Professional Documents

Culture Documents

How To Compute Tonnage Requirements in Hydraulic Press

How To Compute Tonnage Requirements in Hydraulic Press

Uploaded by

Rahul Khosla0 ratings0% found this document useful (0 votes)

53 views2 pagesThis document provides guidelines for calculating the tonnage requirements for various metalworking operations using common formulas:

1. To determine tonnage for general pressing, multiply the pressure per square inch by the area and divide by 2000.

2. For press fits, a formula uses diameter, length, interference, and a pressure factor to calculate tonnage.

3. Punching tonnage can be estimated by multiplying diameter, thickness, and a constant (40 for steel, 20 for brass).

Guidelines are also given for deep drawing, straightening, and determining strokes per minute for hydraulic presses. Engineering consultation is recommended for specific requirements.

Original Description:

Calculation to compute the tonnage required for hydraulic press.

Original Title

How to Compute Tonnage Requirements in Hydraulic Press

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides guidelines for calculating the tonnage requirements for various metalworking operations using common formulas:

1. To determine tonnage for general pressing, multiply the pressure per square inch by the area and divide by 2000.

2. For press fits, a formula uses diameter, length, interference, and a pressure factor to calculate tonnage.

3. Punching tonnage can be estimated by multiplying diameter, thickness, and a constant (40 for steel, 20 for brass).

Guidelines are also given for deep drawing, straightening, and determining strokes per minute for hydraulic presses. Engineering consultation is recommended for specific requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

53 views2 pagesHow To Compute Tonnage Requirements in Hydraulic Press

How To Compute Tonnage Requirements in Hydraulic Press

Uploaded by

Rahul KhoslaThis document provides guidelines for calculating the tonnage requirements for various metalworking operations using common formulas:

1. To determine tonnage for general pressing, multiply the pressure per square inch by the area and divide by 2000.

2. For press fits, a formula uses diameter, length, interference, and a pressure factor to calculate tonnage.

3. Punching tonnage can be estimated by multiplying diameter, thickness, and a constant (40 for steel, 20 for brass).

Guidelines are also given for deep drawing, straightening, and determining strokes per minute for hydraulic presses. Engineering consultation is recommended for specific requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 2

How to compute tonnage requirements:

1. General - When pressure per square inch is known:

psi x area of work/2000 = 2 tons of ram force required

Example: Where it is known that 100 psi is needed to do a o! on a "# x $# wide piece.

100 x "# x $#/2000 = 2 tons

2. Press Fit - %o determine the force required to press fit two round pieces toðer such as a

shaft pressed into a !ushin&' use the followin& formula:

( = ) x * x + x , x -/2

Where ( = force required in tons

) = diameter of the part to !e pressed in inches

+ = len&th of part to !e pressed in inches ./ote: the len&th of the interference fit onl0.1

, = interference in inches .usuall0 .002# to .002#1

- = pressure factor .3ee ta!le !elow1.

Pressure Factors

2

)iameter

.inches1

-ressure

(actor

)iameter

.inches1

-ressure

(actor

)iameter

.inches1

-ressure

(actor

)iameter

.inches1

-ressure

(actor

1 "00 4 1"2 " 51 6 27

18 45" 48 174 "8 $2 68 21

19 42" 49 142 "9 $2 69 "5

1: 262 4: 124 ": 6$ 6: "6

2 270 7 11" 2 6" $ ""

28 212 78 10$ 28 62

29 1$5 79 101 29 25

2: 161 7: 52 2: 22

4. Example: ; steel shaft 2# in diameter pressed into a hole 4# lon&. %he interference fit !etween

the two diameters is .002#.

2# x 4.17 x 4# x .002# x .270/21 = 14."2 tons

7. Punching - ; quick &uide to determine tonna&e requirements for punchin& steel is:

)iameter x thickness x $0 = tons .where $0 is constant for steel. <se 2" for !rass.1

Example: ; 4# hole in .2"0# stock: 4# x .2"0# x $0 = 20 tons

(or noncircular holes' instead of the diameter' use 1/4 of the total len&th of cut.

