Professional Documents

Culture Documents

Dynamic Model of An Industrial Steam Reformer and Its Use For Multiobjective Optimization

Dynamic Model of An Industrial Steam Reformer and Its Use For Multiobjective Optimization

Uploaded by

Dante PhaseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynamic Model of An Industrial Steam Reformer and Its Use For Multiobjective Optimization

Dynamic Model of An Industrial Steam Reformer and Its Use For Multiobjective Optimization

Uploaded by

Dante PhaseCopyright:

Available Formats

Dynamic Model of an Industrial SteamReformer and Its Use for

Multiobjective Optimization

Anjana D. Nandasana,

Ajay K. Ray,

and Santosh K. Gupta*

,

Department of Chemical Engineering, I ndian I nstituteof Technology, Kanpur 208016, I ndia, and

Department of Chemical and Environmental Engineering, National University of Singapore, 10,

Kent RidgeCrescent, Singapore119260

An i ndustri al si de-fi red steam reformer i n a hydrogen pl ant i s si mul ated under dynami c

condi ti ons. A ri gorous model wi th veri fi ed reacti on ki neti cs i s used. Thi s model i ncorporates

aspects of heat transfer i n the furnace and di ffusi on i nsi de the catal yst pel l et. The dynami c

model i s used to study the effects of a few (pl anned) di sturbances that reduce the producti on of

both hydrogen and steam and adversel y i nfl uence the safety of the pl ant i f correcti ve control

acti on i s not taken i n ti me. The operati on of the steam reformer i s si mul ated i n the presence of

three i deal i zed di sturbances i n (1) the i nl et feed temperature, (2) the i nl et feed rate of natural

gas, and (3) the furnace gas temperature. The model i s then used to obtai n opti mal operati ng

condi ti ons requi red to negate the effects of two di sturbances usi ng several control or deci si on

vari abl es. Two objecti ve functi ons are mi ni mi zed si mul taneousl y: the cumul ati ve (i ntegrated

over ti me) devi ati on of the fl ow rate of hydrogen and the cumul ati ve devi ati on of the steam fl ow

rate. The el i ti st nondomi nated sorti ng geneti c al gori thm NSGA-I I i s used to obtai n sol uti ons of

thi s mul ti objecti ve opti mi zati on probl em. Nondomi nati ng Pareto-opti mal sol uti ons are obtai ned.

Introduction

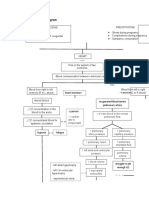

Steam reformi ng of hydrocarbons i s an economi cal

method of produci ng synthesi s gas and generati ng

hydrogen. The former i s the feedstock for the synthesi s

of ammoni a, methanol , etc., and the l atter i s an envi -

ronmental l y cl ean fuel .

1

Steam reformi ng pl ants al so

produce consi derabl e amounts of exportabl e steam. The

process fl ow sheet of a typi cal pl ant i s shown i n Fi gure

1. A hydrocarbon stream, assumed to be essenti al l y

methane (wi th CO

2

and N

2

i mpuri ti es) i n thi s study, i s

desul furi zed and preheated. Thi s stream i s mi xed wi th

appropri ate quanti ti es of steam and recycl ed hydrogen

(both from the plant) and fed to the fi rst reactor (cal l ed

the reformer). The fol l owi ng catal yti c reacti ons take

pl ace i n thi s reactor

The gas exi ti ng the reformer, ri ch i n CO and H

2

,

exchanges heat wi th the boi l er feedwater to generate

very hi gh pressure (VHP) steam. The cool ed process gas

i s then fed to a two-stage adi abati c shi ft converter,

where CO i s converted i nto CO

2

and addi ti onal hydro-

gen. Hydrogen i s separated from the exi t gas i n a

pressure-swi ng adsorpti on (PSA) uni t.

The reformi ng reacti ons (eqs 1 and 3) are strongl y

endothermi c i n nature and requi re l arge energy i nputs.

I ncreasi ng energy costs and competi ti on requi re that

reformi ng pl ants be operated opti mal l y, both under

steady-state condi ti ons and i n the presence of un-

pl anned di sturbances. The effects of these di sturbances

need to be negated by advanced model -based process

control strategi es. A good dynami c model i s a prereq-

ui si te for thi s. The devel opment and appl i cati on of such

a model -based control strategy i s the mai n focus of the

present study.

Several studi es

2-6

have been reported i n the open

l i terature on the steady-state model i ng, si mul ati on,

ki neti cs, opti mi zati on, and control of steam reformers.

These have been revi ewed by El nashai e and El shi shi ni

2

and Rajesh et al .

6

El nashai e and El shi shi ni

7

al so

presented an el aborate study on the dynami c model i ng

of gas-sol i d catal yti c reactors i n general but di d not

study i ndustri al reformers i n detai l . Al ati qi and co-

workers

8-12

reported some work on the dynami c model -

i ng and si mul ati on of i ndustri al steam reformers under

l oad di sturbances and val i dated thei r si mul ati on resul ts

wi th actual pl ant data. However, they di d not provi de

compl ete i nformati on on thei r approach for propri etary

reasons. They used di fferent control methods to mi ni -

mi ze the effects of di sturbances. Thei r dynami c model

uses a si mpl i fi ed overal l reacti on rate expressi on rather

than eqs 1-3. I n addi ti on, the reacti on-cum-di ffusi on

of the several mol ecul ar speci es present i nsi de the

porous catal yst i s not consi dered separatel y. Kvamsdal

et al .

13

al so carri ed out the dynami c si mul ati on of

i ndustri al steam reformers i n the presence of sudden

stoppages (tri ppi ng) of the feed gas fl ow and of the

steam suppl y. They used the pseudo-homogeneous

ki neti c model of Xu and Froment.

3

Agai n, these workers

di d not provi de compl ete detai l s on the reactor. There

i s, thus, a defi ni te need for the devel opment of a

dynami c model based on fi rst pri nci pl es, wi th compl ete

* To whom correspondence shoul d be addressed. E-mai l :

skgupta@i i tk.ac.i n. Fax: 91-512-590104.

I ndi an I nsti tute of Technol ogy.

Nati onal Uni versi ty of Si ngapore.

Reformi ng: CH

4

+ H

2

O h CO + 3H

2

H

r

) 8.623 10

5

kJ/kmol (1)

Shi ft: CO + H

2

O h CO

2

+ H

2

H

r

) -1.7196 10

5

kJ/kmol (2)

Reformi ng: CH

4

+ 2H

2

O h CO

2

+ 4H

2

H

r

) 6.904 10

5

kJ/kmol (3)

4028 I nd. Eng. Chem. Res. 2003, 42, 4028-4042

10.1021/i e0209576 CCC: $25.00 2003 Ameri can Chemi cal Soci ety

Publ i shed on Web 07/23/2003

detai l s provi ded. Such fundamental model s can al so be

used for off-l i ne opti mi zati on purposes to obtai n opti mal

control strategi es requi red to negate the effects of a

number of i deal i zed di sturbances. A fi l e of such strate-

gi es (a few of whi ch are obtai ned here) woul d be of

i mmense use for the opti mal operati on of these pl ants.

I t shoul d be menti oned here that the detai l ed model

devel oped here for the steam reformer i s somewhat

si mi l ar to that for packed-bed adsorbers,

14

i n whi ch no

reacti ons take pl ace.

Formulation

The steady-state model

6

of the reformer i s modi fi ed

i n thi s study to appl y to transi ent condi ti ons. The

concentrati ons, C

i

(Z,t), and the temperature, T(Z,t), of

the gas phase (outsi de the sol i d) are functi ons of both

the axi al l ocati on, Z, and the ti me, t. I t i s assumed

2,7

that there are no radi al gradi ents i n the gas phase. The

equati on for C

i

(Z,t) can be wri tten,

15

for a semi di ffer-

enti al control vol ume of l ength Z, as

Here, v

l

i s the superfi ci al vel oci ty of the gas;

b

i s the

voi d fracti on i n the catal yst bed (outsi de the porous

sol i ds); F

b

i s the densi ty of the catal yst bed (i ncl udi ng

the voi d i n the bed and the pores i n the catal yst); R

i

i s

the net rate of consumpti on of the ith speci es because

of the three reacti ons, whi ch i s rel ated to r

i

, the (net)

forward rate of the ith reacti on (eqs 1-3), at the

condi ti ons just outsi de the catal yst parti cl e, through the

stoi chi ometri c coeffi ci ents

i,k

; and

i

i s the effecti veness

factor for the ith reacti on.

6

No accumul ati on term

correspondi ng to the sol i d i s necessary i n thi s equati on,

as the bal ance i s on the gas al one.

