Professional Documents

Culture Documents

Wing Phase Array

Wing Phase Array

Uploaded by

andyyangyananCopyright:

Available Formats

You might also like

- L211 Series Resonance and TimeFrequency Response of Passive Networks PDFDocument25 pagesL211 Series Resonance and TimeFrequency Response of Passive Networks PDFglenlcy100% (1)

- A318 - A319 - A320 - A321 - NTM - 01-Nov-2022 - DeSC 51-00-00-002 CONF A - Nondestructive Testing MethodsDocument4 pagesA318 - A319 - A320 - A321 - NTM - 01-Nov-2022 - DeSC 51-00-00-002 CONF A - Nondestructive Testing MethodsGladys Reyes RodriguezNo ratings yet

- 00 - C208B - ND (Rev 3) - INTRODUCTIONDocument8 pages00 - C208B - ND (Rev 3) - INTRODUCTIONDoti Tri PrasetioNo ratings yet

- NDT20-00-01 Rev0Document22 pagesNDT20-00-01 Rev0Hung PhanNo ratings yet

- Documentation 1.1. GeneralDocument145 pagesDocumentation 1.1. Generalcoralonso0% (1)

- 128 590001 9 - 05Document244 pages128 590001 9 - 05Rene QueirozNo ratings yet

- 757 Nondestructive Test Manual: BoeingDocument2 pages757 Nondestructive Test Manual: BoeingStephen Rincon GonzalezNo ratings yet

- Corporate Finance - PRACTICE EXAM: (1 Point) Future Value of Annuity FVA 377 006Document4 pagesCorporate Finance - PRACTICE EXAM: (1 Point) Future Value of Annuity FVA 377 006Yuge FanNo ratings yet

- GrgtrhytjyjyDocument2 pagesGrgtrhytjyjyKushanNo ratings yet

- Et ChantsDocument27 pagesEt ChantsAlonsoTezkRodrichSalcedoNo ratings yet

- 208DN00Document168 pages208DN00william abraaoNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument6 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- AC7102.4 Rev DDocument25 pagesAC7102.4 Rev DVijay Yadav100% (1)

- Mil HDBK 337Document345 pagesMil HDBK 337Anonymous omN4DqNo ratings yet

- 04 - C208B - ND (Rev 3) - Part 6 - EDDY CURRENTDocument121 pages04 - C208B - ND (Rev 3) - Part 6 - EDDY CURRENTDoti Tri Prasetio100% (1)

- High Sensitivity Post Emulsifiable - FPI Procedure SheetDocument7 pagesHigh Sensitivity Post Emulsifiable - FPI Procedure SheetrenjithaeroNo ratings yet

- NDE Examination Question PaperDocument6 pagesNDE Examination Question PaperMOhammed PatelNo ratings yet

- Mil-Std-1949a NoticeDocument3 pagesMil-Std-1949a NoticeGökhan ÇiçekNo ratings yet

- Agilent N9310A RF Signal GeneratorN9310-90001Document202 pagesAgilent N9310A RF Signal GeneratorN9310-90001Janaka GamageNo ratings yet

- Dash 8 Classic 49 APU June 2015 BW1 LogoDocument64 pagesDash 8 Classic 49 APU June 2015 BW1 Logomilliewangui157100% (1)

- Fine Defect Detection by Eddy Current Array.: Patrick CabanisDocument33 pagesFine Defect Detection by Eddy Current Array.: Patrick CabanisizmitlimonNo ratings yet

- Ndtcat PDFDocument50 pagesNdtcat PDFeefs1979No ratings yet

- Non-Destructive Test Manual: REVISED MAY 31, 1992Document21 pagesNon-Destructive Test Manual: REVISED MAY 31, 1992anon_852142152No ratings yet

- TB-2100 Operational and Maintenance Manual Rev C OptimiseDocument224 pagesTB-2100 Operational and Maintenance Manual Rev C OptimisearnaudmarielNo ratings yet

- Guide To Penetrant Inspection MaterialsDocument9 pagesGuide To Penetrant Inspection MaterialsNenadNo ratings yet

- YKEPL MPI Procedure For A668 RMDocument4 pagesYKEPL MPI Procedure For A668 RMDeepak HoleNo ratings yet

- 340 Operators ManualDocument119 pages340 Operators Manualcutefrenzy100% (2)

- Inspection Concepts and TechniquesDocument26 pagesInspection Concepts and TechniquesChalidea RamadhinaNo ratings yet

- Omega Flow MweterDocument2 pagesOmega Flow MweterIan G. WalkerNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument58 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás Piratova100% (1)

- Phasec2d Data SheetDocument2 pagesPhasec2d Data SheetMaria DazaNo ratings yet

- 2017 Catalogue GBDocument131 pages2017 Catalogue GBCedric MercadoNo ratings yet

- Magnaflux DN-543 Operation MaterialsDocument35 pagesMagnaflux DN-543 Operation MaterialsMark Evan Salutin100% (2)

- CBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralDocument4 pagesCBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralfallalovaldesNo ratings yet

- NDT - AFT Engine Mount Inspection #2Document5 pagesNDT - AFT Engine Mount Inspection #2David Owen100% (1)

- Api Ut 1Document6 pagesApi Ut 1Ricardo Andres Santamaria Torres100% (1)

- ASTM E1444-E1444M (2021) - Part6Document1 pageASTM E1444-E1444M (2021) - Part6David WongNo ratings yet

- BondMaster1000eplus enDocument2 pagesBondMaster1000eplus enKuKu FunNo ratings yet

- Automated Robotic InspectionDocument6 pagesAutomated Robotic Inspectionprakush01975225403No ratings yet

- Barfield User Manual - 1811H-1811G-101-00165 168 169Document77 pagesBarfield User Manual - 1811H-1811G-101-00165 168 169benjadonnadieuNo ratings yet

- Eddy Current & Ultrassom - Techna NDTDocument48 pagesEddy Current & Ultrassom - Techna NDTBruno BatistaNo ratings yet

- 1 ScopeDocument11 pages1 ScopeMichael SkrableNo ratings yet

- AaaDocument60 pagesAaaNorgjieNo ratings yet

- Eddy Current - USAF - Manual-N-RDocument108 pagesEddy Current - USAF - Manual-N-RShabbir aliNo ratings yet

- E 1135 - 97 RtexmzutotcDocument5 pagesE 1135 - 97 RtexmzutotccarlosNo ratings yet

- An Ultra-High Bypass Ratio Turbofan Engine For The Future PDFDocument40 pagesAn Ultra-High Bypass Ratio Turbofan Engine For The Future PDFFranzAnzuresFroitzheimNo ratings yet

- Equipment CatalogDocument66 pagesEquipment Catalogcristian pedrazaNo ratings yet

- Magnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Document5 pagesMagnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Dinesh Gupta100% (1)

- 607303-664792677redacted T.O. 33B-1-2 (PT Only) PDFDocument52 pages607303-664792677redacted T.O. 33B-1-2 (PT Only) PDFZaid RabaaNo ratings yet

- SAE AMS 5122j-2008Document5 pagesSAE AMS 5122j-2008raulNo ratings yet

- Accessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishDocument3 pagesAccessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishimahidaNo ratings yet

- Turbine Temperature Test SET: User Instruction ManualDocument27 pagesTurbine Temperature Test SET: User Instruction ManualmdhelicoptersNo ratings yet

- Adh-2000 Manual de OpracionDocument48 pagesAdh-2000 Manual de OpracionCarlos MenaNo ratings yet

- To 33B-1-1 01jan2013Document856 pagesTo 33B-1-1 01jan2013izmitlimonNo ratings yet

- Ect EngineDocument63 pagesEct EngineAnonymous gFcnQ4goNo ratings yet

- Non Destructive Testing NDTPDFDocument30 pagesNon Destructive Testing NDTPDFLong BinNo ratings yet

- C1 For UTDocument23 pagesC1 For UTMung Duong XuanNo ratings yet

- BT139394EDocument23 pagesBT139394Ehin wongyai100% (1)

- MOR Training Iss.1 Rev.0 (31 Jul 2020)Document17 pagesMOR Training Iss.1 Rev.0 (31 Jul 2020)Trần Triệu PhongNo ratings yet

