Professional Documents

Culture Documents

It Is Fail

It Is Fail

Uploaded by

reacharunkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

It Is Fail

It Is Fail

Uploaded by

reacharunkCopyright:

Available Formats

426

THEORY OF

ARCIIITECTUUE. EooK IT.

ri

jlLl

Fig. 6 lot.

incli deep; bottom flange G-67 inclies wide, GG inch deep; the areas being -720 and

4-1 inclies. Tlie rib was 2()G inch thick, and the total depth 5~ inches, 'I'he constant or

C was found to be 514 for cwts., or 2G for tons. (Warr.)

lG29a. ]t will scarcely be within our province to describe all the forms of sections, and

the results of the experiments made by Fairbairn in obtaining his box beam or plate girder

in wrought iron, but it is to be noted that all the cylindrical tubes broke by extension at

the rivets before the tube could fail by compression. Fairbalin in his Application

of

Cast

and Wrovght Iron to Building Purposes, edit. 1857-8, p. 80, notices that although the platt

girder be inferior in strength to the box beam, it has nevertheless other valuable proiierties

to recommend it. On comparing the strength of these separate beams, weight for weight,

it will be found that the box beam is as 100 : 9:5. 'I'he plate beam is in some respects

superior to the box beam; it is of more simple construction, less expensive, and more

durable, from the circumstance that the vertical jila'e is thicker than the side plates of the

box beam. It is also easier of access to all its parts for the purposes of cleaning. tS:c.

1G29/). Fairbairn has formed a comparison between a tcrovght iion and a cast iron

g

rder for

a span of 30 feet. The plate girder, jig.GVMi, would be 31 feet G inches in length, and would

be composed of plates 22 inches deep and j'^ths thick

;

with angle iron <

-\..

|ths thick, riveted on both sides at the bottom of the plate, and

'

angle iron

i

inch thick at the top, the widtii o\er the top being

7i

inclies, and" the bottom

5r,

inches. The breaking weight of this

,. ,

"__

.j.rtrfC ^,. 6 X 2.2

X

75

beam, takmg the constant at 1

5,

would be j- = \\

;

or

^^^^

=27-5 tons in the middle, or 55 tons distributed equally over the

surface. In the edition of 1857-8, the angle irons are described as

3 inches by 3 inches,

i

inch thick for the bottom, and 4 inches by

4 inches,

|

inch tliick at the top; it would, therefore, be

85

inches

over at the top, and about

6i

inches at the bottom. Now a "ast

iron girder of the best form and strongest section and calculated

to support the same load, would weigh about 2 tons, the plate beam about 18 cwts., or

less than one half. To secure

uniformity of strength in a rectangidar box beam, the top

is required to be about twice the sectional area of the bottom; hence resulted the use oi

cells in that portion.

lG29c. Fiq. 613/. is ii. plate beam having a single plate for the vertical web, while each

of the flanges consists of a flat bar and a pair of angle irons riveted to each other and to

the vertical web. Fig. 613w. is a

box beam, in which tl)ere are two

vertical webs. Fig. G13. is a plite

girder of greater dimensions than

Jig.

613/. ;

the flanges contain

more

than one layer of flat bars, and the

web, which consists of plates with

their largest dimensions vertical, is

stiHened by vertical T iron ribs at

the joints of those plates, as shown

in the plan or horizontal section

Uttered A. The pieces shoidd abut

closely and truly against each other,

having end surfaces made exactly

perpendicular to the axis of the

beam. Tlie thickness of the web is seldom made less than |ths inch, and except for the

largest beams, this is in general more than sufficient to resist the shearing stress. Above each

of t!ie points of support, the vertical ribs must be placed either closer or made larger, so

tlwt they may be jointly capable of safely bearing as pillars the entire share of the load

which rests on that point of support. A jiair of vertical T iron ribs riveted back to back

through the web plates (as A,

Jig

613.) may be held to act as a pillar of cross-shaped section,

1629c?. The rib or web of a plate beam, as fig. 613/, having little or nothing to do with

the pressure directly, has been replaced in some cases by simple upright struts or diagonal

braces between the flanges, which in cast iron girders are in one casting, but experience has

proved this not altogether politic, particularly in cast iron. Hodgkinson remarked that

such beams were weaker than those with a solid rib. Rankine observes that transverse

rib or feathers on cast iron beams are to be avoided, as forming lodgments for air bubbles,

and as tending to cause cracks in cooling. Open work in the vertical web is also to be

avoided, partly for the same reasons, and partly because it too much diminishes the resist-

ance to distortion by the shearing action of the load.

16i!9e.

