Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

31 viewsProduction Technology

Production Technology

Uploaded by

Zaheer Ahamad Ansariits a production engineering book

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Spe Competency MatrixDocument5 pagesSpe Competency MatrixChijioke Zion OkabieNo ratings yet

- Heriot - Watt University - Production Technology IDocument476 pagesHeriot - Watt University - Production Technology IBrahim Letaief75% (12)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Residential Patio Covers RequirementsDocument6 pagesResidential Patio Covers Requirements63ragtop100% (1)

- Well Performance CourseDocument2 pagesWell Performance CoursevicblanNo ratings yet

- Course Completions and Workovers Caw Virtual Blended DeliveryDocument8 pagesCourse Completions and Workovers Caw Virtual Blended DeliveryShashiz DareNo ratings yet

- Drilling MatrixDocument3 pagesDrilling Matrixjonny727100% (1)

- 2752 Corecompetencies ONGCDocument7 pages2752 Corecompetencies ONGCVivek FinoricNo ratings yet

- NODAL™ Analysis - PO2Document2 pagesNODAL™ Analysis - PO2fuckme123No ratings yet

- Prosper SoftwareDocument6 pagesProsper Softwarebharath35kumar0% (1)

- Spe 181344 MsDocument25 pagesSpe 181344 MsZehron ChemicalsNo ratings yet

- Spe 179137 MSDocument26 pagesSpe 179137 MSaxel.tokoNo ratings yet

- Production EngineeringDocument15 pagesProduction EngineeringMuhammad Mujahid100% (1)

- GB 02 Mixing Process DesignDocument28 pagesGB 02 Mixing Process DesignRamakrishna Somu100% (3)

- SPE-172308-MS Advances in Numerical Modeling of Downhole Dynamics For Perforated Well CompletionsDocument13 pagesSPE-172308-MS Advances in Numerical Modeling of Downhole Dynamics For Perforated Well CompletionsAROLDO BERMUDEZNo ratings yet

- Production 01Document20 pagesProduction 01Rizwan FaridNo ratings yet

- Artical On Artifical Lifts 1Document5 pagesArtical On Artifical Lifts 1Chandhini BatchalaNo ratings yet

- Artical On Artifical Lifts 1Document5 pagesArtical On Artifical Lifts 1Chandhini BatchalaNo ratings yet

- In Development: Production & Economic Analysis of Tight ReservoirsDocument8 pagesIn Development: Production & Economic Analysis of Tight Reservoirsdino_birds6113No ratings yet

- A4 SPEC Pumping Systems 201507 PDFDocument5 pagesA4 SPEC Pumping Systems 201507 PDFJose BijoyNo ratings yet

- Recent Advances in Coring and Core Analysis For Reservoir EvaluationDocument24 pagesRecent Advances in Coring and Core Analysis For Reservoir EvaluationjanlayaNo ratings yet

- Petroleum Production Optimization: TechnologyDocument18 pagesPetroleum Production Optimization: TechnologybehnamjpNo ratings yet

- Reservoir Engineering For Geologist A. OverviewDocument4 pagesReservoir Engineering For Geologist A. OverviewRalmerAlanaPutraNo ratings yet

- Troubleshooting The SeparatorsDocument2 pagesTroubleshooting The SeparatorsrutujaNo ratings yet

- March 2019, Kansao Rami CV - PEDocument3 pagesMarch 2019, Kansao Rami CV - PEJose MaitaNo ratings yet

- SPE 188634 An Automated Approach To Well Design Using A Reservoir Simulator and Analysis NodalDocument12 pagesSPE 188634 An Automated Approach To Well Design Using A Reservoir Simulator and Analysis NodalEdgar GonzalezNo ratings yet

- A Practical Way To Prepare Physical-BasedDocument13 pagesA Practical Way To Prepare Physical-BasedJuan Pablo Guzman CastroNo ratings yet

- SimulationDocument11 pagesSimulationYallarling NagureNo ratings yet

- Improving Real-Time Drilling Optimization Applying Engineering Performance From Offset WellsDocument15 pagesImproving Real-Time Drilling Optimization Applying Engineering Performance From Offset Wellsdrilling moneytreeNo ratings yet

- My Website: Well Testing & Well Test AnalysisDocument23 pagesMy Website: Well Testing & Well Test AnalysisGadhoumiWalidNo ratings yet

- Well Test Analysis PDFDocument23 pagesWell Test Analysis PDFTariq MirzaNo ratings yet

- Well Test Analysis PDFDocument23 pagesWell Test Analysis PDFJaime Alberto Aranibar CabreraNo ratings yet

- Well Test Analysis PDFDocument23 pagesWell Test Analysis PDFJaime Alberto Aranibar CabreraNo ratings yet

- Well Performance Analysis Based On Flow Calculations and IprDocument20 pagesWell Performance Analysis Based On Flow Calculations and Ipregv2000No ratings yet

- Review of Drilling EngineeringDocument4 pagesReview of Drilling EngineeringGuychel mabialaNo ratings yet

- SPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseDocument21 pagesSPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseEdgar GonzalezNo ratings yet

- Troubleshooting, Root Cause AnalysisDocument5 pagesTroubleshooting, Root Cause AnalysisZeeshan HaiderNo ratings yet

