Professional Documents

Culture Documents

GC135 GC160 GC190 GS190: Maintenance Information

GC135 GC160 GC190 GS190: Maintenance Information

Uploaded by

Goran MojsilovicCopyright:

Available Formats

You might also like

- Kawasaki Bayou 300 Service Manual RepairDocument678 pagesKawasaki Bayou 300 Service Manual RepairMac Thon81% (64)

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- 500 Service ManualDocument2 pages500 Service ManualLars Koch100% (2)

- Service Manual 157QMJDocument60 pagesService Manual 157QMJGeert Verfaillie67% (3)

- 14 - H6203 Electrical DiagramsDocument54 pages14 - H6203 Electrical DiagramsRamon MontesNo ratings yet

- Deere - trs22 UserManualDocument23 pagesDeere - trs22 UserManualcimbom1979No ratings yet

- Piaggio X8 125-200 (EN)Document287 pagesPiaggio X8 125-200 (EN)Manualles93% (15)

- Ready Reckoner For Kits - DBUDocument60 pagesReady Reckoner For Kits - DBUkhan khadarNo ratings yet

- Generic Ideo ServicemanualDocument108 pagesGeneric Ideo ServicemanualVinko SaravanjaNo ratings yet

- Gt650r Section 1 General InformationDocument14 pagesGt650r Section 1 General InformationJohn Allen ReihartNo ratings yet

- Manual Taller FCAT MATRIX 50-100 CC (Idioma Ingles)Document115 pagesManual Taller FCAT MATRIX 50-100 CC (Idioma Ingles)CordobessaNo ratings yet

- Piaggio Beverly 500 USADocument383 pagesPiaggio Beverly 500 USAManuallesNo ratings yet

- Motor 2.0 Diesel Journey 2009Document177 pagesMotor 2.0 Diesel Journey 2009Injeletro Diesel100% (1)

- Piaggio Liberty 50 Catalyzed (EN)Document165 pagesPiaggio Liberty 50 Catalyzed (EN)Manualles100% (1)

- Kohler Command CV680 - CV23 Service ManualDocument88 pagesKohler Command CV680 - CV23 Service ManualJames Porter75% (4)

- Twin Splitter Transmission: Service ManualDocument119 pagesTwin Splitter Transmission: Service Manualdieselroarmt875b100% (1)

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- Daelim VJF250 Service ManualDocument288 pagesDaelim VJF250 Service ManualIntyreMC100% (1)

- Trator Case 270 PDFDocument539 pagesTrator Case 270 PDFMarcio Soraia Zopi100% (1)

- Service Manual Generic Xor 125Document96 pagesService Manual Generic Xor 125chicharro88100% (2)

- Yamaha BR250 Bravo Snowmobile Service ManualDocument191 pagesYamaha BR250 Bravo Snowmobile Service ManualSmedlowNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Manual Reparaçao ClioDocument49 pagesManual Reparaçao Clio54adow100% (2)

- Royal Enfield Bullet Workshop Manual PDFDocument110 pagesRoyal Enfield Bullet Workshop Manual PDFaakk7567% (6)

- Ct110 Owners ManualDocument10 pagesCt110 Owners ManualHans van SantenNo ratings yet

- CF250T-5 (V5) Maintenance ManualDocument236 pagesCF250T-5 (V5) Maintenance ManualmoorerhouseNo ratings yet

- Fl-Ti Nr24 Turbolader Psa en WebDocument2 pagesFl-Ti Nr24 Turbolader Psa en Webdublin33No ratings yet

- 2000 Nissan Frontier KA24DE LCDocument16 pages2000 Nissan Frontier KA24DE LCDavid CervantesNo ratings yet

- GX120 GX160 GX200: Maintenance InformationDocument1 pageGX120 GX160 GX200: Maintenance Informationcerimovic0% (1)

- Barossa Sanyang Nca250. - Workshop Manual EngineDocument100 pagesBarossa Sanyang Nca250. - Workshop Manual EngineAlejandro MercadoNo ratings yet

- d8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesDocument5 pagesd8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesJose MontalvoNo ratings yet

- 1ge PDFDocument8 pages1ge PDFJoko SukarionoNo ratings yet

- Fuel System: SectionDocument15 pagesFuel System: SectionRonildo GirardiNo ratings yet