- Installation and Rigging Procedures: Advanced Technology Performance and Environmental Improvement Systems For YourDocument33 pagesInstallation and Rigging Procedures: Advanced Technology Performance and Environmental Improvement Systems For YourRene QueirozNo ratings yet

- A570010 PDFDocument5 pagesA570010 PDFworm_stellNo ratings yet

- DLLec5b NotesDocument4 pagesDLLec5b NotesChintan MandalNo ratings yet

- MATH - Q2 - W3 (Autosaved)Document44 pagesMATH - Q2 - W3 (Autosaved)Rose Amor Mercene-LacayNo ratings yet

- Vmanage How Tos 18 4Document261 pagesVmanage How Tos 18 4Genus SumNo ratings yet

- Right Triangle Trig. - Finding Missing Sides and AngleDocument3 pagesRight Triangle Trig. - Finding Missing Sides and AngleAlfredo Mandia IIINo ratings yet

- Project in Industrial ElectronicsDocument50 pagesProject in Industrial ElectronicsShiela100% (1)

- Isothermal Reactor Design: 1. Batch OperationDocument3 pagesIsothermal Reactor Design: 1. Batch Operationنزار الدهاميNo ratings yet

- Lab 2.5.1C: Basic Switch Configuration: Lab. Session: Name: Cityu Id: Group No.: DateDocument14 pagesLab 2.5.1C: Basic Switch Configuration: Lab. Session: Name: Cityu Id: Group No.: DateLawrenceLamNo ratings yet

- AHD-S 201: AHD-S 201 Hydrostatic Level Transmitter For Shipbuilding and OffshoreDocument4 pagesAHD-S 201: AHD-S 201 Hydrostatic Level Transmitter For Shipbuilding and OffshoreElimat EmbarcacionesNo ratings yet

- Chapter 2 Basic GatesDocument22 pagesChapter 2 Basic GatesRoyal Ritesh SharmaNo ratings yet

- Concepts of RecordDocument29 pagesConcepts of RecordCamille PajarilloNo ratings yet

- 06-TL - SS003 - E01 - 0 ZXSDR R8962 L23A Principle and Hardware Structure Training Manual-39Document39 pages06-TL - SS003 - E01 - 0 ZXSDR R8962 L23A Principle and Hardware Structure Training Manual-39a2227 jglNo ratings yet

- Modeling Thermal Expansion in Ansys: 6/24/2017 Alex Grishin, PHDDocument24 pagesModeling Thermal Expansion in Ansys: 6/24/2017 Alex Grishin, PHDAchmad Nur HusainiNo ratings yet

- Ooad Lab ManualDocument29 pagesOoad Lab ManualDevendra BhagyawantNo ratings yet

- C - 2Y - Dilute Solution and Colligative Properties - Assignment 1Document5 pagesC - 2Y - Dilute Solution and Colligative Properties - Assignment 1Phani PadmasriNo ratings yet

- Final 2020 SolutionDocument12 pagesFinal 2020 SolutionShokhrud SafarovNo ratings yet

- BiotechDocument19 pagesBiotechJagadeesh ValishettyNo ratings yet

- Atoll 3.2.0 Administrator ManualDocument496 pagesAtoll 3.2.0 Administrator Manualmbouchra80No ratings yet

- Technical Report - Determination of Benzoic Acid in Soft DrinkDocument18 pagesTechnical Report - Determination of Benzoic Acid in Soft Drinkmohamad ashaziq100% (14)

- Backer Marathon Stock BookletDocument130 pagesBacker Marathon Stock BookletVladimir Illich Pinzon BallenNo ratings yet

- Holiday HW Cs Class 12Document33 pagesHoliday HW Cs Class 12Arohan BuddyNo ratings yet

- SmartWireless Battery Options PDSDocument2 pagesSmartWireless Battery Options PDSAbdul Hakeem MohammedNo ratings yet

- Introduction To Signals and Systems: M. J. Roberts All Rights Reserved. Edited by Dr. Robert AklDocument18 pagesIntroduction To Signals and Systems: M. J. Roberts All Rights Reserved. Edited by Dr. Robert Aklkumarsumit1942No ratings yet

- SIM SAMPLE Distance Between Two PointsDocument14 pagesSIM SAMPLE Distance Between Two PointsDIOSDADO MADRONIONo ratings yet

- IGL 7.2.1 Configuring WildFly ClusteringDocument57 pagesIGL 7.2.1 Configuring WildFly ClusteringVitor Stachetti de FreitasNo ratings yet

- FHS Zoom Venus LightDocument4 pagesFHS Zoom Venus LightHasan AhmedNo ratings yet

- Computerized Portable EMI Drill Pipe Inspection System Dual-FunctionDocument2 pagesComputerized Portable EMI Drill Pipe Inspection System Dual-FunctionYodilson Sanchez100% (1)

- Notes On Piston Rod BucklingDocument1 pageNotes On Piston Rod Bucklingmunees ckNo ratings yet

- How To Use RMAN To Check For Logical & Physical Database CorruptionDocument4 pagesHow To Use RMAN To Check For Logical & Physical Database Corruptionalok_mishra4533No ratings yet

Wing Phase Array

Wing Phase Array

Uploaded by

andyyangyananOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wing Phase Array

Wing Phase Array

Uploaded by

andyyangyananCopyright:

Available Formats

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

Procedures

** On A/C ALL

Task 57-29-07-270-801-A-01

Inspection of Upper Wing Skin between Trailing Edge and the Forward Fastener Row of the Rear and False Rear Spar

1. Task Supporting Data

A. Area of Applicability

Wing Top Skin panel Trailing Edge in the following areas:

- Area A (See FIGURE 57-29-07-991-001-A, Sheet 1)

Between the Trailing edge and the forward fastener row of the Rear Spar in Rib Bay 3-4 and Rib Bays

9-10 thru 26-27

- Area B (See FIGURE 57-29-07-991-001-A, Sheet 2)

Between the Trailing edge and the forward fastener row of the False Rear Spar

- Area C (See FIGURE 57-29-07-991-001-A, Sheet 3)

Between the forward fastener row and aft fastener row of the Rear Spar in Rib Bays 4-5 and 5-6.

B. Description of Possible Damage

Corrosion, that initiates at the edge of the Wing Top Skin and/or around the Rear Spar bolting, which

penetrates the lower surface 10% of the material thickness with a 10 mm (0.394 in) diameter.

C. Reason for the Job

ISB A320-57-1154

ISB A320-57-1155

D. Job Set-Up Information

(1) Tooling :

REFERENCE DESIGNATION

99D57204164000 REFERENCE BLOCK

AWP05-64-08-050 PROBE

OMNIPPA16128 ULTRASONIC EQUIPMENT OMNISCAN MX PAUT16-128/U8100029

(2) References :

SRM 51-75-11PB001

SRM 57-21-11PB001

ISB A320-57-1154

ISB A320-57-1155

FIGURE 57-29-07-991-001-A - Inspection Area A and Possible Damage

FIGURE 57-29-07-991-002-A - Phased Array Rapid Scan AWP05-64-08-050

FIGURE 57-29-07-991-003-A - Reference Block 99D57204164000

FIGURE 57-29-07-991-004-A - Inspection Area A Scan Paths

FIGURE 57-29-07-991-005-A - Inspection Area B Scan Paths

FIGURE 57-29-07-991-006-A - Inspection Area C Scan Paths

FIGURE 57-29-07-991-007-A - Screen Display Gate Locations

FIGURE 57-29-07-991-008-A - Calibration Screen Display for A-Scan, C-Scan A% (Amplitude Scan)

and C-Scan A-I (Thickness Scan)

FIGURE 57-29-07-991-009-A - Typical Tapered Skin Display Screen

FIGURE 57-29-07-991-010-A - Typical Skin Pocket Display Screen - Rib Bay 19-20 and 20-21

FIGURE 57-29-07-991-011-A - Examples of Signal Loss caused by Skin Pockets, Tapered Skins and

Steep Ramped Skin Areas

FIGURE 57-29-07-991-012-A - Typical Skin Corrosion Display Screen

Page 1

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

2. Procedure

Subtask 57-29-07-271-001-A

A. Preparation for Inspection

(1) Any paint layer on the scan surfaces need not be removed provided it is in good condition with no

bubbles or flakes. If there is any doubt about the condition of a paint layer in the scan areas, the paint

layer (excluding primer) must be removed using an approved method. (See SRM 51-75-11PB001)

(2) Make sure that all decals or other adhered substances are removed from the inspection area.