- SPE-10709 Physics Based Well Design - Beyond The Learning CurveDocument5 pagesSPE-10709 Physics Based Well Design - Beyond The Learning Curvedrilling moneytreeNo ratings yet

- Design and Evaluation of Perforation Performance Using Dynamic Under Balance: North Sea Case HistoriesDocument10 pagesDesign and Evaluation of Perforation Performance Using Dynamic Under Balance: North Sea Case HistoriesJoseAngelVillarViñolesNo ratings yet

- SPE-193121-MS - Integrated Prod Optim Workflow Provides Robust Platform For Significant Oil Gain To A Mature Field-UnlockedDocument22 pagesSPE-193121-MS - Integrated Prod Optim Workflow Provides Robust Platform For Significant Oil Gain To A Mature Field-UnlockedadeeyoNo ratings yet

- Integrated Reservoir ModellingDocument16 pagesIntegrated Reservoir ModellingAl DaNo ratings yet

- Spe 77897 MSDocument6 pagesSpe 77897 MSLulut Fitra FalaNo ratings yet

- SPE 120271 Predicting Production Outcome From Multi-Stage Horizontal Barnett CompletionsDocument10 pagesSPE 120271 Predicting Production Outcome From Multi-Stage Horizontal Barnett CompletionsJose Gregorio FariñasNo ratings yet

- SPE Mexico Corrosion 06Document9 pagesSPE Mexico Corrosion 06henbauNo ratings yet

- Optimising Standard and Produced Water Injection Systems: BackgroundDocument6 pagesOptimising Standard and Produced Water Injection Systems: BackgroundTHANGVUNo ratings yet

- Design Analysis and Scale Up of MixingDocument0 pagesDesign Analysis and Scale Up of MixingAnonymous 1zdRSWskhgNo ratings yet

- Reservoir Management2Document19 pagesReservoir Management2Ashraf BasbarNo ratings yet

- Wellplan Software: Key ValueDocument4 pagesWellplan Software: Key Valuebyed100% (1)

- Dropped Object Effect in Offshore Subsea Structures and Pipeline ApproachDocument15 pagesDropped Object Effect in Offshore Subsea Structures and Pipeline ApproachRaghu MahadevappaNo ratings yet

- SPE-165374-Global Model For Failure Prediction For Rod Pump Artificial Lift SystemsDocument10 pagesSPE-165374-Global Model For Failure Prediction For Rod Pump Artificial Lift SystemsBrenda Rojas CardozoNo ratings yet

- Research Paper Petroleum EngineeringDocument7 pagesResearch Paper Petroleum Engineeringgvzcrpym100% (1)

- Total Well Management IIDocument14 pagesTotal Well Management IIEdgar Tellez100% (1)

- Well Design Drilling and WorkoverDocument6 pagesWell Design Drilling and Workovers33d_2010100% (1)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Investment Performance Measurement: Evaluating and Presenting ResultsFrom EverandInvestment Performance Measurement: Evaluating and Presenting ResultsPhilip Lawton, CIPMRating: 1 out of 5 stars1/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Tổng hợp bài tập ngữ pháp (Trắc nghiệm và tự luận)Document42 pagesTổng hợp bài tập ngữ pháp (Trắc nghiệm và tự luận)Xuan MaiNo ratings yet

- Claus Unit ReliabilityDocument5 pagesClaus Unit Reliabilitybakhtiari_afNo ratings yet

- DNA Extraction From Fungi, Yeast, and BacteriaDocument2 pagesDNA Extraction From Fungi, Yeast, and Bacteriavishankgupta100% (1)

- Operation TorchDocument136 pagesOperation TorchRomana Zaman100% (1)

- Tugas Presentasi PKLDocument3 pagesTugas Presentasi PKLAidil AzharNo ratings yet

- Rankine CycleDocument12 pagesRankine CycleVishant GuliaNo ratings yet

- Europe: Location, Climate, Natural Resources, & Trade: 6 Grade Social Studies Unit 1: Geography of EuropeDocument18 pagesEurope: Location, Climate, Natural Resources, & Trade: 6 Grade Social Studies Unit 1: Geography of Europeapi-275304033No ratings yet

- Identifikasi Hubungan Fluktuasi Nilai Soi Terhadap Curah Hujan Bulanan Di Kawasan Batukaru-Bedugul, BaliDocument7 pagesIdentifikasi Hubungan Fluktuasi Nilai Soi Terhadap Curah Hujan Bulanan Di Kawasan Batukaru-Bedugul, BaliPutra Muhammad AbdillahNo ratings yet

- 2015 LEAF CatalogueDocument64 pages2015 LEAF CatalogueErwin0% (1)

- If Clause LessonDocument8 pagesIf Clause LessonMega NandaNo ratings yet

- ClimatechangeDocument29 pagesClimatechangesidra100% (1)

- SUNCO Tobacco India Crop Profile CatalogDocument7 pagesSUNCO Tobacco India Crop Profile CatalogAchanta SatyaNo ratings yet

- Planning Guide For Power Distribution Plants Design Implementation and Operation of inDocument64 pagesPlanning Guide For Power Distribution Plants Design Implementation and Operation of incarlosmandopintoNo ratings yet

