Professional Documents

Culture Documents

The Effect of Counterface Roughness On The Wear of UHMWPE For Rectangular Wear Paths

The Effect of Counterface Roughness On The Wear of UHMWPE For Rectangular Wear Paths

Uploaded by

José santanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effect of Counterface Roughness On The Wear of UHMWPE For Rectangular Wear Paths

The Effect of Counterface Roughness On The Wear of UHMWPE For Rectangular Wear Paths

Uploaded by

José santanaCopyright:

Available Formats

Wear 259 (2005) 984991

The effect of counterface roughness on the wear of UHMWPE

for rectangular wear paths

M.E. Turell

a

,

b

, G.E. Friedlaender

b

, A. Wang

c

, T.S. Thornhill

a

, A. Bellare

a

,

a

Department of Orthopaedic Surgery, Brigham and Womens Hospital, Harvard Medical School, Boston, MA 02115, USA

b

Department of Orthopaedics and Rehabilitation, Yale University School of Medicine, New Haven, CT 06510, USA

c

Stryker Howmedica Osteonics, 300 Commerce Court, Mahwah, NJ 07430, USA

Received 1 August 2004; received in revised form 30 December 2004; accepted 31 January 2005

Available online 14 March 2005

Abstract

Ultra-high molecular weight polyethylene (UHMWPE) is used worldwide as a bearing material in total joint replacement prostheses.

Multi-directional motion has been identied as a major factor affecting the wear rate of UHMWPE in total hip replacement prostheses. The

trajectory of relative motion between a femoral head and an acetabular cup takes a general quasi-elliptical or rectangular shape during the

patients gait cycle. Differences in motion pattern can affect the in vivo wear rates of UHMWPE cups in patients when all other factors are

equal. In a previous study that utilized smooth CoCr counterfaces, we compared wear factors, k, for UHMWPE articulated in a series of

rectangular wear paths (width = A, length = B) with systematically increasing aspect ratios (B/A) and linear tracking (A = 0), all with identical

path lengths per cycle. The results showed that the wear factor signicantly decreased in the rectangular wear path with the highest aspect

ratio and in linear tracking. The goal of our current study was to quantify the effect of a roughened counterface on the cross-path wear of

UHMWPE. UHMWPE pins were articulated against both smooth and rough CoCr disks in diluted calf serum using a multi-directional

wear tester under physiological loading conditions. Five different rectangular wear path geometries and linear tracking, all with identical path

lengths per cycle, were employed for each wear test. Gravimetric weight loss was converted into volumetric wear rates and wear factors, k.

The results showed that roughened counterfaces produced a larger increase in the wear factor in rectangular wear paths with higher aspect

ratios. The ratio of krough/ksmooth decreased monotonically as a function of increasing width of rectangles, normalized by total path length, or

A/(A + B).

2005 Elsevier B.V. All rights reserved.

Keywords: Ultra-high molecular weight polyethylene; Multi-directional wear; Total joint replacement; Joint arthroplasty

1. Introduction

Ultra-high molecular weight polyethylene (UHMWPE)

has been used worldwide as a bearing surface of total joint

replacement prostheses since 1962. The high entanglement

density associated with high molecular weight imparts su-

perior fracture toughness [1,2] and high wear resistance to

UHMWPE, making it an attractive choice as a bearing surface

Corresponding author. Present address: Orthopaedic Research Labora-

tory, MRB 106, Brigham and Womens Hospital, 75 Francis Street, Boston,

MA 02115, USA. Tel.: +1 617 732 5864; fax: +1 617 732 6705.

E-mail address: anuj@alum.mit.edu (A. Bellare).

0043-1648/$ see front matter 2005 Elsevier B.V. All rights reserved.

doi:10.1016/j.wear.2005.01.050

in both total knee and total hip joint replacement prostheses.

Despite its superior mechanical and tribological properties,

wear damage of UHMWPE continues to limit the clinical

lifespan of implanted knee and hip joint prostheses. Volumet-

ric wear rate of an acetabular cup articulating against a 32 mm

femoral head is approximately 80 mm

3

/year, which translates

into an average linear wear of 0.1 mm annually [36]. The

thickness of UHMWPE components is usually 1 cm or more.

Therefore, it would take 100 years for UHMWPE compo-

nents to wear through. While this estimate eliminates the

likelihood that UHMWPE implant components are in any

danger of wearing through over the course of a patients life-

time, billions of sub-micron wear debris particles are pro-

P(2A + 2B)

P(2A)

P(2A + 2B)

A

k =

V

M.E. Turell et al. / Wear 259 (2005) 984991 985

duced annually [7,8], which continues to be the primary con-

cern in total hip replacement prostheses. The accumulation

of particulate debris in the peri-prosthetic tissue can elicit a

biological response leading to bone loss (osteolysis) and im-

plant loosening, necessitating complicated revision surgery

to replace the implant [911].

Osteolysis associated with particulate wear debris has

prompted numerous investigations, which study the size,

shape and morphology of particulate debris and the biolog-

ical pathway that leads to particle-induced osteolysis. Wear

debris collected from peri-prosthetic tissue retrieval studies

showed that the majority of debris particles associated with

hip replacement prostheses were micron or sub-micron in size

and that particles could generally be categorized as brous or

particulate in shape [1216]. Particulate wear also occurs in

total knee replacement (TKR) components, although the par-

ticle size distribution differs from that of total hip replacement

(THR) wear particles, and TKR particles have been shown to

be generally larger than THR wear particles [17].

Computational and experimental studies have shown that

multi-directional motion or cross-shear motion can affect

wear rate of UHMWPE in total hip and total knee replace-

ments [18,19]. Linear tracking motion, whether unidirec-

tional or reciprocating produces an extremely low wear rate,

and in fact produces two to three orders of magnitude less

wear than is observed clinically in total knee replacement

prostheses [1924]. The higher clinical wear rates of total

knee replacement prostheses can be attributed to both coun-

terface scratching [25,26] as well as the effects of cross-shear

motion. Wang et al. have proposed that in a wear environ-

ment, UHMWPE macromolecules orient preferentially along

the principal direction of sliding [19,2224]. Unlike in lin-

ear tracking, where orientation results in strain hardening of

surface material and ultimately increases wear resistance as

sliding progresses, in multi-directional motion, the wear sur-

face experiences both compressive and shear forces in mul-

tiple directions. As sliding proceeds, the UHMWPE wear

surface may strengthen along the direction of sliding, while

it weakens in the perpendicular direction. It has been demon-

strated that the loci or trajectory of motion at the contact

point between a femoral head of an orthopaedic implant and

an acetabular cup is a quasi-ellipse or an approximate rectan-

gle during a gait cycle [18,19,27]. Some patients have either

more elongated (approximately rectangular) or more closed

(approximately more square-like) motion patterns than oth-

ers [27]. Examples of elongated and closed motion patterns

traced by the contact point between femoral and acetabular

components are illustrated in the examples shown in Fig. 1.

