Professional Documents

Culture Documents

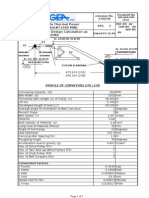

Conveyor Calculation

Conveyor Calculation

Uploaded by

sutanuprojectsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conveyor Calculation

Conveyor Calculation

Uploaded by

sutanuprojectsCopyright:

Available Formats

460

3.166666667

: PT Newmont

750 mm Friction Factor (f)

EP 500/4 f 0.03 Density Table

42 m Lo 49 TABEL 1

L 43 m TABEL 2

H 7 m Slope, Radiant 0.2

V 30 m/min 11.5 Degree K Value 0.625

Fly Ash 0.0625

Material density 0.72 T/Cu.m

Q' 77.76 Ton/hours = 60 min/jam x Area (A) x Material Density x Belt Speed (m/min)

0.06 Sq.m 0.72 T/cum 30 m/min A=K(0.9B-0.05)

2

= 0.060078

Weight of moving parts without material carried

Q 150 Ton/hours W 53

P1 = Power required to move empty belt (kW) Pt = Power to move Tripper (kW)

= 0.06 x f x W x V (L + Lo) 2.65

367

= 0.72 kW

P2 = Power required to move load on level (kW) 1.666666667

= f x Q (L + Lo) 628

367

= 1.13 kW

P3 = Power to Lift load (kW) P = Total Power

= H x Q ( + ) value for ascent conveyor = P1 + P2 + P3 + Pt

367 ( - ) value for descent conveyor = 7.37 kW

= 2.87 kW

11.06 kW Safety factor 1.5

Choice = 12.00 kW Safety factor 1.63

17.00 hp

= 6120 x P

FP V FRICTION FACTOR WEIGHT OF ROTATING PARTS OFCARRIER

= 1503.48 kg 0.2 Wc = 13.9 kg/set

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR WEIGHT OF ROTATING PARTS OF RETURN ROLLER

F2 0.5 Wr = 12.2 kg/set

= 751.74 kg TABEL

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1) WEIGHT OF MATERIAL PER METER LOADED ON CONVEYOR

F3 = 107.77 kg 13 kg/m Wm = Qt

0.06 x V

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

F4 3 m = 83.33 kg/m

= 243.75 kg

CARRY IDLER SPACING (Lc)

1 m

MINIMUM TENSION OF CARRIER SIDE

Counter Weight Calculation (Wt) ~ 2 x T2 = 1503.48 kg Choise the Larger Tension F4c = 12.5 Lc ( Wm + W1 )

~ 2 x T4 = 487.5 kg

= 1204.17 kg

= 7 5 ~ 10 MINIMUM TENSION OF RETURN SIDE

~ 2751.54 kg = Fp + F4c - Fr F4r = 12.5 Lr . W1

or 2034.88 kg = Fp + F4r - Fr

or 2255.22 kg = Fp + F2 = 487.50 kg

or 487.50 kg = Fp + F4r

= 2255.22 kg

Fr = f ( L + Lo)(w1 + Wr/Lr) - (H.W1)

= 75 cm

= 4 nos = -43.896 kg

Breaking Strength of tension layer = FM x SF

BW x n

= 52.6218 kg/cm.ply

= 210.4872 kg/cm

EP 500/4 Table Tensile Strength

Maximum Tension (FM)

Choice Bigest Tension

Number of ply (n)

CHOICE

Belt Width (BW)

Horizontal length of conveyor

C to C conveyor length

Height of level head pulley

Belt speed

POWER MOTOR & COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Safety factor (SF)

Material to handled

Calculation Conveyor Capacity

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

Sag Tension (T4)

m2

COUNTER WEIGHT CALCULATOR

: PT. CAMCO OMYA

450 mm Friction Factor (f)

EP500 f 0.03

200 m Lo 49

L 250 m

H 30 m

V 45 m/min

Calcium Carbonate Weight of moving parts without material carried

Q 60 Ton/hours W 28

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 1.85 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 1.47 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 4.91 kW

= 6120 x P

V FRICTION FACTOR

= 1119.28 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

0.418

= 467.86 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 337.5 kg 9 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 168.75 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 935.72 kg Choise the Larger Tension

~ 2 x T4 = 337.5 kg

PROJECT

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

Sag Tension (T4)

Belt width

Tensile strength of belt

Horizontal length of conveyor

C to C conveyor length

Belt speed

Material to handled

Conveyor Capacity

Height of level head pulley

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 8.23 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

COUNTER WEIGHT CALCULATOR

: EMOMI

450 mm Friction Factor (f)

EP500 f 0.03

201.7 m Lo 49

L 98.7 m

H 21.3 m

V 90 m/min

ASH WASTE Weight of moving parts without material carried

Q 5 Ton/hours W 28

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 1.83 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 0.07 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 0.3 kW

= 6120 x P

V FRICTION FACTOR

= 149.6 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 170.55 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 169.83 kg 7 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 131.25 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 341.1 kg Choise the Larger Tension

~ 2 x T4 = 262.5 kg

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

Sag Tension (T4)

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

C to C conveyor length

Height of level head pulley

Belt speed

Material to handled

Belt Spesification : Scandura PN150 x 3 x 5 + 1.5

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 2.2 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

COUNTER WEIGHT CALCULATOR

: EMOMI

450 mm Friction Factor (f)

