Professional Documents

Culture Documents

VA1 DEC 00100 M M1D CAL 8012 - RevB PDF

VA1 DEC 00100 M M1D CAL 8012 - RevB PDF

Uploaded by

Anonymous JtYvKt5XECopyright:

Available Formats

You might also like

- Arkaz Product BroucherDocument5 pagesArkaz Product Brouchersk mukhtarNo ratings yet

- Multi Organics-MEEP-180118-31.12.2018 PDFDocument28 pagesMulti Organics-MEEP-180118-31.12.2018 PDFArjun KrishnakumarNo ratings yet

- CO2 and Lime Dosage Sea WaterDocument11 pagesCO2 and Lime Dosage Sea WaterNoureddine Merah100% (2)

- Uf Toray PresentationDocument54 pagesUf Toray PresentationPrateek VermaNo ratings yet

- Foundation AccessoriesDocument4 pagesFoundation Accessoriesnatasja8No ratings yet

- DM Water Supply System OverviewDocument20 pagesDM Water Supply System Overviewanon_33553517No ratings yet

- Va1 Dec 00100 I M1D Pid 0001 PDFDocument2 pagesVa1 Dec 00100 I M1D Pid 0001 PDFAnonymous JtYvKt5XENo ratings yet

- 7.5 KLHR MEE Offer (5%)Document10 pages7.5 KLHR MEE Offer (5%)kezaihrajNo ratings yet

- Condensate Polishing UnitDocument35 pagesCondensate Polishing Unitrahult19No ratings yet

- 60-F8451S-H0101-01 RevD DBR of CPPDocument19 pages60-F8451S-H0101-01 RevD DBR of CPPK R Kumar RanjanNo ratings yet

- P&id Demin. Water Supply SystemDocument3 pagesP&id Demin. Water Supply SystemAjeng OctaviaNo ratings yet

- Achieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015Document25 pagesAchieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015ansarNo ratings yet

- Mechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundDocument2 pagesMechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundjokishNo ratings yet

- DM Plant DrawingDocument1 pageDM Plant DrawingMd SuruzzamanNo ratings yet

- Cross ReferenceDocument3 pagesCross ReferenceABDUL MUZAMMILNo ratings yet

- Low Temp. EvaporationDocument40 pagesLow Temp. EvaporationManvi Sharma100% (1)

- PIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Document55 pagesPIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Hesti Fuzi LestariNo ratings yet

- Desalination WriteUpDocument17 pagesDesalination WriteUpguptaaniruddhNo ratings yet

- Quote PDFDocument7 pagesQuote PDFChandu GowdaNo ratings yet

- Data Sheet For Pump: Client NameDocument1 pageData Sheet For Pump: Client NameMarathwada ChemicalsNo ratings yet

- ZLD Presentation 3 PDFDocument24 pagesZLD Presentation 3 PDFJagar Nath Shah100% (1)

- UF Ultrafiltration Manual 45 D00874 enDocument81 pagesUF Ultrafiltration Manual 45 D00874 enKrisNo ratings yet

- ZLD Presentation 4 PDFDocument23 pagesZLD Presentation 4 PDFVineeth SivarajNo ratings yet

- Mr. Manish Kharwade - PrajDocument41 pagesMr. Manish Kharwade - PrajNithi AnandNo ratings yet

- 04 Manifold HydraulicsDocument29 pages04 Manifold HydraulicsVeena NageshNo ratings yet

- Skim Tank T-1019 Data Sheets - SHEET 2Document1 pageSkim Tank T-1019 Data Sheets - SHEET 2arachman297988No ratings yet

- Pump Curve: Colour CodeDocument24 pagesPump Curve: Colour CodeP N100% (1)

- 3.4.B.07.03 Static MixerDocument1 page3.4.B.07.03 Static Mixerwado11100% (1)

- 1 IER FundamentalsDocument54 pages1 IER FundamentalsAdam FendrychNo ratings yet

- Business Activities ProfileDocument35 pagesBusiness Activities ProfileKapa KamalakarNo ratings yet

- Multiorganics 50 KLDDocument24 pagesMultiorganics 50 KLDArjun KrishnakumarNo ratings yet

- Syn CompressorDocument23 pagesSyn CompressorManish GautamNo ratings yet

- AtfdDocument4 pagesAtfdDarshan PatelNo ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- Lombardyne Multiple Effect EvaporatorDocument8 pagesLombardyne Multiple Effect EvaporatorKuldeep BhattNo ratings yet

- TMF Lime SofteningDocument2 pagesTMF Lime SofteningRachel HechanovaNo ratings yet

- Batching of Dosing Chemicals For BoilersDocument4 pagesBatching of Dosing Chemicals For BoilersDavid Muñoz CastroNo ratings yet

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- SUEZ Brochure FGD ENDocument4 pagesSUEZ Brochure FGD ENKumarrathinamNo ratings yet

- G. Pumps and DriversDocument14 pagesG. Pumps and DriversJithinNo ratings yet

- A Presentation On Electrics, Instrumentation & Automation of Demineralization Plant of Capacity 3X89 Cum/Hr. at Tsl-KpoDocument24 pagesA Presentation On Electrics, Instrumentation & Automation of Demineralization Plant of Capacity 3X89 Cum/Hr. at Tsl-KpoAshutosh DubeyNo ratings yet

- 14-Lime Soda Ash Treatment PDFDocument43 pages14-Lime Soda Ash Treatment PDFRaj BisenNo ratings yet

- Carbon Aktif DesignDocument21 pagesCarbon Aktif Designnurrahman.auliaNo ratings yet

- PFD FileDocument11 pagesPFD FileNaveen MahawarNo ratings yet

- Air Cooled COndenser PDFDocument7 pagesAir Cooled COndenser PDFRajAnandNo ratings yet

- LAMELA Plate Separators DFDocument4 pagesLAMELA Plate Separators DFStan MacapiliNo ratings yet

- 1000 Liter Ion Exchange GalleriaDocument5 pages1000 Liter Ion Exchange GalleriaBiswajit SahooNo ratings yet

- STP (200kld) - Technical Datasheet 17.02.23Document150 pagesSTP (200kld) - Technical Datasheet 17.02.23Rajender Chamoli100% (1)

- ZLD ProcessDocument36 pagesZLD ProcessLim Chee Siang100% (1)

- Va1 Tatl 00100 M M7 Cal 0001Document3 pagesVa1 Tatl 00100 M M7 Cal 0001hoangduythanhqbNo ratings yet

- Binder5 PDFDocument73 pagesBinder5 PDFcarmela alburquequeNo ratings yet

- DM PlantDocument3 pagesDM PlantArnab PalNo ratings yet

- VenturiDocument2 pagesVenturiJIANo ratings yet

- Cooling Water PDFDocument32 pagesCooling Water PDFnivasssvNo ratings yet

- Demineralization and Condensate Polishing BasicsDocument16 pagesDemineralization and Condensate Polishing BasicsvenkeekuNo ratings yet

- Removal of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuDocument20 pagesRemoval of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuChuah Chong YangNo ratings yet

- AL MARAI HADCO ETP - Process Description and SeqDocument43 pagesAL MARAI HADCO ETP - Process Description and SeqHumaid ShaikhNo ratings yet

- Calculator GWR Contact Time Calculator v9Document16 pagesCalculator GWR Contact Time Calculator v9HeruNo ratings yet

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApDocument39 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApAnonymous JtYvKt5XENo ratings yet

- Steel Structure ST 37Document11 pagesSteel Structure ST 37aliNo ratings yet

- Earthing CalculationDocument14 pagesEarthing CalculationNatarajan Ramakrishnan100% (20)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Project 60% Quality Field Audit Checklist (Zone-1 Field Tour Quality Audit)Document7 pagesProject 60% Quality Field Audit Checklist (Zone-1 Field Tour Quality Audit)Anonymous JtYvKt5XENo ratings yet