Bennett et al. have postulated that the differences in motion

patterns affect the in vivo wear rates of UHMWPE acetabular

cups in patients where factors such as age, weight and body

proportion were similar, but gait patterns varied widely [27].

The multi-directional sliding, or orientation-softening

wear model, proposed by Wang has been termed the unied

theory of wear for UHMWPE [28]. This theory proposed

that when a femoral head slides against an acetabular cup

Fig. 1. Elongated motion pattern (left) and closed motion pattern (right)

traced by the contact point between the formal and acetabular components

of orthopaedic implants.

along the wear path dened by the rectangular loop, fric-

tional energy is dissipated in both the A and B directions (see

Fig. 1). Since A < B, B denes the principal direction of slid-

ing motion while A is secondary. Previous studies indicated

that motion in the principal sliding direction, B, leads to plas-

tic deformation or macromolecular orientation whereas mo-

tion in the secondary direction, A, leads to material removal

by fracture [19,2224,28]. Therefore, only energy released

in the A direction is directly responsible for wear [28]. The

expression for wear rate can then be expressed as:

V mP(2A) (1)

where V is volumetric wear rate, is the coefcient of fric-

tion, P is the applied normal load and 2A is the sliding dis-

tance in the secondary direction per cycle. Since the wear

coefcient or wear factor, k, is dened as (volumetric wear

rate)/(load total sliding distance), in the case of a rectan-

gular wear path illustrated above, k can be written as:

A + B

(2)

Eq. (2) theoretically quanties the effect of cross-path mo-

tion on the wear factor of UHMWPE. In a previous set of

experiments, we compared wear factors for UHMWPE artic-

ulated in a series of graded wear paths in which the aspect

ratio of the wear path was systematically increased. These

wear tests were conducted using a cobaltchromium articula-

tion surface with an implant-grade smooth nish. The results

showed that the wear factors from these experiments were in

agreement with the proposed model only at high aspect ra-

tios, i.e. wear factors were found to signicantly decrease in

the rectangular wear path with the highest aspect ratio and in

linear tracking [29]. A question that remains to be answered

is whether the proposed model remains valid under condi-

tions of abrasive wear. Studies have shown that the addition

of bone cement (with zirconium and barium sulfate additives)

and bone particles to test serum lubricant produces signi-

cantly greater surface damage to stainless steel articulation

counterfaces which in turn results in surface roughening and

increased wear rates [25]. Similarly, other authors have found

that roughening of the femoral head, to a degree seen typically

in retrieval specimens, can increase the observed variability

of volumetric wear rates approximately seven-fold. This fact

may explain why random femoral head scratching in vivo

accounts for otherwise difcult to explain variations in wear

rates as abrasive wear may be a key factor causing excessive

wear in the most problematic subset of the patients with to-

986 M.E. Turell et al. / Wear 259 (2005) 984991

tal joint replacements [26]. The purpose of the current study

is to determine whether the unied theory of wear is appli-

cable to conditions of abrasive wear, such as the case of a

roughened counterface articulating against UHMWPE along

rectangles of various aspect ratios. It was hypothesized that

under conditions of abrasive wear, the model would in gen-

eral describe the cross-path wear of UHMWPE as accurately

as it had under conditions in which a smooth counterface was

employed.

2. Materials and methods

2.1. UHMWPE starting material

Commercially available, ram-extruded GUR 1050

(Hoechst-Ticona, Bayport, TX) rod stock (PolyHi Solidur,

Ft. Wayne, IN) was used as the starting material for all wear

tests. Rod stock with a diameter of 7.6 cm was machined into

cylindrical pins with overall dimensions of 20 mm in length

and 9 mm in diameter for all wear tests. All pins were tested

in the as-machined condition (no sterilization).

2.2. Wear testing protocol and apparatus

A series of six different articulation patterns including

a 5 mm 5 mm square, 4 mm 6 mm, 3 mm 7 mm,

2 mm 8 mm, and 1 mm 9 mm rectangles, and a

0 mm 10 mm linear tracking pattern were digitized

into an OrthoPOD

TM

(Advanced Mechanical Technology

Inc.) multi-directional wear tester. For each wear test, the

OrthoPOD

TM

multi-directional wear tester was loaded

with six UHMWPE pins as shown in the experimental

set-up in Fig. 2. All wear tests were conducted at a cycle

frequency of 1 Hz (constant sliding speed of 20 mm/s along

the wear track) and with a constant applied load of 192 N

or an applied stress of 3 MPa, well within the physiological

range of 25 MPa for the hip joint. A bovine serum (JRH

Biosciences) lubricant was used for all wear tests, and

was diluted with distilled water to contain 23 g/L protein,

20 mM EDTA, and 0.2% sodium azide. The lubricating

bovine serum temperature was maintained at 37

C using

a re-circulating water bath. Cobaltchromium disks with

dimensions of 25 mm diameter and 3 mm thickness were

used as the articulation counterface. Two series of wear tests

using each of the six experimental articulation patterns were

performed. In one series of tests, cobaltchromium disks

were polished to implant-grade surface smoothness with

a centerline roughness of 0.015 m (Ra). In a second set

of experiments, the cobaltchromium disks were scratched

along random directions using 320 grit emery paper in

accordance with the previously established method of Wang

et al., resulting in an average roughness, Ra, of 0.45 m

[30]. A total of six pins plus an additional pin serving as a

soak control were used for all wear tests.

2.3. Data analysis

Wear rates for each of the six articulation patterns were

determined in experiments in which both smooth and rough

counterfaces were employed. Gravimetric weight loss per pin

was determined approximately every 200,000 cycles. The

soak control consistently revealed that the amount of absorp-

tion of bovine serum by the UHMWPE specimen was unde-

tectable and therefore any corrections to compensate for uid

absorption were unnecessary. For each group, wear tests were

Fig. 2. AMTI OrthoPOD

TM

multi-directional wear tester.

M.E. Turell et al. / Wear 259 (2005) 984991 987

continued until at least one million cycles had been reached.

The gravimetric weight loss per pin was determined by taking

the average weight loss of the six wear tested pins. Prior to

being weighed, UHMWPE pins were rst washed twice with

distilled water followed by an alcohol and acetone rinse, re-

spectively. The pins were dried in air at 25

C for 15 min prior

to determination of weight loss. Gravimetric weight loss was

further converted into volumetric wear data by using a den-

sity value of 0.943 g/cm

3

for UHMWPE. Wear factor values,

k, were also calculated for each sample by dividing the vol-

umetric wear rate by the product of the load and the sliding

distance per cycle.