PN150 x 3 f 0.03

93.647 m Lo 49

L 98.7 m

H 22.133 m

V 60 m/min

ASH WASTE Weight of moving parts without material carried

Q 10 Ton/hours W 28

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 1.22 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 0.13 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 0.61 kW

= 6120 x P

V FRICTION FACTOR

= 199.92 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 227.91 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 175.66 kg 7 kg

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 131.25 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 455.82 kg Choise the Larger Tension

~ 2 x T4 = 262.5 kg

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

Sag Tension (T4)

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

C to C conveyor length

Height of level head pulley

Belt speed

Material to handled

Belt Spesification : Scandura PN150 x 3 x 5 + 1.5

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 1.96 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

COUNTER WEIGHT CALCULATOR

: EMOMI

450 mm Friction Factor (f)

PN150 x 3 f 0.03

93.647 m Lo 49

L 97.947 m

H 22.133 m

V 72 m/min

ASH WASTE Weight of moving parts without material carried

Q 10 Ton/hours W 28

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 1.46 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 0.13 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 0.61 kW

= 6120 x P

V FRICTION FACTOR

= 187 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 213.18 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 175.5 kg 7 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 131.25 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 426.36 kg Choise the Larger Tension

~ 2 x T4 = 262.5 kg

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

Sag Tension (T4)

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

C to C conveyor length

Height of level head pulley

Belt speed

Material to handled

Belt Spesification : Scandura PN150 x 3 x 5 + 1.5

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 2.2 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

: PT. FREEPORT Mc.MORRAN INDONESIA

750 mm Friction Factor (f)

NN200 x 5 X 5/1.5 f 0.03

13 m Lo 49

L 12.76 m

H 0 m

V 142 m/min

SPLIT STONE Weight of moving parts without material carried

Q 200 Ton/hours W 154

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 6.63 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 1.01 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 0 kW

= 6120 x P

V FRICTION FACTOR

= 329.28 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 375.38 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 4.98 kg 13 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 243.75 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 750.76 kg Choise the Larger Tension

~ 2 x T4 = 487.5 kg

Horizontal length of conveyor

C to C conveyor length

Height of level head pulley

Belt speed

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Slope Tension (T3)

Sag Tension (T4)

Material to handled

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 7.64 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

COUNTER WEIGHT CALCULATOR

: PT. Krakatau Bandar Samudra

1000 mm Friction Factor (f)

EP800/4 f 0.03

25.5 m Lo 49

L 25 m

H 0 m

V 142 m/min

SOYBEANS Weight of moving parts without material carried

Q 600 Ton/hours W 154

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 7.94 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 3.63 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 0 kW

= 6120 x P

V FRICTION FACTOR

= 498.66 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 568.48 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 9.75 kg 13 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 243.75 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 1136.96 kg Choise the Larger Tension

~ 2 x T4 = 487.5 kg

Height of level head pulley

Belt speed

Slope Tension (T3)

Sag Tension (T4)

Material to handled

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

C to C conveyor length

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 11.57 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

COUNTER WEIGHT CALCULATOR

: PT. FREEPORT Mc.MORRAN INDONESIA

750 mm Friction Factor (f)

NN200 x 5 X 5/1.5 f 0.03

25.5 m Lo 49

L 28.3 m

H 9.3 m

V 142 m/min

SPLIT STONE Weight of moving parts without material carried

Q 200 Ton/hours W 154

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 8.3 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 1.27 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 5.07 kW

= 6120 x P

V FRICTION FACTOR

= 630.97 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 719.31 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 131.94 kg 13 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 243.75 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 1438.62 kg Choise the Larger Tension

~ 2 x T4 = 487.5 kg

Horizontal length of conveyor

C to C conveyor length

Height of level head pulley

Belt speed

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Slope Tension (T3)

Sag Tension (T4)

Material to handled

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 14.64 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

COUNTER WEIGHT CALCULATOR

: PLN SURALAYA

1800 mm Friction Factor (f)

NN200 x 5 X 5/1.5 f 0.03

528.8 m Lo 49

L 548.5 m

H 9.8 m

V 198 m/min

COAL Weight of moving parts without material carried

Q 2400 Ton/hours W 154

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 89.36 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 117.23 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 64.09 kW

= 6120 x P

V FRICTION FACTOR

= 8366.48 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 9537.79 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 1207.73 kg 46 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 862.5 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 19075.58 kg Choise the Larger Tension

~ 2 x T4 = 1725 kg

C to C conveyor length

Height of level head pulley

Belt speed

Material to handled

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

Sag Tension (T4)

COUNTER WEIGHT CALCULATOR

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 270.68 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

COUNTER WEIGHT CALCULATOR

COUNTER WEIGHT CALCULATOR

: EMOMI

450 mm Friction Factor (f)

PN150 x 3 f 0.03

93.647 m Lo 49

L 98.7 m

H 22.133 m

V 72 m/min

ASH WASTE Weight of moving parts without material carried

Q 10 Ton/hours W 28

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 1.47 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 0.13 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 0.61 kW

= 6120 x P

V FRICTION FACTOR

= 187.85 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

1.14

= 214.15 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

= 175.66 kg 7 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

3 m

= 131.25 kg

Counter Weight Calculation (Wt) ~ 2 x T2 = 428.3 kg Choise the Larger Tension

~ 2 x T4 = 262.5 kg

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

Sag Tension (T4)

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

C to C conveyor length

Height of level head pulley

Belt speed

Material to handled

Belt Spesification : Scandura PN150 x 3 x 5 + 1.5

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 2.21 kW

DRIVING COEFFECIENT FACTOR

BELT WEIGHT STANDART (W1)

