Professional Documents

Culture Documents

Review of Production/operations Management

Review of Production/operations Management

Uploaded by

skyppy20 ratings0% found this document useful (0 votes)

104 views22 pagesDetailed review/description/summary of Production/Operations Management by William J. Stevenson. This is a comprehensive analysis of the book that offers a section-by-section analysis of this textbook.

Original Title

REVIEW OF PRODUCTION/OPERATIONS MANAGEMENT

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDetailed review/description/summary of Production/Operations Management by William J. Stevenson. This is a comprehensive analysis of the book that offers a section-by-section analysis of this textbook.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

104 views22 pagesReview of Production/operations Management

Review of Production/operations Management

Uploaded by

skyppy2Detailed review/description/summary of Production/Operations Management by William J. Stevenson. This is a comprehensive analysis of the book that offers a section-by-section analysis of this textbook.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 22

1

REVIEW OF PRODUCTION/OPERATIONS MANAGEMENT

William J. Stevenson's book, Production/Operations

Management provides an up-to-date introduction to the field.

The book is well written and makes excellent use of charts,

graphs, illustrations and photographs. Each chapter

includes learning objectives and a chapter outline at the

beginning, and concludes with a summary, a list of key terms

and the pages where they are defined, and solved problems.

In addition, there are discussion and review questions as

well as problems without solutions provided. There are two

appendices, one containing solutions to some problems, and

the other containing appropriate tables for calculations.

Stevenson has also included a number of case studies to

encourage the application of what is presented in the text.

By making good use of headings and subheadings, and by using

shaded areas to call attention to real-world examples,

Stevenson has succeeded in creating a text that is eminently

readable and useful to students of production and operations

management.

The text itself is divided into four sections:

introduction, forecasting, design of production systems and

operating and controlling the system. The bulk of the text

(a full eight of 16 chapters) is dedicated to the fourth

section, indicating the importance which the author gives to

operation and control. Five chapters are dedicated to

2

production system design, with the forecasting section made

up of only one chapter. The introduction contains two

chapters, an overview of production management and a chapter

on decision making.

In beginning his book, Stevenson asserts that

operations is one of three main functions of any

organization; marketing and finance comprise the other two

(5). He also defines operations management as being

responsible for the management of productive systems,

"systems that either create goods or provide services" (4).

Recognizing that historically, operations management has

concentrated on manufacturing, Stevenson suggests that the

scope of operations management has expanded to include both

manufacturing and service activities.

Expanding on the idea that operations management is

responsible for all activities directly related to

manufacturing a product or providing a service, the author

suggests that operations management is responsible for

transforming inputs of resources (people, material, energy,

money, information) into useful goods and services. Two

main decision areas have emerged within operations

management as a result: system design and system operation

(11).

System design is concerned with decisions related to

capacity, location, layout and product/process design.

3

System operation, on the other hand, is concerned with human

resources, schedule, inventory, overall project management

and quality. The operations manager is charged with

maintaining a high level of productivity (14), which

Stevenson identifies as the relationship between outputs and

inputs.

Recognizing that operations and production management

has evolved over the years, the author concludes this

chapter by identifying issues facing managers today. He

identifies government regulation, increased foreign

competition, and an exponential rate of growth of technology

as having a great influence on the operations manager. At

the same time that the manager's world is becoming more

complex and subject to the influence of a greater number of

variables, there is also a growing emphasis on controlling

costs, increasing quality and maintaining a flexible

atmosphere. The balance of the book is dedicated to

teaching readers how they can accomplish this.

The second chapter of the introductory section of the

book is dedicated to decision making, which the author

identifies as an "integral" part of operations management

(42). Stevenson presents a seven-step decision process to

aid managers: 1) identify the problem; 2) specify

objectives and the decision criteria for choosing a

solution; 3) develop alternatives; 4) analyze and compare

4

alternatives; 5) select the best alternative; 6) implement

the chosen alternative; and 7) monitor the results to ensure

that desired results are achieved (42). The author also

introduces the use of quantitative systems models.

