Professional Documents

Culture Documents

Fabrication Procedure Flow

Fabrication Procedure Flow

Uploaded by

trikjohOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication Procedure Flow

Fabrication Procedure Flow

Uploaded by

trikjohCopyright:

Available Formats

Number: MOP 002

Revision: 042110

Date: April 21, 2010

Page 1 of 3

QUALITY MANAGEMENT SYSTEM DOCUMENT

Approved By: _________________________________________________Date: ___________________

Controlled Copy, Do Not Duplicate

TITLE: Fabrication Procedure

1.0 PURPOSE

The Purpose of this procedure is to control the fabrication processes. This procedure provides for the

communication of customer requirements to the shop, and inspection of product to the customer

requirements.

2.0 APPLICABLE DOCUMENTS

FORM-015 Fabrication Traveler

QAP-003 Control of Nonconforming Product

Rejected Tag

Customer Drawing

3.0 RESPONSIBILITIES

It is the responsibility of the shop supervisor to maintain this procedure. The Shop supervisor is

responsible to assign and train inspectors. It is the responsibility of the welder to fabricate the part to

the customer drawing and to follow this procedure and not move on to another step without inspection.

The inspector must inspect the parts to the customer drawing.

4.0 PROCEDURE

4.1 The fabrication shop is given a Job Pack to fabricate a product.

4.2 The Shop Lead man looks at the drawings, bills of material, and cut sheets to verify that there is

adequate information to fabricate the part.

4.3 The shop lead man gets the materials from the storage area and verifies that they are correct to

the BOM and Cut sheet requirements and signs the fabrication traveler (FORM-015).

4.4 The shop lead man gives the materials and job pack to a welder to fabricate the parts to the

drawings. The welder completes the layout.

4.5 The shop supervisor or lead man inspects the layout of the part to the drawing and signs the

fabrication traveler (FORM-015).

4.6 The welder cuts the material to match the drawing. The welder or cuts or drills holes in the

material to match the drawing.

Number: MOP 002

Revision: 042110

Date: April 21, 2010

Page 2 of 3

QUALITY MANAGEMENT SYSTEM DOCUMENT

Approved By: _________________________________________________Date: ___________________

Controlled Copy, Do Not Duplicate

4.7 The welder fits up the parts as described on the drawing. If the welder does not understand the

drawing, the welder is to ask the supervisor. If the drawing is still unclear, the QA Manager or

Plant Manager is contacted to resolve the question with the customer in accordance with QAP-

003.

4.8 The shop supervisor or lead man inspects the fit-up of the part to the drawing and signs the

fabrication traveler (FORM-015).

4.9 The weld is completed by the welder.

4.10 The shop supervisor or lead man inspects the weld of the part to the drawing and signs the

fabrication traveler (FORM-015).

4.11 If necessary steps 4.7 to 4.10 are repeated until the part is completed.

4.12 When completed the part and job pack are moved to paint or to Final Inspection.

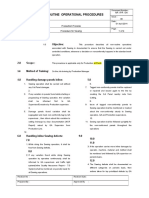

5.0 FLOWCHART

Number: MOP 002

Revision: 042110

Date: April 21, 2010

Page 3 of 3

QUALITY MANAGEMENT SYSTEM DOCUMENT

Approved By: _________________________________________________Date: ___________________

Controlled Copy, Do Not Duplicate

6.0 REVISION HISTORY

042110 Initial Trial Release.

You might also like

- Planning of Product Realization ExampleDocument9 pagesPlanning of Product Realization Examplemdjeckel100% (1)

- Updated Layered Welding Audit ChecklistDocument1 pageUpdated Layered Welding Audit Checklistcarey stewart100% (1)

- D-1 Incoming Material ReceivingDocument3 pagesD-1 Incoming Material ReceivingAlonso Diaz0% (1)

- Quantum Salt Water Boil With Crosshatch TestsDocument9 pagesQuantum Salt Water Boil With Crosshatch TeststrikjohNo ratings yet

- Asme QCMDocument84 pagesAsme QCMCaptainTonies100% (2)

- Work Instruction SampleDocument3 pagesWork Instruction SampleSundarapandiyan Sundaramoorthy89% (9)

- Gap Analysis Template 12Document2 pagesGap Analysis Template 12trikjoh0% (1)

- Quality Assurance ManualDocument51 pagesQuality Assurance ManualMadhan RamamoorthyNo ratings yet