"

Where the span renders it impracticable to roll a beam in one piece," Fairbairn,

page 91, notices that "convenient weights might be rolKd into sections of the proper form

and being united by properly proportioned covering plates at top and bottom, and tC'

You might also like

- Method Statement - Street Lighting InstallationDocument12 pagesMethod Statement - Street Lighting InstallationAzree Mohd Noor100% (10)

- Randy Smith Well Control Kill Sheet - English and MetricDocument2 pagesRandy Smith Well Control Kill Sheet - English and MetricemmanuelNo ratings yet

- Discussion (Bernoulli Theorem)Document2 pagesDiscussion (Bernoulli Theorem)Uztaz Dol Keke83% (23)

- Zick AnalysisDocument12 pagesZick AnalysisrksahayNo ratings yet

- Design and Analysis of Buried Composite Fiberglass PipelineDocument7 pagesDesign and Analysis of Buried Composite Fiberglass PipelineVinh Do ThanhNo ratings yet

- Flexural Strengthing of Beam With FRP LamintaesDocument6 pagesFlexural Strengthing of Beam With FRP LamintaesEngDbtNo ratings yet

- All in " To 'Lo Feet. To Cells Olijeits - 215) - Resist FullDocument1 pageAll in " To 'Lo Feet. To Cells Olijeits - 215) - Resist FullreacharunkNo ratings yet

- May X One The Web MadeDocument1 pageMay X One The Web MadereacharunkNo ratings yet

- Theory: of ArchitectureDocument1 pageTheory: of ArchitecturereacharunkNo ratings yet

- When When WhenDocument1 pageWhen When WhenreacharunkNo ratings yet

- Como Hacen Cañones Er18980121Document24 pagesComo Hacen Cañones Er18980121flamenquitoNo ratings yet

- Torsional Properties of Fabricated I-Beam and Box Sections 1941Document36 pagesTorsional Properties of Fabricated I-Beam and Box Sections 1941Reinaldo Chohfi Jr.No ratings yet

- Maximum 5by: OF ArchitectureDocument1 pageMaximum 5by: OF ArchitecturereacharunkNo ratings yet

- When WhenDocument1 pageWhen WhenreacharunkNo ratings yet

- Theory: ArchitectureDocument1 pageTheory: ArchitecturereacharunkNo ratings yet

- Tliesl-In Ttie Is Tlie Tliis IsDocument1 pageTliesl-In Ttie Is Tlie Tliis IsreacharunkNo ratings yet

- MuchDocument1 pageMuchreacharunkNo ratings yet

- On Roman: ThaiDocument1 pageOn Roman: ThaireacharunkNo ratings yet

- Engineering Vol 72 1901-07-12Document35 pagesEngineering Vol 72 1901-07-12ian_newNo ratings yet

- Short Column Lateral TiesDocument36 pagesShort Column Lateral TiesMark Gerald Oreiro100% (2)

- Tlie Inc! Liie It Is Is Its Its L) e Tlie IsDocument1 pageTlie Inc! Liie It Is Is Its Its L) e Tlie IsreacharunkNo ratings yet

- Engineering Vol 72 1901-07-26Document35 pagesEngineering Vol 72 1901-07-26ian_newNo ratings yet

- Construction of Ordnance.: LnventqrDocument3 pagesConstruction of Ordnance.: LnventqrasdfasfNo ratings yet

- Grillage Foundation DesignDocument6 pagesGrillage Foundation DesignSubhakanta SwainNo ratings yet

- Short Columns (Aci 318-14) PDFDocument90 pagesShort Columns (Aci 318-14) PDFHaseeb AhmedNo ratings yet

- When Some: Tlie Tlie Is It IsDocument1 pageWhen Some: Tlie Tlie Is It IsreacharunkNo ratings yet

- ACI 318 Members With Axial Load & Bending - (Lecture Notes)Document92 pagesACI 318 Members With Axial Load & Bending - (Lecture Notes)tpop1707No ratings yet

- Behviour of Box Girder BridgesDocument34 pagesBehviour of Box Girder BridgesChandra KumarNo ratings yet

- Instructions For Stow and Securing Steel CoilsDocument8 pagesInstructions For Stow and Securing Steel CoilsKhoai Sai GonNo ratings yet

- One Way SlabDocument69 pagesOne Way Slabforlogin018No ratings yet

- F. Hennebioue.: No. 6,907. Construction of Joists, Girders, and The LikeDocument3 pagesF. Hennebioue.: No. 6,907. Construction of Joists, Girders, and The LikeguillermoNo ratings yet

- US2427676Document4 pagesUS2427676udrogono2No ratings yet

- Design of Standard Lugs (30 December 1920)Document12 pagesDesign of Standard Lugs (30 December 1920)raheyo6168No ratings yet