2.4. Statistics

Statistical analysis was conducted using ANOVA with

Fishers protected least signicant difference (PLSD) post-

hoc test in which a p-value of less than 0.05 was used to dene

statistical signicance. In addition, single-factor ANOVA us-

ing a 95% condence interval ( = 0.05) was also used to

more rigorously assess the statistical signicance between

groups. Wear factor values from each wear path geometry

using both smooth and rough counterfaces were compared

against one another in order to establish the level of signi-

cance between different groups.

3. Results

3.1. Wear testing

Wear tests showed that the wear rates increased incre-

mentally as the wear path decreased in aspect ratio and ap-

proached the 3 mm 7 mm conguration. Interestingly, for

both experiments in which smooth counterfaces and rough

counterfaces were used, wear reached a maximum when a

3 mm 7 mm wear path was employed (Fig. 3). In the smooth

counterface test series, the wear factor for the 5 mm 5 mm

square path was found to be 2.5 times greater in comparison

to the 2 mm 8 mm path (p < 0.05, ANOVA with Fishers

PLSD post-hoc test), which agrees remarkably well with the

Fig. 3. Comparison of wear factors for both smooth and rough

cobaltchromium counterfaces.

prediction of Eq. (2). For the same comparison in the rough

counterface test series, the wear factor for the 5 mm 5 mm

square path was found to be only 1.1 times greater than

the wear factor for the 2 mm 8 mm path. Although this

trend was observed, in the case of the rough counterface

test, the differences between the 5 mm 5 mm path and the

2 mm 8 mm path was not statistically signicant.

3.2. Effect of counterface roughness

As predicted, counterface roughness had a substantial ef-

fect on wear rate. Although standard deviations between

groups were large, the differences in wear rates between

rough and smooth tests for each wear path geometry were

statistically signicant (p < 0.05) according to ANOVA (us-

ing a 95% condence interval). This is due to the large

number of data points included in each group. An ex-

ception is that the differences in the wear factor for the

4 mm 6 mm rough versus smooth tests were not statisti-

cally signicant. Using ANOVA (with the 95% condence

interval criteria) within the smooth counterface series, the

wear factor of the 1 mm 9 mm wear path was signicantly

greater than that of the 0 mm 10 mm path as was the

wear factor of the 3 mm 7 mm versus the 2 mm 8 mm.

However, the wear factors of 2 mm 8 mm versus the

1 mm 9 mm, the 4 mm 6 mm versus the 3 mm 7 mm,

and the 5 mm 5 mm versus the 4 mm 6 mm were not sig-

nicantly different from one another. Using this same anal-

ysis, in the rough counterface set of wear tests, the wear

factor associated with the 1 mm 9 mm path was signi-

cantly greater than that of the 0 mm 10 mm path as was

the 3 mm 7 mm path compared to the 4 mm 6 mm path.

The wear factor of the 2 mm 8 mm versus the 1 mm 9 mm

path, the 3 mm 7 mm versus the 2 mm 8 mm path, and the

5 mm 5 mm versus the 4 mm 6 mm path were not statis-

tically different. An important nding of this study was that

the counterface roughness affected wear rates to a greater ex-

tent in experiments in which more linear rectangular paths

were used as compared to the more square-like wear paths.

In comparison to the smooth counterface series, the rough

counterface tests demonstrated wear rates that were signif-

icantly greater than predicted when more linear wear paths

were tested. There was a general decreasing trend in the ratio

of krough/ksmooth as the aspect ratio of the rectangles decreased

(approached the square conguration), as shown in Fig. 4.

3.3. Unied theory of wear

In order to assess the accuracy of the unied theory of

wear in predicting the wear rate of UHMWPE based on a

particular wear path geometry, the experimentally observed

wear factor values for both the smooth and rough counterface

tests were plotted as a function of the ratio A/(A + B) (Fig. 5).

These curves were then compared to predicted wear factor

trends, in which the maximum predicted wear factor was

taken to be the value of the wear factor obtained from the

988 M.E. Turell et al. / Wear 259 (2005) 984991

Fig. 4. Comparison of wear factor ratios (rough/smooth).

5 mm 5 mm square wear path. Analysis revealed that the

orientation-softening theory of wear was unable to accurately

predict wear over the entire range of rectangles for both the

smooth and rough counterface series. In smooth counterface

tests, the parameter A/(A + B) was particularly accurate in the

prediction of wear rates in cases where the aspect ratio of the

rectangular path was highest, such as in the 0 mm 10 mm

to 3 mm 7 mm wear paths. The monotonic increase in wear

factors in the A/(A + B) range of 0.0 and 0.3 for UHMWPE

in both rough and smooth counterfaces suggested a linear

correlation between wear factor, k, and A/(A + B). Therefore,

a linear curve t was conducted in a separate plot (Fig. 6)

for the wear factors in the A/(A + B) range of 0.00.3. Fig. 6

shows that the wear factor values from both the smooth and

rough counterface tests show a strong linear relationship in

this range.

In both the smooth and rough counterface experiments,

the wear factor increased with increasing A/(A + B) ratio, but

only up to a value of 0.3. There were signicant deviations in

the experimental data from the theoretical linear correlation

predicted by the orientational softening theory (Fig. 5). These

differences are particularly apparent in the set of experiments

Fig. 5. Wear factor, k, vs. A/(A + B) ratio.

Fig. 6. Liner t (with maximum A/(A + B) = 0.3) for wear factor, k, vs.

A/(A + B) ratio.

employing rough counterfaces. According to the theoretical

model of Wang [28], the maximum wear factor should occur

at A = B or A/(A + B) = 0.5. Instead the experimentally ob-

served wear factor peaked at A/(A + B) = 0.3 for both smooth

and rough counterface experiments. In fact, the 3 mm 7 mm

showed a 16% increase over the 5 mm 5 mm square path

in the series where smooth counterfaces were used (p < 0.05,

ANOVA with Fishers PLSD post-hoc test).

4. Discussion

4.1. Wear tests

This study was conducted as an extension of a previous

study that sought to quantify the effect of the cross-path mo-

tion on wear rate of UHMWPE. The aim of this study was

to address the effects of counterface roughness on wear rates

for different cross-path motions. For a rectangular wear path

with a width A and a length B (A < B), the numerical param-

eter A/(A + B) is a convenient measure to relate wear factor,

k, to cross-path motion for rectangles with various aspect ra-

tios, B/A. This numerical parameter, dened by the unied

wear model, was relatively accurate in predicting the gen-

eral trend that wear rates would increase as a function of

decreasing aspect ratio (i.e. as a function of the wear path

approaching a square conguration) but only in the range

of the 1 mm 9 mm wear path to the 3 mm 7 mm con-

guration. For both smooth and rough counterface tests, a

linear trend was particularly evident in cases where the as-

pect ratio of the rectangular path was highest, such as in

the 0 mm 10 mm, 1 mm 9 mm, and 2 mm 8 mm wear

paths. In both counterface groups, wear factors reached a

maximum when a 3 mm 7 mm wear path was employed,

and the trend was no longer observed as the aspect ratio of

the wear path continued to decrease beyond this point. The

failure of the unied wear model to predict wear rates in some

cases for both rough and smooth counterface tests raises ques-

A + B

6E08

(

R

=

0

.

