Professional Documents

Culture Documents

VX750

VX750

Uploaded by

TombongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VX750

VX750

Uploaded by

TombongCopyright:

Available Formats

MT VX750M/960M -10. 02.

1,000

HEAVY DUTY VERTICAL MACHINING CENTER

H

e

a

v

y

D

u

t

y

V

e

r

t

i

c

a

l

M

a

c

h

i

n

i

n

g

C

e

n

t

e

r

VX750M/960M VX750M/960M

Vertical Machining Center

High-Rigidity & Heavy duty cutting Vertical Machining Center

3 2

VX750M/960M

New Face in Mold Machining Field

High precision Vertical Machining Center for the Heavy duty cutting, as well

as the mold cutting with extremely minimized vibration from the spindle side

with the high performance and rigid mechanism, and the powerful strong

geared spindle head.

VX750M VX960M ITEM

Table Size mm(in)

Travel(X/Y/Z) mm(in)

Spindle RPM rpm

Spindle Power kW(HP)

Max.Load on the Table kg(lb)

1,800x700(70.9x27.6) 2,700950(106.337.4)

1,550/750/720(61/29.5/28.3) 2,450/960/850(96.4/37.8/33.4)

4,500[8,000][12,000] 8,000[12,000]

18.5/15(25/20)[30/25(40/33.5)] 22/18.5(30/25)[30/25(40/33.5)]

2,000(4,409) 4,500(9,921)

[ ] : Option

World Top Class Quality

HYUNDAI WIA Machine Tools

Vertical Machining Center VX750M/960M

Speed & Power

5 4

VX960M

High Precision, High Rigidity

High-Power & Heavy Duty Cutting

Spindle Construction

VX750M/960M VX750M/960M (Option)

4,500rpm, 18.5/15kW

4,500rpm, 22/18.5kW

8,000rpm, 18.5/15kW

8,000rpm, 22/18.5kW

12,000rpm, 30/25kW

ITEM VX750M VX960M

Standard Option

High Quality Capability & Productivity

VX750M/960M

Spindle Power

18.5/15kW (25/20HP) : VX750M

22/18.5kW (30/25HP) : VX960M

[30/25kW(Built-in Motor) : Option]

Tool Capacity

20EA [30 EA : Option]

Tool Change Time

T .T : 3.5 sec C.C : 10sec

Max. Tool Size x Weight

125300mm20kg

[4.911.844lb]

Spindle Power-Torque Diagram

High- Precision and Rigid Construction

Has been achieved by adopting the nitrogen GAS balancer technique to prevent the vibration

from the vertical movement.

Renovate a structure of Y-axis from 2-way restraint surface to 4-way restraint sur-face to

increase high precision and high rigidity

2 Steps-Geared spindle

High Speed Built-In Spindle [Option]

Big plus spindle allows the spindle can have the same advantage that

only the expensive dual contact / restraint tool can have.[Option]

-VX960M (BT#50) -Built-In Motor Spindle

High-power Generating Spindle Construction for Heavy Duty Cutting

Two auger type chip disposer, unlikely

gravity disposer, it is the best way to

dispose especially heavy chips efficiently.

(all auger conveyors adopted as a standard)

Operators unnecessary movement can

be reduced by the centralized control

panel and the standard remote MPG.

Accuracy

Vertical Machining Center VX750M/960M

Example of Mold process

High speed RISC processor Technology

was adopted to make sure the best travels

of all axes which eventually lead high

precision and best quality products.

Get a feed speed under control not to over an allowable

acceleration speed by managing a feed speed through auto-

recognition of a curved surface

Multi Buffering with Max. 200 Block

Provide a High speed & precise machining without any damage

or servo delay during machining of micro area of a curved

surface by dividing it in a bee-line

High Precision Contour Control(option)

Top Grade Tool Change Time

7 6

Heavy Duty Cutting by

High-Rigid & Accurate Mechanism

The hi gh preci si on CAM compound

enables the machine to have top grade,

the quickest tool change time in its class.

Each axes are designed with large

diameter ball screws, to provide high

rigidity and minimize thermal distortion.