- Patente Aspa Parsons Como Las Que Tengo de 1953 Us3002567Document4 pagesPatente Aspa Parsons Como Las Que Tengo de 1953 Us3002567Mariela TisseraNo ratings yet

- VirginaSteamEnginePlans LBSC SMDocument112 pagesVirginaSteamEnginePlans LBSC SMsteam enggineNo ratings yet

- Carpentry.: Tlieii ItDocument1 pageCarpentry.: Tlieii ItreacharunkNo ratings yet

- Theory: AuchitfxtuiieDocument1 pageTheory: AuchitfxtuiiereacharunkNo ratings yet

- Tabloid Saji 484th Edition Saji Full Chapter Download PDFDocument24 pagesTabloid Saji 484th Edition Saji Full Chapter Download PDFvudlerabesai100% (3)

- RCC NotesDocument88 pagesRCC NotesKung Fu PandaNo ratings yet

- Structure For Archtects - IiDocument9 pagesStructure For Archtects - Iiwafa rafiaNo ratings yet

- Column DetailDocument3 pagesColumn DetailKmrnKhnNo ratings yet

- About The Network ArchDocument36 pagesAbout The Network ArchSergio Adolfo ParedesNo ratings yet

- Sinking No. S Winze at WrightHargreaves MineDocument6 pagesSinking No. S Winze at WrightHargreaves Minetd__1985No ratings yet

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocument12 pagesStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAnonymous qhVGVpNo ratings yet

- Instructions on Modern American Bridge BuildingFrom EverandInstructions on Modern American Bridge BuildingNo ratings yet

- Preparing Shells & FuzesDocument10 pagesPreparing Shells & Fuzesjbart252100% (1)

- Lec 6 (1) - Plate GirderDocument54 pagesLec 6 (1) - Plate GirderMuhammad Faisal AsifNo ratings yet

- Design of Prestressed Concrete Piles For Seismic Loads Adds A NewDocument3 pagesDesign of Prestressed Concrete Piles For Seismic Loads Adds A NewMahindaNo ratings yet

- The Allen Engine-Charles T. PorterDocument3 pagesThe Allen Engine-Charles T. PorterLuis VizcaínoNo ratings yet

- Lonne: Still Is TlieDocument1 pageLonne: Still Is TliereacharunkNo ratings yet

- Reinforced Concrete SlabsDocument29 pagesReinforced Concrete Slabsmansoor azam100% (1)

- Minmum Links in ColumnsDocument12 pagesMinmum Links in ColumnsdurssiNo ratings yet

- Lecture 3 Design of 2 Way Slabs PDFDocument52 pagesLecture 3 Design of 2 Way Slabs PDFOlesea Nesterenco100% (1)

- RC II - chapter-3-LNDocument84 pagesRC II - chapter-3-LNFenta NebiyouNo ratings yet

- Strength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionFrom EverandStrength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionNo ratings yet

- Coffin-Making and Undertaking - Special Appliances, Lancashire Coffins, Southern Counties and Other Coffins, Children's Coffins, Adults' Covered CoffiFrom EverandCoffin-Making and Undertaking - Special Appliances, Lancashire Coffins, Southern Counties and Other Coffins, Children's Coffins, Adults' Covered CoffiRating: 5 out of 5 stars5/5 (1)

- The Boys' Guide to Outdoor Activities - Including Hints on Camping and the Boy ScoutsFrom EverandThe Boys' Guide to Outdoor Activities - Including Hints on Camping and the Boy ScoutsNo ratings yet

- The Development of Armor-piercing Shells with Suggestions for their ImprovementFrom EverandThe Development of Armor-piercing Shells with Suggestions for their ImprovementNo ratings yet

- Woodwork Joints: How They Are Set Out, How Made and Where UsedFrom EverandWoodwork Joints: How They Are Set Out, How Made and Where UsedNo ratings yet

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkNo ratings yet

- General Terms and Conditions of The Pzu NNW (Personal Accident Insurance Pzu Edukacja InsuranceDocument19 pagesGeneral Terms and Conditions of The Pzu NNW (Personal Accident Insurance Pzu Edukacja InsurancereacharunkNo ratings yet

- En (1459)Document1 pageEn (1459)reacharunkNo ratings yet

- En (1386)Document1 pageEn (1386)reacharunkNo ratings yet

- En (1451)Document1 pageEn (1451)reacharunkNo ratings yet

- En (1464)Document1 pageEn (1464)reacharunkNo ratings yet

- En (1458)Document1 pageEn (1458)reacharunkNo ratings yet

- Mate The: (Fig. - VrouldDocument1 pageMate The: (Fig. - VrouldreacharunkNo ratings yet