The most general form of the energy bal ance equa-

ti on

15

woul d make the probl em computati onal l y i ntense

and woul d requi re separate equati ons for the gas and

sol i d phases. I n such a model , the temperature of the

sol i d phase, T

s

(Z,t,l), woul d depend on Z and t as wel l

as the i nternal l ocati on, l. At the sol i d boundary, thi s

temperature woul d be rel ated to the l ocal gas-phase

temperature, T(Z,t), through a gas-fi l m resi stance

model . Si mpl i fyi ng assumpti ons are needed to obtai n a

model that i s useful for opti mi zati on and control . I t i s

known

2,4,16

that the thermal conducti vi ty of the catal yst

pel l et i s qui te hi gh (l ow Prater number). Al so, the

resi stance of the gas fi l m surroundi ng the catal yst

parti cl es i s smal l .

16

Under these condi ti ons, we can

assume that the enti re catal yst parti cl e attai ns the

temperature, T(Z,t), of the gas phase (at axi al posi ti on

Z and ti me t) i nstantl y. Vi l l adsen and Mi chel sen

17

and

El nashai e and El shi shi ni

2

menti on that thi s i s a rea-

sonabl e approxi mati on to make. We can then wri te the

si mpl i fi ed energy bal ance equati on for the semi di ffer-

enti al control vol ume (gas pl us sol i d) of l ength Z as

I n eq 5, G ( F

g

v

l

) i s the mass vel oci ty of the gas;

c

i s

the vol ume fracti on of the pores i nsi de the catal yst

parti cl es, F

s

and F

g

are the densi ti es of the porous

catal yst (ki l ograms of sol i d per cubi c meter of porous

catal yst parti cl es) and of the pure gas, respecti vel y; U

i s the fi l m heat-transfer coeffi ci ent on the i nsi de of the

tube surface (sum of the effects of heat transfer to the

gas and to the sol i d); C

p,g

and C

p,s

are the heat capaci ti es

of the pure gas mi xture (i n the voi ds) and of the sol i d

catal yst (wi thout pores), respecti vel y; T

w,i

i s the tem-

perature at the i nner tube wal l ; and H

i

i s the heat of

reacti on of the ith reacti on. Equati on 5 can easi l y be

deduced from eqs e and f (page 492) of Froment and

Bi schoff,

15

usi ng these assumpti ons. I t woul d be i nter-

esti ng to compare the resul ts obtai ned from the si mpl i -

fi ed model devel oped here wi th those obtai ned usi ng a

more ri gorous model for T

s

(Z,t,l), when the l atter

becomes avai l abl e (work i s i n progress al ong these

l i nes).

The fol l owi ng i ni ti al condi ti ons (I Cs) can be used wi th

eqs 4 and 5

Figure 1. Process fl ow di agram of the steam reformi ng pl ant usi ng natural gas feed.

Z

(v

l

C

i

) )

b

C

i

t

+ F

b

i

R

i

,

i ) CH

4

, H

2

O, CO

2

, CO, H

2

(4)

C

i

(Z,t)0) ) C

i

SS

(Z), 0 e Z e L (6a)

T(Z,t)0) ) T

i

SS

(Z), 0 e Z e L (6b)

Z

(GC

p,g

A

c

T) ) d

i

U(T

w,i

- T) -

({C

p,s

F

b

+ [

b

+ (1 -

b

)

c

]F

g

C

p,g

}A

c

)

T

t

+

A

c

i)I

I I I

(-H

i

)

i

r

i

F

b

(5)

I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003 4029

Here, C

i

SS

and T

SS

are the profi l es that can be obtai ned

usi ng the steady-state (SS) code of Rajesh et al .

6

I t i s

assumed that the reformer i s operati ng at steady state

for t e 0 and that a di sturbance i s i ntroduced at t ) 0.

Because most of the gradi ent i n the catal yst parti cl e

exi sts i n thi n l ayers near the two faces of the Raschi g

ri ng catal yst parti cl e, the l atter can be assumed to have

a sl ab geometry,

6

i .e., i t can be sl i ced al ong the l ength

and opened up to gi ve an equi val ent sl ab geometry

havi ng a cross-secti onal area A

p

[ (r

1

+ r

2

)l

p

] and

thi ckness 2l

c

() r

2

- r

1

) (see Fi gure 2). The si mpl i fi ed

model I I of El nashai e and El shi shi ni

2

gi ves the fol l owi ng

equati ons at ti me t for the i ntrapel l et concentrati ons,

c

i

wi th the fol l owi ng boundary condi ti ons (BCs) at l ) 0

and l ) l

c

I n the above equati ons, N

i

i s the mol ar fl ux of compo-

nent i at any l ocati on l (0 e l e l

c

) i nsi de the catal yst

sl ab, and D

i

e

i s the effecti ve di ffusi vi ty of component i

i n the catal yst.

2

r

k

i s the net forward rate of the kth

reacti on (k ) I -I I I for eqs 1-3, respecti vel y) at any l

and t, and

i,k

i s the stoi chi ometri c coeffi ci ent of the ith

component parti ci pati ng i n the kth reacti on. The con-

centrati ons of CO, CO

2

, and H

2

(and N

2

) i nsi de the

catal yst at any l ocati on l and ti me t are eval uated usi ng

stoi chi ometry.

6

The compl ete set of model equati ons i s

gi ven i n the appendi x. The l i st of model parameters

used, as wel l as the detai l s of the i ndustri al reformer

and the i ni ti al operati ng condi ti ons, are gi ven i n Tabl e

1.

2,4,6,18,19

The correl ati ons for the esti mati on of the

effecti ve di ffusi vi ty are taken from El nashai e and

El shi shi ni ,

2,6

and the correl ati ons for the speci fi c heat,

vi scosi ty, and thermal conducti vi ty are taken from

6

the

HYSYS Process (versi on 1.5) code.

Figure 2. (a) Sketch of the catal yst pel l et (Raschi g ri ng). (b)

Notati on used for the reacti on-di ffusi on probl em.

d

dl

(N

i

A

p

) ) A

p

F

s

k)I

I I I

i,k

r

k

, i ) CH

4

, H

2

O (7a)

N

H

2

) -N

H

2

O

- 2N

CH

4

(7b)

N

CO

) N

H

2

O

- 2N

CH

4

(7c)

N

CO

2

) -N

H

2

O

+ N

CH

4

(7d)

N

i

) -D

i

e

dc

i

dl

, i ) CH

4

, H

2

O, CO, CO

2

, H

2

(7e)

c

i

(l)0,Z,t) ) C

i

(Z,t), i ) CH

4

, H

2

O, CO, CO

2

, H

2

N

i

(l)l

c

,Z,t) ) 0, i ) CH

4

, H

2

O, CO, CO

2

, H

2

(8)

Table 1. Model Parameters for the Industrial Steam

Reformer

2,4,6,17,18

model parameter val ue/speci fi cati on ref

reformer data

heated l ength of reformer

tube, L

11.95 m 2

i nsi de di ameter of reformer

tubes, d

i

0.0795 m 2

outsi de di ameter of

reformer tubes, do

0.102 m 2

rati o of reformer tube pi tch

to di ameter

2.4 2

number of tubes 176 2

refractor surface area, A

ref 1164 m

2

2

number of burners, Nb 112 2

fl ame surface area, Af 0.01 m

2

6

catal yst data

catal yst shape Raschi g ri ng 2

catal yst pel l et di mensi on 16 6 16 mm 2

pel l et porosi ty,

c 0.51963 2

pel l et spheri ci ty, s 0.6563 2

pel l et equi val ent

di ameter, Dp

17.4131 mm 2

pel l et tortuosi ty, 2.74 2

sol i d catal yst densi ty, Fs 2396.965 kg/m

3

cal cd from refs 2, 4

mean pore radi us 80.0 2

pel l et characteri sti c

l ength, l c

1.948 mm 2

catal yst bed densi ty, Fb 946.8 kg/m

3

2

catal yst bed voi d

fracti on, b

0.605 17

other data

carbon di oxi de-to-methane

rati o, D/C

0.091 2

ni trogen-to-methane

rati o, N/C

0.021 2

emi ssi vi ty of fl ames,

f 0.1 2

emi ssi vi ty of furnace

gases, g

0.1 2

emi ssi vi ty of reformer

tubes, t

0.95 18

adi abati c fl ame

temperature, Tf

2200 K 6

tube thermal

conducti vi ty, kw

10.738 +

0.0242Tw

W/(m K)

18

no. of col l ocati on

poi nts, M + 2

10 thi s work

acti ve fracti on, a 0.2 2

k

I , KI , kI I , KI I , kI I I ,

KI I I , Hi

- 2, 6

other properti es - 6

operati ng condi ti ons at SS1

F

CH4,i n 593.564 kmol /h 6

Tg 1625 K 6

S/C 4.8 6

H/C 0.34 6

Pi n 2548.8 kPa 6

Ti n 841.7 K 6

4030 I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003

The profi l es, c

i

(l,Z,t), and the effecti veness factors,

i

,

are eval uated

6

usi ng the method of orthogonal col l oca-

ti on on fi ni te el ements (OCFE).

