Professional Documents

Culture Documents

Paper and Printing Machinery Supporting The Information-Based Society

Paper and Printing Machinery Supporting The Information-Based Society

Uploaded by

Kirk Rodriguez0 ratings0% found this document useful (0 votes)

25 views5 pagesThe document provides an overview of Mitsubishi Heavy Industries' paper and printing machinery business. It discusses the company's history of manufacturing pulp and paper machinery since 1951 and printing machinery since 1961. It also summarizes MHI's technological developments that have supported higher speed and quality in paper making and printing machines. These include the development of its own technologies rather than relying on licenses from foreign companies. The document then outlines MHI's current projects to develop new generation machines using domestic technologies to operate at 2000 meters per minute for paper production and to meet demands for short run printing with high productivity and flexibility.

Original Description:

pm

Original Title

e 401074

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides an overview of Mitsubishi Heavy Industries' paper and printing machinery business. It discusses the company's history of manufacturing pulp and paper machinery since 1951 and printing machinery since 1961. It also summarizes MHI's technological developments that have supported higher speed and quality in paper making and printing machines. These include the development of its own technologies rather than relying on licenses from foreign companies. The document then outlines MHI's current projects to develop new generation machines using domestic technologies to operate at 2000 meters per minute for paper production and to meet demands for short run printing with high productivity and flexibility.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

25 views5 pagesPaper and Printing Machinery Supporting The Information-Based Society

Paper and Printing Machinery Supporting The Information-Based Society

Uploaded by

Kirk RodriguezThe document provides an overview of Mitsubishi Heavy Industries' paper and printing machinery business. It discusses the company's history of manufacturing pulp and paper machinery since 1951 and printing machinery since 1961. It also summarizes MHI's technological developments that have supported higher speed and quality in paper making and printing machines. These include the development of its own technologies rather than relying on licenses from foreign companies. The document then outlines MHI's current projects to develop new generation machines using domestic technologies to operate at 2000 meters per minute for paper production and to meet demands for short run printing with high productivity and flexibility.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

Mitsubishi Heavy I ndustries, Ltd.

Technical Review Vol.40 No.1 (Feb. 2003)

1

Paper and Printing Machinery

Supporting the Information-

Based Society

1. I ntroduction 1. I ntroduction 1. I ntroduction 1. I ntroduction 1. I ntroduction

The Paper & Printing Machinery Division started the

manufacture of pulp and paper machinery in 1951, and

of printing machinery in 1961 at the Mihara Machinery

Works. I n 2000, now renamed as the Mihara Machinery

& Transportation Systems Works, this manufacture and

sales-integrated organization began to supply products

to customers while responding quickly to changes in the

industrial environment. Also manufacturing paper con-

verting machinery, Mitsubishi Heavy I ndustries, Ltd.

(MHI ) is the only company in the world to handle the

three major pillars of paper and printing machinery. I t

is now developing new and attractive products to meet

the needs of customers.

MHI is also developing next-generation high-speed

paper machines that are easy to operate and service, and

printing machines of high productivity and high flexibil-

ity to cope with the trend toward small production and

short delivery to support the information-oriented print-

ing industry.

This paper introduces the past, present and future of

the pulp and paper machinery and printing machinery,

especially sheet-fed offset presses.

2. Past of paper and printing machinery supporting 2. Past of paper and printing machinery supporting 2. Past of paper and printing machinery supporting 2. Past of paper and printing machinery supporting 2. Past of paper and printing machinery supporting

information-based society information-based society information-based society information-based society information-based society

2.1 Old days technology for pulp and paper making 2.1 Old days technology for pulp and paper making 2.1 Old days technology for pulp and paper making 2.1 Old days technology for pulp and paper making 2.1 Old days technology for pulp and paper making

machinery machinery machinery machinery machinery

(1) Start and progress of paper making machinery busi-

ness

I n the days when big paper making machines were

mostly imported, Mihara Machinery Works started de-

vel opment of hi gh-speed paper machi nes, and

delivered the first paper machine for newsprint pa-

per of wire width 1930 mm and design speed 260 m/

min, at Harada Mill of Fuji Paper I ndustry Co., Ltd.

in October 1952 (Fig Fig Fig Fig Fig. .. .. 1 11 11). I n 1957, MHI concl uded a

technical license agreement with Beloit Corporation

of the Uni ted States to acqui re the technol ogy for

bigger size and higher speed machine promptly. And

Nobuo Kiyama

Tetsuo Makino

Shinichi Fujimoto

thereafter, in 1971, the newsprint machine of 8690

mm wire width and of 915 m/min in speed installed

at Tomakomai Mill of Oji Paper Co., Ltd. marked the

100th machine for us. Until now, more than 200 sets

of big and high-speed machines were manufactured

in every detail using specific equipments for the cus-

tomers not onl y i n J apan but al so Korea, Chi na,

Southeast Asian countries and so forth.

