Professional Documents

Culture Documents

Rapid Prototyping Ufluidic Cart Eletrchem

Rapid Prototyping Ufluidic Cart Eletrchem

Uploaded by

eveltoncOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rapid Prototyping Ufluidic Cart Eletrchem

Rapid Prototyping Ufluidic Cart Eletrchem

Uploaded by

eveltoncCopyright:

Available Formats

Sensors and Actuators B 202 (2014) 6066

Contents lists available at ScienceDirect

Sensors and Actuators B: Chemical

j our nal homepage: www. el sevi er . com/ l ocat e/ snb

Rapid prototyping of multifunctional microuidic cartridges for

electrochemical biosensing platforms

Jitae Kim

a,1

, Yong Shin

b,1

, Simon Song

a

, Joohyung Lee

c

, Jungkyu Kim

c,

a

Department of Mechanical Engineering & Institute of Nano Science and Technology, Hanyang University, Seoul, Republic of Korea

b

Institute of Microelectronics, A*STAR (Agency for Science, Technology and Research), 11 Science Park Road, Singapore Science Park II,

Singapore 117685, Singapore

c

Department of Mechanical Engineering, Texas Tech University, Lubbock, TX 79406, USA

a r t i c l e i n f o

Article history:

Received 27 January 2014

Received in revised form26 March 2014

Accepted 5 May 2014

Available online 21 May 2014

Keywords:

Rapid prototyping

Porous membrane

One-shot valve

On-chip chemical storage

Microuidic electrochemical immunoassay

Biomarker screening

a b s t r a c t

A multifunctional microuidic cartridge for electrochemical biosensing (CEB) was developed with

a cleanroom-free rapid prototyping technique. A seven-layered CEB platform including a gold (Au)

electrode substrate was fabricated by alternating patterned thin plastic and adhesive lms. To provide

conformal bonding between layers, pressure sensitive adhesive (PSA) tape was adopted to fabricate a leak-

free, porous membranes embedded CEBplatform compatible with relatively high ow rates. Inaddition,

the embedded porous membranes provide multiple functions in the CEB device, including (1) control-

ling uid ow, (2) storing a dried detergent, and (3) trapping liquid waste. To demonstrate the utility of

the CEB, we performed an electrochemical-based immunoassay to detect various concentrations of Cre-

atine Kinase (CK)-Myocardial Band (MB). During the immunoassay, the membranes controlled the ow

path to minimize a carryover between the assay steps and released the stored dried-reagent to remove

non-specically bound detection antibodies. With a linear sweep voltammetry (LSV) electrochemical

sensing technique, a limit of detection of 0.25 ng mL

1

was achieved. The multilayered prototyping tech-

nique enables rapid and low-cost fabrication of multifunctional microuidic electrochemical devices with

single-use sample processing components.

2014 Elsevier B.V. All rights reserved.

1. Introduction

Miniaturized electrochemical sensors have been broadly

exploredfor rapidandaccuratedetectionof chemical andbiological

agents [15]. Integration of this technology with microuidic sys-

tems enables simple, portableandautomatedbiosensingplatforms.

These benets make microuidic electrochemical (EC) devices an

attractive technology for point-of-care diagnostics and infectious

diseases monitoring in resource-limited settings.

To make the microuidic EC devices more practical, a sig-

nicant effort has been made to develop rapid prototyping

techniques [610]. Soft lithography has been extensively used

due to simplicity, low cost and versatility [7]. To fabricate

the microuidic EC device with the soft-lithography, bonding

between a polydimethylsiloxane (PDMS) channel layer and an

Corresponding author at: Department of Mechanical Engineering, Department

of Internal Medicine, Texas Tech University, Lubbock, TX 79409, USA.

Tel.: +1 806 834 6106.

E-mail address: jungkyu.kim@ttu.edu (J. Kim).

1

These authors contributed equally to this work.

electrode-deposited substrate was performed simply by oxygen

plasma treatment [11] or physical clamping [12]. This is possible

due to the elastomeric property of PDMS which allows conformal

contact with rigid substrates such as silicon and glass. Recently,

other polymeric materials like polycarbonate (PC) [1315], poly-

methyl-meta-acrylate (PMMA) [16,17], cyclic olen copolymer

(COC) [1820] and polyimide [21] have been used as alternatives

due to undesirable properties of PDMS such as poor chemical com-

patibility, gas permeability and innate hydrophobicity. Although

those polymers are superior to PDMS in terms of native proper-

ties, fabrication, integration and packaging procedures with those

polymers can be more difcult. For example, bonding processes

typically involve the use of high temperature or solvents, resulting

in compromised integrity and resolution of microstructures. As a

result, bonding of an electrode-patterned rigid polymer to another

rigid polymer remains challenging due to leakage.

Bartholomeusz et al. [22] developed a rapid prototyping tech-

nique using xurography, where a cutting plotter was used to cut

microstructures on various adhesive lms (pressure sensitive and

thermal activated adhesive lms). Patterned adhesive lms were

laminated for fabricating multilayered microuidic devices rapidly

and inexpensively. By combining plastic microuidic fabrication

http://dx.doi.org/10.1016/j.snb.2014.05.009

0925-4005/ 2014 Elsevier B.V. All rights reserved.

J. Kimet al. / Sensors and Actuators B 202 (2014) 6066 61

methods with xurography, challenges such as the uid leakage and

electrical cross-talk issues were successfully addressed.

Membrane-integrated microuidic chips [2330] have been

studied for enhanced functionality and mass transport control.

