Professional Documents

Culture Documents

Mtech 2013 DPVP Model Question

Mtech 2013 DPVP Model Question

Uploaded by

Mathew JohnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mtech 2013 DPVP Model Question

Mtech 2013 DPVP Model Question

Uploaded by

Mathew JohnCopyright:

Available Formats

(Pages: 2)

Reg. No:...

Name:...

Second Semester M.Tech Degree Examination, Sep 2014

(2013 scheme)

Machine Design

MDE 2003: DESIGN OF PRESSURE VESSELS AND PIPING

(MODEL QUESTION PAPER)

Time : 3 Hours Max Marks : 60

Instructions:

1) Answer any two (full) questions from each Module, all questions carry equal marks.

2) Use of Pressure Vessels design data sheet is permitted.

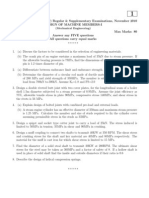

Module I

1. Obtain the expression for stresses in a cylindrical vessel under internal pressure

based on general membrane stress theory.

2. Determine the stresses at the hemispherical headcylindrical joint of a vessel for the

conditions of; radius 1300mm, internal pressure 2 MPa, thickness for both head and

vessel is same and is 25mm, Poissons ratio 0.3 ; and sketch the stress variation near

the joint in the cylindrical portion.

3. Write a note on the ASME code equations for various closure heads used in a

pressure vessel.

Module II

4. Explain different types of pressure vessel supports with suitable sketches.

5. Write a note on the development of pressure vessel construction codes

6. Examine the data given below of a fully radiographed shell to check the compensation

requirement. Outside diameter (OD) of shell 2m, maximum working pressure 3.5MPa,

wall thickness of shell 0.05 m, corrosion allowance 0.003m, allowable stress 96 MPa,

OD of nozzle 0.25m, nozzle wall thickness 0.016m, length of nozzle above surface

0.1m. No extension inside.

(Page 2)

Module III

7. (a) Explain the elastic buckling of long cylinders under external pressure. Calculate the

collapse pressure and critical stress for a long steel pipe with 400 NB, 8 mm thickness

(schedule 20). E = 210 GPa (3)

(b) A 150mm NB pipe has an external design pressure of 30 bar at 400

0

C. The

material of construction of pipe is ASTM A312 stainless steel. The corrosion allowance

is nil and mill tolerance allowance is 12.5%. Based on ASME design criteria, check

whether selection of schedule 5 standard pipe is correct?, if not select proper

schedule. Assume a factor of safety 3. (7)

Data given from pipe thickness chart:

NB OD Sch 5S Sch10S Sch 40S Sch 80 Sch 120

150 168.27 2.77 3.40 7.11 10.97 14.27

7. A pipe with a 48 inch inside diameter and a 60 inch outside diameter is subjected to

an internal pressure of 35MPa Determine the value and place of occurrence of (a) the

maximum tangential stress (b) the maximum radial stress (c) the maximum shear

stress (d) the average tangential stress (e) What percent is this of the maximum

tangential stress

9. Write a note on different piping elements/components in a piping system.

-----------------------------------------------

You might also like

- 2020 Annual Profile - ENDocument64 pages2020 Annual Profile - ENGeraldNo ratings yet

- Evidence Requirements by Key Result Area Key Result Area Objectives Means of VerificationDocument9 pagesEvidence Requirements by Key Result Area Key Result Area Objectives Means of VerificationJoji Matadling Tecson100% (1)

- Somqpit 3Document3 pagesSomqpit 3Anbu SelvanNo ratings yet

- Correlation Between Pipe Bend Geometry and Allowable Pressure in Pipe Bends Using Artificial Neural Network PDFDocument13 pagesCorrelation Between Pipe Bend Geometry and Allowable Pressure in Pipe Bends Using Artificial Neural Network PDFshyfxNo ratings yet

- Pipe Thickness Calculation For Internal PressureDocument12 pagesPipe Thickness Calculation For Internal PressurefsijestNo ratings yet

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Model Q.paperDocument3 pagesModel Q.paperMathew JohnNo ratings yet

- Distribution, Transmission Systems and Design Exam For Jan 2016Document4 pagesDistribution, Transmission Systems and Design Exam For Jan 2016RaimundoNo ratings yet

- Main Exam Paper Nov08, Smt211tDocument6 pagesMain Exam Paper Nov08, Smt211tPortia ShilengeNo ratings yet

- Strengths of MaterialsDocument4 pagesStrengths of Materialsanna juarezNo ratings yet