- 16.CMS-SMP1A-AC00 (06 Sep 2015) PDFDocument1 page16.CMS-SMP1A-AC00 (06 Sep 2015) PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec Li M1D Eng 00442Document1 pageVa1 Dec Li M1D Eng 00442Anonymous JtYvKt5XENo ratings yet

- Shipflow Tutorials - BasicDocument128 pagesShipflow Tutorials - BasicAnonymous JtYvKt5XENo ratings yet

- CV BoDocument8 pagesCV BoAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8301 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8204 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8204 PDFAnonymous JtYvKt5XENo ratings yet

- VA1 DEC 00100 M M1D PHL 8202 - RevD PDFDocument42 pagesVA1 DEC 00100 M M1D PHL 8202 - RevD PDFAnonymous JtYvKt5XENo ratings yet

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApDocument39 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8701 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8701 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8301 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 0001 PDFDocument2 pagesVa1 Dec 00100 I M1D Pid 0001 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8204 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8204 PDFAnonymous JtYvKt5XENo ratings yet

- VA1 YEA 02100 I I1 PID 0001 - RevA PDFDocument7 pagesVA1 YEA 02100 I I1 PID 0001 - RevA PDFAnonymous JtYvKt5XENo ratings yet

- PTW Site Instruction NewDocument17 pagesPTW Site Instruction NewAnonymous JtYvKt5XENo ratings yet

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisAnonymous JtYvKt5XENo ratings yet

- Attender List 1Document2 pagesAttender List 1Anonymous JtYvKt5XENo ratings yet

- PTW Site Instruction: Table of ContendsDocument13 pagesPTW Site Instruction: Table of ContendsAnonymous JtYvKt5XENo ratings yet

- Anti Browning AgentsDocument11 pagesAnti Browning Agentskasun1237459No ratings yet

- Astm E384Document40 pagesAstm E384sud1313No ratings yet

- 02 ChellamaniDocument5 pages02 Chellamanikathirvelus9408No ratings yet

- A Basic Introduction of RheologyDocument20 pagesA Basic Introduction of RheologyLina Mariana Prieto AmadoNo ratings yet

- Measuring Enthalpy ChangeDocument20 pagesMeasuring Enthalpy ChangedhruviniNo ratings yet

- Physical Chemistry Chapter 1 LectureDocument9 pagesPhysical Chemistry Chapter 1 LectureSarah AlexanderNo ratings yet

- Transport For NSW (TFNSW) Qa Specification 3211 Cementitious Materials, Binders and FillersDocument43 pagesTransport For NSW (TFNSW) Qa Specification 3211 Cementitious Materials, Binders and FillersDiana Quintero100% (1)

- 13 Water Treatment Training Pretreatment FiltrationDocument32 pages13 Water Treatment Training Pretreatment Filtrationsantoshkumar gurmeNo ratings yet

- Astm G 61Document5 pagesAstm G 61fdddddddddddddddddddddddNo ratings yet

- Selection of Recombinant ClonesDocument2 pagesSelection of Recombinant ClonesKV Deepika100% (1)

- Biomarkers: PetroleumDocument13 pagesBiomarkers: PetroleumMohamed HaboNo ratings yet

- E7010 P1 - 15680891Document4 pagesE7010 P1 - 15680891Arvind SahaniNo ratings yet

- 26-12-19 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Main - GTM-12 - Key & Sol'sDocument15 pages26-12-19 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Main - GTM-12 - Key & Sol'smahesh tNo ratings yet

- Smart Supercapacitors From Materials To DevicesDocument13 pagesSmart Supercapacitors From Materials To DevicesRavi SuryaNo ratings yet

- Precise Results Accurate DiagnosisDocument33 pagesPrecise Results Accurate DiagnosisAsvene SharmaNo ratings yet

- Carbohydrates: Notes in BiologyDocument3 pagesCarbohydrates: Notes in BiologyAnonymous HXLczq3100% (1)

- TEPZZ 9 5 - 9 B - T: European Patent SpecificationDocument11 pagesTEPZZ 9 5 - 9 B - T: European Patent SpecificationLê CôngNo ratings yet

- SK Nandy-OISD StandardsDocument29 pagesSK Nandy-OISD Standardskselvan_1100% (1)

- ME608 - 2D SIMPLE Solver For Laminar Flow Over A Square Cylinder - Spring 2010Document10 pagesME608 - 2D SIMPLE Solver For Laminar Flow Over A Square Cylinder - Spring 2010saravana pandianNo ratings yet

- Analyticaltechniques12 PDFDocument7 pagesAnalyticaltechniques12 PDFZaidNo ratings yet

- 6.6 The MOS CapacitanceDocument3 pages6.6 The MOS CapacitancePrasanth YgNo ratings yet

- Modul Chemistry Form 5Document101 pagesModul Chemistry Form 5cikgufiezaNo ratings yet

- Sherwood 2005Document7 pagesSherwood 2005Ionela MariaNo ratings yet

- Disclosure To Promote The Right To Information: IS 5057 (1997) : Potassium Nitrite, Food Grade (FAD 8: Food Additives)Document8 pagesDisclosure To Promote The Right To Information: IS 5057 (1997) : Potassium Nitrite, Food Grade (FAD 8: Food Additives)akNo ratings yet

- European Standards For Tile AdhesivesDocument4 pagesEuropean Standards For Tile AdhesivesChiang LoongNo ratings yet

- Lab Report Heat CnductionDocument17 pagesLab Report Heat CnductionainnorNo ratings yet

- Steps of GlycolysisDocument3 pagesSteps of GlycolysisIm jungkook JUSTIN SEAGULL A.K.A jungshookNo ratings yet

- BRENDADocument5 pagesBRENDAnoah676No ratings yet

VA1 DEC 00100 M M1D CAL 8012 - RevB PDF

VA1 DEC 00100 M M1D CAL 8012 - RevB PDF

Uploaded by

Anonymous JtYvKt5XEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VA1 DEC 00100 M M1D CAL 8012 - RevB PDF

VA1 DEC 00100 M M1D CAL 8012 - RevB PDF

Uploaded by

Anonymous JtYvKt5XECopyright:

Available Formats

27 / 39

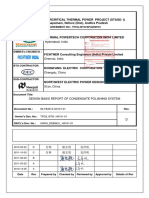

DOCUMENT SUBMISSION STATUS: AP

B 5.18.2012 second Issue

A 3.20.2011 Initial Issue

REV DATE DESCRIPTION DRWN CHKD APPN

OWNER

OWNERS CONSULTANT

EPC CONTRACTOR

EPC CONTRACTORS CONSULTANT

PROJECT TITLE

VUNG ANG 1 THERMAL POWER PLANT 2 x 600MW

M_LOT1D-BOP OF TURBINE

CONTRACT No. 290110/LILAMA-DEC

DRAWING TITLE

Design calculation for condensate polishing system

SUB-CONTRACTOR

FUNCTION NAME SIGN DATE

DRWN Yao J un

5.18.2012

CHKD Zhang Fei

5.18.2012

APPD J iang BaoCai

5.18.2012

DOCUMENT No. VA1-DEC-00100-M-M1D-CAL-8012

SCALE REV B

VIETNAM OIL AND GAS GROUP (PVN)

POYRY ENERGY LTD

VIETNAM MACHINERY

INSTALLATIONCORPPORATION (LILAMA)

