Professional Documents

Culture Documents

Mascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113

Mascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113

Uploaded by

Ying Kei ChanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113

Mascoat - Thermal Insulation Coating 02-MI-DTI Spec Sheet 0113

Uploaded by

Ying Kei ChanCopyright:

Available Formats

Substrates & Surface Protection

Surface Prep

Surface should be dry and free of foreign matter.

Surface prep can be used to NACE 1-3 (SSPC

SP 5-6) when applicable.

Ferrous

Surfaces

Should be primed prior to application of MI-DTI

Insulating Coating. Since the coating is waterbased, it is important to have a boundary layer

of protection to prevent flash rusting.

Non-ferrous

Surfaces

The coating can be applied directly to nonferrous surfaces. Surface should be clean and

free of any oil, dirt or other foreign matter.

Selection & Specification Data

Product Name

Mascoat Industrial-DTI

Product No.

MI-DTI

Description

Mascoat Industrial-DTI is a composite

ceramic & silica-based insulating coating

that provides an insulating barrier, protects

personnel and blocks corrosion all in one

application. The coating is specifically

designed to be a multiple purpose coating

solving painting and insulating issues.

Features

Excellent thermal insulation at low thickness

Excellent personnel protection

Prevents Corrosion Under Insulation (CUI)

Provides anti-condensation protection

Provides inspection ability w/o removal

Fast cure times

Low VOC Product

Highest volume solids insulation coating

on the market

Easy application to irregular surfaces

Base

Water-based Acrylic Insulation Coating

Gloss

Flat

Priming

Self priming over non-ferrous materials

(stainless steel & aluminum). Primer required

for carbon steel substrates.

Topcoats

Please consult Mascoat.

Wet Weight

5.25.3 lbs/gallon

(0.63 kg/liter)

Weight dry film

to area

0.035 lbs/ft at 20 mils dft

2

(0.170 kg/m at 0.50 mm dft)

Practical Volume 7880%

Solids Content

Average Coat

Thickness

2022 mils WFT at 70130F

(0.5 mm WFT at 2154C

Practical Dry

Coat Coverage

5055 ft /gal @ 20 mils

2

(1.3 m /liter @ 0.5 mm)

VOC Content

0.06 lbs/gal

(7.6 grams/liter)

Limitations

Applications should not exceed 375F

(190C).

Storage

Do not subject wet coating in pail form to

freezing conditions. Coating should be kept

in a warehouse between 60F and 90F.

Mascoat

Application Equipment

Listed below are the general equipment guidelines for the application

of this product.

33:1 or larger

Airless Sprayer Pump Ratio:

Volume:

1.5 gpm (5.7 lpm) or greater

Hose:

3/8 or larger with no more

than 3 of 1/4 whip. 1/2

hose recommended for

length above 50.

Tip Size:

0.017 (for tight spots)

0.0190.023 (Normal use)

Pressure:

Minimum of 3000 PSI

Small Spray

Application

Please consult Mascoat for the Small

Application Gun. This gun is excellent for small

applications and touch-ups.

Brush

Brushing is only recommended for touch-up of

2

2

less than 0.5 ft (0.04 m ). Brushing can inhibit

coating performance. Please consult Mascoat

for detailed brushing instructions.

Rolling

Not recommended for this coating

Application Conditions

Surface

Temperatures

Surface temperatures for applications should be

greater than 60F (15C) or above. Lower surface

temperatures will increase dry times.

Applications

Ambient & Cold (60139F, 1559C): For

temperatures (surface or ambient whichever is

lower), an initial tack coat is recommended of 10

mils (0.25 mm or 250 microns). This tack coat will

help eliminate sag on vertical wall applications.

Tack coat should be dry to touch prior to next

pass. Typical coat thickness should not exceed

2022 mils (0.50.55mm) wet. Coating can be

reapplied after each coat is thoroughly dry.

Hot (>140F, >60C): Please consult Mascoat.

Application

Thickness

Product can be applied in successive coats to

increase insulation ability. There are no upper

limitations.

Dryfall

Dryfall within a 3 ft radius

MI-DTI 0113

Other Coating Specifications

Cleanup & Safety

Cleanup

Equipment may be cleaned with soap & water

Safety

Half-face respirator recommended with ammonia

cartridge or better. Eye protection recommended.

ASTM D-5894

Ventilation

Recommended for constricted areas.