(2) Challenge to technology progress

Since the early stage of this business, great efforts

have been exerted on research and development. I n

1982, No.2 pilot coater was newly installed, and in

1985 the first pilot paper machine was constructed.

Leading engineers in the design and research section

were sent to Beloit R & D Center to study the latest

technology. I n 1989, elemental technology test facili-

ti es were establ i shed i n the Paper & Pri nti ng

Research Center of Hiroshima Research & Develop-

ment Center, and the technology of elemental study

and structural analysis of various paper layer which

are closely related to paper making process were up-

graded. I n 1992, the second pilot paper machine was

constructed, and in 1997 dryer section of the highest

drying capacity in the world was added, so that the

paper quality could be evaluated by the sample sheets

taken from the reel. Through such original technical

developments, Acdeflo headbox, MH winder, Sortrex,

Fig. 1 Installation process of the first set of paper machine (1952)

2

Mitsubishi Heavy I ndustries, Ltd.

Technical Review Vol.40 No.1 (Feb. 2003)

MH former, Controlled Crown Roll with multi-shoe,

and many other new products were put on the mar-

ket one after the other.

I n 2000, MHI abandoned the techni cal l i cense

agreement with Beloit, acquired their patents, know-

how, and other intellectual properties, and opened

business operations to the global market, through the

acceleration of the development of new paper machine

with its own technology.

2.2 Past of sheet-fed offset press 2.2 Past of sheet-fed offset press 2.2 Past of sheet-fed offset press 2.2 Past of sheet-fed offset press 2.2 Past of sheet-fed offset press

(1) Beginning and progress

Manufacture of printing machines was started in

1961 with technical assistance from Societe Marinoni

of France.

I ni ti al l y, thi s Di vi si on was a steam l ocomoti ve

manufacturing plant. The printing machinery was of

an utterly different category, demanding high preci-

sion to a micron scale in every part.

Later, with the company's original technology, vari-

ous printing machines were manufactured including

the initial sheet-fed offset press, to be followed by the

commerci al web offset press and newspaper offset

press. The three major pillars of the printing machin-

ery were thus established.

(2) Technical advances

As printing has changed from monochromatic to

full color in order to attract the attention of consum-

ers, four-color machines are now needed. I n Europe

and America, multi-color printing has also been de-

veloped by adding features of several colors to the four

colors. I n the carton and packaging field, an inline

coating device for adding extra value by coating is

required.

Handling of such multi-color machine requires a

considerable amount of labor and skill. Furthermore,

a printing press is a high-precision machine and there-

fore an expensive asset, and an urgent demand from

printing firms is to increase the actual operating time.

To meet this current trend, sheet-fed offset presses

have been developed according to the basic concept of

Q&Q (Quick and Quality).

The forerunner of this concept was the DAI YA-X

exhibited at the first fair of I nternational Graphic Arts

Show (I GAS) in 1974. Since in those days there were

no sensors or computers of high performance, a ma-

chine for controlling the dampening solution and ink

vol ume and automati cal l y control l i ng the regi ster

during the printing operation was presented at the

exhibition. This machine was highly evaluated as a

printing press that pointed the future direction for

printing firms.

A representative practical machine is the Auto Pre-

set I nking (API ) system developed jointly with Dai

Nippon Printing Co., Ltd. in 1981. Combining a de-

vice for reading the plate ratio and ink keys remote

control, this is a practical machine for presetting the

ink key opening degrees to be optimum for the print

i mage and control l i ng col ors promptl y. Today, thi s

system is employed by makers around the world, and

the full digital work flow is an online version from

the prepress.

There was a further requirement to develop a se-

ri es of model s by the same desi gn concept, i f the

machine size differs, in order to enhance service and

maintenance by customers, and development of the

future-oriented F series began in 1985. This machine

had a remote control devi ce for setti ng the pl ate

change operation and printing pressure, which occu-

pies most of the preparation time, for the first time

in the world, and 500 sets were ordered within two

years from the release in 1989, against the background

of the strong economic boom. On the occasion of this

model, the export business began to expand widely.