Although porous membranes are used in a wide range of indus-

trial applications, their usage in microuidic systems has been

limited to ltration [23,31] and chemical reactors [32] due to the

lack of simple and reliable fabrication techniques. Yager et al. [33]

presented a microuidic ow-through membrane immunoassay

with dry-stored reagents in a membrane. The use of functionalized

membranes enabled the simplication of assay operation. How-

ever, on-chip integration of multiple membranes, each responsible

for a different function, remains unexplored.

Inthis study, we report a simple rapid prototyping of a multilay-

ered microuidic cartridge for electrochemical biosensor (CEB)

with integrated Au electrodes. By using layer-by-layer assem-

bly, the patterned plastic lms and double-sided PSA tapes were

alternately bonded to each other to fabricate a disposable, multi-

functional CEB at room temperature. Three porous membranes

were integrated into the CEB during the assembly process to uti-

lizefor air owstopper, reagent storageandliquidwasteabsorbent.

To demonstrate the utility of the CEB, we performed a quan-

titative immunoassay for CK-MB, a cardiac biomarker used for

diagnosis of anacutemyocardial infraction(AMI). Thedevelopment

of multilayer electrochemical biosensor from the rapid prototype

technique, multifunctional membranes andsimpleelectrochemical

detections will be able to facilitate advanced point-of-care device

for various biomarker screenings.

2. Experimental

2.1. Fabrication of CEB platform

Fig. 1 presents a schematic for rapid prototyping of the CEB

(85mm54mm1.8mm) with 3-electrode conguration which

was made of 7 patterned layers, comprised of an Au-coated PET

lm(L1), double-sided tape (L2, L4, L6), an acrylic sheet (L3), and a

PET lm(L5, L7).

To fabricate the Au electrodes on PET lm (L1), 100nm thick

Au was deposited by sputtering process through a shadow mask

containing the patterns for electrodes and alignment holes. The

Au-deposited lm (L1) was then treated with plasma to remove

carbon residue on the Au surfaces, and the Au electrodes fur-

ther underwent an antibody immobilization process (see below

in immunoassay protocol section). The double-sided PSAs (ARseal

90880, Adhesives Research), with two release liners laminated on

both sides, were patterned with a cutting plotter (FC2250-120VC,

Graphtec Inc., USA) to create L2/L4/L6 layer. The acrylic sheet was

cut with a CO

2

laser (VLS 3.60, Universal Laser Systems) to form

uidic reservoirs in L3. Three passes of the laser beam(75% Power,

20% Speed and 1000 PPI) were applied to obtain smooth cutting

edges and near-vertical sidewalls. The laser-cut acrylic sheet was

cleaned in an ultrasonic water bath for 10min, dried with N

2

gas,

and then annealed on a hot plate maintained at 85

C for 90min.

This annealingstepwas includedtoavoidstress cracks intheacrylic

[34].

Once all the layers are ready, assembly began with bonding of

the bottomPET lm(L1) and the rst PSA (L2). In the rst step, cut-

out regions (i.e., channels and reservoirs) of the PSAwere peeled off

from the bottom release liner. An application tape, typically one-

sided adhesive backed lm, was applied to the peeled-off side and

squeezed to hold the pattern in place. Then the release liner was

carefully detached, leaving the engraved pattern on the applica-

tion tape pattern transfer [22]. The application tape bearing the

pattern (L2) was placed on a custom-made aligner with 4 press-

tted dowel pins. Each layer has 4 alignment holes at the corners,

and each hole matches the corresponding dowel pin in its position

for accurate alignment. The PET lm (L1) incorporating immobi-

lized antibody was adhesively bonded to the PSA (L2) held on the

aligner using a hand roller. To integrate the acrylic layer (L3) with

the PET-PSA assembly (L1/L2), the assembly was put back on the

aligner withits adhesive side facing upfollowing the removal of the

top release liner along with the application tape. The acrylic sheet

was mated with the assembly held on the aligner to form a PET-

PSA-acrylic assembly (L1/L2/L3). A laser-cut absorbent pad (M3,

790mthick, pure cellulose bers, 133, Pall) was attached to an

adhesive region of the assembly (L1/L2/L3). Next, a pattern trans-

ferred fromthe second PSA (L4) was bonded to the PET-PSA-acrylic

assembly (L1/L2/L3) in the same way as described above (i.e., bond-

ingof L1andL2). The layer-by-layer assemblyprocess was repeated

Fig. 1. Fabrication process of a multilayered, polymeric microuidic cartridge. (A) Exploded view of all patterned layers. Alternating layers of thin plastic lm/sheet (blue)

and double-sided tape (yellow). (B) Schematic cross-section of all layers in the stack. Liquid is drawn into an absorbent-embedded waste reservoir by vacuum when the

tape is pierced. (C) A photograph (top view) of a 3-D microuidic cartridge (85mm54mm1.8mm) constructed by layer-by-layer assembly. M1, M2 and M3 are the rst,

second and third membrane, respectively. C, R, and Wrepresent the counter, reference and working electrode, respectively. The sense electrodes monitor the position of a

liquid meniscus.

62 J. Kimet al. / Sensors and Actuators B 202 (2014) 6066

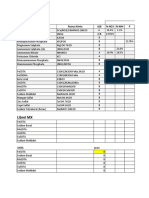

Table 1

Description of each layer regarding material, thickness, function, and patterning

tool. DST represents the double-sided tape.