Air boost slide can greatly reduce

friction way, improve the endurance

and ensure the accuracy.

High-pretension Double Anchor Ball Screw

AIR Lift Slide Method

X Axis : VX750M

X/YAxis : VX960M

[

30EA (option)

20EA (standard)

Centralized Control Panel &

3-MPG Handles for 3Axes

Excellent Chip &

Coolant Disposal

VX750M

VX960M

2,700950 (106.337.4)

4,500 (9,921)

2,450 (96.4)

960 (37.8)

850 (33.4)

200~1,050 (7.9~ 41.3)

1,000 (39.4)

8,000 (12,000)

22/18.5 [30/25] (30/25 [40/33.5])

79.7/67 [42.9/24.3]

(576.5/484.6 [310.3/175.8])

16/16/20 (630/630/787)

850 (224.5)

40 (45)

6,1004,425 (240.2174.2)

3,600 (141.7)

22,000 (48,501)

( ) : Option Machine specifications are subject to change without notice.

9 8

Table Size

Maximum Load Capacity

X Axis

Y Axis

Z Axis

Distance from Table Surface to Sp

Distance from Column to SP. center

Spindle Taper

Spindle RPM

Spindle Power Output (Max./Cont.)

Spindle Torque (Max./Cont.)

Spindle Driving Method

Cutting Feed Rate (X/Y/Z)

Rapid Feed Rate (X/Y/Z)

Number of Tools

Max. Tool Dia.(W/T Adjacent Tool / W/O Adjacent Tool)

Max. Tool Length

Max. Tool Weight

Tool Selection Method

Tool Change Time (T-T/C-C)

Tank Capacity

Hydraulic Tank Capacity

Air Consumption (5kgf/cm2)

Required Power Capacity (220V/60Hz)

Floor Plan (LW)

Machine Height

Machine Weight

Memory Capacity

CNC

mm(in)

kg(lb)

mm(in)

mm(in)

mm(in)

mm(in)

mm(in)

NT

rpm

kW(HP)

kgf.m(lbf.ft)

-

mm/min(ipm)

m/min(ipm)

EA

mm(in)

mm(in)

kg(lb)

-

sec

(Gal)

(Gal)

/min(gal/min)

KVA

mm(in)

mm(in)

kg(lb)

m

-

VX750M VX960M

Specification

Vertical Machining Center VX750M/960M

Table Dimension

Tool Shank

Table Dimension

VX750M VX960M

unit : mm(in)

unit : mm(in)

unit : mm(in)

Specifications

ITEM

TABLE

FEED

SPINDLE

FEED RATE

ATC

COOLANT

POWER

SOURCE

MACHINE

SIZE

CONTROLLER

SPINDLE COOLING UNIT

FLOOD COOLANT

SYSTEM

SEMI-CLOSED SPLASH

GUARD

HAND TOOLS & BOX

LEVELING PAD & BOLTS

INTERNAL SCREW

CONVEYOR

WORK LIGHT

CALL LIGHT(YELLOW)

SPINDLE OVERRIDE

AIR LIFT SLIDING

SYSTEM

REMOTE MPG

CHIP AIR BLOW

DOOR INTER-LOCK

GUN COOLANT

OIL SKIMMER

OIL MIST

TOOL BROKEN DETECTION

DEVICE

TOOL LENGTH MEASURING

DEVICE

WORK COUNTER

SPINDLE RPM METER

SPINDLE LOAD MATER

CIRCUIT BREAKER

CALL LIGHT(3 COLORS)

CHIP CONVEYOR(LEFT)

LINEAR SCALE

BUZZER FOR CYCLE END

AUTO POWER OFF DEVICE

FIXTURE & TOOLS

TOTAL SPLASH GUARD

SPINDLE THRU COOLANT

SPINDLE HEAT CEUPEN SATION

DEVICE

MPG FOR 3 AXES CONTROL

OPTION STANDARD

1,800700 (70.927.6) 2,700950 (106.337.4)

2,000 (4,409) 4,500 (9,921)

1,550 (61) 2,450 (96.4)

750 (29.5) 960 (37.8)