- UK MIKE 21 Guide - MarineDocument20 pagesUK MIKE 21 Guide - MarineRamirez DelgadoNo ratings yet

- Lesson+Plan+1+ +Heat+TransferDocument8 pagesLesson+Plan+1+ +Heat+TransferJessa Mae TiongsonNo ratings yet

- DH 1202Document10 pagesDH 1202The Delphos HeraldNo ratings yet

- Level 3: Sample Questions For - Students From Grade/class IX & XDocument7 pagesLevel 3: Sample Questions For - Students From Grade/class IX & XHarsh KhulbeNo ratings yet

- Economic Value of Trees 2Document57 pagesEconomic Value of Trees 2Christian Rhay PizarroNo ratings yet

- Grade 7 Q2 English LASDocument25 pagesGrade 7 Q2 English LASMiriam Caling100% (1)

- Groundwater Exploration and Exploitation in The PHLDocument2 pagesGroundwater Exploration and Exploitation in The PHLMCJ Nagum40% (10)

- Synthesis of RDXDocument4 pagesSynthesis of RDXmladen lakic100% (4)

- TE255261 TE SensorSolutions - SS TS TE100!09!2016inddDocument100 pagesTE255261 TE SensorSolutions - SS TS TE100!09!2016inddAravind VickyNo ratings yet

- A New Sun The Solar Results From SkylabDocument225 pagesA New Sun The Solar Results From SkylabBob Andrepont100% (2)

- 6688309210Document79 pages6688309210Putta SwamyNo ratings yet

- The National Greening Program (And What UP Can Contribute)Document2 pagesThe National Greening Program (And What UP Can Contribute)Mikki EugenioNo ratings yet

- Chapter 2. Precipitation: BFC 32002 HydrologyDocument62 pagesChapter 2. Precipitation: BFC 32002 HydrologyAsyiqindiniaNo ratings yet

- De Thi Hoc Ki 1 Tieng Anh 10 Friends Global de So 1 1669621904Document17 pagesDe Thi Hoc Ki 1 Tieng Anh 10 Friends Global de So 1 1669621904Minh TrungNo ratings yet

- I Just Called To Say I Love You - ESL ActivityDocument1 pageI Just Called To Say I Love You - ESL ActivitydebNo ratings yet

- Informal Narrative Letter UpdateDocument2 pagesInformal Narrative Letter UpdateMercedes SANo ratings yet

Production Technology

Production Technology

Uploaded by

Zaheer Ahamad Ansari0 ratings0% found this document useful (0 votes)

31 views6 pagesits a production engineering book

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentits a production engineering book

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

31 views6 pagesProduction Technology

Production Technology

Uploaded by

Zaheer Ahamad Ansariits a production engineering book

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

Performance Criteria Production Technology

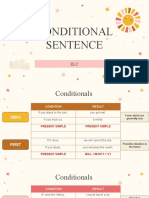

Proficiency Level Awareness Knowledge Skill

Rating 1 2 3

Skill Element Description #

Well Performance Management

Well Flow

Modeling

Predict the rate at which a well

should be capable of

producing, given reservoir and

fluid properties, wellbore

configuration, and flowing

wellhead pressure. Identify

and remediate under-

performing wells.

1.1

Describe typical well

completions in his area. What

are the reservoir conditions

(initial and actual), magnitude

of drawdown and actual

production?

Describe basic reservoir

engineering concepts

(porosity, permeability,

saturation, etc). Explain

typical production strategy.

Explain the concept of Nodal

Analysis and how to calculate

Inflow Performance. What is

the critical rate to lift liquids.

List the assumptions for

decline curve analysis.

Describe how to estimate

permeability, skin factor and

drainage area from production

data and using Nodal

Analysis.

Design the appropriate

wellbore configuration for a

predefined type of well for

given initial and projected

reservoir inflow performance,

surface conditions, and

produced fluid constituents.

Explain how to forecast future

performance from historical

production trends and from

known reservoir properties.

Describe production

prediction of multilaterals.

Identify components of

Bernoulli's equation. Describe

factors that govern flow in

vertical, inclined, and

horizontal flowlines. Explain

components of pressure drop

in these three cases. List

appropriate correlations for oil

and gas.

Design the appropriate tubing

size, wellbore configuration

for surface conditions such as

operations onr high pressure,

high temperature completions

with substantial non-

hydrocarbon components.

Evaluate horizontal wells

performance.

Explain reservoir engineering

concepts for horizontal wells,

productivity of horizontal

wells.

Compare water and gas

coning in vertical and

horizontal wells.

Production

Enhancement

Integrated reservoir review on

a team approach to identify

opportunities and select

candidates for optimum

reservoir exploitation, nodal

analysis techniques,

economic and risk analysis of

the portfolio and

implementation of the well

intervention solutions and

potential consequences.

1.2

Describe various techniques

(isovariables mapping,

normalized production maps,

cross-sections techniques,

integrated reservoir analysis)

to identify production

opportunities.

Explain Nodal Analysis

concept and how inflow and

outflow curves are calculated.

Describe basic reservoir

engineering concepts and

explain typical production

strategy.