Stevenson also presents an overview of decision theory,

which he identifies as providing a framework for decision

analysis. Decision theory includes different techniques

which can be classified according to the level of

uncertainty associated with the particular problem under

consideration (51). Decisions which Stevenson feels are

subject to decision theory are characterized by three

elements: a set of possible future conditions exists that

will have a bearing on the results of the decision; the

manager has a list of alternatives to choose from; there is

a known payoff for each alternative under each possible

future condition (51). The author suggests two visual

tools, decision trees and graphical sensitivity analysis, as

ways of helping managers using decision theory. There is

also a lengthy section on linear programming as a tool for

decision making at the end of the chapter.

The second section of the book, forecasting, has only

one chapter dedicated to it. Stevenson chooses to put this

chapter near the beginning of the text because "forecasts

are the basis for a wide range of design and operating

decisions" (125). In other words, much of what follows in

5

the book assumes a knowledge, or at least a passing

understanding, of forecasting. The author is also careful

to point out that while forecasts are traditionally thought

of as belonging in the province of marketing, operations

also is a significant user and developer of forecasts (125).

According to Stevenson, forecasts can be either

quantitative (measurable) or qualitative (subjective). He

presents two quantitative approaches: time series analysis

and associative techniques. Time series analysis are

historically based and make future predictions based on the

behavior of data in the past. Additional variables which

might influence the factor at hand are not considered.

Associated techniques, such as simple and multiple

regression, attempt to account for these variables which

will have an impact on the factor being predicted.

Qualitative techniques rely on the individual's

experience and expertise to make the forecast. Examples of

this type of technique include consumer surveys, sales force

composites, outside opinion and the Delphi technique. When

the Delphi technique is used, a questionnaire is circulated

among individuals who have the background to accurately

assess the situation at hand. Additional questionnaires are

circulated with information gleaned from previous iterations

incorporated. The goal is to achieve a consensus forecast

from among experts (132).

6

Stevenson cautions that forecasts are predictions of

the future, and therefore, subject to inaccuracy. He then

presents measures of accuracy which he submits should be

incorporated into any forecast. Such measures can identify

whether the forecasting technique is valuable or appropriate

for the issue, as well as whether the forecast is accurate.

Forecasts must be monitored for accuracy, usefulness and

cost. When selecting a forecasting technique, managers must

align the expected accuracy with the associated cost, and

make decisions appropriately. For example, if a forecast

which has an accuracy level of 95 percent costs

significantly less than a forecast with an accuracy level of

98 percent, the manager must weigh whether an increase of

three points is worth the additional cost.

The next five chapters are dedicated to the design of

production systems. Stevenson recognizes that design

decisions are not made just when an organization is starting

out (although design decisions made at that time are

critical). In fact, design decisions are made throughout

the life cycle of an organization. These decisions have an

effect on the long-term goals of the organization and the

costs associated with doing business. They can be costly

and difficult to reverse. Strategic in nature, design

decisions encompass product and service design, location

planning, process selection and capacity planning,

7

facilities layout and the design of work systems. This

section of the text begins with a discussion of product and

service design.

Product and service design is at the heart of a

company's operations because the other design aspects of the

organization are based on the product or service in

question. The dynamic environment in which today's

organizations exist also dictate that product and service

design decisions be subject to constant improvement.

Although costly, research and development (R & D) is an

effective way to develop new products (202). Because of the

cost factor, however, relatively few organizations are able

to indulge in significant R & D efforts. Design by

imitation is less costly than R & D, but does not enable an

organization to be the first provider of a product or

service.

Standardization and reliability are key components of

product design. Uniformity of output and related activities

yields certain economies, but decreases the differentiation

which can be implemented. Reliability has three key

components: probability; definition of failure; and

prescribed operating conditions (207). Reliability is

fundamentally the ability of a part to perform as intended

given a certain set of conditions. Measuring and improving

reliability are key components of systems design.

8

Two tools which have been developed to aid in product

design are computer aided design (CAD) and computer aided

manufacturing (CAM). The two are often used in conjunction

with one another. Such sophisticated tools are necessary

since function and cost, both products of design and

manufacturing, are important factors in the success of an

organization.

Stevenson next turns his attention to location

planning, which has long-term ramifications for new and

existing organizations, alike. New organizations make

location decisions based on their long-term goals, expected

rates of growth, product decisions and the capitalization

behind the organization. The variables are similar for

existing organizations, who must determine whether to expand

existing facilities, move the entire operation to new

facilities, or settle on some combination of the two.

