Professional Documents

Culture Documents

Indr 372 Production Planning and Control: Course Topics

Indr 372 Production Planning and Control: Course Topics

Uploaded by

Öztürk SaraçoğluCopyright:

Available Formats

You might also like

- Process Selection and Facility LayoutDocument59 pagesProcess Selection and Facility LayoutKhietNo ratings yet

- Introduction To The Production Planning and Inventory ControlDocument80 pagesIntroduction To The Production Planning and Inventory ControlAngelina WattssNo ratings yet

- JIT PhylosophyDocument23 pagesJIT PhylosophyFouzan SoniwalaNo ratings yet

- Production & Operation ManagementDocument81 pagesProduction & Operation Managementpura_malliNo ratings yet

- Unit III - Prod. Mgt.Document60 pagesUnit III - Prod. Mgt.coxshulerNo ratings yet

- 0生产计划与控制Document1,051 pages0生产计划与控制Keity QuirinoNo ratings yet

- Facility PlanningDocument171 pagesFacility Planninganon_681273463No ratings yet

- Manufacturing Resource Planning M&IS 34064 Section 001 David F. Bolton, CFPIM, C.P.M. Materials Manager, Rotek IncDocument42 pagesManufacturing Resource Planning M&IS 34064 Section 001 David F. Bolton, CFPIM, C.P.M. Materials Manager, Rotek Inceternal_rhymes6972No ratings yet

- Questionnaire: GS1 WebsiteDocument6 pagesQuestionnaire: GS1 WebsiteSOHEL BANGINo ratings yet

- Plant/Facility LayoutDocument6 pagesPlant/Facility Layoutsourav736eeNo ratings yet

- Operations Management - Session 4 and 5 Chap 3.prof. Furquan 4KtNz4YsKiDocument43 pagesOperations Management - Session 4 and 5 Chap 3.prof. Furquan 4KtNz4YsKiNABARUN MAJUMDARNo ratings yet

- Chap 004Document34 pagesChap 004Mohammed MnhajuddinNo ratings yet

- PPT8-Production and Operations ManagementDocument33 pagesPPT8-Production and Operations ManagementSofyyNo ratings yet

- The Production System: - DefinitionDocument82 pagesThe Production System: - DefinitionLekha DaveNo ratings yet

- Welcome: Consumed at EaseDocument42 pagesWelcome: Consumed at Easekabhaskar2130No ratings yet

- Operations Management: Process Strategies and Layout StrategiesDocument74 pagesOperations Management: Process Strategies and Layout StrategiesAshokNo ratings yet

- Chapter 1 Introduction To POM PDFDocument19 pagesChapter 1 Introduction To POM PDFakankaroraNo ratings yet

- Process Strategy PPT at BEC DOMSDocument68 pagesProcess Strategy PPT at BEC DOMSBabasab Patil (Karrisatte)100% (1)

- Convertion Cycle: Amador, Jeric Ferreras, Christine Lasalita, Kyra Danielle Panganiban, Christine Joy Tolentino, AldrenDocument62 pagesConvertion Cycle: Amador, Jeric Ferreras, Christine Lasalita, Kyra Danielle Panganiban, Christine Joy Tolentino, AldrenChristine Joy PanganibanNo ratings yet

- Conversion Cycle Context-Level Data Flow Diagram-Continuous Processing Make-To-Order Processing - Batch ProcessingDocument4 pagesConversion Cycle Context-Level Data Flow Diagram-Continuous Processing Make-To-Order Processing - Batch ProcessingBrigit MartinezNo ratings yet

- Ais10 ch12Document105 pagesAis10 ch12Shella FrankeraNo ratings yet

- Facility Layout Session 2Document28 pagesFacility Layout Session 2Brijesh BaghelNo ratings yet