Explain what information is

required to perform Nodal

Analysis and what data can be

obtained from review of well

files, pressure tests, geology,

petrophysics, cased hole logs,

reserves estimation, and

production data. Describe the

trade offs between different

well path designs.

Explain how the optimum

producing configuration

depends on of initial reservoir

inflow performance, wellbore

pressure drop, and surface

Demonstrate ability to analyze

reservoir, drainage area,

completion, tubing, lift

equipment, surface network to

evaluate the production

system behavior. Based on

the analyses specify

integrated solutions and

manner in which the wells

should be monitored and

treated.

Demonstrate expertise in

selection of production

enhancement methods and

show familiarity with field

COPYRIGHT 2003, Network of Excellence in Training Ltd. All Rights Reserved. Production Technology Page 1 of 6

Proficiency Level Awareness Knowledge Skill

Rating 1 2 3

Skill Element Description #

List major economic indicators

(rate of return, payback, NPV)

and show how to calculate

them.

conditions. Describe the

requirements to the wellbore

configuration over the full life

cycle of production in order to

accommodate changes in

reservoir performance and

changes in produced fluid

constituents.

Explain the concept of risk

analysis. Show application of

Monte-Carlo simulation in risk

analysis.

operations for production

enhancement.

List major economic indicators

(rate of return, payback, NPV)

and show how to calculate

them.

Explain the concept of risk

analysis. Show application of

simulation (Monte-Carlo)in

risk analysis.

.

Artificial Lift

Artificial Lift

Design

To identify requirements for

anticipated artificial assistance

to production, maximizing

recovery in a cost effective

manner. Selection and Design

of the proper production

method (Natural flow, artificial

gas lift, electrical submersible

pumps, progressive cavity

pumps, rod pumps, hydraulic

pumps)

2.1

Identify major steps in the

selection and design of an

appropriate artificial lift method

to satisfy well productivity

requirements.

Explain the concept of artificial

lift. Describe required surface

and downhole equipment.

Calculate bottomhole flowing

pressure using pressure

traverse and dynamic fluid

level data.

Supervise running artificial lift

completions.

Preliminary design of ESPs

Explain fundamentals of well

completion and of multiphase

flow in vertical/horizontal

pipes. Explain selection

procedure for the proper

artificial lift method. Calculate

inflow and outflow

performance based on the

artificial method.

Describe equipment for

artificial lift used in your area.

Participate in design and

installation of such

completions.

List steps in the ESP design.

Explain ESP performance

curves (head and efficiency

vs. capacity). Describe

requirements to ESP

installations (fluid level above

pump intake, hole deviation,

setting depth).

Demonstrate experience in

designing artificial lift methods

to satisfy well requirements,

including those in sour

environments.

Describe and explain

application of artificial lift

equipment. Demonstrate

competent ability to use

artificial lift design software.

Explain how to determine gas,

energy and diluent's

consumption. List different

types and installations of

ESP's.

Stimulation/Workovers

Acidizing

Specify and define well acid

treatment so that it satisfies

the objectives for improving

productivity and damage

removal. Knowledge in

3.1

Explain the main purpose of

acidizing (damage removal),

various types of acids, and

basic concepts for their

Characterize various types of

skin, their sources, and impact

on well deliverability .

Describe process of candidate

Can use acid treatment

design software to design

jobs.

COPYRIGHT 2003, Network of Excellence in Training Ltd. All Rights Reserved. Production Technology Page 2 of 6

Proficiency Level Awareness Knowledge Skill

Rating 1 2 3

Skill Element Description #

generic formation damage

mechanisms and acidizing

candidate selection and the

correct chemical methods to

treat each case.

selection.

Describe typical field,

pumping, and production

operations.

Describe basic chemistry

concepts as related to removal

of formation damage.

selection for stimulation

Explain the concepts of

acidizing, the various

properties that are important

to acids and in preventing

precipitation during acidizing.

Identify the optimal acid fluid

for anticipated well conditions.

List several acid additives and

their purposes.

Recommend appropriate

elements/additives for iron

control, corrosion inhibition,

clay stabilization. Describe

acid placement and diversion,

mechanical placement

methods.

Describe various chemical

diversion techniques (foams,

gels, particulates), treatment

design (preflush, afterflush,

treatment volumes) for a

broad range of well

conditions.

Hydraulic

Fracturing

Entails identification of well

candidates, design,

formulation and quality control

of treatments, monitoring

response and the resultant

effects on the productivity of

the well.

Types of fracturing

methodologies

3.2

Explain fundamental concepts

of rock mechanics (principal

stresses in rocks), application

of log analysis, and methods

for identifying fracturing

candidates.

Describe basic fracturing

models and their key

parameters.

Calculate basic system

pressure drop due to friction

given all parameters and

bottom hole treating

pressures.

Describe requirements to

fracturing fluids and proppants

how to perform QC of

fracturing fluids and proppants

Explain major concerns in well

preparation for fracturing

(density and type of

perforations, requirements for

clean-up, maximum working

limits). Describe sequence of

actions in a typical fracturing

operation.

Explain data requirements for

fracturing design, calculate or

predict magnitudes of rock

stresses based on sonic logs.

Describe and interpret results

of rock analysis.

.