FICHTNER GmbH & Co. KG

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

2 / 39

Design calculation for condensate

polishing system

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

3 / 39

Approved by: J iang Bao Cai

Examined by: Zhang Fei

Checked by: Zhang Fei

Compiled by: Yao J un

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

4 / 39

Table of content

PART ONE EQUIPPMENTS DETERMINATION CALCULATION ....................... 5

PART TWO PUMP CALCULATION ........................................................................ 14

PART THREE THE PRESSER VESSEL WALL THICKNESS CALCULATION .. 25

PART FOUR WASTEWATER CALCULATION ..................................................... 27

PART FIVE WASTE WATER BASIN AND TRENCH CALCULATION .............. 37

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

5 / 39

PART ONE EQUIPPMENTS DETERMINATION CALCULATION

1. prefilters:

1.1 The condition of prefilters

Tag Number =10(20) LDB22BB001, 10(20) LDB23BB001, 10(20)

LDB24BB001

Configuration =3x50 %( Usually, 2 prefilters will be in operation, 1

perfilter will be reserved)

Incoming Condensate Water =1506m

3

Quantity =3 no

/h

Flow rate into each prefilter Q

1

=753 m

3

1.2 Filter element

/h

Filter area (S

1

) of one filter element=6.5m

Filter rate (V

2

1

) =0.7m

3

/m

2

Rated flow of each filter element q

h

1

=S

1

V

1

=6.50.7=4.55m

3

Quantity of filter element=

/h

5 . 165

55 . 4

753

1

1

= =

q

Q

no

Quantity of running filter element selected: 204

1.3 The Determination of prefilter

The Inside diameter is determined by the quantity of filter element, each prefilter

should include all the filter elements,

The appendix 1 is about the arrangement of the filter elements

Inside diameter =1700mm

Prefilter tube height depends on the filter element height, and to maintain the proper

operation of space. The filter element height is 1788mm.

Prefilter tube height =1788+247+365=2400mm

Where the 247mm means the distance from the bottom of the filter element to the

bottom of the prefilter;

The 365mm means the top of the filter element to the top of the prefilter;

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

6 / 39

The height of the prefilter is selected 2400mm

appendix 1 the arrangement of the filter elements

2. Mixed beds

2.1 The condition of mixed bed

Tag Number =10(20) LDF22BB001, 10(20) LDF23BB001, 10(20)

LDF24BB001

Configuration =3x50 %( Usually, 2 mixed beds will be in operation, 1

mixed bed will be reserved)

Incoming Condensate Water =1506m

3

Quantity =3 no

/h

Flow rate into each mixed bed Q

2

=753 m

3

2.2 The Determination of mixed bed

/h

The mixed beds are designed to spherical vessel

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

7 / 39

Flow velocity (V

2

Flow area (S

) =110m/h

2

2

2

2

84 . 6

110

753

m

V

Q

= = ) =

Inside diameterD

2

4

2

S

= = 2.95m

Inside diameterD

2

Volume of the resin =6.9m

selected =3000mm

Volume of the cation resin =4.6m

3

Volume of the anion resin =2.3m

3

3. Resin trap

3

3.1 The condition of resin traps

Tag Number =10(20) LDF22BB002, 10(20) LDF23BB002, 10(20)

LDF24BB002

Configuration =3x50 %( Usually, 2 resin traps will be in operation, 1 resin

trap will be reserved)

3.2 Design parameters

The flow area of the resin trap is designed to be 3 times as the area of the pipe, So

flow area of the resin trap(S)=30.07=0.21m

The filter wire width (b

2

1

The mesh of filter (b

) =1.9mm

2

The diameter of the filter element (d) =500mm

) =0.20mm

The filter area of rein trap is the total gap area of the filter element, the diameter of the

resin trap (D) is selected as 600mm

The quantity of the wire in 1 meter filter (N),

476

2 . 0 9 . 1

1000 1000

2 1

=

+

=

+

=

b b

N

The area of the mesh in 1 meter filter (S

1

2

2

149 . 0 0002 . 0 5 . 0 14 . 3 476 1 m b d N S = = =

)

The length of the filter element (L

1

)

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

8 / 39

mm 1410

149 . 0

21 . 0

1

1

= = =

S

S

L

The length of the resin trap (L)

mm 2260 650 200

1

= + + = L L

Where the 200mm means the distance from the bottom of the filter element to the

bottom of the resin trap;

The 650mm means the top of the filter element to the top of the resin trap;

The height of the resin trap is selected 2280mm

4. Resin separation tank

4.1 The condition of resin separation tank

Tag Number: =00LDP14BB001

Quantity =1 no

Inside diameter =1.6-0.010=1.59m (the straight part, the 0.010m is the

width of rubber lined)

the cross-sectional area (S1)

2 2

98 . 1 59 . 1

4

14 . 3

2

4

1 m Xd S = = =

4.2 The Determination of resin separation tank

4.2.1 The height of the straight tube

The resin separation tank is designed a straight tube on the bottom part and a cone

shape on the top part.

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

9 / 39

The resin separated tank outline

Because there will be 1 meter high residual resin in the resin separation tank, the

volume of the resin residue (V

m

3

98 . 1 0 . 1 1 m S V

m

= =

)

Volume of the cation resinV

c

=4.6m

3

Volume of the anion resinV

;

a

=2.3m

3

Volume of all the resin (V

;

1

3

1

88 . 8 98 . 1 3 . 2 6 . 4 m V V V V

m a c

= + + = + + =

)

Volume of the resin in the butterfly head (V

2

) =0.62m

Volume of the resin in the straight tubeV

3

3

=V-V

2

=8.88-0.62=8.26m

The resin height in the straight tube (H1)

3

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

10 / 39

m

S

V

H 172 . 4

98 . 1

26 . 8

1

1

1

= = =

Considering the resin inlet, the straight height of the separated tank is selected to

4400mm

4.2.2 The height of the top part (cone part)

The cone part must contain all the resin,

Area of the top cone part S

2 2 2

52 . 4 4 . 2

4

14 . 3

4

m D S

top

= = =

top

S

bottom

=S

1

=1.98m

m

S S S S

V

H

bottom top bottom top

190 . 2

3

2

=

+ +

=

2

H

2

selected =2700mm

5. Anion regeneration tank

5.1 The condition of anion regeneration tank

Tag Number: =00LDP13BB001

Quantity =1 no

Inside diameter =1.5-0.010=1.49m (the straight part, the 0.010m is the

width of rubber lined)

the cross-sectional area (S

a

2 2

74 . 1 49 . 1

4

14 . 3

2

4

m Xd Sa = = =

)

5.2 Determination of anion regeneration tank

Anion regeneration tank is designed as a vertical and cylindrical vessel. The straight

height is determined by the volume of the anion resin.

Volume of the anion resin (V

a

) =2.3m

Volume in the butterfly bed (V

3

3

) =0.61m

Volume of the anion resin in the straight tube (V

3

1

)

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

11 / 39

3

3 1

69 . 1 61 . 0 3 . 2 m V V V

a

= = =

The height of the rein in the straight tubeH

1

m

S

V

H

a

971 . 0

74 . 1

69 . 1

1

1

= = =

the resin expansion heightH

2

m

S

V

H

a

a

322 . 1

74 . 1

3 . 2

2

= = =

H

2

The allowance height (H

selected =1300mm

3

The straight tube height H

) =200mm

mm H H H H 2470

3 2 1

= + + =

6. Cation regeneration tank

6.1 The condition of Cation regeneration tank

Tag Number: =00LDP12BB001

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

12 / 39

Quantity =1 no

Inside diameter =1.8-0.010=1.79m (the straight part, the 0.010m is the

width of rubber lined)

the cross-sectional area (S

c

2 2

515 . 2 79 . 1

4

14 . 3

2

4

m Xd S

c

= = =

)

6.2 Determination of cation regeneration tank

Cation regeneration tank is designed as a vertical and cylindrical vessel. The straight

height is determined by the volume of the cation resin.

