Professional Documents

Culture Documents

F Electro Coagulation

F Electro Coagulation

Uploaded by

BaskaraLaksamanaCopyright:

Available Formats

You might also like

- A Complete Guide To Build A Joe Cell, Orgone Energy 2012 PDFDocument271 pagesA Complete Guide To Build A Joe Cell, Orgone Energy 2012 PDF김종빈No ratings yet

- Kerja Kas JieDocument11 pagesKerja Kas JienazirulaliNo ratings yet

- Treatment of Hospital Effluent by ElectrocoagulationDocument6 pagesTreatment of Hospital Effluent by ElectrocoagulationAtharv DubaleNo ratings yet

- Application of Electrocoagulation For Water ConditioningDocument12 pagesApplication of Electrocoagulation For Water ConditioningGlen ChoNo ratings yet

- Ec Effect StudyDocument15 pagesEc Effect StudyNakclean Water SolutionsNo ratings yet

- Treatment of Hospital Wastewater Using Electrocoagulation - A ReviewDocument4 pagesTreatment of Hospital Wastewater Using Electrocoagulation - A ReviewAtharv DubaleNo ratings yet

- Journal of Water Process Engineering: SciencedirectDocument8 pagesJournal of Water Process Engineering: SciencedirectEricke Nandita MaharaniNo ratings yet

- Singh 2017Document8 pagesSingh 2017Maricruz GarcíaNo ratings yet

- E1JTC5 2017 v8n1 35Document8 pagesE1JTC5 2017 v8n1 35Debi Anggun SariNo ratings yet

- Removal of Natural Organic Matter and Arsenic From Water by Electrocoagulation/ Otation Continuous Ow ReactorDocument8 pagesRemoval of Natural Organic Matter and Arsenic From Water by Electrocoagulation/ Otation Continuous Ow ReactorazerfazNo ratings yet

- Matecconf Sicest2017 02010Document6 pagesMatecconf Sicest2017 02010Trecy RezatantiaNo ratings yet

- Fundamentals Present and Future Perspect PDFDocument12 pagesFundamentals Present and Future Perspect PDFFebrianNo ratings yet

- A Review of Electrocoagulation Process For Wastewater TreatmentDocument15 pagesA Review of Electrocoagulation Process For Wastewater TreatmentIndra Gunawan HaroenNo ratings yet

- The Effects of Ultrasound and Electrocoagulation On Removal of Manganese From WastewaterDocument9 pagesThe Effects of Ultrasound and Electrocoagulation On Removal of Manganese From WastewaterGuillermo CarrasquillaNo ratings yet

- Textile Industries Wastewater Treatment by Electrochemical Oxidation Technique Using Metal PlateDocument13 pagesTextile Industries Wastewater Treatment by Electrochemical Oxidation Technique Using Metal PlateSanti LeoNo ratings yet

- 1 s2.0 S0304389404004170 Main PDFDocument12 pages1 s2.0 S0304389404004170 Main PDFMOISESNo ratings yet

- Journal of Environmental Chemical EngineeringDocument10 pagesJournal of Environmental Chemical EngineeringjuanNo ratings yet

- Electro-Remediation of Lead Contaminated Kaolinite An Electro-Kinetic TreatmentDocument12 pagesElectro-Remediation of Lead Contaminated Kaolinite An Electro-Kinetic TreatmentQuimica Grupo 3No ratings yet

- CYanide Electrocoagulation PDFDocument7 pagesCYanide Electrocoagulation PDFPraveen KumarNo ratings yet

- Desalination: Gholamreza Moussavi, Farzad Majidi, Mahdi FarzadkiaDocument7 pagesDesalination: Gholamreza Moussavi, Farzad Majidi, Mahdi FarzadkiaPraveen KumarNo ratings yet

- Pol J Environ Stud Vol 20 No 1 173-179 PDFDocument7 pagesPol J Environ Stud Vol 20 No 1 173-179 PDFAnonymous XguKEyWNo ratings yet

- Removal of Phosphate From Aqueous Solutions by Electro-CoagulationDocument5 pagesRemoval of Phosphate From Aqueous Solutions by Electro-CoagulationfikaNo ratings yet

- TAN eer-2021-411Document8 pagesTAN eer-2021-411Aini ZahraNo ratings yet

- Electrocoagulation-Electroflotation As A Surface Water Treatment For Industrial UsesDocument6 pagesElectrocoagulation-Electroflotation As A Surface Water Treatment For Industrial UsesadrianqNo ratings yet

- Desalination: Feryal Akbal, Selva Camc IDocument9 pagesDesalination: Feryal Akbal, Selva Camc IMauro FerrareseNo ratings yet

- Treatment of Surface Water Using Cold Plasma For DomesticDocument6 pagesTreatment of Surface Water Using Cold Plasma For DomesticshahinNo ratings yet

- Treatment of A Malaysian Leachate Sample Using ElectrocoagulationDocument4 pagesTreatment of A Malaysian Leachate Sample Using ElectrocoagulationazerfazNo ratings yet

- Al Shannag2015Document8 pagesAl Shannag2015Jihan Khansa NabilaNo ratings yet

- H. Comparison Study On Sonodirect and Sonoalternate CurrentDocument13 pagesH. Comparison Study On Sonodirect and Sonoalternate CurrentAbreham BekeleNo ratings yet

- Electro Voltage 2Document6 pagesElectro Voltage 2Brett Gonzalez CardenasNo ratings yet

- Treatment of Hospitalwastewater Using ElectrocoagulationDocument18 pagesTreatment of Hospitalwastewater Using ElectrocoagulationAtharv DubaleNo ratings yet

- Paper 3Document15 pagesPaper 3Bahaa SalehNo ratings yet

- Treatment of The Textile Wastewaters by Electrocoagulation Effect of Operating PDFDocument8 pagesTreatment of The Textile Wastewaters by Electrocoagulation Effect of Operating PDFBianca OlteanuNo ratings yet

- Electrocatalytic Properties of Diamond in The Oxidation of A (2009)Document6 pagesElectrocatalytic Properties of Diamond in The Oxidation of A (2009)DanielNo ratings yet

- Hardness Removal From Drinking Water Using ElectrochemicalDocument12 pagesHardness Removal From Drinking Water Using ElectrochemicalTàiNo ratings yet

- Influence of Experimental Parameters in The Treatment of Tannery Wastewater by ElectrocoagulationDocument11 pagesInfluence of Experimental Parameters in The Treatment of Tannery Wastewater by Electrocoagulationjuanita18zapataNo ratings yet

- Feasibility Assessment of Electrocoagulation Towards A New Sustainable Wastewater TreatmentDocument6 pagesFeasibility Assessment of Electrocoagulation Towards A New Sustainable Wastewater TreatmentJherson Denys Contreras RamosNo ratings yet

- Separation and Purification Technology: Bassam Al Aji, Yusuf Yavuz, A. Savasß KoparalDocument7 pagesSeparation and Purification Technology: Bassam Al Aji, Yusuf Yavuz, A. Savasß KoparalPraveen KumarNo ratings yet

- Ec For Reactive and Textile DyeDocument10 pagesEc For Reactive and Textile DyeAdditya ChoudhharyNo ratings yet

- Electrocoagulation (With Iron Electrodes) As A Pre-Treatment Part of Brackish Groundwater Desalination SystemDocument13 pagesElectrocoagulation (With Iron Electrodes) As A Pre-Treatment Part of Brackish Groundwater Desalination SystemijasrjournalNo ratings yet

- Natural Organic Matter Removal From AqueDocument10 pagesNatural Organic Matter Removal From Aquelkumar4454No ratings yet

- MyfinalpaperDocument14 pagesMyfinalpaperSantiago TuestaNo ratings yet

- Water 13 01309 v3Document3 pagesWater 13 01309 v3Ahmad Rama RamadhanNo ratings yet

