Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

23 viewsDETAIL Version 10

DETAIL Version 10

Uploaded by

Sunny Singhbest

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5833)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KPC Piping SpecDocument111 pagesKPC Piping Specinfo_shakib100% (1)

- 17DS04 BRENEMAN Structural CLT Floor and Roof Design WSF 171004 PDFDocument58 pages17DS04 BRENEMAN Structural CLT Floor and Roof Design WSF 171004 PDFRicardo Melendez AlvarezNo ratings yet

- Case Study: Self-Leveling Floor Coating of Hippokrates Hospital-AthensDocument1 pageCase Study: Self-Leveling Floor Coating of Hippokrates Hospital-AthensSunny SinghNo ratings yet

- Chennai ListDocument13 pagesChennai Listkinanantha0% (1)

- Balcony BroshureDocument1 pageBalcony BroshureSunny SinghNo ratings yet

- Marine Products BroshureDocument1 pageMarine Products BroshureSunny SinghNo ratings yet

- Mariseal SYSTEM Car Deck Waterproofing A Roof Coating To Waterproof A Road With Vehicular TrafficDocument1 pageMariseal SYSTEM Car Deck Waterproofing A Roof Coating To Waterproof A Road With Vehicular TrafficSunny SinghNo ratings yet

- Floor BroshureDocument1 pageFloor BroshureSunny SinghNo ratings yet

- Freezer Broshure ENGDocument1 pageFreezer Broshure ENGSunny SinghNo ratings yet

- Mariseal SYSTEM: Under-Tile Polyurethane Waterproofing The Terrace Waterproofing SystemDocument1 pageMariseal SYSTEM: Under-Tile Polyurethane Waterproofing The Terrace Waterproofing SystemSunny SinghNo ratings yet

- 2color Roof BroshureDocument1 page2color Roof BroshureSunny SinghNo ratings yet

- Walkway BroshureDocument1 pageWalkway BroshureSunny SinghNo ratings yet

- Stamped Concrete BroshureDocument1 pageStamped Concrete BroshureSunny SinghNo ratings yet

- Maricoat 2000: Polyurethane Self-Leveling Floor CoatingDocument2 pagesMaricoat 2000: Polyurethane Self-Leveling Floor CoatingSunny SinghNo ratings yet

- Panel Adhesive BroshureDocument1 pagePanel Adhesive BroshureSunny SinghNo ratings yet

- Mariseal System The Polyurethane Coating To Protect Polyurethane FoamDocument1 pageMariseal System The Polyurethane Coating To Protect Polyurethane FoamSunny SinghNo ratings yet

- Mariseal 270 Version 10Document2 pagesMariseal 270 Version 10Sunny SinghNo ratings yet

- Filter Resins BroshureDocument1 pageFilter Resins BroshureSunny SinghNo ratings yet

- Mariseal 700 Version 10Document2 pagesMariseal 700 Version 10Sunny SinghNo ratings yet

- Pipe Refresher CourseDocument5 pagesPipe Refresher CourseBanilo BanilaNo ratings yet

- Joints in Wood Structures 2015 PDFDocument33 pagesJoints in Wood Structures 2015 PDFTucara3000No ratings yet

- FBES 01 Book-The-Steel-Book V07.01.0818 WEBDocument116 pagesFBES 01 Book-The-Steel-Book V07.01.0818 WEBrenandNo ratings yet

- Instrument Tube Fitting Instalation Manual PDFDocument76 pagesInstrument Tube Fitting Instalation Manual PDFjhonny sanchezNo ratings yet

- FMDS0707 Semiconductor FacliliDocument56 pagesFMDS0707 Semiconductor Faclilidaniela hritucNo ratings yet

- FyzMat I 3 DislocationsDocument93 pagesFyzMat I 3 DislocationsCesar Vargas ArayaNo ratings yet

- Adsyl 7423 XCP: Lyondellbasell IndustriesDocument4 pagesAdsyl 7423 XCP: Lyondellbasell Industriesnouman ashrafNo ratings yet