Explain pressure transient

methods and interpretation

techniques to evaluate post-

fracturing performance.

Fully experienced in the

design of fracturing

operations: selection of well

candidates according to

economics, data collection

from rock analysis or logs or

correlations, selection of

fracturing fluids and additives,

selection of proppant, design

of pumping schedule.

Describe specifics of

fracturing in HPHT conditions,

gas and of horizontal wells.

Experienced in frac-and-pack

and acid fracking.

Frac-Pack

Applications

(these skills should be in

addition to the ones in

fracturing). To identify wells

candidates to perform gravel

pack with a hydraulic fracture

to by-pass formation damage.

To perform the design of these

operations and recommend

required equipment.

3.3

Explain basic concepts of rock

mechanics as related to sand

production. Describe

mechanisms of sand

production and principles of

fracturing.

List main data along with its

sources that are required for

Describe what input

information is available from

wells files, from results of rock

and log analysis. Explain

principles used in the selection

of wells for frac-pack.

Able to use specialized

software to design the

Experience in selecting fluids,

gravel, and tools for the

operation.

Fully knowledgeable in the

design, operation and

evaluation of frac-packs.

COPYRIGHT 2003, Network of Excellence in Training Ltd. All Rights Reserved. Production Technology Page 3 of 6

Proficiency Level Awareness Knowledge Skill

Rating 1 2 3

Skill Element Description #

frac-pack design.

Explain benefits and

limitations of frac-pack

application.

pumping schedules.

Describe gravel size

calculation with account for

the size of formation sand and

in-situ stresses.

Perform economical

evaluation of wells

candidates.

Completions/Development Scenarios

Well & Sand

Face Completion

To specify and to define Well

to meet the objectives for

which it is drilled. To

understand casing and tubing

design taking into account

stress analysis, corrosion and

well performance.

.

4.1

Describe the different

requirements and equipment

for basic types of wells:

production (liquid, gas, multi-

phase); injection; and

disposal.

Describe what information is

available in well files and

databases. Explain how to

analyze, check, and use this

information to define well

performance.

Explain the concept of Nodal

analysis.

Describe different types of

casing and tubing, tubulars

joints, pressure limitations and

tubulars design safety factors.

. Explain how tubing length

and diameter affect

deliverability of the well

system.

List steps in performing first

draft of completion systems

(selection of tubulars weight,

grade and threads) using

Nodal Analysis, API AND / OR

LOCAL STANDAR standards,

and Company policies.

Describe typical downhole

equipment (packers and

downhole pumps) and their

applications.

Demonstrate application of

Nodal Analysis in designing

completion, perforation;

selecting tubular types, sizes,

threads, and downhole

equipment.

Describe what elements of a

well design help control

borehole instabilities and what

are the production practices

that might cause solids

production.

Perforation

Design

Proper selection of perforating

tools and techniques, proper

size and number of shots

anticipating future

requirements for well

production (sand control,

matrix acidizing, hydraulic

fracturing).

4.2

Identify different types of

perforating techniques.

Calculate pressure drop

across perforations for various

wells scenarios in your area.

Describe common elements of

perforating tools assemblies.

.

Describe design

considerations to satisfy well

production requirements

based on Nodal analysis

sensitivity studies and using

specialized perforating

software.

Explain use and placement of

perforating guns.

Demonstrate experience in

designing perforations,

including those used in

directional wells. Explain

impact of perforating elements

on well productivity.

Describe decision process for

perforating. Explain

perforation requirements for

sand control, matrix

stimulation, and hydraulic

fracturing.

Horizontal Well

Completion

Specify and define horizontal

well components so that it

satisfies the objectives for

which it is drilled and

4.3

Describe the different

requirements for different

types of wells: production

(liquid, gas, multi-phase);

Describe purposes and

functions of tubulars and of

various downhole production

tools. Explain the deliverability

Define and be able to design

appropriate kickoff points,

build rates, required hole

angles, well profile, wellpath,

COPYRIGHT 2003, Network of Excellence in Training Ltd. All Rights Reserved. Production Technology Page 4 of 6

Proficiency Level Awareness Knowledge Skill

Rating 1 2 3

Skill Element Description #

completed. injection; and disposal.

Understand the relationship

between difficulty and lateral

displacement.

of the well system.

Explain basic design principles

(burst, collapse, tension) for

casing.

Demonstrate familiarity with

typical horizontal completions

in your area and explain the

design procedures.

trajectory. Show ability to

design bottom hole

assemblies (production

casing/liner) to maintain well

integrity.

Explain selection of the most

adequate type of completion

for horizontal wells based on

the expected production,

conformance strategies, well

remediation and other

interventions in the life of the

well.

Sand Control

Design

Specify and define well sand

control methods that

minimizes well productivity

index effects with long time

efficiency.

4.4

Describe different

requirements for sand control

on liquid, gas, and multi-phase

production wells.

Explain basic concepts of

rock-fluid system interaction.

Name several technologies for

sand control (resin

consolidation, gravel pack,

screenless, etc).

Describe reasons for sand

control method selection and

functions of various downhole

assemblies (filters, gravel-

packs, frac-packs, gravel and

sand consolidation

techniques). List methods

used in your area.

Explain effect of sand

production on the deliverability

of the well system.

