Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

39 views7 Industrial Automation Boller

7 Industrial Automation Boller

Uploaded by

Debi Prasanna Jenait is an imp material

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASCE 7-16 Controversy PDFDocument1 pageASCE 7-16 Controversy PDFHyunkyoun JinNo ratings yet

- Creative Deviance: Bucking The Hierarchy: SummaryDocument2 pagesCreative Deviance: Bucking The Hierarchy: SummaryDebi Prasanna Jena0% (1)

- A Social Project ReportDocument5 pagesA Social Project ReportDebi Prasanna JenaNo ratings yet

- 03 Intrapersonal Variables For CommunicationDocument25 pages03 Intrapersonal Variables For CommunicationDebi Prasanna Jena0% (1)

- Debi Prasanna JenaDocument2 pagesDebi Prasanna JenaDebi Prasanna JenaNo ratings yet

- Design and Simulation of 4:1 MultiplexerDocument2 pagesDesign and Simulation of 4:1 MultiplexerDebi Prasanna JenaNo ratings yet

- S.No Description As Per Agreement Mbook Ref Qty As Per MbookDocument60 pagesS.No Description As Per Agreement Mbook Ref Qty As Per Mbookpwd2007No ratings yet

- Ce 163 - 1Document16 pagesCe 163 - 1hahaduNo ratings yet

- Rishabh Engineering ServicesDocument19 pagesRishabh Engineering ServicesmayankjainrfNo ratings yet

- My Latest Front PagesDocument7 pagesMy Latest Front PagesAbhishek PhutaneNo ratings yet

- Shop Drawing: Key PlanDocument1 pageShop Drawing: Key PlanEko WiyonoNo ratings yet

- Engineering GraphicsDocument2 pagesEngineering GraphicsSuresh KumarNo ratings yet

- Program Program Type ProgramDocument3 pagesProgram Program Type Programpks009No ratings yet

- Resume Muhammad Ahsan FarooquiDocument1 pageResume Muhammad Ahsan FarooquiAhsan FarooquiNo ratings yet

- Fikru Gebre Dikumbab: Curriculum VitaeDocument3 pagesFikru Gebre Dikumbab: Curriculum VitaeFikru GebreNo ratings yet

- Cen-Tc135 Clarification of Scope of en 1090-1Document4 pagesCen-Tc135 Clarification of Scope of en 1090-1bollascribdNo ratings yet

- Roboethics: (Mechatronics - Robot.Robot Ethics)Document15 pagesRoboethics: (Mechatronics - Robot.Robot Ethics)Alfer FernandezNo ratings yet

- Flow Chart: Element Elastic Design, Uniform Sections (Rafter or Column)Document3 pagesFlow Chart: Element Elastic Design, Uniform Sections (Rafter or Column)Anonymous RrPSDPatRONo ratings yet

- M&E IntegrationDocument18 pagesM&E IntegrationAnonymous wTTx1LNo ratings yet

- Geotechnics For High Speed Corridors-GHC 2019: International Conference OnDocument7 pagesGeotechnics For High Speed Corridors-GHC 2019: International Conference Onu19n6735No ratings yet

- ConcreteCentre - EC2 Bridges ExtractDocument6 pagesConcreteCentre - EC2 Bridges Extractmrzap500713% (8)

- AF1 Equipo Unidad 5Document15 pagesAF1 Equipo Unidad 5Alejandro MartinezNo ratings yet

- UG B.ed. Education 70141 - Educational Technology 4262Document193 pagesUG B.ed. Education 70141 - Educational Technology 4262Jihad MahfoudNo ratings yet

- Damping Interareaand Torsional Oscillations Using Facts DevicesDocument268 pagesDamping Interareaand Torsional Oscillations Using Facts DevicesKrishna ReddyNo ratings yet

- Bose Institute, Kolkata Admission To Ph.D. Programme: Doctoral Research OpportunitiesDocument1 pageBose Institute, Kolkata Admission To Ph.D. Programme: Doctoral Research OpportunitiesSujoy SadhukhanNo ratings yet

- Full Download Solution Manual For Engineering Electromagnetics 9th Edition William Hayt John Buck PDF Full ChapterDocument35 pagesFull Download Solution Manual For Engineering Electromagnetics 9th Edition William Hayt John Buck PDF Full Chapterspunkycantingzcat100% (22)

- Timber 07Document11 pagesTimber 07Mohammed Safaa Al SarrafNo ratings yet

- MSS SP-97-2012Document21 pagesMSS SP-97-2012Marco CarrieriNo ratings yet

- BIM4Water Combined 2015-06-10Document64 pagesBIM4Water Combined 2015-06-10MayconAlvesNo ratings yet