Supply sources, including raw materials and labor

supply, influence location decisions. Market conditions,

housing availability and climate can all affect a company's

location decision. Foreign locations may be attractive

because of lower labor costs and raw material availability.

These advantages must be considered against the

disadvantages of language differences and cultural

differences, as well as the stability of the government in

9

the foreign location and their sentiments toward Americans

and American companies.

In order to decide which location alternative is

optimum for an organization, operations managers can first

determine a region that meets the overall needs, then

identify the communities which may warrant further

evaluation. Stevenson presents a number of methods,

including location cost-volume analysis and factor rating,

which can be used to make determinations among the final

alternatives. He also presents a transportation model as a

supplement to the chapter.

In chapter 6, Stevenson discusses process selection,

which refers to the ways an organization produces or

provides its products and services. Technology is often a

key component of process selection which, in turn, affects

capacity planning and equipment procurement (296). The

methods used by an organization to produce its product

affect productivity, costs, competitiveness and flexibility.

New products and changes in existing products provide the

reason that most organizations are constantly engaged in

some sort of process selection.

Involved in process selection is the type of processing

currently in use (steady and high-volume, or intermittent

and low-volume, for example), the level of automation in use

10

(including computer assisted processing), the amount of

flexibility needed, and processing costs.

Stevenson defines capacity as a "system's potential for

producing goods or delivering services over a specified time

interval" (322). Capacity limitations determine operating

costs as well as provide a maximum level of output which can

be achieved.

Full or maximum capacity is seldom realized; a number

of factors conspire to prevent this. Among these are

facility design and layout, human inefficiency, design,

equipment failures and quality factors. Despite this,

capacity planning has evolved as an integral part of

operations management, with short- and long-term

considerations and goals. Short-term considerations include

anticipating and reacting to variances in demand. Long-term

considerations must account for the overall capacity level,

even with short-term seasonal fluctuations.

Developing capacity alternatives involves taking a

systems approach and realizing that increases in capacity

can be acquired in chunks, rather than units. Flexible

systems which can adapt to short-term fluctuations are

preferable to inflexible systems, and product combinations

which can overcome temporary changes in demand in one

product area are preferable to a one-product system.

11

Quantitative and qualitative techniques are used to

evaluate capacity alternatives. Quantitative techniques are

characterized by consideration of economic factors while

qualitative techniques may include factors such as public

opinion and managers' preferences. Cost-volume analysis,

financial analysis and decision theory are also tools which

can be used for analyzing and selecting alternatives.

Stevenson concludes this chapter with a supplement on

financial analysis, including tax considerations and

financial evaluation methods such as payback and net present

value.

Chapter 7, Facilities Layout, includes four-color

photographs of John Deere and Apple Computer, among other

manufacturers, illustrating the points that Stevenson makes

in the text. Layout decisions are directly affected by

location, product and capacity decisions discussed earlier.

Stevenson identifies three types of processing, each of

which has a bearing on facility layout: continuous,

intermittent, and project. Continuous processing has a high

volume of a few (even one) products. Intermittent

processing is able to provide for a broader range of

products. Projects are used to plan and co-ordinate

complicated jobs with brief life spans.

Product layouts are used for continuous processing,

process layouts for intermittent processing and fixed-

12

position layouts for projects. Some projects do not require

layouts at all. Workers and equipment are allocated based

on the technological requirements of the product. The

operations manager tries to optimize work flow through the

system when designing the layout. Because the alternatives

facing the decision maker can be overwhelming, computer

software has been developed to help determine the best

alternative.

Chapter 8, the last chapter in this section of the

book, focuses on the design of work systems. Stevenson

asserts that work systems involve job design, work

measurement and compensation (394).

Job design is concerned with what jobs are to

accomplish and the method in which they are to accomplish

those tasks. In recent years, there has been an increasing

awareness of the impact jobs have on workers' behavior and

satisfaction, as well. Productivity, which came into

increasing popularity during the 1980s, also has influenced

job design.