Material Thickness (m) Function Pattering tool

Layer 7 PET 125 Lid Cutting plotter

Layer 6 DST 130 Channel Cutting plotter

Layer 5 PET 125 Support Cutting plotter

Layer 4 DST 130 Via hole Cutting plotter

Layer 3 Acrylic 1000 Reservoir CO

2

laser

Layer 2 DST 130 Channel Cutting plotter

Layer 1 PET 125 Electrode Cutting plotter

until the top PET layer (L7) was integrated into a whole assembly

(L1 through L7) as described in Fig. 1B. The whole assembly was

then compressed multiple times using a desktop cold laminator

to ensure sufcient bonding strength as well as a tight seal of the

integrated Au electrodes. Table 1 shows the summary of detailed

information on each layer.

2.2. Integration of porous membranes

Tween-20 detergent is routinely added to phosphate-buffered

saline (PBS) or tris-buffered saline (TBS) wash buffer to minimize

the background noise from non-specic binding in bioassays. To

simplifytheon-chipassayprocedure, weembeddedaporous mem-

brane containing dried Tween-20 in a CEB. In this way, we could

minimize the complexity of device fabrication by eliminating the

need for liquid buffer storage in the CEB. At rst, a porous mem-

brane (419mthick, spun bonded polyester, 6613, Pall) was cut

into 3-mm and 5-mm circles. The 3-mm disk membranes were

immersed in a tube containing 50% Tween-20 (P9416, Sigma) for

1h. The wetted membranes were removed fromthe tube and dried

in a 50

C oven for 4h to prepare detergent-modied membranes.

Similarly, the 5-mm disk membranes were treated with bovine

serumalbumin (BSA) (A2153, Sigma). The BSA-treated membrane

(M1) andthe Tween-20treatedmembrane (M2) were theninserted

into the corresponding grooves formed by three stacked layers

(L4/L5/L6) and tightly xed in place when the top layer (L7) was

capped. Note that nominal thickness of the membrane was chosen

to be slightly higher than the depth of the groove to create tight t.

This conguration allowed liquid to block air owwhen trapped in

the rst membrane (M1) andtopass throughthe secondmembrane

(M2) for reconstitution of the detergent.

2.3. Surface treatment and immunoassay preparation

Toimmobilizecaptureantibodies ontheworkingelectrode, 6L

of monoclonal anti-CK-MB antibody at 10gmL

1

(anti-human

CK-MB 7501 SPRN-2, Medix Biochemica) diluted in a PBS buffer

(10mM PBS, pH 7.4 (Sigma)), was dispensed onto the electrode

and incubated at 4

C for 2h in a perti-dish along with a wet tissue

to prevent evaporation of the antibody solution. After the incuba-

tion, the electrode was washed 3 times with a TBST buffer (20mM

TBS, pH 7.4 (T5912, Sigma) and 10mg mL

1

Tween-20 (P9416,

Sigma)). Then, TBS buffer containing 1% BSA was dropped on all

three electrodes to block the surface. After 1h of incubation at

roomtemperature, the electrodes were washed 3 times with TBST

and dried with N

2

gas. Once the immobilization steps were n-

ished, the PET lm(L1) was stored at 4

C until used. Labeling of a

detection antibody with alkaline phosphatase (ALP) was done by

using an Alkaline Phosphatase Labeling Kit-SH(LK-13-10, Dojindo,

SouthKorea). We followedthe kit procedure to conjugate 100g of

detection anti-CK-MB antibody (Anti-human CK-MB 7502 SPRN-5,

Medix Biochemica). The conjugate solution was diluted 100 times

to be added in samples. CK-MB antigen (30-1081, Fitzgerald) was

spikedand diluted to nal concentrations of 1, 5, 10 and 25ngmL

1

in TBS buffer. Each concentration of the CK-MB antigen was mixed

with the ALP-labeled detection antibody at a volume ratio of 1:10

and incubated at 37

C for 30min to execute the rst immunore-

action. The electrochemical substrate solution was prepared in a

mixture of 40mM 4-aminophenyl phosphate (pAPP, A-292, Gold-

bio), 1mM MgCl

2

(M2393, Sigma) and100mM NaCl (S3014, Sigma)

in 100mM diethyl amine (DEA, pH 9.8, 31589, Sigma).

2.4. Immunoassay for CK-MB detection

Once all the solutions were prepared, an on-chip sandwich-type

immunoassay for CK-MB detection was performed using the CEB

platform. Serially diluted CK-MB antigens (1, 5, 10 and 25ngmL

1

)

werepreparedinTBSbuffer. Beforestartingtheon-chipimmunoas-

say, a mixture of 45L of various concentrations of CK-MBantigens

and 5L of the ALP-conjugated anti-CK-MB antibodies were incu-

bated in a water bath maintained at 37

C for 30min. A 200L

volume of substrate solution was pre-loaded in the substrate reser-

voir (2.0mm width1.2mm height), and pierceable tape was then

attached to seal the valves opening (see Fig. 1B). This type of valve

(normally closed) prevents a liquid plug in a conduit frommoving

away fromone side (valves position) when a negative pressure is

applied on the other side. The valve can be opened by simply per-

forating the tape, resulting in the trapped air being balanced with

an ambient pressure.

A 50L sample containing an antigen-antibody-enzyme com-

plexwas loadedtothesampleport. Thesamplespontaneouslylled

the sample reservoir (0.5mm width1.2mm height) by capillary

wicking and stopped at the rst membrane (M1). Upon applica-

tion of a negative pressure via the vacuumport, the sample began

to ow into the main channel (400m width130m height)

past the membrane to reach the absorbent pad (M3) embedded

in the waste reservoir. The ow was maintained at approximately

0.21L s

1

for 4min (Fig. 2A). Note that the pre-loaded substrate

solution was kept in the substrate reservoir by the normally closed

valve during the sample injection. After the sample injection step,

the wet membrane (M1) stops air owfromleaking intothe sample

reservoir.