16,20,21

The regi on 0 e l

e l

c

i s di vi ded i nto two fi ni te el ements

6

extendi ng over

0 e ve 0.2 (outer regi on) and 0.2 e ve 1 (i nner regi on),

where v l/l

c

. I t i s assumed that al l fl uxes are zero at

Figure3. Axi al profi l es of di fferent vari abl es at the i ni ti al and fi nal steady states and the devi ati ons of these vari abl es from thei r i ni ti al

steady-state val ues at di fferent ti mes for the fi rst si mul ati on probl em (step i ncrease i n the i nl et feed temperature).

I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003 4031

v ) 0.2. Thi s i mpl i es that, i n the i nner regi on of the

catal yst sl ab, the reacti ons are at (i nstantaneous l ocal )

equi l i bri um. There are a total of 10 orthogonal col l oca-

ti on (OC) poi nts (i ncl udi ng two at the boundari es of the

el ement) i n the outer fi ni te el ement, where most of the

concentrati on changes take pl ace.

Figure4. Axi al profi l es of di fferent vari abl es at the i ni ti al and fi nal steady states and the devi ati ons of these vari abl es from thei r i ni ti al

steady-state val ues at di fferent ti mes for the second si mul ati on probl em (step decrease i n the i nl et fl ow rate of natural gas). Approach

numbers (1, 2, and 3) are i ndi cated.

4032 I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003

The PDEs characteri zi ng the gas phase are converted

i nto ODEs usi ng the fi ni te di fference method (the

method of l i nes) wi th unequal spaci ng of the gri d poi nts

[the fi ni te di fference equati ons

21

used are accurate to

O(Z

2

)]. The regi on 0 e Z e 0.5 m, whi ch encompasses

sharp changes i n the vari abl es, i s di vi ded i nto si x

equal l y spaced gri d poi nts (two at Z ) 0 and 0.5 m).

The remai ni ng 11.45 m of the reactor

2,6

i s di vi ded i nto

10 equal l y spaced gri d poi nts. The fi rst poi nt i n 0.5 e Z

e 11.95 m i s the same as the l ast poi nt i n 0 e Z e 0.5

m. The resul ti ng set of ODEs (i n t) i s sol ved wi th the

code D02EJF from the NAG l i brary for the i ntegrati on

of sti ff ordi nary di fferenti al equati ons usi ng Gears

techni que.

20,21

We use the C05NCF subrouti ne of the

NAG l i brary to sol ve the nonl i near al gebrai c col l ocati on

equati ons for c

i

(v,Z,t) for any desi red val ues of C

i

(Z,t)

and T(Z,t) i n the gas phase. These sol uti ons are used

to eval uate the effecti veness factors (eqs A21 and A22,

Appendi x) usi ng appropri ate Gauss-Legendre quadra-

tures.

20,21

The pressure at axi al l ocati on Z and ti me t i s

computed from a fl ui d-mechani cs-based equati on (eq

A4b) by the Eul er techni que.

20,21

Results and Discussion

A Fortran 90 program was wri tten to sol ve the

equati ons for di fferent i deal i zed di sturbances. The CPU

ti me requi red for sol vi ng a typi cal dynami c si mul ati on

i s 2 h on a Penti um 4 computer (1.7 GHz). The code

was tested by starti ng from one steady state, SS1

(generated usi ng an SS code,

6

as gi ven i n Tabl e 1),

provi di ng a step change (at t )0) i n one of the operati ng

vari abl es, and sol vi ng unti l the fi nal SS i s attai ned. The

resul ts obtai ned at l arge val ues of t from the dynami c

code, matched the fi nal SS profi l es generated di rectl y.

6

The model i s then used to sol ve two sampl e mul ti ob-

jecti ve opti mi zati on probl ems under dynami c opti mal

control .

Dynamic Simulation. The fi rst probl em studi ed

i nvol ves a step i ncrease of 100 K i n the feed tempera-

ture. Nonl i near effects of the model are exhi bi ted under

such l arge di sturbances. The axi al profi l es of several

i mportant vari abl es are shown i n Fi gure 3a-h, both at

the i ni ti al and the fi nal steady states, as wel l as thei r

vari ati ons wi th ti me (i n terms of devi ati ons from the

i ni ti al SS). The fi nal SS val ues of the temperature

(Fi gure 3a), are observed to be hi gher than the i ni ti al

SS val ues. There i s an undesi rabl e i ncrease (Fi gure 3c,d)

i n the outer wal l temperature, T

w,o

(even smal l i ncreases

i n T

w,o

beyond 1200 K l ead to a si gni fi cant reducti on i n

the l i fe of the reformer tubes). Hi gher process-gas

temperatures, however, l ead to hi gher conversi ons of

methane (Fi gure 3e,f) and hi gher producti ons of CO

(Fi gure 3g,h) and steam.

2

The mol e fracti on of CO

2

i ncreases from i ts i ni ti al SS val ue i n the earl y part of

the reformer, but fal l s beyond some axi al l ocati on. Thi s

i s because of the i nhi bi ti ng effect of the exothermi c

reacti on (eq 2) at hi gher process-gas temperatures. Pl ots

of both the conversi on of methane and the mol e fracti on

of CO

2

are not shown here, but can be suppl i ed on

request.

The second dynami c si mul ati on studi ed here i nvol ves

a step decrease of 30 kmol /h i n the i nl et fl ow rate of

methane i n the natural gas feed (the correspondi ng fl ow

rates of the accompanyi ng CO

2

and N

2

are al so de-

Figure5. Axi al profi l es of di fferent vari abl es at the i ni ti al and fi nal steady states and the devi ati ons of these vari abl es from thei r i ni ti al

steady-state val ues at di fferent ti mes for the thi rd si mul ati on probl em (step decrease i n the furnace gas temperature).

I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003 4033

4034 I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003

creased), whi l e the fl ow rates of recycl e steam and

hydrogen are mai ntai ned at thei r ori gi nal val ues. The

superfi ci al vel oci ty of the process gas at the feed end

decreases (from 3.24 to 3.21 m/s) i mmedi atel y upon the

i ntroducti on of thi s step di sturbance, and a wave front

(wi th a l ower superfi ci al gas vel oci ty upstream and a

hi gher val ue downstream) travel s through the reformer.

Because of vi scous effects, thi s front does not actual l y

remai n sharp, so one shoul d real l y sol ve the equati ons

of moti on (eq A4b shoul d be repl aced by the hi ghl y

nonl i near PDEs of fl ui d mechani cs) si mul taneousl y wi th

the reacti on equati ons. Thi s woul d make the dynami c

model al most i ntractabl e. Three si mpl er, though em-

pi ri cal , approaches were expl ored to model thi s phen-

omenon, whi l e sti l l usi ng eq A4b and keepi ng the CPU

ti me reasonabl e. I n the fi rst approach (approach 1), we

use the l ower mass vel oci ty G

new,i n

, at al l l ocati ons and

ti mes. I n approach 2, the ori gi nal (hi gher) mass vel oci ty

i s used throughout, even after the di sturbance. I n

approach 3, whi ch i s sl i ghtl y more real i sti c, we assume

that the wave front i s sharp and i s travel i ng through

the reformer tube at a constant vel oci ty of u

new

()

G

new,i n

/F

i n

) 3.21 m/s). The val ue of t* () Z/u

new

) i s

computed at each fi ni te-di fference gri d poi nt. Thi s i s the

ti me at whi ch the wave front passes the parti cul ar gri d

poi nt. The new mass vel oci ty i s used at any gri d poi nt

i f t g t*; otherwi se, the ori gi nal mass vel oci ty i s used.

Fi gure 4a-c shows the resul ts. These resul ts do not

di ffer much even at t ) 3.6 s, and i n fact, al l three

approaches gi ve i denti cal resul ts (not shown) for hi gher

val ues of t. Hence, one can use any one of these three

approaches. Fi gure 4a shows some osci l l ati ons i n the

fl ow rates of H

2

at l ow val ues of t. Such behavi or i s

characteri sti c of the numeri cal sol uti on of probl ems wi th

sharp movi ng fronts and can be mi ni mi zed by usi ng

movi ng fi ni te-el ement techni ques, as for the far si mpl er

col or equati on.

20,21

Fi gure 4d-g shows the profi l es of

several vari abl es at di fferent ti mes.

