Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

66 viewsC 1173 - 97 Qzexnzmtotc - PDF

C 1173 - 97 Qzexnzmtotc - PDF

Uploaded by

Mung Duong XuanThese specifications describe the properties of devices or assemblies suitable for use as Flexible Transition Couplings for underground drainage and sewer piping systems. The values stated in inch-pound units shall be regarded as standard. The ASTM standards referenced herein shall be considered mandatory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Toro 518XI, 520XI, 522XI Service ManualDocument93 pagesToro 518XI, 520XI, 522XI Service ManualKevins Small Engine and Tractor Service80% (5)

- Vibration Analysis For Improving ReliabilityDocument67 pagesVibration Analysis For Improving ReliabilityDevasyruc100% (2)

- C1140 PDFDocument3 pagesC1140 PDFMyriam Carrera100% (2)

- C645 Nonstructural Steel Framing PDFDocument6 pagesC645 Nonstructural Steel Framing PDFkatubelitos100% (1)

- Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete Under Restrained ShrinkageDocument7 pagesDetermining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete Under Restrained ShrinkageSatya kaliprasad vangaraNo ratings yet

- ASTM D 6396 - 99 - Pipe Thread SealantsDocument5 pagesASTM D 6396 - 99 - Pipe Thread SealantsJoão Pedro MoreiraNo ratings yet

- A 74 - 03 Qtc0lvjfraDocument5 pagesA 74 - 03 Qtc0lvjfraMarko's Brazon'No ratings yet

- C 509 - 00 - QzuwoqDocument5 pagesC 509 - 00 - Qzuwoqmercab150% (1)

- D994Document4 pagesD994smanoj354No ratings yet

- C 1173 Coupling StandardDocument4 pagesC 1173 Coupling StandardFernando GonçalvesNo ratings yet

- Flexible Transition Couplings For Underground Piping SystemsDocument4 pagesFlexible Transition Couplings For Underground Piping SystemsPaulo GalvãoNo ratings yet

- Treated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification ForDocument3 pagesTreated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification ForGrato Jr SingcoNo ratings yet

- Astm D3139 (1998)Document3 pagesAstm D3139 (1998)anish_am2005No ratings yet

- C 1541 - 04 Qze1ndeDocument5 pagesC 1541 - 04 Qze1ndecarlosNo ratings yet

- Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsDocument6 pagesTensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsPablo AlcázarNo ratings yet

- Comparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensDocument4 pagesComparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensJosé Ramón Gutierrez100% (1)

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersDocument4 pagesUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersYENCEINo ratings yet

- Astm D2412-2008Document6 pagesAstm D2412-2008hashemNo ratings yet

- C 1497 - 04 Qze0otcDocument4 pagesC 1497 - 04 Qze0otcRufo CascoNo ratings yet

- Norma Astm 2412Document7 pagesNorma Astm 2412Jluis IpnNo ratings yet

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method FordaovandongpktNo ratings yet

- Joints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsDocument3 pagesJoints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsbetopagoadaNo ratings yet

- C 864 - 99 Qzg2naDocument3 pagesC 864 - 99 Qzg2naRufo CascoNo ratings yet

- Astm F477-08Document4 pagesAstm F477-08ALARCONISTANo ratings yet

- C 1461 - 00 - Qze0njetukveDocument4 pagesC 1461 - 00 - Qze0njetukveSamuel EduardoNo ratings yet

- C426 Contraccion Bloques 2010Document6 pagesC426 Contraccion Bloques 2010Javier MendezNo ratings yet

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezNo ratings yet

- Cold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceDocument5 pagesCold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceJosé Ramón GutierrezNo ratings yet

- Treated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification ForDocument3 pagesTreated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification FordorbarelNo ratings yet

- ASTM (Los Angeles Test)Document4 pagesASTM (Los Angeles Test)Efri DwiyantoNo ratings yet

- Astm D-113 PDFDocument3 pagesAstm D-113 PDFjulianovmNo ratings yet

- D 1970 - 00 Rde5nzatukveDocument7 pagesD 1970 - 00 Rde5nzatukvedaovandongpktNo ratings yet