- 17 217 Secula 10Document7 pages17 217 Secula 10azerfazNo ratings yet

- Kobya 2011Document11 pagesKobya 2011Anonymous lFJdkONo ratings yet

- Treatment of Metal Plating Wastewater by ElectrocoagulationDocument11 pagesTreatment of Metal Plating Wastewater by ElectrocoagulationHayat BouchoumNo ratings yet

- Industrial Wastewaters Treated by Electrocoagulation: Electrochimica ActaDocument7 pagesIndustrial Wastewaters Treated by Electrocoagulation: Electrochimica ActaPraveen KumarNo ratings yet

- Performance Evaluation of Electrocoagulation Technique For Removing Groundwater Hardness of Tikrit UniversityDocument12 pagesPerformance Evaluation of Electrocoagulation Technique For Removing Groundwater Hardness of Tikrit UniversityazerfazNo ratings yet

- Investigation of Effect of Electrochemical Process On Detergent Removal From Synthetic Wastewater With Bioassay TestDocument5 pagesInvestigation of Effect of Electrochemical Process On Detergent Removal From Synthetic Wastewater With Bioassay TestvahidNo ratings yet

- Review On Comparison Between Waste Water TreatmentDocument4 pagesReview On Comparison Between Waste Water TreatmentrahulNo ratings yet

- Treatment of Metal Plating Wastewater by ElectrocoagulationDocument11 pagesTreatment of Metal Plating Wastewater by ElectrocoagulationMardaru AnamariaNo ratings yet

- Chem 2015 0054Document6 pagesChem 2015 0054Violeta GarciaNo ratings yet

- Separation and Purification Technology: P. Aswathy, R. Gandhimathi, S.T. Ramesh, P.V. NidheeshDocument8 pagesSeparation and Purification Technology: P. Aswathy, R. Gandhimathi, S.T. Ramesh, P.V. NidheeshMartin FernandezNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document6 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- EN Experimental Design of Electrocoagulatio PDFDocument15 pagesEN Experimental Design of Electrocoagulatio PDFSagar ApteNo ratings yet

- Treatment of Wastewater by Electro Coagulation: A Review: ISO 9001:2008 CertifiedDocument7 pagesTreatment of Wastewater by Electro Coagulation: A Review: ISO 9001:2008 CertifiedImane BendarouachNo ratings yet

- Khaled 2015Document41 pagesKhaled 2015Kim Ryan DinglasanNo ratings yet

- Akyol 2012Document9 pagesAkyol 2012ISAACNo ratings yet

- Bio Process and Chemistry in Industry ReportDocument12 pagesBio Process and Chemistry in Industry ReportUsman HasnainNo ratings yet

- Electrochemical Remediation Technologies for Polluted Soils, Sediments and GroundwaterFrom EverandElectrochemical Remediation Technologies for Polluted Soils, Sediments and GroundwaterNo ratings yet

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationFrom EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationNo ratings yet

- O LVL Chemistry West Spring Sec Prelim 2020iDocument38 pagesO LVL Chemistry West Spring Sec Prelim 2020iMichelle LimNo ratings yet

- Hsslive XII Quick Notes For Half Yera Exam ElvinDocument23 pagesHsslive XII Quick Notes For Half Yera Exam ElvinRavindra100% (1)

- Books Doubtnut Question BankDocument24 pagesBooks Doubtnut Question Bankpratap badigerNo ratings yet

- Electrolytic Refining of CooperDocument2 pagesElectrolytic Refining of CooperAslam PANo ratings yet

- Make Hydrogen in India PDFDocument12 pagesMake Hydrogen in India PDFuss1957No ratings yet

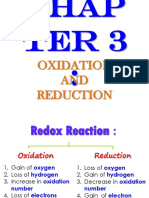

- Oxidation and Reduction SPM Form 5Document63 pagesOxidation and Reduction SPM Form 5Azie Nurul Akhtar85% (13)

- ElectrolysisDocument83 pagesElectrolysismoizbadri100% (3)

- Chemistry Glencoe Chemistry-Laboratory Manual - 0078245249-175-183Document9 pagesChemistry Glencoe Chemistry-Laboratory Manual - 0078245249-175-183ariniNo ratings yet

- Electrochemistry 01 TheoryDocument11 pagesElectrochemistry 01 TheoryRaju SinghNo ratings yet

- 19.1.2 Electrolytic CellsDocument9 pages19.1.2 Electrolytic CellsakshayajagadeeshwarNo ratings yet

- 2018 DHS Prelim Paper 1 To 3Document53 pages2018 DHS Prelim Paper 1 To 3trizillion12No ratings yet

- PH.D - Synopsis - M. Praveen KumarDocument12 pagesPH.D - Synopsis - M. Praveen KumaralexabcdxyzNo ratings yet

- ME2026 Unconventional Machining - PDF.WWW - Chennaiuniversity.net NotesDocument27 pagesME2026 Unconventional Machining - PDF.WWW - Chennaiuniversity.net NotesSiva Raman100% (1)

- ChemistryDocument10 pagesChemistrykahgua0% (1)

- Electrochemical Cell Project FileDocument16 pagesElectrochemical Cell Project Filevabhay22435No ratings yet

- Design of Copper Electrowinning Circuit Using Conventional CellsDocument59 pagesDesign of Copper Electrowinning Circuit Using Conventional Cellsjoseph kafumbila95% (20)

- Literature in English: St. Xavier's School, DorandaDocument18 pagesLiterature in English: St. Xavier's School, DorandaMousmi ChourasiaNo ratings yet

- The Implementation of Photovoltaic System and DC-DC Converter For The Production Process of Hydrogen Gas Through ElectrolysisDocument8 pagesThe Implementation of Photovoltaic System and DC-DC Converter For The Production Process of Hydrogen Gas Through ElectrolysisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- NCM PDFDocument105 pagesNCM PDFChaitanya AnandNo ratings yet

- Metals QuestionsDocument28 pagesMetals QuestionsG M Ali KawsarNo ratings yet

- Oi2I2Oio TP: 2016054 Caribbean ExaminationsDocument11 pagesOi2I2Oio TP: 2016054 Caribbean ExaminationsLaimen ReveskiNo ratings yet

- Nano Hydrogen and AntioxidantDocument10 pagesNano Hydrogen and AntioxidantRobertoNo ratings yet

- PMTLDocument314 pagesPMTLRahoul Chicharito RooneyNo ratings yet

- STPM Baharu Chemistry SyllabusDocument145 pagesSTPM Baharu Chemistry SyllabusChung Chee YuenNo ratings yet

- Electrochemical Activation A Key To Ecologically Pure Technologies of WaterDocument15 pagesElectrochemical Activation A Key To Ecologically Pure Technologies of Watervahid0% (1)

- E Aw EnglishDocument164 pagesE Aw EnglishKlenti ÇukariNo ratings yet

- Sunfire Hylink-Workshop On Advanced PTG and PTL Technologies High-Temperature Electrolysis - PosdziechDocument22 pagesSunfire Hylink-Workshop On Advanced PTG and PTL Technologies High-Temperature Electrolysis - PosdziechdedyNo ratings yet

- Elctrolysis XDocument6 pagesElctrolysis XManash SinghaNo ratings yet

- Cambridge Igcse Chemistry Book TopicsDocument2 pagesCambridge Igcse Chemistry Book TopicsMohammad IslamNo ratings yet

F Electro Coagulation

F Electro Coagulation

Uploaded by

BaskaraLaksamanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F Electro Coagulation

F Electro Coagulation

Uploaded by

BaskaraLaksamanaCopyright:

Available Formats

Separation and Purication Technology 56 (2007) 184191

Fluoride distribution in electrocoagulation deuoridation process

Jun Zhu, Huazhang Zhao, Jinren Ni

Department of Environmental Engineering, Peking University, The Key Laboratory of Water and Sediment Sciences,

Ministry of Education, Beijing 100871, PR China

Received 20 September 2006; received in revised form 24 December 2006; accepted 31 January 2007

Abstract

Electrocoagulation (EC) is an effective process to remove uoride from water, but few of scientic literatures explore its inside mechanism.