720 (28.3) 850 (33.4)

200~920 (7.9~ 36.2) 200~1,050 (7.9~ 41.3)

790 (31.1) 1,000 (39.4)

BT#50 [CAT#50,BBT#50]

4,500 [8,000 , 12,000] 8,000 [12,000]

18.5/15 (25/20) [22/18.5 , 30/25 (30/25 , 40/33.5)] 22/18.5 (30/25) [30/25 (40/33.5)]

91.12/74.69 (659.1/540.2) 79.7/67 (576.5/484.6)

[79.7/67, 42.9/24.3 (576.5/484.6, 310.3/175.8)] [42.9/24.3] (310.3/175.8)]

2 Steps Gear [Built-In (2 Steps)]

10 (394)

16/16/12 (630/630/472) 16/16/20 (630/630/787)

20 [30]

125/240 (4.9/9.5)

300 (11.8)

20 (44.1)

Memory Random

3.5/10.0

470 (124.2) 850(224.5)

(13 : Built-in Spindle)

250 (66.04)

35[40] 40[45]

4,0403,830 (240.2174.2) 6,1004,425(159.1150.8)

3,475 (136.8) 3,600 (141.7)

13,000 (28,660) 22,000 (48,501)

320

FANUC 18i-MB

1O18(4)

2545

(OO98)

(OO59)

1

O

O

O

(3

9

3

)

6

9

8

5

(2

7

5

)

8

O

O

(3

1

5

)

15

6 (O236)

CAT50

PULL STUD

BBT50

PULL STUD

BT50

PULL STUD

1O18(4)

2545

(OO98)

(OO59)

1

O

O

O

(3

9

3

)

6

9

8

5

(2

7

5

)

8

O

O

(3

1

5

)

15

6

(O

2

3

6

)

Specification

11 10

Vertical Machining Center VX750M/960M

FANUC 18i-MB

Controller

Controller

Controlled axes

Simultaneous

controllable axes

Least input increment

Least command increment

Inch / metric conversion

Interlock

Machine lock

Emergency stop

Stored stroke check 1

Mirror image

Follow-up

Servo off

Backlash compensation

Position switch

Stored pitch error

compensation

LCD/MDI

Automatic operation (memory)

MDI operation

Search function

Programrestart

Dry run

Single block

Buffer register

Manual jog feed

Manual handle feed rate

Feed command

Feedrate override

Jog feed

Rapid traverse override

Override cancel

Rapid traverse bell-shaped

acceleration/deceleration

Label skip

Control in/out

Interpolation functions

Exact stop mode / Exact stop

Dwell

Helical interpolation

4 (X, Y, Z, B) axes

3 axes (G00 & G01 : 3 axes,

G02 & G03 : 2 axes)

0.001 mm(0.0001)/1 deg

0.001 mm(0.0001)/1 deg

G20 / G21

Each axis / All axes

All axes

Over-travel

+/- 0~9999 pulse

(rapid traverse & cutting feed)

10.4color LCD

Sequence, program

Rapid, jog, handle

x1, x10 , x100

F code feedrate direct command

0~200%(10%unit)

0~5,000 mm/min (197 ipm)

F0, F25%, F50%, F100%

Positioning/Linear/Circular

(G00/G01/G02/G03)

G61 / G09

G04, 0~9999.9999sec

Programinput & Interpolation functions

Figures in inch are converted from metric values.

Design and specifications subject to change without notice.

10 Mbps

320 m(128Kbyte)

125 ea

Copy, move, change of NC program

Alarm& operator message

Screen saver

#500 to #999

G60

100 Mbps

9 ea (Application can be limited)

3 unit

640 m(256 Kbyte) / 1280 m(512 Kbyte)

KDNC (S/W)

G28

G27

G30

M00, M01 / M02, M30

EIA RS-244 / ISO 840

(Automatic recognition)

1 ea

+/- 9999.9999(+/- 8 digits)

O4 digit

G90 / G91

G17, G18, G19

G52~G59

48 pairs

ONfixed

G10

4 levels of nesting

#100 to #199

G73, G74, G76, G80 ~ G89

G31

M2 digits

S5 digits, binary output

50%~ 120%(10%unit)