- And Rome.: in Front of The Prostyle Existed atDocument1 pageAnd Rome.: in Front of The Prostyle Existed atreacharunkNo ratings yet

- The The Jamb The Name Much The: Tlio CL - AssesDocument1 pageThe The Jamb The Name Much The: Tlio CL - AssesreacharunkNo ratings yet

- En (1383)Document1 pageEn (1383)reacharunkNo ratings yet

- En (1374)Document1 pageEn (1374)reacharunkNo ratings yet

- En (1382)Document1 pageEn (1382)reacharunkNo ratings yet

- En (1376)Document1 pageEn (1376)reacharunkNo ratings yet

- 22 - 07 - 00 - Plumbing Insulation PDFDocument20 pages22 - 07 - 00 - Plumbing Insulation PDFAgung Pramu AjiNo ratings yet

- Beam Design For Moment, Shear & TorsionDocument6 pagesBeam Design For Moment, Shear & TorsionRajendra BadjatyaNo ratings yet

- CV GhazanfarDocument5 pagesCV GhazanfarSyeda Nowaf Zahra NaqviNo ratings yet

- MS 1228-1991Document84 pagesMS 1228-1991Noir Farah Azira AzizNo ratings yet

- Culvert BasicsDocument52 pagesCulvert BasicsXDXDXDNo ratings yet

- Hyperboloid Structures: Asif Ahmed B.Arch 4Th Year Sfs Ar - 406 Theory of StructureDocument16 pagesHyperboloid Structures: Asif Ahmed B.Arch 4Th Year Sfs Ar - 406 Theory of StructureAsif AhmedNo ratings yet

- Pipe Fittings Surface AreaDocument1 pagePipe Fittings Surface AreasajoNo ratings yet

- 1965 Newmark - Earthquakes On Dams and EmbankmentsDocument21 pages1965 Newmark - Earthquakes On Dams and Embankments26283369100% (1)

- Design of RC Structures 2023 2024 V07Document19 pagesDesign of RC Structures 2023 2024 V07SardarNo ratings yet

- District Survey ReportDocument3 pagesDistrict Survey ReportDIPTIMAYEE BEHERANo ratings yet

- Form WorkDocument19 pagesForm WorkAliasgar LokhandwalaNo ratings yet

- Banglieng 3 - INTAKE - KM 1 ADocument4 pagesBanglieng 3 - INTAKE - KM 1 AK'm VPsNo ratings yet

- Federal Highway AdministrationDocument13 pagesFederal Highway AdministrationAlfredo A LopezNo ratings yet

- Direct Displacement Based Seismic Design of Concrete StructuresDocument25 pagesDirect Displacement Based Seismic Design of Concrete StructuresGerardo MendozaNo ratings yet

- AISC DG02 Example 004 PDFDocument11 pagesAISC DG02 Example 004 PDFMohamed Abo-ZaidNo ratings yet

- A Study of Composite Cements Performance in Concrete Using Ultrafine Supplementary Cementitious Materials (Alccofine 1203 or Micro Silica)Document8 pagesA Study of Composite Cements Performance in Concrete Using Ultrafine Supplementary Cementitious Materials (Alccofine 1203 or Micro Silica)International Journal of Innovative Science and Research TechnologyNo ratings yet

- FMDocument34 pagesFMmmNo ratings yet

- 20-Formation Tester PDFDocument11 pages20-Formation Tester PDFEduardo Torres RojasNo ratings yet

- Multi Storey Steel Building 01Document19 pagesMulti Storey Steel Building 01Dan AlexandrescuNo ratings yet

- Geotechnical Investgation Report - PBH-05Document3 pagesGeotechnical Investgation Report - PBH-05nitinsunder1979No ratings yet

- Tutorial 3Document2 pagesTutorial 3Chapagain SundarNo ratings yet

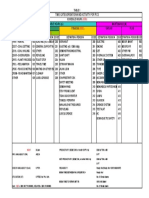

- Time Categorisation and Activity For PCS: Table 1 Schedule Hours Stand by DelayDocument1 pageTime Categorisation and Activity For PCS: Table 1 Schedule Hours Stand by DelayTommyTriantoTandoNo ratings yet

- Pagel - Grout: Fields of Application Properties V1 /50 V1 /10 V1 /160Document4 pagesPagel - Grout: Fields of Application Properties V1 /50 V1 /10 V1 /160wojtNo ratings yet

- Cynthia Trade ProjectDocument15 pagesCynthia Trade ProjectMurimi KelvinNo ratings yet

- Gondola Load CalculationsDocument10 pagesGondola Load CalculationssaskiaNo ratings yet