3. Present technology of paper making machinery and 3. Present technology of paper making machinery and 3. Present technology of paper making machinery and 3. Present technology of paper making machinery and 3. Present technology of paper making machinery and

printing press which support the transmission of printing press which support the transmission of printing press which support the transmission of printing press which support the transmission of printing press which support the transmission of

information in the society information in the society information in the society information in the society information in the society

3.1 Present technology of pulp and paper machinery 3.1 Present technology of pulp and paper machinery 3.1 Present technology of pulp and paper machinery 3.1 Present technology of pulp and paper machinery 3.1 Present technology of pulp and paper machinery

(1) Start of development project

The new machine development project was started

in 1998 to establish original technology on pulp and

paper machinery. After the market survey, technical

trend analysis, and investigation of customers evalu-

ation on MHI machinery, the target period of putting

the new machine on the market was set in October

2001.

The project is named MJ (Mitsubishi, J apan 2000)

to express enthusi asm for presenti ng a brand new

technology from J apan and to make 2000 m/min op-

eration feasible. I t also implies the next generation

of the current best-selling products of the MH series.

The basic strategy for technical originality can be

summarized as follows.

.

To be a reliable supplier who achieves customer sat-

isfaction.

.

To emerge from supplemental development of Beloit

technology to original technology development.

.

To develop a high-speed paper machine using do-

mesti c technol ogy (hardware + paper maki ng

technology).

Thus, the challenging activities toward technical

independence were started.

(2) Features of new machine

To develop the MJ 2000 paper machine, the follow-

i ng tar gets wer e set to r eal i ze wel l -bal anced

performance.

.

Global acceptance

.

Stable operation at high speed over 2000 m/min

and high productivity

.

Operator-friendly manipulable machine

Mitsubishi Heavy I ndustries, Ltd.

Technical Review Vol.40 No.1 (Feb. 2003)

3

.

I ntegrated central operation and remote-controlled

maintenance

.

Realization of excellent paper quality

I n the process of research and development, much

time has been spent on the elemental studies from

the viewpoint of front loading. Extraction and analy-

si s of par amet er s r ul i ng t he per f or mance,

development of simulation technology, and fabrication

of simulation models were thoroughly worked out and

developed, and results were technically reviewed by

the specialists in each field at the MHI Research &

Development Center. On the basis of results of these

elemental studies, each part of the pilot machine were

modified and evaluated in the individual operations

of each section, and integrated paper making trials

were carried out. The latest layout of the second pilot

paper machine is shown in Fig Fig Fig Fig Fig. .. .. 2 22 22.

The outline configuration of the second pilot paper

machine is as follows: The former is of roll blade type,

which is notably enhanced in dewatering capability,

the press i s a non-open draw dual shoe press wi th

advanced water squeezing performance, and the dryer

is an all-top felt arrangement with the air caps dis-

posed i n the l atter secti on. The cal ender i s a shoe

calender capable of getting bulky paper (independent

operati on al so possi bl e), and the reel has a center

winding function also. The wet web is supported by

machine clothings all the way from the former to the

terminal end of the dryer, so threading the machine

is very easy and steady. From the dryer to the reel,

the web i s transferred by a vacuum conveyor type

threadi ng devi ce. By the advantages of thi s stabl e

threading and many other devices, high-speed opera-

tion of 2000 m/min (120 km/h) is realized.

Machi ne confi gurati on and scaffol d l ayout of

MJ 2000 paper machine are presented to major cus-

tomers by 3D-CAD, and mai ntenance faci l i ti es,

devices for clothing change and other points are im-

proved in detail based on the users opinions. Fig Fig Fig Fig Fig. .. .. 3 33 33

shows the appearance of the MJ 2000 paper machine.

I n May 2002, more than a hundred customers

were invited to an open operation trial of the second

pilot machine, and newsprint paper reel take-up was

demonstrated in sensational success at 2000 m/min,

that exceeds the maximum commercial speed of 1700

m/min in J apan.

This pilot paper machine can be utilized to analyse

and evaluate the quality of the paper which is made

out of various paper stock, fillers, and chemicals fol-

lowing to the customers choice.