- Dagmawi ReportDocument5 pagesDagmawi ReportHaben GirmayNo ratings yet

- 3bhs104785 Zab E01 Acs1000 1k STD Eg Icb MCB RevgDocument36 pages3bhs104785 Zab E01 Acs1000 1k STD Eg Icb MCB Revgyvan_huaman100% (1)

- MD NIYAZUDDIN Mechanical (MEP) BIM ModelerDocument2 pagesMD NIYAZUDDIN Mechanical (MEP) BIM ModelerKhalid Bin BreikNo ratings yet

- Priliminary Exam Paper CTDocument3 pagesPriliminary Exam Paper CTspatil1472No ratings yet

- 3 P 132 9301 1a3a N 04 - Rev01Document1 page3 P 132 9301 1a3a N 04 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- L27-38 GenSet TierIIDocument1,132 pagesL27-38 GenSet TierIIartemio CardosoNo ratings yet

7 Industrial Automation Boller

7 Industrial Automation Boller

Uploaded by

Debi Prasanna Jena0 ratings0% found this document useful (0 votes)

39 views9 pagesit is an imp material

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentit is an imp material

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

39 views9 pages7 Industrial Automation Boller

7 Industrial Automation Boller

Uploaded by

Debi Prasanna Jenait is an imp material

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 9

1

Automation and Drives

IEEE 1588 CONFERENCE 2004

Industrial automation requires

synchronization of line topology

Antonius Boller

Siemens AG, A&D PT 2, Nuremberg

Germany

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 2

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Fieldbus solution in Industrial Automation

Fieldbus solution

Ethernet

Fieldbus

Ethernet

Field level

Cell level

MES level

2

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 3

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Fieldbus Foundation H1

PROFIBUS, total

PROFIBUS PA

DeviceNet,

only Rockwell Automation

DeviceNet, total

CC-Link, total

Interbus, total

Installed fieldbus nodes

Time

1990 2000 2005

5 Mio

10 Mio

2002 2003 2004 1999 1994

Installed fieldbus nodes

Market

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 4

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Trends in

automation

Trend away from central

control structures to

distributed local units

Use of Ethernet

at all levels of

automation

Increase in use of open

IT standards in automation

IT- and automation world

are growing together

Technological trends in automation

3

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 5

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Conclusion of all market surveys:

Results of market surveys

Trends in

automation

ARC Advisory Group (2003)

Annual growth rate (2002-2007)

of 90% for Ethernet field devices

Frost & Sullivan (2002)

Market share of Ethernet in the

fieldbus market

2001: < 2,5% 2006: 14,2%

VDC, (Second Edition 2001)

Market share of Ethernet field devices

2000: 11,1% 2006: 26,4%

Conclusion of all market surveys:

Ethernet offers the best growth potential in the future

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 6

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

PROFINET opens up new markets through innovative technology

Installed field-

bus nodes

Time

1990

2000 2010

2003 2007

10 Mio

20 Mio

PROFIBUS and PROFINET (Ethernet)

Trends in

automation

4

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 7

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

A uniform network structure

Reduce the interfaces

Plant wide Engineering

Continuity through to the field level

Use the advantages of IT-techno-

logy in the production area

Remote Access

Web services

Software updates

Improvements relative to

todays systems

High performance

Unlimited quantities

Simple Handling

Benefits of Ethernet in an industrial

environment

Trends in

automation

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 8

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Office and

industrial networks

Plant-specific cable routing

with individual networking

structure

Star, ring and linear structures

Fixed basic installation

combined with variable

device interface

Star and tree structures

Differences between office and industrial

networks

BD BD

PMD PMD

FD

FD

CD

Machine 1 Machine 2

Floor 1

Floor 2

Office

Site

Production

Site

Floor

Distributor

Building

Distributor

Campus

Distributor

CD

PROFINET

Machine

Distributor

5

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 9

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Danger of chemical damaging due to oil

and aggressive environments

Insignificant chemical danger

Danger of mechanical damaging Insignificant mechanical danger

High EMC load Low EMC load

Vibrating machines No vibration loads

Moisture possible (IP65) No moisture

Extreme temperatures (from -20 to +70C) Moderate temperatures (from 0 to 50C)

Extremely high requirements Average requirements of availability

Small data packages (process values) Big data packages (e.g. pictures)

Often line structures

and/ or (redundant) ring structures

Tree network structure

Assembly of the connections in the field Pre-assembled connection cables

Connection points are rarely changed Variable connection of devices

Plant specific cabling routing Separate floor distribution boxes

Extreme plant specific cabling routing

Industry

Fixed basic installation in buildings

Office

Differences between office and industrial

networks

Office and

industrial networks

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 10

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Industrial Ethernet - topologies

