Professional Documents

Culture Documents

Direct Torque Control For Induction Motor Using Intelligent Artificial Neural Network Technique

Direct Torque Control For Induction Motor Using Intelligent Artificial Neural Network Technique

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Direct Torque Control For Induction Motor Using Intelligent Artificial Neural Network Technique

Direct Torque Control For Induction Motor Using Intelligent Artificial Neural Network Technique

Copyright:

Available Formats

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.

com

Volume 3, Issue 4, July-August 2014 ISSN 2278-6856

Volume 3 Issue 4 July-August, 2014 Page 44

Abstract- The purpose of this study is to control the speed of

3-Phase Induction Motor with Artificial Neural Network

(ANN) controller using MATLAB application. The Artificial

Neural Network Controller will be design and must be tune, so

the comparison between simulation result and experimental

result can be made. The scopes includes the simulation and

modelling of 3-Phase Induction Motor, implementation of

Artificial Neural Network Controller into actual 3-Phase

Induction Motor and comparison of MATLAB simulation

result with the experimental result. This research was about

introducing the new ability of in estimating speed and

controlling the 3-phase Induction Motor. In this project, ANN

Controller will be used to control the speed of 3-Phase

Induction Motor. The ANN Controller will be programmed to

control the speed of 3-Phase Induction Motor at certain speed

level. Direct Torque Control (DTC) is one of the latest

technique to control the speed of motor, in this paper, the

control technique of DTC is based on when load changes then

inverter switch position are changed and supply to the motor is

changed, in this paper Proportional Integral (PI), Neural

Network (NN) controller and Adaptive motor model is designed

this is the heart of the DTC, as we know that DTC doesnt

require any feedback and sensors to measure. The NN

structure is to be implemented by input output (nonlinear)

mapping models and is constructed with input, output and

hidden layers of sigmoid activation functions. It has been

introduced as a possible solution to the real multivariate

interpolation problem. To improve the performance of DTC

with the modern technique using NN approach is

implemented, and performance of DTC with PI controller and

NN controller is done, hence, the NN approach shows the

better performance than conventional PI controller.

Keywords-- direct torque control (DTC), induction motor,

artificial neural network (ANN), switching table, SVM

inverter, Backpropagation

1. INTRODUCTION

Induction motor drives controlled by Field Oriented

control (FOC) have been till now employed in high

performance industrial applications, has achieved a quick

torque response, and has been applied in various industrial

applications instead of dc motors. It permit independent

control of the torque and flux by decoupling the stator

current into two orthogonal components FOC, however, is

very sensitive to flux, which is mainly affected by

parameter variations. It depends on accurate parameter

identification to achieve the expected performance. During

the last decade a new control method called DTC (Direct

Torque Control) has been developed for

electricamachines.TC principles were first introduced by

Depenbrock and Takahashi. In this method [1], Stator

voltage vectors is selected according to the differences

between the reference and actual torque and stator flux

linkage. The DTC method is characterised by its simple

implementation and a fast dynamic response. Furthermore,

the inverter is directly controlled by the algorithm, i.e. a

modulation technique for the inverter is not needed.

However if the control is implemented on a digital system

(which can be considered as a standard nowadays), the

actual values of flux and torque could cross their

boundaries too far. The main advantages of DTC are

absence of coordinate transformation and current

regulator; absence of separate voltage modulation block,

Common disadvantages of conventional DTC are high

torque ripple and slow transient response to the step

changes in torque during start-up. For that reason the

application of artificial neural network attracts the

attention of many scientists from all over the world. The

reason for this trend is the many advantages which the

architectures of ANN have over traditional algorithmic

methods [1].Among the advantages of ANN are the ease of

training and generalization, simple architecture, possibility

of approximating nonlinear functions, insensitivity to the

distortion of the network, and inexact input data. In this

paper we present the evaluation of flux and torque using

the three stator currents is the voltage of input inverter,

and artificial neural network has been devised having as

inputs the torque error, the stator flux error and the

position of the stator flux in which it lies, and as output the

voltage space vector to be generate by the inverter. The

ANN then replaces the switching table. The theoretical

Principle, numerical simulation procedures and the results

of these methods are discussed and compared with

conventional DTC [1].

2. DIRECT TORQUE CONTROL WITH

TWO-LEVEL INVERTER

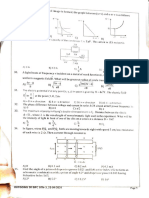

Fig. 1 shows the schematic of The basic functional blocks

used to implement the DTC of induction motor drive. A

voltage source inverter (VSI) supplies the motor and it is

possible to control directly the stator flux and the

electromagnetic torque by the selection of optimum

inverter switching modes [1]-[4].