Max. T8 digits

G40~G42

G43, G44, G49

+/- 6 digits

99 pairs

RS232C

Threading/synchronous feed

Manual reference point return

1st Reference point return

Reference point return check

2nd Reference point return

Programstop/end

Tape code

Optional block skip

Maximumprogrammable

dimensions

Programnumber

Absolute and incremental command

Decimal point input

Plane selection

Work coordinate systemsetting

Additional work coordinate system

Manual absolute

Programmable data input

Sub programcall

Custommacro B

Circular interpolation by radius R

Canned cycle

Optional chamfering/corner R

Skip function

Automatic coordinate

systemsetting

Coordinate systemrotation

Programmable mirror image

Miscellaneous function

Miscellaneous function lock

Spindle speed command

Spindle speed override

Spindle orientation

Rigid tapping

Tool function

Cutter compensation C

Tool length compensation

Tool offset amount

Tool offset pairs

Tool life management

Reader/Puncher interface

Memory card input/output

Embedded ethernet

Part programstorage length

Registered programs

Memory lock

Back ground editing

Extended part programediting

External message

Self-diagnosis function

History display

Help function

Run hour / Parts count display

Actual cutting feedrate display

Graphic display

Spindle / Servo setting screen

Multi-language display

Erase CRT screen display

Additional 1 axis

Addition to custommacro

common variables

Polar coordinate command /

interpolation

Cylindrical interpolation

Single direction positioning

Tool length measurement

External data input

Remote buffer

Ethernet

Data server

Ai contour control (AICC)

Ai nano contour control

(AI nano CC)

Ai high precision contour

control (AI HPCC)

Ai nano hpcc

Manual Guide i

Optional block skip add

Handle interrupt

Manual handle feed

Part programstorage

Dynamic graphic display

DNC operation

Axis control / Display unit

Operation

Feed functions

Programinput & Interpolation functions

Tool functions / Tool compensation

Data input/output & Editing functions

Auxiliary / Spindle functions

Data input/output & Editing functions

Setting, display, diagnosis

Option

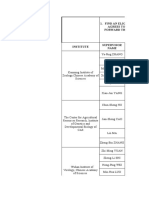

Namsan Plant Jungdong Plant Banwol Plant Gwangju Plant

FA Plant Head Office Posung Plant Seosan Plant China Plant

Head Office & Factory

391-8 Kaumjung-Dong, Changwon, Gyeongnam, Korea

TEL : +82 55 280 9114, FAX : +82 55 282 9680

http : //www.hyundai-wia.com, E-mail : trade@hyundai-wia.com

Seoul Office

10th Floor Landmark Tower 837-36, Yeoksam Dong,

Gangnam-Gu, Seoul, Korea

TEL : +82 2 2112 8451, FAX : +82 2 2112 8400

HYUNDAI-KIAAMERICA CORP.

30 Murray Hill Parkway, Suite 300. East Ruthergord, NJ 07073 U.S.A.

TEL : +1 201 489 2887 FAX : +1 201 489 2723

http ://www.hyundai-kiamachine.com

E-mail : sales@hyundai-kiamachine.com

CHICAGO OFFICE

751 Landmeier Rd. Elk Grove Village, IL 60007 U.S.A.

TEL : +1 847 640 8870(#201) FAX : +1 847 640 8701

http ://www.hyundai-kiamachine.com

E-mail : sales@hyundai-kiamachine.com

L.A OFFICE

11155 Knott Ave, Suit F, Cypress, CA 90630 U.S.A

TEL : +1 714 373 5480 FAX : +1 714 373 5485

http ://www.hyundai-kiamachine.com

E-mail : sales@hyundai-kiamachine.com

ARGENTINA OFFICE

AV, Alicia Moreau de Justo 1848 of 4-6 Puerto Madero(C1107AFL).