- OTM Slides1Document24 pagesOTM Slides1Sushuma NallaNo ratings yet

- ͻ New or modified product/service to be offered ͻ Quality to be improved ͻ Competitive priorities have changed ͻ Demand for product/service is changing ͻ Cost/availability of inputs have changedDocument31 pagesͻ New or modified product/service to be offered ͻ Quality to be improved ͻ Competitive priorities have changed ͻ Demand for product/service is changing ͻ Cost/availability of inputs have changedOmid PtokNo ratings yet

- Simple Manufacturing Process:: OM Viva NotesDocument6 pagesSimple Manufacturing Process:: OM Viva NotesMinhans SrivastavaNo ratings yet

- DR Akarte NITIE Perspectives in Manufacturing ManagementDocument18 pagesDR Akarte NITIE Perspectives in Manufacturing ManagementDIPAK VINAYAK SHIRBHATENo ratings yet

- Industrial AutomationDocument21 pagesIndustrial Automationsanju245100% (1)

- Introduction To Production and Operations Management: Module 1Document17 pagesIntroduction To Production and Operations Management: Module 1KabeerBharaliNo ratings yet

- Industrial Automation: David O'Sullivan WWW - Owl.ieDocument33 pagesIndustrial Automation: David O'Sullivan WWW - Owl.ieruby_evangelinNo ratings yet

- IE305 CH 2 Production SystemsDocument31 pagesIE305 CH 2 Production Systemsmuhendis_8900No ratings yet

- Erp & MRPDocument44 pagesErp & MRPsobithkcNo ratings yet

- Prod Sys For Focused FactoryDocument30 pagesProd Sys For Focused FactorymandydamleNo ratings yet

- 5 ProcessesDocument56 pages5 Processeshayder nuredinNo ratings yet

- Practical Enterprise Modelling: ISA 88 and ISA 95 StandardsDocument59 pagesPractical Enterprise Modelling: ISA 88 and ISA 95 StandardsAngie GordiansNo ratings yet

- Manufacturing AND Warehousing: Unit 2Document41 pagesManufacturing AND Warehousing: Unit 2D SimmiNo ratings yet

- Just in Time System (2) 10000Document24 pagesJust in Time System (2) 10000John GriffiesNo ratings yet

- Lean Manufacturing Presentation 1Document20 pagesLean Manufacturing Presentation 1AlangAki HanafiahNo ratings yet

- Glossary of Lean Manufacturing TermscDocument13 pagesGlossary of Lean Manufacturing TermscRatjaga TaraNo ratings yet

- Sap Infosys FICODocument145 pagesSap Infosys FICOAdminnivas83% (6)

- Premiere Manufacturing Case Study, Step 1: Background: The Present SituationDocument161 pagesPremiere Manufacturing Case Study, Step 1: Background: The Present Situationaqsa imranNo ratings yet

- Introduction To Operation Management: Club Kaizen, IIM IndoreDocument32 pagesIntroduction To Operation Management: Club Kaizen, IIM Indore9755348070No ratings yet

- Study On Lean Manufacturing Process in Garments ProductionDocument4 pagesStudy On Lean Manufacturing Process in Garments ProductionAnaliza IcsNo ratings yet

- OPC - LectureDocument70 pagesOPC - LectureJoju JohnyNo ratings yet

- 1-Process SelectionDocument43 pages1-Process SelectionTejas BhavsarNo ratings yet

- 17PME328E: Process Planning and Cost EstimationDocument48 pages17PME328E: Process Planning and Cost EstimationDeepak MisraNo ratings yet

- Industrial PlanningDocument5 pagesIndustrial PlanningAizen SousukeNo ratings yet

- mrp2-3 FinalDocument33 pagesmrp2-3 FinalMatthew Smith50% (2)

- Warehouse DesignDocument37 pagesWarehouse Designedgeban100% (2)

- Manufacturing Planning and ControlDocument17 pagesManufacturing Planning and Controlvipulruiwale100% (4)

- Chap006 - Process Selection & Facility LayoutDocument25 pagesChap006 - Process Selection & Facility LayoutTanmay SharmaNo ratings yet

- Pom 1Document26 pagesPom 1Die8sight SiegeNo ratings yet

- Computer Aided Production Planning and Control JomyDocument32 pagesComputer Aided Production Planning and Control JomyJo100% (2)