DIRECT TORQUE CONTROL FOR INDUCTION MOTOR

USING INTELLIGENT ARTIFICIAL NEURAL NETWORK TECHNIQUE

Devender Kumar, Ishan Thakur, Kanika Gupta

1,2,3

Electrical Department, Baddi University,India

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 3, Issue 4, July-August 2014 ISSN 2278-6856

Volume 3 Issue 4 July-August, 2014 Page 45

Fig 1: Figure 1. Basic direct torque control scheme for AC

motor drives

3. VECTOR MODEL OF INVERTER

OUTPUT VOLTAGE

In the PWM voltage source inverters, considering the

combinations of the states of switching functions inverter

switching state functions (C1,C2,C3) which can take either

1 or 0, the voltage vector becomes[7][8][9]:

(1)

Eight switching combinations can be taken according to

the above relationship: two zero voltage vectors and six

non-zero voltage vectors show by Fig.2 [1][2].

Fig 2: Partition of the d q plane into 6 angular sectors

4. STATOR FLUX AND TORQUE

ESTIMATION

The components of the current (Is , Is , and stator

voltage (Vs , Vs are obtained by the application of the

transformation given by (2) and (3) :.

(2)

(3)

The components of the stator flux ( s , s given by (4).

. (4)

The stator flux linkage phase is given by (5).

(5)

The electromagnetic couple be obtained starting from the

estimated sizes of flux ( , ) and calculated sizes of

the current ( , )

(6)

The stator resistance Rs can be assumed constant during a

large number of converter switching periods Te. The

voltage vector applied to the induction motor remains also

constant one period Te. Therefore, resolving first equation

of system leads to:

(7)

(8)

In equation (8); stands for the initial stator flux

condition. This equation shows that when the term RsIs

can be neglected, (in high speed operating condition for

example), the extremity of stator flux vector Vs.

Furthermore, the instantaneous flux speed is only governed

by voltage vector amplitude .

In fact, we have the following Fig.3 Established

for the case Vs =V3.

Fig 3: An example for flux deviation

Therefore, by adequate voltage vector selection we can

increase or decrease the stator flux amplitude and phase to

obtain the required performances. The deviation obtained

at the end of the switching period Te can be approached by

the first order Taylor Seri as below. The radial component

(component of flux) of the vector of tension acts on the

amplitude of the vector flux and its tangential component

(component of the torque) on the position of the vector

flux. By choosing a suitable sequence of the vectors of

tension, one can force the end of the vector flux to follow a

desired trajectory. To function with a module of practically

constant flux s, it is enough to choose an almost circular

trajectory for the end of the vector flux. That is not

possible that if the period of control is very weak for you in

front of the period of rotation of flux.

5. SWITCHING TABLE

When flux is in zone I, the vectors Vi+1 or Vi-1 are

selected to increase the amplitude of flux, and Vi+2 or Vi-

2 to decrease it. What shows that the choice of the vector

tension depends on the sign of the error of flux,

independently of its amplitude. This explains why the exit

of the corrector of flux can be a Boolean variable. One

adds a band of hysteresis around zero to avoid useless

commutations when the error of flux is very small. Indeed,

with this type of corrector inspite of his simplicity, one can

easily control and maintain the end of the vector flux, in a

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 3, Issue 4, July-August 2014 ISSN 2278-6856

Volume 3 Issue 4 July-August, 2014 Page 46

circular ring. The switching table proposed by Takahashi,

as given by

Table1

6. DTC BASED NEURAL NETWORK

Principles of Artificial Neural Networks

Artificial neural networks use a dense interconnection of

computing nodes toapproximate nonlinear functions .Each

node constitutes a neuron and performs themultiplication

of its input signals by constant weights, sums up the results

and maps the sum to a nonlinear activation function g; the

result is then transferred to its output. A feed forward ANN

is organized in layers: an input layer, one or morehidden

layers and an output layer. A MLP consists of an input

layer, several hidden layers, and an output layer. Node i,

also called aneuron, in a MLP network is shown in Fig.4.

It includes a summer and a nonlinear activation function g

[1],[10],[13].

Fig 4.:A multilayer perceptron network with one hidden

Layer.

The inputs , k = 1...K to the neuron are multiplied by

weights and summed up together with the constant

bias term . The resulting I n is the input to the activation

function g. The activation function was originally chosen

to be a relay function, but for mathematical convenience a

hyperbolic tangent (tanh) or a sigmoid function are most

commonly used.