RETURN IDLER SPACING (Lr)

Choise the Larger Tension

: MODIFIKASI CONV. BF11 / BF.12 PLN SURALAYA

1400 mm Friction Factor (f)

EP500/4 f 0.03

9.5 m Lo 49

L 8.5 m

H 0 m

V 165 m/min

COAL Weight of moving parts without material carried

Q 2000 Ton/hours W 154

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 7.17 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 9.41 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 0 kW

= 6120 x P

FP V FRICTION FACTOR

= 614.97 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

F2 0.638

= 392.36 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

F3 = 8.42 kg 33 kg/m

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

F4 3 m

= 618.75 kg

CARRY IDLER SPACING (Lc)

0.7 m

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Material to handled

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Horizontal length of conveyor

C to C conveyor length

Height of level head pulley

Belt speed

Slope Tension (T3)

Sag Tension (T4)

Counter Weight Calculation (Wt) ~ 2 x T2 = 784.72 kg Choise the Larger Tension

~ 2 x T4 = 1237.5 kg

= 7 5 ~ 10

~ 2598.66 kg = Fp + F4c - Fr

or 1779.73 kg = Fp + F4r - Fr

or 1007.33 kg = Fp + F2

or 1237.50 kg = Fp + F4r

= 2598.66 kg

= 140 cm

= 4 nos

Breaking Strength of tension layer = FM x SF

BW x n

= 32.48324085 kg/cm.ply

= 129.9329634 kg/cm

EP 500/4 Table Tensile Strength

Choice Bigest Tension

Belt Width (BW)

Number of ply (n)

CHOICE

Safety factor (SF)

Maximum Tension (FM)

Density Table

TABEL 1

TABEL 2

K Value

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

= P1 + P2 + P3 + Pt

= 16.58 kW

20.73 kW Safety factor 25%

21.00 kW Round up

WEIGHT OF ROTATING PARTS OFCARRIER

Wc = 90 kg/set

DRIVING COEFFECIENT FACTOR WEIGHT OF ROTATING PARTS OF RETURN ROLLER

Wr = 27.5 kg/set

TABEL

BELT WEIGHT STANDART (W1) WEIGHT OF MATERIAL PER METER LOADED ON CONVEYOR

Wm = Qt

0.06 x V

RETURN IDLER SPACING (Lr)

= 202.02 kg/m

CARRY IDLER SPACING (Lc)

MINIMUM TENSION OF CARRIER SIDE

COUNTER WEIGHT CALCULATOR

Choise the Larger Tension F4c = 12.5 Lc ( Wm + W1 )

= 2056.43 kg

MINIMUM TENSION OF RETURN SIDE

F4r = 12.5 Lr . W1

= 1237.50 kg

Fr = f ( L + Lo)(w1 + Wr/Lr) - (H.W1)

= 72.7375 kg

: MODIFIKASI CON-1014, PLANT FEED CONVEYOR

750 mm Friction Factor (f)

PN450/3 f 0.03

74 m Lo 49

L 85 m

H 10.5 m

V 102 m/min

COAL Weight of moving parts without material carried

Q 360 Ton/hours W 154

P1 = Power required to move empty belt (kW)

= 0.06 x f x W x V (L + Lo)

367

= 10.33 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 3.95 kW

P3 = Power to Lift load (kW)

= H x Q ( + ) value for ascent conveyor

367 ( - ) value for descent conveyor

= 10.3 kW

= 6120 x P

FP V FRICTION FACTOR

= 1474.8 kg 0.2

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR

F2 0.638

= 940.93 kg

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1)

F3 = 430.65 kg 33

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

F4 3

= 618.75 kg

CARRY IDLER SPACING (Lc)

0.7

Counter Weight Calculation (Wt) ~ 2 x T2 = 1881.86 kg Choise the Larger Tension

~ 2 x T4 = 1237.5 kg

Slope Tension (T3)

Sag Tension (T4)

Height of level head pulley

Belt speed

Material to handled

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

C to C conveyor length

= 7 5 ~ 10

~ 2455.25 kg = Fp + F4c - Fr

or 2889.29 kg = Fp + F4r - Fr

or 2415.73 kg = Fp + F2

or 1237.50 kg = Fp + F4r

= 2889.29 kg

= 75 cm

= 4 nos

Breaking Strength of tension layer = FM x SF

BW x n

= 67.41676667 kg/cm.ply

= 269.6670667 kg/cm

EP 500/4

Safety factor (SF)

Maximum Tension (FM)

Table Tensile Strength

Choice Bigest Tension

Belt Width (BW)

Number of ply (n)

CHOICE

Friction Factor (f)

Density Table

TABEL 1

TABEL 2

K Value

Weight of moving parts without material carried

Pt = Power to move Tripper (kW)

P = Total Power

( + ) value for ascent conveyor = P1 + P2 + P3 + Pt

( - ) value for descent conveyor = 24.58 kW

30.73 kW Safety factor 25%

15.00 kW Round up

FRICTION FACTOR WEIGHT OF ROTATING PARTS OFCARRIER

Wc = 90 kg/set

DRIVING COEFFECIENT FACTOR WEIGHT OF ROTATING PARTS OF RETURN ROLLER

Wr = 27.5 kg/set

TABEL

BELT WEIGHT STANDART (W1) WEIGHT OF MATERIAL PER METER LOADED ON CONVEYOR

kg/m Wm = Qt

0.06 x V

RETURN IDLER SPACING (Lr)

m = 58.82 kg/m

CARRY IDLER SPACING (Lc)

m

MINIMUM TENSION OF CARRIER SIDE

Choise the Larger Tension F4c = 12.5 Lc ( Wm + W1 )