Next, a wash step was initiated by perforating the tape with

a sharp needle. The substrate solution was drawn into the main

channel and reconstituted the dried Tween-20 in the second mem-

brane (M2). Subsequently, air owfromthe positive pressure port

was supplied to the junction, thereby generating air bubbles in a

streamof the substrate solution containing the detergent (Fig. 2B).

Such a segmented ow [35] is known to assist in washing on the

electrode surface due to meniscus force and internal recirculation

owinduced within liquid segments. By the time the washing step

was nished, air bubble generation was ended by switching off the

positive pressure port (Fig. 2C). In the meantime, the substrate con-

tinued owing at a owrate of 5.0L s

1

for 15s. This is to bring a

fresh volume of the substrate, containing little or no Tween-20,

over the electrode region. Lastly, the solution was stopped and

held immobile during the enzymatic reaction by turning off all

the pumps and then venting the remaining pressure in the CEB

(Fig. 2D). After a 5-min enzymatic reaction, linear sweep voltam-

metry(LSV) signals weremeasuredwithaParstat 2273potentiostat

(Princeton Applied Research) in the range of 0.2 to 0.3V at a scan

rate of 0.1Vs

1

.

3. Results and discussion

To evaluate sealing performance of the CEB device, we per-

formed leakage tests for liquid and air in the microuidic channels.

Fig. 3A represents the magnied top view of a uidic channel

(the middle region denoted by PET) which is overlapped with Au

J. Kimet al. / Sensors and Actuators B 202 (2014) 6066 63

Fig. 2. Images of a microuidic cartridge during immunoassay operation. The state of pressure (positive, upper port) and vacuum(negative, lower port) pumps for each step

is denoted. (A) Sample transport to the antibody derivatized working electrode (denoted by W). Sample (red arrow) ows through the main channel for immunoreaction

by turning on the negative pressure while substrate solution is held in the reservoir (orange dotted line). (B) Electrode washing and addition of substrate. Air bubbles are

generated at the junction by applying a positive pressure, and non-specically bound target are removed by a meniscus force (blue and orange arrows). (C) By switching off

the positive pressure, air bubbles are removed, and a fresh substrate solution was delivered over the electrodes (orange arrow). (D) By switching off all the pressure sources,

the substrate solution is held on the electrodes during enzymatic reaction and electrochemical detection (orange dotted line).

Fig. 3. Leak-proof sealing of integrated electrodes using a double-sided tape. (A) A magnied viewof an Au electrode-deposited PET lmcrossed by a uidic channel (400m

width 130mheight) formed by cutting a double-sided tape. (B) A red liquid dye owing in the uidic channel which is overlapped with three electrodes (100nmthick)

at a owrate of 9.1L s

1

(scale bar, 500m).

electrodes on the PET lm(L1). To performa liquid leak test, a red-

dyed liquid was owed through the uidic channel and drained

into a bottle which was connected to the waste reservoir (with no

absorbent pad in this test). The vacuum-driven ow was visually

checked for leakage while the ow rate was gradually increased.

Therewas novisibleleakagearoundtheuidic channel at owrates

upto9.1L s

1

as showninFig. 3B. Inaddition, we conducteda pre-

liminary test for gas leakage. To detect air leaks out of the CEB,

a syringe pump was set to slowly increase air pressure inside the

CEB that was immersed in water. No air bubbles were observed

up to 20psi. This result demonstrates that the PSA-based bonding

technique is suitable for leak-proof sealing of metal electrodes over

rigid substrates.

For diverse functionality of integrated membranes, we utilized

the rst membrane (M1) as a valve. As depicted in Fig. 4A, a liquid

solution continuously ows to the main channel past the M1 by a

vacuumpump until the solution fromthe reservoir is all dissipated

and captured by the membrane. At this time, a positive pressure is

applied from the right side of the main channel to allow the solu-

tion to be separated fromthe membrane. When M1 was wetted by

the sample solution, it functions as a valve to prevent air inside the

channel frombeing discharged to the reservoir via the membrane.

As shown in Fig. 4B, air can only ow along the main channel but

cannot ow in the direction blocked by the liquid and the mem-

brane. In a similar manner, the third membrane (M3) was used

for isolating the waste solutions from both the main channel and

64 J. Kimet al. / Sensors and Actuators B 202 (2014) 6066

Fig. 4. Operation of the rst membrane (M1) for valve function. (A) A liquid (dotted arrow) passes through the membrane and moves to the main channel by a vacuumpump.

The valve in its open state is used in the sample transport step (red arrow). (B) When the liquid in the sample reservoir is all dissipated, a pressure pump applies a force to

separate the liquid fromthe main channel. The valve in its closed state blocks air ow(blue arrow) fromleaking into the sample reservoir in the air bubble generation step.

the vacuumport. This function will be very useful for the safety of

operators, particularly in screening for contagious diseases.