3.2 Present situation of sheet-fed offset press 3.2 Present situation of sheet-fed offset press 3.2 Present situation of sheet-fed offset press 3.2 Present situation of sheet-fed offset press 3.2 Present situation of sheet-fed offset press

(1) I nauguration of project

Existing sheet-fed offset presses are often called

by the name "DI AMOND series" in order to publicize

the corporate identity. However, the "mechatronics"

philosophy proposed by MHI is no longer unique these

days as the technical level has been averaged owing

to advances in computer technology and intensified

competition among manufacturers. I n J apan, mean-

while, the decline of the bubble economy was followed

by a low-growth era, and customers are much more

demanding about the degree of finishing of machines,

printing quality and performance, while needs and

preferences of printing are more diversified, and uni-

form massive lot production is being replaced by small

lot production in a wide variety.

Against this background, for survival of sheet-fed

offset press along with retention of customers, im-

provement of producti on effi ci ency i s urgentl y

required. For this purpose, the keenest needs are con-

centrated on the perfect pri nti ng press capabl e of

printing two faces by one path and enhancing pro-

ductivity substantially, and MHI 's efforts are being

accelerated. The present situation of development of

the perfect printing press is here introduced.

(2) Features and merits of major products

For paper travel of recent sheet-fed offset presses,

the ideas of fluid dynamics based on MHI 's accumu-

lated aircraft technology are utilized in various parts.

The technology of installing air chambers under the

paper gui de of the del i very uni t of DI AMOND and

skeleton transfer cylinder and conveying thin sheets

by ai r cushi on has been i ntroduced i n wi der stock

Fig. 2 Layout of No.2 pilot paper machine

Fig. 3 MJ2000 paper machine

Mitsubishi Heavy I ndustries, Ltd.

Technical Review Vol.40 No.1 (Feb. 2003)

4

range press. Thi s technol ogy has been further en-

hanced so that it can be applied in the perfect printing

press. I nk for sheet-fed press is cured by oxidative

polymerization, and is not dried for several hours af-

ter printing. I n the perfect printing press, therefore,

a higher technology of flawless transfer of sheets to

the delivery unit without making contact is required.

Combi ni ng these technol ogi es, a converti bl e

pr ess capabl e of changi ng si des appl i cabl e to

double-face coating has been developed for the first

ti me i n the worl d and del i vered to a customer i n

the Uni ted States (Fig Fig Fig Fig Fig. .. ..4 44 44).

With regard to the exclusive perfect printing press

without reversing mechanism, in the type of printing

one color alternately on the face and reverse side, since

the sheet is elongated during printing, the precision

of register is lowered, and high printing quality is hard

to obtain. This problem was radically solved by de-

vel opi ng the Tandem Per fector appl i cabl e to

stretchable thick sheets and UV (Ultra Violet) print-

ing field. This printing machine is an original MHI

perfect printing press having a unique cylinder con-

figuration capable of finishing printing of the reverse

side in the first half of the process, and transferring

the sheet to the front side printing unit by an even

number of transfer cylinders to conclude perfect print-

ing. Great expectations are held of it in the printing

industry (Fig Fig Fig Fig Fig. .. ..5 55 55).

From now on, efforts will be accelerated in the de-

velopment of one path both side coating.

4. Future of paper and printing machinery 4. Future of paper and printing machinery 4. Future of paper and printing machinery 4. Future of paper and printing machinery 4. Future of paper and printing machinery

4.1 Future technology of pulp and paper machinery 4.1 Future technology of pulp and paper machinery 4.1 Future technology of pulp and paper machinery 4.1 Future technology of pulp and paper machinery 4.1 Future technology of pulp and paper machinery

(1) Outlook and vision

Reviewing the consumption trends of paper and

paper board in the world, an annual growth rate of

about 2.8% is continued, and a steady increase is pre-

dicted also in the years to come. On the other hand,

the Kyoto Protocol requires that J apan, the European

Union, and other industrialized nations must reduce

emissions of greenhouse effect gases at a specific rate

as compared with 1990 level, and J apan must realize

6% reduction. To protect the environment on a global

scale, various action programs are being promoted

i ntensi vel y, i ncl udi ng recycl i ng of paper, savi ng of

energy, and planting of forests.

J apan's pulp and paper companies have the tech-

nology to operate machines at the highest production

efficiency in the world. MHI has developed MJ series

paper machines on the basis of high paper quality cul-

tivated in the market in J apan and high-speed paper

machines of high production efficiency. I t is MHI 's ob-

jective to upgrade this series machines in the global

market, and by developing a new technology vigor-

ously, to realize the still higher productivity machine

with less sheet break and to realize energy-saving

machine to conserve environment, thus contribute to

the whole world.