- Mercedes - 560 SL - Wiring Diagram - 1989 - 1989Document1,928 pagesMercedes - 560 SL - Wiring Diagram - 1989 - 1989OudayNo ratings yet

- Piagio 500ccDocument65 pagesPiagio 500ccChucky69No ratings yet

- Hyundai Beta, L4GCDocument140 pagesHyundai Beta, L4GCJesus VelardeNo ratings yet

- Honda Goldwing 1800 Service ManualDocument3 pagesHonda Goldwing 1800 Service ManualTyson14% (7)

- TM 120 MaintenanceDocument24 pagesTM 120 Maintenanceahmedsaid85No ratings yet

- AA02083G Approved GE LubesDocument4 pagesAA02083G Approved GE LubesSebastiao Duarte100% (1)

- FinalDocument3 pagesFinalSutiknoNo ratings yet

- TSBDocument63 pagesTSBDragoș L. I. Teodorescu75% (4)

- 2004 Txtpro Manual enDocument31 pages2004 Txtpro Manual enPrzemek KubiakNo ratings yet

- Warranty Extension CVT Start Clutch JudderDocument8 pagesWarranty Extension CVT Start Clutch JudderDavid ChalkerNo ratings yet

- Service - Service Manual Code 950 - 994 - 653Document30 pagesService - Service Manual Code 950 - 994 - 653Victor UribeNo ratings yet

- Lubrication PDFDocument22 pagesLubrication PDFAndrey GladyshevNo ratings yet

- Engine 3.0 v6Document130 pagesEngine 3.0 v6Wlises GonzalezNo ratings yet

- SD50 Service ManualDocument128 pagesSD50 Service ManualCorey StarlingNo ratings yet

- TP 6101Document2 pagesTP 6101Roberto Sanchez ZapataNo ratings yet

- Uuuuuuuuuuuuuuuuu: General Maintenance InformationDocument36 pagesUuuuuuuuuuuuuuuuu: General Maintenance InformationAdwaith AnikkalNo ratings yet

- Nissan 350Z Z33 2006-2013 Engine Lubrication SystemDocument16 pagesNissan 350Z Z33 2006-2013 Engine Lubrication Systemhoman83No ratings yet

- Lubrication System (2Az-Fe) : On-Vehicle InspectionDocument22 pagesLubrication System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- 07 Preventive Maintenance ProcedureDocument21 pages07 Preventive Maintenance ProcedureHải Lưu Minh100% (1)

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- Oil ConsumptionDocument6 pagesOil ConsumptionprashantNo ratings yet

- Piaggio Beverly 500 I.E. (EN)Document382 pagesPiaggio Beverly 500 I.E. (EN)ManuallesNo ratings yet

- Image Server HandlerDocument12 pagesImage Server Handlerbobcat1810No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- UF300 PanJitInternationalDocument2 pagesUF300 PanJitInternationalGoran MojsilovicNo ratings yet

- 250 Itv ManualDocument62 pages250 Itv ManualGoran MojsilovicNo ratings yet

- Thank You For Your Interest in Our SchematicsDocument2 pagesThank You For Your Interest in Our SchematicsGoran MojsilovicNo ratings yet

- Motherboard Manual Bx2000 1101 eDocument44 pagesMotherboard Manual Bx2000 1101 eGoran MojsilovicNo ratings yet

- Tajne Keopsove Piramide - Dimenzije Velike PiramideDocument1 pageTajne Keopsove Piramide - Dimenzije Velike PiramideGoran MojsilovicNo ratings yet

- Candy Alise870Document19 pagesCandy Alise870Goran MojsilovicNo ratings yet

- Carburetor Repair Kit PDFDocument15 pagesCarburetor Repair Kit PDFGoran MojsilovicNo ratings yet

- NS Seme - KukuruzDocument8 pagesNS Seme - KukuruzGoran MojsilovicNo ratings yet

- Kama Sutra - Anne Hooper's (Photo Book)Document123 pagesKama Sutra - Anne Hooper's (Photo Book)Tony Cakebread83% (6)