In addition, the second membrane (M2) was used as a dried

chemical storage. Once the membrane is wetted with a buffer solu-

tion, we can simply reconstitute to obtain the desired buffer. In

the CEB, the substrate solution was exploited for wash (modi-

ed usage) as well as enzymatic reaction (original usage), greatly

simplifying an immunoassay design. For the washing step, by pass-

ing the solution through a Tween-20 dried membrane, the solution

was modiedto 1%Tween-20 buffer to remove the non-specically

bound protein on the electrodes. After reconstituting the dried

Tween-20, the unmodied substrate solution was delivered over

the electrodes for enzymatic reaction. With this simplied forma-

tion, wash performance during the immunoassay was evaluated by

comparing non-specic background signals associated with two

types of membranes (i.e., in the presence vs. absence of Tween-

20). We used 50L of sample containing CK-MB antibody-enzyme

conjugate and 100L of substrate solution (out of total 200L)

with or without 1% Tween-20 in the wash test. The rst 100L

was supplied at different owrates of 0.71, 1.43 and 5.0L s

1

, fol-

lowed by the second (unmodied) 100L with a xed ow rate

of 5.0L s

1

. No air bubbles were produced in this procedure in

order to only test the role of Tween-20 rehydrated fromthe mem-

brane to washing efciency. As shown in Fig. 5, the CEB utilizing

the Tween-20 coated membrane yielded a lower background sig-

nal thanone without Tween-20, demonstrating that the membrane

with Tween-20 enhanced washing efciency.

To demonstrate the assay capability of the CEB, we performed

an electrochemical immunoassay for 5 different target concen-

trations (1, 5, 10, 25ngmL

1

including a negative control). As

described above, a 50L sample containing an antigen-ALP labeled

detection antibody was applied to the CEBs sample port, and

immunoreactionoccurredduringsample ow. Then, 200L of sub-

strate solution was constantly pumped at a ow rate of 5.0L s

1

for washandhaltedfor a 5-minenzymatic reaction. Fig. 6Apresents

the current responses at the working electrode plotted against

the applied potential in LSV. Faradic current contribution was

Fig. 5. Comparison of background currents (with no target antigen) for wash

performance in the sandwich electrochemical immunoassay. 100L samples of

electrochemical substrate solution with (modied) vs. without (unmodied) 1%

Tween-20 were applied at different ow rates of 0.71, 1.43 and 5.0L s

1

for the

rst wash. Subsequently, another 100L of unmodied substrate solution was sup-

plied for both second wash and enzymatic reaction. The error bar represents the

standard deviation fromthree independent measurements.

extracted at a xed potential of 0.15V to give a peak anodic cur-

rent. Fig. 6B exhibits the calibration curve of the peak anodic

current versus the concentration of CK-MB. The current responses

changed log-linearly as the analyte concentration increased, which

indicates that the on-chip electrochemical scheme could be used

for quantitative detection in immunoassays. From a series of the

immunoassays, we achieved a limit of detection of 0.25ngmL

1

in

theCK-MBassay. ElevatedCK-MBlevel has beencorrelatedwiththe

incidence of myocardial damage, and regular screening of CK-MB

levels has been suggested for the early detection of acute myocar-

dial infarction (AMI) [36]. Although there is no clear threshold

CK-MB value that is denitively diagnostic for AMI, 10ngmL

1

has been proposed as an acceptable detection limit for early AMI

J. Kimet al. / Sensors and Actuators B 202 (2014) 6066 65

Fig. 6. (A) Current responses obtained fromon-cartridge immunoassay for CK-MB at different concentrations of 25, 10, 5, 1 and 0ngmL

1

. Linear sweep voltammetry was

run in the range of 0.2 to 0.3V at a scan rate of 0.1Vs

1

. The immunoassay was processed on the microuidic cartridge with Tween-20 modied membrane. A 200L

volume of substrate solution was constantly supplied at 5.0L s

1

during wash step. (B) Calibration plot of the anodic peak current vs. the input concentration of CK-MB (1,

5, 10 and 25ngmL

1

) including a control. The background current (with no target) was 0.110.014A. The test was repeated three times for each concentration.

screening assays [37]. Thus, the performance of the CEB platform

for CK-MB assay is within clinical norms.

4. Conclusion

The development of microuidic systems has promoted

advances in miniaturization and automation of molecular diagnos-

tic testing, however high fabrication costs are often a barrier to

commercializationand/or adaptationtoresource poor settings. The

CEB including a passive valve, reagent storage and electrochemi-

cal sensors was fabricated by alternately stacking thin plastic lms

and double-sided PSA tapes. Our rapid fabrication technique elim-

inates the need for specialized cleanroom equipment and would

provide a miniaturized, affordable platformfor point-of-care (POC)

testing. In addition, the use of pierceable tape and porous mem-

branes in CEB enables programmable control of uid owduring

the performance of an assay. This capability eliminates the need for

mechanical microvalves in the design, thereby signicantly reduc-

ing the amount of off-chip control equipment. The process that is

automated by our CEB platformcan be useful for a broad range of

targets that employ similar immunoassay protocols. In this work,

we demonstrated an on-chip electrochemical immunoassay for

CK-MB and achieved clinically relevant sensitivity. The rapid fab-

rication technique that we present enables the design, fabrication,

and testing of newdevices within a single day.

Acknowledgments

This research was supported by Basic Science Research Pro-

gram through the National Research Foundation of Korea (NRF)

funded by the Ministry of Education, Science and Technology

(2012R1A6A1029029). J. Kim would like to thank Texas Tech

University for nancial support of this project through newinves-

tigator start-up funding. The authors would also like to thank Dr.

Jensen for fruitful scientic discussions.

References

[1] J. Kim, J. Elsnab, C. Gehrke, J. Li, B.K. Gale, Microuidic integrated multi-walled

carbon nanotube (MWCNT) sensor for electrochemical nucleic acid concentra-

tion measurement, Sens. Actuator B 185 (2013) 370376.