Because of the decrease i n the i nl et feed rate of

natural gas, the concentrati on of methane i n the process

gas decreases. Thi s reduces the extent of the endother-

mi c reacti ons (referred to as the concentrati on effect)

and reduces the fl ow rates of both H

2

and CO (and

steam; see Fi gure 4f,g). However, the hi gher tempera-

tures of the process gas tend to i ncrease the conversi on

to hydrogen and carbon monoxi de by the endothermi c

reacti ons. Thi s can be referred to as the temperature

effect. Fi gure 4f and g i ndi cates that the l atter effect

domi nates. The compl ex i nterpl ay of several opposi ng

physi cal phenomena i s exhi bi ted here qui te wel l . Agai n,

there i s an i ncrease i n the outer wal l temperature.

I n the thi rd dynami c si mul ati on probl em studi ed, a

step decrease of 200 K i s i ntroduced i n the furnace gas

temperature. Such a di sturbance can ari se i n i ndustry

through burner fai l ure or a change i n the feed rate of

the fuel . No changes i n the mass vel oci ty are i nvol ved.

Because l ess heat i s transferred from the furnace after

the di sturbance, the process-gas temperature, as wel l

as T

w,o

, decreases wi th ti me to new SS val ues (Fi gure

5a,b). Thi s l eads to a si mul taneous reducti on i n the

producti on of H

2

and CO (and thus al so steam; see

Fi gure 5c,d). Obvi ousl y, the negati ve effect of such a

fai l ure on the producti on of desi red chemi cal s needs to

be compensated by appropri ate control acti on, e.g., an

i ncrease i n the feed temperature.

Optimization. We now study two sampl e opti mi za-

ti on probl ems (referred to as probl ems 1 and 2) to

i l l ustrate the use of our dynami c model . A step pul se (0

e t e t

T

, t

T

) 0.0245 h) of -20 kmol /h i n the i nl et fl ow

rate of methane i s taken as the di sturbance

There i s a correspondi ng reducti on i n the fl ows of CO

2

and N

2

(i n the natural gas) as wel l . I f the i nput fl ow

rates of (recycl e) hydrogen and steam remai ned un-

changed, there woul d be a decrease i n the i nl et concen-

trati on of methane. Such a decrease woul d l ead to a

decrease i n the outl et conversi ons associ ated wi th the

reformi ng reacti ons and to a decrease i n the heat

consumed by these endothermi c reacti ons. I f, i n addi -

ti on, the suppl y of heat from the furnace i s unchanged,

thi s woul d l ead to an i ncrease i n the temperature, T

w,o

,

of the outer wal l of the reformer tube. I ndeed, Kvamsdal

et al .

13

have shown that a decrease i n the fl ow rate of

methane coul d l ead to thermal runaways i n the re-

former. Thi s can reduce the l i fe of the reformer tubes

or cause thei r rupture. To counter the i l l effects of thi s

di sturbance, we use the fol l owi ng general control acti on

(pul se over 0 e t e t

T

)

Figure 6. Pareto set, deci si on vari abl es, and dynami c vari ati ons of some vari abl es at the outl et for the mul ti objecti ve opti mi zati on

probl em 1 (sol i d l i ne, wi th opti mal control acti on; broken l i ne, wi thout opti mal control acti on). Chromosome numbers 1, 2, and 3 i ndi cated

i n pl ots i and j.

F

CH

4

,i n

) F

CH

4

,i n,SS

() 593.564 kmol /h, SS1),

t e 0 or t g t

T

F

CH

4

,i n

) F

CH

4

,i n,SS

- 20 kmol /h, 0 e t e t

T

(9)

I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003 4035

The deci si on vari abl es are, thus, T

g

, (S/C), and

(H/C).

Two objecti ve functi ons ar e mi ni mi zed si mul ta-

neousl y. They are the total (cumul ati ve over t) devi a-

ti ons

22

of the producti on of (a) hydrogen and (b) steam,

from thei r SS1 val ues, i ntegrated over an appropri atel y

l ong ti me span, 0 e t e t

f

(t

f

) 0.05 h), so that thei r

rates of producti on reattai n thei r i ni ti al steady-state

val ues. The fl ow rate of steam i s rel ated to that of CO,

and we can mi ni mi ze the cumul ati ve devi ati on of the

producti on of CO.

6

The fi nal opti mi zati on probl em

(referred to as probl em 1) i s wri tten mathemati cal l y

(al ong wi th the constrai nts and bounds) as

subject to (s.t.) the constrai nt

and the bounds

I n eqs 11, F

H2,out

(t) and F

CO,out

(t) are the mass fl ow rates

of H

2

and CO, respecti vel y, i n the syngas exi ti ng the

reformer. I t can be noted that we do not use the squares

of the i ntegrands i n eqs 11a and b, because any short-

term i ncreases i n the fl ow rates above the steady-state

val ues need not be penal i zed because they are benefi ci al .

The constrai nt on T

w,o

i s that used by Rajesh et al .

6

I n

these equati ons, the bounds on (S/C) and (H/C) are

taken to be about 5% of the SS val ues and are of the

same order as the devi ati on i n the methane fl ow rate.

The fol l owi ng penal ty

23

i s added to both objecti ve

functi ons

to take care of the constrai nt on T

w,o

. (Al ternati ves

exi st.

23

) The mul ti pl i er (10

4

) was suffi ci entl y l arge, and

the resul ts were found to be i nsensi ti ve to an i ncrease

i n i ts val ue.

The second mul ti objecti ve opti mi zati on probl em (prob-

l em 2) i nvol ves a pul se decrease i n the feed temperature

wi th t

T

taken as 0.023 h (sl i ghtl y di fferent than for

probl em 1). Because of the decrease i n the i nl et feed

temperature, the outl et temperature of the syngas and

the conversi on of methane decrease. Thi s resul ts i n a

decrease i n the producti on of both hydrogen and steam.

The effects of thi s di sturbance are negated once agai n

usi ng step changes i n the furnace gas temperature, T

g

;

the steam-to-methane rati o, S/C; and the hydrogen-to-

methane rati o, H/C, as fol l ows

t

1

and t

2

are addi ti onal deci si on vari abl es used to make

the probl em general . An i ncrease i n the temperature of

the furnace gas i ncreases the heat content of the

reformer gases and hel ps compensate for the effect of

the decrease i n the i nl et feed temperature. Hi gher

steam-to-methane rati os hel p to i ncrease the hydrogen

producti on, whi l e hi gher hydrogen-to-methane rati os

i ncrease the carbon monoxi de (and, therefore, al so the

steam) producti on. Probl em 2 can, thus, be wri tten as

s.t.

wi th t

f

) 0.058 h. The l ower bound on T

g

i s rel ati vel y

uni mportant because, i ntui ti vel y, i t i s expected that T

g

wi l l be posi ti ve. The upper bound on T

g

was deter-

mi ned on the basi s of the normal operati ng condi ti ons

possi bl e i n i ndustri al reformers. The ranges of (S/C)

T

i n

) T

i n,SS

() 841.7 K

6

), t e 0, t g t

T

T

i n

) T

i n,SS

- 50 K, 0 e t e t

T

(13)

T

g

) T

g,SS

() 1625 K

6

), t e t

1

or t g t

2

(14a)

T

g

) T

g,SS

+ T

g

, t

1

e t e t

2

(14b)

S/C ) (S/C)

SS

() 4.8

6

), t e t

1

or t g t

2

(14c)

S/C ) (S/C)

SS

+ (S/C), t

1

e t e t

2

(14d)

H/C ) (H/C)

SS

() 0.34

6

), t e t

1

or t g t

2

(14e)

H/C ) (H/C)

SS

+ (H/C), t

1

e t e t

2

(14f)

Probl em 2

mi n f

1

[T

g

,(S/C),(H/C),t

1

,t

2

]

0

t

f

[F

H

2

,SS,out

-

F

H

2

,out

(t)] dt (15a)

mi n f

2

[T

g

,(S/C),(H/C),t

1

,t

2

]

0

t

f

[F

CO,SS,out

-

F

CO,out

(t)] dt (15b)

T

w,o

e 1200 K (15c)

-15 e T

g

e 25 K (15d)

-0.4 e (S/C) e 0.3 (15e)

-0.03 e (H/C) e 0.03 (15f)

0 e t

1

e 0.023 h (15g)

0.023 e t

2

e 0.058 h (15h)

T

g

) T

g,SS

() 1625 K

6

), t e 0, t g t

T

(10a)

T

g

) T

g,SS

- T

g

, 0 e t e t

T

(10b)

S/C ) (S/C)

SS

() 4.8

6

), t e 0, t g t

T

(10c)

S/C ) (S/C)

SS

+ (S/C), 0 e t e t

T

(10d)