(3) Make sure that the inspection area is free from any visible damage or discontinuities.

(4) Use an approved marker to mark the centre line of Wing Ribs and Rear Spar.

(5) Identify the interface of Wing Ribs and Rear Spar to allow Rib Bay identification.

(6) Inspection Area A. (See FIGURE 57-29-07-991-004-A)

(a) Identify the Rib Bay to be inspected.

(b) Locate the first row of fasteners forward of the Rear Spar interface and identify the first and last

fastener in the row.

(c) Measure 20 mm (0.787 in) from the forward edge of the first fastener head of the fastener row

and mark the position with an approved marker.

(d) Measure 20 mm (0.787 in) from the forward edge of the last fastener head of the fastener row

and mark the position with an approved marker.

(e) Using a straight edge and an approved marker, draw a line between the marked positions Rib to

Rib.

(f) Measure 40 mm (1.575 in) scan pitch intervals aft from the marked line in LIST STRUCTURE

towards trailing edge of the skin. Using an approved marker mark the remaining scan paths.

Make sure that the final scan path overlaps the trailing skin edge.

(g) Repeat steps LIST STRUCTURE thru or LIST STRUCTURE for each Rib Bay to be inspected

within Area A.

(7) Inspection Area B. (See FIGURE 57-29-07-991-005-A)

(a) Identify the False Rear Spar.

(b) Locate the first row of fasteners forward of the False Rear Spar and identify the first and last

fastener in the row.

(c) Measure 20 mm (0.787 in) from the forward edge of the first fastener head of the fastener row

and mark the position with an approved marker.

(d) Measure 20 mm (0.787 in) from the forward edge of the last fastener head of the fastener row

and mark the position with an approved marker.

(e) Using a straight edge and an approved marker, draw a line between the marked positions.

(f) Measure 40 mm (1.575 in) scan pitch intervals aft from the marked line in LIST STRUCTURE to

the trailing edge of the skin. Using an approved marker mark the remaining scan paths. Make

sure that the final scan path overlaps the trailing skin edge.

(g) Repeat steps LIST STRUCTURE thru or LIST STRUCTURE for the complete False Rear Spar

interface.

(8) Identify Inspection Area C. (See FIGURE 57-29-07-991-006-A)

(a) Identify the Rib Bay to be inspected.

Page 2

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

(b) Locate the first row of fasteners forward of the Rear Spar interface and identify the first and last

fastener in the row.

(c) Measure 20 mm (0.787 in) from the forward edge of the first fastener head of the fastener row

and mark the position with an approved marker.

(d) Measure 20 mm (0.787 in) from the forward edge of the last fastener head of the fastener row

and mark the position with an approved marker.

(e) Using a straight edge and an approved marker, draw a line between the marked positions.

(f) Measure 40 mm (1.575 in) scan pitch intervals aft from the marked line in LIST STRUCTURE

until the last scan path is at least 20 mm (0.787 in) aft from the aft row of fasteners on the Rear

Spar. Using an approved marker mark the remaining scan paths.

(g) Repeat steps LIST STRUCTURE thru or LIST STRUCTURE for each Rib Bay to be inspected

within Area C.

Subtask 57-29-07-272-001-A

B. Instrument Adjustment

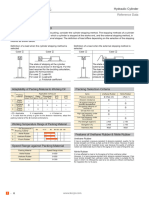

(1) The equipment used in the development of this procedure is shown in TABLE 1.

Item Equipment

Instrument ULTRASONIC EQUIPMENT OMNISCAN MX

PAUT16-128/U8100029 (OMNIPPA16128) with software

version MXU 2.0 R7 or higher

Probe PROBE (AWP05-64-08-050), 5MHz Phased Array Rapid

Scan, 50 mm (1.969 in) wheel probe, 64 elements, 0.8

element pitch, 5 m (16.40 ft) connection cable (See

FIGURE 57-29-07-991-002-A)

Reference Block REFERENCE BLOCK (99D57204164000) (See FIGURE

57-29-07-991-003-A)

Inspection Software CD Rom CD Rom NTMSA572907WPXXX supplied with

AWP05-64-08-050 contains the OMNIPPA16128 software

file

Probe Guide Spirit Level 1 m (3.28 ft)

Couplant Water Spray

Measure Aid Tape Measure

Approved Marker EDDING 8404

Equipment and Materials

TABLE 1

NOTE : Any comparable ultrasonic instrument may be used provided that it satisfies the requirements of

this procedure and is capable of resolving the reference defect in the reference block at the

required level of sensitivity.

NOTE : A PC that has a CD reader and a USB1 port will be required to load the files from PROBE

(AWP05-64-08-050) CD Rom. ULTRASONIC EQUIPMENT OMNISCAN MX

PAUT16-128/U8100029 (OMNIPPA16128) is fitted with a SD Card reader with USB1

connector. The SD Card is located in ULTRASONIC EQUIPMENT OMNISCAN MX

PAUT16-128/U8100029 (OMNIPPA16128).

Page 3

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

NOTE : The use of USB mouse improves the navigation of the ULTRASONIC EQUIPMENT

OMNISCAN MX PAUT16-128/U8100029 (OMNIPPA16128) menu.

NOTE : CD Rom NTMSA572907WPXXX is supplied with PROBE (AWP05-64-08-050) when loaned

from AIRBUS. If you do not have the CD Rom all of the required parameters contained within

the procedure can be manually inputted. (See TABLE 3)

NOTE : Acquisition Module is only required if the operators own OMNISCAN has a different module

fitted.

(2) Connect the PROBE (AWP05-64-08-050) and Encoder connector to the ULTRASONIC EQUIPMENT

OMNISCAN MX PAUT16-128/U8100029 (OMNIPPA16128).

(3) Connect the USB mouse if available.

(4) Preload SD Card with the files from CD ROM NTMSA572907WPXXX. Using ULTRASONIC

EQUIPMENT OMNISCAN MX PAUT16-128/U8100029 (OMNIPPA16128) SD Card Reader connected

via a USB1 port to a PC with CD reader.

(5) Insert the flash card into the ULTRASONIC EQUIPMENT OMNISCAN MX PAUT16-128/U8100029

(OMNIPPA16128).

(6) Make sure the PROBE (AWP05-64-08-050) wheel is full of water.

(7) Make sure that no air bubbles are present within the wheel water path.

(8) Tighten the adjusting nut on the PROBE (AWP05-64-08-050) wheel until the nut is approximately 3

mm (0.118 in) from the end of the thread. (See FIGURE 57-29-07-991-002-A)

(9) Calibrate the Instrument in accordance manufacturers instructions and TABLE 2.

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

File File Open Setup >

NTMSA572907.ops

Preferences Pref Units Millimeters

Display Selection Display A-C-[C]

Display Selection C-Scan 1 A %

Display Selection C-Scan 2 Thickness

Display Color Select Amplitude

Display Color Load Listed Files >

ONDT_RFTOFD.pal

Display Color Start (%) 0

Display Color End (%) 100

Display Color Select Depth

Display Color Load PALSA572907.pal

Measurements Reading List 1

Measurements Reading Group Custom

Measurements Reading Field 1 A %

Measurements Reading Field 2 T (A - I)

Measurements Reading Field 3 None

General Settings

Measurements Reading Field 4 None

Page 4

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

Probe/ part Select Select Select Tx/Rx

Probe/ part Select Probe User>

NDTS_5MHZ_WHEEL

Probe/ part Select Wedge User > Wheel

Probe/ part Select Auto Detect Off

Probe/ part Parts Geometry Plate

Probe/ part Parts Thickness (mm) 20

Probe/ part Parts Material Aluminium

Probe/ part Position Scan Offset (mm) 0.00

Probe / Wedge

Settings

Probe/ part Position Skew (deg) 90.0

Focal Law Configuration Law Configuration Linear

Focal Law Aperture Elements Qty 8

Focal Law Aperture First Element 1

Focal Law Aperture Last Element 64

Focal Law Aperture Element Step 1

Focal Law Aperture Wave Type LW

Focal Law Beam Min Angle 0.0

Sector Scan settings

Focal Law Beam Focus Depth 50

UT Settings General Gain (dB) 15.0

UT Settings General Wedge Delay (s) 0.00

UT Settings General Velocity (m/s) 6300

UT Settings Pulser Tx/Rx Mode PE

UT Settings Pulser Voltage (V) 40

UT Settings Pulser PW (ns) Auto

UT Settings Pulser Max PRF Optimum

UT Settings Pulser Pulser 1

UT Settings Receiver Filter None

UT Settings Receiver Rectifier FW

UT Settings Receiver Video Filter Off

UT Settings Receiver Averaging 1

UT Settings Receiver Reject (%) 0

UT Settings

UT Settings Beam Beam Delay (s) 25.91 (or

approximate)

Initial Setup Settings

TABLE 2

(10) Set the instrument in accordance with CD Rom NTMSA572907WPXXX or TABLE 3.