- Manufacturing: By: Arsalan NajmiDocument35 pagesManufacturing: By: Arsalan NajmiMuhammad Naveed IkramNo ratings yet

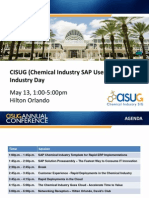

- Chemical Industry TemplateDocument25 pagesChemical Industry Templatedoriangray661No ratings yet

- 6 Sigma Project Selection GuidelinesDocument7 pages6 Sigma Project Selection Guidelineschteo1976No ratings yet

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesFrom EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesRating: 4.5 out of 5 stars4.5/5 (3)

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Liebert - CRV Series Air Conditioner User Manual: V1.4 Revision Date May 28, 2012 BOM 31011886Document79 pagesLiebert - CRV Series Air Conditioner User Manual: V1.4 Revision Date May 28, 2012 BOM 31011886Dam Ngoc KienNo ratings yet

- Introduction To The Multi MeterDocument3 pagesIntroduction To The Multi MeterFaiz FauziNo ratings yet

- Pneumatic Circuit DesignDocument17 pagesPneumatic Circuit DesignSriram SastryNo ratings yet

- Rajasthan Cooperative Recruitment Board: On-Line Examination - Recruitment of Manager & Sr. ManagerDocument7 pagesRajasthan Cooperative Recruitment Board: On-Line Examination - Recruitment of Manager & Sr. ManagerHardik MehraNo ratings yet

- 語音學及語音聲學實作考試2021 Praat final examDocument6 pages語音學及語音聲學實作考試2021 Praat final examJingnaNo ratings yet

- CH 02Document104 pagesCH 02Tabish NomanNo ratings yet

- Commissioning Methodology For Boiler-1Document17 pagesCommissioning Methodology For Boiler-1Subhankar ChaudhuriNo ratings yet

- Student Affairs ResumeDocument6 pagesStudent Affairs Resumeusuoezegf100% (1)

- Porferio Marcos JR.: The Ecology of Public AdministrationDocument16 pagesPorferio Marcos JR.: The Ecology of Public AdministrationsunshineNo ratings yet

- 01 Introduction KMDocument15 pages01 Introduction KMDiyana Sri WahyuNo ratings yet

- Bab 1-5 The Use Textless To Narrative TextDocument51 pagesBab 1-5 The Use Textless To Narrative TextRestu MiasariNo ratings yet

- List of Instrument Available at Wagoora Sub-StationDocument2 pagesList of Instrument Available at Wagoora Sub-StationBilal AhmadNo ratings yet

- Extra Practice 2Document3 pagesExtra Practice 2alberto MoralesNo ratings yet

- As 4649-1999 Brake Shoe Assemblies and Disc Brake Pad Assemblies - AttachmentDocument7 pagesAs 4649-1999 Brake Shoe Assemblies and Disc Brake Pad Assemblies - AttachmentSAI Global - APACNo ratings yet

- JM holistik,+RIVAI+JournalDocument18 pagesJM holistik,+RIVAI+Journalsawit borneoNo ratings yet

- Ship Collision Risk Assessment For The Singapore StraitDocument7 pagesShip Collision Risk Assessment For The Singapore StraitImam FirdausNo ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- Electrical Machines DC MotorDocument5 pagesElectrical Machines DC MotorKitkay NivramNo ratings yet

- Bomba de Agua SubaruDocument2 pagesBomba de Agua Subarurodrigo dubonNo ratings yet

- Asme11 Division1 PDFDocument528 pagesAsme11 Division1 PDFABDIELNo ratings yet

- Microsoft SQL Server 2005 Integration Services Step by StepDocument4 pagesMicrosoft SQL Server 2005 Integration Services Step by StepShamaprasad C GNo ratings yet

- Power Tour Electric GuitarDocument12 pagesPower Tour Electric GuitarOmar SánchezNo ratings yet