H/C ) (H/C)

SS

() 0.34

6

), t e 0, t g t

T

(10e)

H/C ) (H/C)

SS

+ (H/C), 0 e t e t

T

(10f)

Probl em 1

mi n f

1

[T

g

,(S/C),(H/C)]

0

t

f

[F

H

2

,SS,out

-

F

H

2

,out

(t)] dt (11a)

mi n f

2

[T

g

,(S/C),(H/C)]

0

t

f

[F

CO,SS,out

-

F

CO,out

(t)] dt (11b)

T

w,o

e 1200 K (11c)

-25 e T

g

e 5 (11d)

-0.4 e (S/C) e 0.3 (11e)

-0.02 e (H/C) e 0.02 (11f)

P 10

4

[(T

w,o

- 1200) + abs(T

w,o

- 1200)] (12)

4036 I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003

and (H/C) were determi ned on the basi s of the mag-

ni tude of the di sturbance. The l ower bound on t

1

i s the

ti me at whi ch the di sturbance i s i ntroduced (t ) 0),

whi l e the upper bound (and the l ower bound on t

2

) i s

set at a conservati vel y hi gh val ue of t

T

, the ti me at whi ch

the i nput di sturbance ceases (hi gher val ues of t

1

are

nonopti mal ). The upper bound on t

2

i s the ti me corre-

spondi ng to the fi nal steady state, t

f

. The val ue of t

f

i s

sel ected on the basi s of experi ence wi th si mul ati on runs.

The recentl y devel oped robust and effi ci ent techni que

cal l ed the el i ti st nondomi nated sorti ng geneti c al go-

ri thm (NSGA-I I )

23,24

i s used to sol ve these probl ems. The

parameters associ ated

23-25

wi th NSGA-I I for probl ems

1 and 2 are gi ven i n Tabl e 2. The CPU ti mes requi red

to sol ve probl ems 1 (9 generati ons) and 2 (18 genera-

ti ons) on a Si l i con Graphi cs server (SGI ori gi n 270, 400

MHz) are 110 and 144 h, respecti vel y. The hi ghl y

computati onal l y i ntensi ve nature of these probl ems puts

constrai nts on the number of runs (or the si ze of

popul ati ons or the number of generati ons), and we have

to be content wi th the reasonabl e Pareto sol uti ons

obtai ned. Because the mai n focus i n thi s paper was not

opti mi zati on, we di d not expl ore other techni ques (e.g.,

usi ng paral l el computi ng pl atforms or devel opi ng em-

pi ri cal and faster model equati ons) to i mprove the

sol uti ons. Several checks were made on our code, as

di scussed by Kasat et al .,

26

to ensure that the sol uti ons

obtai ned were correct. I n addi ti on, we used the -con-

strai nt techni que

27

(i n whi ch one objecti ve functi on i s

taken as a constant, , to form an addi ti onal constrai nt

and the resul ti ng si ngl e-objecti ve-functi on opti mi zati on

probl em i s sol ved usi ng a di fferent code) and found that

the sol uti ons matched those obtai ned usi ng NSGA-I I ,

confi rmi ng that we di d, i ndeed, attai n opti mal sol uti ons.

The resul ts for probl em 1 are shown i n Fi gure 6. I f

we go from any one poi nt (say, 1) to another (say, 2) i n

Fi gure 6a, we fi nd that f

1

i mproves (decreases) whereas

f

2

worsens (i ncreases). Thi s pl ot, therefore, represents

a Pareto set.

23-25

Cl earl y, the control acti on taken to

negate the effect of thi s di sturbance i s unabl e to i ncrease

the rates of producti on of both hydrogen and steam. A

deci si on maker woul d have to deci de on the preferred

sol uti on (operati ng poi nt) from among these several ,

equal l y good, Pareto poi nts. Fi gure 6b-d shows the

correspondi ng deci si on vari abl es (actual val ues). Hi gh

val ues of T

g

and the S/C rati o are associ ated wi th l ower

f

1

val ues (l arger hydrogen producti on) and hi gher f

2

val ues (l ower CO or steam producti on) under opti mal

condi ti ons. The opti mal val ues of H/C do not appear to

exhi bi t any defi ni te trend, and we bel i eve that there i s

some scatter i n these data. Such scatter i n one or more

deci si on vari abl es seems to be the norm rather than an

excepti on for most real -l i fe probl ems

25

and to refl ect the

rel ati ve i nsensi ti vi ty of the objecti ve functi ons to vari a-

ti ons i n these deci si on vari abl es. As menti oned before,

the resul ts coul d be i mproved but at the cost of excessi ve

computati onal effort. A study of several members of the

i ni ti al (nonopti mal ) sol uti ons reveal s that chromosomes

havi ng hi gh val ues of T

g

and rel ati vel y l ow val ues of

S/C vi ol ate the constrai nt on the outer wal l tempera-

ture, T

w,o

, and are ki l l ed over the generati ons. Tabl e

3 reports the val ues of the deci si on vari abl es for three

di fferent chromosomes, 1-3 (i n Fi gure 6a), i n the Pareto

set.

The vari ati on of several i mportant vari abl es over

ti me, both i n the absence (broken curves) and i n the

presence (conti nuous curves) of opti mal control acti on

for chromosome 1, are shown i n Fi gure 6e-h. I t i s

observed that the outer tube-wal l temperature at the

exi t (the hi ghest val ue i n the reformer) under opti mal

condi ti ons hovers around i ts bound of 1200 K (see Fi gure

6g). I f control acti on were not used, the tube-wal l

temperature woul d vi ol ate thi s constrai nt. Thi s si mul -

taneousl y l eads to the gas temperature at the exi t of

the reformer l yi ng near i ts steady-state val ue of 1076

K. The l ower process-gas temperatures i n the presence

of opti mal control l ead to l ower conversi ons of methane

and l ower producti ons of both hydrogen and carbon

monoxi de/steam. Fi gure 6i and j shows the vari ati ons

of the exi t fl ow rates of both hydrogen and carbon

monoxi de for chromosomes 1-3. Chromosomes havi ng

hi gh val ues of S/C (e.g., chromosome 3) are associ ated

wi th a l ower cumul ati ve devi ati on i n the fl ow rate of

hydrogen but a hi gher devi ati on i n the fl ow rate of

carbon monoxi de.

Fi gure 7a shows the Pareto set at the 18th generati on

for probl em 2. I t can be noted that negati ve val ues (hi gh

total producti on of hydrogen under dynami c control ) of

f

1

are obtai ned here. Thi s, of course, occurs wi th a

worseni ng of f

2

. Fi gure 7b-f shows the correspondi ng

deci si on vari abl es. I t i s observed that the furnace gas

temperature, T

g

, remai ns at sl i ghtl y hi gher val ues (than

the SS val ue) for al l of the Pareto poi nts. I n contrast,

S/C and t

2

decrease as the opti mal val ue of f

1

i ncreases.

The opti mal val ues of t

1

remai n near thei r l ower bounds.

Fi gure 7g-j shows the vari ati ons of some i mportant

vari abl es over ti me for chromosome 2 of the Pareto set.

The hi gh val ue of S/C used for thi s chromosome i n-

creases the producti on of hydrogen (to even better

val ues than i n the absence of the di sturbance; see

Fi gure 7i ) and reduces the producti on of carbon mon-

oxi de and steam. Fi gure 7k and l shows the vari ati ons

of the exi t fl ow rates of both hydrogen and carbon

monoxi de wi th ti me for chromosomes 1-3 i n Fi gure 7a.

I t can be observed from these di agrams that chromo-

somes havi ng hi gher S/C val ues have l ower devi ati ons

i n the exi t fl ow rate of hydrogen and hi gher devi ati ons

i n the exi t fl ow rate of carbon monoxi de. Hi gh val ues of

T

g

i mprove both objecti ve functi ons. Tabl e 4 provi des

val ues of the deci si on vari abl es for the three di fferent

chromosomes, 1-3, shown i n Fi gure 7a.

Conclusions

A dynami c model for the fi rst reactor, the reformer,

i n a steam reformer pl ant i s presented. The effects of a

Table 2. GA Parameters Used for Optimization

parameter probl em 1 probl em 2

total chromosome l ength (Nchr) 22 20

popul ati on si ze (Np) 70 50

number of generati ons (Nga) 9 18

crossover probabi l i ty (pc) 0.95 0.95

mutati on probabi l i ty (pm) 0.01 0.05

random seed number 0.888 76 0.888 76

Table 3. Decision Variables (in Nondeviation Form) and

Objective Functions for Three Chromosomes in

Figure 6a

chromosome

deci si on

vari abl e 1 2 3

Tg 1609.8 1619.2 1620.4

S/C 4.63 5.01 5.09

H/C 0.326 0.358 0.359

f1 3.12 1.50 0.645

f2 7.84 6.69 8.92

I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003 4037

4038 I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003

few i deal i zed di sturbances are studi ed. The model i s

then used to study two sampl e mul ti objecti ve opti mi za-

ti on probl ems for thi s reactor, and Pareto-opti mal

sol uti ons are obtai ned. An extensi ve fi l e of si mi l ar

opti mal control acti ons under a vari ety of di sturbances

can be generated for l ater use.