Volume of the anion resin (V

c

) =4.6m

Volume in the butterfly bed (V

3

3

) =0.79m

Volume of the anion resin in the straight tube (V

3

1

3

3 1

81 . 3 79 . 0 6 . 4 m V V V

c

= = =

)

The height of the rein in the straight tubeH

1

m

S

V

H

c

515 . 1

515 . 2

81 . 3

1

1

= = =

When the anion resin is transferred into the cation resin regeneration tank, the height

of the cation and anion resinH

2

m

S

V V V

H

c

a c

430 . 2

515 . 2

79 . 0 9 . 6

3

2

=

=

+

=

H

2

The expansion height (H

selected =2500mm

3

mm H H 1050 2500 42 . 0 % 42

2 3

= = =

)

The allowance heights (H

4

The straight tube height H

) =400mm

mm H H H H 3950

4 3 2

= + + =

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

13 / 39

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

14 / 39

PART TWO PUMP CALCULATION

1. Acid metering pump

1.1 The condition of acid metering pump:

Tag Number: =00LDN21AP001/00LDN21AP002

Quantity =2 no (Usually, 1 pump will be in operation, the other will

be reserved)

1.2 Design Data

fluid type =hydrochloric acid

concentration (C

HCL

density(

) =30%

HCL

) =1150kg/m

Cation resin regeneration velocity in the vesselV

3

c

The cross-sectional area (S

=5m/h

c

) =2.515m

1.3 The cation resin regeneration flow (Q

2

c

h m V S Q

c c c

/ 6 . 12 5 515 . 2

3

= = =

)

Diluted acid regeneration fluid density (

c

)

c

=1000kg/m

3

, the mass flow of acid

regeneration fluid (Q

mc

h Q Q

c c mc

/ kg 12600 1000 6 . 12 = = =

)

Diluted acid concentrationC

c

Acid mass flow rate Q

=5%

m1

=C

c

Q

mc

The needed acid volume flow (Q

=0.0512600=630kg/h

v1

h

C

Q

Q

HCL HCL

m

v

/ m 83 . 1

1150 30 . 0

630

3 1

1

=

)

The acid metering pump flow (Q

1

) =1.251.83=2.29m

3

The selected acid metering pump flow =2.5m

/h

3

The acid metering pump head is designed to be higher than the pressure of the pipe

where the acid is added, the pressure of the pipe where the acid is added is usually 0.3

0.4MPa, so the head of the acid metering pump is selected as 0.5MPa.

/h

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

15 / 39

2. Caustic metering pump

2.1 The condition of caustic metering pump:

Tag Number: =00LDN22AP001/00LDN22AP002

Quantity =2 no (Usually, 1 pump will be in operation, the other will

be reserved)

2.2 Design Data

fluid type =Sodium hydroxide

concentration (C

NaOH

density (

) =30%

NaOH

) =1370kg/m

Anion resin regeneration velocity in the vesselV

3

a

The cross-sectional area (S

=5m/h

a

) =1.74m

2.3 The anion resin regeneration flow (Q

2

a

h m V S Q

a a a

/ 7 . 8 5 74 . 1

3

= = =

)

Diluted acid regeneration fluid density (

a

)

a

=1000kg/m

3

, the mass flow of acid

regeneration fluid (Q

ma

h Q Q

a a ma

/ kg 8700 1000 7 . 8 = = =

)

Diluted concentrationC

a

Acid mass flow rate Q

=4%

m2

=C

a

Q

ma

The needed alkali volume flow (Q

=0.048700=348kg/h

v2

h

C

Q

Q

NaOH NaOH

m

v

/ m 85 . 0

1370 30 . 0

348

3 2

2

=

)

The caustic metering pump flow =1.250.85=1.06 m

3

The selected caustic metering pump flow =1.5 m

/h

3

The caustic metering pump head is designed to be higher than the pressure of the pipe

where the caustic is added, the pressure of the pipe where the caustic is added is

usually 0.30.4MPa, so the head of the caustic metering pump is selected as 0.5MPa.

/h

3. Backwashing pump

3.1 The condition of backwashing pump:

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

16 / 39

Tag Number: =00LDB10AP001/00LDB10AP002

Quantity =2 no (Usually, 1 pump will be in operation, the other will

be reserved)

3.2 Design Data

fluid type =demineralized water

density(

NaOH

) =1000kg/m

3.3 the backwashing pump rated flow

3

The backwashing pump flow is determined by the requirement of filter element, since

one filter elements backwashing flow is 0.55m

3

/h ,the backwashing pump

flow(Q

b

)=2040.55=112.2m

3

The pump flow rate is selected as 110m

/h

3

The pump rated head (H) =the pressure needed (25m) by the filter element added to

the pressure

/h.

H=25+6.57=31.57mH

2

O, the pump head is selected 35m

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

17 / 39

BACKWASHING PUMP HEAD CALCULATION

Equipment :Backwashing pump Tag Number :00LDB10AP001/00LDB10AP002

DESIGN DATA

1 Fluid type =Water

2 Viscosity =1.00 cP 1.000 cst

3 Specific gravity =1.00

Use the formula for pipe pressure loss

3 . 1

2

00107 . 0

j

d

V

I =

Where I :pressure loss for 1m length pipe(m/m)

d

j

V: Velocity inside pipe (m/s)

inside diameter(m)

4 the flow rate(Q) =110m

3

5 pipe size =130mm ID d

/h

j

6 pipe material =304SS

FORMULA d

j

V(m/s) (m) I(m/m) PIPE

LENGTH

PRESSURE

LOSS(m)

A) PIPE

3 . 1

2

00107 . 0

j

d

V

I =

0.13 2.49 0.099 30 2.97

B)FITTING

d

j

V(m/s) (m) K QTY

PRESSURE

LOSS(m)

Elbow 90

g

V

K

2

2

0.13 2.49 0.60 4 0.76

Equal Tee

Branch

0.13 2.49 0.84 1 0.27

C )VALVE

butterfly

g

V

K

2

2

0.13 2.49 0.63 1 0.2

check

0.13 2.49 7.5 1 2.37

6.57

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

18 / 39

4. Recirculating pump

4.1 The condition of recirculating pump

One recirculating pump is designed for one unit

Pump capacity required =0.6Q

2

=451.9m

3

Pump rated flow rate =470m

/h

3

4.2 Pump head

/h

The pump head is to overcome the friction loss when the water is passing the mixed

bed and resin trap

max friction loss passing mixed bed=0.175MPa

max friction loss passing resin trap=0.1MPa

Piping friction loss =2.584mH

2

Calculation result =0.175+0.1+0.026=0.301MPa

O

Pump head selected =0.32MPa

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

19 / 39

RECIRCULATING PUMP HEAD CALCULATION

Equipment :Recirculating pump Tag Number :10LDF20AP001/20LDF20AP001

DESIGN DATA

1 Fluid type =Water

2 Viscosity =1.00 cP 1.000 cst

3 Specific gravity =1.00

Use the formula for pipe pressure loss

3 . 1

2

00107 . 0

j

d

V

I = where I :pressure loss for 1m length pipe(m/m)

d

j

V: Velocity inside pipe (m/s)

inside diameter(m)

4 the flow rate(Q) =470m3/h

5 pipe size =258mm ID d

j

6 pipe material =304SS

FORMULA d

j

V(m/s) (m) I(m/m) PIPE LENGTH PRESSURE LOSS(m)

A PIPE 0.258 2.48 0.039 10 0.39

B)FITTING d

j

V(m/s) (m) K QTY PRESSURE LOSS(m)

Elbow 90

g

V

K

2

2

0.258 2.48 0.60 3 0.565

C )VALVE

butterfly

g

V

K

2

2

0.258 2.48 0.70 1 0.219

check

0.258 2.48 4.5 1 1.41

2.584

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

20 / 39

5. ROOTS BLOWER

5.1 design condition

Tag Number: =00LDC21AN001/00LDC22AN001

Quantity =2 no (Usually, 1 air blower will be in operation, the other

will be reserved)

5.2 Design Data

fluid type =air

temperature =25

pressure in atmosphere =1.0110

5

5.3 The rated flow

Pa

the air from the roots blower outlet is used as the power source of the resin cleaning

based on the design standards:

the strength of the air washing (q) =3.6Nm

3

/m

2

the rated flow of the air blower(Q)=qS

min

where Sthe cross-sectional area of the resin separation tank or cation regeneration

tank or the anion regeneration tank; the largest one is the area of the cation

regeneration tank.