[2] Y. Sameenoi, K. Koehler, J. Shapiro, K. Boonsong, Y. Sun, J. Collett Jr., et al.,

Microuidic electrochemical sensor for on-line monitoring of aerosol oxidative

activity, J. Am. Chem. Soc. 134 (2012) 1056210568.

[3] J. Wang, Electrochemical biosensors: towards point-of-care cancer diagnostics,

Biosens. Bioelectron. 21 (2006) 18871892.

[4] J.W. Choi, K.W. Oh, J.H. Thomas, W.R. Heineman, H.B. Halsall, J.H. Nevin,

et al., An integrated microuidic biochemical detection system for protein

analysis with magnetic bead-based sampling capabilities, Lab Chip 2 (2002)

2730.

[5] A. Bange, H.B. Halsall, W.R. Heineman, Microuidic immunosensor systems,

Biosens. Bioelectron. 20 (2005) 24882503.

[6] T.W. de Haas, H. Fadaei, D. Sinton, Laminated thin-lmTeon chips for petro-

chemical applications, Lab Chip 12 (2012) 42364239.

[7] D.C. Duffy, J.C. McDonald, O.J. Schueller, G.M. Whitesides, Rapid prototyp-

ing of microuidic systems in poly(dimethylsiloxane), Anal. Chem. 70 (1998)

49744984.

[8] Y. Lu, W. Shi, L. Jiang, J. Qin, B. Lin, Rapid prototyping of paper-based microu-

idics with wax for low-cost, portable bioassay, Electrophoresis 30 (2009)

14971500.

[9] E. Sollier, C. Murray, P. Maoddi, D. Di Carlo, Rapid prototyping polymers

for microuidic devices and high pressure injections, Lab Chip 11 (2011)

37523765.

[10] T. Yasukawa, A. Glidle, M. Nomura, J.M. Cooper, Fabrication of robust 2-D and

3-D microuidic networks for lab-on-a-chip bioassays, J. Microelectromech.

Syst. 14 (2005) 839846.

[11] A. Plecis, Y. Chen, Fabrication of microuidic devices based on

glassPDMSglass technology, Microelectron. Eng. 84 (2007) 12651269.

[12] A. Yamaguchi, P. Jin, H. Tsuchiyama, T. Masuda, K. Sun, S. Matsuo, et al., Rapid

fabrication of electrochemical enzyme sensor chip using polydimethylsiloxane

microuidic channel, Anal. Chim. Acta 468 (2002) 143152.

[13] Z. Chen, J. Wang, S. Qian, H.H. Bau, Thermally-actuated, phase change ow

control for microuidic systems, Lab Chip 5 (2005) 12771285.

[14] J. Kim, D. Byun, M.G. Mauk, H.H. Bau, A disposable, self-contained PCR chip, Lab

Chip 9 (2009) 606612.

[15] J. Yang, Y. Liu, C.B. Rauch, R.L. Stevens, R.H. Liu, R. Lenigk, et al., High sensitivity

PCR assay in plastic micro reactors, Lab Chip 2 (2002) 179187.

[16] L. Yao, B. Liu, T. Chen, S. Liu, T. Zuo, Micro ow-through PCR in a PMMA chip

fabricated by KrF excimer laser, Biomed. Microdev. 7 (2005) 253257.

[17] W. Zhang, S. Lin, C. Wang, J. Hu, C. Li, Z. Zhuang, et al., PMMA/PDMS valves and

pumps for disposable microuidics, Lab Chip 9 (2009) 30883094.

[18] Q. Pu, O. Oyesanya, B. Thompson, S. Liu, J.C. Alvarez, On-chipmicropatterning of

plastic (cylic olen copolymer, COC) microuidic channels for the fabrication

of biomolecule microarrays using photografting methods, Langmuir 23 (2007)

15771583.

[19] J. Steigert, S. Haeberle, T. Brenner, C. Muller, C.P. Steinert, P. Koltay, et al., Rapid

prototyping of microuidic chips in COC, J. Micromech. Microeng. 17 (2007)

333341.

[20] R. Novak, N. Ranu, R.A. Mathies, Rapid fabrication of nickel molds for

prototyping embossed plastic microuidic devices, Lab Chip 13 (2013)

14681471.

[21] B.C. Giordano, J. Ferrance, S. Swedberg, A.F. Huhmer, J.P. Landers, Polymerase

chain reaction in polymeric microchips: DNA amplication in less than 240s,

Anal. Biochem. 291 (2001) 124132.

[22] D.A. Bartholomeusz, R.W. Boutte, J.D. Andrade, Xurography rapid prototyping

of microstructures using a cutting plotter, J. Microelectromech. Syst. 14 (2005)

13641374.

[23] J. Kim, B.K. Gale, Quantitative and qualitative analysis of a microuidic DNA

extractionsystemusing a nanoporous AlOx membrane, Lab Chip8 (2008) 1516.

[24] J. Kim, M. Mauk, D. Chen, X. Qiu, J. Kim, B. Gale, et al., A PCR reactor with an

integrated alumina membrane for nucleic acid isolation, Analyst 135 (2010)

2408.

[25] J. Kim, R. Surapaneni, B.K. Gale, Rapidprototyping of microuidic systems using

a PDMS/polymer tape composite, Lab Chip 9 (2009) 1290.