- Starter Motors EngDocument21 pagesStarter Motors EngGoran MojsilovicNo ratings yet

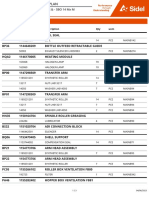

- Sbo 14 MX M sbmxmm110487 Hours 6000Document3 pagesSbo 14 MX M sbmxmm110487 Hours 6000Mohamed GhonemNo ratings yet

- OP All Ride 1008Document20 pagesOP All Ride 1008Sinead1990No ratings yet

- GY6 ModsDocument5 pagesGY6 ModsKevin TagorNo ratings yet

- Kinetic HondaDocument2 pagesKinetic HondaVinod kumarNo ratings yet

- TA40 - 871 Dry BrakeDocument440 pagesTA40 - 871 Dry BrakeAnangtri Wahyudi100% (1)

- Catalogo Token 2018 SpainDocument84 pagesCatalogo Token 2018 SpainRed Blue Racing WorksNo ratings yet

- Brochure Fork Lifts GBDocument2 pagesBrochure Fork Lifts GBaskopmaNo ratings yet

- 20t KATO CR-200Ri PDFDocument8 pages20t KATO CR-200Ri PDFMGNMNo ratings yet

- Komatsu TruckDocument16 pagesKomatsu TruckLuis Ramirez100% (1)

- KMS Lengkap 35+5Document19 pagesKMS Lengkap 35+5Felix AustenNo ratings yet

- Manual de Partes 5400-5500-5600 - 00100-Up - PM - 1062278Document507 pagesManual de Partes 5400-5500-5600 - 00100-Up - PM - 1062278Jose MoraNo ratings yet

- Uputstvo Citroen c4 Picasso 1Document36 pagesUputstvo Citroen c4 Picasso 1Aleksandar SimićNo ratings yet

- Mazda cx5 Bodyshop Manual5 PDFDocument1 pageMazda cx5 Bodyshop Manual5 PDFДаниил РоманюкNo ratings yet

- Competency-Based Learning Material: Automotive / Land TransportDocument38 pagesCompetency-Based Learning Material: Automotive / Land TransportMonique MontalboNo ratings yet

- 920E (Tier 2) - Cummins - 东康Document2 pages920E (Tier 2) - Cummins - 东康Michael Wang Xinbin100% (2)

- Fuses and RelaysDocument32 pagesFuses and RelaysbtmgrupNo ratings yet

- Wheel and Rim Truing - WWW - Parktool - ComDocument5 pagesWheel and Rim Truing - WWW - Parktool - ComJose Luis SabinoNo ratings yet

- Dodge Durango 2002 DN Parts CatalogueDocument20 pagesDodge Durango 2002 DN Parts CatalogueRichard100% (61)

- Dtvs Product Awareness Training PPT - Bsiii, Bsiv & BsviDocument52 pagesDtvs Product Awareness Training PPT - Bsiii, Bsiv & BsviRuhan100% (1)

- Maxxecu Plugin - Engine Specifics Audi 1.8T Me 7.5: Vehicle Enginecode Year Lsu Sensor NoteDocument4 pagesMaxxecu Plugin - Engine Specifics Audi 1.8T Me 7.5: Vehicle Enginecode Year Lsu Sensor NoteMaxuel Antunes100% (1)

- MAZDA32315 I 16 VZ5Document83 pagesMAZDA32315 I 16 VZ5John Snow50% (2)

- PropcalcDocument13 pagesPropcalcJl RuMbOsNo ratings yet

- 2015 BMW X6 X16 Specifications (Australia)Document16 pages2015 BMW X6 X16 Specifications (Australia)JamesNo ratings yet

- 2014 Subaru XV Crosstrek 88570 PDFDocument482 pages2014 Subaru XV Crosstrek 88570 PDFjuan arenasNo ratings yet

- GSX-R600L8: Parts CatalogueDocument115 pagesGSX-R600L8: Parts CatalogueTara ChandNo ratings yet

GC135 GC160 GC190 GS190: Maintenance Information

GC135 GC160 GC190 GS190: Maintenance Information

Uploaded by

Goran MojsilovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GC135 GC160 GC190 GS190: Maintenance Information

GC135 GC160 GC190 GS190: Maintenance Information

Uploaded by

Goran MojsilovicCopyright:

Available Formats

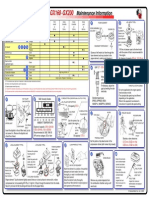

GC135 GC160 GC190 GS190 Maintenance Information

I

C D

K

K

D

M

L

N

E

ALIGNMENT MARKS

Set the piston at top dead center of the

compression stroke (both valves fully closed).