A new approach was used in this study to investigate uoride distribution in the EC deuoridation process, which divided the uoride into three

parts: remained in water, removed by electrodes, and adsorbed on hydroxide aluminum ocs. The uoride distribution was investigated in terms

of several critical parameters such as pH, charge loading, current density and initial uoride concentration. The experimental results showed that

the removal by electrodes was primarily responsible for the high deuoridation efciency, and the adsorption by hydroxide aluminum ocs gave

a secondary effect. The parameters affected the efciencies of deuoridation in a way of changing the uoride distribution in the EC process.

A chemical complex of Al

n

(OH)

m

F

k

3nmk

was formulated to explain the mechanism inside the EC deuoridation process. The new approach

provides a detailed insight of the electrocondensation effect, which helps to gain more scientic comprehension about the cooperation between

electrochemical and chemical ways occurring inside the EC process.

2007 Elsevier B.V. All rights reserved.

Keywords: Fluoride; Electrocoagulation; Chemical coagulation; Electrocondensation

1. Introduction

Fluoride is recognized as an essential constituent in the

human diet. Lowuoride concentration (<1 mg/L) could prevent

dental problem, but higher uoride concentration (>1.5 mg/L)

will cause dental and skeletal uorosis [1]. Many countries,

such as China, Egypt, India, Kenya, etc., have areas where

uorosis is endemic [1]. Fluoride pollution in environment

occurs through two different channels: natural sources and

anthropogenic sources. Fluoride is frequently encountered in

minerals and in geochemical deposits. Because of the erosion

and weathering of uoride-bearing minerals, it becomes a

surface species. The discharge of industrial wastewater, such

as semiconductor industries, aluminum industries, and glass

manufacturing industries, also contributes uoride in water

pollution, especially in groundwater.

Many methods have been developed to remove excessive u-

oride from drinking water. These methods can be categorized

into four categories: adsorption [2,3], chemical precipita-

tion [4,5], membrane separation [6,7], and electrocoagulation

[810].

Corresponding author. Tel.: +86 1 62751185; fax: +86 1 62756526.

E-mail address: nijinren@iee.pku.edu.cn (J.R. Ni).

The electrocoagulation (EC) is the process utilizing sacri-

ced anodes to form active coagulant which is used to remove

pollutant by precipitation and otation in situ. Compared with

traditional chemical coagulation (CC), EC process reportedly

requires less space and does not require chemical storage, dilu-

tion, and pH adjustment [11]. It is proven to be effective in

water treatment such as drinking water supply for small or

medium sized community [12]. EC process has been widely

studied in water and wastewater treatment to remove heavy met-

als [13,14], organics [15,16], bacteria [17], turbidity [18] and

inorganic anions [1921]. Because of its proven ability to effec-

tively remove wide range of pollutants, together with its inherent

simplicity of design and operation, EC is being re-examined as

potential treatment technology [22].

Some researchers [810,23,24] have demonstrated that EC

using aluminum electrodes is effective in deuoridation. They

focused on investigating the effects of critical operating param-

eters, such as inter-electrode distance, inuent pH, charge

loading, current density, electrode area/volume ratio, and ini-

tial F

concentration. The kinetics of EC deuoridation process

was reported to followthe exponential function with time [9,25].

Emamjomeh [10] developed an empirical model using critical

parameters to evaluate the rate constant (K) for uoride removal

by a monopolar EC-otation process.

1383-5866/$ see front matter 2007 Elsevier B.V. All rights reserved.

doi:10.1016/j.seppur.2007.01.030

J. Zhu et al. / Separation and Purication Technology 56 (2007) 184191 185

The mechanism of uoride removal process was a chemi-

cal adsorption process with F

replacing the OH group from

the Al

n

(OH)

3n

ocs [26]. Fluoride ions and hydroxide ions can

clearly coprecipitate with Al

3+

ions to form Al

n

F

m

(OH)

3nm

[27]:

nAl

3+

(aq)

+3n mOH

(aq)

+mF

(aq)

Al

n

F

m

(OH)

3nm(s)

(1)

However, the uoride ions in the precipitate are very easily

substituted for hydroxide ions:

Al

n

F

m

(OH)

3nm(s)

+OH

(aq)

Al

n

F

m1

(OH)

3nm+1(s)

+F

(aq)

(2)

It was reported that EC system performed better than CC

system in deuoridation efciency [24,25,27]. However, only

simple explanation was offered about the electrocondensation

effect near the surface of electrode without directly experimental

proof.

EC is a complex electrochemical process, which comprises

chemical and physical processes involving many surface and

interfacial phenomena. The technology lies at the intersection of

three more fundamental technologieselectrochemistry, coag-

ulation and otation [22]. When a potential is applied to form

an external power source, the anode material undergoes oxi-

dation, while the cathode will be subjected to reduction or

reductive depositionof elemental metals. If aluminumelectrodes

are used, the generated Al

3+

(aq)

ions will immediately undergo

further spontaneous reactions to produce corresponding hydrox-

ides and/or polyhydroxides. These hydroxides compounds have

strong afnity for dispersed particles as well as counter ions

to cause coagulation. The gases evolved at the electrodes may

impinge on and cause otation of the coagulated materials.

However, fundamental researches on physical, chemical and

electrochemical interactions are still needed for successful engi-

neering design of EC reactor [28].

A new approach to investigate the uoride distribution could

provide more detailed information on the deuoridation in EC

process. The uoride in the EC process was divided into three

parts: (1) remain in water; (2) adsorbed by ocs generated and

formed in situ; and (3) removed by the gelatinous layer attached

on the electrodes which were immediately taken out of the reac-

tor after the electrolysis reaction. The uoride attaching on the

electrodes resulted from the electrophoresis and/or electrocon-

densation effects in the electric eld.

The objective of this study is to explore the electrochemi-

cal and the chemical interaction in EC deuoridation process.

The membrane ltration was used after the coagulation pro-

cesses to eliminate the removal effects from precipitation or

otation. The effects of the inuent pH, charge loading, current

density and initial uoride concentration on the uoride distri-

bution were further investigated. From the experimental results,

a mechanism of uoride removal by EC was proposed and

described. The deuoridation performance of EC and CC was

also compared.

2. Experimental

2.1. Materials

Deionized water with 3.0 mM NaHCO

3

and 2.0 mM NaCl

was used to simulate natural water with a certain degree of alka-

linity and ionic strength. Desired concentrations of F

solution

were made by adding proper amount of sodium uoride into

the water. The conductivities of the sample water in all the

experiments are between 500 and 750 S/cm.

2.2. Analytical methods

The pHwas measured by a pHmeter (Hanna, PH201), which

was freshly calibrated by 2 points (6.86, 9.18) before each test.

The uoride concentration was determined by an ion chromato-

graph (Dionex, ICS 2500).

2.3. Electrocoagulation test

A 300-mL of sample solution was placed into a batch reac-

tor for each test run. Two monopolar aluminum electrodes,

both having a purity of 99.999%, were used as the anode and

cathode, respectively. The dimensions of the electrodes were

90 mm60 mm and the A/V is 18 m

2

/m

3

. Before each test,

organic impurities on electrode surfaces were removed by wash-

ing with acetone and follow-up HCl solution (10% wt) prior to

use. The two electrodes were placed at a distance of 10 mm. The

current density was maintained constant by using a potentiostat

in intensiostat mode.