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Page 5

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

Scan Encoder Type Quad

Scan Encoder Origin 0.0

Scan Inspection Type One-Line Scan

Scan Inspection Scan Encoder 1

Scan Inspection Max. Scan Speed

(mm/s)

84.00 (or

approximate)

Scan Area Scan Start (mm) 0.00

Scan Area Scan End (mm) 200

Scan Area Scan Resolution (mm) 0.80 (or approximate)

Encoder Settings

Scan Area Encoder Tolerance

(mm)

0.00

Encoder Settings

TABLE 3

(11) Calibrate the Encoder.

(a) Open the WIZARD function and select an Encoder Type Calibration. (See TABLE 4)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Wizard Calibration Type Encoder Encoder Calibration

Wizard Calibration Select Calibration Start

Encoder Calibration 1

TABLE 4

(b) Select a INPUT VALUE start position Origin of 0.00 mm. (See TABLE 5)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

N/A N/A Origin (mm) 0.00 Encoder Calibration

N/A N/A Set Origin Next

Encoder Calibration 2

TABLE 5

(c) Select a INPUT VALUE of 50.00 mm. Rotate the wheel 50 mm (1.969 in) in the scanning

direction with the aid of a tape measure and select Calibrate. (See TABLE 6)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

N/A N/A Distance (mm) 50.00 Encoder Calibration

N/A N/A Set Distance Calibrate

Encoder Calibration 3

TABLE 6

(d) Rotate the wheel 50 mm (1.969 in) back to the start position of the scan and observe the upper

Page 6

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

left of the screen and make sure the Calibrated Axis (X) returns to 0.00 mm. (See TABLE 7)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Encoder Calibration N/A N/A Accept Accept

Encoder Calibration 4

TABLE 7

(e) If INPUT VALUE is:

- Acceptable select ACCEPT

- Unacceptable repeat steps LIST STRUCTURE thru or LIST STRUCTURE.

(12) Set the Interface Gate location.

(a) Put the PROBE (AWP05-64-08-050) on a flat surface.

(b) Set the Range to 31.5 mm (or approximate). (See TABLE 8)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Adjust A-Scan Display UT Settings General Range 31.5 mm (or

approximate)

A-Scan Range Settings

TABLE 8

(c) Apply hand pressure on the PROBE (AWP05-64-08-050) handle until the spring resistance is met

and the PROBE (AWP05-64-08-050) wheel is in contact with the flat surface.

(d) Set the A-Scan Interface Signal start position in accordance with TABLE 9 and FIGURE

57-29-07-991-007-A, Screen Display A.

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Adjust A-Scan Display UT Settings General Start <Adjust Accordingly>

A-Scan Start Settings

TABLE 9

(e) Set the Interface Gate start position in accordance with TABLE 10 and FIGURE

57-29-07-991-007-A, Screen Display A.

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Gate/Alarm Gate Gate I

Gate/Alarm Gate Parameters Position

Alter Interface Gate

Gate/Alarm Gate Start <Adjust Accordingly>

Interface Gate Start Settings

TABLE 10

(f) Release hand pressure from the PROBE (AWP05-64-08-050) handle.

(g) Adjust the Interface Gate width to cover this signal in accordance with TABLE 11 and FIGURE

Page 7

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

57-29-07-991-007-A, Screen Display B.

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Gate/Alarm Gate Gate I

Gate/Alarm Gate Parameters Position

Alter Interface Gate

Gate/Alarm Gate Width <Adjust Accordingly>

Interface Gate Width Settings

TABLE 11

(h) Adjust the Interface Gate threshold to 20% Full Screen Height (FSH). (Refer to TABLE 12)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Gate/Alarm Gate Gate I

Gate/Alarm Gate Parameters Position

Alter Interface Gate

Gate/Alarm Gate Threshold 20

Interface Gate Threshold Settings

TABLE 12

(13) Select REFERENCE BLOCK (99D57204164000).

(14) Do a Zero-Degree Sensitivity Calibration away from spotfaces in accordance with the manufacturers

instructions with a Reference Amplitude of 80% FSH.

NOTE : During the Zero-Degree Sensitivity Calibration it is possible to identify any failing elements

within the array.

(15) Do a TCG Calibration away from the spotfaces in accordance with manufacturers instructions on steps

1, 2 and 3 of the REFERENCE BLOCK (99D57204164000) with a Reference Amplitude of 80% 5%.

(16) Set Gate A to a start position of 2 mm (or approximate) with a width of 20 mm and a threshold of

25% FSH. (See TABLE 13)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Gate/Alarm Gate Gate A

Gate/Alarm Gate Parameters Position

Gate/Alarm Gate Start 2 (or approximate)

Gate/Alarm Gate Width 20

Gate Settings

Gate/Alarm Gate Threshold (%) 25

Gate A Settings

TABLE 13

(17) Put the PROBE (AWP05-64-08-050) away from spotfaces on Step 1 of REFERENCE BLOCK

(99D57204164000) and apply hand pressure on the PROBE (AWP05-64-08-050) handle until the spring

resistance is met and establish a Back Wall Echo (BWE). Adjust the Gain to 80% FSH. (See TABLE

Page 8

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

14)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

UT Settings UT Settings General Gain (dB) <Adjust Accordingly>

Gain Settings

TABLE 14

(18) Do a scan over the spotfaces on the REFERENCE BLOCK (99D57204164000). When the scan is

complete Pause the Screen Display. (See TABLE 15)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Starting the Scan Scan Start Start N/A

Pausing the Scan Scan Start Pause N/A

Starting and Pausing the Scan

TABLE 15

(19) Enter the thickness of the Step. (See TABLE 16)

DESCRIPTION F1 KEY MENU KEYS F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Measurements Thickness Source A - I

Measurements Thickness Min (mm) 0.05

Measurements Thickness Max (mm) <Adjust Accordingly>

(Enter Reference

Standard Step

Thickness)

General Settings

Measurements Thickness Echo Qty 1

Thickness Measurement Settings

TABLE 16

(20) Make sure that both spotfaces are clearly displayed on both uncorrected C-Scan displays. (See FIGURE

57-29-07-991-008-A)

(a) If spotfaces:

- Cannot be displayed clearly check that max thickness reading is correct in accordance with

TABLE 16

- Still cannot be clearly displayed repeat steps LIST STRUCTURE thru or LIST STRUCTURE.

(21) Turn off the Screen Display Pause. (See TABLE 17)

DESCRIPTION F1 KEY MENU KEYS F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Turn Pause Off Scan Start Pause N/A

Pause Settings

TABLE 17

(22) Put the PROBE (AWP05-64-08-050) away from spotfaces on Steps 2 and 3 of REFERENCE BLOCK

Page 9

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

(99D57204164000) and repeat steps LIST STRUCTURE thru or LIST STRUCTURE.