Buenos Aires, Argentina

TEL : +54 11 4313 1917 FAX : +54 11 4313 1929

http ://www.hyundai-kiamachine.com

E-mail : sales@hyundai-kiamachine.com

HYUNDAI-KIA EUROPE GMBH

Kaiserleipromenade 5, D-63067 Offenbach,Germany

TEL : +49 69 271 472700 FAX : +49 69 271 472719

http ://www.hyundai-kia.de

E-mail : sales@hyundai-kia.de

RAUNHEIM SERVICE CENTER

Kelsterbacher Str. 38-46 D-65479 Raunheim, Germany

TEL : +49 6142 834 0 FAX : +49 6142 834 100

http ://www.hyundai-kia.de

E-mail : service@hyundai-kia.de

CHINA BEIGING OFFICE

Room 908 No. 38 Xiaoyun Road, Chaoyang District, Beijing China 100027

TEL : +86 10 8453 9850~2 FAX : +86 10 8453 9853

E-mail : sangho@hyundai-wia.com

SANGHAI OFFICE

Room 501 Ocular B/D, No.1366 Wu Zhong Road, 201103 Shanghai, Chian

TEL : +86 21 3431 0370~2 FAX : +86 21 3431 0376

E-mail : ymlee@hyundai-wia.com

GUANGZHOU OFFICE

Room 906, International Finance Place, No.8 Huaxia Road, Pearl River New

Town, Tianhe District, Guangzhou, China, 510623

TEL : +86 20 8550 6595~6 FAX : +86 20 8550 6597

E-mail : iclee@hyundai-wia.com

CHENGDU OFFICE

Room 2103, Block A, Times Plaza, Zongfu Road, Chengdu, China 610016

TEL : +86 28 8665 5550 FAX : +86 28 8665 2985

E-mail : nlee@hyundai-wia.com

WUHAN OFFICE

Room 43-05, New World International Trade Building(Wuhan) No.568 Jianshe

Avenue, Jianghan District, Hankou, Wuhan, Hubei 430022

TEL : +86 - 27 - 5952- 3256~7 FAX : +86 - 27 - 5952 - 3258

E-mail : bhyun@hyundai-wia.com

QINGDAO OFFICE

Room 1207, Zhaoyin Building, 36 Hongkong Middle Road, Qungdao,

shandong 266071, China

TEL : +86 - 532 - 8667-9333~5 FAX : +86 - 532 - 8667-9338

E-mail : parkpal@hyundai-wia.com

INDIA INDIA OFFICE

6B, EGA Trade Center, 809 Poonamallee High Load, Kilpauk,

Chennai - 600 010. Tamilnadu, India

TEL : +91 44 4305 7112 FAX : +91 44 4305 7116

E-mail : bikehyk@hyundai-wia.com

Specifications are subject to change for improvement without notice.

You might also like

- Installation of Artisman CNC RouterDocument39 pagesInstallation of Artisman CNC RouterSamuel MarquezNo ratings yet

- Boomer L2 D - Technical SpecificationDocument4 pagesBoomer L2 D - Technical SpecificationKickbutowski KiNo ratings yet

- 100 RDDocument4 pages100 RDMahmoud EldabahNo ratings yet

- Rotaclip PlanosDocument121 pagesRotaclip PlanosEnrique Martinez RojasNo ratings yet

- RM6 Series (9426)Document140 pagesRM6 Series (9426)Pur WantoNo ratings yet

- SMC Air Cylinder CatalogDocument31 pagesSMC Air Cylinder Catalogmon012100% (1)

- JCB 8025-8035Document8 pagesJCB 8025-8035SC Colosseum Print SRL100% (1)

- 118 - Puma 240Document24 pages118 - Puma 240TombongNo ratings yet

- Huanyang InverterDocument1 pageHuanyang InverterTombongNo ratings yet

- Hmaxseries DRDSFSDDocument6 pagesHmaxseries DRDSFSDMarius UrzicăNo ratings yet

- Tongil Gu SeriesDocument3 pagesTongil Gu Seriesmatthew_k_kohNo ratings yet

- TLD56 1325 Vacuum Table - CNC Router MachineDocument1 pageTLD56 1325 Vacuum Table - CNC Router MachineBroe CasNo ratings yet