Example: ; rectan&ular hole 7# x 2# in .2"0# stock: .7# = 2# = 7# = 2#/41 x .2"0# x $0 = 144.4

tons

". Deep Drawing - )eep-drawin& calculations can !e complex. %he press' dies' material'

radius' and part shape all ha>e !earin&. (or drawin& round shells' the followin& formula is a

simple &uide:

? x % x %s = tons

Where ? = circumference of the finished part@ % = material thickness in inches@ and

%s = tensile stren&th of the material.

2. Example: %o draw a "# diameter cup of .070# stock with a tensile stren&th of 72'000 psi would

require the followin& tonna&e:

." x 4.17121 x .070 x .72000/20001 = 17.77 tons

; 20-ton press would !e recommended

6. Straightening - %he pressure required to strai&hten a piece of metal depends on its

shape. Aelow is an approximate formula with a further definition for different shapes.

Where ( is the ram force in tons@ 2 is a constant@ < is ultimate stren&th of the material in psi@ B

is the section modulus .see !elow1@ and + is the distance !etween the strai&htenin& !locks in

inches.

Example: ; 2# diameter shaft' 1$# !etween the !locks' 100'000 psi ultimate stren&th.

How to determine strokes per minute for a hdraulic press

%he num!er of strokes per minute for a h0draulic press is determined !0 calculatin& a

separate time for each phase of the ram stroke. %he rapid ad>ance time is calculated' then

the pressin& time' .the work stroke1@ then' if there is no dwell time' the rapid return.

%he !asic formula for determinin& the len&th of time in seconds for each phase of the stroke:

Example: a h0draulic press with a 200 ,-C rapid ad>ance' 20 ,-C pressin& speed' and

200 ,-C rapid return. %he work requires a 4# ad>ance' 1# work stroke' and 7# rapid return.

20 D 2.155 = 26 c0cles per minute.

E Electrical actuation and >al>e shift time >aries dependin& on the t0pe of h0draulic circuit. Fne half

second is a reasona!le a>era&e fi&ure.

1 %hese formulae are intended as &uidelines onl0. -lease consult a qualified manufacturin& en&ineer

for recommendations concernin& 0our specific requirements.

2 Aased on steel shaft and cast iron !ushin& .with F)/,) G 21.

7--F3% H ;AF<% <3 H ;IAFI H ?F/%;?% <3 H ?-; H J?; H J?I

J?% H J-A H JK)I;<+,? H /EW3 L EME/%3 H 3-E?,;+ H +,%EI;%<IE

N<,)E %F -IE33 -IF)<?%,M,%K H JFCE

%his site last updated on (rida0' Oune 2' 2004.

You might also like

- Time Study PresentationDocument16 pagesTime Study PresentationMubasher RajputNo ratings yet

- Sand BlastingDocument1 pageSand BlastingReynaldo PesqueraNo ratings yet

- Tonnage CalculationDocument3 pagesTonnage CalculationEmba MadrasNo ratings yet

- ASTM-A370 For Mechanical Testing PDFDocument46 pagesASTM-A370 For Mechanical Testing PDFRahul Khosla75% (4)

- Sodium Silicate Moulding ProcessDocument82 pagesSodium Silicate Moulding ProcessRahul KhoslaNo ratings yet

- Die Casting Process: Okky Helja Octora SR 2006492843Document11 pagesDie Casting Process: Okky Helja Octora SR 2006492843Okky Helja100% (1)

- Asa - Injection Mould Component Cost EstimationDocument7 pagesAsa - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Electric Water HeaterDocument28 pagesElectric Water HeateraschalewNo ratings yet

- Line BalancingDocument5 pagesLine Balancingsaravananpg8697No ratings yet

- Die Casting ResearchDocument10 pagesDie Casting Researchمحمد الخالديNo ratings yet

- Heaters WaterDocument8 pagesHeaters WaterkittieyNo ratings yet

- Studies On Flow Characteristics at High-Pressure Die-CastingDocument6 pagesStudies On Flow Characteristics at High-Pressure Die-CastingRashed KaiserNo ratings yet