(23) Save the calibration file on the unit with a relevant filename. (See TABLE 18)

DESCRIPTION F1 KEY MENU KEYS F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Save Calibration Setup

file

File File Save Setup As File Name:

Calibration_Setup

Save Calibration Setup File

TABLE 18

Subtask 57-29-07-273-001-A

C. Inspection

CAUTION : YOU MUST BE AWARE OF THE STRUCTURE CONFIGURATION IN THE INSPECTION

AREAS, INSPECTION AREAS WILL CONTAIN SKIN THICKNESS CHANGES, SKIN POCKETS,

TAPERED SKINS AND RADII. STRUCTURAL CHANGES WILL AFFECT THE INSPECTION

AND SCREEN DISPLAYS. (SEE SRM 57-21-11PB001, FIGURE 57-29-09-010, FIGURE

57-29-09-011 AND FIGURE 57-29-09-012).

(1) Open the Calibration Setup File. (See TABLE 19)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Save Calibration Setup

file

File File Open Open:

Calibration_Setup

Open Calibration Setup File

TABLE 19

(2) Identify the inspection area.

(3) Measure the scan path distance of the inspection area and enter the scan path length + 50 mm in

accordance with TABLE 20.

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Enter Scan Path

Length

Scan Area Scan End (mm) <Adjust Accordingly>

(Scan Path Distance

+ 50 mm)

Enter Scan Path Length

TABLE 20

(4) Put the Spirit Level on the Wing Skin as a PROBE (AWP05-64-08-050) wheel guide for the scan

paths.

(5) Spray Water onto the inspection area to aid coupling.

(6) Put the PROBE (AWP05-64-08-050) wheel at the start position of the scan and make sure that the

index of the PROBE (AWP05-64-08-050) wheel lines up with the marked scan path.

(7) Apply hand pressure to the PROBE (AWP05-64-08-050) wheel until spring resistance is met and adjust

the gain to place the BWE at 80% FSH.

Page 10

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

(8) Start the scan and rotate the PROBE (AWP05-64-08-050) wheel along the marked scan path, using

the Spirit Level as a guide.

(9) Make sure that the index of the PROBE (AWP05-64-08-050) wheel is following the scan path.

(10) Complete the scan path and Pause the Screen Display. (See TABLE 21)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Starting the Scan Scan Start Start N/A

Pausing the Scan Scan Start Pause N/A

Starting and Pausing the Scan

TABLE 21

(11) Thickness readings must not be taken directly from the A-Scan Screen Display. Readings must be taken

from the number in the field labelled as T(A - I) located in the top portion of the Screen Display.

(12) Using the USB mouse double click on the C-Scan A - I (Thickness Scan) display in ten evenly spaced

random areas along the complete scan. Read off the obtained thickness readings and input the

maximum thickness reading obtained in accordance with TABLE 22.

NOTE : Rib Bays and False Rear Spar Inspection Areas containing Tapered Skin thickness will be

identified on the C-Scan A - I (Thickness Scan) Screen Display as a gradual thickness change.

(See FIGURE 57-29-07-991-009-A)

NOTE : Skin Pockets are located in Rib Bays 19-20 thru 22-23 and False Rear Spar Inspection Areas.

Pockets will be displayed as a distinct shape on the C-Scan A% (Amplitude Scan) and a

thickness change and distinct shape on the C-Scan A - I (Thickness Scan) Screen Display.

(See SRM 57-21-11PB001 and FIGURE 57-29-07-991-010-A, Sheets 1 and 2)

NOTE : False Rear Spar Inspection area contain Steep Ramped skin thickness. The Steep Ramped areas

can cause a loss of signal to occur. (See FIGURE 57-29-07-991-011-A)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

Inputting maximum

part thickness

Measurements Thickness Max. (mm) <Adjust Accordingly>

(Enter Maximum

Thickness across the

scan)

Inputting Maximum Thickness

TABLE 22

(13) Analysis the C-Scan A% (Amplitude Scan) and C-Scan A - I (Thickness Scan) displays using the

zoom function in accordance with manufacturers instructions and SRM 57-21-11PB001.

(14) Corrosion will be indicated by a reduction in the BWE reduction of 4dB (or 30% FSH) with a

corresponding thickness change of 10% of the material thickness. (See FIGURE 57-29-07-991-012-A)

(15) Repeat steps LIST STRUCTURE thru or LIST STRUCTURE for all scan paths and all areas to be

inspected.

Page 11

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

Subtask 57-29-07-971-001-A

D. Acceptance Criteria

(1) All indications that show a BWE reduction of 4dB (or 30% FSH) with a corresponding thickness

reduction 10% of the material thickness, which do not correspond the structural configuration given

in SRM 57-21-11PB001, must be classified as corrosion and recorded then reported to AIRBUS stating:

(See FIGURE 57-29-07-991-012-A)

- The location of the corrosion within the Rib Bay or False Rear Spar

- The depth range of the corrosion

- The size of the corrosion area

- The scan must be saved as a DATA file for later referral. (See TABLE 23)

DESCRIPTION F1 KEY MENU F2 -- F6 KEYS SUB

MENU

F7 -- F12 KEYS

PARAMETER

INPUT VALUE

File File Save Mode Inspection Data

File File File Name Enter: File Name

Saving a DATA file

File File Save Data N/A

Save DATA Files

TABLE 23

Subtask 57-29-07-943-001-A

E. Final NDT Requirements

(1) Remove all inspection equipment, couplant and markings from the inspection area.

Page 12

Nov 01/10

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

INSPECTION AREA A

RIB BAY 3 4

INSPECTION AREA A

RIB BAY 9 10 THRU 26 27

INSPECTION

AREA

POSSIBLE

CORROSION

TOP SKIN

REAR SPAR

TYPICAL

RECESS

RADIUS

TYPICAL

N_NT_572907_1_0010101_01_00

A A

RIB27

RIB9

RIB3

RIB4

A

A

Page 13

Nov 01/10

FIGURE 57-29-07-991-001-A SHEET 01

Inspection Area A and Possible Damage

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

INSPECTION AREA B

FALSE REAR SPAR

INSPECTION

AREA

POSSIBLE

CORROSION

TOP SKIN

FALSE REAR SPAR

TYPICAL

RECESS

RADIUS

RIB9

RIB3

RIB4

N_NT_572907_1_0010102_01_00

B B

B B

Page 14

Nov 01/10

FIGURE 57-29-07-991-001-A SHEET 02

Inspection Area B and Possible Damage

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

INSPECTION AREA C

RIB BAY 4 5 AND 5 6

INSPECTION

AREA

POSSIBLE

CORROSION

REAR SPAR

TYPICAL

RECESS

RADIUS

RIB4

RIB6

C

C

C C

TOP SKIN

N_NT_572907_1_0010103_01_01

Page 15

Nov 01/10

FIGURE 57-29-07-991-001-A SHEET 03

Inspection Area C and Possible Damage

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

NOTE: DIMENSIONS IN MILLIMETERS (INCHES IN BRACKETS)

140.0

(5.51)

PROBE INDEX

PROBE INDEX

SPRING ADJUSTMENT

NUT

173.0

(6.81)

151.0

(5.95)

112.0

(4.41)

PROBE INDEX

N_NT_572907_1_0020101_01_01

Page 16

Nov 01/10

FIGURE 57-29-07-991-002-A SHEET 01

Phased Array Rapid Scan AWP05-64-08-050

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

15.0

(0.59)

20.0

(0.79)

15.0

(0.59)

15.0

(0.59)

20.0

(0.79)

20.0

(0.79)

15.0

(0.59)

15.0

(0.59)

15.0

(0.59)

50.0

(1.97)

4.0

(0.16)

0.50

(0.02)

1.0

(0.04)

1.0

(0.04)

2.00

(0.08)

1.5

(0.06)

3.0

(0.12)

5.0

(0.20)

10.0

(0.40)

15.0

(0.60)

200.0

(7.87)

50.0

(1.97)

50.0

(1.97)

50.0

(1.97)

150.0

(5.91)

A

A

A A

NOTE:

ITEM NOMENCLATURE

1 REFERENCE BLOCK

2

SIMULATED

CORROSION

3 LABEL

QTY

1

6

4 USE 3.0 (0.12) HIGH CHARACTERS

10.0 (0.39) DIA SPOTFACES

AI 7150T651 OR SIMILAR

TO MINIMUM DEPTH

MATERIAL / REMARKS

PAINT ALL SURFACES WITH PRIMER (MATERIAL NO 16006)

AND FINISH NONSPOTFACE SURFACES

AFTER PAINTING ENGRAVE PART NUMBER AND STEP

IDENTIFICATIONS. USE 3.0 (0.12) HIGH CHARACTERS TO

MINIMUM DEPTH. FILL IN TOP COAT (MATERIAL NO. 16018).

