDocument10 pagesProbabilistic Seismic Hazard Assessment For Albania, Macedonia and Serbiasofronije2005100% (1)

- Prefunctional Test Checklist-13 - VFDDocument6 pagesPrefunctional Test Checklist-13 - VFDlong minn2No ratings yet

- Hybrid Daylight Models in Architectural Design Education, Max C. Doelling.Document13 pagesHybrid Daylight Models in Architectural Design Education, Max C. Doelling.Max C DNo ratings yet

- Property Journal April 2013Document56 pagesProperty Journal April 2013David FehertyNo ratings yet

- 338 Iran GCCDocument53 pages338 Iran GCCPaulo BottaNo ratings yet

- The Kazakhstan'S Architecture of The: in The World Architectural ContextDocument140 pagesThe Kazakhstan'S Architecture of The: in The World Architectural ContextKonstantin SamoilovNo ratings yet

- AERMEC Katalog 2008Document139 pagesAERMEC Katalog 2008Mikhail0% (1)

- OE Watch, Vol 09, Issue 12 December 2019Document76 pagesOE Watch, Vol 09, Issue 12 December 2019Dorjee SengeNo ratings yet

- Oee Fmso Oe Watch 11-2016Document65 pagesOee Fmso Oe Watch 11-2016prabhatNo ratings yet

- LL Top PortsDocument89 pagesLL Top PortsLuka VukicNo ratings yet

- ARCHITECTURAL RENOVATIONS: the modern Kazakhstan’s architecture building shapes remodeling in the World architectural context / the Album of typical examples / by Dr. Konstantin I.Samoilov. - Almaty, 2017. - 81 p.Document82 pagesARCHITECTURAL RENOVATIONS: the modern Kazakhstan’s architecture building shapes remodeling in the World architectural context / the Album of typical examples / by Dr. Konstantin I.Samoilov. - Almaty, 2017. - 81 p.Konstantin SamoilovNo ratings yet

- The Barcelona Pass Guidebook - en FR deDocument50 pagesThe Barcelona Pass Guidebook - en FR deAna Maria CristianaNo ratings yet

- Prefunctional Test Checklist-12 - VavDocument6 pagesPrefunctional Test Checklist-12 - Vavlong minn2No ratings yet

- Advances in Mechanical Engineering Selected Contributions From TheDocument223 pagesAdvances in Mechanical Engineering Selected Contributions From TheSwan Zay AungNo ratings yet

- Pgl40 Ukca Declaration of ConformityDocument1 pagePgl40 Ukca Declaration of ConformityILNo ratings yet

- Index Titanic Belfasst OwnDocument8 pagesIndex Titanic Belfasst OwnCompadre FernandezNo ratings yet

- OE Watch, Vol 12, Issue 09, 2022Document33 pagesOE Watch, Vol 12, Issue 09, 2022Anton MihailovNo ratings yet

- Evaluation and Selection of Energy Storage SystemsDocument12 pagesEvaluation and Selection of Energy Storage SystemsMarco Antonio Miranda Rodriguez100% (1)

- Assessming ImpactDocument360 pagesAssessming ImpactSANDRANo ratings yet

- Ansi-Asa s12.60 Part 1Document46 pagesAnsi-Asa s12.60 Part 1Inriyani DulminNo ratings yet

- Prefunctional Test Checklist - Chilled Water Pump - AirportDocument7 pagesPrefunctional Test Checklist - Chilled Water Pump - Airportlong minn2No ratings yet

- MI Healthy Climate Plan: DraftDocument45 pagesMI Healthy Climate Plan: DraftWXMINo ratings yet

- Model Tuning - Mentum PlanetDocument36 pagesModel Tuning - Mentum Planettomarnitin19833526No ratings yet

- Inspection Data Sheet (I.D.S.) : Company Job. Country RevisionDocument2 pagesInspection Data Sheet (I.D.S.) : Company Job. Country Revisionbrome2014No ratings yet

- SOR DefaultDocument7 pagesSOR DefaultOscar Newton LuvisNo ratings yet

- Assignment 4/5 Statistics 5.301 Due: Nov. 29: Rule 1: If One or More of The Next Seven Samples Yield Values of The SampleDocument6 pagesAssignment 4/5 Statistics 5.301 Due: Nov. 29: Rule 1: If One or More of The Next Seven Samples Yield Values of The SamplePatih Agung SNo ratings yet

- DS1000D E User's GuideDocument166 pagesDS1000D E User's GuideRicardo de Azambuja100% (1)

- Mill OptimizationDocument45 pagesMill OptimizationDSG100% (5)