Methods analysis and motion studies can be used to

determine the efficiency of jobs, but they ignore the

behavioral aspects. At the same time, working conditions

are an important part of job design in that they can

increase efficiency and augment behavioral factors, and can

also determine the health and safety of workers.

13

Work measurement refers to efforts to determine how

long it should take to complete a given job in a given set

of circumstances. Measurements such as this are necessary

for human resource planning, cost forecasting, budgeting and

scheduling equipment. Stopwatch time studies and

predetermined times are two commonly used approaches. Work

sampling can also be used to determine activity time.

The last eight chapters of the book are dedicated to

operating and controlling the system used to produce the

product, be it a good or a service. Here Stevenson

addresses aggregate planning, inventory management, material

requirements planning (MRP), just-in-time systems (JIT),

scheduling, project management, waiting lines and quality

assurance. This section begins with a bridge between the

design aspects of the first chapters and the operating

aspects of the last chapters.

In fact, aggregate planning seeks to "achieve a

production plan that will effectively utilize the

organization's resources to satisfy expected demand" within

a two- to 18-month timeframe (466). Aggregate planning is

between the broad design decisions necessary for the long-

term goals of the organization and the detailed short-range

decisions that comprise day-to-day operations. Aggregate

planning is characterized by an overall forecast for the

14

period in question and methods for applying the plan to

specific products.

The heart of aggregate planning is the combining of an

organization's products and services into one "product."

Such a combination enables the planners to consider overall

employment and inventory levels without becoming bogged down

in the day-to-day details.

Stevenson considers inventory management central to the

success of most organizations, and devotes the tenth chapter

to this issue. Inventory must be maintained at a level

which permits optimum output, but which does not burden the

company with inefficiency. There are holding costs

associated with inventory, just as there are costs

associated with providing a given level of customer

satisfaction. Inventory management is successful when it is

able to balance the two.

The author presents four classes of inventory

management models: economic order quantity (EOQ), reorder

point (ROP), fixed-interval and single-period. If unused

parts can be carried over into subsequent periods, then the

first three models are used. The single-period model is

appropriate, as its name implies, when items cannot be

carried over into the next time period.

EOQ models are based on how much to order. ROP models

are based on when to order and are optimum when there are

15

variations in item availability or lead time. Fixed

interval models are useful when the time between orders is

predetermined. Stevenson presents formulas for each of

these models under various conditions, and discusses their

implementation under the same conditions.

In Chapter 11, Stevenson addresses a specific

information system, material requirements planning (MRP),

used to order dependent-demand items, such as components of

assembled products (609). Planning begins with customer

orders, which are used to develop a schedule showing the

timing and quantity of finished products. The finished

items are then "exploded" using their bill of materials, and

plans are developed indicating the quantity and timing for

ordering or producing components.

The salient components of MRP are the timeliness of

requirements, determining what the components are, and

ordering according to planned releases. To be successful,

MRP requires computers and accurate schedules along with

bills of material and inventory data. The lack of any of

these components can cause the failure of the system as a

whole.

MRP II is the term given to recent innovations in MRP.

It refers to manufacturing resource planning and links the

business plan with the production plan and the master

schedule. It does not replace MRP, nor is it simply an

16

improved version. Instead, MRP II seeks to incorporate

marketing and finance within the manufacturing plan.

Just-in-time systems (JIT) move items through a system

in such a way that the items reach the next point in the

system at the exact point they are needed. One of the

advantages of such systems is that when successfully

implemented, they reduce the inventory that is carried on

hand because each item arrives just as it is needed.

Because of the nature of JIT, it is best suited to

repetitive manufacturing environments (627).

JIT demands that an even rate of work flow be

maintained as much as possible. High quality is also

necessary to the success of the system since any defective

parts throw off the entire process. Quick set-ups and

special layouts are characteristic of JIT, since they allow

for items to be "pulled" through the system. At the same

time, problem solving within JIT systems tends to be

directed at keeping disruptions to the system at a minimum

and making the system more efficient.

The benefits of JIT, in addition to lower inventory

carrying costs, include high quality, a flexible system,

increased productivity and reduced rework due to poor

quality.

Manufacturers who are considering converting to a JIT

system should consider the support both of management and

17

employees, since a high spirit of co-operation is necessary

for its successful implementation. This co-operation also

carries over into the relationships that the manufacturer

enjoys with the suppliers, as vendor compliance with

schedules is also necessary for the success of the system.