- M-172SJT/203SJT: Computerized Flat Knitting MachineDocument67 pagesM-172SJT/203SJT: Computerized Flat Knitting MachineAmira's Clothes100% (1)

- 2 SK 3476Document5 pages2 SK 3476Bravo KiloNo ratings yet

- Cat 320d LRRDocument28 pagesCat 320d LRRt1meNo ratings yet

- HC Cone Crusher: Main FeaturesDocument3 pagesHC Cone Crusher: Main FeaturesDian WangNo ratings yet

- Elektrim Techtop CatalogueDocument20 pagesElektrim Techtop CatalogueCao Trang PhamNo ratings yet

- 5phaseinterface Lead With Electrical IsolationDocument40 pages5phaseinterface Lead With Electrical IsolationsiromexNo ratings yet

- Cat Rope ShowelDocument2 pagesCat Rope ShowelGanapati HegdeNo ratings yet

- Specification - MechanicalDocument5 pagesSpecification - MechanicalEDEN FALCONINo ratings yet

- Prcat Toleranceandconversiontables PDFDocument19 pagesPrcat Toleranceandconversiontables PDFeko wahyudiNo ratings yet

- Komatsu Wheel Loader WA100-3 - SpecificationDocument3 pagesKomatsu Wheel Loader WA100-3 - SpecificationAdicandra46No ratings yet

- Wistron Dasher 1 - Thinkpad X220 SchematicsDocument101 pagesWistron Dasher 1 - Thinkpad X220 Schematicsnroach44No ratings yet

- Brosur Loader CaterpillarDocument4 pagesBrosur Loader CaterpillarWildan KurniaNo ratings yet

- BB N BB N EsDocument22 pagesBB N BB N EsZira FitriNo ratings yet

- Tire RollerDocument1 pageTire RollerKresna Andrew100% (1)

- 1004Tg1 1000 Series: Diesel Engine - ElectropakDocument2 pages1004Tg1 1000 Series: Diesel Engine - ElectropakRobertIsaiRuizAcostaNo ratings yet

- Rubber Block Flexible Coupling: IntroductionDocument2 pagesRubber Block Flexible Coupling: IntroductionjonnelNo ratings yet

- DC VoltmeterDocument10 pagesDC VoltmeterGokul SubramaniNo ratings yet

- DustBoss ManualDocument33 pagesDustBoss ManualMichael Huffman100% (1)

- NAK80 MaterialDocument3 pagesNAK80 MaterialRicky Indra DjunawanNo ratings yet

- Inventor Project Dynamic Simulation Guide enDocument17 pagesInventor Project Dynamic Simulation Guide enheveton777No ratings yet

- 07 Ermaksan - HGS01Document1 page07 Ermaksan - HGS01Copia DemimNo ratings yet

- Toshiba Inverter VFS9 Instr D301Document209 pagesToshiba Inverter VFS9 Instr D301Kostas Athanasiadis100% (1)

- Sem 636DDocument2 pagesSem 636DVinoth KumarNo ratings yet

- QXR 1320 Specification Completed March 26 2010Document3 pagesQXR 1320 Specification Completed March 26 2010death666dark100% (1)

- RS-WZ3WZ1-N01-1 Operation Manual of Temperature Vibration Transmitter (RS485Type)Document14 pagesRS-WZ3WZ1-N01-1 Operation Manual of Temperature Vibration Transmitter (RS485Type)Vendas BPSNo ratings yet

- Metasol Susol ACB Technical 201210 PDFDocument156 pagesMetasol Susol ACB Technical 201210 PDFHoang GiangNo ratings yet

- Manual CONDOR 2A - InglêsDocument35 pagesManual CONDOR 2A - InglêsPetrus Josue ValcanaiaNo ratings yet

- Harga Panel AMFDocument4 pagesHarga Panel AMFBobby Underscore TanggerNo ratings yet

- Pioneer Avh-P3100dvd p3150dvd SMDocument190 pagesPioneer Avh-P3100dvd p3150dvd SMRogerio E. SantoNo ratings yet