Valve clearance: 0.15 mm 0.04 mm (IN)

0.20 mm 0.04 mm (EX)

To increase valve clearance, screw out.

To decrease valve clearance, screw in.

Do not use excessive force to remove

carbon from the aluminum head.

Do not allow the cleaning brush to contact

the cylinder wall.

FUEL TUBE

Check the fuel lines for deterioration, cracks,

or signs of leakage.

A

UPPER LIMIT

LOWER LIMIT

C

D E F

Standard spark plug: BPR6ES (NGK)

THROTTLE STOP SCREW

CAM

PULLEY

CYLINDER HEAD COVER MATING SURFACE

J

VALVE

ADJUSTING

SCREW

VALVE

ADJUSTING

LOCK NUT

VALVE ADJUSTING WRENCH B

FEELER GAUGE

VALVE

ADJUSTING

LOCK NUT

VALVE ADJUSTING

SCREW

VALVE STEM

CLEANING

BRUSH

Use thick

paper or

equivalent to

protect the

cylinder.

ELECTRIC DRILL

FUEL TANK

Clean the strainer with nonflammable

solvent, and check to be sure the strainer

screen is undamaged.

Wash with solvent

to remove the

sediment, and

dry thoroughly before

installing.

FUEL PUMP

FUEL

TANK TUBE

OIL DRAIN

PLUG BOLT

Tap the element several times on a hard

surface to remove dirt, or blow

compressed air (not exceeding 207 kPa

<2.1 kgf/cm, 30 psi>) through the element

from the clean side that faces the engine.

AIR CLEANER ELEMENT

SIDE ELECTRODE

Measure the plug gap

with a wire-type feeler

gauge.

If necessary, adjust

the gap by bending

the side electrode.

GAP: 0.7 - 0.8 mm

MUFFLER

PROTECTOR

Honda Motor Co., Ltd. 2009

Insert the dipstick in the oil filter neck, but do

not screw it in. Remove the dipstick and

check the oil level.

B

API service category: SF or later

Engine oil capacity: 0.58 (0.61 US qt)

SAE Viscosity Grades

AMBIENT TEMPERATURE

On some applications the engine speed is

fixed and does not idle.

The standard idle speed may be different

depending on the application.

Refer to the equipment manufacturer's

instructions for specific idle speed setting.

H

Standard idle speed:

1,400 150 rpm

SPARK

ARRESTER

(OPTIONAL PART)

SPARK

ARRESTER

SCREEN

WIRE

BRUSH

G

TIMING BELT

Check that the belt is not worn or cracked,

and do not bend or twist the belt.

OIL FILLER CAP/DIPSTICK

OIL DRAIN

PLUG WASHER

CONTAINER

Drain the used engine oil while the engine is

warm. Warm oil drains quickly and completely.

FUEL STRAINER

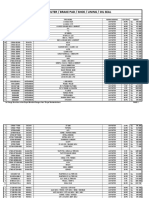

REGULAR SERVICE PERIOD (1)

Perform at every indicated month or operating

hour interval, whichever comes first.

ITEM

Check level

Change (2)

Check

Clean (3)

Replace

Timing belt Check

Check-adjust

Replace

Spark arrester

(applicable types)

Idle speed Check-adjust (5)

Valve clearance Check-adjust (5)

Combustion chamber Clean

Fuel tank and filter Clean (5)

Fuel tube Check

(1) For commercial use, log hours of operation to determine proper maintenance intervals.

(2) Change engine oil every 25 hours when used under heavy load or in high ambient temperature.

(3) Service more frequently when used in dusty areas.

(4) Check that there are no cracks or abnormal wear in the belt, and replace it if necessary.

(5) These items should be serviced by your servicing dealer, unless you have the proper tools and are mechanically proficient. Refer to Honda shop manual for servicing procedures.