Stevenson next takes on the issue of scheduling, which

he identifies as the timing and co-ordination of operations.

Scheduling is basic to every organization. Problems arise

depending on whether a scheduling system is set up for high

volume, intermediate volume, or as a job shop. The

complexity increases in job shops because the number of jobs

that may be processed is quite large.

Two major problems arise in scheduling job shops:

assigning jobs to machines and designating the sequence of

jobs to be processed at those machines. Gantt charts can be

used to help managers obtain a visual picture of the problem

(657) and are also useful to describe and sequence

alternatives.

Scheduling in service systems is significantly

different from that in manufacturing. Appointment and

reservations systems are often employed, but the goal of

balancing the system given the multiple resources involved

(customers, human resources) can be complex and difficult to

manage.

18

Chapter 14 focuses on project management. Projects are

defined has having a unique set of activities which seek to

meet a given set of objectives within a certain timeframe

(696). Projects are nonroutine in nature and are co-

ordinated not by the operations manager directly, but by

project managers.

Program evaluation and review techniques (PERT) and

critical path methods (CPM) are two widely used techniques

for managing projects. Both of these methods enable the

project manager to have a graphical model of the project.

Both provide an estimate of how long the project will take.

PERT and CPM both provide an indication of which activities

are most critical to complete the project on time. In

addition, both provide information which can be used to

determine how long any one activity can be delayed without

upsetting the entire project schedule.

Two different methods are used to construct a network

diagram. In one method, arrows are used to show activities.

In the other method, nodes are used to show activities.

Stevenson uses the arrow method to avoid confusion.

Since developing and updating project networks takes a

considerable amount of time for even mildly complex

projects, computer software programs have been written which

can simplify the task. When activity times are generally

accepted and subject to little variance, a deterministic

19

approach can be used. When those activity times are subject

to greater variance and some degree of uncertainty, a

probabilistic approach is called for.

In some cases, it is possible to decrease the time it

will take to complete a project by decreasing one or more of

the component activities. Additional resources can be used

to accomplish this, or resources already allocated to the

project might be moved about. Projects are generally

shortened to the point of realizing some gain over the

additional resource cost, or, when resources are moved in an

existing project, when gain is realized over any training

costs.

Waiting lines are associated with service systems and

generally form even when the system is underloaded.

Customers arrive at random times and service times vary.

The result can be temporary overloads. This is the subject

of Chapter 15. Waiting lines appear during overload

periods, but even with good scheduling techniques, there

will be times when human resources (servers) will be idle.

When considering waiting lines and queuing systems, it

is necessary to consider whether the potential number of

customers is unlimited (infinite source) or limited (finite

source) (745). Stevenson describes four models for handling

infinite source situations, and one model based on a finite

source of customers.

20

Only one chapter, the last one, is given to quality

assurance, but it is one of Stevenson's longest. Quality

assurance is a comprehensive approach that begins with the

design phase and which continues even after the product or

service has been delivered. Successful quality assurance

demands a clear definition of what is acceptable. Goods and

services must conform to the standards established by the

organization. Samples are taken to determine if the

organization is meeting this level of quality since it is

not generally feasible to actually examine each product.

Stevenson has produced a text which provides a solid

understanding of operations management. Although he tries

to cover both manufacturing and service industries, his

comments on the service area are generally considerably less

than those directed at manufacturers, and he might do well

to separate the two into different texts. This is a small

complaint, however, given the text as a whole.

In fact, Stevenson provides a selected bibliography at

the end of each chapter as well as short readings from

outside sources which serve to give the interested reader

additional sources. Those interested in JIT, for example,

can find additional sources listed at the end of the

chapter.

In all, Stevenson has done a good job of producing a

text which not only explains the salient points of

21

operations management, but which also serves to expose the

reader to considerations which are not readily quantifiable.

The book is a good introductory text and is also likely to

be used for reference by current operations managers.

22

SOURCE

Stevenson, William J. Production/Operations Management

(Homewood, IL: Irwin, 1990).