= 803.46 kg

COUNTER WEIGHT CALCULATOR

MINIMUM TENSION OF RETURN SIDE

Fp + F4c - Fr F4r = 12.5 Lr . W1

Fp + F4r - Fr

= 1237.50 kg

Fr = f ( L + Lo)(w1 + Wr/Lr) - (H.W1)

= -176.99 kg

: PT. SELAT NASIK INDOKWARSA

750 mm Friction Factor (f)

EP 400/3 f 0.03 Density Table

47.5 m Lo 49 TABEL 1

L 50 m TABEL 2

H 15.5 m

V 65 m/min K Value

PASIR KWARSA

Q' 9.009 Ton/hours = Area (A) x Material Density x Belt Speed (m/min)

0.066 Sq.m 2.1 T/cum 65 m/min

Weight of moving parts without material carried

Q 20 Ton/hours W 154

P1 = Power required to move empty belt (kW) Pt = Power to move Tripper (kW)

= 0.06 x f x W x V (L + Lo)

367

= 4.87 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 0.17 kW

P3 = Power to Lift load (kW) P = Total Power

= H x Q ( + ) value for ascent conveyor = P1 + P2 + P3 + Pt

367 ( - ) value for descent conveyor = 5.89 kW

= 0.85 kW

8.84 kW Safety factor 1.5

Choice = 9.20 kW Safety factor 1.57

= 6120 x P

FP V FRICTION FACTOR WEIGHT OF ROTATING PARTS OFCARRIER

= 554.57 kg 0.2 Wc = 13.9 kg/set

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR WEIGHT OF ROTATING PARTS OF RETURN ROLLER

F2 1.14 Wr = 12.2 kg/set

= 632.21 kg TABEL

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1) WEIGHT OF MATERIAL PER METER LOADED ON CONVEYOR

F3 = 391 kg 23 kg/m Wm = Qt

0.06 x V

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

F4 3 m = 5.13 kg/m

= 431.25 kg

CARRY IDLER SPACING (Lc)

1 m

MINIMUM TENSION OF CARRIER SIDE

Counter Weight Calculation (Wt) ~ 2 x T2 = 1264.42 kg Choise the Larger Tension F4c = 12.5 Lc ( Wm + W1 )

~ 2 x T4 = 862.5 kg

= 351.60 kg

= 7 5 ~ 10 MINIMUM TENSION OF RETURN SIDE

~ 1182.28 kg = Fp + F4c - Fr F4r = 12.5 Lr . W1

or 1693.18 kg = Fp + F4r - Fr

or 1186.78 kg = Fp + F2 = 862.50 kg

or 862.50 kg = Fp + F4r

= 1182.28 kg

Fr = f ( L + Lo)(w1 + Wr/Lr) - (H.W1)

= 75 cm

= 4 nos = -276.112 kg

Breaking Strength of tension layer = FM x SF

BW x n

= 27.58663983 kg/cm.ply

= 110.3465593 kg/cm

EP 400/3

Belt Width (BW)

Number of ply (n)

Sag Tension (T4)

Calculation Conveyor Capacity

Slope Tension (T3)

Maximum Tension (FM)

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Height of level head pulley

Belt speed

Horizontal length of conveyor

C to C conveyor length

Table Tensile Strength

Material to handled

Conveyor Capacity

Effective tension (Te)

Safety factor (SF)

CHOICE

Choice Bigest Tension

Slack Side Tension (T2)

: PT.PURABARUTAMA - KUDUS

1000 mm Friction Factor (f)

EP 400/3 f 0.03 Density Table

10 m Lo 49 TABEL 1

L 10 m TABEL 2

H 0 m

V 65 m/min K Value

PULP PAPER

Q' 15.288 Ton/hours = Area (A) x Material Density x Belt Speed (m/min)

0.112 Sq.m 2.1 T/cum 65 m/min

Weight of moving parts without material carried

Q 20 Ton/hours W 154

P1 = Power required to move empty belt (kW) Pt = Power to move Tripper (kW)

= 0.06 x f x W x V (L + Lo)

367

= 2.9 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 0.1 kW

P3 = Power to Lift load (kW) P = Total Power

= H x Q ( + ) value for ascent conveyor = P1 + P2 + P3 + Pt

367 ( - ) value for descent conveyor = 3 kW

= 0 kW

4.50 kW Safety factor 1.5

Choice = 4.50 kW Safety factor 1.5

= 6120 x P

FP V FRICTION FACTOR WEIGHT OF ROTATING PARTS OFCARRIER

= 282.47 kg 0.2 Wc = 13.9 kg/set

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR WEIGHT OF ROTATING PARTS OF RETURN ROLLER

F2 1.14 Wr = 12.2 kg/set

= 322.02 kg TABEL

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1) WEIGHT OF MATERIAL PER METER LOADED ON CONVEYOR

F3 = 6.9 kg 23 kg/m Wm = Qt

0.06 x V

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

F4 3 m = 5.13 kg/m

= 431.25 kg

CARRY IDLER SPACING (Lc)