- Elevators Quality Assurance Manual With Organisation ChartDocument11 pagesElevators Quality Assurance Manual With Organisation ChartVijay Singh100% (1)

- QMS 065 SampleDocument6 pagesQMS 065 SamplebaluchakpNo ratings yet

- ProQC ExampleReport ISO13485 Audit PDFDocument28 pagesProQC ExampleReport ISO13485 Audit PDFAlex Ramadhan Sabananyo100% (3)

- New Vendor System Audit Check SheetDocument6 pagesNew Vendor System Audit Check SheetJetesh Devgun71% (7)

- Quality Assurance Manual: MIL-STD-45208ADocument37 pagesQuality Assurance Manual: MIL-STD-45208AJessica JamesNo ratings yet

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailFrom EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailRating: 5 out of 5 stars5/5 (3)

- Non - Halogen Flame RetardantsDocument8 pagesNon - Halogen Flame RetardantsJimmy Wong100% (1)

- Watertight IntegrityDocument16 pagesWatertight IntegrityAnonymous S9ObmiLKV75% (8)

- Fabrication ProcedureDocument3 pagesFabrication ProcedureAndreMarcel100% (1)

- Fabrication ProcedureDocument3 pagesFabrication ProcedureAjay G GopalNo ratings yet

- 7 Steps To Writing A ProcedureDocument4 pages7 Steps To Writing A ProcedureZubair KhanNo ratings yet

- Fabrication Quality Control 2-20-08Document4 pagesFabrication Quality Control 2-20-08Vinoth KumarNo ratings yet

- Standard Operating Procedure For Design & Development DepartmentDocument5 pagesStandard Operating Procedure For Design & Development Departmentfahadfiaz100% (1)

- Control of NC ComponentDocument3 pagesControl of NC Componentdanaka007No ratings yet

- Manufacturing ProcedureDocument3 pagesManufacturing ProcedureAkhilesh KumarNo ratings yet

- QA QC Manual 2008Document86 pagesQA QC Manual 2008netomeller100% (2)

- On Site Assessment TemplateDocument8 pagesOn Site Assessment TemplatewentropremNo ratings yet

- AC7126-1 Rev B 23-AUG-2016Document26 pagesAC7126-1 Rev B 23-AUG-2016unknown1711No ratings yet

- Centinela Flot Column Quality Plan WVendor AuditDocument15 pagesCentinela Flot Column Quality Plan WVendor AuditAndrés RodríguezNo ratings yet

- System Audit RequirementDocument37 pagesSystem Audit Requirementavinashbatra171% (7)

- Qms ManualDocument60 pagesQms ManualMayur RankNo ratings yet

- Production 1.0 Purpose: Work InstructionDocument2 pagesProduction 1.0 Purpose: Work Instructionvikasphopale1No ratings yet

- Cma Cable Supplier Quality ManualDocument26 pagesCma Cable Supplier Quality ManualtimkoidNo ratings yet

- QMS 055 SampleDocument8 pagesQMS 055 Samplebaluchakp100% (1)

- ISO - PurchasingDocument5 pagesISO - PurchasingAlmario SagunNo ratings yet

- General Rework ProcedureDocument1 pageGeneral Rework ProcedureLuke BilisNo ratings yet

- 8 - Product Audit Checklist ASAP 7 11Document10 pages8 - Product Audit Checklist ASAP 7 11Sachin KumbharNo ratings yet

- Updated Quality PlanDocument23 pagesUpdated Quality PlanThi PhamNo ratings yet

- 4.NR SewingDocument4 pages4.NR SewingVivekanandan NarasimmanNo ratings yet

- First Article Inspection 001ADocument21 pagesFirst Article Inspection 001AWalt PrystajNo ratings yet

- Quality ManualDocument19 pagesQuality ManualKung Karona100% (2)

- Quality ControlDocument6 pagesQuality ControlEileen WongNo ratings yet

- Y11 Iso 9001Document7 pagesY11 Iso 9001meeshu1133No ratings yet

- Supplier Quality ManualDocument19 pagesSupplier Quality ManualDurai Murugan100% (2)

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- Works Instruction For Piping Welding InspectionDocument5 pagesWorks Instruction For Piping Welding InspectionAbg SepulNo ratings yet

- IZO Appliances (PVT) LTD: Quality Management System Procedure For System of ProductionDocument7 pagesIZO Appliances (PVT) LTD: Quality Management System Procedure For System of ProductionS M Arif HussainNo ratings yet