You might also like

- Supplier Self Audit Checklist: Formulaire Référence AA-FEQ-15-Rév.03Document2 pagesSupplier Self Audit Checklist: Formulaire Référence AA-FEQ-15-Rév.03Mandy NormanNo ratings yet

- Porter - What Is Strategy - HBRDocument21 pagesPorter - What Is Strategy - HBRbasmaNo ratings yet

- 9001 14001 45001 Comparison Table 14 March 2018Document3 pages9001 14001 45001 Comparison Table 14 March 2018narendra100% (1)

- ASIS Certification-Handbook FinalDocument38 pagesASIS Certification-Handbook Finalismailov25No ratings yet

- Project Report EditedDocument16 pagesProject Report EditedKishor PakhareNo ratings yet

- Hima BarotDocument51 pagesHima BarotHima BarotNo ratings yet

- Project Report Divya Mohan B, 121923Document104 pagesProject Report Divya Mohan B, 121923sreelakshmi.rNo ratings yet

- HCL InfosystemDocument83 pagesHCL InfosystembhavanshujNo ratings yet

- ACC Summer Project (MBA Operation)Document47 pagesACC Summer Project (MBA Operation)Niket DattaniNo ratings yet

- AfMcoft PDFDocument177 pagesAfMcoft PDFAmit KumarNo ratings yet

- World Class Operations - 2Document12 pagesWorld Class Operations - 2OmeYadavNo ratings yet

- AbhishkeDocument95 pagesAbhishkeAkash GuptaNo ratings yet

- A Project On Supply Chain ManagementDocument95 pagesA Project On Supply Chain Managementutpalbagchi67% (3)

- Financial Statement Analysis at Kirloskar GroupDocument89 pagesFinancial Statement Analysis at Kirloskar GroupRajesh InsbNo ratings yet

- Rane DocumentDocument90 pagesRane DocumentVasanth KumarNo ratings yet

- Project Report On - HRM IN AN ORGANIZATIONSDocument17 pagesProject Report On - HRM IN AN ORGANIZATIONSHoney VoraNo ratings yet

- BHVL Project Inventory ManagementDocument87 pagesBHVL Project Inventory ManagementPrasanthiNo ratings yet

- Final Projct (ZUARI CEMENTS)Document49 pagesFinal Projct (ZUARI CEMENTS)JabeerNo ratings yet

- Project Report Tata Motors Vaibhav Gupta 6th Sem Bba Scholars .Docx Final2Document98 pagesProject Report Tata Motors Vaibhav Gupta 6th Sem Bba Scholars .Docx Final2VaibhAv GuPtaNo ratings yet

- To Study The Impact of TQM Practices On Aviation Industry Performance and Stakeholder Satisfaction (A Case Study of Air India)Document52 pagesTo Study The Impact of TQM Practices On Aviation Industry Performance and Stakeholder Satisfaction (A Case Study of Air India)Amit KakashiNo ratings yet

- A Study On Inventory Management at Flow Serve India Controls PVT - LTDDocument51 pagesA Study On Inventory Management at Flow Serve India Controls PVT - LTDVettri VenthanNo ratings yet

- Shruti Zanjad Bmss34 ProjectDocument73 pagesShruti Zanjad Bmss34 ProjectSmily ShaikhNo ratings yet

- Sqa Lecture 09Document30 pagesSqa Lecture 09Anzala DarNo ratings yet

- Charan Project WorkDocument60 pagesCharan Project WorkDurga PrasadNo ratings yet

- Amity Business School: Submitted by Tanya Sharma M.B.A (HR) 2008-2010 (A0102308288)Document68 pagesAmity Business School: Submitted by Tanya Sharma M.B.A (HR) 2008-2010 (A0102308288)Chaiten GuptaNo ratings yet

- Intial Information Report (Financial Analysis)Document13 pagesIntial Information Report (Financial Analysis)NiveditaSnehiNo ratings yet

- Gaurav Sir Coke 2015Document78 pagesGaurav Sir Coke 2015Swarnesh GuptaNo ratings yet

- AMARARAJA COMPANY ANALYSISs CompDocument24 pagesAMARARAJA COMPANY ANALYSISs CompJaveed GurramkondaNo ratings yet