- P1 Istc HT Ar 00001 - R01 PDFDocument7 pagesP1 Istc HT Ar 00001 - R01 PDFcarlomaderazoNo ratings yet

- Draft F02 F06 - WKL Weekly Report 27122022 Rev00Document13 pagesDraft F02 F06 - WKL Weekly Report 27122022 Rev00azwanawalludin247No ratings yet

- Product Data Sheet: DimensionalDocument1 pageProduct Data Sheet: DimensionalIvanNo ratings yet

- FIG. 1 Rectangular Tension Test SpecimensDocument1 pageFIG. 1 Rectangular Tension Test SpecimensAlvaro Alexis Mendoza PradaNo ratings yet

- 214-1197 - EM RD LD 214-1101N - Ld-E: H11/HB3/PY21W/W5W Manual/Elec H4Document3 pages214-1197 - EM RD LD 214-1101N - Ld-E: H11/HB3/PY21W/W5W Manual/Elec H4Emerson Orlando Delgado PortocarreroNo ratings yet

- Winkel Wincut Stainless Steel OilDocument1 pageWinkel Wincut Stainless Steel Oilgopalakrishna100% (1)

- Rendering A Practical Handbook PDFDocument21 pagesRendering A Practical Handbook PDFAman Sahadeo100% (1)

- Student Handbook On Workshop SafetyDocument41 pagesStudent Handbook On Workshop Safetyapi-268626890No ratings yet

- Analysis and Design of Doubly Reinforced BeamDocument1 pageAnalysis and Design of Doubly Reinforced BeamLouise DiazNo ratings yet

- Design of Blowout Preventer Lifting FrameDocument10 pagesDesign of Blowout Preventer Lifting FrameSisu StefanNo ratings yet

- Casestudy Uttarayan Art Village JhaspurDocument5 pagesCasestudy Uttarayan Art Village JhaspurAnonymous BqLSSexONo ratings yet

- TDS Dekguard E2000 India3Document4 pagesTDS Dekguard E2000 India3Er Krishan YadavNo ratings yet

- Zeeshan Ejaz, B.E (MechDocument4 pagesZeeshan Ejaz, B.E (Mechajs580No ratings yet

- Losses in PrestressDocument9 pagesLosses in Prestresswendell bravoNo ratings yet

- To 1-1a-9Document288 pagesTo 1-1a-9CarlozNo ratings yet

- Sa516 70Document3 pagesSa516 70Thinh ViproNo ratings yet

- ASME BPE InfoDocument18 pagesASME BPE InfoThaMaestroNo ratings yet

- CH-3 Arch & Buttress DamDocument9 pagesCH-3 Arch & Buttress DamPoly ZanNo ratings yet

- UP TO 24kV 630A 21ka Modular Rmu: Maintenance Free, Compact & Modular SF Gas Insulated Distribution SwitchgearDocument2 pagesUP TO 24kV 630A 21ka Modular Rmu: Maintenance Free, Compact & Modular SF Gas Insulated Distribution SwitchgearAyman AliNo ratings yet

- Test Certificate (PPC) : Kalburgi Cement Pvt. LTDDocument1 pageTest Certificate (PPC) : Kalburgi Cement Pvt. LTDAmanUllahNo ratings yet

- Keenkid's It Report Third YearDocument38 pagesKeenkid's It Report Third YearD A R K S K YNo ratings yet

DETAIL Version 10

DETAIL Version 10

Uploaded by

Sunny Singh0 ratings0% found this document useful (0 votes)

23 views2 pagesbest

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbest

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

23 views2 pagesDETAIL Version 10

DETAIL Version 10

Uploaded by

Sunny Singhbest

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

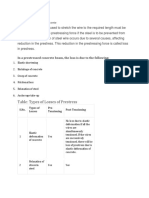

TECHNICAL DATA SHEET

Date: 01.06.2011 Version 10

MARISEAL DETAIL

Liquid-applied polyurethane waterproofing membrane

For complex roof details. Fiber-reinforced

Product description Advantages

MARISEAL DETAIL is a liquid-applied, thixotropic,

permanent elastic, fiber-reinforced, cold applied and cold

curing, one component polyurethane membrane used for

long-lasting waterproofing.