8821)

A + B

+

4E07

(

R

=

0

.

9922)

M.E. Turell et al. / Wear 259 (2005) 984991 989

tions about some of the underlying assumptions upon which

the model is based. For example, for any rectangular wear

path with sides A and B, where A < B, the model assumes

that orientation on the molecular level occurs in the B di-

rection, while fracture, or the actual wearing of UHMWPE,

occurs in the A direction. Based on the results of this study, in

which wear reached a maximum for the 3 mm 7 mm wear

path, this assumption may not be a valid description of the

orientation and wear processes. It is possible that complete

orientation and strain hardening of UHMWPE in the B direc-

tion is required for wear to occur solely in the A direction,

and that this is only achieved at 7 mm of sliding. It is there-

fore possible that for the 5 mm 5 mm and 4 mm 6 mm

wear paths, there is signicant reorientation in the A direc-

tion as well rather than fracture of the fully oriented, strain

hardened UHMWPE brils. Reorientation would imply that

a different wear mechanism is operative since biaxial ori-

entation prior to wear would suggest that a more sheet-like

material wears rather than splitting of brillar UHMWPE.

These wear and orientation mechanisms appeared to occur in

two discrete A/(A + B) ranges, irrespective of the roughness

of counterface.

Fig. 6 shows that there was a linear correlation between

wear factor, k, and the numerical parameter A/(A + B), regard-

less of counterface roughness. The linear equations for these

correlations as well as the R-values (to measure the degree of

t) were obtained for both the smooth and rough counterface

tests. In the equation for the line, k = m[A/(A + B)] + c, the

constant c (y-intercept) represents the fraction of wear factor

that is due to linear, abrasive wear and the constant m (slope)

is a measure of the dependence of cross-path wear on the

wear path geometry. The following equations were obtained

for the linear correlations:

k = 7E06

A

(smooth counterface) (3)

k = 1E05

A

(rough counterface) (4)

It is evident that the constant c cannot assume a negative

value, and the low, negative wear factor value of 6E08

for linear tracking for smooth heads obtained from the lin-

ear t is merely a consequence of experimental error, which

can be taken to be zero or replaced by the experimentally

measured positive value of 5.06E08. The value of m was

higher in the rough counterface series of wear tests. The

ratio of mrough/msmooth was 1.4, revealing that there was a

steeper dependence of wear factor, k, on the numerical pa-

rameter, A/(A + B), in the case of rough counterface. For both

the smooth and rough counterface, the high R-values indi-

cated a strong linear correlation between the wear factor and

A/(A + B). The good t of the wear factors in the series of

wear paths in the range of 0 mm 10 mm to 3 mm 7 mm

paths suggests that complete orientation followed by frac-

ture of brils was the primary mechanism of wear in both

of these cases. Independent of the accuracy with which the

model investigated in this paper predicted wear rate, the over-

all experimental results support the hypothesis that wear rate

is in fact dependent upon the wear path geometry, counterface

roughness and the interplay of these two variables.

4.2. Clinical relevance

The nding that wear rate is dependent upon both wear

path pattern and counterface roughness has a number of clin-

ically relevant implications. The observation that differences

in wear rates, between tests employing rough versus smooth

counterfaces, are greater in more linear motion path patterns

and that these differences systematically decrease as the wear

approaches a square pattern is an important nding. In total

joint replacement applications where linear wear is known to

be operative and to have a signicant impact upon the life-

time of the joint replacement, for example, as is the case in

the knee joint, the effects of abrasive wear (simulated by a

roughened counterface in this study) are of greater concern.

It should be noted that the results of this study reveal a some-

what oversimplication of the wear mechanisms as they oc-

cur in clinical application since the effects of third body wear

and fatigue-related wear mechanisms were not investigated.

A question which remains to be answered is whether it may

be possible to predict motion path patterns by conducting

gait analysis and if so, whether motion path pattern can be

therapeutically manipulated using methods of gait training or

by making improvements to implant design. A challenge in

addressing these questions lies in the difculty in assessing

gait in patients who require total joint replacement surgery

as gait in these individuals may be altered from their normal

baseline gait due to the orthopaedic complications, which ne-

cessitate surgery in the rst place. Similarly, gait patterns in

these individuals may be dramatically altered following total

joint replacement surgery, making it difcult to predict the

effects of implant design in advance of surgery.

4.3. Limitations

The results of this study represent an attempt to quantify

the effect of the motion path pattern and counterface rough-

ness on wear rate of UHMWPE. It should be noted that the

data, in particular the wear factor values, that have been ana-

lyzed in this paper represent the results of preliminary wear

tests conducted for each wear path geometry to a period of at

least one million cycles. A more comprehensive study, and

one that would employ more rigorous wear testing would

generate a larger number of samples for tests encompassing

a broader range of motion path patterns. From such experi-

ments, trends in the values of UHMWPE wear rates would

be more reliably generated and would be of a greater level

of clinical signicance. A study of the morphology of wear

990 M.E. Turell et al. / Wear 259 (2005) 984991

particles generated from the various motion path patterns for

both smooth and rough counterface tests is also necessary

(and forthcoming) to obtain a more accurate understanding

of the wear mechanisms that are operative during the various

wear paths. In addition, the wear tests in this paper employed

a constant applied load and it is important for future studies

to include wear test loading parameters which more closely

model the loading conditions found in knee and hip joints

in vivo. The relationship between wear path and wear rates

established in this study applies only to uncrosslinked med-

ical grade UHMWPE. Further wear testing on the various

crosslinked UHMWPEs currently in clinical use is required

for such relationships to be established.

5. Conclusions

Wear of UHMWPE as it articulates against a metallic

counterface in a particular wear path and under conditions

that mimic wear in a total hip replacement prosthesis, likely

occurs via two discrete steps for rectangles with an aspect

ratio greater than 2.33 (3 mm 7 mm rectangular path). For

such rectangles, the wear tests of this study support the hy-

pothesis that there is orientation or texturing of UHMWPE

on parallel edges of the rectangle followed by wear of the

textured UHMWPE on the other two parallel edges. How-

ever, for rectangles in the aspect ratio range of 1.02.33

(5 mm 5 mm to 4 mm 6 mm paths), the decline in wear

rates for both smooth and rough counterface experiments

provide evidence that wear and orientation processes may

not occur in discrete stages. In addition, the unied wear

model predicts zero wear for linear tracking, which is not

the case, especially when more abrasive conditions of wear

occur such as the case of a roughened counterface. A more

robust model is required to predict wear of UHMWPE during

articulation against a metallic counterface along a rectangu-

lar path covering the entire range of aspect ratios of rectan-

gles.