- Projects Topics For MBADocument2 pagesProjects Topics For MBAAthul Krishnan MNo ratings yet

- MRF Project Report PDFDocument79 pagesMRF Project Report PDFBikash PattnayakNo ratings yet

- "Study of Inventory Management System of Amazon": Summer Internship Project (SIP)Document72 pages"Study of Inventory Management System of Amazon": Summer Internship Project (SIP)tarunprasadNo ratings yet

- "Inventory Management Technique": A Project Report OnDocument33 pages"Inventory Management Technique": A Project Report OnLavesh SethiaNo ratings yet

- Inventory ManagementDocument93 pagesInventory ManagementMohan ANo ratings yet

- 1Document95 pages1Gargy GuptaNo ratings yet

- ppt2 HCLDocument20 pagesppt2 HCLMrinal KalitaNo ratings yet

- Synopsis o ODDocument15 pagesSynopsis o ODBrandon JonesNo ratings yet

- Inventory Management of Anji at SCCL Final ReportDocument67 pagesInventory Management of Anji at SCCL Final ReportRaMa CHaitanyaNo ratings yet

- OM ProjectDocument71 pagesOM ProjectM KNo ratings yet

- Worksheet For Evaluating Alternatives: Use This Tool To Help You Think Through Your AlternativesDocument2 pagesWorksheet For Evaluating Alternatives: Use This Tool To Help You Think Through Your AlternativesrameelNo ratings yet

- Shubham Sip ProjectDocument50 pagesShubham Sip Projectkrushna dhokchauleNo ratings yet

- Q.P. Code:36461: Activity Preceding Activity NT (Days) CT (Days) Blenders Packers FillersDocument3 pagesQ.P. Code:36461: Activity Preceding Activity NT (Days) CT (Days) Blenders Packers Fillersmms a19No ratings yet

- Project Chiru Mba 28Document29 pagesProject Chiru Mba 28chiranjeevi kvNo ratings yet

- Industry ProfileDocument52 pagesIndustry ProfileDini DominicNo ratings yet

- Production Planning and Control - EicherDocument36 pagesProduction Planning and Control - EicherBhoopal Padmanabhan100% (2)

- The Impact of Working Capital Management On The Performance of Food and Beverages IndustryDocument6 pagesThe Impact of Working Capital Management On The Performance of Food and Beverages IndustrySaheed NureinNo ratings yet

- Project Synopsis TQMDocument2 pagesProject Synopsis TQMWaqar Ali Khan100% (1)

- SS Performance Apperial PROJECTDocument101 pagesSS Performance Apperial PROJECTashokNo ratings yet

- Hero CyclesDocument87 pagesHero Cyclesanon_61822950% (4)

- Bharat Petroleum Corporation Limited: DiagnosesDocument11 pagesBharat Petroleum Corporation Limited: DiagnosesAishwarya SanjeevNo ratings yet

- Inventory-Management - Theory & DIDocument102 pagesInventory-Management - Theory & DIAnil Kumar SinghNo ratings yet

- Whole ReportDocument49 pagesWhole ReportAnuja GenjiNo ratings yet

- Mini ProjDocument27 pagesMini ProjMekhajith MohanNo ratings yet

- A Project Report On Evaluation of Distribution Channels in The Riddhi Siddhi Gluco Boils LTDDocument82 pagesA Project Report On Evaluation of Distribution Channels in The Riddhi Siddhi Gluco Boils LTDBabasab Patil (Karrisatte)No ratings yet

- Cost Analysis and Control HeroDocument8 pagesCost Analysis and Control HeroVinay SurendraNo ratings yet

- A Project Report On Financial Analysis of Eicher Motors LimitedDocument15 pagesA Project Report On Financial Analysis of Eicher Motors LimitedKaran OberoiNo ratings yet

- Techniques For Productivity ImprovementDocument2 pagesTechniques For Productivity ImprovementArun Singh100% (1)

- Synopsis FinalDocument7 pagesSynopsis FinalssiddharthaNo ratings yet

- Impact of Supply Chain Management Strategies On Business PerformanceDocument6 pagesImpact of Supply Chain Management Strategies On Business PerformanceKamran RaufNo ratings yet

- Summer Internship ReportDocument57 pagesSummer Internship ReportparulNo ratings yet