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliNo ratings yet

- Design of Machine Elements2Document14 pagesDesign of Machine Elements2Satwik PriyadarshiNo ratings yet

- 9A01301 Mechanics of SolidsDocument4 pages9A01301 Mechanics of SolidssivabharathamurthyNo ratings yet

- 9A01401 Strength of Materials - IIDocument4 pages9A01401 Strength of Materials - IIsivabharathamurthyNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model PaperVinay Karanam100% (1)

- MCEN30017 Tutorial 5Document2 pagesMCEN30017 Tutorial 5vsanthanamNo ratings yet

- EMM7241-Advanced Machine Design Examination June 2016Document8 pagesEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNo ratings yet

- MDPE Final TutorialDocument4 pagesMDPE Final Tutoriallata sinsinwarNo ratings yet

- Mechanicsofsolids Dec 2010Document10 pagesMechanicsofsolids Dec 2010simalaraviNo ratings yet

- MOM OU Old Question PaperDocument2 pagesMOM OU Old Question PaperAmmineni Syam PrasadNo ratings yet

- Basic of Piping Stress Analysis - Part-1Document9 pagesBasic of Piping Stress Analysis - Part-1zafarbadal100% (1)

- Design of Machine Members - IDocument8 pagesDesign of Machine Members - IPradeepkumarKatgiNo ratings yet

- DMM - MID-I Important QuestionsDocument2 pagesDMM - MID-I Important QuestionsV.Nagaraju 19O17-M-O5ONo ratings yet

- (Ensc 13) Probset 1 - Stresses (2ND - Sem - Ay2016-2017)Document4 pages(Ensc 13) Probset 1 - Stresses (2ND - Sem - Ay2016-2017)Bianca AsisNo ratings yet

- NR-310305-Design of Machine ElementsDocument9 pagesNR-310305-Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Design of Stiffeners For Industrial Piping Under External Pressure Using FemDocument6 pagesDesign of Stiffeners For Industrial Piping Under External Pressure Using FemJosip KacmarcikNo ratings yet

- Basics of Pipe Stress Analysis-PartDocument5 pagesBasics of Pipe Stress Analysis-Part7761430No ratings yet

- R7310305-Design of Machine Members-IDocument4 pagesR7310305-Design of Machine Members-Isivabharathamurthy0% (1)

- 9A01301 Mechanics of SolidsDocument1 page9A01301 Mechanics of SolidssivabharathamurthyNo ratings yet

- ME2303Document5 pagesME2303balameckNo ratings yet

- Mechanical ScienceDocument12 pagesMechanical ScienceFernando EyzaguirreNo ratings yet

- Department of Mechanical EngineeringDocument4 pagesDepartment of Mechanical EngineeringAshok DaraNo ratings yet

- PED AssignmentProblems 2017 PDFDocument10 pagesPED AssignmentProblems 2017 PDFSwapnil GudmalwarNo ratings yet

- Analysis of Simple StressesDocument39 pagesAnalysis of Simple StressesEduCartNo ratings yet

- DomeDocument3 pagesDomevikaskumar1986No ratings yet

- 9A01301 Mechanics of SolidsDocument4 pages9A01301 Mechanics of SolidssivabharathamurthyNo ratings yet

- Fakulti Kejuruteraan Mekanikal Universiti Teknikal Malaysia Melaka Tutorial 2Document4 pagesFakulti Kejuruteraan Mekanikal Universiti Teknikal Malaysia Melaka Tutorial 2Hilmi YunosNo ratings yet

- Fig. P3.129, P3.130Document4 pagesFig. P3.129, P3.130Alen RustemovicNo ratings yet

- Design of Machine ElementsDocument4 pagesDesign of Machine ElementsBinyamin ChinikamwalaNo ratings yet

- r13 Mos Old Q PapersDocument21 pagesr13 Mos Old Q PapersSrinu ReddyNo ratings yet

- Mechanical PapersDocument23 pagesMechanical PapersSachin AgrawalNo ratings yet

- Mechanics of SolidsDocument9 pagesMechanics of SolidsSrikanth GogineniNo ratings yet

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- Assignment 1Document3 pagesAssignment 1154 ahmed ehabNo ratings yet

- DesignDocument21 pagesDesignmeindyaNo ratings yet

- Determination of Design Parameters in Large Size Reinforced Polyethylene PipesDocument6 pagesDetermination of Design Parameters in Large Size Reinforced Polyethylene PipesTon PhichitNo ratings yet