S =2.54m

Q =qS=3.62.54=9.14Nm

2

3

The selected =9.36Nm

/min

3

5.4 The rated head

/min

The air blower rated head (H) =the pressure needed (7m) for the resin washing added

to the pressure loss

H=7+0.3035=7.03mH

2

O, the air blower head is selected 8mH

2

O

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

21 / 39

ROOTS BLOWER HEAD CALCULATION

Equipment :air blower Tag Number ::00LDC21AN001/00LDC22AN001

DESIGN DATA

1 Fluid type =air

2 density =1.205kg/m

3

Use the formula for pipe pressure loss

m / a 5 . 30 P I = where I :pressure loss for 1m length pipe(m/m)

based on the standards, I=30.5Pa/m

3 the flow rate(Q) =5.22m

3

4 pipe size =80mm ID d

/min(at the condition :200.08MPa)

j

5 pipe material =340SS

FORMULA d

j

V(m/s) (m) I(Pa/m) PIPE

LENGTH

PRESSURE LOSS

pa)

A)PIPE 0.080 16.4 30.5 20 610

B)FITTING

kg./m3

V(m/s) K QTY

PRESSURE

LOSS(kg/m2)

Elbow 90

g 2

2

V

K

1.205 16.4 1 5 82.5

C )VALVE

kg./m3

V(m/s) K

QTY

PRESSURE

LOSS(kg/m2)

butterfly

g 2

2

V

K

1.205 16.4 0 1 0

check 1.205 16.4 0 1 0

silencer 1.205 16.4 10 1 165

3035 Pa(0.3035mH

2

O)

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

22 / 39

6. Flushing pump

6.1. design condition:

Tag Number: =00LDP10AP001/00LDP10AP002

Quantity =2 no (Usually, 1 pump will be in operation, the other will

be reserved)

6.2. Design Data

fluid type =Demineralized water

density =1000kg/m

6.3. the flushing pump rated flow

3

The flushing pump is used to supply water for the resin backwash, separation and

regeneration. When the resin is transferred, the flushing pump is also used to supply

water to transfer the resin. The maximum flow is the flow when the exhausted cation

resin is backwashed. The maximum flow is the rated flow of the flushing pump.

According to the characteristic of resin, the cation resin backwash velocity must reach

to 40m/h, the cation resin backwash expansion ratio can reach 100%

Here 1g/(mft

2

)=2.938m

3

/m

2

h, the backwash ratio of the cation resin (v)

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

23 / 39

V=2.93813.5=40m

3

/m

2

The cross-sectional area of the cation regeneration tank (S

hthe backwash ratio is selected 40m/h

c

) =2.515m

So the rated flow is Q

2

= = = 40 515 . 2 v S Q

c

100.6m

3

The rated flow is selected 100m

/h

3

In order to reduce the damage when the flushing pump is not used at the rated flow, a

return branch is designed.

/h

6.4. The flushing pump rated head

In order to maintain the resin transfer frequently, the resin need 0.35MPa pressure, the

outlet of the pump is designed a regulator valve to keep the pressure. The transfer

ratio is selected 3 m/s, the ratio in the main pipe is 1.13m/s

The pressure loss is 11.5mH

2

The rated head (H) =35+11.5=46.5 mH

O

2

O, the rated head is selected as 50 mH

2

FLUSHING PUMP HEAD CALCULATION

O

Equipment : Flushing pump Tag Number : 00LDP10AP001/00LDP10AP002

DESIGN DATA

1 Fluid type =Water

2 Viscosity =1.00 cP 1.000 cst

3 Specific density =1.00

Use the formula for pipe pressure loss

3 . 1

2

00107 . 0

j

d

V

I =

where I :pressure loss for 1m length pipe(m/m)

d

j

V: Velocity inside pipe (m/s)

inside diameter(m)

4 the transfer ratio (V) =3m/s

5 pipe size =80mom ID d

j

6 pipe material =304SS

FORMULA d

j

V(m/s) (m) I(m/m) PIPE

LENGTH

PRESSURE

LOSS(m)

A) PIPE

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

24 / 39

3 . 1

2

00107 . 0

j

d

V

I =

0.08 3 0.257 40 10.28

B)FITTING

d

j

V(m/s) (m) K QTY

PRESSURE

LOSS(m)

Elbow 90

g

V

K

2

2

0.08 3 0.30 5 0.69

Equal Tee

Branch

0.08 3 0 1 0

C )VALVE

butterfly

g

V

K

2

2

0.13 1.13 0.65 1 0.04

check

0.13 1.13 7.5 1 0.49

11.5

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

25 / 39

PART THREE THE PRESSER VESSEL WALL THICKNESS CALCULATION

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

26 / 39

NO.

NAME ID(m

m)

Design

pressure(M

Pa)

Design

tempera

ture

()

Material Permiss

ible

stress(

MPa)

Formula

Welding

coefficient

Thickness by

calculation(mm)

Thicknes

s

selected(

mm)

1

Prefiliter

1700 4.0 60

Sa516Gr7

0

160

Tc T

P E S

R P

T

m r

+ +

=

6 . 0

Where

T

r

P: design pressure (MPa)

: thickness by

calculation(mm)

R:vesselsradius 0.5ID

S:permissible stress (MPa)

E:welding coefficient

Tm: negative deviation of the

material, 0.25mm

Tc: corrosion allowance,2mm

1.0 23.85 30

2

Resin trap

600 4.0 60

Sa516Gr7

0

160 1.0 9.86 14

3

Resin

separation

tank

1600 0.6 50 A36 133 0.85 7.22 10

4

Cation

regenerati

on tank

1800 0.6 50 A36 133 0.85 7.84 10

5

Anion

regenerati

on tank

1500 0.6 50 A36 133 0.85 6.91 8

6

Air tank A

and B

1800

1.0 50

Sa516Gr7

0

160 0.85 7.56 8

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

27 / 39

NO.

NAME ID(m

m)

Design

pressure(M

Pa)

Design

tempera

ture

()

Material Permiss

ible

stress(

MPa)

Formula

Welding

coefficient

Thickness by

calculation(mm)

Thicknes

s

selected(

mm)

7

Air tank C 1600

1.0 50

Sa516Gr7

0

160 0.85 6.97 8

8

Electric

water

heater

1800 0.6 99 304 138 0.85 7.64 10

9

Mixed

bed

3000 4.0 60

Sa516Gr7

0

160

Tc T

P E S

D P

T

m r

+ +

=

4

Where

T

r

P: design pressure (MPa)

:thickness by

calculation(mm)

D:vesselsinside diameter

S:permissible stress (MPa)

E:welding coefficient

Tm:negative deviation of the

material, 0.25mm

1.0 21.1 28

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

28 / 39

NO.