According to conventional mixing mode, the rapid mixing by

a magnetic stirrer was used to enhance full contact between the

solution and the coagulant produced in situ. After electrolysis,

the electrodes were taken out and the solution was occulated for

10 min by gentle mixing. Samples taken from the reactor were

directly ltered by syringe lter (0.22 um, PSE membrane). The

residual uoride in the ltrate was then measured. At the end of

each run, the electrodes were washed thoroughly with water to

remove any solid residues on the surfaces, and then dried and

re-weighted. The calculated current efciency in this study was

around 111%.

2.4. Coagulation test

A proper amount coagulant of Al(NO

3

)

3

was added to the

sample water containing uoride, and then the water was mixed

rapidly for 1 min. During the mixing, the pH of the water was

adjusted to the desired value with dilute acid (HCl) or base

(NaOH) solution. After mixing, the solution was occulated for

10 min by gently mixing. The samples taken from coagulation

test were also directly ltered by syringe lter.

2.5. Fluoride distribution experiment

The ion chromatograph method has been used in several

studies [24,27] to measure uoride concentration, which is not

limitedbypHandcoexistingcations. Thus, the uoride adsorbed

186 J. Zhu et al. / Separation and Purication Technology 56 (2007) 184191

Fig. 1. Selected area energy dispersive X-ray spectra of the electrodes: (a) anode and (b) cathode.

on the ocs can be measured by adjusting the sample pH with

1 M NaOH to exceed 13, then completely dissolving aluminum

hydroxide particles and releasing the F

ions adsorbed on the

ocs. The eluents used in the ion chromatograph is NaOH and

high purity water, so the high pH will not affect the result. Each

test was run more than three times to eliminate the experimental

errors. The experimental procedure was as follows:

(1) Add 300 mL of test water with initial F

concentration

([F

]

initial

) into the EC reactor.

(2) Take out the electrodes immediately when the electrolysis

reaction is nished.

(3) Flocculate the solution for 10 min by gentle mixing.

(4) Take samples fromthe occulated solution; ltrate the sam-

ple by 0.22 m lter for uoride analysis and express the

result as [F

]

remain

(F

in water).

(5) Mix the residual occulated solution rapidly; take samples

for pH adjustment (pH>13) with 1 M NaOH. Take sample

for uoride analysis and express the result as [F

]

oc+remain

(F

in water and ocs) until the ocs is completely dis-

solved.

Based on the aforementioned experiments, the distribution

of uoride concentration including [F

]

remain

, [F

]

ocs

and

[F

]

electrodes

could be obtained, of which [F

]

ocs

(uoride

adsorbed on ocs) =[F

]

ocs+remain

[F

]

remain

; [F

]

electrodes

(uoride removal by electrodes) =[F

]

initial

[F

]

ocs+remain

.

Furthermore, the efciency of uoride removal can be dened

as

F

=1 [F

]

remain

/[F

]

initial

.

3. Results and discussion

3.1. Characteristics of Al electrodes

The Al electrodes after EC deuoridation was analyzed by

using EDXand XPS to prove the existence of uoride ions in the

surface layer of electrodes. The results were given in Fig. 1 and

Table 1, respectively (operation: [F

]

initial

=1 mmol/L, pH 6.5,

charge loading =2.07 F/m

3

), which showed that the uoride ions

exist on both the anode and the cathode after EC deuoridation

process.

3.2. Fluoride distribution in the EC process

3.2.1. Effect of inuent pH

The inuent pH is one of the important factors affecting the

performance of electrochemical process [15]. In the EC sys-

tem, the uoride removal efciency is solely determined by the

uoride on electrodes and ocs. The uoride distribution was

shown in Fig. 2, from which the variation of overall removal

efciency of uoride with the inuent pHcould be clearly identi-

ed. The optimal pHrange was 5.56.5, at which higher uoride

removal efciency could be reached. Similar results have also

been reported by other investigators [26].

The adsorption on ocs is of primary importance to under-

standing of the uoride distribution. Based on the chemical Eqs.

(1) and (2), lower pHis favorable for uoride removal. In the EC

process, however, the pH could be increased not only because

Table 1

The surface composition of the electrodes analyzed by XPS

Atomic concentration (%) C O F Na Al Cl

Anode 28.44 48.60 1.93 0.58 19.19 1.25

Cathode 24.26 46.69 0.56 4.03 23.89 0.56

Fig. 2. Fluoride distribution at various pH values; initial [F

] =5 mg/L, charge

loading =1.55 F/m

3

, t =10 min.

J. Zhu et al. / Separation and Purication Technology 56 (2007) 184191 187

of the hydrogen generation at the EC cathodes [29], but also

the liberation of hydroxide ions from aluminum hydroxide due

to the substitution of uoride ions. Therefore, further increase

of the inuent pH would decrease the deuoridation capabil-

ity. In Fig. 2, the adsorbed uoride on ocs declined quickly

to be neglected as the inuent pH was getting over 7.5. Since

aluminum hydroxide is an amphoteric hydroxide, high pH will

lead to the formation of Al(OH)

4

, which is soluble and useless

for deuoridation.

The deuoridation by electrodes is a major contributor to

overall removal efciency in an EC system. Higher removal

efciency of electrodes was corresponding to the inuent pH

range of 6.07.0, but the efciency would decrease as the inu-

ent becoming acidic or basic. However, the removal efciency of

electrodes would become dominant even under basic conditions

(pH7.5). The variation of deuoridation with the inuent pH

implied that different interactions might exist around the elec-

trodes, such as electrophoresis, adsorption and precipitation of

hydrouoroaluminumcomplexes. It is the complexes formed on

electrodes that vary with the inuent pH, which in turn lead to

the change of uoride removed by electrodes.

3.2.2. Effect of charge loading

The quality of EC efuent depends on the amount of coag-

ulant produced (mg) or applied charge loading [12]. In this

study, charge loading was obtained at the same reaction time

by changing current density. The uoride distribution with dif-

ferent charge loading was illustrated in Fig. 3. Initial sharp

increase of overall removal efciency could be clearly seen. As

charge loading was over 1.55 F/m

3

, the overall removal ef-

ciency approached a plateau at 91%. The same tendency was

also observed by other investigators [15]. The optimal charge

loading appeared at the end of the sharp increasing stage.

Similar trends were found between variations of removal ef-

ciency of electrodes and those of the overall removal efciency,

whereas removal efciency of the hydro-aluminum ocs tended

to decrease with increasing charge loading. The applied poten-

tial increased with the current densities rising, which enhanced

the electrophoresis effect. The higher Al

3+

concentration on the

Fig. 3. Fluoride distribution at various charge loadings; initial [F

] =5 mg/L,

pH 6.5, t =10 min.

Fig. 4.

e/f

at various charge loadings.

surface of anode could also help to capture the uoride ions

by complexation, adsorption and coprecipitation. Consequently,

uoride ions were attracted to the electrodes and the uoride

concentration near the electrodes exceeded that in bulk solu-

tion. Lower uoride concentration in bulk solution reduced the

possibility of removal by ocs adsorption, although the amount

of hydro-aluminumocs was increased. This indicated that uo-

ride ions were apt to be removed by the electrodes, which proved

the occurrence of the electrocondensation effect [24,25,27].

Therefore, greater deuoridation efciency by electrodes could

be expected than hydroxide aluminum ocs.

In order to compare the removal effects of electrodes and

ocs, we calculated the ratio (r

e/f

) of removal efciency of elec-

trodes (

electrodes

) to that of ocs (

ocs

). As results, the rise of r

e/f

with increasing charge loading as shown in Fig. 4 implied that

electrochemical effect was enhanced signicantly with chemical

effect weakened relatively.

3.2.3. Effect of current density

Many researchers studied the inuence of current density

based on varying charge loading [9,20]. In this study, the effect

of current density was investigated based on a constant applied

charge loadingbyvaryingreactiontime. It was foundthat current

density has little effect on deuoridation by ocs (Fig. 5). The

reason is that the principal factors inuencing adsorption of u-

oride by ocs are coagulant dosage and solution pH. Moreover,

the experimental results showed that (Table 2) the current ef-

ciency changed little with varying current density for the same

charge loading.