- LogDocument6 pagesLognadiafirdiana1973No ratings yet

- Concretemixdesign 150329082925 Conversion Gate01Document167 pagesConcretemixdesign 150329082925 Conversion Gate01PARASASRINIVASNo ratings yet

- Basic Macroeconomics Module Part 2Document206 pagesBasic Macroeconomics Module Part 2Ikrima ibn abdisaNo ratings yet

- Theory of Structures 2017 2018Document103 pagesTheory of Structures 2017 2018aula100% (3)

- Emotion Focused CopingDocument8 pagesEmotion Focused CopingMahrukh KhalidNo ratings yet

- Freshman Survival Guide 2013Document28 pagesFreshman Survival Guide 2013The TechniqueNo ratings yet

Indr 372 Production Planning and Control: Course Topics

Indr 372 Production Planning and Control: Course Topics

Uploaded by

Öztürk SaraçoğluOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indr 372 Production Planning and Control: Course Topics

Indr 372 Production Planning and Control: Course Topics

Uploaded by

Öztürk SaraçoğluCopyright:

Available Formats

1

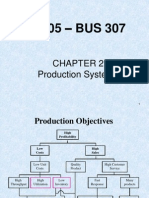

Indr 372

Production Planning and

Control

Chapter 1

Introduction

1

Course topics

Introduction

Forecasting Forecasting

Aggregate Production Planning

Inventory Management

Material Requirements Planning

JIT Production

2

Supply Chain Management

Quality Control and Management

2

Some tools to remember

Forecasting statistics, regression

Inventory management probabilistic models Inventory management probabilistic models

Aggregate production planning linear

optimization

3

Introduction

Planning and organizing production in order to

minimize the operational costs while satisfying

customer service objectives

4

3

Introduction

Customer service

objectives objectives

Delivery times

Service (i.e. fill rate)

levels

Major cost components

Raw material purchasing

5

costs

Production costs

Inventory costs

Why do inventory management and

production planning matter?

Operating Profit = Revenue Operating Expenses

Better inventory management

-> more sales

-> increased revenue

Improved production planning

-> reduced operating expenses

6

> reduced operating expenses

4

A hierarchy of planning problems

Horizon Decisions Examples of decisions

D i

l t

- Facility location

- Production line design

Design

long term

Production line design

- Distribution network design

- Warehouse design

Aggregate Production

Planning

medium term

- Allocation of production between factories

- Planning anticipation inventories

- Planning overtimes, extra shifts

- Subcontracting decisions

- Production order release

7

Material Flow Control

short term

- Production order release

- Replenishment orders

- Planning deliveries

Scheduling Very short term

- Scheduling a job-shop

- Allocation of jobs to machines

- Routing of deliveries

A framework for production

planning

Different environments

Job shops highly customized products Job shops highly customized products

Flow shops less customization

Assembly lines little customization + automation

Process typically continuous flow (chemicals,

drugs, petroleum)

8

5

The Product Life-Cycle Curve

9

Process life cycle

Job shop, low-volume varied

Early

Job shop, low volume varied

mix

stage

Automation starts, volume

increases, unit production costs

decline with learning

Middle

stage

10

Automated, continuous flow

Mature

stage

6

The Process Life Cycle

and the Experience Curve

11

The product-process matrix

Hayes and Wheelright, 1979

Few of each;

custom

Low volume,

many

products

High volume,

several

major

Very high

volume,

commodity

Product

mix

Process

pattern products major

products

commodity

Job shop Aerospace

Batch flow Machine

tools

Worker paced

line flow

Electrical and

electronics

Machine Automobile

p

12

Machine

paced line

flow

Automobile

Continuous,

automated

rigid flow

Paper, oil,

steel

You might also like

- Process Selection and Facility LayoutDocument59 pagesProcess Selection and Facility LayoutKhietNo ratings yet

- Introduction To The Production Planning and Inventory ControlDocument80 pagesIntroduction To The Production Planning and Inventory ControlAngelina WattssNo ratings yet