Excellent 2000 hrs

ASTM D-4585

Caution

This material is not for human consumption

Excellent 2000 hrs

ASTM G-154

Clothing

Safety clothing & gloves are recommended

Item

English Value

(Metric Value)

Test Method

Cyclic Salt Fog

Excellent 2000 hrs

ASTM B-117

UV-A Exposure

Excellent 2000 hrs

Humidity Cabinet

QUV

Low 4.98 perms

Permeability

(3.28 grams/24 hrs/m2/mm/hg

2

Transmission

Low 4.14 grains/hr/ft

Cross Hatch

Adhesion

100% 5 B

ASTM D-3359

Pull Apart Strength

260360 psi

ASTM D-4541

Elongation Rate

Above 30%

ASTM D-638

Thermal

Conductivity

0.4381 Btu-in/ft -hr-F

(0.0698 W/m/K)

Thermal Probe

Study

Thermal Emittance

0.85

ASTM C-1371

Solar Reflectivity

0.820.86

ASTM C-1549

Transmittance

0.00

Calculated

Emissivity/

Absorptance

0.140.18

Calculated

Flame Spread

Class A

ASTM E-84/87

Smoke Developed

Class A

ASTM E-84/87

Cone Calorimiter

>6

ASTM E- 1384-97

Dry Times vs. Humidity

ASTM 1653-03

ASTM 1653-03

Surface Temperature

% Humidity

Time Between

Coats (hours)

6.00

8.00

10.00

12.50

4.00

5.50

6.50

8.00

2.00

3.00

3.50

4.00

1.50

2.00

2.50

3.00

1.25

1.50

1.75

2.00

1.00

1.25

1.50

1.75

0.75

1.00

1.25

1.50

0.50

0.75

0.75

1.00

1030%

3150%

5160F (1015C)

5170%

>70%

1030%

3150%

6170F (1621C)

5170%

>70%

1030%

3150%

7180F (2226C)

5170%

>70%

1030%

3150%

8190F (2732C)

5170%

>70%

1030%

Mixing & Thinning

5170%

>70%

Only a mud mixing paddle should be used.

Use 1/2 drill motor to stir contents with paddle.

Make sure drill is set to reverse to ensure that

the paddle will not mar the buckets inner wall.

Please consult Mascoat for paddle, if needed.

DO NOT MECHANICALLY SHAKE.

101110F (3843C)

Thinning

DO NOT THIN unless authorized in writing by

Mascoat.

111120F (4449C)

Pot life

Coating is one part, so no catalyzation is

needed. Pail can be reused if properly sealed.

Container

5 gallon pail (18.92 liters)

Mixing

3150%

91100F (3337C)

1030%

3150%

5170%

>70%

1030%

3150%

5170%

>70%

1030%

3150%

121130F (5054C)

Package, Handling & Storage

5170%

>70%

Use 90 thumb test or moisture meter prior to recoat. This is the estimated dry time for 1520

mils (0.380.50 mm) of Mascoat Industrial-DTI wet. Dry time may vary depending on other

conditions such as wind or enclosed environments. Lighter thickness passes will expedite dry

times. Forced ventilation in confined areas will also expedite dry times.

Container Wet

(with pail/lid)

27.528.0 lbs per 5 gallon pail

(12.4712.7 kg per 18.92 liters)

Net Contents

25.9 lbs per 5 gallon pail

(11.7 kg per 18.92 liters)

Flash Point

(Setaflash)

None

Storage

Do not subject wet coating in pail form to

freezing conditions. Coating should be kept in

a warehouse between 60F and 90F.

Cure Times

Shelf Life

18 months shelf life from manufacture date.

Caution

Do not let product freeze.

Temperature

Cure Time

5060F (1015C)

6072 hrs

6170F (1621C)

4860 hrs

7180F (2226C)

3648 hrs

8190F (2732C)

2024 hrs

91100F (3337C)

1820 hrs

>100F (>37C)

1416 hrs

The data within is true to the best of our knowledge on the date of publication and is subject to change without prior notice. We guarantee our products to conform to

Mascoat quality control. We assume no responsibility for coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. All

logos are property of their respective owners.

www.mascoat.com

You might also like

- SB 221Document9 pagesSB 221Siva PrasadNo ratings yet

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Xylar Data SheetDocument3 pagesXylar Data Sheetsarath6725100% (1)

- BS 436Document8 pagesBS 436Raja RaoNo ratings yet

- Resist GTI - English (Uk) - Issued.06.12.2007Document4 pagesResist GTI - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Vinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Document3 pagesVinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Mohamed FaragNo ratings yet