1 m

MINIMUM TENSION OF CARRIER SIDE

Counter Weight Calculation (Wt) ~ 2 x T2 = 644.04 kg Choise the Larger Tension F4c = 12.5 Lc ( Wm + W1 )

~ 2 x T4 = 862.5 kg

= 351.60 kg

= 7 5 ~ 10 MINIMUM TENSION OF RETURN SIDE

~ 586.16 kg = Fp + F4c - Fr F4r = 12.5 Lr . W1

or 1097.06 kg = Fp + F4r - Fr

or 604.49 kg = Fp + F2 = 862.50 kg

or 862.50 kg = Fp + F4r

= 1097.06 kg

Fr = f ( L + Lo)(w1 + Wr/Lr) - (H.W1)

= 100 cm

= 3 nos = 47.908 kg

Breaking Strength of tension layer = FM x SF

BW x n

= 25.59806667 kg/cm.ply

= 76.7942 kg/cm

EP 400/3

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

C to C conveyor length

Height of level head pulley

Belt speed

Material to handled

Effective tension (Te)

Calculation Conveyor Capacity

Conveyor Capacity

Sag Tension (T4)

Safety factor (SF)

Slack Side Tension (T2)

Table Tensile Strength

Choice Bigest Tension

Belt Width (BW)

Number of ply (n)

CHOICE

Maximum Tension (FM)

Slope Tension (T3)

: PT. SUMATERA PRIMA FIBREBOARD

1200 mm Friction Factor (f)

EP 400/3 f 0.03 Density Table

47.5 m Lo 49 TABEL 1

L 70 m TABEL 2

H 5 m Slope, Radiant 0.104877

V 65 m/min 6.1 Degree K Value

WOOD CHIP

Q' 120 Ton/hours = Area (A) x Material Density x Belt Speed (m/min)

Sq.m T/cum 65 m/min

Weight of moving parts without material carried

Q 120 Ton/hours W 154

P1 = Power required to move empty belt (kW) Pt = Power to move Tripper (kW)

= 0.06 x f x W x V (L + Lo)

367

= 5.85 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 1.17 kW

P3 = Power to Lift load (kW) P = Total Power

= H x Q ( + ) value for ascent conveyor = P1 + P2 + P3 + Pt

367 ( - ) value for descent conveyor = 8.66 kW

= 1.64 kW

12.99 kW Safety factor 1.5

Choice = 22.00 kW Safety factor 2.55

= 6120 x P

FP V FRICTION FACTOR WEIGHT OF ROTATING PARTS OFCARRIER

= 815.38 kg 0.2 Wc = 13.9 kg/set

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR WEIGHT OF ROTATING PARTS OF RETURN ROLLER

F2 1.14 Wr = 12.2 kg/set

= 929.54 kg TABEL

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1) WEIGHT OF MATERIAL PER METER LOADED ON CONVEYOR

F3 = 163.3 kg 23 kg/m Wm = Qt

0.06 x V

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

F4 3 m = 30.77 kg/m

= 431.25 kg

CARRY IDLER SPACING (Lc)

1 m

MINIMUM TENSION OF CARRIER SIDE

Counter Weight Calculation (Wt) ~ 2 x T2 = 1859.08 kg Choise the Larger Tension F4c = 12.5 Lc ( Wm + W1 )

~ 2 x T4 = 862.5 kg

= 672.12 kg

= 7 5 ~ 10 MINIMUM TENSION OF RETURN SIDE

~ 1505.87 kg = Fp + F4c - Fr F4r = 12.5 Lr . W1

or 1696.25 kg = Fp + F4r - Fr

or 1744.92 kg = Fp + F2 = 862.50 kg

or 862.50 kg = Fp + F4r

= 1505.87 kg

Fr = f ( L + Lo)(w1 + Wr/Lr) - (H.W1)

= 120 cm

= 4 nos = -18.372 kg

Breaking Strength of tension layer = FM x SF

BW x n

= 21.96056603 kg/cm.ply

= 87.8422641 kg/cm

EP 400/3

COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

C to C conveyor length

Height of level head pulley

Belt speed

Material to handled

Effective tension (Te)

Calculation Conveyor Capacity

Conveyor Capacity

Sag Tension (T4)

Safety factor (SF)

Slack Side Tension (T2)

Table Tensile Strength

Choice Bigest Tension

Belt Width (BW)

Number of ply (n)

CHOICE

Maximum Tension (FM)

Slope Tension (T3)

: PT. ABC

1200 mm Friction Factor (f)

EP 630/4 f 0.03 Density Table

200 m Lo 49 TABEL 1

L 200 m TABEL 2

H 4 m Slope, Radiant 0.02

V 120 m/min 1.2 Degree K Value

BATUBARA

Material density 0.95 T/Cu.m

Q' 1012.32 Ton/hours = 60 min/jam x Area (A) x Material Density x Belt Speed (m/min)

0.148 Sq.m 0.95 T/cum 120 m/min

Weight of moving parts without material carried

Q 1000 Ton/hours W 154

P1 = Power required to move empty belt (kW) Pt = Power to move Tripper (kW)

= 0.06 x f x W x V (L + Lo)

367

= 22.57 kW

P2 = Power required to move load on level (kW)

= f x Q (L + Lo)