NAME ID(m

m)

Design

pressure(M

Pa)

Design

tempera

ture

()

Material Permiss

ible

stress(

MPa)

Formula

Welding

coefficient

Thickness by

calculation(mm)

Thicknes

s

selected(

mm)

Tc:corrosion allowance,2mm

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

27 / 39

PART FOUR WASTEWATER CALCULATION

There are two kind wastewaters in the process of condensate polishing system running:

a) the wastewater when the filter elements are backwashed

b) the wastewater when the resin is regenerated

1. backwash of the prefilter

process Times

seconds

Backwash

flow(m

3

Volume

of

discharge

/h)

(m

3

Remark

)

1

Pressure discharge 120

No water will be

discharged

2

Backwash and

discharge until to

the 2/3 level

140 110 6.31

Backwash water

volume :4.28

The drainage from

the prefilter:2.03

3

Backwash by the

compressed air and

water(first)

5 110 0.15

4

Backwash and

discharge until to

the 1/3 level

120 110 5.94

Backwash water

volume :3.67

The drainage from

the pre-filter:2.27

5

Backwash by the

compressed air and

water(second)

5 110 0.15

6

Backwash and

discharge until to

the bottom of the

filter element

100 110 4.24

Backwash water

volume :3.06

The drainage from

the pre-filter:1.18

7 Backwash by the 5 110 0.15

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

28 / 39

compressed air and

water(third)

8

Backwash and

discharge until to

the bottom of the

pre- filter

120 110 4.97

Backwash water

volume :3.67

The drainage from

the pre-filter:1.30

9

Discharge until to

the level to the

bottom of the pre-

filter

120 ~0.05

Discharge without

pressure

10

Water filling until

to the top of the

pre-filter

120 110

No water will be

discharged

21.96 once

Usually the backwash will be done at less three times, so the total discharge water

volume is 21.963=65.88 m

3

2. the exhausted resins backwash and regeneration

Where SPT: resin separation tank;

CRT: cation regeneration tank

ART: anion regeneration tank

MB: mixed bed

2.1 the exhausted resin transfer from the mixed bed to the resin separation tank

process

time

seconds

flushing or

backwash

flow(m

3

Volume

of

discharge /h)

(m

3

remarks

)

1

Pressure

discharge of MB

30

2 Resin transfer 600 2.02 The water in the

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

29 / 39

by the

compressed air

mixed bed

3

Resin transfer

by the

compressed air

and the flushing

water

900 45 11.25

4

MB discharge

and the resin

pipe

flushing(first)

180

The resin

pipe

rush:45m

3

2.75

/h;

the resin pipe will be

flushed while the

residue

water(about~0.5m

3

) in

the mixed bed will be

discharged ,

5

MB discharge

and the resin

pipe

flushing(second)

60

The resin

pipe

flush:90m

3

1.5

/h;

17.52

2.2 the spare resin transfer from the cation regeneration tank to the mixed bed

process

time

seconds

Flushing or

backwash

flow(m

3

Volume of

discharge

/h) (m

3

remarks

)

1

The spair resin

transfer to MB

by the

compressed air

300

No water will

be discharged

2

The spair resin

transfer to MB

by the

compressed air

500 30

No water will

be discharged

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

30 / 39

and water

3

The flushing of

CRT

180 60 3

4

The resin pipe is

flushed while

MB is filled

600

45

7.5

5 CRT is filled 900

No water will

be discharged

10.5

2.3 the exhausted resin separation and transfer to the anion regeneration tank and the

cation regeneration tank

process

time

seconds

Flushing or

backwash

flow(m

3

Volume

of

discharge /h)

(m

3

remarks

)

1 SPT is filled 600

No water will be

discharged

2

Discharge of

SPT

180 8.88

The water above the

resin:8.88m

3

3

Pressure in the

SPT discharge

60

No water will be

discharged

4

Resin scrub by

the air from the

roots blower

900

No water will be

discharged

5

Backwash of

the resin in SPT

360 20

No water will be

discharged

6

SPT pressure

drainage

~6.05

7 flushing of the 60 36 0.6

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

31 / 39

upper part

8

Resin first

separation (1)

600 100 36.60

9

Resin first

separation (2)

600 50 18.30

10

Resin first

separation (3)

600 30 5

11

Resin first

separation (4)

600 15 2.5

12

Resin first

separation (5)

600 7.5 1.2

13

Anion resin is

waiting to be

transferred to the

ART

60 2 0.03

14

Anion resin is

transferred to

ART

420 18 2.1

15

second separation

prepare

120 2.5 0.07

16 Second seperstion 81.33

17

Cation resin transfer

prepare

120 2.5 0.07

18

Cation resin

transfer to CRT

360 20 2

19

flushing of the

resin pipe

120 60 2

20 ART filled 300

No water will be

discharged

21 CRT filled 600

No water will be

discharged

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

32 / 39

166.73

2.4 the regeneration of the cation and anion resin

process

time

seconds

flushing or

backwash

flow(m

3

Volume

of

discharge

/h)

(m

3

remarks

)

1

Anion resin

scrub

first

1-1

ART

discharge by

the

compressed

air

180 2.54

The water above the

anion resin

1-2

ART

discharge

30

No water will be

discharged

1-3

Anion resin

scrub by the

air from the

roots blower

120

No water will be

discharged

1-4

Anion resin

scrub by the

air and water

300 20

Water will be added into

the tank until the level is

above the resin

1-5

ART

pressured

20

No water will be

discharged

1-6

ART

discharge by

the air

90 0.8 Water above the resin

1-7 ART filled 360

No water will be

discharged

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

33 / 39

2

Cation resin

scrub

first

2-1

CRT

discharge by

the

compressed

air

180 5.9

Water above the cation

resin

2-2

CRT

discharge

30

2-3

Cation resin

scrub by the

air from the

roots blower

120

No water will be

discharged

2-4

Cation resin

scrub by the

air and water

300 30

Water will be added into

the tank until the level is

above the resin

2-5

CRT

pressured

20

2-6

CRT

discharge by

the air

90 2.5

The water above the

resin

2-7 CRT filled 450 12

No water will be

discharged

3

Prepare for

regeneration

60 22 0.37

4 regeneration 3600 22 22

5

CRT/ART

exchange

2400 22 14.7

6 CRT/ART 1200 22 7.4

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

34 / 39

flushing

7

Anion resin

scrub

second

7-1

ART

discharge by

the

compressed

air

180 2.54

The water above the

resin

7-2

ART

discharge

30

7-3

Anion resin

scrub by the

air from the

roots blower

120

7-4

Anion resin

scrub by the

air and water

360 20

7-5

ART

pressured

20

7-6

ART

discharge by

the air

120 0.8

7-7 ART filled 480 20

8 ART rinse 1500 18 7.5

9

Cation resin

scrub

second

9-1

Cation resin

scrub

180 5.9

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

35 / 39

9-2

CRT

discharge by

the

compressed

air

30

9-3

CRT

discharge

120

No water will be

discharged

9-4

Cation resin

scrub by the

air from the

roots blower

360 30

Water will be added into

the tank until the level is

above the resin

9-5

CRT

pressured

20

9-6

CRT

discharge by

the air

90 2.5

9-7 CRT filled 450 12

No water will be

discharged

10 CRT rinse 1500 36 15

11 Adjust 180

90.45

2.5 anion resin transfer to CRT

process

time

seconds

Flushing or

backwash

flow(m

3

Volume of

discharge

/h) (m

3

remarks

)

1 ART flushing 180 20 1.0

2

Anion resin

transfer to

CRT by the air

and water

300 10 0.83

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

36 / 39

3 ART flushing 60 20 0.33

4 Pipe flushing 60 60 1.0

5 ART filled 1200 20

No water will

be discarged

6 CRT filled 1200 20

No water will

be discarged

3.16

2.6 resin mix and rinse

process

time

seconds

flushing

or

backwash

flow(m

3

Volume

of

discharge

/h) (m

3

remarks

)