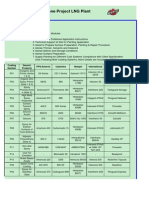

- Wheatstone Project LNG Plant: MR Number XX Title: Scope of WoDocument4 pagesWheatstone Project LNG Plant: MR Number XX Title: Scope of WoLegend AnbuNo ratings yet

- Modelbuilder - Automate ProcessingDocument7 pagesModelbuilder - Automate ProcessingKhalid ChadliNo ratings yet

- 564shj22-01-Gym-Tc-100 R1Document1 page564shj22-01-Gym-Tc-100 R1IbrahimUnesNo ratings yet

- 16997-02 Prefunctional Test Checklist - Switchgear, Switchboards, EtcDocument6 pages16997-02 Prefunctional Test Checklist - Switchgear, Switchboards, Etclong minn2No ratings yet

- Interface Component Supplementary Record of Inspection and TestingDocument2 pagesInterface Component Supplementary Record of Inspection and TestingaamedNo ratings yet

- 303-08B Engine Emission Control - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Diagnosis and TestingDocument3 pages303-08B Engine Emission Control - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Diagnosis and TestingHenrique AlmeidaNo ratings yet

- Interpret Standard Deviation Outlier Rule: Using Normalcdf and Invnorm (Calculator Tips)Document12 pagesInterpret Standard Deviation Outlier Rule: Using Normalcdf and Invnorm (Calculator Tips)maryrachel713No ratings yet

- Reflection By: Wan Ahmad Fayadh Bin Wan IbrahimDocument3 pagesReflection By: Wan Ahmad Fayadh Bin Wan IbrahimcfghdftNo ratings yet

- Wisdom-Sophia: Contrasting Approaches To A Complex ThemeDocument12 pagesWisdom-Sophia: Contrasting Approaches To A Complex ThemeDramonesNo ratings yet

- Development of Virtual Museum Model For YouthDocument5 pagesDevelopment of Virtual Museum Model For YouthSoumyadip RoyNo ratings yet

- Use of Realism in Mulk Raj Anand's Novels: Karan SharmaDocument2 pagesUse of Realism in Mulk Raj Anand's Novels: Karan SharmasirajahmedsNo ratings yet

- Geronimo StiltonDocument2 pagesGeronimo StiltonRajeshNo ratings yet

- Rethinking Kraljic:: Towards A Purchasing Portfolio Model, Based On Mutual Buyer-Supplier DependenceDocument12 pagesRethinking Kraljic:: Towards A Purchasing Portfolio Model, Based On Mutual Buyer-Supplier DependencePrem Kumar Nambiar100% (2)

- Corporal Punishment, Physical AbuseDocument10 pagesCorporal Punishment, Physical AbuseCarla Isabel Ramírez SantosNo ratings yet

- Day 1 NotesDocument4 pagesDay 1 NotesPawan KumarNo ratings yet

- 2nd Bimonth Test 7th FORMDocument7 pages2nd Bimonth Test 7th FORMFranco AleNo ratings yet

- Hotel ReservationDocument5 pagesHotel ReservationRia YuliantiNo ratings yet

- Long TailDocument3 pagesLong TailSagar TanejaNo ratings yet

- Construction ProductivityDocument9 pagesConstruction ProductivityCristian ZúñigaNo ratings yet

- Desires - How Are You Feeling Today Sir? If Huminto Po Si PT, Iallow Po Natin Siya & Bigyan Siya NG Time To Fully Undertand What He Is Feeling Right Now.Document19 pagesDesires - How Are You Feeling Today Sir? If Huminto Po Si PT, Iallow Po Natin Siya & Bigyan Siya NG Time To Fully Undertand What He Is Feeling Right Now.melodia gandezaNo ratings yet

- Reading Circle 2 - Vocabulary EnricherDocument7 pagesReading Circle 2 - Vocabulary EnricherLee Jia XiNo ratings yet

- Hvpe Syl andDocument9 pagesHvpe Syl andosho_peaceNo ratings yet

- Canon INC. Et Al Vs Joey Fang Et Al.Document4 pagesCanon INC. Et Al Vs Joey Fang Et Al.Michael ZhangNo ratings yet

- Problems Process Costing SOLUTIONDocument12 pagesProblems Process Costing SOLUTIONPatDabz67% (3)

- Veilofreality Com 2011 04 18 Organic-Portals-Soulless-HuDocument47 pagesVeilofreality Com 2011 04 18 Organic-Portals-Soulless-Huapi-23178167550% (2)

- McDonald Family History v35Document45 pagesMcDonald Family History v35David McDonaldNo ratings yet