DIMENSIONS IN MILLIMETERS (INCHES IN BRACKETS)

SPOTFACE MILLED TO A TOLERANCE OF +/ 0.05 (0.002)

ALL OTHER TOLERANCES +/ 0.20 (0.008).

STEP 3

STEP 2

STEP 1

99D57204164000

ITEM 3

ITEM 1

ITEM 2

WITH TOP COAT (MATERIAL NO 16018).

N_NT_572907_1_0030101_01_02

Page 17

Nov 01/10

FIGURE 57-29-07-991-003-A SHEET 01

Reference Block 99D57204164000

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

4

0

.

0

(

1

.

5

7

)

2

0

.

0

(

0

.

7

9

)

4

0

.

0

(

1

.

5

7

)

S

C

A

N

D

I

R

E

C

T

I

O

N

P

R

O

B

E

P

O

S

I

T

I

O

N

A

T

S

T

A

R

T

O

F

S

C

A

N

,

I

N

D

E

X

P

O

I

N

T

O

F

P

R

O

B

E

O

N

T

H

E

I

N

T

E

R

F

A

C

E

O

F

T

H

E

R

I

B

C

E

N

T

E

R

L

I

N

E

A

N

D

T

H

E

S

C

A

N

P

A

T

H

R

I

B

C

E

N

T

E

R

L

I

N

E

R

I

B

C

E

N

T

E

R

L

I

N

E

F

I

R

S

T

S

C

A

N

P

A

T

H

2

0

.

0

(

0

.

7

9

)

F

O

R

W

A

R

D

F

R

O

M

F

I

R

S

T

R

O

W

O

F

B

O

L

T

S

F

O

R

W

A

R

D

O

F

R

E

A

R

S

P

A

R

R

E

A

R

S

P

A

R

B

O

L

T

I

N

G

F

I

N

A

L

S

C

A

N

P

A

T

H

O

V

E

R

L

A

P

P

I

N

G

S

K

I

N

E

D

G

E

F

W

D

I

N

B

D

N

O

T

E

:

T

H

E

D

R

A

W

I

N

G

I

S

N

O

T

T

O

S

C

A

L

E

.

T

H

E

A

C

T

U

A

L

N

U

M

B

E

R

O

F

S

C

A

N

P

A

T

H

S

W

I

T

H

I

N

T

H

E

I

N

S

P

E

C

T

I

O

N

A

R

E

A

W

I

L

L

V

A

R

Y

.

D

I

M

E

N

S

I

O

N

S

I

N

M

I

L

L

I

M

E

T

E

R

S

(

I

N

C

H

E

S

I

N

B

R

A

C

K

E

T

S

)

.

S

C

A

N

P

A

T

H

(

P

R

O

B

E

C

E

N

T

E

R

L

I

N

E

)

E

D

G

E

O

F

S

K

I

N

P

A

N

E

L

N

_

N

T

_

5

7

2

9

0

7

_

1

_

0

0

4

0

1

0

1

_

0

1

_

0

1

Page 18

Nov 01/10

FIGURE 57-29-07-991-004-A SHEET 01

Inspection Area A Scan Paths

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

4

0

.

0

(

1

.

5

7

)

2

0

.

0

(

0

.

7

9

)

4

0

.

0

(

1

.

5

7

)

S

C

A

N

D

I

R

E

C

T

I

O

N

P

R

O

B

E

P

O

S

I

T

I

O

N

A

T

S

T

A

R

T

O

F

S

C

A

N

,

I

N

D

E

X

P

O

I

N

T

O

F

P

R

O

B

E

O

N

T

H

E

I

N

T

E

R

F

A

C

E

O

F

T

H

E

R

I

B

C

E

N

T

E

R

L

I

N

E

A

N

D

T

H

E

S

C

A

N

P

A

T

H

F

I

R

S

T

S

C

A

N

P

A

T

H

2

0

.

0

(

0

.

7

9

)

F

O

R

W

A

R

D

F

R

O

M

F

I

R

S

T

R

O

W

O

F

B

O

L

T

S

F

O

R

W

A

R

D

O

F

F

A

L

S

E

R

E

A

R

S

P

A

R

S

P

A

R

B

O

L

T

I

N

G

N

O

T

E

:

T

H

E

D

R

A

W

I

N

G

I

S

N

O

T

T

O

S

C

A

L

E

.

T

H

E

A

C

T

U

A

L

N

U

M

B

E

R

O

F

S

C

A

N

P

A

T

H

S

W

I

T

H

I

N

T

H

E

I

N

S

P

E

C

T

I

O

N

A

R

E

A

W

I

L

L

V

A

R

Y

.

D

I

M

E

N

S

I

O

N

S

I

N

M

I

L

L

I

M

E

T

E

R

S

(

I

N

C

H

E

S

I

N

B

R

A

C

K

E

T

S

)

.

F

W

D

I

N

B

D

F

I

N

A

L

S

C

A

N

P

A

T

H

O

V

E

R

L

A

P

P

I

N

G

S

K

I

N

E

D

G

E

S

C

A

N

P

A

T

H

(

P

R

O

B

E

C

E

N

T

E

R

L

I

N

E

)

E

D

G

E

O

F

S

K

I

N

P

A

N

E

L

S

C

A

N

P

A

T

H

T

O

C

O

N

T

I

N

U

E

U

N

T

I

L

T

H

E

L

A

S

T

B

O

L

T

I

N

G

I

N

T

H

E

F

A

L

S

E

R

E

A

R

S

P

A

R

F

A

L

S

E

R

E

A

R

N

_

N

T

_

5

7

2

9

0

7

_

1

_

0

0

5

0

1

0

1

_

0

1

_

0

1

Page 19

Nov 01/10

FIGURE 57-29-07-991-005-A SHEET 01

Inspection Area B Scan Paths

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

4

0

.

0

(

1

.

5

7

)

2

0

.

0

(

0

.

7

9

)

4

0

.

0

(

1

.

5

7

)

S

C

A

N

D

I

R

E

C

T

I

O

N

P

R

O

B

E

P

O

S

I

T

I

O

N

A

T

S

T

A

R

T

O

F

S

C

A

N

,

I

N

D

E

X

P

O

I

N

T

O

F

P

R

O

B

E

O

N

T

H

E

I

N

T

E

R

F

A

C

E

O

F

T

H

E

R

I

B

C

E

N

T

E

R

L

I

N

E

A

N

D

T

H

E

S

C

A

N

P

A

T

H

R

I

B

C

E

N

T

E

R

L

I

N

E

R

I

B

C

E

N

T

E

R

L

I

N

E

F

I

R

S

T

S

C

A

N

P

A

T

H

2

0

.

0

(

0

.

7

9

)

F

O

R

W

A

R

D

F

R

O

M

F

I

R

S

T

R

O

W

O

F

B

O

L

T

S

F

O

R

W

A

R

D

O

F

R

E

A

R

S

P

A

R

R

E

A

R

S

P

A

R

B

O

L

T

I

N

G

N

O

T

E

:

T

H

E

D

R

A

W

I

N

G

I

S

N

O

T

T

O

S

C

A

L

E

.

T

H

E

A

C

T

U

A

L

N

U

M

B

E

R

O

F

S

C

A

N

P

A

T

H

S

W

I

T

H

I

N

T

H

E

I

N

S

P

E

C

T

I

O

N

A

R

E

A

W

I

L

L

V

A

R

Y

.

D

I

M

E

N

S

I

O

N

S

I

N

M

I

L

L

I

M

E

T

E

R

S

(

I

N

C

H

E

S

I

N

B

R

A

C

K

E

T

S

)

.

F

W

D

I

N

B

D

F

I

N

A

L

S

C

A

N

P

A

T

H

A

T

L

E

A

S

T

2

0

.

0

(

0

.