- D628 PDFDocument4 pagesD628 PDFArnold RojasNo ratings yet

- Astm D 897 - 01 - RDG5NWDocument3 pagesAstm D 897 - 01 - RDG5NWphaindikaNo ratings yet

- C 803 - C 803M - 97 Qzgwmy9dodazts1sruqDocument6 pagesC 803 - C 803M - 97 Qzgwmy9dodazts1sruqTemur LomidzeNo ratings yet

- Norma TestDocument3 pagesNorma TestIvan Huilcapaz MoraNo ratings yet

- B 565 - 04 - Qju2nqDocument3 pagesB 565 - 04 - Qju2nqmalika_00No ratings yet

- Determining Dimensions of Thermoplastic Pipe and Fittings: Standard Test Method ForDocument5 pagesDetermining Dimensions of Thermoplastic Pipe and Fittings: Standard Test Method ForhashemNo ratings yet

- D897 617621-1Document3 pagesD897 617621-1Fernando Cardeño LopezNo ratings yet

- C 1135 - 00 QzexmzuDocument4 pagesC 1135 - 00 QzexmzuRufo CascoNo ratings yet

- D 2122 - 98 RdixmjitotgDocument5 pagesD 2122 - 98 RdixmjitotgHumberto GutierrezNo ratings yet

- C 932 - 03 QZKZMGDocument5 pagesC 932 - 03 QZKZMGHumberto GutierrezNo ratings yet

- Astm F 1092 - 04Document9 pagesAstm F 1092 - 04Juan Pablo Garcia100% (1)

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00No ratings yet

- Astm d1871Document5 pagesAstm d1871Edwin RamirezNo ratings yet

- ASTMDocument6 pagesASTMcarmin79100% (2)

- ASTM D 2290Document5 pagesASTM D 2290Pablo AlcázarNo ratings yet

- Astm C143Document4 pagesAstm C143Audrey Schwartz100% (2)

- C 1460 - 04 - Qze0njaDocument4 pagesC 1460 - 04 - Qze0njaSamuel EduardoNo ratings yet

- F2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic PipeDocument8 pagesF2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic Pipemasoud132No ratings yet

- A 822 - 90 r00 Qtgymi9bodiytqDocument3 pagesA 822 - 90 r00 Qtgymi9bodiytqsachinguptachdNo ratings yet

- D3034 16Document12 pagesD3034 16masoudNo ratings yet

- Astm D3212.380331 1Document3 pagesAstm D3212.380331 1anish_am2005No ratings yet

- Self-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectionDocument5 pagesSelf-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectiondaovandongpktNo ratings yet

- F 477 - 02 RJQ3NWDocument4 pagesF 477 - 02 RJQ3NWHumberto GutierrezNo ratings yet

- Astm c131 06 LaavDocument4 pagesAstm c131 06 LaavRasya FiezaNo ratings yet

- Welded Steel Plain Bar or Rod Mats For Concrete ReinforcementDocument2 pagesWelded Steel Plain Bar or Rod Mats For Concrete ReinforcementGustavo SuarezNo ratings yet

- C 1330 - 02 - QzezmzaDocument2 pagesC 1330 - 02 - Qzezmzamercab15No ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- ts619 PDFDocument12 pagests619 PDFMung Duong XuanNo ratings yet

- ts617 PDFDocument34 pagests617 PDFMung Duong XuanNo ratings yet

- ts609 PDFDocument18 pagests609 PDFMung Duong XuanNo ratings yet

- ts510 PDFDocument31 pagests510 PDFMung Duong XuanNo ratings yet

- ts603 PDFDocument35 pagests603 PDFMung Duong XuanNo ratings yet

- ts610 PDFDocument18 pagests610 PDFMung Duong XuanNo ratings yet

- ts606 PDFDocument33 pagests606 PDFMung Duong XuanNo ratings yet

- ts501 PDFDocument162 pagests501 PDFMung Duong XuanNo ratings yet

- ts513 PDFDocument6 pagests513 PDFMung Duong XuanNo ratings yet

- Slop Reception and Processing Facilities: ShipsDocument10 pagesSlop Reception and Processing Facilities: ShipsMung Duong XuanNo ratings yet