- PM - 8.06 Non-Conforming Product ControlDocument3 pagesPM - 8.06 Non-Conforming Product ControlMangBedjoNo ratings yet

- SA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewDocument6 pagesSA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewdwarakababuNo ratings yet

- Procedure For Traffic Light Quality System-LibreDocument8 pagesProcedure For Traffic Light Quality System-LibreAnonymous wA6NGuyklDNo ratings yet

- IQA Learning Session-Customer CommunicationDocument30 pagesIQA Learning Session-Customer CommunicationLyne LerinNo ratings yet

- Engine Repair ILT Participant GuideDocument15 pagesEngine Repair ILT Participant Guidejordan navarroNo ratings yet

- SUF PR 14 Quality AuditingDocument8 pagesSUF PR 14 Quality Auditingscriptd_ozd3nNo ratings yet

- Supplier Evaluation Process BHELDocument63 pagesSupplier Evaluation Process BHELBaalu KathirveluNo ratings yet

- Quality Control SystemsDocument8 pagesQuality Control SystemsCarlos Nombela PalaciosNo ratings yet

- Procedure For ProductionDocument7 pagesProcedure For ProductionTuan Anh100% (1)

- PT Vs SOP 17 Tooling RepairDocument7 pagesPT Vs SOP 17 Tooling RepairRidwanNo ratings yet

- ISO 9000 ChecklistDocument10 pagesISO 9000 ChecklistWaqas AhmadNo ratings yet

- VDA 6.3 Issue 04Document15 pagesVDA 6.3 Issue 04Umit KaramanNo ratings yet

- IATF 16949:2016: Quality Management Systems DocumentationDocument28 pagesIATF 16949:2016: Quality Management Systems DocumentationMariyappanNo ratings yet

- IATF 16949:2016: Quality Management Systems DocumentationDocument10 pagesIATF 16949:2016: Quality Management Systems DocumentationKhaoula RezzoukNo ratings yet

- Gap Analysis Tool: Task To Measure System To Meet Criteria Implementation DateDocument2 pagesGap Analysis Tool: Task To Measure System To Meet Criteria Implementation DatetrikjohNo ratings yet

- Contingency Plan RDocument6 pagesContingency Plan RtrikjohNo ratings yet

- Gap Analysis Template 10Document1 pageGap Analysis Template 10trikjohNo ratings yet

- Gap Analysis Template 37Document2 pagesGap Analysis Template 37trikjohNo ratings yet

- Gap Analysis - Action Plan: Relevant Gaps Action Needed Prioritized Action Responsible PartyDocument2 pagesGap Analysis - Action Plan: Relevant Gaps Action Needed Prioritized Action Responsible PartytrikjohNo ratings yet

- Failed Standards Gaps Current Situation Possible SolutionsDocument2 pagesFailed Standards Gaps Current Situation Possible SolutionstrikjohNo ratings yet

- Gap Analysis-Root Cause of ConflictDocument2 pagesGap Analysis-Root Cause of ConflicttrikjohNo ratings yet

- Christmas Party PrayerDocument1 pageChristmas Party PrayertrikjohNo ratings yet

- Gap Analysis Template TITLEDocument1 pageGap Analysis Template TITLEtrikjohNo ratings yet

- Gap Analysis Template 13Document2 pagesGap Analysis Template 13trikjohNo ratings yet

- Gap Analysis: Competence Name Value 1 2 3 4 5 6 Team Work LearningDocument1 pageGap Analysis: Competence Name Value 1 2 3 4 5 6 Team Work LearningtrikjohNo ratings yet

- Gap Analysis Template 05Document1 pageGap Analysis Template 05trikjohNo ratings yet

- Gap Analysis Template 01Document1 pageGap Analysis Template 01trikjohNo ratings yet

- Automotive QMS Update IATF 16949:2016 September 2016Document121 pagesAutomotive QMS Update IATF 16949:2016 September 2016trikjohNo ratings yet

- Form - Employee Opinion SurveyDocument1 pageForm - Employee Opinion SurveyTrustEmmaNo ratings yet

- Short-Term Loan (STL) HQP-SLF-005: Basic RequirementsDocument1 pageShort-Term Loan (STL) HQP-SLF-005: Basic RequirementstrikjohNo ratings yet