- JIT PhylosophyDocument23 pagesJIT PhylosophyFouzan SoniwalaNo ratings yet

- Production & Operation ManagementDocument81 pagesProduction & Operation Managementpura_malliNo ratings yet

- Unit III - Prod. Mgt.Document60 pagesUnit III - Prod. Mgt.coxshulerNo ratings yet

- 0生产计划与控制Document1,051 pages0生产计划与控制Keity QuirinoNo ratings yet

- Facility PlanningDocument171 pagesFacility Planninganon_681273463No ratings yet

- Manufacturing Resource Planning M&IS 34064 Section 001 David F. Bolton, CFPIM, C.P.M. Materials Manager, Rotek IncDocument42 pagesManufacturing Resource Planning M&IS 34064 Section 001 David F. Bolton, CFPIM, C.P.M. Materials Manager, Rotek Inceternal_rhymes6972No ratings yet

- Questionnaire: GS1 WebsiteDocument6 pagesQuestionnaire: GS1 WebsiteSOHEL BANGINo ratings yet

- Plant/Facility LayoutDocument6 pagesPlant/Facility Layoutsourav736eeNo ratings yet

- Operations Management - Session 4 and 5 Chap 3.prof. Furquan 4KtNz4YsKiDocument43 pagesOperations Management - Session 4 and 5 Chap 3.prof. Furquan 4KtNz4YsKiNABARUN MAJUMDARNo ratings yet

- Chap 004Document34 pagesChap 004Mohammed MnhajuddinNo ratings yet

- PPT8-Production and Operations ManagementDocument33 pagesPPT8-Production and Operations ManagementSofyyNo ratings yet

- The Production System: - DefinitionDocument82 pagesThe Production System: - DefinitionLekha DaveNo ratings yet

- Welcome: Consumed at EaseDocument42 pagesWelcome: Consumed at Easekabhaskar2130No ratings yet

- Operations Management: Process Strategies and Layout StrategiesDocument74 pagesOperations Management: Process Strategies and Layout StrategiesAshokNo ratings yet

- Chapter 1 Introduction To POM PDFDocument19 pagesChapter 1 Introduction To POM PDFakankaroraNo ratings yet

- Process Strategy PPT at BEC DOMSDocument68 pagesProcess Strategy PPT at BEC DOMSBabasab Patil (Karrisatte)100% (1)

- Convertion Cycle: Amador, Jeric Ferreras, Christine Lasalita, Kyra Danielle Panganiban, Christine Joy Tolentino, AldrenDocument62 pagesConvertion Cycle: Amador, Jeric Ferreras, Christine Lasalita, Kyra Danielle Panganiban, Christine Joy Tolentino, AldrenChristine Joy PanganibanNo ratings yet

- Conversion Cycle Context-Level Data Flow Diagram-Continuous Processing Make-To-Order Processing - Batch ProcessingDocument4 pagesConversion Cycle Context-Level Data Flow Diagram-Continuous Processing Make-To-Order Processing - Batch ProcessingBrigit MartinezNo ratings yet

- Ais10 ch12Document105 pagesAis10 ch12Shella FrankeraNo ratings yet

- Facility Layout Session 2Document28 pagesFacility Layout Session 2Brijesh BaghelNo ratings yet

- OTM Slides1Document24 pagesOTM Slides1Sushuma NallaNo ratings yet

- ͻ New or modified product/service to be offered ͻ Quality to be improved ͻ Competitive priorities have changed ͻ Demand for product/service is changing ͻ Cost/availability of inputs have changedDocument31 pagesͻ New or modified product/service to be offered ͻ Quality to be improved ͻ Competitive priorities have changed ͻ Demand for product/service is changing ͻ Cost/availability of inputs have changedOmid PtokNo ratings yet

- Simple Manufacturing Process:: OM Viva NotesDocument6 pagesSimple Manufacturing Process:: OM Viva NotesMinhans SrivastavaNo ratings yet

- DR Akarte NITIE Perspectives in Manufacturing ManagementDocument18 pagesDR Akarte NITIE Perspectives in Manufacturing ManagementDIPAK VINAYAK SHIRBHATENo ratings yet