- Katalog MaktecDocument12 pagesKatalog MaktecAsdar AsdarNo ratings yet

- Box Speaker 15 Inch LapanganDocument3 pagesBox Speaker 15 Inch LapanganWilli Je WilliamNo ratings yet

- XS85 To XS145 Specs - March 2011-4Document8 pagesXS85 To XS145 Specs - March 2011-4lucioleo1975No ratings yet

- Manual AutonicsDocument205 pagesManual Autonicsfey_tunerNo ratings yet

- Linuxcnc GcodeDocument1 pageLinuxcnc Gcodekk_kamalakkannanNo ratings yet

- JFE HitenDocument19 pagesJFE HitenPandu PhintaruNo ratings yet

- Opening, Dosing and Sorting Systems, Mixing and Conditioning Units, Stationary ShreddersDocument43 pagesOpening, Dosing and Sorting Systems, Mixing and Conditioning Units, Stationary ShreddersAhmed AbdulnaimNo ratings yet

- K3HB - VLC 100-240vacDocument15 pagesK3HB - VLC 100-240vacSatya Narayana VarmaNo ratings yet

- 16838244474Document2 pages16838244474bahaoubaidaNo ratings yet

- TD20830201 D1272AT Indicator enDocument4 pagesTD20830201 D1272AT Indicator enIgor TomanNo ratings yet

- GE Bently Nevada PDFDocument31 pagesGE Bently Nevada PDFAhmad FuadNo ratings yet

- TecData SR SRM SRHDocument1 pageTecData SR SRM SRHAir Repair, LLCNo ratings yet

- LT9Document3 pagesLT9Aradea DesmiokoNo ratings yet

- 2 - Fast Installation manual-mill-TAC2000MDocument16 pages2 - Fast Installation manual-mill-TAC2000MartZara 12No ratings yet

- Current Location Home - SAE 100 R2AT/ EN 853 2SNDocument1 pageCurrent Location Home - SAE 100 R2AT/ EN 853 2SNBoris Felipe Barcelos RibeiroNo ratings yet

- Waiting PR Transmisi ScaniaDocument4 pagesWaiting PR Transmisi ScaniaADITIYANo ratings yet

- YCM NT SeriesDocument6 pagesYCM NT SeriesCNC SYSTEMSNo ratings yet

- NVX5000Document16 pagesNVX5000Solomon NicuNo ratings yet

- XV1020A MXP100iB PDFDocument8 pagesXV1020A MXP100iB PDFbreaker1999No ratings yet

- First MCV 300 Katalogu 318Document6 pagesFirst MCV 300 Katalogu 318Stoian ValentinNo ratings yet

- Bolt MaterialDocument817 pagesBolt MaterialTombongNo ratings yet

- COM - Doosan TX Series Servo Drive Operation Manual (Rev B01) - 131204Document92 pagesCOM - Doosan TX Series Servo Drive Operation Manual (Rev B01) - 131204Tombong100% (1)

- 09 Mo1517Document2 pages09 Mo1517TombongNo ratings yet

- Casinghardware Saga Trade Product RDocument37 pagesCasinghardware Saga Trade Product RTombongNo ratings yet

- 国勤 第三轨 cataluge third railDocument12 pages国勤 第三轨 cataluge third railPour RezNo ratings yet

- Engineering StructuresDocument67 pagesEngineering StructuresMwangi MuraguriNo ratings yet

- Textbook Proceedings of The Second International Conference On Mechatronics and Automatic Control 1St Edition Wego Wang Eds Ebook All Chapter PDFDocument54 pagesTextbook Proceedings of The Second International Conference On Mechatronics and Automatic Control 1St Edition Wego Wang Eds Ebook All Chapter PDFalbert.milburn935100% (7)

- BRICS Business Session ProgrammeDocument15 pagesBRICS Business Session ProgrammeJosé EstevesNo ratings yet

- Wuhan University Booklet - FINAL - 011819Document31 pagesWuhan University Booklet - FINAL - 011819napinnvoNo ratings yet

- Practical Design of Ships and Other Floating Structures Vol 2Document646 pagesPractical Design of Ships and Other Floating Structures Vol 2VOKRAMNo ratings yet