Acknowledgment

Parti al fi nanci al support from the Department of

Sci ence and Technol ogy, Government of I ndi a, New

Del hi , I ndi a [through grant I I I -5(13)/2001-ET] i s grate-

ful l y acknowl edged.

Nomenclature

a ) fracti onal l ength of the hal f-catal yst sl ab i n whi ch the

concentrati on vari es

A

c

) i nsi de cross-secti onal area of the reformer tube, m

2

A

f

) surface area of the fl ame produced by a si ngl e burner,

m

2

A

p

) cross-secti onal area of the catal yst sl ab, m

2

A

ref

) surface area of the refractor, m

2

A

t,i

) total i nternal surface area of reformer tubes, m

2

c

i

) concentrati on of speci es i i n the catal yst sl ab, kmol

m

-3

C

i

) concentrati on of speci es i i n the gas phase, kmol m

-3

C

p,g

) speci fi c heat of the process gas, kJ kmol

-1

K

-1

C

p,s

) speci fi c heat of the sol i d (catal yst), kJ kmol

-1

K

-1

C

p,t

) speci fi c heat of the bed, kJ kmol

-1

K

-1

C

t

)mol ar concentrati on of the gas mi xture ()P/RT), kmol

m

-3

d

i

, d

o

) i nner and outer di ameters, respecti vel y, of the

reformer tube, m

D

i

e

) effecti ve di ffusi vi ty of speci es i i n the catal yst at

axi al l ocati on Z and ti me t, m

2

h

-1

D

p

) equi val ent di ameter of the catal yst pel l et (Raschi g

ri ng), m

D/C ) rati o of carbon di oxi de to methane i n feed, (kmol /h

of CO

2

)/[kmol /h of methane fed (F

CH4,i n

)]

E ) quanti ty defi ned i n eq A11

f

i

) objecti ve functi on, i ) 1, 2

F ) total feed rate, kmol h

-1

F

CH4

) fl ow rate of methane, kg h

-1

F

CO

) fl ow rate of CO, kg h

-1

F

H2

) fl ow rate of H

2

, kg h

-1

G ) mass vel oci ty of the process gas i n the reformer, kg

m

-2

h

-1

H/C ) rati o of hydrogen to methane i n feed, (kmol /h of

hydrogen recycl ed)/[kmol /h of methane fed (F

CH4,i n

)]

Figure 7. Pareto set, deci si on vari abl es, and dynami c vari ati ons of some vari abl es at the outl et, for the mul ti objecti ve opti mi zati on

probl em 2 (sol i d l i ne, wi th opti mal control acti on; broken l i ne, wi thout opti mal control acti on). Chromosome numbers 1, 2, and 3 i ndi cated

i n pl ots k and l .

Table 4. Decision Variables (in Nondeviation Form) and

Objective Functions for Three Chromosomes in

Figure 7a

chromosome

deci si on

vari abl e 1 2 3

Tg 1633.8 1633.8 1627.1

S/C 4.87 5.03 5.02

H/C 0.367 0.366 0.368

t1 0.0084 0.00726 0.0028

t2 0.0331 0.0383 0.056

f1 -0.0443 -0.679 -0.986

f2 2.79 4.44 8.59

I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003 4039

H

i

) enthal py of the ith reacti on, kJ kmol

-1

k

g

) thermal conducti vi ty of the process gas, kJ h

-1

m

-1

K

-1

k

w

) thermal conducti vi ty of the tube-wal l materi al , kJ h

-1

m

-1

K

-1

k

i

)rate constant of the ith (i )I -I I I ) reacti on, kmol kPa

0.5

kg

cat

-1

h

-1

or kmol kPa

-1

kg

cat

-1

h

-1

K

I

, K

I I

, K

I I I

) equi l i bri um constants of reacti ons I -I I I ,

respecti vel y

K

i

) equi l i bri um adsorpti on constant for speci es i (i ) CH

4

,

H

2

, CO, H

2

O), kPa

-1

l ) axi al l ocati on i n the catal yst sl ab, m

l

c

) thi ckness of the wal l of the Raschi g ri ng, m

l

p

) l ength of the Raschi g ri ng, m

L ) total l ength of the reactor, m

M ) number of i nternal col l ocati on poi nts

N/C ) rati o of carbon di oxi de to methane i n feed, (kmol /h

of ni trogen)/[kmol /h of methane fed (F

CH4,i n

)]

N

b

) number of burners i n the reformer furnace

N

chr

) total chromosome l ength for NSGA-I I

N

ga

) number of generati ons for NSGA-I I

N

i

) fl ux of speci es i at any axi al l ocati on l i nsi de the

catal yst sl ab, kmol m

-2

h

-1

N

p

) popul ati on si ze for NSGA-I I

p

c

) probabi l i ty of crossover

p

m

) probabi l i ty of mutati on

P ) operati ng pressure at axi al l ocati on Z and ti me t, kPa

q

cond

) conducti ve heat fl ux based on the average surface

area of the tube, kJ m

-2

h

-1

q

conv

) convecti ve heat fl ux based on the i nner surface area

of the tube, kJ m

-2

h

-1

q

rad

) radi ati ve heat fl ux based on the outer surface area

of the tube, kJ m

-2

h

-1

r ) radi al posi ti on, m

r

i

) rate of the ith reacti on (i ) I -I I I ) correspondi ng to

condi ti ons at the catal yst surface at axi al l ocati on Z and

ti me t, kmol h

-1

kg

cat

-1

R ) sum of feed mol ar rati os

R

i

) rate of producti on of the ith component at the catal yst

surface at any axi al l ocati on Z and ti me t, kmol h

-1

kg

cat

-1

R

i,n

) rate of producti on of the ith component at the nth

col l ocati on poi nt i nsi de the catal yst sl ab at axi al l ocati on

Z and ti me t, kmol h

-1

kg

cat

-1

S/C ) rati o of carbon di oxi de to methane i n feed, (kmol /h

of steam recycl ed)/[kmol /h of methane fed (F

CH4,i n

)]

t ) ti me, h

T ) process-gas temperature at axi al l ocati on Z and ti me

t, K

T

f

) adi abati c fl ame temperature at any axi al l ocati on i n

the reactor, K

T

g

) temperature of the furnace gas, K

T

w

) tube-wal l temperature, K

U ) fi l m heat-transfer coeffi ci ent on the i nsi de of the tube

(to gas + catal yst), kJ h

-1

m

-2

K

-1

v) di mensi onl ess di stance wi thi n the catal yst sl ab () l/l

c

)

(v ) 0 at catal yst surface)

v

l

) superfi ci al vel oci ty of gas i n the reformer, m h

-1

y

i

) mol e fracti on of speci es i i n the gas phase at axi al

l ocati on Z and ti me t

yj

i,n

) mol e fracti on of component i at the nth col l ocati on

poi nt i nsi de the catal yst sl ab at axi al l ocati on Z and ti me

t

Z ) axi al l ocati on, m

Greek Symbols

b

) voi d fracti on i n the catal yst bed (outsi de the porous

catal yst pel l et)

c

) vol ume fracti on of pores i nsi de a catal yst pel l et

I

,

I I

,

I I I

) effecti veness factors for reacti ons I -I I I , re-

specti vel y, at axi al l ocati on Z and ti me t

i

) effecti veness factor for component i at axi al l ocati on

Z and ti me t

) vi scosi ty of the gas mi xture at axi al l ocati on Z and

ti me t, kg m

-1

h

-1

g

) emi ssi vi ty of the furnace gas

f

) emi ssi vi ty of the fl ames

t

) emi ssi vi ty of the tube materi al

F

b

) densi ty of the catal yst bed (sol i d + voi ds + pores), kg

m

-3

F

g

) densi ty of the gas mi xture, kg m

-3

F

s

) densi ty of the catal yst pel l et (sol i d + pores), kg m

-3

) Stefan-Bol tzmann constant, kJ h

-1

m

-2

K

-4

ik

) stoi chi ometri c coeffi ci ent of the ith component par-

ti ci pati ng i n the kth reacti on

) tortuosi ty of the catal yst pel l et

s

) spheri ci ty of the catal yst pel l et

Subscripts/ Superscripts

i , 1 ) i nner or i ni ti al

i n ) i nl et of the reformer

o, 2 ) outer

out ) outl et of the reformer

SS ) steady state

SS1 ) i ni ti al steady state

w ) wal l

Appendix

Model Equations.