367

= 20.36 kW

P3 = Power to Lift load (kW) P = Total Power

= H x Q ( + ) value for ascent conveyor = P1 + P2 + P3 + Pt

367 ( - ) value for descent conveyor = 53.83 kW

= 10.9 kW

80.75 kW Safety factor 1.5

Choice = 80.00 kW Safety factor 1.49

= 6120 x P

FP V FRICTION FACTOR WEIGHT OF ROTATING PARTS OFCARRIER

= 2745.33 kg 0.2 Wc = 13.9 kg/set

= Te x 1/e (Driving Coeffecient Factor) DRIVING COEFFECIENT FACTOR WEIGHT OF ROTATING PARTS OF RETURN ROLLER

F2 1.14 Wr = 12.2 kg/set

= 3129.68 kg TABEL

= W1 ( H +/- f x L ) BELT WEIGHT STANDART (W1) WEIGHT OF MATERIAL PER METER LOADED ON CONVEYOR

F3 = 230 kg 23 kg/m Wm = Qt

0.06 x V

= 50/8 x Lr x W1 RETURN IDLER SPACING (Lr)

F4 3 m = 138.89 kg/m

= 431.25 kg

CARRY IDLER SPACING (Lc)

1 m

MINIMUM TENSION OF CARRIER SIDE

Counter Weight Calculation (Wt) ~ 2 x T2 = 6259.36 kg Choise the Larger Tension F4c = 12.5 Lc ( Wm + W1 )

~ 2 x T4 = 862.5 kg

= 2023.61 kg

= 7 5 ~ 10 MINIMUM TENSION OF RETURN SIDE

~ 4658.75 kg = Fp + F4c - Fr F4r = 12.5 Lr . W1

or 3497.64 kg = Fp + F4r - Fr

or 5875.01 kg = Fp + F2 = 862.50 kg

or 862.50 kg = Fp + F4r

= 5875.01 kg

Fr = f ( L + Lo)(w1 + Wr/Lr) - (H.W1)

= 120 cm

= 4 nos = 110.188 kg

Breaking Strength of tension layer = FM x SF

BW x n

= 85.67722917 kg/cm.ply

= 342.7089167 kg/cm

EP 630/4

Height of level head pulley

Belt speed

Safety factor (SF)

Material to handled

Calculation Conveyor Capacity

Conveyor Capacity

Effective tension (Te)

Slack Side Tension (T2)

Slope Tension (T3)

Sag Tension (T4)

POWER MOTOR & COUNTER WEIGHT CALCULATOR

PROJECT

Belt width

Tensile strength of belt

Horizontal length of conveyor

C to C conveyor length

Table Tensile Strength

Maximum Tension (FM)

Choice Bigest Tension

Number of ply (n)

CHOICE

Belt Width (BW)

You might also like

- Belt Conveyor Capacity - CalculatorDocument6 pagesBelt Conveyor Capacity - CalculatorRolando Daclan67% (3)

- Chain Conveyor CapacityDocument1 pageChain Conveyor Capacitysubathramesh100% (1)

- Bucket Elevator Calculation - Rev. 1Document8 pagesBucket Elevator Calculation - Rev. 1Jose David Jurado100% (4)

- Drag and Flight Conveyors Design CalculationDocument3 pagesDrag and Flight Conveyors Design Calculationsudip giri100% (1)

- Chain Pull and Power Calculation - WC 2125 KGMDocument2 pagesChain Pull and Power Calculation - WC 2125 KGMdeddy ariyanto100% (1)

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcsjnmanivannan100% (4)

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Conveyor Design-DraftDocument42 pagesConveyor Design-Draftmkchy1295% (22)

- BELT CONVEYOR - Discharge TrajectoryDocument3 pagesBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNo ratings yet

- Bucket Elevator Load CalculationsDocument2 pagesBucket Elevator Load CalculationsElwathig Bakhiet80% (5)

- Belt Conveyor Pulley Design - Why The FailuresDocument16 pagesBelt Conveyor Pulley Design - Why The FailuresenrimauryNo ratings yet

- Spider Air Slide Design For Line-1Document8 pagesSpider Air Slide Design For Line-1Irfan AhmedNo ratings yet

- Simple Belt Conveyor Calculation ExampleDocument3 pagesSimple Belt Conveyor Calculation ExampleBerk Koç100% (6)

- Gas Laws CrosswordDocument2 pagesGas Laws CrosswordHailey Rutherford0% (1)

- Screw ConveyorDocument7 pagesScrew ConveyorTots HolaresNo ratings yet

- Bucket Elevator ChainDocument4 pagesBucket Elevator Chainluisreng100% (1)

- Belt Conveyors With Shaft SizingDocument5 pagesBelt Conveyors With Shaft SizingRakhi Mor100% (2)

- Rumus BucketDocument4 pagesRumus BucketBimahsNo ratings yet

- Conveyor Design DraftDocument47 pagesConveyor Design DraftSandi Apriandi100% (1)

- Conveyor CalculationDocument40 pagesConveyor CalculationAnonymous 5XvUbWynnNo ratings yet

- Bucket Elevator Design StudyDocument24 pagesBucket Elevator Design StudyIrfan AhmedNo ratings yet

- Bucket Elevator Calculation: Yellow Cell To Be FilledDocument2 pagesBucket Elevator Calculation: Yellow Cell To Be FilledBùi Hắc HảiNo ratings yet

- BELT CONVEYOR - Discharge TrajectoryDocument1 pageBELT CONVEYOR - Discharge TrajectoryEslam FaroukNo ratings yet