- AO Smith Commercial Electric Water HeatersDocument84 pagesAO Smith Commercial Electric Water HeatersKathryn WorkmanNo ratings yet

- Sand Blasting MachineDocument3 pagesSand Blasting MachineCarl Diaz100% (1)

- Induction MotorDocument4 pagesInduction MotorPauline JacintoNo ratings yet

- Line Balancing Problem: 3.4 MinsDocument11 pagesLine Balancing Problem: 3.4 MinsSureshMandwaniNo ratings yet

- ChimneyDocument5 pagesChimneyrajachandaNo ratings yet

- Low Cost AutomationDocument88 pagesLow Cost AutomationvijisathishNo ratings yet

- Line BalancingDocument18 pagesLine BalancingSivakumar K100% (1)

- Work StudyDocument16 pagesWork StudyAkanksha kondaNo ratings yet

- Gtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWDocument19 pagesGtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWNachiket MujumdarNo ratings yet

- Pressure Die CastingDocument5 pagesPressure Die CastingIdrisNo ratings yet

- Air Cooler E-Catalogue SUMMER 2022Document9 pagesAir Cooler E-Catalogue SUMMER 2022ABHISHEK CHAUDHARYNo ratings yet

- Hydraulic Baling PressDocument3 pagesHydraulic Baling Pressajay pandeyNo ratings yet

- Low Cost Automation DeeDocument16 pagesLow Cost Automation DeeDeekshu 4141likilNo ratings yet

- Work Study 1Document47 pagesWork Study 1Anonymous phDoExVlNo ratings yet

- 09 ST-Water HeaterDocument56 pages09 ST-Water HeaterMisdehRasmanNo ratings yet

- Assembly Line BalancingDocument19 pagesAssembly Line BalancingMilan MeeraNo ratings yet

- Work StudyDocument58 pagesWork StudyHaseeb KazmiNo ratings yet

- Productivity Improvement by Line Balancing On JacketDocument47 pagesProductivity Improvement by Line Balancing On JacketAmanuel Mulatu Boche100% (1)

- Bending and DrawingDocument14 pagesBending and DrawingStelwin FernandezNo ratings yet

- Washing Machine Motor ControllerDocument2 pagesWashing Machine Motor ControllerSuneel Venkat100% (1)

- Induction MotorDocument74 pagesInduction Motormera nam chinNo ratings yet

- Godrej InterioDocument33 pagesGodrej InterioTarun MaheshwariNo ratings yet

- Section 2 Gmaw Fundamentals: 2-1. Basic InformationDocument9 pagesSection 2 Gmaw Fundamentals: 2-1. Basic InformationEnriquinoNo ratings yet

- Welded Tube PDFDocument17 pagesWelded Tube PDFhirenkumar patelNo ratings yet

- Figure 1: SMED SystemDocument13 pagesFigure 1: SMED SystemAbdulziz kurdiNo ratings yet

- 09 Strip LayoutDocument28 pages09 Strip LayoutvivekNo ratings yet

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Shop Manual Igx270 390 enDocument26 pagesShop Manual Igx270 390 enEdgarRetuertoNo ratings yet

- Defect Minimizing Control of Low Pressure Die CastingDocument228 pagesDefect Minimizing Control of Low Pressure Die CastingMostafaNo ratings yet

- Basic Heat TreatmentDocument8 pagesBasic Heat TreatmentAnonymous VRspXsmNo ratings yet

- LG Refrigerator Repair in HyderabadDocument22 pagesLG Refrigerator Repair in HyderabaddharaniNo ratings yet

- Work StudyDocument20 pagesWork Studyjesus784No ratings yet

- Bend Tonnage CalculationDocument2 pagesBend Tonnage CalculationLingarajan RamasamyNo ratings yet

- Design of Mechanical Press PDFDocument8 pagesDesign of Mechanical Press PDFArsl RanaNo ratings yet

- 7-Manual Process Planning (AMS May13 - 13) PDFDocument24 pages7-Manual Process Planning (AMS May13 - 13) PDFtadele10No ratings yet

- Casting ProcessesDocument42 pagesCasting ProcessesVijay PawarNo ratings yet

- Kaff Kitchen AppliancesDocument16 pagesKaff Kitchen Appliancesraj dubeyNo ratings yet