7. SIMULATION MODEL AND

STRUCTURE OF DTC SYSTEM BASED

ANN

The ANN is trained by a learning algorithm which

performs the adaptation of weights of the network

iteratively until the error between target vectors and the

output of the ANN is less than an error goal. The most

popular learning algorithm for multilayer networks is the

back propagation algorithm and its variants. The latter is

Implemented by many ANN software packages such as the

neural network toolbox from MATLAB.In the case

presented in this paper the DTC control strategy shown on

table I has been implemented. Neural network has been

devised having as inputs the torque error, the stator flux

error and the position of the stator flux, and as output the

voltage space vector to be generate by the inverter. The

ANN block then replaces the switching table selector block

of Fig.5.

Fig. 5. Direct Torque Control with Neural network

Applied

Creating a Simulink model for the motor of desired

specification operated by a programmable voltage source.

For this purpose we will use the Matlab version 7.10.0.499

(R2010a) [23].

The motor specification that we have chosen is

5HP, 460Volts, 60Hz, 1750 RPM and reference

we have chosen is stationary.

The Specification of the Programmable voltage

source is 460V, 60Hz, with initially zero phase.

The speed value initially applied to the motor is

200 rpm and step signal from 100 rpm to 200

rpm. The figure below shows the Simulink model

of the 3-phase IM connected to the DTC block

which is given the specified supply, speed,

electromagnetic torque, stator current_a/b/c

response connected to the waveform visualization

(scope).

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 3, Issue 4, July-August 2014 ISSN 2278-6856

Volume 3 Issue 4 July-August, 2014 Page 47

Fig. 6. DTC Control application in controlling the 3-phase

induction motor

Fig. 7. Detailed Simulink model of DTC

We have designed a neural network and trained it so that it

can replace the switching table to get the desired response.

Network formed is feed forward with one input, one

hidden and one output layer. The training is done using

Levenberg Marquardt Back-propagation Algorithm with

30 neurons through nftool in Matlab [10]. Neural network

for DTC is created by following steps-

For this we have to create the inputs and outputs

.for the inputs we have the switching table as

Table 3. The Expanded switching table of DTC

Input X is a [3 X 24] matrix. In which 1st row is for flux

error values , 2nd row is for torque error values and 3rd

row is for flux angle sector whereas each row contains 24

values as stated above in proper correspondence .In this we

have 24 samples set we have to create more samples. So

for that we have to increase the no of samples in order to

do that Horzcat function of matlab will be used.

X1=horzcat(X,X);This will create 48 samples. Now further

applying horzcat function as X2=horzcat(X1,X1);This will

create 96 samples. Now further applying the function

again X3=horzcat(X2,X2);This will create 192 samples.

Now this will give [3X192] dimension matrix which

means 192 samples in the form of column vectors with 3

values in each. Output Y is a [6 X 24] matrix. In this each

of this column represents a output vector i.e

V1/V2/V3/V4/V5/V6 and each of these vectors are

represented by the six bit binary code as stated below. So

the neural network will gives its output in the form of these

6 bits for the specified vector angle output.

In this we have results of 24 samples respectively. As we

have created 192 samples. So for that we have to take care

of the result in the same quantity in order to do that

Horzcat function of matlab will be used.

Y1=horzcat(Y,Y);

This will create 48 samples result. Now further applying

horzcat function as

Y2=horzcat(Y1,Y1);

This will create 96 samples result. Now further applying

the function again

Y3=horzcat(Y2,Y2);

This will create 192 samples result. Now this will give

[6X192] dimension matrix which means 192 samples

result in the form of 6 binary value (either 0 or 1) in each.

Now we will design a neural network and train it as we

have 192 input samples and their respective results.

X3 input,Y3 output.For that we have nftool in matlab

by using this we will design the network. Give it the input

(X3) that have been created above in the workspace of

matlab in the column format. Also give it the output (Y3)

that have been created above in the workspace of matlab in

the same column format [23].Now train them using the

Levenberg Marquardt Back propagation algorithm using

30 neurons to create a two-layer feed-forward network with

sigmoid hidden neurons and linear output neurons

(newfit), can fit multi-dimensional mapping problems

arbitrarily well, given consistent data and enough neurons

in its hidden layer.The three parameters are firstly given

given to the matrix concatenate i.e Flux error, Torque

error, Flux angle vector position (sector). In matrix

concatenate Block Number of inputs is 3 and mode is

vector. Then this output in single dimension is given to the

Neural Network and output is given to the Rounding off

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 3, Issue 4, July-August 2014 ISSN 2278-6856

Volume 3 Issue 4 July-August, 2014 Page 48

Block and then given to the gate finally. Finally generating

the Simulink model of the neural network and using it as

a substitution to the switching table used in the Direct

Torque Control drive AC4 created before. And then

comparing the results.