Acknowledgments

This project was funded through a biomedical engineering

grant provided by the Whitaker Foundation and by a fellow-

ship provided by the Orthopaedic Research and Education

Foundation.

References

[1] A. Gomoll, T. Wanich, A. Bellare, J-integral fracture toughness and

tearing modulus measurement of radiation cross-linked UHMWPE,

J. Orthop. Res. 20 (6) (2002) 11521156.

[2] L.C. Duus, H.A. Walsh, A.M. Gillis, E. Noisiez, S. Li, The effect of

resin grade, manufacturing method and cross linking on the fracture

toughness of commercially available UHMWPE, Trans. Orthop. Res.

Soc. 25 (2000) 544.

[3] M. Grifth, M. Seidenstein, D. Williams, J. Charnley, Socket wear

in Charnley low friction arthroplasty of the hip, Clin. Orthop. 137

(1978) 3747.

[4] J. Livermore, D. Ilstrupand, B. Morrey, Effect of femoral head size

on wear of the polyethylene acetabular component, J. Bone Joint

Surg. 72A (4) (1990) 518528.

[5] R. Hall, A. Unsworth, P. Siney, B. Wroblewski, Wear in retrieved

Charnley acetabular sockets, Proc. Inst. Mech. Eng. H: J. Eng. Med.

210 (1996) 197207.

[6] H. Oonishi, E. Tsuji, Y. Kim, Retrieved total hip prostheses. Part I.

The effects of cup thickness, head size and fusion defects on wear,

J. Mater. Sci.: Mater. Med. 9 (1998) 394401.

[7] I.C. Clarke, J.M. Kabo, Wear in total hip replacement, in: H.C.

Amstutz (Ed.), Hip Arthroplasty, Churchill Livingstone, New York,

1991.

[8] G. Lewis, Polyethylene wear in total hip and knee arthroplasties, J.

Biomed. Mater. Res. (Appl. Biomater.) 38 (1997) 5575.

[9] H. Amstutz, P. Campbell, N. Kossovsky, I. Clarke, Mechanisms and

clinical signicance of wear debris-induced osteolysis, Clin. Orthop.

Relat. Res. 276 (1992) 718.

[10] W. Harris, The problem is osteolysis, Clin. Orthop. Relat. Res. 311

(1995) 4653.

[11] T. Schmalzried, L. Kwong, M. Jasty, R. Sedlacek, T. Haire, D.

OConnor, C. Bragdon, J. Kabo, A. Malcolm, W. Harris, The mech-

anism of loosening of cemented acetabular components in total hip

arthroplasty: analysis of specimens retrieved at autopsy, Clin. Orthop.

Relat. Res. 274 (1992) 6078.

[12] P. Campbell, S. Ma, B. Yeom, H. McKellop, T. Schmalzried, H.

Amstrutz, Isolation of predominantly submicron-sized UHMWPE

wear particles from periprosthetic tissues, J. Biomed. Mater. Res.

29 (1995) 127131.

[13] A. Shanbhag, J. Jacobs, T. Glant, J. Gilbert, J. Black, J. Galante,

Composition and morphology of wear debris in failed uncemented

total hip replacement, J. Bone Joint Surg. 76B (1994) 6067.

[14] J. Savio, L. Overcamp, J. Black, Size and shape of biomaterial wear

debris, Clin. Mater. 15 (1994) 101119.

[15] K. Margevicius, T. Bauer, J. McMahon, S. Brown, K. Merritt, Isola-

tion and characterization of debris in membranes around total joint

prostheses, J. Bone Joint Surg. 76A (1994) 16641676.

[16] P. Campbell, P. Doorn, F. Dorey, H. Amstutz, Wear and morphology

of ultra-high molecular weight polyethylene wear particles from total

hip replacements, Proc. Inst. Mech. Eng. H: J. Eng. Med. 210 (1996)

167175.

[17] A. Shanbhag, H. Bailey, D. Hwang, C. Cha, N. Eror, H. Rubash,

Quantitative analysis of ultrahigh molecular weight polyethylene

(UHMWPE) wear debris associated with total knee replacements,

J. Biomed. Mater. Res. 53 (1) (2000) 100110.

[18] B. Ramamurti, C. Bragdon, D. OConnor, J. Lowenstein, M. Jasty, D.

Estok, W. Harris, Loci of movement of selected points on the femoral

head during normal gait, J. Arthroplasty 11 (7) (1996) 852855.

[19] A. Wang, D. Sun, S.-S. Yau, B. Edwards, M. Sokol, A. Essner, V.

Polineni, C. Stark, J. Dumbelton, Orientation softening in the defor-

mation and wear of ultra-high polyethylene, Wear 203204 (1997)

230241.

[20] V. Saikko, T. Ahlroos, Type of motion and lubricant in wear simu-

lation of polyethylene acetabular cup, Proc. Inst. Mech. Eng. H: J.

Eng. Med. 213 (1999) 301310.

[21] C. Bragdon, D. OConnor, J. Lowenstein, M. Jasty, W. Syniuta, The

importance of multidirectional motion on the wear of polyethylene,

Proc. Inst. Mech. Eng. H: J. Eng. Med. 210 (1996) 157166.

[22] A. Wang, C. Stark, J. Dumbleton, Mechanistic and morphological

origins of ultra-high molecular weight polyethylene wear debris in

total joint replacement prostheses, Proc. Inst. Mech. Eng. H: J. Eng.

Med. 210 (1996) 141155.

[23] A. Wang, V. Polineni, A. Essner, M. Sokol, D. Sun, C. Stark, J. Dum-

bleton, The signicance of non-linear motion in the wear screening

of orthopaedic implant materials, Test. Eval. 25 (2) (1997) 239245.

M.E. Turell et al. / Wear 259 (2005) 984991 991

[24] A. Wang, A. Essner, V. Polineni, C. Stark, J. Dumbleton, Lubrication

and wear of ultra-high molecular weight polyethylene in total joint

replacements, Tribol. Int. 31 (13) (1998) 1733.

[25] L. Caravia, D. Dowson, J. Fisher, B. Jobbins, The inuence of

bone and bone cement debris on counterface roughness in slid-

ing wear tests of ultra-high molecular weight polyethylene on stain-

less steel, Proc. Inst. Mech. Eng. H: J. Eng. Med. 204 (1) (1990)

6570.

[26] T.D. Brown, K.J. Stewart, J.C. Nieman, D.R. Pedersen, J.J.

Callaghan, Local head roughening as a factor contributing to vari-

ability of total hip wear: a nite element analysis, J. Biomech. Eng.

124 (6) (2002) 691698.

[27] D. Bennett, J. Orr, R. Baker, Movement loci of selected points on

the femoral head for individual total hip arthroplasty patients using

three-dimensional computer simulation, J. Arthroplasty 15 (7) (2000)

909915.

[28] A. Wang, A unied theory of wear for ultra-high molecular weight

polyethylene in multidirectional sliding, Wear 248 (2001) 3847.