- 01 Reinforcement Material AnswersDocument5 pages01 Reinforcement Material Answerspicoleta2No ratings yet

- IntrotovedicmathDocument3 pagesIntrotovedicmathmathandmultimediaNo ratings yet

- Case Studies of Lower Respiratory Tract InfectionsDocument25 pagesCase Studies of Lower Respiratory Tract InfectionsMarianNo ratings yet

- Customizable Daily Growth PlanDocument12 pagesCustomizable Daily Growth PlanManojkumar Nair100% (1)

- 4000.essential - English.words.4 WWW - Download.irDocument193 pages4000.essential - English.words.4 WWW - Download.irNguyen Hoang Thanh CungNo ratings yet

- (Journal) Iain L. Densten and Judy H. Gray - Leadership Development and Reflection What Is The Connection PDFDocument6 pages(Journal) Iain L. Densten and Judy H. Gray - Leadership Development and Reflection What Is The Connection PDFAzwinNo ratings yet

- Mindanao State University: College of Health Sciences Marawi CityDocument2 pagesMindanao State University: College of Health Sciences Marawi CityYanumy limb100% (1)

- Winton Oil Color ChartDocument1 pageWinton Oil Color ChartfreshjuiceNo ratings yet

Standard Commissioning Procedure For Daylighting Controls

Standard Commissioning Procedure For Daylighting Controls

Uploaded by

Carolina HernándezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Commissioning Procedure For Daylighting Controls

Standard Commissioning Procedure For Daylighting Controls

Uploaded by

Carolina HernándezCopyright:

Available Formats

Seattle City Light Daylighting Control Commissioning Procedure, page 1

April 1999

STANDARD COMMISSIONING PROCEDURE FOR

DAYLIGHTING CONTROLS

BUILDING NAME: APPLICATION #:

BUILDING ADDRESS:

NAME & FIRM OF PERSON(S) DOING TEST:

DATE(S) OF TEST:

General Notes:

1. This is a generic test procedure for daylighting control systems. If the complexity, configuration, or other aspects

of a specific project require substitute tests or additional tests, explain on the comments sheets, and attach the

additional test procedures and field data. Use additional copies of this procedure as required for the total

number of zones to be commissioned.

2. In all test sections, circle or otherwise highlight any responses that indicate deficiencies (i.e. responses that dont

meet the criteria for acceptance). Acceptance requires correction and retest of all deficiencies, as defined in

each test section under Criteria for Acceptance or Acceptance. Attach all retest data sheets. Complete the

Deficiency Report Form for all deficiencies.

3. This Commissioning Procedure does not address fire and life safety or basic equipment safety controls.

4. To ensure that this Commissioning Procedure will not damage any equipment or affect any equipment

warranties, have the equipment manufacturers representative review any interventive test procedures prior to

execution.

OPERATOR INTERVIEW (Existing Buildings Only):

Determine from a discussion with the building operator whether the daylighting controls are operating properly to

the best of their knowledge. Note any known problems, and possible solutions.

LIGHTING ZONE SCHEDULE:

For the purposes of this commissioning procedure, a lighting zone is defined as a group of luminaires that are

controlled by a single daylighting/lumen maintenance signal output.

Sampling: If there are more than 8 lighting zones in the building, you may select a sample for the following

performance tests. The sample should include at least 10% of the total number of zones, or 8 zones, whichever is

greater. Zones should be selected from different areas of each floor, and from different floors. Also, if banks of

luminaires in spaces are controlled by separate sensors/controllers, include at least one space with two such zones,

and test both zones. Note in the table below which zones are selected for the sample.

Criteria for Acceptance: Lighting zoning must be in accordance with submittals as approved by Designer.

ZONE # SAMPLE

ZONE? ()

DESCRIPTION OF LOCATION CIRCUIT # (if available)

Building Name:

Seattle City Light Daylighting Control Commissioning Procedure, page 2

April 1999

ZONE # SAMPLE

ZONE? ()

DESCRIPTION OF LOCATION CIRCUIT # (if available)

COMMENTS ON ZONING (add more sheets if needed):

ZONE # COMMENT

DAYLIGHTING CONTROL SYSTEM, INSTALLED CHARACTERISTICS (from field inspection):

Criteria for Acceptance: Installed characteristics must be in accordance with submittals as approved by designer,

or as noted otherwise. No answers to questions marked with an shall also be considered deficiencies.

DESCRIPTION

RESPONSE

(Note: If different lighting zones have different responses to these questions, respond specifically

to each group of zones and define which zones lie within each group. Add sheets as necessary.)

1. Does system include lumen maintenance**

control? If so, describe scope & intent.