Cures by reaction with ground and air moisture.

Simple application (brush or roller).

It forms seamless membrane without joints or leak possibilities.

Resistant to water and rain.

Maintains its mechanical properties over a temperature span of

-30

o

C to +80

o

C.

Resistant to frost.

Provides water vapor permeability.

Full surface adherence without any additional anchoring.

Even if the membrane gets damaged, it can be easily repaired

locally within minutes.

Low cost

Uses Consumption

The MARISEAL DETAIL is mainly used to create

waterproof seals on difficult and complex roofing details

such as:

Wall-floor connections

Flashings and 90

o

angles

Lightdomes,

Rooflights,

Chimneys,

Pipes,

Gutters, etc.

1, 5 3, 5 kg/m

2

depending on application.

Surfaces

The MARISEAL DETAIL is mainly used to create waterproof

seals between different construction materials as :

Bitumen felts

PVC membranes

Concrete / Mortar / Cement screed

Various Metals

Wood, etc

Colors

The MARISEAL DETAIL is supplied in Grey and Black

Technical data

PROPERTY RESULTS TEST METHOD

Composition Polyurethane high-solids pre-polymer

Elongation at Break > 250 % ASTM D 412

Tensile Strength > 2 N/mm

2

ASTM D 412

Water Vapor Permeability > 20 gr/m

2

per 24 hours ISO 9932:91

Resistance to Water

Pressure

No Leak (1m water column, 24h) DIN EN 1928

Adhesion to concrete > 2,0 N/mm

2

(concrete failure) ASTM D 903

Hardness (Shore A Scale) 65-70 ASTM D 2240

Application Temperature 5

0

C to 35

0

C

Conditions: 20

o

C, 50% RH

Rain Stability Time 3-4 hours

Light Pedestrian Traffic 12-18 hours

Final Curing time 7 days

Chemi cal Pr oper t i es Good resistance against acidic and alcalic solutions (5%), detergents, seawater and oils.

Application

Surface Preparation / Priming

Careful surface preparation is essential for optimum finish and durability. The surface needs to be clean, dry and sound, free of

any contamination, which may harmfully affect the adhesion of the coating. New concrete structures need to dry for at least 28

days. Old coatings, dirt, fats, oils, organic substances and dust need to be removed by a grinding machine. Possible surface

irregularities need to be smoothened. Any loose surface pieces and grinding dust need to be thoroughly removed. Do not wash

surface with water!

Please refer to MASTIC LIQUIDDETAIL surface preparation / priming table.

Waterproofing membrane

Stir MARISEAL DETAIL slowly and well with wooden staff before using. Do not use a mechanical drill.

Apply the MARISEAL DETAIL onto the prepared and/or primed surface by roller or brush, until all surface is covered.

If necessary apply a second layer.

For detailed application instructions, contact our R+D department.

ATTENTION: Do not apply the MARISEAL DETAIL when the ambient temperature is below +5

0

C during the application and 4

hours afterwards, on surfaces with Temperature below +5

0

C, on frozen surfaces, during rain or mist, on wet MARISEAL

DETAIL Primer and on surfaces with ascending humidity. Low temperatures retard cure while high temperature speed up

curing.

WARNING: The MARISEAL DETAIL is slippery when wet. In order to avoid slipperiness during wet days, sprinkle suitable

aggregates onto the still wet coating to create an anti-slip surface. Please contact our R+D Dept. for more details.

Packaging

MARISEAL DETAIL is supplied in 6 kg pails. Pails should be stored in dry and cool rooms for up to 9 months. Protect the

material against moisture and direct sunlight. Storage temperature: 5

0

-30

0

C. Products should remain in their original,

unopened containers, bearing the manufacturers name, product designation, batch number and application precaution labels.

Safety measures

MARISEAL DETAIL contains isocyanates. See information supplied by the manufacturer. Please study the Safety Data sheet.