- Belt Conveyor PowerDocument10 pagesBelt Conveyor PowerRyukiNo ratings yet

- Conveyor CapacityDocument3 pagesConveyor Capacityx30patelNo ratings yet

- Conveyor Tension and Trajectory CalculationDocument8 pagesConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- Mechanical Conveyors: 29 Materials HandlingDocument2 pagesMechanical Conveyors: 29 Materials HandlingSMNCI Cadet EngineersNo ratings yet

- Bucket Elevator Design StudyDocument24 pagesBucket Elevator Design StudyVeena100% (1)

- The Values Are Not Linked With Anywhere ..: Conveyor ProfileDocument33 pagesThe Values Are Not Linked With Anywhere ..: Conveyor ProfileMustafa Akbar100% (1)

- Screw ConveyorsDocument4 pagesScrew ConveyorsAshish SharmaNo ratings yet

- Design (Metric) 6.25Document8 pagesDesign (Metric) 6.25Salih Has100% (2)

- Manual Helix Delta t6Document309 pagesManual Helix Delta t6Ricardo Garay Reinoso100% (2)

- Screw Conveyor CalculationDocument14 pagesScrew Conveyor Calculationvvijaybhan100% (2)

- D-Bucket ChainsDocument45 pagesD-Bucket ChainsMuhammad Irvan FNo ratings yet

- Apron Weigh FeederDocument4 pagesApron Weigh FeederRaji SuriNo ratings yet

- Pipe ConveyorDocument4 pagesPipe ConveyorDIBYENDU MONDALNo ratings yet

- DAT Belt ConveyorDocument8 pagesDAT Belt ConveyorEDUARDONo ratings yet

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- Screw Conveyor RatingDocument6 pagesScrew Conveyor RatingPereiraeNo ratings yet

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunNo ratings yet

- Bag House Filter DesignDocument5 pagesBag House Filter DesignShermal FernandoNo ratings yet

- Bearing Centre and Face Width in Conveyor PulleyDocument8 pagesBearing Centre and Face Width in Conveyor PulleyPrashant MishraNo ratings yet

- Bucket ElevatorDocument2 pagesBucket ElevatorAndrés Lagos Méndez100% (5)

- Pipe Conv Presentation ColourDocument25 pagesPipe Conv Presentation Colourgunduanil17No ratings yet

- Calculation CEMA 5 - Parte4Document5 pagesCalculation CEMA 5 - Parte4Angel AlvarezNo ratings yet

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- Conveyor Belt Engineering TablesDocument5 pagesConveyor Belt Engineering Tablestaohung1120No ratings yet

- P139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)Document6 pagesP139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)CongOanh PHAN100% (1)

- Apron FeederDocument2 pagesApron FeederRaji Suri100% (2)

- Chain Conveyor ExampleDocument4 pagesChain Conveyor ExampledeeptidhaNo ratings yet

- Belt Cleaner HandbookDocument40 pagesBelt Cleaner Handbooklinmar7071100% (1)

- CEMA8 5pgDocument5 pagesCEMA8 5pgkmats100% (2)

- Screw Conveyor CalculationDocument1 pageScrew Conveyor CalculationRavindra RautNo ratings yet

- Screw Conveyor Excel CalculationDocument8 pagesScrew Conveyor Excel Calculationhardik033No ratings yet

- Conveyor CalculationDocument48 pagesConveyor CalculationearthplightNo ratings yet

- Revised Conveyor Belt CalDocument66 pagesRevised Conveyor Belt CalAndres Jr Quiambao100% (1)

- Conveyor CalculationDocument56 pagesConveyor CalculationsigisyahNo ratings yet

- Conveyor CalculationDocument46 pagesConveyor CalculationBuditama Chandranegara100% (1)

- PurlinDocument8 pagesPurlinRafaArdiSyahrezaNo ratings yet

- Data SheetDocument7 pagesData SheetsutanuprojectsNo ratings yet

- Coverage Calculator Pipeline CoatingsDocument2 pagesCoverage Calculator Pipeline CoatingssutanuprojectsNo ratings yet

- Egyptian Co Chemica Edile - TIGER - Expansive Mortar For Fracturing Rocks and ConcreteDocument4 pagesEgyptian Co Chemica Edile - TIGER - Expansive Mortar For Fracturing Rocks and ConcretesutanuprojectsNo ratings yet

- Paharpur Cooling Towers Ltd. Plot Plan For Ct-04: Main RoadDocument1 pagePaharpur Cooling Towers Ltd. Plot Plan For Ct-04: Main RoadsutanuprojectsNo ratings yet

- Cover Letter Administrative Sample: Julie Zhang, B.A 2 Bloor Street St. E, Toronto, Ontario M2S 3G3Document1 pageCover Letter Administrative Sample: Julie Zhang, B.A 2 Bloor Street St. E, Toronto, Ontario M2S 3G3sutanuprojectsNo ratings yet

- SKF Seize Resistant Bearing: Design AdvantagesDocument2 pagesSKF Seize Resistant Bearing: Design AdvantagessutanuprojectsNo ratings yet

- Plummer BlockDocument66 pagesPlummer BlockmmkattaNo ratings yet

- Transformer Sizing CalculationDocument6 pagesTransformer Sizing CalculationAvijnan Mitra100% (3)

- Density of Some Common Building MaterialsDocument26 pagesDensity of Some Common Building MaterialssutanuprojectsNo ratings yet

- Check If Dissemination Should Be at RTD Rate or 100% and Choose at C18Document8 pagesCheck If Dissemination Should Be at RTD Rate or 100% and Choose at C18sutanuprojectsNo ratings yet