2. Luminaire control (dimming or switching)?

3. If luminaire control is dimming, what is

setpoint for minimum % of full light output?

Acceptance: <30% of full light output

4. Design illuminance setpoint (foot-candles at

work plane**). Acceptance: per design or

<100fc, whichever is less.

5. Define work plane for this application (e.g.

desk level, 10 feet from windows).

6. Is there at least one lighting control zone per

each perimeter exposure on each floor?

7. Were controls calibrated as part of system

start-up? (If not, do not proceed with this

procedure until calibration is complete.)

8. Was calibration done with finishings and

furniture in place, and after approximately

100 hours of lamp burn-in?

9. Daylighting control type (closed-loop

integral** or open-loop proportional**; or

describe other control sequence)?

Acceptance: Open-loop control may not be

used for applications that include lumen

Building Name:

Seattle City Light Daylighting Control Commissioning Procedure, page 3

April 1999

DESCRIPTION

RESPONSE

(Note: If different lighting zones have different responses to these questions, respond specifically

to each group of zones and define which zones lie within each group. Add sheets as necessary.)

maintenance.

10. Describe any special system features (e.g.

light shelves, skylights, fins, sloped ceilings,

special glazings, tracking mirrors, automatic

window aperture controls, etc.)

11. Have occupants been explained the intent

and operation of the control system?

12. Describe any other ways in which the

installed system differs from the design

intent &/or approved submittals.

** See glossary on last page of test.

COMMENTS ON INSTALLED CHARACTERISTICS (add more sheets if needed):

ITEM # COMMENT

NAMEPLATE DATA (from equipment nameplates, as recorded in field):

Criteria for Acceptance: Nameplate data must be in accordance with submittals as approved by Designer.

DESCRIPTION Manufacturer Model # Comments

Photosensor

Lighting Controller

Controlled Ballasts

EMS Interface

Other:

Other:

INSTALLATION VERIFICATION:

Instructions: Under each zone write "Y" for yes, "N" for no, "NA" for not applicable, or a number to refer to any

needed comments. Explain any N answers in the comment section. If other information is requested, write the

appropriate values.

Criteria for Acceptance: All items require answers of Y (or NA, where relevant) except where other criteria are

noted. If there is failure in any of the following tests for more than 20% of the sampled zones (or 2 zones,

whichever is more), then the entire daylighting control installation shall be considered to be not in conformance. In

this case, the installing contractor is responsible to test all zones prior to calling for a retest under this procedure.

ZONE #

DESCRIPTION

1. Lighting zone generally correlates with

area of daylight availability

2. There is separate control of luminaires

close to and far from the windows

3. Photosensor is mounted in proper

location, per manufacturers directions &

Building Name:

Seattle City Light Daylighting Control Commissioning Procedure, page 4

April 1999

ZONE #

DESCRIPTION

in a position to accurately control work

plane illuminance.

4. Photosensor is protected from direct

sunlight.

5. If indirect lighting** is used, photosensor

is mounted at lower plane of fixture, facing

down

6. Are interior finishes and work space

location consistent with efficient use of

daylighting?

7. Are skylights & other toplighting glazing

clean?

8. Do all lamps in lighting zone dim to

approximately the same level?

9. If lamp switching is used, do controls

include deadband & time delay?

10. Describe in comments any thing that

interferes with design intent of system

1

11.

12.

Notes To Table:

1

For example, storage or dirt on light shelves, dark interior surfaces, blinds that are closed all the time, exterior obstructions,

glare, solar gain problems, objectionable changes in light level, etc.

COMMENTS ON INSTALLATION VERIFICATION CHECKLIST ITEMS (add more sheets if needed):

ITEM # ZONE # COMMENT

Building Name:

Seattle City Light Daylighting Control Commissioning Procedure, page 5

April 1999

FUNCTIONAL PERFORMANCE VERIFICATION:

Daylighting & Lumen Maintenance Control Tests: Perform the following tests by monitoring and/or observing

each lighting zone under actual operation. If the actual control sequence differs from that implied by the tests,

attach a description of the control sequence, the tests that were done to verify the sequence, and your conclusions.

Use of current dataloggers over a period of several days to document operation is recommended, though visual

observation is acceptable. Annotate any logger data and graphs so that it is clear what the data are proving, and

attach these to this form. Attach sketch (or marked-up floor plan) showing location of illuminance test points. Trend

logs of EMS outputs or schedule print-outs are not acceptable as proof of operation.

Test Conditions: Do day-time tests on a bright day, preferably between 10am and 2pm. There should be no direct

sun shining on the work plane at the time of testing.