(6) In Europe and other countries where the machinery directive 2006/42/EC is enforced, this cleaning should be done by your servicing dealer.

Engine oil

Every

6 months

or

50 hrs.

Every

3 months

or

25 hrs.

Every

year

or

100 hrs.

Each use

First

month

or

5 hrs.

Every

2 years

or

250 hrs.

Air cleaner

After every 250 hrs. (4) (5)

(6)

After every 250 hrs. (5)

Every 2 years (Replace if necessary) (5)

Spark plug

Clean

C

E

F

G

H

K

L

N

B

D

J I

A

M

You might also like

- Kawasaki Bayou 300 Service Manual RepairDocument678 pagesKawasaki Bayou 300 Service Manual RepairMac Thon81% (64)

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- 500 Service ManualDocument2 pages500 Service ManualLars Koch100% (2)

- Service Manual 157QMJDocument60 pagesService Manual 157QMJGeert Verfaillie67% (3)

- 14 - H6203 Electrical DiagramsDocument54 pages14 - H6203 Electrical DiagramsRamon MontesNo ratings yet

- Deere - trs22 UserManualDocument23 pagesDeere - trs22 UserManualcimbom1979No ratings yet

- Piaggio X8 125-200 (EN)Document287 pagesPiaggio X8 125-200 (EN)Manualles93% (15)

- Ready Reckoner For Kits - DBUDocument60 pagesReady Reckoner For Kits - DBUkhan khadarNo ratings yet

- Generic Ideo ServicemanualDocument108 pagesGeneric Ideo ServicemanualVinko SaravanjaNo ratings yet

- Gt650r Section 1 General InformationDocument14 pagesGt650r Section 1 General InformationJohn Allen ReihartNo ratings yet

- Manual Taller FCAT MATRIX 50-100 CC (Idioma Ingles)Document115 pagesManual Taller FCAT MATRIX 50-100 CC (Idioma Ingles)CordobessaNo ratings yet

- Piaggio Beverly 500 USADocument383 pagesPiaggio Beverly 500 USAManuallesNo ratings yet

- Motor 2.0 Diesel Journey 2009Document177 pagesMotor 2.0 Diesel Journey 2009Injeletro Diesel100% (1)

- Piaggio Liberty 50 Catalyzed (EN)Document165 pagesPiaggio Liberty 50 Catalyzed (EN)Manualles100% (1)

- Kohler Command CV680 - CV23 Service ManualDocument88 pagesKohler Command CV680 - CV23 Service ManualJames Porter75% (4)

- Twin Splitter Transmission: Service ManualDocument119 pagesTwin Splitter Transmission: Service Manualdieselroarmt875b100% (1)

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- Daelim VJF250 Service ManualDocument288 pagesDaelim VJF250 Service ManualIntyreMC100% (1)

- Trator Case 270 PDFDocument539 pagesTrator Case 270 PDFMarcio Soraia Zopi100% (1)

- Service Manual Generic Xor 125Document96 pagesService Manual Generic Xor 125chicharro88100% (2)

- Yamaha BR250 Bravo Snowmobile Service ManualDocument191 pagesYamaha BR250 Bravo Snowmobile Service ManualSmedlowNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Manual Reparaçao ClioDocument49 pagesManual Reparaçao Clio54adow100% (2)

- Royal Enfield Bullet Workshop Manual PDFDocument110 pagesRoyal Enfield Bullet Workshop Manual PDFaakk7567% (6)

- Ct110 Owners ManualDocument10 pagesCt110 Owners ManualHans van SantenNo ratings yet

- CF250T-5 (V5) Maintenance ManualDocument236 pagesCF250T-5 (V5) Maintenance ManualmoorerhouseNo ratings yet

- Fl-Ti Nr24 Turbolader Psa en WebDocument2 pagesFl-Ti Nr24 Turbolader Psa en Webdublin33No ratings yet

- 2000 Nissan Frontier KA24DE LCDocument16 pages2000 Nissan Frontier KA24DE LCDavid CervantesNo ratings yet

- GX120 GX160 GX200: Maintenance InformationDocument1 pageGX120 GX160 GX200: Maintenance Informationcerimovic0% (1)