Hence, change of the overall removal efciency should be

primarily attributed to the variation of deuoridation efciency

of the electrodes. The overall removal efciency would decrease

as current density exceeds 9.26 A/m

2

as shown in Fig. 5. Current

Table 2

Aluminum electrodes behavior during the EC test at various current densities

1 2 3 4 5

Current density (A/m

2

) 4.63 9.26 18.52 37.04 92.59

[Al

3+

] (mg/L) (theoretical) 9.33 9.33 9.33 9.33 9.33

[Al

3+

] (mg/L) 9.77 9.77 9.93 10.50 10.03

Current efciency (%) 104 104 106 112 107

188 J. Zhu et al. / Separation and Purication Technology 56 (2007) 184191

Fig. 5. Fluoride distribution at various current densities; initial [F

] =5 mg/L,

charge loading =1.04 F/m

3

, pH 6.5.

density directly affected coagulant dosage and bubble genera-

tion rate, as well as the mixing intensity and mass transfer near

electrodes [22], so increasing current density would accelerate

the liberation rate of Al

3+

and OH

ions. Furthermore, the run

time was varied to keep the same charge loading, of which the

biggest and smallest run times differed by a factor of about 20,

e.g. the run time was only 1 min when the current density was

applied at 92.59 A/m

2

. Thus, both rapid liberation and short run

time wouldleadtoincomplete reactionaroundthe electrodes due

to insufcient time to reach dynamic equilibrium. In addition,

the rapid liberation of Al

3+

and OH

ions from the surface of

electrode would make the solution around the anode and cathode

extremely acidic or basic respectively, which would decrease the

removal efciency of electrodes as discussed in Section 3.2.1.

Experiments ondeuoridationunder different appliedcurrent

densities revealed that operating current was of less signicance

to removal efciency of electrode as current density was below

9.26 A/m

2

(Fig. 5). Furthermore, long reaction time was unde-

sirable from the engineering viewpoint. For the current density

of 9.26 A/m

2

, 10-min reaction time was enough to equilibrate

solution pH and form hydrouoroaluminum complexes. Thus,

Fig. 7.

e/f

at various initial uoride concentrations.

there should be an optimal current density at a certain applied

charge loading for the EC system.

3.2.4. Effect of initial F

concentration

Fig. 6 showed the general relation between the overall deu-

oridation efciency and initial F

concentration, from which

we could see that the former gradually decreased from 92 to

80% as the latter increased from 3 to 15 mg/L. Moreover, deu-

oridation efciency and capacity were also shown in Fig. 6a

and b, respectively. It was observed that the deuoridation ef-

ciency of electrodes tended to decrease although deuoridation

capacity increased relatively with the initial F

concentration

rising. However, both removal efciency and capacity of ocs

increased when the initial F

concentration went up. The rela-

tionship between r

e/f

and initial F

concentration as shown in

Fig. 7revealedthat the increase of initial F

concentrationwould

improve the chemical effect by increasing uoride concentration

in bulk solution.

Adsorption isotherm of the EC process was drawn by the

mass of uoride adsorption and the equilibrium concentration

of uoride remained in the water. Both Freundlich and Lang-

muir equations were used to specify the data, and a better t was

found for the latter as shown in Fig. 8. Although the EC deu-

oridation process could be well described by the conventional

Langmuir equation as also reported in other similar studies [30],

the uoride distribution provided more detailed information on

Fig. 6. Fluoride distribution at various initial F

concentrations (a) deuoridation efciency (b) deuoridation capacity; charge loading =2.07 F/m

3

, pH6.5, t =10 min.

J. Zhu et al. / Separation and Purication Technology 56 (2007) 184191 189

Fig. 8. Equilibrium isothems.

the removal mechanisms inside ECprocess under different oper-

ating conditions.

3.3. Proposed mechanism of uoride removal by EC

From above discussions, it is found that the removal by

electrodes was primarily responsible for the high deuorida-

tion efciency, and the adsorption by hydroxide aluminum ocs

gave a secondary effect. In order to have a deeper under-

standing of the EC process, hydro-uoro-aluminum complex

Al

n

(OH)

m

F

k

3nmk

was used to describe various chemical

species containing uoride, hydroxide and Al

3+

, such as AlF

complexes, AlOH complexes and the hydro-uoro- aluminum

colloid ocs.

An schematic of Al

n

(OH)

m

F

k

3nmk

complex based on ion

structure was shown in Fig. 9. At 3n =m+k, Al

n

(OH)

m

F

k

3nmk

complexes were likely to exist in the form of colloid species,

which could be removed by the follow-up membrane ltration.

At 3n <m+k, the negatively charged Al

n

(OH)

m

F

k

3nmk

com-

plexes would move towards the anode by electric migration.

In the immediate region around the anode, there was a locally

higher concentration of hydro-uoro-aluminumcomplexes. The

Al

n

(OH)

m

F

k

3nmk

complexes could integrate with dense Al

3+

ions on the surface of anode to form colloid ocs precipitated

or adsorbed on the anode surface. At 3n >m+k, the positively

charged Al

n

(OH)

m

F

k

3nmk

complex would also be attracted to

the adjacent area of the cathode by the electrophoretic effect.

The liberated hydroxide ions near the cathode could neutralize

Fig. 9. Scheme of proposed deuoridation process in EC.

Fig. 10. Enhancement in uoride removal from 2 to 40 times at higher Al

3+

and

F

concentrations. Final Al

3+

=10 mg/L, nal F

=5 mg/L, pH 6.5.

the charge of the Al

n

(OH)

m

F

k

3nmk

complexes to formcolloid

ocs precipitated or adsorbed on the cathode surface. Both kinds

of Al

n

(OH)

m

F

k

3nmk

would be removed when electrodes were

taken out of the reactor. It was electrical eld that encouraged

Al

n

(OH)

m

F

k

3nmk

to be condensed near the electrodes, which

made the uoride adsorbed mostly on the electrodes so that the

EC process had a higher deuoridation efciency.

According to the previous studies [31], the F

/Al

3+

ratio

of hydro-uoro-aluminum precipitated at a high concentration

of uoride exceeded that at a low concentration of uoride. A

CC process with manually concentrating Al

3+

and uoride was

designed to simulate the EC process for local condensation in

the area near the electrodes [17]. Fig. 10 summarized the deuo-

ridation efciency for various Al

3+

and F

concentration. From

Fig. 10, it could be seen that locally high concentration of Al

3+

and F

ions signicantly improved F

removal.

3.4. Comparison of EC and CC

Tests were conducted to compare EC and CC under vari-

ous Al

3+

dosages and pH values at an initial F

concentration

of 5 mg/L. Samples obtained from CC and EC efuent were

ltrated with micro-membrane (0.22 m) to eliminate precip-

itation or otation. The experimental results are summarized

in Fig. 11, in which the pH range of CC process was referred

to other studies [32]. Fig. 11 showed that EC process signif-

icantly outperformed CC process for uoridation removal for

all the Al

3+

concentrations tested in the pH range of 6.07.0,

especially for low Al

3+

dosages. For example, 80% reduction

of uoride was achieved by EC process at an Al

3+

dosage of

1020 mg/L, whereas the same reduction achieved by CC pro-

cess required Al

3+

dosage of 3040 mg/L. It is well understood

that it was electrocondensation that made EC outperform CC in

the low coagulant dosage, which was essentially absent in the

CC process.

Although the present study indicated the contribution of

electrodes to deuoridation in the EC process by investigat-

ing uoride distribution, efforts are still needed to understand

the uoride removal mechanism with particular attention to the

potential applications, such as removal by otation and by pre-

190 J. Zhu et al. / Separation and Purication Technology 56 (2007) 184191

Fig. 11. Comparison of deuoridation efciency between the EC process and CC process.

cipitation. The removal by electrodes is the dominant contributor

to the deuoridation of EC process, but the complexes near the

electrode would more or less passivate the electrodes. From the

engineering viewpoint, more practical issues should be consid-

ered before the nal purpose of designing a uoride removal

system would be achieved.