Our technical advice for use, whether verbal, written or in tests, is given in good faith and reflect the current level of knowledge and experience with our products. When using our

products, a detailed object-related and qualified inspection is required in each individual case in order to determine whether the product and /or application technology in question

meets the specific requirements and purposes. We are liable only for our products being free from faults; correct application of our products therefore falls entirely within your scope

of liability and responsibility. We will, of course, provide products of consistent quality within the scope of our General Conditions of Sale and Delivery. Users are responsible for

complying with local legislation and for obtaining any required approvals or authorizations. Values in this technical data sheet are given as examples and may not be regarded as

specifications. For product specifications contact our R+D department. The new edition of the technical data sheet supersedes the previous technical information and renders it

invalid. It is therefore necessary that you always have to hand the current code of practice.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5833)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KPC Piping SpecDocument111 pagesKPC Piping Specinfo_shakib100% (1)

- 17DS04 BRENEMAN Structural CLT Floor and Roof Design WSF 171004 PDFDocument58 pages17DS04 BRENEMAN Structural CLT Floor and Roof Design WSF 171004 PDFRicardo Melendez AlvarezNo ratings yet

- Case Study: Self-Leveling Floor Coating of Hippokrates Hospital-AthensDocument1 pageCase Study: Self-Leveling Floor Coating of Hippokrates Hospital-AthensSunny SinghNo ratings yet

- Chennai ListDocument13 pagesChennai Listkinanantha0% (1)

- Balcony BroshureDocument1 pageBalcony BroshureSunny SinghNo ratings yet

- Marine Products BroshureDocument1 pageMarine Products BroshureSunny SinghNo ratings yet

- Mariseal SYSTEM Car Deck Waterproofing A Roof Coating To Waterproof A Road With Vehicular TrafficDocument1 pageMariseal SYSTEM Car Deck Waterproofing A Roof Coating To Waterproof A Road With Vehicular TrafficSunny SinghNo ratings yet

- Floor BroshureDocument1 pageFloor BroshureSunny SinghNo ratings yet

- Freezer Broshure ENGDocument1 pageFreezer Broshure ENGSunny SinghNo ratings yet

- Mariseal SYSTEM: Under-Tile Polyurethane Waterproofing The Terrace Waterproofing SystemDocument1 pageMariseal SYSTEM: Under-Tile Polyurethane Waterproofing The Terrace Waterproofing SystemSunny SinghNo ratings yet

- 2color Roof BroshureDocument1 page2color Roof BroshureSunny SinghNo ratings yet

- Walkway BroshureDocument1 pageWalkway BroshureSunny SinghNo ratings yet

- Stamped Concrete BroshureDocument1 pageStamped Concrete BroshureSunny SinghNo ratings yet

- Maricoat 2000: Polyurethane Self-Leveling Floor CoatingDocument2 pagesMaricoat 2000: Polyurethane Self-Leveling Floor CoatingSunny SinghNo ratings yet

- Panel Adhesive BroshureDocument1 pagePanel Adhesive BroshureSunny SinghNo ratings yet

- Mariseal System The Polyurethane Coating To Protect Polyurethane FoamDocument1 pageMariseal System The Polyurethane Coating To Protect Polyurethane FoamSunny SinghNo ratings yet

- Mariseal 270 Version 10Document2 pagesMariseal 270 Version 10Sunny SinghNo ratings yet

- Filter Resins BroshureDocument1 pageFilter Resins BroshureSunny SinghNo ratings yet

- Mariseal 700 Version 10Document2 pagesMariseal 700 Version 10Sunny SinghNo ratings yet

- Pipe Refresher CourseDocument5 pagesPipe Refresher CourseBanilo BanilaNo ratings yet

- Joints in Wood Structures 2015 PDFDocument33 pagesJoints in Wood Structures 2015 PDFTucara3000No ratings yet

- FBES 01 Book-The-Steel-Book V07.01.0818 WEBDocument116 pagesFBES 01 Book-The-Steel-Book V07.01.0818 WEBrenandNo ratings yet