Criteria for Acceptance: Foot-candle reading during night-time test should be within 20% of design illuminance.

(Use 50 to 100 foot-candles for office occupancies if no design values are available.) For day-time test 1, circuit

amps must be at least 25% lower than night-time test values. Foot-candle values for both day-time tests may not

exceed design illuminance by more than 20% unless amp readings indicate circuit is fully dimmed. If there is failure

in any of the following tests for more than 20% of the sampled zones (or 2 zones, whichever is more), then the

entire daylighting control installation shall be considered to be not in conformance. In this case, the installing

contractor is responsible to test all zones prior to calling for a retest under this procedure.

ZONE #

DESCRIPTION

1. Night-time test: record foot-candles at

work plane. Record lighting circuit amps.

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

2. Day-time test 1: record work plane fc &

lighting circuit amps with blinds open.

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

3. Day-time test 2: record work plane fc &

lighting circuit amps w/ blinds 1/2 closed.

(This test is not required for closed loop

control zones.)

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

fc

amps

4. Observe zone during daytime under

normal operation, 3 times in a 12 hour

period, at least 3 hours apart and for at

least 5 minutes each time. Verify that there

is no unusual ballast hum, light level

hunting, or other problems.

COMMENTS ON FUNCTIONAL PERFORMANCE VERIFICATION ITEMS (add more sheets as needed):

ITEM # ZONE # COMMENT

I certify that the data and test results as recorded herein are accurate.

Signature, Commissioning Agent Date

Firm Name (Area Code) Phone Number

Building Name:

Seattle City Light Daylighting Control Commissioning Procedure, page 6

April 1999

GLOSSARY OF TERMS:

Closed Loop Integral Control: A closed loop integral controller continuously adjusts the output of the electric

lights so that the photosensor output is maintained at the setpoint level. As the photosensor detects an increase in

light in the space due to daylight, the controller reduces the electric light level to restore the photosensor signal to

the setpoint level. This algorithm only works if the photosensor can see the electric light it controls.

Indirect Lighting: A lighting design in which the fixtures direct the lighting upward to reflect against the ceiling.

The luminaires are not directly visible from the space below.

Lamp Switching: Use of photoelectric control switches to switch off, rather than dim, lights in daylight perimeter

zones. These switches should incorporate a dead-band so that the lights dont cycle between levels if the ambient

light level is near the sensor trip level. Some switches also allow the user to adjust a time delay constant that

reduces the likelihood of cycling.

Lumen Maintenance: A control strategy that uses a photocell to detect the actual illuminance in the space, and

adjusts the light level accordingly, so that the design illuminance is maintained at setpoint at all times, not just at

the end of the maintenance cycle.

Open Loop Proportional Control: With an open loop proportional controller, the photosensor is mounted so that it

does not detect the light that is controlled. The photosensor detects only the independent stimulus of daylight.

Work Plane: The level (plane) and general location to which the daylight zone illuminance setpoint applies. In

office occupancies, this is usually at desk level, and about 10 to 15 feet from the perimeter windows. In retail

applications the work plane may be vertical, extending from about 3 feet to 6 feet above the floor.

REFERENCE:

Advanced Lighting Guidelines: 1993. Eley Associates. Prepared for U.S. Department of Energy, California Energy

Commission, and Electric Power Research Institute. Available from National Technical Information Service,

DOE/EE-0008

file:\msoffice\winword\docs\scl\cxproc\dayltqas.pro

You might also like

- SM JCB 3CX 4CX 328739808-9803-3280-9 PDFDocument1,212 pagesSM JCB 3CX 4CX 328739808-9803-3280-9 PDFСергей Ганкевич97% (33)

- 1.1.3.11 Lab - Draw A Process DiagramDocument4 pages1.1.3.11 Lab - Draw A Process DiagramJoshua ManalotoNo ratings yet

- Heat Transfer Phenomena and ApplicationsDocument382 pagesHeat Transfer Phenomena and ApplicationsSchreiber_DiesesNo ratings yet

- Procedures or Subprograms: ObjectivesDocument65 pagesProcedures or Subprograms: ObjectivesFebwin VillaceranNo ratings yet

- Lesson Plan in Mathematics 7Document6 pagesLesson Plan in Mathematics 7Pomendia PaulrolandNo ratings yet

- Daylight Sensor Design and App Guide SGDocument24 pagesDaylight Sensor Design and App Guide SGniti860No ratings yet