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aNo ratings yet

- TDS - Resist 86Document4 pagesTDS - Resist 86EricNo ratings yet

- TO 1.58 Transozinc Silicate 158 ENDocument5 pagesTO 1.58 Transozinc Silicate 158 ENTirumala PrasadNo ratings yet

- Marathon IQ GF - English (Uk) - Issued.06.12.2007Document3 pagesMarathon IQ GF - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Xylan 80-018-g6706 Black - BeDocument2 pagesXylan 80-018-g6706 Black - BeSYED MAZHARNo ratings yet

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Document4 pagesTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNo ratings yet

- Barrier 90 - English (Uk) - Issued.06.12.2007Document3 pagesBarrier 90 - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- MI DTI SpecSheetDocument2 pagesMI DTI SpecSheetMarco AntonioNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Jotaguard 630Document4 pagesJotaguard 630Christine HermawanNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Sigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableDocument4 pagesSigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableKopnang AristideNo ratings yet

- Megayacht Imperial Antifouling DataDocument3 pagesMegayacht Imperial Antifouling DatakormatekNo ratings yet

- Jet Mastic 800Document3 pagesJet Mastic 800jopersa9No ratings yet

- New Guard Group: CoatingsDocument7 pagesNew Guard Group: CoatingsFON NelsonNo ratings yet

- Carboguard 888 PDSDocument3 pagesCarboguard 888 PDSsalamrefighNo ratings yet

- TDS-JOTACOTE 5-EnglishDocument4 pagesTDS-JOTACOTE 5-EnglishthirdNo ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- Barrier 80 - English (Uk) - Issued.07.01.2008Document3 pagesBarrier 80 - English (Uk) - Issued.07.01.2008Mohamed FaragNo ratings yet

- Transolac Undercoat 321Document2 pagesTransolac Undercoat 321mido medoNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- Jotazinc PDFDocument4 pagesJotazinc PDFAnonymous YtgIj2A9nWNo ratings yet

- Penguard HBDocument4 pagesPenguard HBhedisanjayaNo ratings yet

- Penguard Primer Datasheet " Azadjotun"Document3 pagesPenguard Primer Datasheet " Azadjotun"AzadAhmadNo ratings yet

- Interplus 1180: Protective CoatingsDocument4 pagesInterplus 1180: Protective CoatingsAnindya Aulia PratiwiNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- Penguard Stayer - English (Uk) - Issued.06.12.2007Document3 pagesPenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Muki Z 2001 - TDSDocument4 pagesMuki Z 2001 - TDSshameelNo ratings yet

- Vinyl Ester-Glass Flake PaintDocument4 pagesVinyl Ester-Glass Flake PaintSimbu ArasanNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- TDS - Solvalitt Midtherm - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Solvalitt Midtherm - English (Uk) - Issued.26.11.2010Fauzan BenraxidNo ratings yet

- Technical Data Sheet Jazeera Marine Primer JM-31001: Description: Recommended Use: CharacteristicsDocument3 pagesTechnical Data Sheet Jazeera Marine Primer JM-31001: Description: Recommended Use: CharacteristicsMark DingalNo ratings yet

- Dimetcote 9 Sigmazinc 9Document6 pagesDimetcote 9 Sigmazinc 9kaleshNo ratings yet

- Transunilac Finish 331Document4 pagesTransunilac Finish 331bhukyanaik02No ratings yet

- TDS - Penguard Midcoat - Issu.26.11.2010 PDFDocument4 pagesTDS - Penguard Midcoat - Issu.26.11.2010 PDFvitharvanNo ratings yet

- Jotun Resist 5WFDocument4 pagesJotun Resist 5WFSergio SmithNo ratings yet

- Naviguard ME - English (Uk) - Issued.06.12.2007Document3 pagesNaviguard ME - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- 2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Document3 pages2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Jafffar MahasnehNo ratings yet

- 01 Mascoat Industrial Application InstructionsDocument7 pages01 Mascoat Industrial Application Instructionsböhmit100% (1)

- Tds - Antifouling Seaforce 60 - English (Uk) - IssueDocument3 pagesTds - Antifouling Seaforce 60 - English (Uk) - Issuewey5316No ratings yet

- Carbo Zinc 11 HsDocument2 pagesCarbo Zinc 11 Hstyto_rmzNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- TDS - Resist 78 - English (Uk) - Issued.02.04.2010Document4 pagesTDS - Resist 78 - English (Uk) - Issued.02.04.2010PaulSwinbankNo ratings yet