(2) Productivity improvement of new machine

Productivity improvement by prevention of mist in

the former and press, prevention of paper dust gen-

erati on i n tri mmi ng and tai l cutti ng devi ces, and

development of a stable running device in the dryer,

make the target frequency of sheet break into half of

the conventional level. Sheet break suddenly increases

the working load of the operators, and automation is

required for broke removed and machine cleaning.

There is a requirement to develop automatic starting

and stopping of the machine and to develop technol-

ogy to keep machi ne cl ean for the extensi on of

continuous operation period. I n the operation of next-

generati on paper machi nes, remote moni tori ng i s

realized in the less-man power central control room

by using a monitoring device, (Fig Fig Fig Fig Fig. .. .. 6 66 66), and all the pa-

per machine including the winder is operated only by

three operators.

(3) For conservation of the environment and energy sav-

ing

Construction of new paper machines is necessary

to cope with the growth in global demand for paper,

and at the same time it is essential to lower the en-

ergy consumption rate. MHI is now concentrating its

efforts on drasti c energy savi ng i n the screen and

pulper, reducing sliding resistance in the former, and

squeezi ng the requi red power i n the shoe press.

Equally important is the design concept for minimiz-

i ng the mechani cal parts that requi re peri odi cal

Fig. 4 DIAMOND 3000R for DYNA GRAF Fig. 5 DIAMOND 3000TP

Fig. 6 Central control room of next-generation paper machine

Mitsubishi Heavy I ndustries, Ltd.

Technical Review Vol.40 No.1 (Feb. 2003)

5

maintenance. The roll cover material of wear-resis-

tant ceramics make the roll change frequency to less

than half of now. The clothing life will be extended

substantially by joint development with clothing sup-

pliers. With these environment-conscious machines and

through continuous development of energy-saving tech-

nol ogy, MHI wi l l contri bute to conservati on of the

environment.

4.2 Future of sheet-fed offset presses 4.2 Future of sheet-fed offset presses 4.2 Future of sheet-fed offset presses 4.2 Future of sheet-fed offset presses 4.2 Future of sheet-fed offset presses

(1) Outlook and vision

Human beings cannot exist without culture, and

no culture can exist without printing. I n every coun-

try around the world, printing offices are concentrated

in the capitals and major cities from which informa-

ti on i s transmi tted. The pri nti ng i ndustry i s the

business of converting information into media and

transmitting it to the people. A few years ago, elec-

tronic media began to grow rapidly as new media, and

pri nti ng was predi cted to fade away. However, to-

gether wi th the advancement and popul ari ty of

personal computers, mobile phones, information-re-

lated appliances and the I nternet, the environment

of information-sharing by the public grew larger, and

the total volume of information has increased explo-

sively. Data of commercial printing is digitized, and

the data can be directly uploaded to the I nternet. I n

the printing business alone, as lifestyles become di-

ver si fi ed, l ar ge-scal e j obs ar e decr easi ng, but

small-scale jobs are increasing steadily. I ncluding the

design business, the entire printing industry is clearly

becoming transformed into an information transmit-

ti ng i ndustr y. I n thi s si tuati on, the speed of

transmission of information in the world is becoming

faster and faster, as compared with the manufacture

of electronic media, and the manufacturing speed of

printing equipment needs further improvement.

(2) Enhancement of producti on effi ci ency of new ma-

chines

I n order for a machine to exhibit high productiv-

i ty, changes i n the operati ng envi ronment and the

people using it must be taken into account.

What must be kept i n mi nd i s devel opment of

"printing machines used by people, friendly to people,

and friendly to the environment."

A printing machine is basically a machine for mass

production of duplicates of the designer's image, and

it is required to print at a specified repeatability. For

this purpose, (1) elements and components compos-

ing the machine must work reliably, (2) maintenance

must be easy or not requi red, and (3) response to

mechanical operation is always constant, are needed.

Especially, when the digital image data created by the

designer is distributed through the communication

network and printed at shops, the printing machine

is a printer at the terminal of the network, and it is

even more important to exhibit a specific repeatabil-

i ty al l the ti me. On the other hand, the pri nti ng

machine is an expensive asset in production, and it is

required to enhance production efficiency, that is, to

maximize the actual operating time.

(3) For the environment and energy saving

Onl y part of pri nted matter i s reserved i n book

form, and the majority is consumed. That is, once read,

printing matter is destined to be discarded. Paper is

made from forest resources, and images are formed

on the sheet of paper by usi ng i nk and dampeni ng

solution by operating the printing press while con-

suming electric energy. After the operation, the ink is

washed away from the machi ne by usi ng sol uti on.