1

CRT

discharge

600 4.18

The water above the

mixed resin

2

Resin mixed

by the air

from roots

blower

600

No water will be

discharged

3

Resin mixed

while CRT

discharge

300 0.3

4 CRT filled 600

No water will be

discharged

5 CRT rinse 900 30 7.5

6 Pipe adjust 300

12.0

The total volume of the discharge: 17.52+10.5+166.73+90.45+3.16+12.0=300.36 m

3

VUNG ANG 1 THERMAL POWER PLANT 2x600MW CONDENSATE POLISHING SYSTEM

37 / 39

PART FIVE WASTE WATER BASIN AND TRENCH CALCULATION

1. the calculation of waste water basin

the total drain when pre-filter backwashed: 67.77 m

the total drain when mixed bed regenerated: 300.36 m

3

the capacity of waste water pump : 60 m

3

3

the needed waste water basin volume: 300.36-60=240.36 m

/h

the recommended waste water basin volume: 250 m

3

LLM requested waste water basin volume: 60 m

3

2. the calculation of waste water trench

3

the capacity of backwash pump : 110 m

3

the capacity of flushing pump : 100 m

/h

3

the max drainage (Q

/h

d

) will not exceed 110+100=210 m

3

the drainage velocity v=0.6 m/s

/h

the needed trench area

v

Q

A

d

=

3600

=0.097 m

the chosen trench fullness coefficient: 0.5

2

the recommended trench area 2A=0.194 m

the width of recommended trench

2

A W = 2 =0.441 m

the chosen dimension of drainage trench is 600mm600mm(WH).

You might also like

- Arkaz Product BroucherDocument5 pagesArkaz Product Brouchersk mukhtarNo ratings yet

- Multi Organics-MEEP-180118-31.12.2018 PDFDocument28 pagesMulti Organics-MEEP-180118-31.12.2018 PDFArjun KrishnakumarNo ratings yet

- CO2 and Lime Dosage Sea WaterDocument11 pagesCO2 and Lime Dosage Sea WaterNoureddine Merah100% (2)

- Uf Toray PresentationDocument54 pagesUf Toray PresentationPrateek VermaNo ratings yet

- Foundation AccessoriesDocument4 pagesFoundation Accessoriesnatasja8No ratings yet

- DM Water Supply System OverviewDocument20 pagesDM Water Supply System Overviewanon_33553517No ratings yet

- Va1 Dec 00100 I M1D Pid 0001 PDFDocument2 pagesVa1 Dec 00100 I M1D Pid 0001 PDFAnonymous JtYvKt5XENo ratings yet

- 7.5 KLHR MEE Offer (5%)Document10 pages7.5 KLHR MEE Offer (5%)kezaihrajNo ratings yet

- Condensate Polishing UnitDocument35 pagesCondensate Polishing Unitrahult19No ratings yet

- 60-F8451S-H0101-01 RevD DBR of CPPDocument19 pages60-F8451S-H0101-01 RevD DBR of CPPK R Kumar RanjanNo ratings yet

- P&id Demin. Water Supply SystemDocument3 pagesP&id Demin. Water Supply SystemAjeng OctaviaNo ratings yet

- Achieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015Document25 pagesAchieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015ansarNo ratings yet

- Mechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundDocument2 pagesMechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundjokishNo ratings yet

- DM Plant DrawingDocument1 pageDM Plant DrawingMd SuruzzamanNo ratings yet

- Cross ReferenceDocument3 pagesCross ReferenceABDUL MUZAMMILNo ratings yet

- Low Temp. EvaporationDocument40 pagesLow Temp. EvaporationManvi Sharma100% (1)

- PIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Document55 pagesPIPE-100: Variabel Satuan Sumur HCE 29 Pad 7Hesti Fuzi LestariNo ratings yet

- Desalination WriteUpDocument17 pagesDesalination WriteUpguptaaniruddhNo ratings yet

- Quote PDFDocument7 pagesQuote PDFChandu GowdaNo ratings yet

- Data Sheet For Pump: Client NameDocument1 pageData Sheet For Pump: Client NameMarathwada ChemicalsNo ratings yet

- ZLD Presentation 3 PDFDocument24 pagesZLD Presentation 3 PDFJagar Nath Shah100% (1)

- UF Ultrafiltration Manual 45 D00874 enDocument81 pagesUF Ultrafiltration Manual 45 D00874 enKrisNo ratings yet

- ZLD Presentation 4 PDFDocument23 pagesZLD Presentation 4 PDFVineeth SivarajNo ratings yet

- Mr. Manish Kharwade - PrajDocument41 pagesMr. Manish Kharwade - PrajNithi AnandNo ratings yet

- 04 Manifold HydraulicsDocument29 pages04 Manifold HydraulicsVeena NageshNo ratings yet

- Skim Tank T-1019 Data Sheets - SHEET 2Document1 pageSkim Tank T-1019 Data Sheets - SHEET 2arachman297988No ratings yet

- Pump Curve: Colour CodeDocument24 pagesPump Curve: Colour CodeP N100% (1)

- 3.4.B.07.03 Static MixerDocument1 page3.4.B.07.03 Static Mixerwado11100% (1)

- 1 IER FundamentalsDocument54 pages1 IER FundamentalsAdam FendrychNo ratings yet

- Business Activities ProfileDocument35 pagesBusiness Activities ProfileKapa KamalakarNo ratings yet

- Multiorganics 50 KLDDocument24 pagesMultiorganics 50 KLDArjun KrishnakumarNo ratings yet

- Syn CompressorDocument23 pagesSyn CompressorManish GautamNo ratings yet

- AtfdDocument4 pagesAtfdDarshan PatelNo ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- Lombardyne Multiple Effect EvaporatorDocument8 pagesLombardyne Multiple Effect EvaporatorKuldeep BhattNo ratings yet

- TMF Lime SofteningDocument2 pagesTMF Lime SofteningRachel HechanovaNo ratings yet

- Batching of Dosing Chemicals For BoilersDocument4 pagesBatching of Dosing Chemicals For BoilersDavid Muñoz CastroNo ratings yet

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- SUEZ Brochure FGD ENDocument4 pagesSUEZ Brochure FGD ENKumarrathinamNo ratings yet

- G. Pumps and DriversDocument14 pagesG. Pumps and DriversJithinNo ratings yet

- A Presentation On Electrics, Instrumentation & Automation of Demineralization Plant of Capacity 3X89 Cum/Hr. at Tsl-KpoDocument24 pagesA Presentation On Electrics, Instrumentation & Automation of Demineralization Plant of Capacity 3X89 Cum/Hr. at Tsl-KpoAshutosh DubeyNo ratings yet

- 14-Lime Soda Ash Treatment PDFDocument43 pages14-Lime Soda Ash Treatment PDFRaj BisenNo ratings yet

- Carbon Aktif DesignDocument21 pagesCarbon Aktif Designnurrahman.auliaNo ratings yet

- PFD FileDocument11 pagesPFD FileNaveen MahawarNo ratings yet

- Air Cooled COndenser PDFDocument7 pagesAir Cooled COndenser PDFRajAnandNo ratings yet

- LAMELA Plate Separators DFDocument4 pagesLAMELA Plate Separators DFStan MacapiliNo ratings yet

- 1000 Liter Ion Exchange GalleriaDocument5 pages1000 Liter Ion Exchange GalleriaBiswajit SahooNo ratings yet

- STP (200kld) - Technical Datasheet 17.02.23Document150 pagesSTP (200kld) - Technical Datasheet 17.02.23Rajender Chamoli100% (1)