4. Conclusion

The uoride in the EC process could be distributed into three

parts, i.e. remained in water, adsorbed by ocs generated and

formed in situ, and removed by the gelatinous layer attached

on the electrodes. In this study, the existence of the uoride on

the electrodes was proved experimentally with help of EDX and

XPS analysis. The overall deuoridation efciency varies with

uoride distribution that is altered by operating parameters such

as pH, charge loading, current density and initial uoride con-

centration. The removal efciency of electrodes was compared

with that of ocs, and the ratio between them (r

e/f

) was found

to be increased with the rise of charge loading but decreased

with increasing initial F

concentration. The existence of elec-

tric eld would enhance the concentration of the Al

3+

and F

around the surface of electrode, and thus signicantly improve

F

removal in EC process. As far as the uoridation removal

is concerned, the EC process has obvious advantages over the

CC process at various Al

3+

concentrations (especially low Al

3+

dosages) with pH of 6.07.0. The approach proposed in this

study could provide not only insight into electrocondensation

around the surface of electrode but also more detailed infor-

mation on electrochemical and chemical interactions in the EC

process.

Acknowledgements

The authors are thankful to Professor Alistair Borthwick in

University of Oxford and Professor C.F. Chiang in China Med-

ical University for their valuable help in English editing during

the preparation of the paper. Thanks are also to J.L Xie and

W.W. Zhou, College of Chemistry and Molecular Engineering in

Peking University, for their assistance in XPSand EDXanalysis.

References

[1] World Health Organization, Fluoride in drinking water, WHO Guidelines

for Drinking Water Quality, 2004. www.who.int/entity/water sanitation

health/dwq/chemicals/uoride.pdf.

[2] H. Lounici, L. Addour, D. Belhocine, H. Grib, S. Nicolas, B. Bariou,

N. Mameri, Study of a new technique for uoride removal from water,

Desalination 114 (1997) 241251.

[3] S. Ghorai, K.K. Pant, Equilibrium, kinetics and breakthrough studies for

adsorption of uoride on activated alumina, Sep. Purif. Technol. 42 (2005)

265271.

[4] G.L. He, S.R. Cao, Assessment of uoride removal from drinking water

by calcium phosphate systems, Fluoride 29 (1996) 212216.

[5] M. Pinon-Miramontes, R.G. Bautista-Margulis, A. Perez-Hernandez,

Removal of arsenic and uoride from drinking water with cake alum and

a polymeric anionic occulent, Fluoride 36 (2003) 122128.

[6] P.I. Ndiayea, P. Moulin, L. Dominguez, J.C. Millet, F. Charbit, Removal

of uoride from electronic industrial efuent by RO membrane separation,

Desalination 173 (2005) 2532.

[7] Z. Amor, B. Bariou, N. Mameri, M. Taky, S. Nicolas, A. Elmidaoui, Flu-

oride removal from brackish water by electrodialysis, Desalination 133

(2001) 215223.

[8] S.C. Li, Electro-chemiclal method to remove uoride from drinking water,

Water Supply 3 (1985) 177186.

[9] N. Mameri, A.R. Yeddou, H. Lounici, D. Belhocine, H. Grib, B. Bariou,

Deuoridation of septentrional Sahara water of north Africa by electro-

coagulation process using bipolar aluminium electrodes, Water Res. 32

(1998) 16041612.

[10] M.M. Emamjomeh, M. Sivakumar, An empirical model for deuoridation

by batch monopolar electrocoagulation/otation (ECF) process, J. Hazard.

Mater. 131 (2006) 118125.

[11] M.Y.A. Mollah, R. Schennach, J.R. Parga, D.L. Cocke, Electrocoagulation

(EC)science and applications, J. Hazard. Mater. 84 (2001) 2941.

[12] G.H. Chen, Electrochemical technologies in wastewater treatment, Sep.

Purif. Technol. 38 (2004) 1141.

[13] N. Adhoum, L. Monser, N. Bellakhal, J.E. Belgaied, Treatment of

electroplating wastewater containing Cu

2+

, Zn

2+

and Cr(VI) by electro-

coagulation, J. Hazard. Mater. 112 (2004) 207213.

[14] P. Gao, X.M. Chen, F. Shen, G.H. Chen, Removal of chromium(VI) from

wastewater bycombinedelectrocoagulationelectrootationwithout a lter,

Sep. Purif. Technol. 43 (2005) 117123.

[15] G.H. Chen, X.M. Chen, P.L. Yue, Electrocoagulation and electrootation

of restaurant wastewater, J. Environ. Eng. -ASCE 126 (2000) 858863.

[16] X.H. Xu, X.F. Zhu, Treatment of refectory oily wastewater by electro-

coagulation process, Chemosphere 56 (2004) 889894.

[17] B.T. Zhu, D.A. Clifford, S. Chellam, Comparison of electrocoagulation

and chemical coagulation pretreatment for enhanced virus removal using

microltration membranes, Water Res. 39 (2005) 30983108.

J. Zhu et al. / Separation and Purication Technology 56 (2007) 184191 191

[18] M.J. Matteson, R.L. Dobson, R.W. Glenn, N.S. Kukunoor, W.H. Waits,

E.J. Clayeld, Electrocoagulation and separation of aqueous suspensions

of ultrane particles, Colloid Surf. A-Physicochem. Eng. Asp. 104 (1995)

101109.

[19] A.S. Koparal, U.B. Ogutveren, Removal of nitrate fromwater by electrore-

duction and electrocoagulation, J. Hazard. Mater. 89 (2002) 8394.

[20] A. Murugananthan, G.B. Raju, S. Prabhakar, Removal of sulde, sulfate

and sulte ions by electro coagulation, J. Hazard. Mater. 109 (2004) 3744.

[21] N. Bektas, H. Akbulut, H. Inan, A. Dimoglo, Removal of phosphate from

aqueous solutions by electro-coagulation, J. Hazard. Mater. 106 (2004)

101105.

[22] P.K. Holt, G.W. Barton, C.A. Mitchell, The future for electrocoagulation as

a localised water treatment technology, Chemosphere 59 (2005) 355367.

[23] N. Mameri, H. Lounici, D. Belhocine, H. Grib, D.L. Piron, Y. Yahiat, Deu-

oridation of Sahara water by small plant electrocoagulation using bipolar

aluminium electrodes, Sep. Purif. Technol. 24 (2001) 113119.

[24] C.Y. Hu, S.L. Lo, W.H. Kuan, Effects of co-existing anions on uoride

removal in electrocoagulation (EC) process using aluminum electrodes,

Water Res. 37 (2003) 45134523.

[25] M. Lui, R.Y. Sun, J.H. Zhang, Y. Bina, L. Wei, Elimination of excess

uoride in potable water with coarcervation by electrolysis using aluminum

anode, Fluoride 20 (1983) 5463.

[26] F. Shen, X.M. Chen, P. Gao, G.H. Chen, Electrochemical removal of u-

oride ions from industrial wastewater, Chem. Eng. Sci. 58 (2003) 987

993.

[27] C.Y. Hu, S.L. Lo, W.H. Kuan, Effects of the molar ratioof hydroxide andu-

oride to Al(III) on uoride removal by coagulation and electrocoagulation,

J. Colloid Interface Sci. 283 (2005) 472476.

[28] M.Y.A. Mollah, P. Morkovsky, J.A.G. Gomes, M. Kesmez, J. Parga, D.L.

Cocke, Fundamentals, present and future perspectives of electrocoagula-

tion, J. Hazard. Mater. 114 (2004) 199210.