66 J. Kimet al. / Sensors and Actuators B 202 (2014) 6066

[26] B.H. Chueh, D. Huh, C.R. Kyrtsos, T. Houssin, N. Futai, S. Takayama, Leakage-free

bonding of porous membranes into layered microuidic array systems, Anal.

Chem. 79 (2007) 35043508.

[27] P. Guo, E.W. Hall, R. Schirhagl, H. Mukaibo, C.R. Martin, R.N. Zare, Microuidic

capture and release of bacteria in a conical nanopore array, Lab Chip 12 (2012)

558561.

[28] F. Saharil, F. Forsberg, Y. Liu, P. Bettotti, N. Kumar, F. Niklaus, et al., Dry adhesive

bonding of nanoporous inorganic membranes to microuidic devices using the

OSTE(+) dual-cure polymer, J. Micromech. Microeng. 23 (2013) 025021.

[29] F. Tan, P.H.M. Leung, Z.-b. Liu, Y. Zhang, L. Xiao, W. Ye, et al., A PDMS microu-

idic impedance immunosensor for E. coli O157:H7 and Staphylococcus aureus

detection via antibody-immobilized nanoporous membrane, Sens. Actuator B

159 (2011) 328335.

[30] J. Yu, Z. Liu, Q. Liu, K.T. Yuen, A.F.T. Mak, M. Yang, et al., A polyethylene glycol

(PEG) microuidic chip with nanostructures for bacteria rapid patterning and

detection, Sens. Actuator A 154 (2009) 288294.

[31] H.B. Wei, B.H. Chueh, H.L. Wu, E.W. Hall, C.W. Li, R. Schirhagl, et al., Particle

sorting using a porous membrane in a microuidic device, Lab Chip 11 (2011)

238245.

[32] D.S. Peterson, T. Rohr, F. Svec, J.M.J. Frechet, Enzymatic microreactor-on-a-

chip: proteinmappingusingtrypsinimmobilizedonporous polymer monoliths

molded in channels of microuidic devices, Anal. Chem. 74 (2002) 40814088.

[33] D.Y. Stevens, C.R. Petri, J.L. Osborn, P. Spicar-Mihalic, K.G. McKenzie, P. Yager,

Enabling a microuidic immunoassay for the developing world by integration

of on-card dry reagent storage, Lab Chip 8 (2008) 20382045.

[34] H. Klank, J.P. Kutter, O. Geschke, CO

2

-laser micromachining and back-end

processing for rapid productionof PMMA-based microuidic systems, Lab Chip

2 (2002) 242246.

[35] V. Linder, S.K. Sia, G.M. Whitesides, Reagent-loaded cartridges for valveless and

automated uid delivery in microuidic devices, Anal. Chem. 77 (2005) 6471.

[36] D. Chan, L.L. Ng, Biomarkers in acute myocardial infarction, BMC Med. 8 (2010)

34.

[37] A. Qureshi, Y. Gurbuz, J.H. Niazi, Biosensors for cardiac biomarkers detection:

a review, Sens. Actuator B 171 (2012) 6276.

Biographies

Jitae Kim received a Ph.D. in mechanical & aerospace engineering from the Uni-

versity of California, Irvine (2006). His B.S. and M.S. degrees, both in mechanical

engineering, are fromHanyang University in South Korea (1999) and the University

of Southern California (2001), respectively. He is currently a research professor at

the Institute of Nano Science &Technology (INST), Hanyang University. His interests

andresearchincludedroplet-basedmicrouidics, point-of-care(POC) immunoassay

and microuidic nucleic acid testing (NAT).

Yong Shin received the M.S. degree in Cancer Biology fromSeoul National Univer-

sity, South Korea in 2005 and Ph.D. degree in Molecular Neuro-Biology from Max

Planck Institute of Experimental Medicine and Georg-August-University Goettin-

gen, Germany in 2008. He currently joined Institute of Microelectronics, A*STAR as

a Scientist, Singapore. His research is nowfocused on the development of molecular

diagnostic platform based on optical biophotonics for detection of disease related

biomarkers.

Simon Song received his B.S. (1995) in Mechanical Engineering Department,

Hanyang University, Seoul, Korea and M.S. (1997) and Ph.D. (2002) in Mechan-

ical Engineering Department, Stanford University, USA. He joined faculties at

Hanyang University since 2004 and has interest in the development of microu-

idic chips for chemical sensing or sensor synthesis on a microchip as well as

ow visualization technology using medical equipment like magnetic resonance

imaging.

Joohyung Lee received both B.S. (2009) and M.S. (2011) degrees in Biomedical Engi-

neering fromYonsei University, South Korea. He is currently a Ph.D. student in the

biomedical micro/nano device (BMND) lab at the Texas Tech University, USA. His

research activities are now focused on developing microengineered biomimetic

organ-on-a-chip and chemical/biochemical analysis platforms for environmental

monitoring and biomarker screening.