- A Study On Operation ManagementDocument78 pagesA Study On Operation Managementfreak badNo ratings yet

- Beml Report HemaDocument62 pagesBeml Report HemaSharon J 334No ratings yet

- Capital Budget Impact in Banking SectorDocument85 pagesCapital Budget Impact in Banking SectorVickram JainNo ratings yet

- Green Products A Complete Guide - 2020 EditionFrom EverandGreen Products A Complete Guide - 2020 EditionRating: 5 out of 5 stars5/5 (1)

- CH 04Document9 pagesCH 04jaysonNo ratings yet

- Easa-Icaa Sms m5Document13 pagesEasa-Icaa Sms m5Husam FNo ratings yet

- CMR Workshop - PPT NewDocument13 pagesCMR Workshop - PPT NewKing Balmilero50% (2)

- Ch3 Toys R UsDocument2 pagesCh3 Toys R UsfrankmarsonNo ratings yet

- Press Release: Edelman Announces Harlan Loeb As Global Chair of Crisis & Risk Management PracticeDocument2 pagesPress Release: Edelman Announces Harlan Loeb As Global Chair of Crisis & Risk Management PracticeEdelmanNo ratings yet

- LDRS 420 Notes - Cameron Green 4th Ed., Chap. 08 Cultural ChangeDocument39 pagesLDRS 420 Notes - Cameron Green 4th Ed., Chap. 08 Cultural ChangeEzekielNo ratings yet

- Maud Quaye CV VecheDocument1 pageMaud Quaye CV VechemaudgnkquayeNo ratings yet

- Review Notes On Auditing and Assurance PrincipleDocument140 pagesReview Notes On Auditing and Assurance PrincipleChandria FordNo ratings yet

- CV Endri GinantakaDocument1 pageCV Endri GinantakaEndri GinantakaNo ratings yet

- Project Life Cycle and Its ClassificationDocument25 pagesProject Life Cycle and Its ClassificationNabid Alam AntuNo ratings yet

- Dr. Ombaba B. Mwengei Kennedy Curriculum VitaeDocument8 pagesDr. Ombaba B. Mwengei Kennedy Curriculum VitaeDr. Kennedy Mwengei B. Ombaba100% (1)

- Maturidade em GPDocument15 pagesMaturidade em GPNyemer BaruelNo ratings yet

- Process of Environmental AnalysisDocument2 pagesProcess of Environmental Analysisshrisha sharmaNo ratings yet

- Unit 1Document13 pagesUnit 1ठाकुर अनमोल राजपूत100% (1)

- Infosys ConsultingDocument4 pagesInfosys Consultingrush2jananiNo ratings yet

- Achilles Verify Scheme Rule Book Issue1 2014 PDFDocument23 pagesAchilles Verify Scheme Rule Book Issue1 2014 PDFMarian GumielNo ratings yet

- Strategic IT Planning TemplatesDocument5 pagesStrategic IT Planning TemplatesStaporn KasemsripitakNo ratings yet

- Checklist For Iso 17021Document9 pagesChecklist For Iso 17021Rajesh SapNo ratings yet

- Third Party Logistics / Fourth Party Logistics: Presented byDocument52 pagesThird Party Logistics / Fourth Party Logistics: Presented byABRAR AHMEDNo ratings yet

- Department of Education Organisational ChartDocument1 pageDepartment of Education Organisational ChartJack LinNo ratings yet

- Course GuideDocument31 pagesCourse GuideLilly BrownNo ratings yet

- April Tam ResumeDocument1 pageApril Tam Resumeapi-599299090No ratings yet

- KFC Is The Largest FastDocument4 pagesKFC Is The Largest FastAkshath MavinkurveNo ratings yet

- System Development Life CycleDocument8 pagesSystem Development Life CycleHackers100% (1)

- Robbins Fom8 TB 05Document51 pagesRobbins Fom8 TB 05davidsaucedaiii100% (1)

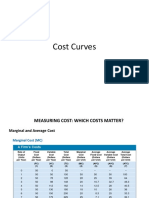

- Cost CurvesDocument40 pagesCost CurvesNRK Ravi Shankar CCBMDO - 16 BatchNo ratings yet