- Rules For Certification 5th EdDocument70 pagesRules For Certification 5th Edtrikjoh100% (1)

- HAC GuideDocument16 pagesHAC GuideARC Electrical Safety ConsultingNo ratings yet

- Servo - Cookbook - MbedDocument6 pagesServo - Cookbook - MbedCảnh ManuNo ratings yet

- Piping & Instrument Diagrams PDFDocument12 pagesPiping & Instrument Diagrams PDFSuresh KumarNo ratings yet

- Flanges and Their Joints IDENTITYDocument3 pagesFlanges and Their Joints IDENTITYSamuel Blandes RwegasiraNo ratings yet

- The Properties of Chopped Basalt Fibre Reinforced Self-CompactingDocument8 pagesThe Properties of Chopped Basalt Fibre Reinforced Self-CompactingEjaz RahimiNo ratings yet

- Cooling Water TreatmentDocument115 pagesCooling Water TreatmentMuhammad Abdullah100% (1)

- 5070 - W1past Paper o LevelDocument20 pages5070 - W1past Paper o LevelRafayNo ratings yet

- TB 03 02 BR5 36 Load SpansDocument28 pagesTB 03 02 BR5 36 Load Spansnumber_25No ratings yet

- Electrical Safety Standards For LV-MV-HV Part-1)Document12 pagesElectrical Safety Standards For LV-MV-HV Part-1)Suresh UmadiNo ratings yet

- Exhibitor List 2015Document5 pagesExhibitor List 2015Ravishankar BKNo ratings yet

- Atr42-400/500 - Structural Repair Manual: Printed in FranceDocument25 pagesAtr42-400/500 - Structural Repair Manual: Printed in FranceJeison GuisaoNo ratings yet

- Solenoid-Driven Metering Pump Gamma/ X: Gamma/ X - The Proven Best-Seller Intelligently ExtendedDocument2 pagesSolenoid-Driven Metering Pump Gamma/ X: Gamma/ X - The Proven Best-Seller Intelligently ExtendedBelalNorNo ratings yet

- Factory Assembled Insulated Sandwich Panels Using Puf: M/s Metecno (India) Pvt. LTDDocument38 pagesFactory Assembled Insulated Sandwich Panels Using Puf: M/s Metecno (India) Pvt. LTDDiya MakanurNo ratings yet

- Bhi Drilling Fluids Cross ReferencesDocument15 pagesBhi Drilling Fluids Cross ReferencesMiguel Apaclla Enriquez100% (1)

- FLAMMABILITYDocument19 pagesFLAMMABILITYnandini kapuNo ratings yet

- TMG PC Strands, Wire & BarDocument10 pagesTMG PC Strands, Wire & BarHenrique Braglia PachecoNo ratings yet

- S-LINE Pipe Suppliers SharjahDocument48 pagesS-LINE Pipe Suppliers SharjahJino VargheseNo ratings yet

- Environmental Test Chamber QuestionnaireDocument4 pagesEnvironmental Test Chamber QuestionnaireTong YeNo ratings yet

- Sight Flow Indicators - JohnsonDocument6 pagesSight Flow Indicators - JohnsonltorrNo ratings yet

- PyrovatexDocument12 pagesPyrovatexahsan888No ratings yet

- De Jager - D - DTech Thesis 2013 FINALDocument247 pagesDe Jager - D - DTech Thesis 2013 FINALbobbymayaaNo ratings yet

- 3132 Datasheet Sensor Magnetico PDFDocument7 pages3132 Datasheet Sensor Magnetico PDFSimNo ratings yet

- Cu-XLPE-SWA - PVC 3X50 mm2Document1 pageCu-XLPE-SWA - PVC 3X50 mm2Jalal AlbadriNo ratings yet

- Capacitance InductanceDocument68 pagesCapacitance InductanceRonnel MontanezNo ratings yet

- TF100-32C - STD Tube SZ and Variable Dia V-Band CoupDocument16 pagesTF100-32C - STD Tube SZ and Variable Dia V-Band CoupScaricatore92No ratings yet

- 2023 Pharmaceutical Manufacturing Supplychain TrendsDocument11 pages2023 Pharmaceutical Manufacturing Supplychain TrendsfresultaNo ratings yet

- Insulation SpecificationDocument1 pageInsulation SpecificationKittisak SungsanaNo ratings yet

- TheoryDocument3 pagesTheoryAhmad SyamilNo ratings yet