I ndeed, this is an industry that imposes a heavy en-

vironmental load. Accordingly, recycled paper and soy

oil ink are used, and water less printing not requir-

ing the use of dampening water is being evaluated

anew.

From the pri nti ng machi ne si de, attempts have

been made to decrease waste paper occurring in the

process of color adjustment at the start of printing,

reduce the operating power, and recycle the cleaning

solution, and this campaign must be further intensi-

fied so as to reduce the environmental load.

5. Conclusion 5. Conclusion 5. Conclusion 5. Conclusion 5. Conclusion

The Paper & Printing Machinery Division is the only

company in the world capable of researching and devel-

opi ng both paper and pri nti ng, and i t i s henceforth

determined to make its merits known widely to custom-

ers in the pulp and paper field, paper converting field,

and printing field, to expand its operation while making

best use of its advantages, and to develop further tech-

nology and products. Your kind suggestions and advice

to MHI will be greatly appreciated.

(Home page address: http://www.mhi.co.jp/mihara/)

Director, General Manager,

Paper & Printing Machinery Division

Nobuo Kiyama

PAPER & PRINTING MACHINERY DIVISION

Tetsuo Makino Shinichi Fujimoto

You might also like

- Lesson Plan of COPA Sem-1Document74 pagesLesson Plan of COPA Sem-1ManishShilu87% (62)

- REPORTDocument31 pagesREPORTSyaa Malyqa100% (3)

- Words That Look Alike: Pass The TOEIC TestDocument2 pagesWords That Look Alike: Pass The TOEIC TestLành CaNo ratings yet

- HMT PinjoreDocument45 pagesHMT PinjoreJaskiratSinghNo ratings yet

- Static Trip ManualDocument52 pagesStatic Trip ManualRavijoisNo ratings yet

- Knowledge Creation in Public Administrations PDFDocument348 pagesKnowledge Creation in Public Administrations PDFPreciosaAngelaMaiquezNo ratings yet

- E401074 PDFDocument5 pagesE401074 PDFAnthony HzmNo ratings yet

- Shoe Press c3Document32 pagesShoe Press c3Nipun DograNo ratings yet

- Textile Digital Printing TechnologiesDocument65 pagesTextile Digital Printing TechnologiesJothi Vel Murugan100% (2)

- Guide To Digital PrintingDocument12 pagesGuide To Digital PrintingJesus FernandezNo ratings yet

- Overview of Printing IndustryDocument7 pagesOverview of Printing IndustryHarish Pillu.No ratings yet

- Times of India: Yc Yc Yc Yc Yc Yc Yc YcDocument2 pagesTimes of India: Yc Yc Yc Yc Yc Yc Yc YcAditi ChaturvediNo ratings yet

- Final Edition - 2Document57 pagesFinal Edition - 2Zemichael MesfinNo ratings yet

- Trends in Apparel Manufacturing TechnologyDocument8 pagesTrends in Apparel Manufacturing TechnologyAmit SinghNo ratings yet

- 3D PrintingDocument45 pages3D Printingbrian3442No ratings yet

- Guide For Purchase of A PhotocopierDocument29 pagesGuide For Purchase of A PhotocopierpreetamdoorgahNo ratings yet

- Indian Printing IndustryDocument3 pagesIndian Printing Industryrajmalhar123456No ratings yet

- Objectives: The Purpose of This Study Is To Determine The Effect of The Product's Country of OriginDocument10 pagesObjectives: The Purpose of This Study Is To Determine The Effect of The Product's Country of OriginSatish KumarNo ratings yet

- The Latest Trends in Printing Technology-LibreDocument9 pagesThe Latest Trends in Printing Technology-LibreAnkit BansalNo ratings yet

- Cloud Printing An Upcoming TechnologyDocument21 pagesCloud Printing An Upcoming TechnologyPurushothama ReddyNo ratings yet

- Case Study On FujitsuDocument14 pagesCase Study On Fujitsuhimanisharma9No ratings yet

- 3D PrintingDocument20 pages3D PrintingveeraraghavendrabalinaNo ratings yet

- SqueegeeDocument49 pagesSqueegeeKeerthanaNo ratings yet

- Lokmat Newspaper Rupesh KumarDocument5 pagesLokmat Newspaper Rupesh Kumarrupeshverma491993No ratings yet

- Chapter Three ModularDocument19 pagesChapter Three ModularJombola HamdinoNo ratings yet

- Additive Manufacturing Progress As A NewDocument8 pagesAdditive Manufacturing Progress As A Newsayansantra336.hitche2020No ratings yet