- ts613 PDFDocument44 pagests613 PDFMung Duong XuanNo ratings yet

- DNV 100 Above Hull StructuralDocument187 pagesDNV 100 Above Hull StructuralDaniela AleidanNo ratings yet

- ts602 PDFDocument15 pagests602 PDFMung Duong XuanNo ratings yet

- ts511 PDFDocument30 pagests511 PDFMung Duong XuanNo ratings yet

- ts502 PDFDocument152 pagests502 PDFMung Duong XuanNo ratings yet

- Management of Safety and Environmental Protection (SEP) : Ships / High Speed, Light Craft and Naval Surface CraftDocument1 pageManagement of Safety and Environmental Protection (SEP) : Ships / High Speed, Light Craft and Naval Surface CraftMung Duong XuanNo ratings yet

- ts402 PDFDocument12 pagests402 PDFMung Duong XuanNo ratings yet

- Hull Structural Design - Ships With Length Less Than 100 MetresDocument107 pagesHull Structural Design - Ships With Length Less Than 100 MetresMung Duong XuanNo ratings yet

- ts802 PDFDocument1 pagets802 PDFMung Duong XuanNo ratings yet

- ts634 PDFDocument6 pagests634 PDFMung Duong XuanNo ratings yet

- ts633 PDFDocument22 pagests633 PDFMung Duong XuanNo ratings yet

- ts702 PDFDocument34 pagests702 PDFMung Duong XuanNo ratings yet

- Tentative Rules For Gas Ready ShipsDocument10 pagesTentative Rules For Gas Ready ShipsMung Duong XuanNo ratings yet

- ts630 PDFDocument15 pagests630 PDFMung Duong XuanNo ratings yet

- ts632 PDFDocument37 pagests632 PDFMung Duong XuanNo ratings yet

- SILENT Class Notation: ShipsDocument21 pagesSILENT Class Notation: ShipsMung Duong XuanNo ratings yet

- BarSplice BarGrip DataSheet Metric RevJ PDFDocument2 pagesBarSplice BarGrip DataSheet Metric RevJ PDFBárbara Constanza Valenzuela ValdiviaNo ratings yet

- 102 80 - DE - 4322 4372 - Withpermanent Magnet - IO PDFDocument56 pages102 80 - DE - 4322 4372 - Withpermanent Magnet - IO PDFandersson benito herreraNo ratings yet

- BR Cat Cafs STD Eng R02 0 PDFDocument572 pagesBR Cat Cafs STD Eng R02 0 PDFRafael HenriquesNo ratings yet

- Technical Spec & BOQ Screw ConveyorDocument7 pagesTechnical Spec & BOQ Screw ConveyorjhsudhsdhwuNo ratings yet

- Modelling and Vibration Analysis of Misaligned Rotor-Ball Bearing SystemsDocument16 pagesModelling and Vibration Analysis of Misaligned Rotor-Ball Bearing Systemsmanjunath k sNo ratings yet

- Conveyor System ReportDocument14 pagesConveyor System ReportTawanda NyambiyaNo ratings yet

- Escorts EC2420 Parts CatalogDocument202 pagesEscorts EC2420 Parts CatalogPrakash Niroula0% (1)

- Valve StatusDocument18 pagesValve Statussinghrakes@gmail.comNo ratings yet

- L011393 - Rotex Standard 28 SeriesDocument4 pagesL011393 - Rotex Standard 28 SeriesCAT MINING SHOVELNo ratings yet

- Puranmal Lahoti Government Polytechnic Latur: Name of The StudentsDocument11 pagesPuranmal Lahoti Government Polytechnic Latur: Name of The Studentsshankar biradarNo ratings yet

- Diaphragm Coupling - P-7491-AcDocument4 pagesDiaphragm Coupling - P-7491-AcAndrea GentileNo ratings yet

- TESCO MLT Torque Ring Field Make-Up Handbook PDFDocument44 pagesTESCO MLT Torque Ring Field Make-Up Handbook PDFRene Torres HinojosaNo ratings yet

- ANSI AGMA 6113-B16 Factor de ServicioDocument84 pagesANSI AGMA 6113-B16 Factor de ServiciovortegabNo ratings yet