Fig. 8. Neural Network instead of switching Table for the

Vector model of Inverter output voltage

8. SIMULATION RESULTS

The Induction motor speed controlling model using

Conventional DTC and ANN applied DTC has been

designed and studied successfully and the results of the

thesis work are almost satisfying by using ANN in it as a

substitution of the switching table. The Sampling period of

s. To compare with Conventional DTC

and ANN DTC for Induction motor are simulated. In two

cases, the dynamic responses of speed, flux, torque and

stator current for the starting process with 0 Nm load

torque and input speed reference of 200 wm applied are

shown in Figure from 9 to 16 respectively. Figs.9 and 10

show the response of electric torque of the Conventional

DTC, and ANN DTC respectively. It can be seen that the

ripple in torque with ANN DTC control is less than 0.3

Nm and with conventional direct torque control the ripple

is about 2 Nm at the same operating conditions. Figs.11

and 12 show the response of stator flux magnitude of the

Conventional DTC and ANN DTC respectively. By ANN

DTC technique shown Fig 12, the stator flux are the fast

response in transient state and the ripple in steady state is

reduced remarkably compared with conventional DTC, the

flux changes through big oscillation and the torque ripple

is bigger in Conventional DTC. In Fig 13 and 14, It can be

seen that the ripple in speed with ANN DTC control is less

than 0.3 wm and with conventional direct torque control

the ripple is about 2 wm at the same operating conditions.

Figs 15 and 16 show the steady state current response of

the ANN_DTC has negligible ripple in stator current and

a nearly sinusoidal wave form while as with conventional

DTC the stator current has considerably very high ripple.

Fig. 9 Electromagnetic torque Response of Conventional

DTC

Fig. 10. Electromagnetic torque Response of ANN DTC

Fig. 11. Stator flux direct axis of Conventional DTC

Fig. 12. Stator flux direct axis of ANN DTC

Fig. 13. Rotor Speed Response using Conventional DTC

Fig. 14. Rotor Speed Response using ANN DTC

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 3, Issue 4, July-August 2014 ISSN 2278-6856

Volume 3 Issue 4 July-August, 2014 Page 49

Fig. 15. Stator Current phase-A in Conventional DTC

Fig. 16. Stator Current phase-A in ANN DTC

9. CONCLUSION

Direct Torque Control System Using a Neural Network is

successfully implemented on three phase induction motor.

In this work, using the MATLAB simulation, a robustly

stable neural network for the induction motor system using

the ANN toolbox is presented. A high power 3-level fed

induction motor with direct torque control system is

developed. To cope with the inherent uncertainties such as

parametric uncertainty, external disturbance and modeled

dynamics, the NN is used as an uncertainty observer.In

this thesis a ANN DTC of induction machine have been

proposed. An improved torque, speed and flux response

was achieved with the ANN DTC than the conventional

DTC. The performance has been tested by simulations.

Also, a command flux optimization scheme has been

proposed to reduce the torque ripple. The optimization was

tested using simulation. The results show a reasonable

improvement by flux optimization. The main

improvements shown are:

Reduction of torque and current ripples in transient

and steady state response.

No flux droppings caused by sector changes

circular trajectory.

Fast stator flux response in transient state.

Reduction of speed ripples in transient and steady

state response

REFERENCES

[1] Riad toufouti, Salima meziane, Hocine benalla, Direct

torque control for induction motor using intelligent

techniques, Journal of Theoretical and Applied

Information Technology, (toufoutidz,mezianedz,

Benalladz)@yahoo.fr

[2] Riad toufouti, Salima meziane, Hocine benalla, Direct

torque control strategy of induction motors, ISSN 1335-

8243 2007 Faculty of Electrical Engineering and

Informatics, Technical University of Koice, Slovak

Republic, Acta Electrotechnica et Informatica No. 1, Vol.

7, 2007.

[3] Takahashi, T. Noguchi, A new quick response and high-

efficiency control strategy of induction motor, IEEE

Trans. On IA, Vol.22, N.5, Sept/Oct 1986, PP.820-827.

[4] M. Depenbrock, Direct self control (DSC) of inverter

fed induction machine , IEEE Trans. Power Electronics,

Vol.3, N.4, Oct 1988, PP.420-829.

[5] Texas Instruments, Field Orientated Control of 3-Phase

AC-Motors, Literature Number: BPRA073, Texas

Instruments Europe February 1998.

[6] Bilal Akin and Manish Bhardwaj, Sensored Field

Oriented Control of 3-Phase Induction Motors, Copyright

2013, Texas Instruments Incorporated, SPRABP8July

2013.

[7] Tobias Geyer and Georgios Papafotiou, Direct Torque

Control for Induction Motor Drives: A Model Predictive

Control Approach Based on Feasibility, M. Morari and L.

Thiele (Eds.): HSCC 2005, LNCS 3414, pp. 274290,

2005, Springer-Verlag Berlin Heidelberg 2005.