2,6

(a) Gas Phase

F

CH

4

,i n

) 16

F

R

,

where R ) [1 + (S/C) + (H/C) + (D/C) + (N/C)]

(A1)

F

H

2

,out

) 2C

H

2

,out

(v

l ,out

A

c

) (A2)

F

CO,out

) 28C

CO,out

(v

l ,out

A

c

) (A3)

C

i

t

)

1

b

[

(v

l

C

i

)

Z

- F

b

i

R

i]

,

i ) CH

4

, H

2

O, CO, CO

2

, H

2

(A4a)

P

Z

) -

1.75G

2

(1 -

b

)

s

D

p

b

3

F

g

(A4b)

T

t

)

1

C

p,t

[

4U(T

w,i

- T)

d

i

- F

g

C

p,g

v

l

T

Z

+

F

b

i)I

I I I

(-H

i

)

i

r

i

]

(A4c)

C

p,t

) F

b

C

p,s

+ [

b

+ (1 -

b

)

c

]F

g

C

p,g

(A4d)

I ni ti al Condi ti ons

C

i

(Z,t)0) ) C

i

SS

(Z),

0 e Z e L; i ) CH

4

, H

2

O, CO, CO

2

, H

2

(A4e)

4040 I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003

The i nner tube wal l temperature, T

w,i

, i s obtai ned by

equati ng the heat fl uxes due to (i ) radi ati ve transfer

from the furnace gases to the exteri or surface of the

tubes

(i i ) conducti ve transfer through the tube materi al

and (i i i ) convecti ve transfer to the gas mi xture and

catal yst bed from the i nner surface of the tubes

(b) Solid (Catalyst) Phase. The i ntraparti cl e mol e

fracti on, yj

i,n

(v), of speci es i at the nth orthogonal

col l ocati on poi nt for a catal yst sl ab at axi al l ocati on Z

and ti me t i s obtai ned by sol vi ng the coupl ed set of 5M

equati ons (n ) 1 i s the fi rst col l ocati on poi nt at v ) 0;

n ) M + 2 i s the l ast col l ocati on poi nt at v ) 0.2; n ) 2,

3, ..., M + 1 are the i nternal col l ocati on poi nts i n 0 e v

e 0.2): 3M al gebrai c and 2M di fferenti al equati ons

(whi ch are transformed i nto al gebrai c equati ons by the

method of orthogonal col l ocati on on fi ni te el ements)

(where the rates, R

i

, are gi ven i n eqs A7-A11)

Effecti veness factors for the components are eval uated

from those for the reacti ons

2

through the equati on

Literature Cited

(1) Armor, J. N. The Mul ti pl e Rol es for Catal ysi s i n the

Producti on of H2. Appl. Catal. A 1999, 176, 159.

(2) El nashai e, S. S. E. H.; El shi shi ni , S. S. Modeling, Simula-

tion and Optimization of I ndustrial CatalyticFixed Bed Reactors;

Gordon and Breach: Amsterdam, The Netherl ands, 1993.

(3) Xu, J.; Froment, G. F. Methane Steam Reformi ng, Metha-

nati on and Water-Gas Shi ft: I . I ntri nsi c Ki neti cs. AI ChE J . 1989,

35, 88.

(4) Xu, J.; Froment, G. F. Methane Steam Reformi ng: I I .

Di ffusi onal Li mi tati ons and Reactor Si mul ati on. AI ChE J . 1989,

35, 97.

(5) Si ngh, C. P. P.; Saraf, D. N. Si mul ati on of Si de Fi red

Steam-Hydrocarbon Reformers. I nd. Eng. Chem. Process Des.

Dev. 1979, 18, 1.

P(Z,t)0) ) P

SS

(Z), 0 e Z e L (A4f)

T(Z,t)0) ) T

SS

(Z), 0 e Z e L (A4g)

y

i

) C

i

/C

t

, i ) CH

4

, H

2

O, CO, CO

2

, H

2

(A5)

y

N

2

) 1 - (y

CH

4

+ y

H

2

O

+ y

CO

+ y

CO

2

+ y

H

2

) (A6)

R

i

)

k)I

I I I

ik

r

k

, i ) CH

4

, H

2

O, CO, CO

2

, H

2

(A7)

r

I

)

k

I

E

2

y

H

2

2.5

P

(

y

CH

4

y

H

2

O

-

P

2

y

H

2

3

y

CO

K

I

)

(A8)

r

I I

)

k

I I

P

E

2

y

H

2

(

y

CO

y

H

2

O

-

y

H

2

y

CO

2

K

I I I

)

(A9)

r

I I I

)

k

I I I

E

2

y

H

2

3.5

P

(

y

CH

4

y

H

2

O

2

-

P

2

y

H

2

4

y

CO

2

K

I

K

I I

)

(A10)

E )

[

1 + P(K

CO

y

CO

+ K

CH

4

y

CH

4

+ K

H

2

y

H

2

) +

K

H

2

O

y

H

2

O

y

H

2

]

(A11)

q

rad

)

(A

t,o

+ A

ref

)

g

t

(A

t,o

+ A

ref

)

g

+ A

t,o

(1 -

g

)

t

(T

g

4

- T

w,o

4

) +

N

b

A

f

t

(1 -

g

)

A

t,o

T

f

4

(A12)

q

cond

)

2k

w

(T

w,o

- T

w,i

)

l n(d

o

/d

i

)

(A13)

q

conv

) U(T

w,i

- T) (A14)

U ) 0.4

k

g

D

p

[

2.58

(

D

p

G

)

1/3

(

C

p,g

k

g

)

1/3

+

0.094

(

D

p

G

)

0.8

(

C

p,g

k

g

)

0.4

]

(A15)

d

2

yj

CH

4

,n

dv

2

) a

2

l

c

2

[

F

s

(r

I

+ r

I I

+ r

I I I

)

b

(P/RT)D

CH

4

e

]

R

CH

4

,n

R

H

2

O,l

,

n ) 2, 3, ..., M + 1 (A16)

d

2

yj

H

2

O,n

dv

2

) a

2

l

c

2

[

F

s

(r

I

+ r

I I

+ 2r

I I I

)

b

(P/RT)D

H

2

O

e

]

R

H

2

O,n

R

H

2

O,l

,

n ) 2, 3, ..., M + 1 (A17)

yj

CO,n

) y

CO

-

1

D

CO

e

[2D

CH

4

e

(yj

CH

4

,n

- y

CH

4

) -

D

H

2

O

e

(yj

H

2

O,n

- y

H

2

O

)], n ) 2, 3, ..., M + 1 (A18)

yj

CO

2

,n

) y

CO

2

+

1

D

CO

2

e

[D

CH

4

e

(yj

CH

4

,n

- y

CH

4

) -

D

H

2

O

e

(yj

H

2

O,n

- y

H

2

O

)], n ) 2, 3, ..., M + 1 (A19)

yj

H

2

,n

) y

H

2

-

1

D

H

2

e

[2D

CH

4

e

(yj

CH

4

,n

- y

CH

4

) +

D

H

2

O

e

(yj

H

2

O,n

- y

H

2

O

)], n ) 2, 3, ..., M + 1 (A20)

Boundary Condi ti ons

(at Axi al Locati on Z and Ti me t)

yj

i,1

) y

i

(Z,t), i ) CH

4

, H

2

O, CO, CO

2

, H

2

dyj

i,M+2

dv

) 0, i ) CH

4

, H

2

O, CO, CO

2

, H

2

k

)

v)0

v)a

r

k

(yj

i

,T,P) dv

r

k

(y

i

,T,P)l

c

, k ) I , I I , I I I (A21)

i

)

k)I

I I I

ik

k

r

k

k)I

I I I

ik

r

k

, i ) CH

4

, H

2

O, CO, CO

2

, H

2

(A22)

I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003 4041

(6) Rajesh, J. K.; Gupta, S. K.; Rangai ah, G. P.; Ray, A. K.

Mul ti objecti ve Opti mi zati on of Steam Reformer Performance

Usi ng Geneti c Al gori thm. I nd. Eng. Chem. Res. 2000, 39,

706.

(7) El nashai e, S. S. E. H.; El shi shi ni , S. S. DynamicModelling,

Bifurcation and Chaotic Behaviour of Gas-Solid Catalytic Reac-

tors; Gordon and Breach: Amsterdam, The Netherl ands,

1996.

(8) Al ati qi , I . M. Onl i ne Qual i ty Control Methods for Steam-

Gas Reformers. I nt. J . Hydrogen Energy 1990, 15, 179.