- Oasis QD Special PrimerDocument2 pagesOasis QD Special PrimerMaurice DavisNo ratings yet

- Penguard Express ZPDocument5 pagesPenguard Express ZPMustafa Al-YasseriNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertherm - 3350 - Eng - A4 - 20150818vtnhoemNo ratings yet

- Penguard Midcoat - English (Uk) - Issued.26.11.2010Document4 pagesPenguard Midcoat - English (Uk) - Issued.26.11.2010Faisal NismarNo ratings yet

- Marathon XHB - English (Uk) - Issued.06.12.2007Document3 pagesMarathon XHB - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Masterflex 700 GGDocument3 pagesMasterflex 700 GGHaresh BhavnaniNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- Jotatemp 650 (ENG)Document3 pagesJotatemp 650 (ENG)Dedi KartiwaNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- 2017 Glass BrochureDocument6 pages2017 Glass BrochureYing Kei ChanNo ratings yet

- 3M High Flow Filter System Brochure 2019Document12 pages3M High Flow Filter System Brochure 2019Ying Kei ChanNo ratings yet

- 1 Rath Filtration Presentation For Hungarian Silicate Industrial Society 20190507Document19 pages1 Rath Filtration Presentation For Hungarian Silicate Industrial Society 20190507Ying Kei ChanNo ratings yet

- Short Test of Strength For Production WasteDocument12 pagesShort Test of Strength For Production WasteYing Kei ChanNo ratings yet

- Rpbid: Serial SolutionDocument5 pagesRpbid: Serial SolutionYing Kei ChanNo ratings yet

- Operation Manual: Mist CollectorDocument40 pagesOperation Manual: Mist CollectorYing Kei ChanNo ratings yet

- EGE Metal DetectorsDocument8 pagesEGE Metal DetectorsYing Kei ChanNo ratings yet

- 3M Liqui-Cel Membrane Contactors Beverage Brochure UK Ire 2018Document8 pages3M Liqui-Cel Membrane Contactors Beverage Brochure UK Ire 2018Ying Kei ChanNo ratings yet

- EGE Inductive SensorsDocument72 pagesEGE Inductive SensorsYing Kei ChanNo ratings yet

- EGE Level SensorsDocument40 pagesEGE Level SensorsYing Kei ChanNo ratings yet

- EGE Pressure SensorsDocument8 pagesEGE Pressure SensorsYing Kei ChanNo ratings yet

- EGE Infrared DetectorsDocument12 pagesEGE Infrared DetectorsYing Kei ChanNo ratings yet

- Pentair Mecair Threaded Pulse Jet ValvesDocument5 pagesPentair Mecair Threaded Pulse Jet ValvesYing Kei ChanNo ratings yet

- EGE Opto SensorsDocument16 pagesEGE Opto SensorsYing Kei ChanNo ratings yet

- PMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Document8 pagesPMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Ying Kei ChanNo ratings yet

- Protect Public Spaces From Pathogens With UV Solutions From American UltravioletDocument6 pagesProtect Public Spaces From Pathogens With UV Solutions From American UltravioletYing Kei ChanNo ratings yet

- M12 Connector: Cable Plug Housing Pin-AssignmentDocument10 pagesM12 Connector: Cable Plug Housing Pin-AssignmentYing Kei ChanNo ratings yet

- Solar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaDocument40 pagesSolar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaYing Kei ChanNo ratings yet

- CAMFILL HEPA Ispe ArticleDocument12 pagesCAMFILL HEPA Ispe ArticleYing Kei ChanNo ratings yet

- Paper Joggers CatalogDocument20 pagesPaper Joggers CatalogYing Kei ChanNo ratings yet

- ASCO Fluid Control-ChapH-2 - 2-Dust Collector Valves-CAT-gbDocument6 pagesASCO Fluid Control-ChapH-2 - 2-Dust Collector Valves-CAT-gbYing Kei ChanNo ratings yet

- American Ultraviolet Packaged Equipment Kit (PEK) SeriesDocument2 pagesAmerican Ultraviolet Packaged Equipment Kit (PEK) SeriesYing Kei ChanNo ratings yet

- Isolation Valve RSK: A Passive Device For Isolating Dust Explosions. Certification According To 94/9/ECDocument3 pagesIsolation Valve RSK: A Passive Device For Isolating Dust Explosions. Certification According To 94/9/ECYing Kei ChanNo ratings yet