[8] S. Buso, L. Malesani, P. Mattavelli, "Comparison of

Current Control Techniques for Active Filter Applications",

IEEE Transaction on Industrial Electronics, Vol. 45, No.5,

October 1998., pp.722-729.

[9] M.P. Kazmierkowski, L. Malesani, "Current control

techniques for three phase voltage-source PWM

converters: a survey", Industrial Electronics, IEEE

Transactions on Industrial Electronics, Vol. 45, No. 5,

Oct.1998., pp. 691 -703.

[10] Ashutosh Mishra , Prashant Choudhary, Artificial

Neural Network Based Controller for Speed Control of

an Induction Motor using Indirect Vector Control

Method, International Journal of Power Electronics

and Drive System (IJPEDS) , Vol.2, No.4, December

2012, pp. 402~408 ,ISSN: 2088-8694.

[11] Suresh Kumar Chiluka, S. Nagarjuna Chary, E

Chandra Mohan Goud, Direct torque control using

neural network approach, IJRET | APR 2013,

Volume: 2 Issue: 4, 682 686, ISSN: 2319 1163.

[12] M. zerikat, and A. chekroun, Adaptation learning

speed control for a high- performance induction motor

using neural networks, World Academy of Science,

Engineering and Technology 21 2008, P-293-298.

[13] Alberico Menozzi, Mo-yuen Chow, A design

methodology for an intelligent controller using fuzzy

logic and Artificial Neural Networks, 0-7803-0891-

3/93$03.00@1993 IEEE, P-408-413.

[14] Antsaklis, P.J., K. M. Passino and S. J. Wang,

Towards intelligent autonomous control systems:

Web Site: www.ijettcs.org Email: editor@ijettcs.org, editorijettcs@gmail.com

Volume 3, Issue 4, July-August 2014 ISSN 2278-6856

Volume 3 Issue 4 July-August, 2014 Page 50

Architecture and fundamental issues, Intelligent

Robotics System, Vol. 1,PP. 315-342, 1989.

[15] G. Kohlrusz, D. Fodor, Comparison of scalar and

vector control strategies of induction motors,

Hungarian Journal Of Industrial Chemistry Veszprem,

vol. 39(2) pp. 265-270 (2011).

[16] Anders Kronberg , Design and Simulation of Field

Oriented Control and Direct Torque Control for a

Permanent Magnet Synchronous Motor with Positive

Saliency ISRN UTH-INGUTB-EX-E-2012/05-SE,

Examensarbete 15 hp, Maj 2012.

[17] Giuseppe Buja, Domenico Casadei and Giovanni

Serra, Direct torque control of induction motor

drives, IEEE Catalog Number: 97TH8280, ISIE97-

Guimaraes, Portugal.

[18] Texas Instruments, Field Orientated Control of 3-

Phase AC-Motors, Literature Number: BPRA073,

Texas Instruments Europe, February 1998.

[19] S. Buso, L. Malesani, P. Mattavelli, "Comparison of

Current Control Techniques for Active Filter

Applications", IEEE Transaction on Industrial

Electronics, Vol. 45, No.5, October 1998., pp.722-729

[20] Bilal Akin and Nishant Garg, Scalar (V/f) Control

of 3-Phase Induction Motors, Texas Instruments,

SPRABQ8July 2013, www.ti.com.

[21] F. Parasiliti, Appunti delle lezioni di Azionamenti

Elettrici: Controllo Vettoriale ad Orientamento di

Campo, Universit degli Studi di LAquila

[22] R. Di Gabriele, F. Parasiliti, M. Tursini, Digital

Field Oriented Control for induction motors:

implementation and experimental results,

Universities Power Engineering Conference

(UPEC97)

[23] www.mathworks.com

[24] www.wikipedia.com

[25] www.naptel.co.in

You might also like

- Ieee 43 2013 - Recommended Practice For Testing Insulation Resistance ofDocument37 pagesIeee 43 2013 - Recommended Practice For Testing Insulation Resistance ofpaoloesquivel100% (6)

- High Performance Direct Torque Control of Induction Motor Drives Using Space Vector ModulationDocument9 pagesHigh Performance Direct Torque Control of Induction Motor Drives Using Space Vector ModulationMefisto ElNo ratings yet

- Comparision Between Two Level and Three Level Inverter For Direct Torque Control Induction Motor DriveDocument8 pagesComparision Between Two Level and Three Level Inverter For Direct Torque Control Induction Motor DriveMatanAbutbulNo ratings yet

- Performance Analysis On Direct Torque Controlled Induction Motor Drive With Varying Hysteresis Controller BandwidthDocument10 pagesPerformance Analysis On Direct Torque Controlled Induction Motor Drive With Varying Hysteresis Controller Bandwidthaswardi8756No ratings yet