[29] M. Turell, A. Wang, A. Bellare, Quantication of the effect of

cross-path motion on the wear rate of ultra-high molecular weight

polyethylene, Wear 255 (2003) 10341039.

[30] A. Wang, V.K. Polineni, C. Stark, J.H. Dumbleton, Effect of femoral

head surface roughness on the wear of ultrahigh molecular weight

polyethylene acetabular cups, J. Arthroplasty 6 (1998) 615620.

You might also like

- Anesthesia Equipment - Principles and Applications - Ehrenwerth-Eisenkraft-Berry - 2ed. - 2013 - 714 PáginasDocument705 pagesAnesthesia Equipment - Principles and Applications - Ehrenwerth-Eisenkraft-Berry - 2ed. - 2013 - 714 Páginasmaria lacayo80% (5)

- Service Manual E0S6B-PTA PDFDocument341 pagesService Manual E0S6B-PTA PDFAhmed Kamal100% (3)

- Sample BQ 1Document76 pagesSample BQ 1marani_rahmat100% (2)

- Ready To Download: Sandisk® Secureaccess™ For Mac UsersDocument1 pageReady To Download: Sandisk® Secureaccess™ For Mac UsersJosé santanaNo ratings yet

- It600 Wiring Centre Kl08rf 028 v9Document2 pagesIt600 Wiring Centre Kl08rf 028 v9NataLeeNo ratings yet

- Introduction To Mass Communication: Media Literacy and CultureDocument28 pagesIntroduction To Mass Communication: Media Literacy and CultureMirza AimanNo ratings yet

- A Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingDocument10 pagesA Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingJosé santanaNo ratings yet

- PINO DISCO Influence OfcrosslinkedpolyethylenestructureonwearofjointreplacementsDocument13 pagesPINO DISCO Influence OfcrosslinkedpolyethylenestructureonwearofjointreplacementsJosé santanaNo ratings yet

- Total Ankle Replacement: The Results in 200 Ankles P. L. R. Wood, S. DeakinDocument8 pagesTotal Ankle Replacement: The Results in 200 Ankles P. L. R. Wood, S. Deakinashut1No ratings yet

- Applied Biomechanics: Forces Acting On The HipDocument10 pagesApplied Biomechanics: Forces Acting On The HipNguyên Nguyễn TrungNo ratings yet

- Finite Element Method Simulation of Bone Resorption Beneath A Complete DentureDocument4 pagesFinite Element Method Simulation of Bone Resorption Beneath A Complete DentureFiru LgsNo ratings yet

- Costo de Energia Paso A Paso en AmputadosDocument6 pagesCosto de Energia Paso A Paso en AmputadosJorge Eduardo Jiménez SimpsonsNo ratings yet

- Advanced Biomechanics For Total Arch Movement & Non-Surgical Treatment For Hyperdivergent FacesDocument21 pagesAdvanced Biomechanics For Total Arch Movement & Non-Surgical Treatment For Hyperdivergent FacesLady SolarteNo ratings yet

- Project Group 10Document26 pagesProject Group 10amitgourav9No ratings yet

- Implant-Bone Load Transfer Mechanisms in Complete-Arch Prostheses Supported by Four Implants: A Three-Dimensional Finite Element ApproachDocument13 pagesImplant-Bone Load Transfer Mechanisms in Complete-Arch Prostheses Supported by Four Implants: A Three-Dimensional Finite Element ApproachMR GOKCHENNo ratings yet

- Finite-Element Analysis To Determine Effect of MonDocument20 pagesFinite-Element Analysis To Determine Effect of MonRufaida HussainNo ratings yet

- Knee MobilebearingkneeDocument20 pagesKnee MobilebearingkneeJobin VargheseNo ratings yet

- Ebacher2007 Dynamic Cimp TractDocument11 pagesEbacher2007 Dynamic Cimp Tractimen mehriNo ratings yet

- K.A. Laux, C.J. Schwartz: Article InfoDocument8 pagesK.A. Laux, C.J. Schwartz: Article InfoAhda Dapong Rizqy MaulanaNo ratings yet

- Lateral Uka Survivorship Short To MidtermDocument5 pagesLateral Uka Survivorship Short To Midtermapi-267962692No ratings yet

- Biomaterials Total Joint ReplacementDocument9 pagesBiomaterials Total Joint ReplacementAnas KRGNo ratings yet

- The Impact of Plate Length, Fibula Integrity and Plate Placement On Tibial Shaft Fixation Stability - A Finite Element Study.Document7 pagesThe Impact of Plate Length, Fibula Integrity and Plate Placement On Tibial Shaft Fixation Stability - A Finite Element Study.lliuyueeNo ratings yet

- Durham Research Online: Deposited in DRODocument10 pagesDurham Research Online: Deposited in DROjainshani2No ratings yet

- Mechanical Properties of Opus Closing Loops, L-Loops, and T-Loops Investigated With Finite Element AnalysisDocument9 pagesMechanical Properties of Opus Closing Loops, L-Loops, and T-Loops Investigated With Finite Element AnalysisElla GolikNo ratings yet

- IMP PaperDocument8 pagesIMP PapersunilbabaNo ratings yet

- Surface Engineering of Prosthetic Knee Components: J. NevelosDocument5 pagesSurface Engineering of Prosthetic Knee Components: J. NevelosJoko TriwardonoNo ratings yet

- Weight-Bearing Recommendations After First Metatarsophalangeal Joint Arthrodesis Fixation: A Biomechanical ComparisonDocument6 pagesWeight-Bearing Recommendations After First Metatarsophalangeal Joint Arthrodesis Fixation: A Biomechanical Comparisonmavriska.chairunnisaNo ratings yet

- SPE 148078 Dual-Permeability Model For Coupled Reservoir Geomechanical Modeling: Application For Field Production DataDocument10 pagesSPE 148078 Dual-Permeability Model For Coupled Reservoir Geomechanical Modeling: Application For Field Production DataRomel Angel Erazo BoneNo ratings yet

- Microsoft Word - THR Preprint - Thr+PreprintDocument2 pagesMicrosoft Word - THR Preprint - Thr+PreprintNuno GueiralNo ratings yet

- FulltextDocument10 pagesFulltextDenis AlexandruNo ratings yet

- Alhassan - 2008Document6 pagesAlhassan - 2008Marina MalafaiaNo ratings yet

- 1471 2474 12 79 PDFDocument7 pages1471 2474 12 79 PDFElAhijadoNo ratings yet

- (OKAMURA) Displacement of Gravity Retaining Walls Under Seismic LoadingDocument9 pages(OKAMURA) Displacement of Gravity Retaining Walls Under Seismic Loadinghal9000_mark1No ratings yet