7

9

)

A

F

T

O

F

T

H

E

A

F

T

R

O

W

O

F

F

A

S

T

E

N

E

R

S

O

N

T

H

E

R

E

A

R

S

P

A

R

S

C

A

N

P

A

T

H

(

P

R

O

B

E

C

E

N

T

E

R

L

I

N

E

)

N

_

N

T

_

5

7

2

9

0

7

_

1

_

0

0

6

0

1

0

1

_

0

1

_

0

1

Page 20

Nov 01/10

FIGURE 57-29-07-991-006-A SHEET 01

Inspection Area C Scan Paths

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

N_NT_572907_1_0070101_01_00

GATE B

INTERFACE SIGNAL

GATE A

SCREEN DISPLAY A

INTERFACE GATE

SCREEN DISPLAY B

GATE B

INTERFACE SIGNAL

GATE A

INTERFACE GATE

NO PRESSURE

PRESSURE

Page 21

Nov 01/10

FIGURE 57-29-07-991-007-A SHEET 01

Screen Display Gate Locations

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

APPROXIMATLEY 4dB ATTENUATION DIFFERENCE

20% THICKNESS CHANGE

10% THICKNESS CHANGE

N_NT_572907_1_0080101_01_00

Page 22

Nov 01/10

FIGURE 57-29-07-991-008-A SHEET 01

Calibration Screen Display for A-Scan, C-Scan A%

(Amplitude Scan) and C-Scan A-I (Thickness Scan)

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

SKIN THICKNESS TAPER

N_NT_572907_1_0090101_01_01

Page 23

Nov 01/10

FIGURE 57-29-07-991-009-A SHEET 01

Typical Tapered Skin Display Screen

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

RIB BAY 2021 DISPLAY SCREEN

RIB BAY 1920 DISPLAY SCREEN

SKIN POCKETS

SKIN POCKETS

N_NT_572907_1_0100101_01_01

Page 24

Nov 01/10

FIGURE 57-29-07-991-010-A SHEET 01

Typical Skin Pocket Display Screen - Rib Bay 19-20 and

20-21

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

RIB BAY 2122 SCREEN DISPLAY

RIB BAY 2223 SCREEN DISPLAY

SKIN POCKETS

SKIN POCKETS

N_NT_572907_1_0100102_01_00

Page 25

Nov 01/10

FIGURE 57-29-07-991-010-A SHEET 02

Typical Skin Pocket Display Screen - Rib Bay 21-22 and

22-23

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

AREAS OF SIGNAL LOSS

CAUSED BY STEEP

RAMPED AREAS

TAPERED SKINS SKIN POCKETS

N_NT_572907_1_0110101_01_01

Page 26

Nov 01/10

FIGURE 57-29-07-991-011-A SHEET 01

Examples of Signal Loss caused by Skin Pockets, Tapered

Skins and Steep Ramped Skin Areas

57-29-07-PB4

Revision n: 86

@A318/A319/A320/A321

NONDESTRUCTIVE TESTING MANUAL

** On A/C ALL

CORROSION

INDICATION CAUSING

AN ATTENUATION LOSS

> 4dB

CORROSION

INDICATION CAUSING

MATERIAL LOSS > 10%

N_NT_572907_1_0120101_01_01

Page 27

Nov 01/10

FIGURE 57-29-07-991-012-A SHEET 01

Typical Skin Corrosion Display Screen

57-29-07-PB4

Revision n: 86

You might also like

- L211 Series Resonance and TimeFrequency Response of Passive Networks PDFDocument25 pagesL211 Series Resonance and TimeFrequency Response of Passive Networks PDFglenlcy100% (1)

- A318 - A319 - A320 - A321 - NTM - 01-Nov-2022 - DeSC 51-00-00-002 CONF A - Nondestructive Testing MethodsDocument4 pagesA318 - A319 - A320 - A321 - NTM - 01-Nov-2022 - DeSC 51-00-00-002 CONF A - Nondestructive Testing MethodsGladys Reyes RodriguezNo ratings yet

- 00 - C208B - ND (Rev 3) - INTRODUCTIONDocument8 pages00 - C208B - ND (Rev 3) - INTRODUCTIONDoti Tri PrasetioNo ratings yet

- NDT20-00-01 Rev0Document22 pagesNDT20-00-01 Rev0Hung PhanNo ratings yet

- Documentation 1.1. GeneralDocument145 pagesDocumentation 1.1. Generalcoralonso0% (1)

- 128 590001 9 - 05Document244 pages128 590001 9 - 05Rene QueirozNo ratings yet

- 757 Nondestructive Test Manual: BoeingDocument2 pages757 Nondestructive Test Manual: BoeingStephen Rincon GonzalezNo ratings yet

- Corporate Finance - PRACTICE EXAM: (1 Point) Future Value of Annuity FVA 377 006Document4 pagesCorporate Finance - PRACTICE EXAM: (1 Point) Future Value of Annuity FVA 377 006Yuge FanNo ratings yet

- GrgtrhytjyjyDocument2 pagesGrgtrhytjyjyKushanNo ratings yet

- Et ChantsDocument27 pagesEt ChantsAlonsoTezkRodrichSalcedoNo ratings yet

- 208DN00Document168 pages208DN00william abraaoNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument6 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- AC7102.4 Rev DDocument25 pagesAC7102.4 Rev DVijay Yadav100% (1)

- Mil HDBK 337Document345 pagesMil HDBK 337Anonymous omN4DqNo ratings yet

- 04 - C208B - ND (Rev 3) - Part 6 - EDDY CURRENTDocument121 pages04 - C208B - ND (Rev 3) - Part 6 - EDDY CURRENTDoti Tri Prasetio100% (1)

- High Sensitivity Post Emulsifiable - FPI Procedure SheetDocument7 pagesHigh Sensitivity Post Emulsifiable - FPI Procedure SheetrenjithaeroNo ratings yet

- NDE Examination Question PaperDocument6 pagesNDE Examination Question PaperMOhammed PatelNo ratings yet

- Mil-Std-1949a NoticeDocument3 pagesMil-Std-1949a NoticeGökhan ÇiçekNo ratings yet

- Agilent N9310A RF Signal GeneratorN9310-90001Document202 pagesAgilent N9310A RF Signal GeneratorN9310-90001Janaka GamageNo ratings yet

- Dash 8 Classic 49 APU June 2015 BW1 LogoDocument64 pagesDash 8 Classic 49 APU June 2015 BW1 Logomilliewangui157100% (1)

- Fine Defect Detection by Eddy Current Array.: Patrick CabanisDocument33 pagesFine Defect Detection by Eddy Current Array.: Patrick CabanisizmitlimonNo ratings yet

- Ndtcat PDFDocument50 pagesNdtcat PDFeefs1979No ratings yet

- Non-Destructive Test Manual: REVISED MAY 31, 1992Document21 pagesNon-Destructive Test Manual: REVISED MAY 31, 1992anon_852142152No ratings yet

- TB-2100 Operational and Maintenance Manual Rev C OptimiseDocument224 pagesTB-2100 Operational and Maintenance Manual Rev C OptimisearnaudmarielNo ratings yet

- Guide To Penetrant Inspection MaterialsDocument9 pagesGuide To Penetrant Inspection MaterialsNenadNo ratings yet

- YKEPL MPI Procedure For A668 RMDocument4 pagesYKEPL MPI Procedure For A668 RMDeepak HoleNo ratings yet

- 340 Operators ManualDocument119 pages340 Operators Manualcutefrenzy100% (2)

- Inspection Concepts and TechniquesDocument26 pagesInspection Concepts and TechniquesChalidea RamadhinaNo ratings yet

- Omega Flow MweterDocument2 pagesOmega Flow MweterIan G. WalkerNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument58 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás Piratova100% (1)

- Phasec2d Data SheetDocument2 pagesPhasec2d Data SheetMaria DazaNo ratings yet

- 2017 Catalogue GBDocument131 pages2017 Catalogue GBCedric MercadoNo ratings yet

- Magnaflux DN-543 Operation MaterialsDocument35 pagesMagnaflux DN-543 Operation MaterialsMark Evan Salutin100% (2)

- CBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralDocument4 pagesCBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralfallalovaldesNo ratings yet

- NDT - AFT Engine Mount Inspection #2Document5 pagesNDT - AFT Engine Mount Inspection #2David Owen100% (1)