- Industrial AutomationDocument21 pagesIndustrial Automationsanju245100% (1)

- Introduction To Production and Operations Management: Module 1Document17 pagesIntroduction To Production and Operations Management: Module 1KabeerBharaliNo ratings yet

- Industrial Automation: David O'Sullivan WWW - Owl.ieDocument33 pagesIndustrial Automation: David O'Sullivan WWW - Owl.ieruby_evangelinNo ratings yet

- IE305 CH 2 Production SystemsDocument31 pagesIE305 CH 2 Production Systemsmuhendis_8900No ratings yet

- Erp & MRPDocument44 pagesErp & MRPsobithkcNo ratings yet

- Prod Sys For Focused FactoryDocument30 pagesProd Sys For Focused FactorymandydamleNo ratings yet

- 5 ProcessesDocument56 pages5 Processeshayder nuredinNo ratings yet

- Practical Enterprise Modelling: ISA 88 and ISA 95 StandardsDocument59 pagesPractical Enterprise Modelling: ISA 88 and ISA 95 StandardsAngie GordiansNo ratings yet

- Manufacturing AND Warehousing: Unit 2Document41 pagesManufacturing AND Warehousing: Unit 2D SimmiNo ratings yet

- Just in Time System (2) 10000Document24 pagesJust in Time System (2) 10000John GriffiesNo ratings yet

- Lean Manufacturing Presentation 1Document20 pagesLean Manufacturing Presentation 1AlangAki HanafiahNo ratings yet

- Glossary of Lean Manufacturing TermscDocument13 pagesGlossary of Lean Manufacturing TermscRatjaga TaraNo ratings yet

- Sap Infosys FICODocument145 pagesSap Infosys FICOAdminnivas83% (6)

- Premiere Manufacturing Case Study, Step 1: Background: The Present SituationDocument161 pagesPremiere Manufacturing Case Study, Step 1: Background: The Present Situationaqsa imranNo ratings yet

- Introduction To Operation Management: Club Kaizen, IIM IndoreDocument32 pagesIntroduction To Operation Management: Club Kaizen, IIM Indore9755348070No ratings yet

- Study On Lean Manufacturing Process in Garments ProductionDocument4 pagesStudy On Lean Manufacturing Process in Garments ProductionAnaliza IcsNo ratings yet

- OPC - LectureDocument70 pagesOPC - LectureJoju JohnyNo ratings yet

- 1-Process SelectionDocument43 pages1-Process SelectionTejas BhavsarNo ratings yet

- 17PME328E: Process Planning and Cost EstimationDocument48 pages17PME328E: Process Planning and Cost EstimationDeepak MisraNo ratings yet

- Industrial PlanningDocument5 pagesIndustrial PlanningAizen SousukeNo ratings yet

- mrp2-3 FinalDocument33 pagesmrp2-3 FinalMatthew Smith50% (2)

- Warehouse DesignDocument37 pagesWarehouse Designedgeban100% (2)

- Manufacturing Planning and ControlDocument17 pagesManufacturing Planning and Controlvipulruiwale100% (4)

- Chap006 - Process Selection & Facility LayoutDocument25 pagesChap006 - Process Selection & Facility LayoutTanmay SharmaNo ratings yet

- Pom 1Document26 pagesPom 1Die8sight SiegeNo ratings yet

- Computer Aided Production Planning and Control JomyDocument32 pagesComputer Aided Production Planning and Control JomyJo100% (2)

- Manufacturing: By: Arsalan NajmiDocument35 pagesManufacturing: By: Arsalan NajmiMuhammad Naveed IkramNo ratings yet

- Chemical Industry TemplateDocument25 pagesChemical Industry Templatedoriangray661No ratings yet

- 6 Sigma Project Selection GuidelinesDocument7 pages6 Sigma Project Selection Guidelineschteo1976No ratings yet

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesFrom EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesRating: 4.5 out of 5 stars4.5/5 (3)