- r059210303 Mechanics of SolidsDocument8 pagesr059210303 Mechanics of SolidsSrinivasa Rao GNo ratings yet

- ENSC 13 Problem Set 1Document4 pagesENSC 13 Problem Set 1Roxanne de RoxasNo ratings yet

- R5 210304 Mechanics of SolidsDocument2 pagesR5 210304 Mechanics of SolidssivabharathamurthyNo ratings yet

- Mechanics of Solids PDFDocument8 pagesMechanics of Solids PDFprashanthreddy26No ratings yet

- Ameron Calculation Manual For Bondstrand GRE Pipe Systems: Technical Bulletin 3Document16 pagesAmeron Calculation Manual For Bondstrand GRE Pipe Systems: Technical Bulletin 3Fabricio Vega EstrellaNo ratings yet

- ES 13 ProbSet 1Document2 pagesES 13 ProbSet 1Sammy Marquez50% (2)

- ASME B31.5-Refrigeration-PipingDocument11 pagesASME B31.5-Refrigeration-PipingJai100% (2)

- Pipping FormulaDocument8 pagesPipping Formularajeshsabitha80No ratings yet

- Principal Stresses & Strains Theories of Failures Unit-IvDocument2 pagesPrincipal Stresses & Strains Theories of Failures Unit-IvSujeet SinghNo ratings yet

- R7310305-Design of Machine Members-I2Document4 pagesR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- Machine Design I Nme 501 Eme501Document3 pagesMachine Design I Nme 501 Eme501himanshujaiswal04596No ratings yet

- ME2303Document5 pagesME2303Galih PramuditaNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Continuum Mechanics - Module 3 To StudentsDocument36 pagesContinuum Mechanics - Module 3 To StudentsMathew JohnNo ratings yet

- PSC List 2013-Lecturer MEDocument6 pagesPSC List 2013-Lecturer MEMathew JohnNo ratings yet

- ICONs-2018 BrochureDocument2 pagesICONs-2018 BrochureMathew JohnNo ratings yet

- Topics - Ijbsfmm2018Document1 pageTopics - Ijbsfmm2018Mathew JohnNo ratings yet

- NDE 6310 Assignment 1Document1 pageNDE 6310 Assignment 1Mathew JohnNo ratings yet

- Phased Array UTDocument32 pagesPhased Array UTMathew John100% (1)

- "Do Not Worry About Your First Job" Says Tanuj Tdot' Jhunjhunwala - Chennai36Document8 pages"Do Not Worry About Your First Job" Says Tanuj Tdot' Jhunjhunwala - Chennai36Mathew JohnNo ratings yet

- Composites Mod03lec01Document27 pagesComposites Mod03lec01Mathew JohnNo ratings yet

- CompositesDocument17 pagesCompositesMathew JohnNo ratings yet

- Mod 04 Lec 01Document4 pagesMod 04 Lec 01Mathew JohnNo ratings yet

- Mod 04 Lec 01Document4 pagesMod 04 Lec 01Mathew JohnNo ratings yet

- Maximum Longitudinal Bending Stress S in The MidspanDocument3 pagesMaximum Longitudinal Bending Stress S in The MidspanMathew JohnNo ratings yet

- Long Beam With Load (P) or Moment (M) at The CentreDocument6 pagesLong Beam With Load (P) or Moment (M) at The CentreMathew JohnNo ratings yet

- Composite MaterialsDocument30 pagesComposite MaterialsMathew JohnNo ratings yet

- Composites Mod03lec01Document27 pagesComposites Mod03lec01Mathew JohnNo ratings yet

- Composites Mod02lec01Document49 pagesComposites Mod02lec01Mathew JohnNo ratings yet

- Government Engineering College, Barton Hill, Thiruvananthapuram First Series Test, February 2014 08.602: Dynamics of Machinery (S6 - Mechanical)Document2 pagesGovernment Engineering College, Barton Hill, Thiruvananthapuram First Series Test, February 2014 08.602: Dynamics of Machinery (S6 - Mechanical)Mathew JohnNo ratings yet

- S6 ME - DOM QN PaperDocument2 pagesS6 ME - DOM QN PaperMathew JohnNo ratings yet

- M-428-Malhari Mahatmya - Kavikulguru Kalidas Sanskrit University Ramtek CollectionDocument47 pagesM-428-Malhari Mahatmya - Kavikulguru Kalidas Sanskrit University Ramtek Collectionshubhpatil1313No ratings yet