- Flameless Vent - FLEX ProDocument2 pagesFlameless Vent - FLEX ProYing Kei ChanNo ratings yet

- XP Drum Kit: Installation, Operation, and Maintenance Manual Patent Pending - Utility 35 Usc 111 (A)Document16 pagesXP Drum Kit: Installation, Operation, and Maintenance Manual Patent Pending - Utility 35 Usc 111 (A)Ying Kei ChanNo ratings yet

- Explosion Proof "Mini" Drum KitDocument2 pagesExplosion Proof "Mini" Drum KitYing Kei ChanNo ratings yet

- 91 - Gus L - Maw of SnailsDocument1 page91 - Gus L - Maw of SnailsОлег КацыNo ratings yet

- St. Elizabeth Global Skills Institute, Inc.: Institutional Assessment in Gas Tungsten Arc WeldingDocument3 pagesSt. Elizabeth Global Skills Institute, Inc.: Institutional Assessment in Gas Tungsten Arc WeldingJimMarkGasparCabanisasNo ratings yet

- 2010 Nighthawk Custom CatalogDocument68 pages2010 Nighthawk Custom CatalogMario LopezNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- Brosur Ground RodDocument2 pagesBrosur Ground Rodahmad yusufNo ratings yet

- Catalogo LAMINADocument389 pagesCatalogo LAMINAJose' TNo ratings yet

- Parametric Optimization in Die Sinking Edm of Inconel 825 Using Copper ElectrodeDocument9 pagesParametric Optimization in Die Sinking Edm of Inconel 825 Using Copper ElectrodeManishNo ratings yet

- Calculation of Corrosion Rates and Related Information From Electrochemical MeasurementsDocument7 pagesCalculation of Corrosion Rates and Related Information From Electrochemical MeasurementsDhamodharanNo ratings yet

- ITT American Electric Ballast-In-Arm Series 165 & 166 Spec Sheet 2-79Document8 pagesITT American Electric Ballast-In-Arm Series 165 & 166 Spec Sheet 2-79Alan MastersNo ratings yet

- Defect TrainingDocument16 pagesDefect Trainingdedikartiwa_dk100% (1)

- ASTM A252 (Versi 2010)Document7 pagesASTM A252 (Versi 2010)Herman SandyNo ratings yet

- Clase N 5Document4 pagesClase N 5Xthian Vidal CortezNo ratings yet

- Analytic ChemistryDocument115 pagesAnalytic ChemistryRalyn BasisNo ratings yet

- Isothermal Transformation DiagramsDocument6 pagesIsothermal Transformation DiagramsSalem GarrabNo ratings yet

- Me218 Fa15 W3 HoDocument10 pagesMe218 Fa15 W3 HonhiuNo ratings yet

- Armox 600T: General Product DescriptionDocument2 pagesArmox 600T: General Product Descriptionehudingram6535No ratings yet

- Construction and Operation of Turbogenerator: BY P.Ram Prathap Executive Trainee GMR GroupDocument19 pagesConstruction and Operation of Turbogenerator: BY P.Ram Prathap Executive Trainee GMR Groupsantoshkumar100% (2)

- KST Plumbing Tools, Construction PDFDocument73 pagesKST Plumbing Tools, Construction PDFNick GeneseNo ratings yet

- Certificate of Compliance: Trade Name: Usa 7018Document1 pageCertificate of Compliance: Trade Name: Usa 7018Khaled A MarashliNo ratings yet

- CATALOGO Scorziello SASADocument52 pagesCATALOGO Scorziello SASAantonio_militeNo ratings yet

- Steel Crankshaft HardeningDocument2 pagesSteel Crankshaft Hardening13311A0341 S SHIVA SAI KIRANNo ratings yet

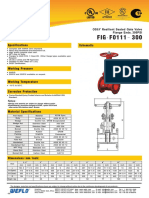

- OS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Document1 pageOS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Fight FireNo ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- 1108 Metric Data SheetDocument1 page1108 Metric Data SheetVoele paterNo ratings yet

- SUBSEA ConnectorsDocument32 pagesSUBSEA Connectorslijojose1No ratings yet

- Brochure Valves PDFDocument36 pagesBrochure Valves PDFYahooNo ratings yet

- Dremel ManualDocument76 pagesDremel ManualJohn Paul RicheyNo ratings yet

- Investment MaterialsDocument191 pagesInvestment MaterialsPriyanka SetiaNo ratings yet