[29] E.A. Wik, D.A. Carlson, A.S. Eikum, Electrocoagulation of potable water,

Water Res. 18 (1984) 13551360.

[30] M. Carmona, M. Khemis, J.P. Lecler, F. Lapicque, Asimple model topredict

the removal of oil suspensions from water using the electrocoagulation

technique, Chem. Eng. Sci. 61 (2006) 12371246.

[31] J. Bufe, N. Parthasarathy, W. Haerdi, Importance of speciation

methods in analytical control of water treatment processes with appli-

cation to uoride removal from wastewater, Water Res. 19 (1985) 7

23.

[32] G.H. Zhang, Y. Gao, Y. Zhang, P. Gu, Removal of uoride from drinking

water by a membrane coagulation reactor (MCR), Desalination 177 (2005)

143155.

You might also like

- A Complete Guide To Build A Joe Cell, Orgone Energy 2012 PDFDocument271 pagesA Complete Guide To Build A Joe Cell, Orgone Energy 2012 PDF김종빈No ratings yet

- Kerja Kas JieDocument11 pagesKerja Kas JienazirulaliNo ratings yet

- Treatment of Hospital Effluent by ElectrocoagulationDocument6 pagesTreatment of Hospital Effluent by ElectrocoagulationAtharv DubaleNo ratings yet

- Application of Electrocoagulation For Water ConditioningDocument12 pagesApplication of Electrocoagulation For Water ConditioningGlen ChoNo ratings yet

- Ec Effect StudyDocument15 pagesEc Effect StudyNakclean Water SolutionsNo ratings yet

- Treatment of Hospital Wastewater Using Electrocoagulation - A ReviewDocument4 pagesTreatment of Hospital Wastewater Using Electrocoagulation - A ReviewAtharv DubaleNo ratings yet

- Journal of Water Process Engineering: SciencedirectDocument8 pagesJournal of Water Process Engineering: SciencedirectEricke Nandita MaharaniNo ratings yet

- Singh 2017Document8 pagesSingh 2017Maricruz GarcíaNo ratings yet

- E1JTC5 2017 v8n1 35Document8 pagesE1JTC5 2017 v8n1 35Debi Anggun SariNo ratings yet

- Removal of Natural Organic Matter and Arsenic From Water by Electrocoagulation/ Otation Continuous Ow ReactorDocument8 pagesRemoval of Natural Organic Matter and Arsenic From Water by Electrocoagulation/ Otation Continuous Ow ReactorazerfazNo ratings yet

- Matecconf Sicest2017 02010Document6 pagesMatecconf Sicest2017 02010Trecy RezatantiaNo ratings yet

- Fundamentals Present and Future Perspect PDFDocument12 pagesFundamentals Present and Future Perspect PDFFebrianNo ratings yet

- A Review of Electrocoagulation Process For Wastewater TreatmentDocument15 pagesA Review of Electrocoagulation Process For Wastewater TreatmentIndra Gunawan HaroenNo ratings yet

- The Effects of Ultrasound and Electrocoagulation On Removal of Manganese From WastewaterDocument9 pagesThe Effects of Ultrasound and Electrocoagulation On Removal of Manganese From WastewaterGuillermo CarrasquillaNo ratings yet

- Textile Industries Wastewater Treatment by Electrochemical Oxidation Technique Using Metal PlateDocument13 pagesTextile Industries Wastewater Treatment by Electrochemical Oxidation Technique Using Metal PlateSanti LeoNo ratings yet

- 1 s2.0 S0304389404004170 Main PDFDocument12 pages1 s2.0 S0304389404004170 Main PDFMOISESNo ratings yet

- Journal of Environmental Chemical EngineeringDocument10 pagesJournal of Environmental Chemical EngineeringjuanNo ratings yet

- Electro-Remediation of Lead Contaminated Kaolinite An Electro-Kinetic TreatmentDocument12 pagesElectro-Remediation of Lead Contaminated Kaolinite An Electro-Kinetic TreatmentQuimica Grupo 3No ratings yet

- CYanide Electrocoagulation PDFDocument7 pagesCYanide Electrocoagulation PDFPraveen KumarNo ratings yet

- Desalination: Gholamreza Moussavi, Farzad Majidi, Mahdi FarzadkiaDocument7 pagesDesalination: Gholamreza Moussavi, Farzad Majidi, Mahdi FarzadkiaPraveen KumarNo ratings yet

- Pol J Environ Stud Vol 20 No 1 173-179 PDFDocument7 pagesPol J Environ Stud Vol 20 No 1 173-179 PDFAnonymous XguKEyWNo ratings yet

- Removal of Phosphate From Aqueous Solutions by Electro-CoagulationDocument5 pagesRemoval of Phosphate From Aqueous Solutions by Electro-CoagulationfikaNo ratings yet

- TAN eer-2021-411Document8 pagesTAN eer-2021-411Aini ZahraNo ratings yet

- Electrocoagulation-Electroflotation As A Surface Water Treatment For Industrial UsesDocument6 pagesElectrocoagulation-Electroflotation As A Surface Water Treatment For Industrial UsesadrianqNo ratings yet

- Desalination: Feryal Akbal, Selva Camc IDocument9 pagesDesalination: Feryal Akbal, Selva Camc IMauro FerrareseNo ratings yet

- Treatment of Surface Water Using Cold Plasma For DomesticDocument6 pagesTreatment of Surface Water Using Cold Plasma For DomesticshahinNo ratings yet

- Treatment of A Malaysian Leachate Sample Using ElectrocoagulationDocument4 pagesTreatment of A Malaysian Leachate Sample Using ElectrocoagulationazerfazNo ratings yet

- Al Shannag2015Document8 pagesAl Shannag2015Jihan Khansa NabilaNo ratings yet

- H. Comparison Study On Sonodirect and Sonoalternate CurrentDocument13 pagesH. Comparison Study On Sonodirect and Sonoalternate CurrentAbreham BekeleNo ratings yet

- Electro Voltage 2Document6 pagesElectro Voltage 2Brett Gonzalez CardenasNo ratings yet

- Treatment of Hospitalwastewater Using ElectrocoagulationDocument18 pagesTreatment of Hospitalwastewater Using ElectrocoagulationAtharv DubaleNo ratings yet

- Paper 3Document15 pagesPaper 3Bahaa SalehNo ratings yet

- Treatment of The Textile Wastewaters by Electrocoagulation Effect of Operating PDFDocument8 pagesTreatment of The Textile Wastewaters by Electrocoagulation Effect of Operating PDFBianca OlteanuNo ratings yet

- Electrocatalytic Properties of Diamond in The Oxidation of A (2009)Document6 pagesElectrocatalytic Properties of Diamond in The Oxidation of A (2009)DanielNo ratings yet

- Hardness Removal From Drinking Water Using ElectrochemicalDocument12 pagesHardness Removal From Drinking Water Using ElectrochemicalTàiNo ratings yet

- Influence of Experimental Parameters in The Treatment of Tannery Wastewater by ElectrocoagulationDocument11 pagesInfluence of Experimental Parameters in The Treatment of Tannery Wastewater by Electrocoagulationjuanita18zapataNo ratings yet

- Feasibility Assessment of Electrocoagulation Towards A New Sustainable Wastewater TreatmentDocument6 pagesFeasibility Assessment of Electrocoagulation Towards A New Sustainable Wastewater TreatmentJherson Denys Contreras RamosNo ratings yet

- Separation and Purification Technology: Bassam Al Aji, Yusuf Yavuz, A. Savasß KoparalDocument7 pagesSeparation and Purification Technology: Bassam Al Aji, Yusuf Yavuz, A. Savasß KoparalPraveen KumarNo ratings yet

- Ec For Reactive and Textile DyeDocument10 pagesEc For Reactive and Textile DyeAdditya ChoudhharyNo ratings yet