- Api Ut 1Document6 pagesApi Ut 1Ricardo Andres Santamaria Torres100% (1)

- ASTM E1444-E1444M (2021) - Part6Document1 pageASTM E1444-E1444M (2021) - Part6David WongNo ratings yet

- BondMaster1000eplus enDocument2 pagesBondMaster1000eplus enKuKu FunNo ratings yet

- Automated Robotic InspectionDocument6 pagesAutomated Robotic Inspectionprakush01975225403No ratings yet

- Barfield User Manual - 1811H-1811G-101-00165 168 169Document77 pagesBarfield User Manual - 1811H-1811G-101-00165 168 169benjadonnadieuNo ratings yet

- Eddy Current & Ultrassom - Techna NDTDocument48 pagesEddy Current & Ultrassom - Techna NDTBruno BatistaNo ratings yet

- 1 ScopeDocument11 pages1 ScopeMichael SkrableNo ratings yet

- AaaDocument60 pagesAaaNorgjieNo ratings yet

- Eddy Current - USAF - Manual-N-RDocument108 pagesEddy Current - USAF - Manual-N-RShabbir aliNo ratings yet

- E 1135 - 97 RtexmzutotcDocument5 pagesE 1135 - 97 RtexmzutotccarlosNo ratings yet

- An Ultra-High Bypass Ratio Turbofan Engine For The Future PDFDocument40 pagesAn Ultra-High Bypass Ratio Turbofan Engine For The Future PDFFranzAnzuresFroitzheimNo ratings yet

- Equipment CatalogDocument66 pagesEquipment Catalogcristian pedrazaNo ratings yet

- Magnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Document5 pagesMagnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Dinesh Gupta100% (1)

- 607303-664792677redacted T.O. 33B-1-2 (PT Only) PDFDocument52 pages607303-664792677redacted T.O. 33B-1-2 (PT Only) PDFZaid RabaaNo ratings yet

- SAE AMS 5122j-2008Document5 pagesSAE AMS 5122j-2008raulNo ratings yet

- Accessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishDocument3 pagesAccessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishimahidaNo ratings yet

- Turbine Temperature Test SET: User Instruction ManualDocument27 pagesTurbine Temperature Test SET: User Instruction ManualmdhelicoptersNo ratings yet

- Adh-2000 Manual de OpracionDocument48 pagesAdh-2000 Manual de OpracionCarlos MenaNo ratings yet

- To 33B-1-1 01jan2013Document856 pagesTo 33B-1-1 01jan2013izmitlimonNo ratings yet

- Ect EngineDocument63 pagesEct EngineAnonymous gFcnQ4goNo ratings yet

- Non Destructive Testing NDTPDFDocument30 pagesNon Destructive Testing NDTPDFLong BinNo ratings yet

- C1 For UTDocument23 pagesC1 For UTMung Duong XuanNo ratings yet

- BT139394EDocument23 pagesBT139394Ehin wongyai100% (1)

- MOR Training Iss.1 Rev.0 (31 Jul 2020)Document17 pagesMOR Training Iss.1 Rev.0 (31 Jul 2020)Trần Triệu PhongNo ratings yet

- Installation and Rigging Procedures: Advanced Technology Performance and Environmental Improvement Systems For YourDocument33 pagesInstallation and Rigging Procedures: Advanced Technology Performance and Environmental Improvement Systems For YourRene QueirozNo ratings yet

- A570010 PDFDocument5 pagesA570010 PDFworm_stellNo ratings yet

- DLLec5b NotesDocument4 pagesDLLec5b NotesChintan MandalNo ratings yet

- MATH - Q2 - W3 (Autosaved)Document44 pagesMATH - Q2 - W3 (Autosaved)Rose Amor Mercene-LacayNo ratings yet

- Vmanage How Tos 18 4Document261 pagesVmanage How Tos 18 4Genus SumNo ratings yet

- Right Triangle Trig. - Finding Missing Sides and AngleDocument3 pagesRight Triangle Trig. - Finding Missing Sides and AngleAlfredo Mandia IIINo ratings yet

- Project in Industrial ElectronicsDocument50 pagesProject in Industrial ElectronicsShiela100% (1)

- Isothermal Reactor Design: 1. Batch OperationDocument3 pagesIsothermal Reactor Design: 1. Batch Operationنزار الدهاميNo ratings yet

- Lab 2.5.1C: Basic Switch Configuration: Lab. Session: Name: Cityu Id: Group No.: DateDocument14 pagesLab 2.5.1C: Basic Switch Configuration: Lab. Session: Name: Cityu Id: Group No.: DateLawrenceLamNo ratings yet

- AHD-S 201: AHD-S 201 Hydrostatic Level Transmitter For Shipbuilding and OffshoreDocument4 pagesAHD-S 201: AHD-S 201 Hydrostatic Level Transmitter For Shipbuilding and OffshoreElimat EmbarcacionesNo ratings yet

- Chapter 2 Basic GatesDocument22 pagesChapter 2 Basic GatesRoyal Ritesh SharmaNo ratings yet

- Concepts of RecordDocument29 pagesConcepts of RecordCamille PajarilloNo ratings yet

- 06-TL - SS003 - E01 - 0 ZXSDR R8962 L23A Principle and Hardware Structure Training Manual-39Document39 pages06-TL - SS003 - E01 - 0 ZXSDR R8962 L23A Principle and Hardware Structure Training Manual-39a2227 jglNo ratings yet

- Modeling Thermal Expansion in Ansys: 6/24/2017 Alex Grishin, PHDDocument24 pagesModeling Thermal Expansion in Ansys: 6/24/2017 Alex Grishin, PHDAchmad Nur HusainiNo ratings yet

- Ooad Lab ManualDocument29 pagesOoad Lab ManualDevendra BhagyawantNo ratings yet

- C - 2Y - Dilute Solution and Colligative Properties - Assignment 1Document5 pagesC - 2Y - Dilute Solution and Colligative Properties - Assignment 1Phani PadmasriNo ratings yet

- Final 2020 SolutionDocument12 pagesFinal 2020 SolutionShokhrud SafarovNo ratings yet

- BiotechDocument19 pagesBiotechJagadeesh ValishettyNo ratings yet

- Atoll 3.2.0 Administrator ManualDocument496 pagesAtoll 3.2.0 Administrator Manualmbouchra80No ratings yet

- Technical Report - Determination of Benzoic Acid in Soft DrinkDocument18 pagesTechnical Report - Determination of Benzoic Acid in Soft Drinkmohamad ashaziq100% (14)

- Backer Marathon Stock BookletDocument130 pagesBacker Marathon Stock BookletVladimir Illich Pinzon BallenNo ratings yet

- Holiday HW Cs Class 12Document33 pagesHoliday HW Cs Class 12Arohan BuddyNo ratings yet

- SmartWireless Battery Options PDSDocument2 pagesSmartWireless Battery Options PDSAbdul Hakeem MohammedNo ratings yet

- Introduction To Signals and Systems: M. J. Roberts All Rights Reserved. Edited by Dr. Robert AklDocument18 pagesIntroduction To Signals and Systems: M. J. Roberts All Rights Reserved. Edited by Dr. Robert Aklkumarsumit1942No ratings yet

- SIM SAMPLE Distance Between Two PointsDocument14 pagesSIM SAMPLE Distance Between Two PointsDIOSDADO MADRONIONo ratings yet

- IGL 7.2.1 Configuring WildFly ClusteringDocument57 pagesIGL 7.2.1 Configuring WildFly ClusteringVitor Stachetti de FreitasNo ratings yet

- FHS Zoom Venus LightDocument4 pagesFHS Zoom Venus LightHasan AhmedNo ratings yet

- Computerized Portable EMI Drill Pipe Inspection System Dual-FunctionDocument2 pagesComputerized Portable EMI Drill Pipe Inspection System Dual-FunctionYodilson Sanchez100% (1)

- Notes On Piston Rod BucklingDocument1 pageNotes On Piston Rod Bucklingmunees ckNo ratings yet

- How To Use RMAN To Check For Logical & Physical Database CorruptionDocument4 pagesHow To Use RMAN To Check For Logical & Physical Database Corruptionalok_mishra4533No ratings yet