- Direct Torque Control of Induction Motor Using Artificial Neural NetworkDocument7 pagesDirect Torque Control of Induction Motor Using Artificial Neural NetworkMohamed SomaiNo ratings yet

- Comparative Analysis of Different Control Approaches of Direct Torque Control Induction Motor DriveDocument5 pagesComparative Analysis of Different Control Approaches of Direct Torque Control Induction Motor DrivepkshanumehaboobNo ratings yet

- Im 8Document7 pagesIm 8maheswaranNo ratings yet

- DC Link Approach To Variable-Speed, Sensorless,: Induction Motor DriveDocument5 pagesDC Link Approach To Variable-Speed, Sensorless,: Induction Motor DrivesamirmansourNo ratings yet

- Performance Analysis of Direct Torque Control of 3-Phase Induction MotorDocument6 pagesPerformance Analysis of Direct Torque Control of 3-Phase Induction MotormaheswaranNo ratings yet

- Induction Motor ControlDocument4 pagesInduction Motor ControlJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- New Direct Torque Control Scheme of Induction Motor For Electric VehiclesDocument7 pagesNew Direct Torque Control Scheme of Induction Motor For Electric VehiclesPrasanth RamavarapuNo ratings yet

- Ds PICDocument6 pagesDs PICSindhuja VijayaraghavanNo ratings yet

- A Direct Torque Controlled Induction Motor With Variable Hysteresis BandDocument6 pagesA Direct Torque Controlled Induction Motor With Variable Hysteresis BandMuhammad SaadNo ratings yet

- Fast Direct Torque Control of An Open-End Induction Motor Drive Using 12-Sided Polygonal Voltage Space VectorsDocument11 pagesFast Direct Torque Control of An Open-End Induction Motor Drive Using 12-Sided Polygonal Voltage Space VectorsMuhammad UmarNo ratings yet

- Application of Space Vector Modulation in Direct Torque Control of PMSMDocument4 pagesApplication of Space Vector Modulation in Direct Torque Control of PMSMenmnabilNo ratings yet

- A Simple Direct-Torque Neuro-Fuzzy Control of PWM-Inverter-Fed Induction Motor DriveDocument8 pagesA Simple Direct-Torque Neuro-Fuzzy Control of PWM-Inverter-Fed Induction Motor DrivegsmaniprabaNo ratings yet

- Im 6 PDFDocument12 pagesIm 6 PDFmaheswaranNo ratings yet

- An044259264 PDFDocument6 pagesAn044259264 PDFmazenNo ratings yet

- Direct Torque Control of Induction Motor ThesisDocument5 pagesDirect Torque Control of Induction Motor Thesiscrystaljacksonnewhaven100% (2)

- Direct Torque Control PHD ThesisDocument7 pagesDirect Torque Control PHD Thesisheathervargaspeoria100% (2)

- Bldc motor controlDocument6 pagesBldc motor controlLalithNo ratings yet

- Untitled 1Document9 pagesUntitled 1sarita kumariNo ratings yet

- 245915-FinalDocument13 pages245915-FinalUtkarsh PrakashNo ratings yet

- Position Control Performance Improvement of DTC-SVM For An Induction Motor: Application To Photovoltaic Panel PositionDocument14 pagesPosition Control Performance Improvement of DTC-SVM For An Induction Motor: Application To Photovoltaic Panel PositionأسامةبوعزيزNo ratings yet

- Sensorless Three-Phase Induction Motor Direct TorqDocument7 pagesSensorless Three-Phase Induction Motor Direct TorqSakthivelNo ratings yet

- Design and Implementation of Flux Vector PDFDocument15 pagesDesign and Implementation of Flux Vector PDFBelal AshrafNo ratings yet

- Speed Regulation and Torque Ripple Minimization of Induction Motor by DTC With PI and Fuzzy Logic ControllerDocument6 pagesSpeed Regulation and Torque Ripple Minimization of Induction Motor by DTC With PI and Fuzzy Logic ControllerVijay KumarNo ratings yet

- A Variable-Speed, Sensorless, Induction Motor Drive Using DC Link MeasurementsDocument6 pagesA Variable-Speed, Sensorless, Induction Motor Drive Using DC Link Measurementsgowtam_raviNo ratings yet

- New DTC Control Scheme For Induction Motors Fed With A Three-Level InverterDocument9 pagesNew DTC Control Scheme For Induction Motors Fed With A Three-Level InverterANKIT PRAJAPATINo ratings yet

- Jeas 0408 94Document7 pagesJeas 0408 94Jun Chee LimNo ratings yet

- Design and Customization of Embedded Based Direct Torque Controller OfInduction MotorDocument6 pagesDesign and Customization of Embedded Based Direct Torque Controller OfInduction MotorTJPRC PublicationsNo ratings yet