- Drawing PracticesDocument60 pagesDrawing Practicespverma02No ratings yet

- Presses For Sheet Metal WorkingDocument4 pagesPresses For Sheet Metal WorkingJony Oliver Lazo RamosNo ratings yet

- IPD Costing PDFDocument10 pagesIPD Costing PDFSaddy DipoNo ratings yet

- Final ReportDocument25 pagesFinal ReportAdil SaleemNo ratings yet

- How To Trade The Budget PDFDocument33 pagesHow To Trade The Budget PDFrishab agarwalNo ratings yet

- Assembly Line BalancingDocument46 pagesAssembly Line Balancingshewalepp100% (1)

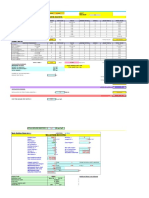

- Costing Calculations:: Date: Revision: 0 Mezzanine MachineDocument5 pagesCosting Calculations:: Date: Revision: 0 Mezzanine MachineRakesh SharmaNo ratings yet

- Supplier Cost Increase1Document3 pagesSupplier Cost Increase1prasad_kcpNo ratings yet

- 1488644012final Bending - Forming, DrawingDocument31 pages1488644012final Bending - Forming, DrawingasifNo ratings yet

- Washing Machine: Case Study: Embedded SystemDocument16 pagesWashing Machine: Case Study: Embedded SystemPreetam KarmakarNo ratings yet

- Introduction To Foundry ProcessesDocument22 pagesIntroduction To Foundry ProcessesAtul Gaur100% (1)

- TechnicalDocument36 pagesTechnicalshahzad afzal100% (1)

- Tonnage CalculationDocument3 pagesTonnage CalculationEmba MadrasNo ratings yet

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaNo ratings yet

- Ador - Catalouge - GOUGING TORCHESDocument1 pageAdor - Catalouge - GOUGING TORCHESRahul KhoslaNo ratings yet

- Chromium-Nickel Stainless SteelsDocument8 pagesChromium-Nickel Stainless SteelsRahul KhoslaNo ratings yet

- Alloy 80ADocument1 pageAlloy 80ARahul KhoslaNo ratings yet

- CG IronDocument14 pagesCG IronRahul KhoslaNo ratings yet

- Specification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Document2 pagesSpecification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Rahul KhoslaNo ratings yet

- Kanthal Surface Load Data PDFDocument24 pagesKanthal Surface Load Data PDFRahul KhoslaNo ratings yet

- Alloy 80ADocument1 pageAlloy 80ARahul KhoslaNo ratings yet

- Kanthal Surface Load Data PDFDocument24 pagesKanthal Surface Load Data PDFRahul KhoslaNo ratings yet

- Hydraulic Press Consideration GuidelinesDocument2 pagesHydraulic Press Consideration GuidelinesRahul KhoslaNo ratings yet

- Astm A 297Document3 pagesAstm A 297Rahul KhoslaNo ratings yet

- Various Bs Astm German Rsa StandardsDocument40 pagesVarious Bs Astm German Rsa StandardsRahul KhoslaNo ratings yet

- Alloy 80A Nimonic 80A: Data SheetDocument1 pageAlloy 80A Nimonic 80A: Data SheetRahul KhoslaNo ratings yet

- Chemicalcompositions PDFDocument1 pageChemicalcompositions PDFhadeNo ratings yet

- Automatic Temp Control in InductionDocument2 pagesAutomatic Temp Control in InductionRahul Khosla100% (1)

- Ashoka CastingDocument6 pagesAshoka CastingRahul KhoslaNo ratings yet

- HeadToHead Yr7 FormingExpressionsDocument18 pagesHeadToHead Yr7 FormingExpressionsJude HassanNo ratings yet

- GL Vi-7-8 e PDFDocument82 pagesGL Vi-7-8 e PDFDerick MendozaNo ratings yet

- 1807 Asiatic Researches Vol 9 SDocument511 pages1807 Asiatic Researches Vol 9 SVirgoMoreNo ratings yet