- Jang 2008Document9 pagesJang 2008Marco Morillo RodríguezNo ratings yet

- Reduction of Implant Loading Using A Modified Centric Occlusal AnatomyDocument16 pagesReduction of Implant Loading Using A Modified Centric Occlusal AnatomyPablo Gutiérrez Da VeneziaNo ratings yet

- 208-The Versatility and EffectivenessDocument11 pages208-The Versatility and Effectivenessezfresh100% (1)

- This Paper Must Be Cited As:: Document Downloaded FromDocument52 pagesThis Paper Must Be Cited As:: Document Downloaded FromTesfa HunderaNo ratings yet

- Gait Patterns in Individuals With AmputationDocument7 pagesGait Patterns in Individuals With AmputationSangeetha GnaneswaranNo ratings yet

- Journal of Biomechanics: Junyan Li, Todd D. Stewart, Zhongmin Jin, Ruth K. Wilcox, John FisherDocument7 pagesJournal of Biomechanics: Junyan Li, Todd D. Stewart, Zhongmin Jin, Ruth K. Wilcox, John FisherRenka BlodersNo ratings yet

- Stress Distribution in The Abutment and Retention Screw of A Single Implant Supporting A Prosthesis With Platform SwitchingDocument10 pagesStress Distribution in The Abutment and Retention Screw of A Single Implant Supporting A Prosthesis With Platform SwitchingMarlene Kasumi Gantier TakanoNo ratings yet

- No AntropomorficoDocument5 pagesNo Antropomorficoana márquezNo ratings yet

- J Arth 2015 09 001Document7 pagesJ Arth 2015 09 001Carlos Mauricio Salazar BedollaNo ratings yet

- The Knee Wear Prediction of UHMWPE Tibial Insert Using VIPRO PlatformDocument10 pagesThe Knee Wear Prediction of UHMWPE Tibial Insert Using VIPRO PlatformMia AmaliaNo ratings yet

- Journal Orthopaedic Research - 2023 - Bishop - Tricompartment Offloader Knee Brace Reduces Contact Forces in Adults WithDocument9 pagesJournal Orthopaedic Research - 2023 - Bishop - Tricompartment Offloader Knee Brace Reduces Contact Forces in Adults WithCarlosNo ratings yet

- Fatigue Strength of Bovine Articular Cartilage-On-Bone Under Three-Point Bending: The Effect of Loading FrequencyDocument8 pagesFatigue Strength of Bovine Articular Cartilage-On-Bone Under Three-Point Bending: The Effect of Loading FrequencyDicky Pratama PutraNo ratings yet

- 10 1016@j Jos 2016 04 015Document7 pages10 1016@j Jos 2016 04 015osmann52No ratings yet

- A Comparative Study of Wear Laws For Soft-On-hard Hip Implants Using A Mathematical Wear ModelDocument12 pagesA Comparative Study of Wear Laws For Soft-On-hard Hip Implants Using A Mathematical Wear ModelLeelakrishnan EthirajNo ratings yet

- Can Internal Stresses Explain The Fracture Resistance of Cusp Replacing Composite RestorationsDocument7 pagesCan Internal Stresses Explain The Fracture Resistance of Cusp Replacing Composite RestorationsSara FarisNo ratings yet

- Iliotibial Band TenodesisDocument10 pagesIliotibial Band Tenodesisjgold05No ratings yet

- Buckling and Design of Columns With Intermediate Elastic Torsional RestraintDocument14 pagesBuckling and Design of Columns With Intermediate Elastic Torsional Restraintfahmi aballiNo ratings yet

- Sun JWB Asec98Document8 pagesSun JWB Asec98Angela CollinsNo ratings yet

- A Comparison Between Two Different Tech For Transverse Patella FracturesDocument25 pagesA Comparison Between Two Different Tech For Transverse Patella FracturesPurushotham NalamatiNo ratings yet

- Motion Response of A Floating Offshore Wind Turbine FoundationDocument4 pagesMotion Response of A Floating Offshore Wind Turbine Foundationdeepak_dce_meNo ratings yet

- Semi Rigid ModelDocument54 pagesSemi Rigid ModelmdkmlNo ratings yet

- Effect of Eccentric Loading On Footings PDFDocument21 pagesEffect of Eccentric Loading On Footings PDFprraaddeej chatelNo ratings yet

- Honeycomb Cell DimensionsDocument11 pagesHoneycomb Cell DimensionsRizwana JyotiNo ratings yet

- An Elastohydrodynamic Lubrication (EHL) Model of Wear Particle Migration in An Artificial Hip JointDocument13 pagesAn Elastohydrodynamic Lubrication (EHL) Model of Wear Particle Migration in An Artificial Hip JointVincent IrawanNo ratings yet

- An Evidence-Based TicDocument2 pagesAn Evidence-Based TicmothannaNo ratings yet

- Seismic Performance of Brace-Beam-Column Connections in Concentrically Braced FramesDocument13 pagesSeismic Performance of Brace-Beam-Column Connections in Concentrically Braced FramesAlexander BrennanNo ratings yet

- Comparison Ofthree Facebowsemiadjustable Articulator2233Document6 pagesComparison Ofthree Facebowsemiadjustable Articulator2233Brijesh MaskeyNo ratings yet

- 9 - Analysis of Wear ..... 2-10Document5 pages9 - Analysis of Wear ..... 2-10dfrasNo ratings yet

- Distal Humeral Fractures-Current Concepts PDFDocument11 pagesDistal Humeral Fractures-Current Concepts PDFRina AlvionitaNo ratings yet

- UHMWPE and Vitamin E Bioactivity: An Emerging Perspective: Filippo Reno', Mario CannasDocument5 pagesUHMWPE and Vitamin E Bioactivity: An Emerging Perspective: Filippo Reno', Mario CannasJobin VargheseNo ratings yet

- Agonist-Antagonist Active Knee Prosthesis - A Preliminary Study in Level-Ground WalkingDocument13 pagesAgonist-Antagonist Active Knee Prosthesis - A Preliminary Study in Level-Ground Walkingrkp17No ratings yet

- Selected Instructional Course Lectures: The American Academy of Orthopaedic SurgeonsDocument23 pagesSelected Instructional Course Lectures: The American Academy of Orthopaedic SurgeonsGERARDO TORRES RUIZNo ratings yet

- Orthodontically Driven Corticotomy: Tissue Engineering to Enhance Orthodontic and Multidisciplinary TreatmentFrom EverandOrthodontically Driven Corticotomy: Tissue Engineering to Enhance Orthodontic and Multidisciplinary TreatmentFederico BrugnamiNo ratings yet

- The Prediction of Conveyor Trajectories: DB Hastie and PW WypychDocument17 pagesThe Prediction of Conveyor Trajectories: DB Hastie and PW WypychJosé santanaNo ratings yet

- Analytical and Numerical Investigations Into Belt Conveyor TransfersDocument34 pagesAnalytical and Numerical Investigations Into Belt Conveyor TransfersJosé santanaNo ratings yet