Explain application of

geomechanical analysis to

predict potential sand

production.

Using Nodal Analysis select

the preferred sand control

technique and calculate skin

due to sand control.

Is familiar with the

development and causes of

principal stresses in rocks and

can predict sanding as a

result of the decrease in

reservoir pressure.

Use specialized software to

design sand control

treatments. Describe the

elements of a well design to

control borehole instabilities

and production practices that

affect solids production.

Coiled Tubing

Completion

Techniques, applications and

methods used to drill and

service wells with coiled

tubing.

4.5

Describe differences

associated with this type of

well operation. Has limited

exposure to this technology

and its uses.

Describe development of

operating plans involving

coiled tubing activities

Identify equipment and

services to implement coiled

tubing in production

operations completion, and

workover activities.

.

Identify opportunities for

coiled tubing in production

operations, completion and

workover operations and

assist with the development of

coiled tubing production

operations / completion/

workover policies and

procedures.

Participates in organization

study groups and actively

transfers knowledge of the

COPYRIGHT 2003, Network of Excellence in Training Ltd. All Rights Reserved. Production Technology Page 5 of 6

Proficiency Level Awareness Knowledge Skill

Rating 1 2 3

Skill Element Description #

technology in the analysis of

performance efficiency and

well selection

Multilateral Well

Completion

An extension of the horizontal

well technology, this

technology addresses the

special challenges of multiple

laterals and the completion of

same.

4.6

Using appropriate terminology,

describe the different ways

multilateral wells may be

constructed.

Explain conceptual design and

feasibility evaluation of

multilateral wells.

Demonstrate understanding of

uses and limitations of this

technology obtained from

interacting with other

production operations

organization & production

technology team members.

Assists with development of

workover programs for this

type of well.

Describe considerations

involved in evaluation and

selection of service

companies and technology

providers for multilateral

projects.

Explain development of well

plans and designs that are

optimal for the objectives of

the well.

Works closely with the various

service providers for the

multilateral and interacts with

them as needed to audit and

review the applicability of their

services and equipment to the

needs of the project.

Intelligent

Completion

Those solutions and

processes associated with

data acquisition, management

and automated response to

monitored well conditions.

4.7

Describe the concept of

intelligent completions and

some of the potential

advantages of same.

Provides assistance to the

production operations

organization & completion

team to identify equipment

and services that may have

application to instrumentation

and collection of data from

completed wells.

Works with other disciplines

(e.g. instrumentation) to

develop policies and

procedure for the use and

application of remote data

collection and information

management tools for its use.

Recommends devices and

uses for intelligent

completions.

Interfaces with other

disciplines to define

environments and needs for

remote sensing devices.

COPYRIGHT 2003, Network of Excellence in Training Ltd. All Rights Reserved. Production Technology Page 6 of 6

You might also like

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Spe Competency MatrixDocument5 pagesSpe Competency MatrixChijioke Zion OkabieNo ratings yet

- Heriot - Watt University - Production Technology IDocument476 pagesHeriot - Watt University - Production Technology IBrahim Letaief75% (12)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Residential Patio Covers RequirementsDocument6 pagesResidential Patio Covers Requirements63ragtop100% (1)

- Well Performance CourseDocument2 pagesWell Performance CoursevicblanNo ratings yet

- Course Completions and Workovers Caw Virtual Blended DeliveryDocument8 pagesCourse Completions and Workovers Caw Virtual Blended DeliveryShashiz DareNo ratings yet

- Drilling MatrixDocument3 pagesDrilling Matrixjonny727100% (1)

- 2752 Corecompetencies ONGCDocument7 pages2752 Corecompetencies ONGCVivek FinoricNo ratings yet

- NODAL™ Analysis - PO2Document2 pagesNODAL™ Analysis - PO2fuckme123No ratings yet

- Prosper SoftwareDocument6 pagesProsper Softwarebharath35kumar0% (1)

- Spe 181344 MsDocument25 pagesSpe 181344 MsZehron ChemicalsNo ratings yet

- Spe 179137 MSDocument26 pagesSpe 179137 MSaxel.tokoNo ratings yet

- Production EngineeringDocument15 pagesProduction EngineeringMuhammad Mujahid100% (1)

- GB 02 Mixing Process DesignDocument28 pagesGB 02 Mixing Process DesignRamakrishna Somu100% (3)

- SPE-172308-MS Advances in Numerical Modeling of Downhole Dynamics For Perforated Well CompletionsDocument13 pagesSPE-172308-MS Advances in Numerical Modeling of Downhole Dynamics For Perforated Well CompletionsAROLDO BERMUDEZNo ratings yet

- Production 01Document20 pagesProduction 01Rizwan FaridNo ratings yet

- Artical On Artifical Lifts 1Document5 pagesArtical On Artifical Lifts 1Chandhini BatchalaNo ratings yet

- Artical On Artifical Lifts 1Document5 pagesArtical On Artifical Lifts 1Chandhini BatchalaNo ratings yet

- In Development: Production & Economic Analysis of Tight ReservoirsDocument8 pagesIn Development: Production & Economic Analysis of Tight Reservoirsdino_birds6113No ratings yet