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Liebert - CRV Series Air Conditioner User Manual: V1.4 Revision Date May 28, 2012 BOM 31011886Document79 pagesLiebert - CRV Series Air Conditioner User Manual: V1.4 Revision Date May 28, 2012 BOM 31011886Dam Ngoc KienNo ratings yet

- Introduction To The Multi MeterDocument3 pagesIntroduction To The Multi MeterFaiz FauziNo ratings yet

- Pneumatic Circuit DesignDocument17 pagesPneumatic Circuit DesignSriram SastryNo ratings yet

- Rajasthan Cooperative Recruitment Board: On-Line Examination - Recruitment of Manager & Sr. ManagerDocument7 pagesRajasthan Cooperative Recruitment Board: On-Line Examination - Recruitment of Manager & Sr. ManagerHardik MehraNo ratings yet

- 語音學及語音聲學實作考試2021 Praat final examDocument6 pages語音學及語音聲學實作考試2021 Praat final examJingnaNo ratings yet

- CH 02Document104 pagesCH 02Tabish NomanNo ratings yet

- Commissioning Methodology For Boiler-1Document17 pagesCommissioning Methodology For Boiler-1Subhankar ChaudhuriNo ratings yet

- Student Affairs ResumeDocument6 pagesStudent Affairs Resumeusuoezegf100% (1)

- Porferio Marcos JR.: The Ecology of Public AdministrationDocument16 pagesPorferio Marcos JR.: The Ecology of Public AdministrationsunshineNo ratings yet

- 01 Introduction KMDocument15 pages01 Introduction KMDiyana Sri WahyuNo ratings yet

- Bab 1-5 The Use Textless To Narrative TextDocument51 pagesBab 1-5 The Use Textless To Narrative TextRestu MiasariNo ratings yet

- List of Instrument Available at Wagoora Sub-StationDocument2 pagesList of Instrument Available at Wagoora Sub-StationBilal AhmadNo ratings yet

- Extra Practice 2Document3 pagesExtra Practice 2alberto MoralesNo ratings yet

- As 4649-1999 Brake Shoe Assemblies and Disc Brake Pad Assemblies - AttachmentDocument7 pagesAs 4649-1999 Brake Shoe Assemblies and Disc Brake Pad Assemblies - AttachmentSAI Global - APACNo ratings yet

- JM holistik,+RIVAI+JournalDocument18 pagesJM holistik,+RIVAI+Journalsawit borneoNo ratings yet

- Ship Collision Risk Assessment For The Singapore StraitDocument7 pagesShip Collision Risk Assessment For The Singapore StraitImam FirdausNo ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- Electrical Machines DC MotorDocument5 pagesElectrical Machines DC MotorKitkay NivramNo ratings yet

- Bomba de Agua SubaruDocument2 pagesBomba de Agua Subarurodrigo dubonNo ratings yet

- Asme11 Division1 PDFDocument528 pagesAsme11 Division1 PDFABDIELNo ratings yet

- Microsoft SQL Server 2005 Integration Services Step by StepDocument4 pagesMicrosoft SQL Server 2005 Integration Services Step by StepShamaprasad C GNo ratings yet

- Power Tour Electric GuitarDocument12 pagesPower Tour Electric GuitarOmar SánchezNo ratings yet

- LogDocument6 pagesLognadiafirdiana1973No ratings yet

- Concretemixdesign 150329082925 Conversion Gate01Document167 pagesConcretemixdesign 150329082925 Conversion Gate01PARASASRINIVASNo ratings yet

- Basic Macroeconomics Module Part 2Document206 pagesBasic Macroeconomics Module Part 2Ikrima ibn abdisaNo ratings yet

- Theory of Structures 2017 2018Document103 pagesTheory of Structures 2017 2018aula100% (3)

- Emotion Focused CopingDocument8 pagesEmotion Focused CopingMahrukh KhalidNo ratings yet

- Freshman Survival Guide 2013Document28 pagesFreshman Survival Guide 2013The TechniqueNo ratings yet