- Validation of Particle Flow Through A Conveyor Transfer Hood Via Particle Velocity AnalysisDocument6 pagesValidation of Particle Flow Through A Conveyor Transfer Hood Via Particle Velocity AnalysisJosé santanaNo ratings yet

- W13018-YT01-GDF-457110 Rev 5-APVDocument8 pagesW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNo ratings yet

- Conveyor Trajectory Discharge AnglesDocument10 pagesConveyor Trajectory Discharge AnglesJosé santanaNo ratings yet

- The Prediction of Conveyor Trajectories: DB Hastie and PW WypychDocument17 pagesThe Prediction of Conveyor Trajectories: DB Hastie and PW WypychJosé santanaNo ratings yet

- Luis 48Document7 pagesLuis 48José santanaNo ratings yet

- The Profile of Conveyor TrajectoriesDocument11 pagesThe Profile of Conveyor TrajectoriesJosé santanaNo ratings yet

- Modelling and Design of Complete Conveyor Transfers: D.B. Hastie, A.P. Grima and P.W. WypychDocument20 pagesModelling and Design of Complete Conveyor Transfers: D.B. Hastie, A.P. Grima and P.W. WypychJosé santanaNo ratings yet

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityDocument19 pagesBelt Conveyors: Mechanical Engineering Department Carlos III UniversityJosé santanaNo ratings yet

- Polyethylene Particles From A Hip Simulator Cause Ca Release From Cultured BoneDocument8 pagesPolyethylene Particles From A Hip Simulator Cause Ca Release From Cultured BoneJosé santanaNo ratings yet

- A Hip Wear Simulator With 100 Test StationsDocument10 pagesA Hip Wear Simulator With 100 Test StationsJosé santanaNo ratings yet

- Design of A Hip Joint Simulator According To The ISO 14242: Nikolaos I. Galanis, Member, IAENG and Dimitrios E. ManolakosDocument6 pagesDesign of A Hip Joint Simulator According To The ISO 14242: Nikolaos I. Galanis, Member, IAENG and Dimitrios E. ManolakosJosé santanaNo ratings yet

- A Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingDocument10 pagesA Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingJosé santanaNo ratings yet

- In Vivo: Nanometer Size Wear Debris Generated From Ultra High Molecular Weight PolyethyleneDocument7 pagesIn Vivo: Nanometer Size Wear Debris Generated From Ultra High Molecular Weight PolyethyleneJosé santanaNo ratings yet

- Can Centrifugation Affect The Morphology of Polyethylene Wear Debris?Document4 pagesCan Centrifugation Affect The Morphology of Polyethylene Wear Debris?José santanaNo ratings yet

- What Is The Role of Wear Testing and Joint Simulator Studies in Discriminating Among Materials and Designs?Document9 pagesWhat Is The Role of Wear Testing and Joint Simulator Studies in Discriminating Among Materials and Designs?José santanaNo ratings yet

- PINO DISCO Influence OfcrosslinkedpolyethylenestructureonwearofjointreplacementsDocument13 pagesPINO DISCO Influence OfcrosslinkedpolyethylenestructureonwearofjointreplacementsJosé santanaNo ratings yet

- Airex C70: Universal Structural FoamDocument3 pagesAirex C70: Universal Structural FoamBaris senelNo ratings yet

- EvapEmission PDFDocument8 pagesEvapEmission PDFpivillamilNo ratings yet

- Air TestDocument2 pagesAir TestAli HaiderNo ratings yet

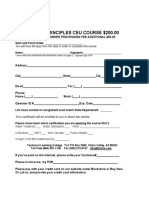

- Pumping Principles Ceu Course $200.00: Registration FormDocument54 pagesPumping Principles Ceu Course $200.00: Registration FormGkou DojkuNo ratings yet

- Site Exploration: Vedprakash C. MarlapalleDocument45 pagesSite Exploration: Vedprakash C. Marlapallevedprakash marlapalle100% (1)

- Flus 06 Uv / Fls 09 Uv: User ManualDocument24 pagesFlus 06 Uv / Fls 09 Uv: User ManualDuyNo ratings yet

- Flow Meter 2.04.5Document24 pagesFlow Meter 2.04.5Sitto JosephNo ratings yet

- Particle Size US Sieve Series and Tyler Mesh Size EquivalentsDocument3 pagesParticle Size US Sieve Series and Tyler Mesh Size EquivalentsAiman HakimNo ratings yet

- Spherical Storage Tank Presentation - Rev.0Document33 pagesSpherical Storage Tank Presentation - Rev.0Rino Rapada100% (5)

- ReadmeDocument16 pagesReadmeLuzMaríaSotoNo ratings yet

- INSPECT Features and Benefits - CodewareDocument5 pagesINSPECT Features and Benefits - CodewareLibardo Bahamón LiscanoNo ratings yet

- ObjectiveDocument19 pagesObjectiveAmmir JusohNo ratings yet

- Prius P Hev ManualDocument16 pagesPrius P Hev Manualrey1004No ratings yet

- Contacts Backup 2014-03-08 11-21Document69 pagesContacts Backup 2014-03-08 11-21Matthew BaileyNo ratings yet

- 02 Oliver NenadovicDocument39 pages02 Oliver NenadovicRinu RavikumarNo ratings yet

- Optimal Location of Unified Power Flow Controller (Upfc) in Nigerian Grid System Using Modified Sensitivity AnalysisDocument11 pagesOptimal Location of Unified Power Flow Controller (Upfc) in Nigerian Grid System Using Modified Sensitivity AnalysisSteven Jones100% (1)

- Materials System SpecificationDocument12 pagesMaterials System SpecificationFlorante NoblezaNo ratings yet

- Ceiling Cassette Split SystemsDocument240 pagesCeiling Cassette Split SystemsRicardo Molina SánchezNo ratings yet

- Low Profile Hammer Union Caps - 2017Document2 pagesLow Profile Hammer Union Caps - 2017Hector Luis MejiaNo ratings yet

- 3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Document7 pages3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Sri Wahyuni HandayaniNo ratings yet

- Analysis of The Cost of Infrastructure Failures in A Developing EconomyDocument44 pagesAnalysis of The Cost of Infrastructure Failures in A Developing Economymexx4u2nv100% (1)

- Single Axis Tracker Sat Control STL36 Solar Tracker DrawingsDocument1 pageSingle Axis Tracker Sat Control STL36 Solar Tracker DrawingsNahuel BritoNo ratings yet

- Daily Material, Gate Pass FormetDocument5 pagesDaily Material, Gate Pass FormetS.m. MoniruzzamanNo ratings yet

- Power Factor Correction Mkk480-D-25-01Document3 pagesPower Factor Correction Mkk480-D-25-01Halil DemirNo ratings yet

- 1ab367c9 PDFDocument88 pages1ab367c9 PDFRS Rajib sarkerNo ratings yet