Jungkyu (Jay) Kim is Assistant Professor, Department of Mechanical Engi-

neering at Texas Tech University. His research expertise includes lab-on-a

chip devices that require a variety of microuidic components for com-

plex chemical/biomedical assays. His work has involved the development of

microuidic control system, microuidic sample processing, nucleic acid sam-

ple preparation and on-chip amplication, protein microarray, CNT biosensor

and immunomagnetic detection. He has authored and co-authored more than

50 peer-reviewed journal and conference publications, 1 book chapters, and 6

patents issued or pending in the area of microuidics, biosensor and cell/tissue

engineering.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Anatomy of The Reproductive System EDocument4 pagesAnatomy of The Reproductive System EshreeNo ratings yet

- Optical Fiber Sensor For BODDocument6 pagesOptical Fiber Sensor For BODeveltoncNo ratings yet

- Ka Detn SpectrophDocument3 pagesKa Detn SpectropheveltoncNo ratings yet

- Zn3p2 Photovolt CellsDocument11 pagesZn3p2 Photovolt CellseveltoncNo ratings yet

- Nitrosaminas em Preservativos e BalõesDocument4 pagesNitrosaminas em Preservativos e BalõeseveltoncNo ratings yet

- Cuprous Chloride SynthesisDocument9 pagesCuprous Chloride SynthesiseveltoncNo ratings yet

- ICC300 Cabinet Datasheet V01 20130609Document1 pageICC300 Cabinet Datasheet V01 20130609Krishna ManandharNo ratings yet

- Prof. D. Pulla RaoDocument20 pagesProf. D. Pulla RaoAppan Kandala VasudevacharyNo ratings yet

- Lightolier Lytespan Track Lighting Systems Catalog 1984Document94 pagesLightolier Lytespan Track Lighting Systems Catalog 1984Alan Masters100% (1)

- Warrant: Catherine Lynn JarveyDocument4 pagesWarrant: Catherine Lynn JarveyLeigh EganNo ratings yet

- Excel Meracik Nutrisi Bandung 11 Feb 2018Document30 pagesExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNo ratings yet

- Evidence From QuranDocument6 pagesEvidence From QuranHaziq Hakeem Ahmad Affandi100% (1)

- Pub - Vectors Matrices and Geometry PDFDocument357 pagesPub - Vectors Matrices and Geometry PDFSalami Blessing100% (1)

- Wallace Stevens - Thirteen Ways of Looking at A BlackbirdDocument1 pageWallace Stevens - Thirteen Ways of Looking at A Blackbirdba belNo ratings yet

- HIPPROSTHESISCATALOGDocument98 pagesHIPPROSTHESISCATALOGBrenda Martinez RomanNo ratings yet

- SP-1102A Specification For Design of 33kV Overhead Power Lines On Wooden PolesDocument118 pagesSP-1102A Specification For Design of 33kV Overhead Power Lines On Wooden Polesarjunprasannan7No ratings yet

- Sri Chaitanya IIT Academy., India.: SyllabusDocument16 pagesSri Chaitanya IIT Academy., India.: SyllabusPrabhakar BandaruNo ratings yet

- Death in The Blue Ocean: by Caleb SmithDocument193 pagesDeath in The Blue Ocean: by Caleb SmithpolarisincNo ratings yet

- CBSE Sample Papers For Class 3 English - Mock Paper 1Document6 pagesCBSE Sample Papers For Class 3 English - Mock Paper 1Rita KumariNo ratings yet

- Statement of Purpose For TU DElft-1updatedDocument5 pagesStatement of Purpose For TU DElft-1updatedDhriti NayyarNo ratings yet

- 8fe8c95c08fa432b6352Document14 pages8fe8c95c08fa432b6352Harry keenNo ratings yet

- Battery-Box Hvs / HVM: PremiumDocument2 pagesBattery-Box Hvs / HVM: PremiumIulian GrigoreNo ratings yet

- 10.4 Diagnostic Based in Vibrations AnalysisDocument35 pages10.4 Diagnostic Based in Vibrations AnalysisgabrielNo ratings yet

- Impact of Climate Change On The Extent of Favorable Areas For The Future Distribution of Multipurpose Agro Forestry Species in Niger: The Case of Vitellaria Paradoxa C.F. GaertnDocument8 pagesImpact of Climate Change On The Extent of Favorable Areas For The Future Distribution of Multipurpose Agro Forestry Species in Niger: The Case of Vitellaria Paradoxa C.F. GaertnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sony KV 13TR27 Chasis.P 3BDocument29 pagesSony KV 13TR27 Chasis.P 3BTereza Yamileth Coto ENo ratings yet

- Interconnecting Cisco Networking Devices Part 2 (ICND2 v1.0)Document15 pagesInterconnecting Cisco Networking Devices Part 2 (ICND2 v1.0)amapreet.scorpioNo ratings yet

- IND110321USA6 Bayou CatDocument1 pageIND110321USA6 Bayou CatMichel MichelNo ratings yet

- Potassium AcetateDocument1 pagePotassium Acetaterushikesh pandyaNo ratings yet

- Numerical Analysis of A Bisection-Exclusion Method To Find Zeros of Univariate Analytic FunctionsDocument39 pagesNumerical Analysis of A Bisection-Exclusion Method To Find Zeros of Univariate Analytic FunctionsLucas SantosNo ratings yet

- IV Infusion: Purpose of Starting IV'sDocument6 pagesIV Infusion: Purpose of Starting IV'sKiara Denise TamayoNo ratings yet

- D 661Document20 pagesD 661CristianNo ratings yet

- Feb 3 Questions Nuclear WasteDocument4 pagesFeb 3 Questions Nuclear WastedcudfhiudfiuNo ratings yet

- Peugeot 206 P Dag Owners ManualDocument119 pagesPeugeot 206 P Dag Owners ManualAlex Rojas AguilarNo ratings yet

- 26 Spruit DragonairDocument2 pages26 Spruit DragonairW.J. ZondagNo ratings yet

- Waqia Karbala Tareekh Ke Aine Me - Urdu BookDocument86 pagesWaqia Karbala Tareekh Ke Aine Me - Urdu BookABBAS ZAIDINo ratings yet