- Direct Torque Control InductionDocument9 pagesDirect Torque Control InductiononafetsNo ratings yet

- Thesis On Direct Torque ControlDocument6 pagesThesis On Direct Torque Controlericabaldwinpittsburgh100% (2)

- Direct Torque Control of Induction MotorsDocument6 pagesDirect Torque Control of Induction MotorsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Paper 78Document8 pagesPaper 78Sanker VikramNo ratings yet

- Vector Control Simulation of AC MotorDocument16 pagesVector Control Simulation of AC MotorJosedocampocastro100% (1)

- Adaptive Bandwidth Approach ON DTC Controlled Induction MotorDocument9 pagesAdaptive Bandwidth Approach ON DTC Controlled Induction MotorijicsjournalNo ratings yet

- 7117ijics02 PDFDocument10 pages7117ijics02 PDFijicsjournalNo ratings yet

- Paper 21Document7 pagesPaper 21Anu AthiraNo ratings yet

- Energies 11 01793Document14 pagesEnergies 11 01793DiegoTorresNo ratings yet

- Torque Ripple Reduction Technique With Improved Flux Response For A Direct Torque Control Induction Motor DriveDocument17 pagesTorque Ripple Reduction Technique With Improved Flux Response For A Direct Torque Control Induction Motor DriveMuhammad UmarNo ratings yet

- Education DTC 380 PDFDocument6 pagesEducation DTC 380 PDFНебојша МитровићNo ratings yet

- Dynamic Performance and Analysis of Direct Torque Control Method Based On DSP For PMSM DrivesDocument5 pagesDynamic Performance and Analysis of Direct Torque Control Method Based On DSP For PMSM DrivesRaspy ReddyNo ratings yet

- Full Text 302010Document8 pagesFull Text 302010belsebtiNo ratings yet

- Mathematical Analysis of SVPWM For Inverter Fed DTC of Induction Motor DriveDocument6 pagesMathematical Analysis of SVPWM For Inverter Fed DTC of Induction Motor DriveNicola Claudiu-IonelNo ratings yet

- Speed Control of PMSM by Using DSVM - DTC TechniqueDocument5 pagesSpeed Control of PMSM by Using DSVM - DTC TechniqueKushagra KhamesraNo ratings yet

- Ijaiem 2013 08 25 054Document11 pagesIjaiem 2013 08 25 054International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Direct Torque ControlDocument5 pagesDirect Torque Controlvineeth kumarNo ratings yet

- CMP0193 SynopsisDocument6 pagesCMP0193 Synopsissumiths32No ratings yet

- Thesis Direct Torque ControlDocument7 pagesThesis Direct Torque Controljuliemoralesomaha100% (2)

- Space Vector Flux Weakening Control of PMSM DriverDocument8 pagesSpace Vector Flux Weakening Control of PMSM DriverOsama AttookNo ratings yet

- Ijetae 1013 117Document9 pagesIjetae 1013 117rasim_m1146No ratings yet

- Brushed DC Sensorless FeedbackDocument3 pagesBrushed DC Sensorless FeedbackHoon Miew JieNo ratings yet

- Applsci 08 01073 PDFDocument13 pagesApplsci 08 01073 PDFErsi Ago100% (1)

- Direct Torque Control Using Phase Current Reconstruction Algorithm in Induction MotorDocument6 pagesDirect Torque Control Using Phase Current Reconstruction Algorithm in Induction MotorquocyenkcdNo ratings yet

- Implementation of A Fuzzy PI Controller For Speed Control of Induction Motors Using FPGADocument7 pagesImplementation of A Fuzzy PI Controller For Speed Control of Induction Motors Using FPGABharati RajaNo ratings yet

- PID Controller For A Two Quadrant Chopper Fed DC Motor DriveDocument5 pagesPID Controller For A Two Quadrant Chopper Fed DC Motor DriveSalman HabibNo ratings yet

- Design and Implementation of Conveyor Line Speed Synchroniser For Industrial Control Applications: A Case Study of Champion'S Breweries PLC, UyoDocument9 pagesDesign and Implementation of Conveyor Line Speed Synchroniser For Industrial Control Applications: A Case Study of Champion'S Breweries PLC, UyomyselfdebjyotiNo ratings yet