- A4 SPEC Pumping Systems 201507 PDFDocument5 pagesA4 SPEC Pumping Systems 201507 PDFJose BijoyNo ratings yet

- Recent Advances in Coring and Core Analysis For Reservoir EvaluationDocument24 pagesRecent Advances in Coring and Core Analysis For Reservoir EvaluationjanlayaNo ratings yet

- Petroleum Production Optimization: TechnologyDocument18 pagesPetroleum Production Optimization: TechnologybehnamjpNo ratings yet

- Reservoir Engineering For Geologist A. OverviewDocument4 pagesReservoir Engineering For Geologist A. OverviewRalmerAlanaPutraNo ratings yet

- Troubleshooting The SeparatorsDocument2 pagesTroubleshooting The SeparatorsrutujaNo ratings yet

- March 2019, Kansao Rami CV - PEDocument3 pagesMarch 2019, Kansao Rami CV - PEJose MaitaNo ratings yet

- SPE 188634 An Automated Approach To Well Design Using A Reservoir Simulator and Analysis NodalDocument12 pagesSPE 188634 An Automated Approach To Well Design Using A Reservoir Simulator and Analysis NodalEdgar GonzalezNo ratings yet

- A Practical Way To Prepare Physical-BasedDocument13 pagesA Practical Way To Prepare Physical-BasedJuan Pablo Guzman CastroNo ratings yet

- SimulationDocument11 pagesSimulationYallarling NagureNo ratings yet

- Improving Real-Time Drilling Optimization Applying Engineering Performance From Offset WellsDocument15 pagesImproving Real-Time Drilling Optimization Applying Engineering Performance From Offset Wellsdrilling moneytreeNo ratings yet

- My Website: Well Testing & Well Test AnalysisDocument23 pagesMy Website: Well Testing & Well Test AnalysisGadhoumiWalidNo ratings yet

- Well Test Analysis PDFDocument23 pagesWell Test Analysis PDFTariq MirzaNo ratings yet

- Well Test Analysis PDFDocument23 pagesWell Test Analysis PDFJaime Alberto Aranibar CabreraNo ratings yet

- Well Test Analysis PDFDocument23 pagesWell Test Analysis PDFJaime Alberto Aranibar CabreraNo ratings yet

- Well Performance Analysis Based On Flow Calculations and IprDocument20 pagesWell Performance Analysis Based On Flow Calculations and Ipregv2000No ratings yet

- Review of Drilling EngineeringDocument4 pagesReview of Drilling EngineeringGuychel mabialaNo ratings yet

- SPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseDocument21 pagesSPE 185098 Gas Lift Production Benchmarking Using IPR Risked Inflow Modeling CaseEdgar GonzalezNo ratings yet

- Troubleshooting, Root Cause AnalysisDocument5 pagesTroubleshooting, Root Cause AnalysisZeeshan HaiderNo ratings yet

- SPE-10709 Physics Based Well Design - Beyond The Learning CurveDocument5 pagesSPE-10709 Physics Based Well Design - Beyond The Learning Curvedrilling moneytreeNo ratings yet

- Design and Evaluation of Perforation Performance Using Dynamic Under Balance: North Sea Case HistoriesDocument10 pagesDesign and Evaluation of Perforation Performance Using Dynamic Under Balance: North Sea Case HistoriesJoseAngelVillarViñolesNo ratings yet

- SPE-193121-MS - Integrated Prod Optim Workflow Provides Robust Platform For Significant Oil Gain To A Mature Field-UnlockedDocument22 pagesSPE-193121-MS - Integrated Prod Optim Workflow Provides Robust Platform For Significant Oil Gain To A Mature Field-UnlockedadeeyoNo ratings yet

- Integrated Reservoir ModellingDocument16 pagesIntegrated Reservoir ModellingAl DaNo ratings yet

- Spe 77897 MSDocument6 pagesSpe 77897 MSLulut Fitra FalaNo ratings yet

- SPE 120271 Predicting Production Outcome From Multi-Stage Horizontal Barnett CompletionsDocument10 pagesSPE 120271 Predicting Production Outcome From Multi-Stage Horizontal Barnett CompletionsJose Gregorio FariñasNo ratings yet

- SPE Mexico Corrosion 06Document9 pagesSPE Mexico Corrosion 06henbauNo ratings yet

- Optimising Standard and Produced Water Injection Systems: BackgroundDocument6 pagesOptimising Standard and Produced Water Injection Systems: BackgroundTHANGVUNo ratings yet

- Design Analysis and Scale Up of MixingDocument0 pagesDesign Analysis and Scale Up of MixingAnonymous 1zdRSWskhgNo ratings yet

- Reservoir Management2Document19 pagesReservoir Management2Ashraf BasbarNo ratings yet

- Wellplan Software: Key ValueDocument4 pagesWellplan Software: Key Valuebyed100% (1)

- Dropped Object Effect in Offshore Subsea Structures and Pipeline ApproachDocument15 pagesDropped Object Effect in Offshore Subsea Structures and Pipeline ApproachRaghu MahadevappaNo ratings yet

- SPE-165374-Global Model For Failure Prediction For Rod Pump Artificial Lift SystemsDocument10 pagesSPE-165374-Global Model For Failure Prediction For Rod Pump Artificial Lift SystemsBrenda Rojas CardozoNo ratings yet