Office and

industrial networks

Nutzen:

Line

Star

Ring

All topologies can be used

Ring structure guarantees high availability

Line minimizes the cabling overheads

Tree

Optimized network structures for cost savings

in all applications

6

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 11

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Requirements for

Ethernet in

automation

Requirements for Ethernet in Automation

Topology

All network topologies possible (star,tree, line, ring)

Redundancy

IT and Standard Functionality

Open for TCP/IP and IT applications

Unlimited network access for any devices

Real-Time

Real-time features for motion control

Maintain real-time features under any network situation

Interrupt-free redundancy

Technology

Use of future oriented switching technology

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 12

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Benefits of Switching Technology

Reason for use of end-to-end switching technology

State of the art in the world of communication

Prospects for further development

Prevent collisions

Transmit full duplex, parallel data exchange

Quality of service (prioritizing real-time messages)

Switch integration in the device

Simplify installation of devices

Minimizes the cabling

Device Device Device Device Device Device Device

Controller Controller

Requirements for

Ethernet in

automation

7

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 13

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Modular Machine Application Example

Backbone Backbone

PC HMI HMI HMI HMI HMI HMI HMI

MC MC MC MC MC MC MC MC MC

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Engineering

Motion Controller

with integrated

4-port switch

MC

Network

device

Drive with

integrated

2-port switch

Machine

module

Requirements for

Ethernet in

automation

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 14

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

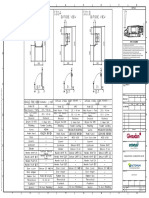

Cascade of switches in automation

Main line

Sub line

Requirements for motion control

Cascade up to 25 nodes

Cycle time < 1 ms

Jitter < 1 s

Clock

bridge

Sub line Sub line Sub line

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Clock

bridge

Requirements for

Ethernet in

automation

8

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 15

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Issues of 1588

Issues of 1588

1588 method for switches in a line

Cascade of Boundary Clocks (Switches)

Series connection of control loops

Synchronization frequency in seconds

Jitter accuracy > 1s for cascaded switches (with COTS.

oscillator)

Start up time up to several minutes

Boundary Clock (Switch) needs extensive software

Boundary

Clock

Boundary

Clock

Boundary

Clock

Boundary

Clock

Boundary

Clock

Boundary

Clock

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 16

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Synchronization requirements

Requirements for

synchronization in

automation

LZ12 LZ23 LZ34

T2 T3

Tx: Transfer time through switch x

Grand-Master

1 2 3 4

Jitter <1ss

LZxy: propagation time between

switch x and switch y

LZ45

5

Requirements for synchronization in automation

Simple and fast method

Robust and stable

Easy and cheap software implementation for every device

Possibility for hardware implementation

Jitter accuracy < 1 s for line topology

Permanent operation of active components

Redundancy aspects

9

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 17

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Compatibility with 1588

Requirements for

synchronization in

automation

Backbone with 1588

synchronized

automation network

with enhanced 1588

synchronized

automation network

with enhanced 1588

synchronized

automation network

with enhanced 1588

Requirements for compatibility

Compatible with 1588

Transparent for 1588

Seamless clock synchronization

Automation and Drives

PROFINET

IEEE 1588 conference 2004 A&D PT 2 M, 09/27/2004 18

Trends in

automation

Automation and Drives

Issues of 1588

Market

Fieldbus solution

Office and industrial

networks

Conclusion

Requirements for

Ethernet in

automation

Requirements for

synchronization in

automation

Conclusion

Conclusion

Requirements in automation

All network topologies (star,tree, line, ring)

Use of future oriented switching technology

Switch integration in the device

Real-time features for motion control

Interrupt-free redundancy

Easy and cheap implementation

Potential of 1588

1588 is a standard with high potential for automation

Solution for precise synchronization of line topology required

Consideration of devices with integrated switch are required

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASCE 7-16 Controversy PDFDocument1 pageASCE 7-16 Controversy PDFHyunkyoun JinNo ratings yet

- Creative Deviance: Bucking The Hierarchy: SummaryDocument2 pagesCreative Deviance: Bucking The Hierarchy: SummaryDebi Prasanna Jena0% (1)

- A Social Project ReportDocument5 pagesA Social Project ReportDebi Prasanna JenaNo ratings yet

- 03 Intrapersonal Variables For CommunicationDocument25 pages03 Intrapersonal Variables For CommunicationDebi Prasanna Jena0% (1)

- Debi Prasanna JenaDocument2 pagesDebi Prasanna JenaDebi Prasanna JenaNo ratings yet