- Screw ConveyorDocument5 pagesScrew ConveyorsutanuprojectsNo ratings yet

- Screw ConveyorDocument5 pagesScrew ConveyorsutanuprojectsNo ratings yet

- Belt Selection CalculationDocument18 pagesBelt Selection CalculationsutanuprojectsNo ratings yet

- Bonatrans IndiaDocument20 pagesBonatrans IndiasutanuprojectsNo ratings yet

- Uco Mbanking & ImpsDocument2 pagesUco Mbanking & ImpssutanuprojectsNo ratings yet

- Technical Specification TZ 13 012 PMDocument14 pagesTechnical Specification TZ 13 012 PMsutanuprojectsNo ratings yet

- Gas Pipeline HydraulicsDocument23 pagesGas Pipeline HydraulicssulaimanidreesNo ratings yet

- B.Sc. II Semester Physics:: Paper II Thermal Physics:: Imp QuestionsDocument2 pagesB.Sc. II Semester Physics:: Paper II Thermal Physics:: Imp QuestionsReddyvari Venugopal100% (1)

- Strain Gauge: Keci ShahDocument15 pagesStrain Gauge: Keci ShahAkip PrayotoNo ratings yet

- Eng1001 Vectors ExamplesDocument2 pagesEng1001 Vectors ExamplesAhza JufriNo ratings yet

- AIIMS Solved Paper 2017Document30 pagesAIIMS Solved Paper 2017Jagmohan SinghNo ratings yet

- SW Simulation PDFDocument6 pagesSW Simulation PDFamokhta50% (2)

- Revision Notes - Unit 2 AQA Physics A-LevelDocument12 pagesRevision Notes - Unit 2 AQA Physics A-LevelElliot ThomasNo ratings yet

- Boats and Streams Aptitude Questions With SolutionsDocument64 pagesBoats and Streams Aptitude Questions With SolutionsFahim UddinNo ratings yet

- The Nature of Forces: Evangelical Christian Montessori School Cor. DC - 3, Alijis RD, Brgy. Alijis, Bacolod City ScienceDocument12 pagesThe Nature of Forces: Evangelical Christian Montessori School Cor. DC - 3, Alijis RD, Brgy. Alijis, Bacolod City ScienceLydie Sheena IllutNo ratings yet

- Torsion Short Report Lab SheetDocument4 pagesTorsion Short Report Lab SheetAbdul Azeez Ismaila ShuaibuNo ratings yet

- A History of The AtomDocument4 pagesA History of The AtomKeith Kevin ChuaNo ratings yet

- Electromechanical System Transfer FunctionsDocument15 pagesElectromechanical System Transfer FunctionsCandy ChocolateNo ratings yet

- Skin Pass LiteratureDocument7 pagesSkin Pass LiteraturePartho ChoudhuryNo ratings yet

- Basics of Turbomachinery BalanceDocument14 pagesBasics of Turbomachinery BalanceSuthan RNo ratings yet

- Physics137a sp2014 mt2 Markov Soln PDFDocument7 pagesPhysics137a sp2014 mt2 Markov Soln PDFHawtShawtNo ratings yet

- Amjad Ashoorioon Et Al - M-Flation: Inflation From Matrix Valued Scalar FieldsDocument31 pagesAmjad Ashoorioon Et Al - M-Flation: Inflation From Matrix Valued Scalar FieldsTurmav12345No ratings yet

- Math 1210 Signature Assignment Derivatives 3Document6 pagesMath 1210 Signature Assignment Derivatives 3api-245099625No ratings yet

- Jahn-Teller VibronicDocument10 pagesJahn-Teller VibronicAlexanderNo ratings yet

- Sicence 8 CotDocument3 pagesSicence 8 CotHappy HookNo ratings yet

- J-R Behaviour of 20mnmoni55 Pressure Vessel Steel: Aravind K ROLL NO: 207MM112Document107 pagesJ-R Behaviour of 20mnmoni55 Pressure Vessel Steel: Aravind K ROLL NO: 207MM112Денис ПекшуевNo ratings yet

- 03-Unit and Dimension (Question) 2 (55-60)Document7 pages03-Unit and Dimension (Question) 2 (55-60)rahul singhNo ratings yet

- Inno2018 Emt2502 Vibrations Free Vibration SdofDocument15 pagesInno2018 Emt2502 Vibrations Free Vibration SdofinnoodiraNo ratings yet

- Albert EinsteinDocument10 pagesAlbert EinsteinAishwaria VarugheseNo ratings yet

- SRB CH 04 Equilibrium of Force SystemDocument8 pagesSRB CH 04 Equilibrium of Force SystemViper ivyNo ratings yet

- Mass Transfer NotesDocument37 pagesMass Transfer Notesapi-3852712No ratings yet

- Fluid Mechanics 101: Calculators & ToolsDocument11 pagesFluid Mechanics 101: Calculators & ToolsHaseebPirachaNo ratings yet

- Unit 1 Quantum Mechanics PDFDocument32 pagesUnit 1 Quantum Mechanics PDFDeveshNo ratings yet

- Steady Heat Transfer AND Thermal Resistance Networks: Dr. Şaziye Balku 1Document24 pagesSteady Heat Transfer AND Thermal Resistance Networks: Dr. Şaziye Balku 1Pankaj KumarNo ratings yet

- VFD PDFDocument26 pagesVFD PDFKamal Arreaza100% (1)