- Barossa Sanyang Nca250. - Workshop Manual EngineDocument100 pagesBarossa Sanyang Nca250. - Workshop Manual EngineAlejandro MercadoNo ratings yet

- d8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesDocument5 pagesd8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesJose MontalvoNo ratings yet

- 1ge PDFDocument8 pages1ge PDFJoko SukarionoNo ratings yet

- Fuel System: SectionDocument15 pagesFuel System: SectionRonildo GirardiNo ratings yet

- Mercedes - 560 SL - Wiring Diagram - 1989 - 1989Document1,928 pagesMercedes - 560 SL - Wiring Diagram - 1989 - 1989OudayNo ratings yet

- Piagio 500ccDocument65 pagesPiagio 500ccChucky69No ratings yet

- Hyundai Beta, L4GCDocument140 pagesHyundai Beta, L4GCJesus VelardeNo ratings yet

- Honda Goldwing 1800 Service ManualDocument3 pagesHonda Goldwing 1800 Service ManualTyson14% (7)

- TM 120 MaintenanceDocument24 pagesTM 120 Maintenanceahmedsaid85No ratings yet

- AA02083G Approved GE LubesDocument4 pagesAA02083G Approved GE LubesSebastiao Duarte100% (1)

- FinalDocument3 pagesFinalSutiknoNo ratings yet

- TSBDocument63 pagesTSBDragoș L. I. Teodorescu75% (4)

- 2004 Txtpro Manual enDocument31 pages2004 Txtpro Manual enPrzemek KubiakNo ratings yet

- Warranty Extension CVT Start Clutch JudderDocument8 pagesWarranty Extension CVT Start Clutch JudderDavid ChalkerNo ratings yet

- Service - Service Manual Code 950 - 994 - 653Document30 pagesService - Service Manual Code 950 - 994 - 653Victor UribeNo ratings yet

- Lubrication PDFDocument22 pagesLubrication PDFAndrey GladyshevNo ratings yet

- Engine 3.0 v6Document130 pagesEngine 3.0 v6Wlises GonzalezNo ratings yet

- SD50 Service ManualDocument128 pagesSD50 Service ManualCorey StarlingNo ratings yet

- TP 6101Document2 pagesTP 6101Roberto Sanchez ZapataNo ratings yet

- Uuuuuuuuuuuuuuuuu: General Maintenance InformationDocument36 pagesUuuuuuuuuuuuuuuuu: General Maintenance InformationAdwaith AnikkalNo ratings yet

- Nissan 350Z Z33 2006-2013 Engine Lubrication SystemDocument16 pagesNissan 350Z Z33 2006-2013 Engine Lubrication Systemhoman83No ratings yet

- Lubrication System (2Az-Fe) : On-Vehicle InspectionDocument22 pagesLubrication System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- 07 Preventive Maintenance ProcedureDocument21 pages07 Preventive Maintenance ProcedureHải Lưu Minh100% (1)

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- Oil ConsumptionDocument6 pagesOil ConsumptionprashantNo ratings yet

- Piaggio Beverly 500 I.E. (EN)Document382 pagesPiaggio Beverly 500 I.E. (EN)ManuallesNo ratings yet

- Image Server HandlerDocument12 pagesImage Server Handlerbobcat1810No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- UF300 PanJitInternationalDocument2 pagesUF300 PanJitInternationalGoran MojsilovicNo ratings yet

- 250 Itv ManualDocument62 pages250 Itv ManualGoran MojsilovicNo ratings yet

- Thank You For Your Interest in Our SchematicsDocument2 pagesThank You For Your Interest in Our SchematicsGoran MojsilovicNo ratings yet

- Motherboard Manual Bx2000 1101 eDocument44 pagesMotherboard Manual Bx2000 1101 eGoran MojsilovicNo ratings yet

- Tajne Keopsove Piramide - Dimenzije Velike PiramideDocument1 pageTajne Keopsove Piramide - Dimenzije Velike PiramideGoran MojsilovicNo ratings yet

- Candy Alise870Document19 pagesCandy Alise870Goran MojsilovicNo ratings yet

- Carburetor Repair Kit PDFDocument15 pagesCarburetor Repair Kit PDFGoran MojsilovicNo ratings yet