- THE KAZAKHSTAN’S ARCHITECTURE of the Nineteenth century (THE FORMS SUMMATION) / Research paper by Konstantin I.SAMOILOV. – the Thematic brochures series: STYLES OF THE KAZAKHSTAN’S ARCHITECTURE. – Almaty, 2016. – 42 p.Document43 pagesTHE KAZAKHSTAN’S ARCHITECTURE of the Nineteenth century (THE FORMS SUMMATION) / Research paper by Konstantin I.SAMOILOV. – the Thematic brochures series: STYLES OF THE KAZAKHSTAN’S ARCHITECTURE. – Almaty, 2016. – 42 p.Konstantin SamoilovNo ratings yet

- The Almaty Lawn-And-Park Ensemble "Promenade": EntertainmentDocument52 pagesThe Almaty Lawn-And-Park Ensemble "Promenade": EntertainmentKonstantin SamoilovNo ratings yet

- January 2012Document84 pagesJanuary 2012yawarmiNo ratings yet

- Automatic Time Switches:: 09 Attachment 3 - ECM Functional Test Instructions, P. 13Document4 pagesAutomatic Time Switches:: 09 Attachment 3 - ECM Functional Test Instructions, P. 13iman2222No ratings yet

- 1881 and 1949 Earthquakes at The Chios-Cesme Strait (Aegean Sea)Document9 pages1881 and 1949 Earthquakes at The Chios-Cesme Strait (Aegean Sea)Stauros StephanidesNo ratings yet

- Prefunctional Test Checklist - Exhaust - AirportDocument7 pagesPrefunctional Test Checklist - Exhaust - Airportlong minn2No ratings yet

- Delta Times: of Climate ChangeDocument68 pagesDelta Times: of Climate ChangeDaisyNo ratings yet

- SimAUD2018 Proceedings LoResDocument400 pagesSimAUD2018 Proceedings LoResSofea14No ratings yet

- OE Watch - Foreign Military Studies OfficeDocument53 pagesOE Watch - Foreign Military Studies Officecondorblack2001No ratings yet

- Prefunctional Test Checklist - PipingDocument7 pagesPrefunctional Test Checklist - Pipinglong minn2No ratings yet

- LR HorizonsDocument21 pagesLR HorizonsIrina MaltopolNo ratings yet

- A Review of Seismic Design and Behavior of Gali-Zakho Tunnel Lining PDFDocument9 pagesA Review of Seismic Design and Behavior of Gali-Zakho Tunnel Lining PDFwaimaungNo ratings yet

- Energy ConservationDocument250 pagesEnergy ConservationSchreiber_DiesesNo ratings yet

- Horizons, Issue 34, May 2012Document31 pagesHorizons, Issue 34, May 2012silidiriNo ratings yet

- Acoustic Performance ANSI S12.60-2002Document6 pagesAcoustic Performance ANSI S12.60-2002yomama3No ratings yet

- The New Sharing EconomyDocument13 pagesThe New Sharing EconomyDaisy100% (4)

- Daylight Booklet 3 Nov 2017 Med Single PagesDocument48 pagesDaylight Booklet 3 Nov 2017 Med Single PagesNipun GeorgeNo ratings yet

- Prefunctional Test Checklist-11 - Fan Supply AirDocument7 pagesPrefunctional Test Checklist-11 - Fan Supply Airlong minn2No ratings yet

- Moscow Defense Brief 1-2006Document32 pagesMoscow Defense Brief 1-2006yawarmiNo ratings yet

- Moscow Defense Brief 1-2007Document28 pagesMoscow Defense Brief 1-2007yawarmiNo ratings yet

- Probabilistic Seismic Hazard Assessment For Albania, Macedonia and SerbiaDocument10 pagesProbabilistic Seismic Hazard Assessment For Albania, Macedonia and Serbiasofronije2005100% (1)

- Prefunctional Test Checklist-13 - VFDDocument6 pagesPrefunctional Test Checklist-13 - VFDlong minn2No ratings yet

- Hybrid Daylight Models in Architectural Design Education, Max C. Doelling.Document13 pagesHybrid Daylight Models in Architectural Design Education, Max C. Doelling.Max C DNo ratings yet

- Property Journal April 2013Document56 pagesProperty Journal April 2013David FehertyNo ratings yet

- 338 Iran GCCDocument53 pages338 Iran GCCPaulo BottaNo ratings yet

- The Kazakhstan'S Architecture of The: in The World Architectural ContextDocument140 pagesThe Kazakhstan'S Architecture of The: in The World Architectural ContextKonstantin SamoilovNo ratings yet

- AERMEC Katalog 2008Document139 pagesAERMEC Katalog 2008Mikhail0% (1)

- OE Watch, Vol 09, Issue 12 December 2019Document76 pagesOE Watch, Vol 09, Issue 12 December 2019Dorjee SengeNo ratings yet