- Us History-Modern EraDocument14 pagesUs History-Modern EraCattleya JadeNo ratings yet

- Photocopier Industry: at The Forefront of ServitizationDocument22 pagesPhotocopier Industry: at The Forefront of ServitizationGinny MontalbanNo ratings yet

- Photo TypesettingDocument4 pagesPhoto TypesettingPaula ZorziNo ratings yet

- Printer DesignDocument54 pagesPrinter DesignOjobo BlessingNo ratings yet

- FinalDocument66 pagesFinalBasu KumashiNo ratings yet

- Case - La PresseDocument1 pageCase - La PresseValentina GomezNo ratings yet

- HMTDocument26 pagesHMTGanesh B NairNo ratings yet

- Info Tech Word AssignmentDocument9 pagesInfo Tech Word Assignmentnyasha gundaniNo ratings yet

- 126792231-6 enDocument9 pages126792231-6 enyisakabera123No ratings yet

- Study of Programmable Logic Controller (Simatic S7-200 in Paper Mill)Document55 pagesStudy of Programmable Logic Controller (Simatic S7-200 in Paper Mill)b_sravaniprasadNo ratings yet

- Screen PintingDocument40 pagesScreen PintingAllen CardonaNo ratings yet

- CSR Fashion ProjectDocument30 pagesCSR Fashion ProjectAnil RajNo ratings yet

- FLEXPRINTINGDocument2 pagesFLEXPRINTINGbishnuds25No ratings yet

- Final 3d Printing RajatDocument20 pagesFinal 3d Printing RajatRajat KhannaNo ratings yet

- Study of PrintersDocument10 pagesStudy of PrintersPravendra KushwahaNo ratings yet

- Revised Despro GamingDocument54 pagesRevised Despro GamingJoseph Alvin Manzano Palma100% (1)

- Evolution of Lean - PaperDocument7 pagesEvolution of Lean - PaperDash CorderoNo ratings yet

- Gherzi: Digital Textile PrintingDocument8 pagesGherzi: Digital Textile Printingpassions4friendsNo ratings yet

- COMEZ Tech Tex - enDocument23 pagesCOMEZ Tech Tex - enErkam AlpaslanNo ratings yet

- Hmtcomplete 131026233634 Phpapp02Document48 pagesHmtcomplete 131026233634 Phpapp02kiranNo ratings yet

- "Increase in Productivity of Turret Punching Process (TPP) ": P. Venkataramana & G.GurumaheshDocument8 pages"Increase in Productivity of Turret Punching Process (TPP) ": P. Venkataramana & G.GurumaheshTJPRC PublicationsNo ratings yet

- Trust International Paper Corporation (Tipco) Mabalacat, Pampanga January 20, 2015Document21 pagesTrust International Paper Corporation (Tipco) Mabalacat, Pampanga January 20, 2015Anonymous 0zrCNQNo ratings yet

- Machine Vision Technology Take-Up in Industrial ApplicationsDocument7 pagesMachine Vision Technology Take-Up in Industrial ApplicationsMekaTronNo ratings yet

- Lecture 1 PDFDocument20 pagesLecture 1 PDFKe WalNo ratings yet

- Master Copy AllDocument10 pagesMaster Copy AllNikhilesh ThakurNo ratings yet

- Digital Printing - WWW - Kainosprint.com - AuDocument8 pagesDigital Printing - WWW - Kainosprint.com - AulinksmasterNo ratings yet

- T JD Cover Auto SavedDocument36 pagesT JD Cover Auto SavedMouhamed BouazziNo ratings yet

- Developments in Digital Print StandardizationDocument13 pagesDevelopments in Digital Print StandardizationsaszamaszaNo ratings yet

- Chapter-1: An Exhaustive Case Study of Lean ManufacturingDocument57 pagesChapter-1: An Exhaustive Case Study of Lean ManufacturinganimeshNo ratings yet

- Inkjet Printing of MicrocomponentsDocument19 pagesInkjet Printing of Microcomponentsflo ngoNo ratings yet

- Institute of Professional Education and Research, BhopalDocument8 pagesInstitute of Professional Education and Research, BhopalSai VasudevanNo ratings yet

- Lesson Plan-2014Document74 pagesLesson Plan-2014ManishShilu100% (6)

- Company Perspectives Flex LTDDocument6 pagesCompany Perspectives Flex LTDCarlos BringasNo ratings yet