- ZLD ProcessDocument36 pagesZLD ProcessLim Chee Siang100% (1)

- Va1 Tatl 00100 M M7 Cal 0001Document3 pagesVa1 Tatl 00100 M M7 Cal 0001hoangduythanhqbNo ratings yet

- Binder5 PDFDocument73 pagesBinder5 PDFcarmela alburquequeNo ratings yet

- DM PlantDocument3 pagesDM PlantArnab PalNo ratings yet

- VenturiDocument2 pagesVenturiJIANo ratings yet

- Cooling Water PDFDocument32 pagesCooling Water PDFnivasssvNo ratings yet

- Demineralization and Condensate Polishing BasicsDocument16 pagesDemineralization and Condensate Polishing BasicsvenkeekuNo ratings yet

- Removal of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuDocument20 pagesRemoval of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuChuah Chong YangNo ratings yet

- AL MARAI HADCO ETP - Process Description and SeqDocument43 pagesAL MARAI HADCO ETP - Process Description and SeqHumaid ShaikhNo ratings yet

- Calculator GWR Contact Time Calculator v9Document16 pagesCalculator GWR Contact Time Calculator v9HeruNo ratings yet

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApDocument39 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApAnonymous JtYvKt5XENo ratings yet

- Steel Structure ST 37Document11 pagesSteel Structure ST 37aliNo ratings yet

- Earthing CalculationDocument14 pagesEarthing CalculationNatarajan Ramakrishnan100% (20)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Project 60% Quality Field Audit Checklist (Zone-1 Field Tour Quality Audit)Document7 pagesProject 60% Quality Field Audit Checklist (Zone-1 Field Tour Quality Audit)Anonymous JtYvKt5XENo ratings yet

- 16.CMS-SMP1A-AC00 (06 Sep 2015) PDFDocument1 page16.CMS-SMP1A-AC00 (06 Sep 2015) PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec Li M1D Eng 00442Document1 pageVa1 Dec Li M1D Eng 00442Anonymous JtYvKt5XENo ratings yet

- Shipflow Tutorials - BasicDocument128 pagesShipflow Tutorials - BasicAnonymous JtYvKt5XENo ratings yet

- CV BoDocument8 pagesCV BoAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8301 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8204 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8204 PDFAnonymous JtYvKt5XENo ratings yet

- VA1 DEC 00100 M M1D PHL 8202 - RevD PDFDocument42 pagesVA1 DEC 00100 M M1D PHL 8202 - RevD PDFAnonymous JtYvKt5XENo ratings yet

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApDocument39 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Document Submission Status: ApAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8701 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8701 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8301 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 0001 PDFDocument2 pagesVa1 Dec 00100 I M1D Pid 0001 PDFAnonymous JtYvKt5XENo ratings yet

- Va1 Dec 00100 I M1D Pid 8204 PDFDocument1 pageVa1 Dec 00100 I M1D Pid 8204 PDFAnonymous JtYvKt5XENo ratings yet

- VA1 YEA 02100 I I1 PID 0001 - RevA PDFDocument7 pagesVA1 YEA 02100 I I1 PID 0001 - RevA PDFAnonymous JtYvKt5XENo ratings yet

- PTW Site Instruction NewDocument17 pagesPTW Site Instruction NewAnonymous JtYvKt5XENo ratings yet

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisAnonymous JtYvKt5XENo ratings yet

- Attender List 1Document2 pagesAttender List 1Anonymous JtYvKt5XENo ratings yet

- PTW Site Instruction: Table of ContendsDocument13 pagesPTW Site Instruction: Table of ContendsAnonymous JtYvKt5XENo ratings yet

- Anti Browning AgentsDocument11 pagesAnti Browning Agentskasun1237459No ratings yet

- Astm E384Document40 pagesAstm E384sud1313No ratings yet

- 02 ChellamaniDocument5 pages02 Chellamanikathirvelus9408No ratings yet

- A Basic Introduction of RheologyDocument20 pagesA Basic Introduction of RheologyLina Mariana Prieto AmadoNo ratings yet

- Measuring Enthalpy ChangeDocument20 pagesMeasuring Enthalpy ChangedhruviniNo ratings yet

- Physical Chemistry Chapter 1 LectureDocument9 pagesPhysical Chemistry Chapter 1 LectureSarah AlexanderNo ratings yet

- Transport For NSW (TFNSW) Qa Specification 3211 Cementitious Materials, Binders and FillersDocument43 pagesTransport For NSW (TFNSW) Qa Specification 3211 Cementitious Materials, Binders and FillersDiana Quintero100% (1)

- 13 Water Treatment Training Pretreatment FiltrationDocument32 pages13 Water Treatment Training Pretreatment Filtrationsantoshkumar gurmeNo ratings yet

- Astm G 61Document5 pagesAstm G 61fdddddddddddddddddddddddNo ratings yet

- Selection of Recombinant ClonesDocument2 pagesSelection of Recombinant ClonesKV Deepika100% (1)

- Biomarkers: PetroleumDocument13 pagesBiomarkers: PetroleumMohamed HaboNo ratings yet

- E7010 P1 - 15680891Document4 pagesE7010 P1 - 15680891Arvind SahaniNo ratings yet

- 26-12-19 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Main - GTM-12 - Key & Sol'sDocument15 pages26-12-19 - SR - IIT - N-SUPER CHAINA&N-CHAINA - Jee-Main - GTM-12 - Key & Sol'smahesh tNo ratings yet

- Smart Supercapacitors From Materials To DevicesDocument13 pagesSmart Supercapacitors From Materials To DevicesRavi SuryaNo ratings yet

- Precise Results Accurate DiagnosisDocument33 pagesPrecise Results Accurate DiagnosisAsvene SharmaNo ratings yet

- Carbohydrates: Notes in BiologyDocument3 pagesCarbohydrates: Notes in BiologyAnonymous HXLczq3100% (1)

- TEPZZ 9 5 - 9 B - T: European Patent SpecificationDocument11 pagesTEPZZ 9 5 - 9 B - T: European Patent SpecificationLê CôngNo ratings yet

- SK Nandy-OISD StandardsDocument29 pagesSK Nandy-OISD Standardskselvan_1100% (1)

- ME608 - 2D SIMPLE Solver For Laminar Flow Over A Square Cylinder - Spring 2010Document10 pagesME608 - 2D SIMPLE Solver For Laminar Flow Over A Square Cylinder - Spring 2010saravana pandianNo ratings yet

- Analyticaltechniques12 PDFDocument7 pagesAnalyticaltechniques12 PDFZaidNo ratings yet

- 6.6 The MOS CapacitanceDocument3 pages6.6 The MOS CapacitancePrasanth YgNo ratings yet

- Modul Chemistry Form 5Document101 pagesModul Chemistry Form 5cikgufiezaNo ratings yet

- Sherwood 2005Document7 pagesSherwood 2005Ionela MariaNo ratings yet

- Disclosure To Promote The Right To Information: IS 5057 (1997) : Potassium Nitrite, Food Grade (FAD 8: Food Additives)Document8 pagesDisclosure To Promote The Right To Information: IS 5057 (1997) : Potassium Nitrite, Food Grade (FAD 8: Food Additives)akNo ratings yet

- European Standards For Tile AdhesivesDocument4 pagesEuropean Standards For Tile AdhesivesChiang LoongNo ratings yet

- Lab Report Heat CnductionDocument17 pagesLab Report Heat CnductionainnorNo ratings yet

- Steps of GlycolysisDocument3 pagesSteps of GlycolysisIm jungkook JUSTIN SEAGULL A.K.A jungshookNo ratings yet

- BRENDADocument5 pagesBRENDAnoah676No ratings yet