- Sensorless Vector Controller For A Synchronous Reluctance MotorDocument9 pagesSensorless Vector Controller For A Synchronous Reluctance MotorUma SathyadevanNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Effect of Work Involvement and Work Stress On Employee Performance: A Case Study of Forged Wheel Plant, IndiaDocument5 pagesThe Effect of Work Involvement and Work Stress On Employee Performance: A Case Study of Forged Wheel Plant, IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Manufacturing of 6V 120ah Battery Container Mould For Train Lighting ApplicationDocument13 pagesDesign and Manufacturing of 6V 120ah Battery Container Mould For Train Lighting ApplicationInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Swot Analysis of Backwater Tourism With Special Reference To Alappuzha DistrictDocument5 pagesSwot Analysis of Backwater Tourism With Special Reference To Alappuzha DistrictInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Ijaiem 2021 01 28 6Document9 pagesIjaiem 2021 01 28 6International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Side Lobe Level Reduction in Antenna Array Using Weighting FunctionDocument5 pagesSide Lobe Level Reduction in Antenna Array Using Weighting FunctionghorbanlNo ratings yet

- Semiconductor Technical Data: L SuffixDocument12 pagesSemiconductor Technical Data: L SuffixSuwandra I Gede PutuNo ratings yet

- Nte 722Document2 pagesNte 722WilliamNo ratings yet

- ExcelStor Technology ATA & SATA Installation Guide (User Manual) (Rev. E)Document6 pagesExcelStor Technology ATA & SATA Installation Guide (User Manual) (Rev. E)MechDRNo ratings yet

- Controlling The Temperature Inside Equipment Racks © 2002-2010 Middle Atlantic Products, IncDocument36 pagesControlling The Temperature Inside Equipment Racks © 2002-2010 Middle Atlantic Products, Incvoltus88No ratings yet

- Adobe Scan 26-Apr-2024Document1 pageAdobe Scan 26-Apr-2024amayaimaneulNo ratings yet

- 亿光EL817Document11 pages亿光EL817Douglas RodriguesNo ratings yet

- DTMF Signalling in 3gDocument10 pagesDTMF Signalling in 3gFaheem AkhtarNo ratings yet

- Axial Fan DELTAQFR1212GHEDocument1 pageAxial Fan DELTAQFR1212GHEJosé Edilson da PazNo ratings yet

- Vijay FPP ESD PT11Document65 pagesVijay FPP ESD PT11Swathi PrasadNo ratings yet

- Control System Grounding - Part 2 - Ground Wiring, Shield Grounds, and Power Supply GroundingDocument10 pagesControl System Grounding - Part 2 - Ground Wiring, Shield Grounds, and Power Supply Groundingwaqas_a_shaikh4348No ratings yet

- CD1000A - User Manual V1.0Document88 pagesCD1000A - User Manual V1.0Engr ShoaibNo ratings yet

- Page 44Document1 pagePage 44Abhishek ShatagopachariNo ratings yet

- 203: Electrical Installations Technology: Handout 3: DrawingsDocument4 pages203: Electrical Installations Technology: Handout 3: DrawingsUsman AshrafNo ratings yet

- 1035 Mitsubishi M56733afpDocument4 pages1035 Mitsubishi M56733afpHenrique Tannús CarvalhoNo ratings yet

- Microwave New Bench ManualDocument51 pagesMicrowave New Bench Manual039 MeghaEceNo ratings yet

- Vibration Energy Harvesting Using Piezoelectric Transducer and Non-Controlled Rectifiers CircuitsDocument8 pagesVibration Energy Harvesting Using Piezoelectric Transducer and Non-Controlled Rectifiers Circuitsrajeev_kumar365No ratings yet

- Ts-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMDocument2 pagesTs-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMmohd darusNo ratings yet

- Intelligent Detector Bases: FeaturesDocument3 pagesIntelligent Detector Bases: FeaturesMarcelo FradeNo ratings yet

- Loop SounderDocument1 pageLoop Sounderhiddenhidden16No ratings yet

- Bicolour LED Flasher CircuitDocument5 pagesBicolour LED Flasher CircuitAnkita WalkeNo ratings yet

- FK202 SeriesDocument4 pagesFK202 Serieskylegaze100% (1)

- Catalog 12 PagesDocument12 pagesCatalog 12 PagesueksinNo ratings yet

- Line To Line Fault ExperimentsDocument6 pagesLine To Line Fault ExperimentsXian ChaoweNo ratings yet

- Introduction To Wireless Network EquipmentDocument291 pagesIntroduction To Wireless Network EquipmentMesfin TibebeNo ratings yet

- DMT 219004 AbDocument518 pagesDMT 219004 AbCiprian MariusNo ratings yet

- 2010 Legacy and Outback Wiring DiagramDocument262 pages2010 Legacy and Outback Wiring DiagramWilliam Guillen DamianNo ratings yet

- Socomec Delphys GP 2.0 500kva Control PanelDocument20 pagesSocomec Delphys GP 2.0 500kva Control PanelsharifmousaviNo ratings yet

- DDC For HVACDocument23 pagesDDC For HVACTorus EngenhariaNo ratings yet