- Instrument Tube Fitting Instalation Manual PDFDocument76 pagesInstrument Tube Fitting Instalation Manual PDFjhonny sanchezNo ratings yet

- FMDS0707 Semiconductor FacliliDocument56 pagesFMDS0707 Semiconductor Faclilidaniela hritucNo ratings yet

- FyzMat I 3 DislocationsDocument93 pagesFyzMat I 3 DislocationsCesar Vargas ArayaNo ratings yet

- Adsyl 7423 XCP: Lyondellbasell IndustriesDocument4 pagesAdsyl 7423 XCP: Lyondellbasell Industriesnouman ashrafNo ratings yet

- P1 Istc HT Ar 00001 - R01 PDFDocument7 pagesP1 Istc HT Ar 00001 - R01 PDFcarlomaderazoNo ratings yet

- Draft F02 F06 - WKL Weekly Report 27122022 Rev00Document13 pagesDraft F02 F06 - WKL Weekly Report 27122022 Rev00azwanawalludin247No ratings yet

- Product Data Sheet: DimensionalDocument1 pageProduct Data Sheet: DimensionalIvanNo ratings yet

- FIG. 1 Rectangular Tension Test SpecimensDocument1 pageFIG. 1 Rectangular Tension Test SpecimensAlvaro Alexis Mendoza PradaNo ratings yet

- 214-1197 - EM RD LD 214-1101N - Ld-E: H11/HB3/PY21W/W5W Manual/Elec H4Document3 pages214-1197 - EM RD LD 214-1101N - Ld-E: H11/HB3/PY21W/W5W Manual/Elec H4Emerson Orlando Delgado PortocarreroNo ratings yet

- Winkel Wincut Stainless Steel OilDocument1 pageWinkel Wincut Stainless Steel Oilgopalakrishna100% (1)

- Rendering A Practical Handbook PDFDocument21 pagesRendering A Practical Handbook PDFAman Sahadeo100% (1)

- Student Handbook On Workshop SafetyDocument41 pagesStudent Handbook On Workshop Safetyapi-268626890No ratings yet

- Analysis and Design of Doubly Reinforced BeamDocument1 pageAnalysis and Design of Doubly Reinforced BeamLouise DiazNo ratings yet

- Design of Blowout Preventer Lifting FrameDocument10 pagesDesign of Blowout Preventer Lifting FrameSisu StefanNo ratings yet

- Casestudy Uttarayan Art Village JhaspurDocument5 pagesCasestudy Uttarayan Art Village JhaspurAnonymous BqLSSexONo ratings yet

- TDS Dekguard E2000 India3Document4 pagesTDS Dekguard E2000 India3Er Krishan YadavNo ratings yet

- Zeeshan Ejaz, B.E (MechDocument4 pagesZeeshan Ejaz, B.E (Mechajs580No ratings yet

- Losses in PrestressDocument9 pagesLosses in Prestresswendell bravoNo ratings yet

- To 1-1a-9Document288 pagesTo 1-1a-9CarlozNo ratings yet

- Sa516 70Document3 pagesSa516 70Thinh ViproNo ratings yet

- ASME BPE InfoDocument18 pagesASME BPE InfoThaMaestroNo ratings yet

- CH-3 Arch & Buttress DamDocument9 pagesCH-3 Arch & Buttress DamPoly ZanNo ratings yet

- UP TO 24kV 630A 21ka Modular Rmu: Maintenance Free, Compact & Modular SF Gas Insulated Distribution SwitchgearDocument2 pagesUP TO 24kV 630A 21ka Modular Rmu: Maintenance Free, Compact & Modular SF Gas Insulated Distribution SwitchgearAyman AliNo ratings yet

- Test Certificate (PPC) : Kalburgi Cement Pvt. LTDDocument1 pageTest Certificate (PPC) : Kalburgi Cement Pvt. LTDAmanUllahNo ratings yet

- Keenkid's It Report Third YearDocument38 pagesKeenkid's It Report Third YearD A R K S K YNo ratings yet