- Research Paper Petroleum EngineeringDocument7 pagesResearch Paper Petroleum Engineeringgvzcrpym100% (1)

- Total Well Management IIDocument14 pagesTotal Well Management IIEdgar Tellez100% (1)

- Well Design Drilling and WorkoverDocument6 pagesWell Design Drilling and Workovers33d_2010100% (1)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Investment Performance Measurement: Evaluating and Presenting ResultsFrom EverandInvestment Performance Measurement: Evaluating and Presenting ResultsPhilip Lawton, CIPMRating: 1 out of 5 stars1/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Tổng hợp bài tập ngữ pháp (Trắc nghiệm và tự luận)Document42 pagesTổng hợp bài tập ngữ pháp (Trắc nghiệm và tự luận)Xuan MaiNo ratings yet

- Claus Unit ReliabilityDocument5 pagesClaus Unit Reliabilitybakhtiari_afNo ratings yet

- DNA Extraction From Fungi, Yeast, and BacteriaDocument2 pagesDNA Extraction From Fungi, Yeast, and Bacteriavishankgupta100% (1)

- Operation TorchDocument136 pagesOperation TorchRomana Zaman100% (1)

- Tugas Presentasi PKLDocument3 pagesTugas Presentasi PKLAidil AzharNo ratings yet

- Rankine CycleDocument12 pagesRankine CycleVishant GuliaNo ratings yet

- Europe: Location, Climate, Natural Resources, & Trade: 6 Grade Social Studies Unit 1: Geography of EuropeDocument18 pagesEurope: Location, Climate, Natural Resources, & Trade: 6 Grade Social Studies Unit 1: Geography of Europeapi-275304033No ratings yet

- Identifikasi Hubungan Fluktuasi Nilai Soi Terhadap Curah Hujan Bulanan Di Kawasan Batukaru-Bedugul, BaliDocument7 pagesIdentifikasi Hubungan Fluktuasi Nilai Soi Terhadap Curah Hujan Bulanan Di Kawasan Batukaru-Bedugul, BaliPutra Muhammad AbdillahNo ratings yet

- 2015 LEAF CatalogueDocument64 pages2015 LEAF CatalogueErwin0% (1)

- If Clause LessonDocument8 pagesIf Clause LessonMega NandaNo ratings yet

- ClimatechangeDocument29 pagesClimatechangesidra100% (1)

- SUNCO Tobacco India Crop Profile CatalogDocument7 pagesSUNCO Tobacco India Crop Profile CatalogAchanta SatyaNo ratings yet

- Planning Guide For Power Distribution Plants Design Implementation and Operation of inDocument64 pagesPlanning Guide For Power Distribution Plants Design Implementation and Operation of incarlosmandopintoNo ratings yet

- UK MIKE 21 Guide - MarineDocument20 pagesUK MIKE 21 Guide - MarineRamirez DelgadoNo ratings yet

- Lesson+Plan+1+ +Heat+TransferDocument8 pagesLesson+Plan+1+ +Heat+TransferJessa Mae TiongsonNo ratings yet

- DH 1202Document10 pagesDH 1202The Delphos HeraldNo ratings yet

- Level 3: Sample Questions For - Students From Grade/class IX & XDocument7 pagesLevel 3: Sample Questions For - Students From Grade/class IX & XHarsh KhulbeNo ratings yet

- Economic Value of Trees 2Document57 pagesEconomic Value of Trees 2Christian Rhay PizarroNo ratings yet

- Grade 7 Q2 English LASDocument25 pagesGrade 7 Q2 English LASMiriam Caling100% (1)

- Groundwater Exploration and Exploitation in The PHLDocument2 pagesGroundwater Exploration and Exploitation in The PHLMCJ Nagum40% (10)

- Synthesis of RDXDocument4 pagesSynthesis of RDXmladen lakic100% (4)

- TE255261 TE SensorSolutions - SS TS TE100!09!2016inddDocument100 pagesTE255261 TE SensorSolutions - SS TS TE100!09!2016inddAravind VickyNo ratings yet

- A New Sun The Solar Results From SkylabDocument225 pagesA New Sun The Solar Results From SkylabBob Andrepont100% (2)

- 6688309210Document79 pages6688309210Putta SwamyNo ratings yet

- The National Greening Program (And What UP Can Contribute)Document2 pagesThe National Greening Program (And What UP Can Contribute)Mikki EugenioNo ratings yet

- Chapter 2. Precipitation: BFC 32002 HydrologyDocument62 pagesChapter 2. Precipitation: BFC 32002 HydrologyAsyiqindiniaNo ratings yet

- De Thi Hoc Ki 1 Tieng Anh 10 Friends Global de So 1 1669621904Document17 pagesDe Thi Hoc Ki 1 Tieng Anh 10 Friends Global de So 1 1669621904Minh TrungNo ratings yet

- I Just Called To Say I Love You - ESL ActivityDocument1 pageI Just Called To Say I Love You - ESL ActivitydebNo ratings yet

- Informal Narrative Letter UpdateDocument2 pagesInformal Narrative Letter UpdateMercedes SANo ratings yet