- NS Seme - KukuruzDocument8 pagesNS Seme - KukuruzGoran MojsilovicNo ratings yet

- Kama Sutra - Anne Hooper's (Photo Book)Document123 pagesKama Sutra - Anne Hooper's (Photo Book)Tony Cakebread83% (6)

- Starter Motors EngDocument21 pagesStarter Motors EngGoran MojsilovicNo ratings yet

- Sbo 14 MX M sbmxmm110487 Hours 6000Document3 pagesSbo 14 MX M sbmxmm110487 Hours 6000Mohamed GhonemNo ratings yet

- OP All Ride 1008Document20 pagesOP All Ride 1008Sinead1990No ratings yet

- GY6 ModsDocument5 pagesGY6 ModsKevin TagorNo ratings yet

- Kinetic HondaDocument2 pagesKinetic HondaVinod kumarNo ratings yet

- TA40 - 871 Dry BrakeDocument440 pagesTA40 - 871 Dry BrakeAnangtri Wahyudi100% (1)

- Catalogo Token 2018 SpainDocument84 pagesCatalogo Token 2018 SpainRed Blue Racing WorksNo ratings yet

- Brochure Fork Lifts GBDocument2 pagesBrochure Fork Lifts GBaskopmaNo ratings yet

- 20t KATO CR-200Ri PDFDocument8 pages20t KATO CR-200Ri PDFMGNMNo ratings yet

- Komatsu TruckDocument16 pagesKomatsu TruckLuis Ramirez100% (1)

- KMS Lengkap 35+5Document19 pagesKMS Lengkap 35+5Felix AustenNo ratings yet

- Manual de Partes 5400-5500-5600 - 00100-Up - PM - 1062278Document507 pagesManual de Partes 5400-5500-5600 - 00100-Up - PM - 1062278Jose MoraNo ratings yet

- Uputstvo Citroen c4 Picasso 1Document36 pagesUputstvo Citroen c4 Picasso 1Aleksandar SimićNo ratings yet

- Mazda cx5 Bodyshop Manual5 PDFDocument1 pageMazda cx5 Bodyshop Manual5 PDFДаниил РоманюкNo ratings yet

- Competency-Based Learning Material: Automotive / Land TransportDocument38 pagesCompetency-Based Learning Material: Automotive / Land TransportMonique MontalboNo ratings yet

- 920E (Tier 2) - Cummins - 东康Document2 pages920E (Tier 2) - Cummins - 东康Michael Wang Xinbin100% (2)

- Fuses and RelaysDocument32 pagesFuses and RelaysbtmgrupNo ratings yet

- Wheel and Rim Truing - WWW - Parktool - ComDocument5 pagesWheel and Rim Truing - WWW - Parktool - ComJose Luis SabinoNo ratings yet

- Dodge Durango 2002 DN Parts CatalogueDocument20 pagesDodge Durango 2002 DN Parts CatalogueRichard100% (61)

- Dtvs Product Awareness Training PPT - Bsiii, Bsiv & BsviDocument52 pagesDtvs Product Awareness Training PPT - Bsiii, Bsiv & BsviRuhan100% (1)

- Maxxecu Plugin - Engine Specifics Audi 1.8T Me 7.5: Vehicle Enginecode Year Lsu Sensor NoteDocument4 pagesMaxxecu Plugin - Engine Specifics Audi 1.8T Me 7.5: Vehicle Enginecode Year Lsu Sensor NoteMaxuel Antunes100% (1)

- MAZDA32315 I 16 VZ5Document83 pagesMAZDA32315 I 16 VZ5John Snow50% (2)

- PropcalcDocument13 pagesPropcalcJl RuMbOsNo ratings yet

- 2015 BMW X6 X16 Specifications (Australia)Document16 pages2015 BMW X6 X16 Specifications (Australia)JamesNo ratings yet

- 2014 Subaru XV Crosstrek 88570 PDFDocument482 pages2014 Subaru XV Crosstrek 88570 PDFjuan arenasNo ratings yet

- GSX-R600L8: Parts CatalogueDocument115 pagesGSX-R600L8: Parts CatalogueTara ChandNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-1-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)