- Iti Bangalore Report AbstractDocument9 pagesIti Bangalore Report AbstractSagar NagarajNo ratings yet

- Understanding the Industrial Internet the $$$ Trillion Opportunities for Your EnterprisesFrom EverandUnderstanding the Industrial Internet the $$$ Trillion Opportunities for Your EnterprisesNo ratings yet

- 3D Printing: A Revolutionary Process for Industry ApplicationsFrom Everand3D Printing: A Revolutionary Process for Industry ApplicationsNo ratings yet

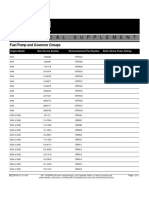

- FuelPump&GovernorGroups SELD0135 11Document11 pagesFuelPump&GovernorGroups SELD0135 11narit00007No ratings yet

- Humanism and Law SchoolDocument48 pagesHumanism and Law SchoolStock SpacesNo ratings yet

- C-CS-50-002 Tuberias Metalicas v3Document26 pagesC-CS-50-002 Tuberias Metalicas v3Jorge Johnny Chipana MachacaNo ratings yet

- Performance Correction Chart of Centrifugal Oil Pump For Handling Viscous LiquidsDocument7 pagesPerformance Correction Chart of Centrifugal Oil Pump For Handling Viscous LiquidsalikajbafNo ratings yet

- Phlebotomist TrackerDocument62 pagesPhlebotomist Trackertarun sharmaNo ratings yet

- (Firm Name:-Ajanta Paint House, Siyana) (GST No.: - 09BSDPP4052K1ZG) (Year 2018-2019)Document3 pages(Firm Name:-Ajanta Paint House, Siyana) (GST No.: - 09BSDPP4052K1ZG) (Year 2018-2019)Vatsal RastogiNo ratings yet

- Omengan Vs PNBDocument3 pagesOmengan Vs PNBJim de los Santos100% (1)

- Annexure 6.0 Candidate InstructionsDocument8 pagesAnnexure 6.0 Candidate Instructionschiluverushivaprasad02No ratings yet

- First Certificate Booklet 2Document89 pagesFirst Certificate Booklet 2Alina TeranNo ratings yet

- Sexy Book 121Document252 pagesSexy Book 121Irepan Ponce50% (2)

- DBEBEE601Document4 pagesDBEBEE601bariNo ratings yet

- Tugas Inggris M Edi SuryaDocument9 pagesTugas Inggris M Edi SuryaAstaghfirullahNo ratings yet

- OfficialRules-BritneySpearsNYE CRDocument9 pagesOfficialRules-BritneySpearsNYE CRAbelardo Ch.No ratings yet

- Api 577 Q 114Document31 pagesApi 577 Q 114Mohammed YoussefNo ratings yet

- Greenhouse Manual2Document106 pagesGreenhouse Manual2Amit ShresthaNo ratings yet

- CDHA Infection ControlDocument2 pagesCDHA Infection ControlAliaa El WakeelNo ratings yet

- Apbush DBQDocument2 pagesApbush DBQMaria Ines Carrillo100% (1)

- Alter Ego 181 PreviewDocument20 pagesAlter Ego 181 PreviewJohn LloydNo ratings yet

- PFIN7 Chapter 1Document30 pagesPFIN7 Chapter 1Madison WalkerNo ratings yet

- ECO Drive Display: Honda Fit GP5 Driving AidsDocument3 pagesECO Drive Display: Honda Fit GP5 Driving Aidsmzee233100% (1)

- JK Civil Sevices Classification Control and AppealpdfDocument35 pagesJK Civil Sevices Classification Control and AppealpdfShuja Malik100% (1)

- Spare Parts CatalogueDocument45 pagesSpare Parts CatalogueАлексей ДомнинNo ratings yet

- A Concept Paper About LoveDocument5 pagesA Concept Paper About LoveStephen Rivera100% (1)

- PHD Thesis Library Science DownloadDocument8 pagesPHD Thesis Library Science Downloadyvrpugvcf100% (2)

- Handout - Education in EmergenciesDocument31 pagesHandout - Education in EmergenciesFortunatoNo ratings yet

- المؤسسات الناشئة وامكانيات النمو-دراسة في انشاء حاضنات الأعمال لمرافقة المشروعات الناشئةDocument16 pagesالمؤسسات الناشئة وامكانيات النمو-دراسة في انشاء حاضنات الأعمال لمرافقة المشروعات الناشئةoussama bekhitNo ratings yet

- Module 4Document18 pagesModule 4Christian Diki JooeNo ratings yet