(9) Al ati qi , I . M.; Mezi ou, A. M. Dynami c Si mul ati on and

Adapti ve Control of an I ndustri al Steam Reformer. Comput. Chem.

Eng. 1991, 15, 147.

(10) Mezi ou, A. M.; Deshpande P. B.; Al ati qi , I . M. Dynami c

Matri x Control of an I ndustri al Steam Gas Reformer. I nt. J .

Hydrogen Energy 1995, 20, 187.

(11) Al ati qi , I . M.; Mezi ou, A. M.; Gasmel seed, G. A. Model i ng,

Si mul ati on and Sensi ti vi ty Anal ysi s of Steam-Methane Reform-

ers. I nt. J . Hydrogen Energy 1989, 14, 241.

(12) Mezi ou, A. M.; Al ati qi , I . M. I denti fi cati on and Control of

an I ndustri al Steam-Reformi ng Pl ant. Can. J . Chem. Eng. 1994,

72, 321.

(13) Kvamsdal , H. M.; Svendsen, H. F.; Hertzberg, T.; Ol svi k

O. Dynami c Si mul ati on and Opti mi zati on of a Catal yti c Steam

Reformer. Chem. Eng. Sci. 1999, 54, 2697.

(14) Serbezov, A.; Soti rchos, S. V. Parti cl e-Bed Model for

Mul ti component Adsorpti on-based Separati ons: Appl i cati ons to

Pressure Swi ng Adsorpti on. Chem. Eng. Sci. 1999, 54, 5647.

(15) Froment, G. F.; Bi schoff, K. B. Chemical Reactor Analysis

and Design, 2nd ed.; Wi l ey: New York, 1990.

(16) Deken, J. C. D.; Devos, E. F.; Froment, G. F. Steam

Reformi ng of Natural Gas: I ntri nsi c Ki neti cs, Di ffusi onal I nfl u-

ences, and Reactor Desi gn. ACS Symp. Ser. 1982, 196, 181.

(17) Vi l l adsen, J.; Mi chel sen, M. L. Solution of Differential

Equation Models by Polynomial Approximation; Prenti ce Hal l :

Engl ewood Cl i ffs, NJ, 1978.

(18) Seader, J. D.; Henl ey, E. J. Separation Process Principles;

Wi l ey: New York, 1997.

(19) Pl ehi ers, P. M.; Froment, G. F. Coupl ed Si mul ati on of Heat

Transfer and Reacti on i n a Steam Reformi ng Furnace. Chem. Eng.

Technol. 1989, 12, 20.

(20) Fi nl ayson, B. A. Nonlinear Analysis in Chemical Engineer-

ing; McGraw-Hi l l : New York, 1980.

(21) Gupta, S. K. Numerical Methods for Engineers; Wi l ey

Eastern/New Age I nternati onal : New Del hi , I ndi a, 1995.

(22) Ray, W. H.; Szekel y, J. Process Optimization; Wi l ey: New

York, 1973.

(23) Deb, K. Multi-ObjectiveOptimization UsingEvolutionary

Algorithms. Wi l ey: Chi chester, U.K., 2001.

(24) Deb, K.; Pratap, A.; Agarwal , S.; Meyari van, T. A Fast and

El i ti st Mul ti objecti ve Geneti c Al gori thm: NSGA-I I . I EEE Trans.

Evol. Comput. 2002, 182, 6.

(25) Bhaskar, V.; Gupta, S. K.; Ray, A. K. Appl i cati ons of

Mul ti objecti ve Opti mi zati on i n Chemi cal Engi neeri ng. Rev. Chem.

Eng. 2000, 16, 1.

(26) Kasat, R. B.; Kunzru, D.; Saraf, D. N.; Gupta, S. K.

Mul ti objecti ve Opti mi zati on of I ndustri al FCC Uni t Usi ng El i ti st

Nondomi nated Sorti ng Geneti c Al gori thm. I nd. Eng. Chem. Res.

2002, 4765, 41.

(27) Chankong, V.; Hai mes, Y. Y. Multiobjective Decision

MakingsTheory and Methodology; El sevi er: New York, 1983.

Received for review December 3, 2002

Revised manuscript received Apri l 15, 2003

Accepted June 14, 2003

I E0209576

4042 I nd. Eng. Chem. Res., Vol . 42, No. 17, 2003

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Personality and LifestylesDocument8 pagesPersonality and LifestylesRandika FernandoNo ratings yet

- Sewage Treatment Plant - Operation Manual PDFDocument64 pagesSewage Treatment Plant - Operation Manual PDFDinhQuangDat100% (1)

- Skip To Primary NavigationDocument118 pagesSkip To Primary NavigationMclin Jhon Marave MabalotNo ratings yet

- AE23 Capital BudgetingDocument4 pagesAE23 Capital BudgetingCheska AgrabioNo ratings yet

- Ansys - WS20 - BladeModelerDocument20 pagesAnsys - WS20 - BladeModelercoolkaisy100% (1)

- Form REN-01 Application For REN RegistrationDocument2 pagesForm REN-01 Application For REN RegistrationNajib MohamedNo ratings yet

- Hubspot CaseDocument4 pagesHubspot CaseTatsat Pandey100% (1)

- ABAP Program Tips v3 PDFDocument157 pagesABAP Program Tips v3 PDFRui AlmeidaNo ratings yet

- DTU BTech Evening Application FormDocument8 pagesDTU BTech Evening Application FormAnweshaBoseNo ratings yet

- Dijkstra's AlgorithmDocument59 pagesDijkstra's AlgorithmTanmay BaranwalNo ratings yet

- 712 35 35 Rev C Knee Truliant Porous Tibia Operative TechniqueDocument16 pages712 35 35 Rev C Knee Truliant Porous Tibia Operative TechniqueValaMelkorNo ratings yet

- Multiparametros PONSEL - ODEONDocument4 pagesMultiparametros PONSEL - ODEONLucila Pelayo SerranoNo ratings yet

- Guia Entrenamiento en Habilidades de Cuiado en Familiares de Niñs Con DiscapacidadDocument20 pagesGuia Entrenamiento en Habilidades de Cuiado en Familiares de Niñs Con DiscapacidadAbigail MJNo ratings yet

- Path o PhysiologyDocument2 pagesPath o PhysiologyPotato BroNo ratings yet

- S16r-Pta (T13-0311-E)Document4 pagesS16r-Pta (T13-0311-E)Dikdik Sidqi100% (1)

- Principles or Elements If Effective DocumentationDocument9 pagesPrinciples or Elements If Effective DocumentationHoney Bitas OriasNo ratings yet

- Razer Global OfferingDocument391 pagesRazer Global OfferingCYCNo ratings yet

- Factors Affecting The Quality of Auditing: The Case of Jordanian Commercial BanksDocument3 pagesFactors Affecting The Quality of Auditing: The Case of Jordanian Commercial Bankswali ahmedNo ratings yet

- TUNTAP InterfacesDocument8 pagesTUNTAP Interfacesarpit guptaNo ratings yet

- De Thi Thu TN THPT 2022 Lan 1 Mon Tieng Anh Truong THPT Han Thuyen Bac NinhDocument6 pagesDe Thi Thu TN THPT 2022 Lan 1 Mon Tieng Anh Truong THPT Han Thuyen Bac NinhM Huy TranNo ratings yet

- Could Vs Be Able To WorksheetDocument1 pageCould Vs Be Able To WorksheetJeronimo RiveroNo ratings yet

- Normativa ASTM A586Document4 pagesNormativa ASTM A586Breyen Esaú Ríos100% (2)

- Curriculum Vitae: 1 .Personal DataDocument2 pagesCurriculum Vitae: 1 .Personal DataMamadou Gueye100% (1)

- Lecture 2 AERONAUTICAL NOMENCLATUREDocument20 pagesLecture 2 AERONAUTICAL NOMENCLATUREIvan GluhenkiyNo ratings yet

- Designed For Power and Performance: Technical SpecificationsDocument2 pagesDesigned For Power and Performance: Technical SpecificationsRobertNo ratings yet

- SANS MGTPS METRICS v1.3 01-23Document2 pagesSANS MGTPS METRICS v1.3 01-23fapaba6010No ratings yet

- Submittal Chiler 205 TRDocument5 pagesSubmittal Chiler 205 TRcarmen hernandezNo ratings yet

- Human Retention Using Data ScienceDocument16 pagesHuman Retention Using Data ScienceDivya PatilNo ratings yet

- Strategic Information Systems ManagementDocument6 pagesStrategic Information Systems ManagementStephen Lundall0% (1)

- Sap Bydesign 1702 Product Info Product DataDocument116 pagesSap Bydesign 1702 Product Info Product DataMohammed DobaiNo ratings yet