- Ecosystems ThermodynamicsDocument27 pagesEcosystems Thermodynamicsapi-326805662No ratings yet

- SPE-174937-MS Optimizing Separation Efficiency of Produced Water Tanks by Installing CFD Designed InternalsDocument11 pagesSPE-174937-MS Optimizing Separation Efficiency of Produced Water Tanks by Installing CFD Designed InternalsSajad FalahNo ratings yet

- Es TG Module 2 Climate RevisedDocument23 pagesEs TG Module 2 Climate RevisedNikkieIrisAlbañoNovesNo ratings yet

- DSP Question Paper April 2012Document2 pagesDSP Question Paper April 2012Famida Begam100% (1)

- 1standing Waves On A StringDocument2 pages1standing Waves On A StringKateNo ratings yet

- Calculation For Steel Lift Pit at Concourse LevelDocument5 pagesCalculation For Steel Lift Pit at Concourse LevelSUBIR KARMAKARNo ratings yet

- Aqua MCA Queries Clarifications - 2 - (2) - MEICA Comments V1R2 - DP PDFDocument4 pagesAqua MCA Queries Clarifications - 2 - (2) - MEICA Comments V1R2 - DP PDF3238NDNo ratings yet

- Safety Moment Manual LiftingDocument1 pageSafety Moment Manual LiftingEvert W. VanderBerg100% (1)

- EasyIP 4.0 BrochureDocument8 pagesEasyIP 4.0 BrochureanggityudhaNo ratings yet

- Thapar University, Patiala: Roll NumberDocument2 pagesThapar University, Patiala: Roll NumberThakurSinglaNo ratings yet

- 6 35 11kV Single CoreDocument9 pages6 35 11kV Single CoreKhanSA786No ratings yet

- Pencil Graphite Electrodes OK PDFDocument156 pagesPencil Graphite Electrodes OK PDFOmar ReynosoNo ratings yet

- Seminar ReportDocument43 pagesSeminar ReportRamaswamy Koodalloor Parasuraman67% (3)

- ABB Surge Arresters - Product Overview 1HC0075750 AD enDocument16 pagesABB Surge Arresters - Product Overview 1HC0075750 AD enlagm54No ratings yet

- AP Calculus BC Course of StudyDocument12 pagesAP Calculus BC Course of Studydanvelezz100% (2)

- Materials: Taguchi Grey Relational Analysis For Multi-Response Optimization of Wear in Co-Continuous CompositeDocument17 pagesMaterials: Taguchi Grey Relational Analysis For Multi-Response Optimization of Wear in Co-Continuous CompositeAshwin arjunanNo ratings yet

- Rigid Body Dynamics SolutionDocument229 pagesRigid Body Dynamics SolutionVishnu SinhaNo ratings yet

- Champ FMV Led Floodlights 2lDocument4 pagesChamp FMV Led Floodlights 2lJohn ThomasNo ratings yet

- Silicon: MOS: Metal Oxide SemiconductorDocument17 pagesSilicon: MOS: Metal Oxide SemiconductorDilanWijerathnaNo ratings yet

- Mass Effect - SagaDocument96 pagesMass Effect - SagaRayssa GoulartNo ratings yet

- Deutz Fallas Faults TableDocument1 pageDeutz Fallas Faults TablePabsepulvNo ratings yet

- Hestcraft Catalog 6-22-10Document44 pagesHestcraft Catalog 6-22-10johnpotterNo ratings yet

- Form 5 Add Math - Chapter 3Document27 pagesForm 5 Add Math - Chapter 3surya vishnuNo ratings yet

- Physics Test 46 Electromagnetic Waves QDocument10 pagesPhysics Test 46 Electromagnetic Waves Q123No ratings yet

- Automated Geometry Control For Segmental BridgesDocument7 pagesAutomated Geometry Control For Segmental BridgesKavinkumar ShanmugamNo ratings yet

- Construction Materials and Testing Chapter 5Document25 pagesConstruction Materials and Testing Chapter 5Yena Cabalu67% (3)

- GEM 802 Chapter 1Document52 pagesGEM 802 Chapter 1Leah Ann ManuelNo ratings yet