- Drywall (Systems Catalogue) 2019Document24 pagesDrywall (Systems Catalogue) 2019Kim Kenneth AsiaNo ratings yet

- Advance Numerical Mechanical SimulationDocument259 pagesAdvance Numerical Mechanical SimulationSankit SinghNo ratings yet

- Salt Analysis Chemistry Lab PDFDocument9 pagesSalt Analysis Chemistry Lab PDFkushal aggarwalNo ratings yet

- Handout Physics 101 ForceDocument12 pagesHandout Physics 101 ForceMary Grace AcostaNo ratings yet

- Matter Around Us: You May Have Heard The Phrases LikeDocument14 pagesMatter Around Us: You May Have Heard The Phrases Likedvrao_chowdaryNo ratings yet

- C23 01 DecisionDocument13 pagesC23 01 DecisionBobbyApryantoSanderNo ratings yet

- 2021 Ford® Ranger Midsize Pickup Truck - BrochuresDocument5 pages2021 Ford® Ranger Midsize Pickup Truck - BrochuresRizal Mohamad Al-AyyubiNo ratings yet

- 34 Concrete ShearDocument4 pages34 Concrete ShearMario Sajulga Dela CuadraNo ratings yet

- Question Bank Module-1: Computer Networks 18EC71Document4 pagesQuestion Bank Module-1: Computer Networks 18EC71richa100% (1)

- Ref: IS:875 - 1984 (Part III), Calculation of Wind Loads On BuildingsDocument4 pagesRef: IS:875 - 1984 (Part III), Calculation of Wind Loads On BuildingsRaviKiranNo ratings yet

- Teachers' Challenges in Implementing The Highly Immersive Programme (HIP) in The ClassroomsDocument14 pagesTeachers' Challenges in Implementing The Highly Immersive Programme (HIP) in The ClassroomsNURSHUHADA BINTI MOHD NASIR MoeNo ratings yet

- Manually Operated Power Dynamo in Lighting Up Led: Results and DiscussionDocument2 pagesManually Operated Power Dynamo in Lighting Up Led: Results and DiscussionJoy ManangoNo ratings yet

- Counseling Pro Inv - SKDocument13 pagesCounseling Pro Inv - SKPadam PandeyaNo ratings yet

- GPP Action PlanDocument3 pagesGPP Action PlanSwen CuberoNo ratings yet

- MVCT101 Advanced Mathematics UNIT 1 Capsule 1 Objective Question Notes RGPV MTECH CTM (Notescivil - Blogspot.com)Document8 pagesMVCT101 Advanced Mathematics UNIT 1 Capsule 1 Objective Question Notes RGPV MTECH CTM (Notescivil - Blogspot.com)sgupta792No ratings yet

- Haskell Ebook ReaderDocument1,610 pagesHaskell Ebook ReaderhoogggleeeNo ratings yet

- 12262/Csmt Duronto Ex Third Ac (3A)Document2 pages12262/Csmt Duronto Ex Third Ac (3A)Abhishek DashNo ratings yet

- NOTES - GUIDANCE AND COUNSELLING Manual 2021Document30 pagesNOTES - GUIDANCE AND COUNSELLING Manual 2021Mercy GakiiNo ratings yet

- FH35 FH40 FH45 FH50: Tier 4 Final EngineDocument8 pagesFH35 FH40 FH45 FH50: Tier 4 Final EngineSabahNo ratings yet

- Bleed/safe Zone GuideDocument7 pagesBleed/safe Zone Guidehasan tareqNo ratings yet

- Bertrand's Postulate Proof - Michael TangDocument7 pagesBertrand's Postulate Proof - Michael Tanggauss202No ratings yet

- Mete AggiesDocument16 pagesMete AggiesJohn Renzel RiveraNo ratings yet

- Chandorkar Meghna - Resume May 2020Document2 pagesChandorkar Meghna - Resume May 2020api-374397440No ratings yet

- SasDocument2 pagesSassravanthiNo ratings yet

- 12k Eixo DianteiroDocument3 pages12k Eixo DianteiroCesar AugustoNo ratings yet

- ORA LM Vol. IV Section 15 Drug and Device MicrobiologyDocument83 pagesORA LM Vol. IV Section 15 Drug and Device MicrobiologyDO KHNo ratings yet

- Orientation On The Manual For The Evaluation (Autosaved)Document31 pagesOrientation On The Manual For The Evaluation (Autosaved)Em Boquiren CarreonNo ratings yet