- Design and Simulation of 4:1 MultiplexerDocument2 pagesDesign and Simulation of 4:1 MultiplexerDebi Prasanna JenaNo ratings yet

- S.No Description As Per Agreement Mbook Ref Qty As Per MbookDocument60 pagesS.No Description As Per Agreement Mbook Ref Qty As Per Mbookpwd2007No ratings yet

- Ce 163 - 1Document16 pagesCe 163 - 1hahaduNo ratings yet

- Rishabh Engineering ServicesDocument19 pagesRishabh Engineering ServicesmayankjainrfNo ratings yet

- My Latest Front PagesDocument7 pagesMy Latest Front PagesAbhishek PhutaneNo ratings yet

- Shop Drawing: Key PlanDocument1 pageShop Drawing: Key PlanEko WiyonoNo ratings yet

- Engineering GraphicsDocument2 pagesEngineering GraphicsSuresh KumarNo ratings yet

- Program Program Type ProgramDocument3 pagesProgram Program Type Programpks009No ratings yet

- Resume Muhammad Ahsan FarooquiDocument1 pageResume Muhammad Ahsan FarooquiAhsan FarooquiNo ratings yet

- Fikru Gebre Dikumbab: Curriculum VitaeDocument3 pagesFikru Gebre Dikumbab: Curriculum VitaeFikru GebreNo ratings yet

- Cen-Tc135 Clarification of Scope of en 1090-1Document4 pagesCen-Tc135 Clarification of Scope of en 1090-1bollascribdNo ratings yet

- Roboethics: (Mechatronics - Robot.Robot Ethics)Document15 pagesRoboethics: (Mechatronics - Robot.Robot Ethics)Alfer FernandezNo ratings yet

- Flow Chart: Element Elastic Design, Uniform Sections (Rafter or Column)Document3 pagesFlow Chart: Element Elastic Design, Uniform Sections (Rafter or Column)Anonymous RrPSDPatRONo ratings yet

- M&E IntegrationDocument18 pagesM&E IntegrationAnonymous wTTx1LNo ratings yet

- Geotechnics For High Speed Corridors-GHC 2019: International Conference OnDocument7 pagesGeotechnics For High Speed Corridors-GHC 2019: International Conference Onu19n6735No ratings yet

- ConcreteCentre - EC2 Bridges ExtractDocument6 pagesConcreteCentre - EC2 Bridges Extractmrzap500713% (8)

- AF1 Equipo Unidad 5Document15 pagesAF1 Equipo Unidad 5Alejandro MartinezNo ratings yet

- UG B.ed. Education 70141 - Educational Technology 4262Document193 pagesUG B.ed. Education 70141 - Educational Technology 4262Jihad MahfoudNo ratings yet

- Damping Interareaand Torsional Oscillations Using Facts DevicesDocument268 pagesDamping Interareaand Torsional Oscillations Using Facts DevicesKrishna ReddyNo ratings yet

- Bose Institute, Kolkata Admission To Ph.D. Programme: Doctoral Research OpportunitiesDocument1 pageBose Institute, Kolkata Admission To Ph.D. Programme: Doctoral Research OpportunitiesSujoy SadhukhanNo ratings yet

- Full Download Solution Manual For Engineering Electromagnetics 9th Edition William Hayt John Buck PDF Full ChapterDocument35 pagesFull Download Solution Manual For Engineering Electromagnetics 9th Edition William Hayt John Buck PDF Full Chapterspunkycantingzcat100% (22)

- Timber 07Document11 pagesTimber 07Mohammed Safaa Al SarrafNo ratings yet

- MSS SP-97-2012Document21 pagesMSS SP-97-2012Marco CarrieriNo ratings yet

- BIM4Water Combined 2015-06-10Document64 pagesBIM4Water Combined 2015-06-10MayconAlvesNo ratings yet

- Dagmawi ReportDocument5 pagesDagmawi ReportHaben GirmayNo ratings yet

- 3bhs104785 Zab E01 Acs1000 1k STD Eg Icb MCB RevgDocument36 pages3bhs104785 Zab E01 Acs1000 1k STD Eg Icb MCB Revgyvan_huaman100% (1)

- MD NIYAZUDDIN Mechanical (MEP) BIM ModelerDocument2 pagesMD NIYAZUDDIN Mechanical (MEP) BIM ModelerKhalid Bin BreikNo ratings yet

- Priliminary Exam Paper CTDocument3 pagesPriliminary Exam Paper CTspatil1472No ratings yet

- 3 P 132 9301 1a3a N 04 - Rev01Document1 page3 P 132 9301 1a3a N 04 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- L27-38 GenSet TierIIDocument1,132 pagesL27-38 GenSet TierIIartemio CardosoNo ratings yet