- Oee Fmso Oe Watch 11-2016Document65 pagesOee Fmso Oe Watch 11-2016prabhatNo ratings yet

- LL Top PortsDocument89 pagesLL Top PortsLuka VukicNo ratings yet

- ARCHITECTURAL RENOVATIONS: the modern Kazakhstan’s architecture building shapes remodeling in the World architectural context / the Album of typical examples / by Dr. Konstantin I.Samoilov. - Almaty, 2017. - 81 p.Document82 pagesARCHITECTURAL RENOVATIONS: the modern Kazakhstan’s architecture building shapes remodeling in the World architectural context / the Album of typical examples / by Dr. Konstantin I.Samoilov. - Almaty, 2017. - 81 p.Konstantin SamoilovNo ratings yet

- The Barcelona Pass Guidebook - en FR deDocument50 pagesThe Barcelona Pass Guidebook - en FR deAna Maria CristianaNo ratings yet

- Prefunctional Test Checklist-12 - VavDocument6 pagesPrefunctional Test Checklist-12 - Vavlong minn2No ratings yet

- Advances in Mechanical Engineering Selected Contributions From TheDocument223 pagesAdvances in Mechanical Engineering Selected Contributions From TheSwan Zay AungNo ratings yet

- Pgl40 Ukca Declaration of ConformityDocument1 pagePgl40 Ukca Declaration of ConformityILNo ratings yet

- Index Titanic Belfasst OwnDocument8 pagesIndex Titanic Belfasst OwnCompadre FernandezNo ratings yet

- OE Watch, Vol 12, Issue 09, 2022Document33 pagesOE Watch, Vol 12, Issue 09, 2022Anton MihailovNo ratings yet

- Evaluation and Selection of Energy Storage SystemsDocument12 pagesEvaluation and Selection of Energy Storage SystemsMarco Antonio Miranda Rodriguez100% (1)

- Assessming ImpactDocument360 pagesAssessming ImpactSANDRANo ratings yet

- Ansi-Asa s12.60 Part 1Document46 pagesAnsi-Asa s12.60 Part 1Inriyani DulminNo ratings yet

- Prefunctional Test Checklist - Chilled Water Pump - AirportDocument7 pagesPrefunctional Test Checklist - Chilled Water Pump - Airportlong minn2No ratings yet

- MI Healthy Climate Plan: DraftDocument45 pagesMI Healthy Climate Plan: DraftWXMINo ratings yet

- Model Tuning - Mentum PlanetDocument36 pagesModel Tuning - Mentum Planettomarnitin19833526No ratings yet

- Inspection Data Sheet (I.D.S.) : Company Job. Country RevisionDocument2 pagesInspection Data Sheet (I.D.S.) : Company Job. Country Revisionbrome2014No ratings yet

- SOR DefaultDocument7 pagesSOR DefaultOscar Newton LuvisNo ratings yet

- Assignment 4/5 Statistics 5.301 Due: Nov. 29: Rule 1: If One or More of The Next Seven Samples Yield Values of The SampleDocument6 pagesAssignment 4/5 Statistics 5.301 Due: Nov. 29: Rule 1: If One or More of The Next Seven Samples Yield Values of The SamplePatih Agung SNo ratings yet

- DS1000D E User's GuideDocument166 pagesDS1000D E User's GuideRicardo de Azambuja100% (1)

- Mill OptimizationDocument45 pagesMill OptimizationDSG100% (5)

- Wheatstone Project LNG Plant: MR Number XX Title: Scope of WoDocument4 pagesWheatstone Project LNG Plant: MR Number XX Title: Scope of WoLegend AnbuNo ratings yet

- Modelbuilder - Automate ProcessingDocument7 pagesModelbuilder - Automate ProcessingKhalid ChadliNo ratings yet

- 564shj22-01-Gym-Tc-100 R1Document1 page564shj22-01-Gym-Tc-100 R1IbrahimUnesNo ratings yet

- 16997-02 Prefunctional Test Checklist - Switchgear, Switchboards, EtcDocument6 pages16997-02 Prefunctional Test Checklist - Switchgear, Switchboards, Etclong minn2No ratings yet

- Interface Component Supplementary Record of Inspection and TestingDocument2 pagesInterface Component Supplementary Record of Inspection and TestingaamedNo ratings yet

- 303-08B Engine Emission Control - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Diagnosis and TestingDocument3 pages303-08B Engine Emission Control - 1.4L Duratorq-Tdci (DV) Diesel 2004 - 2012 Fusion Diagnosis and TestingHenrique AlmeidaNo ratings yet