- Global and China CNC Machine Tool ReportDocument2 pagesGlobal and China CNC Machine Tool ReportIves LeeNo ratings yet

- PDF The 8Th International Conference On Computer Engineering and Networks Cenet2018 Qi Liu Ebook Full ChapterDocument53 pagesPDF The 8Th International Conference On Computer Engineering and Networks Cenet2018 Qi Liu Ebook Full Chapterglenn.simmons577100% (1)

- La Trobe University Sydney Campus Agent ListDocument19 pagesLa Trobe University Sydney Campus Agent ListfdfddfNo ratings yet

- vx400 500 650 - v1 (En)Document8 pagesvx400 500 650 - v1 (En)deisonlrfNo ratings yet

- 3.TQSX De-StonerDocument11 pages3.TQSX De-StonerCrhistian MadrigalNo ratings yet

- Developments and Prospects of Long Span High Speed Railway Bridge Technologies in China PDFDocument8 pagesDevelopments and Prospects of Long Span High Speed Railway Bridge Technologies in China PDFIndra MishraNo ratings yet

- Invited Name ListDocument10 pagesInvited Name Listapi-3767913No ratings yet

- CUG-Handbook For New International Students (2020)Document18 pagesCUG-Handbook For New International Students (2020)Ghulam MurtazaNo ratings yet

- Master Data - UniversityDocument417 pagesMaster Data - UniversityAshton FNo ratings yet

- List of Chinese Supervisors 2023Document23 pagesList of Chinese Supervisors 2023arooj kainatNo ratings yet

- Art Integrated Test Class 4 Anita Pandey (Responses)Document4 pagesArt Integrated Test Class 4 Anita Pandey (Responses)Anita PandeyNo ratings yet

- ChinaDocument42 pagesChinasalimbabliNo ratings yet

- 10 Sajorec+Supervisor Info+Scholarship+Master Degree ProgramDocument12 pages10 Sajorec+Supervisor Info+Scholarship+Master Degree ProgramGetinet SeidNo ratings yet

- Ooitech Solar Panel Production Line Solution BriefDocument6 pagesOoitech Solar Panel Production Line Solution BriefINDIA LINERNo ratings yet

- 2017 Tech Fast500 Apac Ranking ReportDocument13 pages2017 Tech Fast500 Apac Ranking ReportLisa GridnevaNo ratings yet

- Semi-Automatic 1600AT 4 in 1 Aerosol Filling Machine-JrpackingDocument8 pagesSemi-Automatic 1600AT 4 in 1 Aerosol Filling Machine-JrpackingHuzaifa Muneer Khan MuhammadNo ratings yet

- DocumentDocument25 pagesDocumentilyas muhammadNo ratings yet

- k8262 Traffic Management in Wuhan China CsDocument17 pagesk8262 Traffic Management in Wuhan China CsAlwin SebastianNo ratings yet

- Advances in Graphic Communication, Printing and Packaging: Proceedings of 2018 9th China Academic Conference On Printing and Packaging Pengfei ZhaoDocument54 pagesAdvances in Graphic Communication, Printing and Packaging: Proceedings of 2018 9th China Academic Conference On Printing and Packaging Pengfei Zhaolorna.rayfield998100% (6)

- Siemens A&D Training Course List From Oct.2007 To Sept.2008)Document10 pagesSiemens A&D Training Course List From Oct.2007 To Sept.2008)serkalemtNo ratings yet

- China 2016 Training Courses PDFDocument10 pagesChina 2016 Training Courses PDFArdila YanantoNo ratings yet

- Real Estate Investments in China and India: Big Returns in Big Countries?Document23 pagesReal Estate Investments in China and India: Big Returns in Big Countries?Chirag MoriNo ratings yet

- 1000w Fiber Laser Cutting Machine For Sheet and TubeDocument3 pages1000w Fiber Laser Cutting Machine For Sheet and TubeJustas SRNo ratings yet

- LWF1000 - Technical Proposal-HGTECHDocument6 pagesLWF1000 - Technical Proposal-HGTECHSagar KumarNo ratings yet