- Electrocoagulation (With Iron Electrodes) As A Pre-Treatment Part of Brackish Groundwater Desalination SystemDocument13 pagesElectrocoagulation (With Iron Electrodes) As A Pre-Treatment Part of Brackish Groundwater Desalination SystemijasrjournalNo ratings yet

- Natural Organic Matter Removal From AqueDocument10 pagesNatural Organic Matter Removal From Aquelkumar4454No ratings yet

- MyfinalpaperDocument14 pagesMyfinalpaperSantiago TuestaNo ratings yet

- Water 13 01309 v3Document3 pagesWater 13 01309 v3Ahmad Rama RamadhanNo ratings yet

- 17 217 Secula 10Document7 pages17 217 Secula 10azerfazNo ratings yet

- Kobya 2011Document11 pagesKobya 2011Anonymous lFJdkONo ratings yet

- Treatment of Metal Plating Wastewater by ElectrocoagulationDocument11 pagesTreatment of Metal Plating Wastewater by ElectrocoagulationHayat BouchoumNo ratings yet

- Industrial Wastewaters Treated by Electrocoagulation: Electrochimica ActaDocument7 pagesIndustrial Wastewaters Treated by Electrocoagulation: Electrochimica ActaPraveen KumarNo ratings yet

- Performance Evaluation of Electrocoagulation Technique For Removing Groundwater Hardness of Tikrit UniversityDocument12 pagesPerformance Evaluation of Electrocoagulation Technique For Removing Groundwater Hardness of Tikrit UniversityazerfazNo ratings yet

- Investigation of Effect of Electrochemical Process On Detergent Removal From Synthetic Wastewater With Bioassay TestDocument5 pagesInvestigation of Effect of Electrochemical Process On Detergent Removal From Synthetic Wastewater With Bioassay TestvahidNo ratings yet

- Review On Comparison Between Waste Water TreatmentDocument4 pagesReview On Comparison Between Waste Water TreatmentrahulNo ratings yet

- Treatment of Metal Plating Wastewater by ElectrocoagulationDocument11 pagesTreatment of Metal Plating Wastewater by ElectrocoagulationMardaru AnamariaNo ratings yet

- Chem 2015 0054Document6 pagesChem 2015 0054Violeta GarciaNo ratings yet

- Separation and Purification Technology: P. Aswathy, R. Gandhimathi, S.T. Ramesh, P.V. NidheeshDocument8 pagesSeparation and Purification Technology: P. Aswathy, R. Gandhimathi, S.T. Ramesh, P.V. NidheeshMartin FernandezNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document6 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- EN Experimental Design of Electrocoagulatio PDFDocument15 pagesEN Experimental Design of Electrocoagulatio PDFSagar ApteNo ratings yet

- Treatment of Wastewater by Electro Coagulation: A Review: ISO 9001:2008 CertifiedDocument7 pagesTreatment of Wastewater by Electro Coagulation: A Review: ISO 9001:2008 CertifiedImane BendarouachNo ratings yet

- Khaled 2015Document41 pagesKhaled 2015Kim Ryan DinglasanNo ratings yet

- Akyol 2012Document9 pagesAkyol 2012ISAACNo ratings yet

- Bio Process and Chemistry in Industry ReportDocument12 pagesBio Process and Chemistry in Industry ReportUsman HasnainNo ratings yet

- Electrochemical Remediation Technologies for Polluted Soils, Sediments and GroundwaterFrom EverandElectrochemical Remediation Technologies for Polluted Soils, Sediments and GroundwaterNo ratings yet

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationFrom EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationNo ratings yet

- O LVL Chemistry West Spring Sec Prelim 2020iDocument38 pagesO LVL Chemistry West Spring Sec Prelim 2020iMichelle LimNo ratings yet

- Hsslive XII Quick Notes For Half Yera Exam ElvinDocument23 pagesHsslive XII Quick Notes For Half Yera Exam ElvinRavindra100% (1)

- Books Doubtnut Question BankDocument24 pagesBooks Doubtnut Question Bankpratap badigerNo ratings yet

- Electrolytic Refining of CooperDocument2 pagesElectrolytic Refining of CooperAslam PANo ratings yet

- Make Hydrogen in India PDFDocument12 pagesMake Hydrogen in India PDFuss1957No ratings yet

- Oxidation and Reduction SPM Form 5Document63 pagesOxidation and Reduction SPM Form 5Azie Nurul Akhtar85% (13)

- ElectrolysisDocument83 pagesElectrolysismoizbadri100% (3)

- Chemistry Glencoe Chemistry-Laboratory Manual - 0078245249-175-183Document9 pagesChemistry Glencoe Chemistry-Laboratory Manual - 0078245249-175-183ariniNo ratings yet

- Electrochemistry 01 TheoryDocument11 pagesElectrochemistry 01 TheoryRaju SinghNo ratings yet

- 19.1.2 Electrolytic CellsDocument9 pages19.1.2 Electrolytic CellsakshayajagadeeshwarNo ratings yet

- 2018 DHS Prelim Paper 1 To 3Document53 pages2018 DHS Prelim Paper 1 To 3trizillion12No ratings yet

- PH.D - Synopsis - M. Praveen KumarDocument12 pagesPH.D - Synopsis - M. Praveen KumaralexabcdxyzNo ratings yet

- ME2026 Unconventional Machining - PDF.WWW - Chennaiuniversity.net NotesDocument27 pagesME2026 Unconventional Machining - PDF.WWW - Chennaiuniversity.net NotesSiva Raman100% (1)

- ChemistryDocument10 pagesChemistrykahgua0% (1)

- Electrochemical Cell Project FileDocument16 pagesElectrochemical Cell Project Filevabhay22435No ratings yet

- Design of Copper Electrowinning Circuit Using Conventional CellsDocument59 pagesDesign of Copper Electrowinning Circuit Using Conventional Cellsjoseph kafumbila95% (20)

- Literature in English: St. Xavier's School, DorandaDocument18 pagesLiterature in English: St. Xavier's School, DorandaMousmi ChourasiaNo ratings yet

- The Implementation of Photovoltaic System and DC-DC Converter For The Production Process of Hydrogen Gas Through ElectrolysisDocument8 pagesThe Implementation of Photovoltaic System and DC-DC Converter For The Production Process of Hydrogen Gas Through ElectrolysisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- NCM PDFDocument105 pagesNCM PDFChaitanya AnandNo ratings yet

- Metals QuestionsDocument28 pagesMetals QuestionsG M Ali KawsarNo ratings yet

- Oi2I2Oio TP: 2016054 Caribbean ExaminationsDocument11 pagesOi2I2Oio TP: 2016054 Caribbean ExaminationsLaimen ReveskiNo ratings yet

- Nano Hydrogen and AntioxidantDocument10 pagesNano Hydrogen and AntioxidantRobertoNo ratings yet

- PMTLDocument314 pagesPMTLRahoul Chicharito RooneyNo ratings yet

- STPM Baharu Chemistry SyllabusDocument145 pagesSTPM Baharu Chemistry SyllabusChung Chee YuenNo ratings yet

- Electrochemical Activation A Key To Ecologically Pure Technologies of WaterDocument15 pagesElectrochemical Activation A Key To Ecologically Pure Technologies of Watervahid0% (1)

- E Aw EnglishDocument164 pagesE Aw EnglishKlenti ÇukariNo ratings yet

- Sunfire Hylink-Workshop On Advanced PTG and PTL Technologies High-Temperature Electrolysis - PosdziechDocument22 pagesSunfire Hylink-Workshop On Advanced PTG and PTL Technologies High-Temperature Electrolysis - PosdziechdedyNo ratings yet

- Elctrolysis XDocument6 pagesElctrolysis XManash SinghaNo ratings yet

- Cambridge Igcse Chemistry Book TopicsDocument2 pagesCambridge Igcse Chemistry Book TopicsMohammad IslamNo ratings yet