- Interpret Standard Deviation Outlier Rule: Using Normalcdf and Invnorm (Calculator Tips)Document12 pagesInterpret Standard Deviation Outlier Rule: Using Normalcdf and Invnorm (Calculator Tips)maryrachel713No ratings yet

- Reflection By: Wan Ahmad Fayadh Bin Wan IbrahimDocument3 pagesReflection By: Wan Ahmad Fayadh Bin Wan IbrahimcfghdftNo ratings yet

- Wisdom-Sophia: Contrasting Approaches To A Complex ThemeDocument12 pagesWisdom-Sophia: Contrasting Approaches To A Complex ThemeDramonesNo ratings yet

- Development of Virtual Museum Model For YouthDocument5 pagesDevelopment of Virtual Museum Model For YouthSoumyadip RoyNo ratings yet

- Use of Realism in Mulk Raj Anand's Novels: Karan SharmaDocument2 pagesUse of Realism in Mulk Raj Anand's Novels: Karan SharmasirajahmedsNo ratings yet

- Geronimo StiltonDocument2 pagesGeronimo StiltonRajeshNo ratings yet

- Rethinking Kraljic:: Towards A Purchasing Portfolio Model, Based On Mutual Buyer-Supplier DependenceDocument12 pagesRethinking Kraljic:: Towards A Purchasing Portfolio Model, Based On Mutual Buyer-Supplier DependencePrem Kumar Nambiar100% (2)

- Corporal Punishment, Physical AbuseDocument10 pagesCorporal Punishment, Physical AbuseCarla Isabel Ramírez SantosNo ratings yet

- Day 1 NotesDocument4 pagesDay 1 NotesPawan KumarNo ratings yet

- 2nd Bimonth Test 7th FORMDocument7 pages2nd Bimonth Test 7th FORMFranco AleNo ratings yet

- Hotel ReservationDocument5 pagesHotel ReservationRia YuliantiNo ratings yet

- Long TailDocument3 pagesLong TailSagar TanejaNo ratings yet

- Construction ProductivityDocument9 pagesConstruction ProductivityCristian ZúñigaNo ratings yet

- Desires - How Are You Feeling Today Sir? If Huminto Po Si PT, Iallow Po Natin Siya & Bigyan Siya NG Time To Fully Undertand What He Is Feeling Right Now.Document19 pagesDesires - How Are You Feeling Today Sir? If Huminto Po Si PT, Iallow Po Natin Siya & Bigyan Siya NG Time To Fully Undertand What He Is Feeling Right Now.melodia gandezaNo ratings yet

- Reading Circle 2 - Vocabulary EnricherDocument7 pagesReading Circle 2 - Vocabulary EnricherLee Jia XiNo ratings yet

- Hvpe Syl andDocument9 pagesHvpe Syl andosho_peaceNo ratings yet

- Canon INC. Et Al Vs Joey Fang Et Al.Document4 pagesCanon INC. Et Al Vs Joey Fang Et Al.Michael ZhangNo ratings yet

- Problems Process Costing SOLUTIONDocument12 pagesProblems Process Costing SOLUTIONPatDabz67% (3)

- Veilofreality Com 2011 04 18 Organic-Portals-Soulless-HuDocument47 pagesVeilofreality Com 2011 04 18 Organic-Portals-Soulless-Huapi-23178167550% (2)

- McDonald Family History v35Document45 pagesMcDonald Family History v35David McDonaldNo ratings yet

- 01 Reinforcement Material AnswersDocument5 pages01 Reinforcement Material Answerspicoleta2No ratings yet

- IntrotovedicmathDocument3 pagesIntrotovedicmathmathandmultimediaNo ratings yet

- Case Studies of Lower Respiratory Tract InfectionsDocument25 pagesCase Studies of Lower Respiratory Tract InfectionsMarianNo ratings yet

- Customizable Daily Growth PlanDocument12 pagesCustomizable Daily Growth PlanManojkumar Nair100% (1)

- 4000.essential - English.words.4 WWW - Download.irDocument193 pages4000.essential - English.words.4 WWW - Download.irNguyen Hoang Thanh CungNo ratings yet

- (Journal) Iain L. Densten and Judy H. Gray - Leadership Development and Reflection What Is The Connection PDFDocument6 pages(Journal) Iain L. Densten and Judy H. Gray - Leadership Development and Reflection What Is The Connection PDFAzwinNo ratings yet

- Mindanao State University: College of Health Sciences Marawi CityDocument2 pagesMindanao State University: College of Health Sciences Marawi CityYanumy limb100% (1)

- Winton Oil Color ChartDocument1 pageWinton Oil Color ChartfreshjuiceNo ratings yet