- Aurora Pump MaintenanceDocument35 pagesAurora Pump MaintenancemetropumpsNo ratings yet

- En Omk TD 50HZDocument78 pagesEn Omk TD 50HZMatsumura SokonNo ratings yet

- EjesDocument32 pagesEjesbexehenNo ratings yet

- 5837 15542 1 SM PDFDocument5 pages5837 15542 1 SM PDFDaiNguyenNo ratings yet

- Driveline: SectionDocument263 pagesDriveline: SectionАндрей НадточийNo ratings yet

- Wartsila Water Lubricated Brochure v4 2Document7 pagesWartsila Water Lubricated Brochure v4 2Marlon Alejandro Arboleda TapiaNo ratings yet

- Tolerances DimensionsDocument2 pagesTolerances Dimensionsagox194No ratings yet

- Cat IcsDocument31 pagesCat IcsSrinivas RegulavalasaNo ratings yet

- ICC ES Report: Barsplice Products, IncDocument6 pagesICC ES Report: Barsplice Products, IncXiomara Muñoz MendozaNo ratings yet

- Metaflex Coupling - RSV IndustriesDocument43 pagesMetaflex Coupling - RSV IndustriesInamMuradNo ratings yet

- Axle and Bogie Wheel AssemblyDocument10 pagesAxle and Bogie Wheel AssemblyHarish KumarNo ratings yet

- Design of Machine Elements SyllabusDocument2 pagesDesign of Machine Elements SyllabusGirish HanumaiahNo ratings yet

- 135MW CFBC Operation Manual 1 20080306Document148 pages135MW CFBC Operation Manual 1 20080306Sakthi Sekar CbiNo ratings yet

- SRB CatalogDocument236 pagesSRB CatalogpbsrivinayNo ratings yet

- P 1819 AcDocument52 pagesP 1819 AcUdayan BasuNo ratings yet

C 1173 - 97 Qzexnzmtotc - PDF

C 1173 - 97 Qzexnzmtotc - PDF

Uploaded by

Mung Duong Xuan0 ratings0% found this document useful (0 votes)

66 views4 pagesThese specifications describe the properties of devices or assemblies suitable for use as Flexible Transition Couplings for underground drainage and sewer piping systems. The values stated in inch-pound units shall be regarded as standard. The ASTM standards referenced herein shall be considered mandatory.

Original Description:

Original Title

C 1173 _ 97 ;QZEXNZMTOTC_.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThese specifications describe the properties of devices or assemblies suitable for use as Flexible Transition Couplings for underground drainage and sewer piping systems. The values stated in inch-pound units shall be regarded as standard. The ASTM standards referenced herein shall be considered mandatory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

66 views4 pagesC 1173 - 97 Qzexnzmtotc - PDF

C 1173 - 97 Qzexnzmtotc - PDF

Uploaded by

Mung Duong XuanThese specifications describe the properties of devices or assemblies suitable for use as Flexible Transition Couplings for underground drainage and sewer piping systems. The values stated in inch-pound units shall be regarded as standard. The ASTM standards referenced herein shall be considered mandatory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

Designation: C 1173 97

Standard Specication for

Flexible Transition Couplings for Underground Piping

Systems

1

This standard is issued under the xed designation C 1173; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These specications describe the properties of devices

or assemblies suitable for use as exible transition couplings,

hereinafter referred to as couplings, for underground drainage

and sewer piping systems.

1.2 Couplings that may include bushings or inserts and that

meet the requirements of this standard are suitable for joining

plain end pipe or ttings. The pipe to be joined shall be of

similar or dissimilar materials, size, or both.

1.3 The values stated in inch-pound units shall be regarded

as standard.

1.4 The ASTM standards referenced herein shall be consid-

ered mandatory.

2. Referenced Documents

2.1 ASTM Standards:

C 717 Terminology of Building Seals and Sealants

2

D 412 Test Methods for Vulcanized Rubber and Thermo-

plastic Rubbers and Thermoplastic ElastomersTension

3

D 471 Test Method for Rubber PropertyEffect of Liq-

uids

3

D 518 Test Method for Rubber DeteriorationSurface

Cracking

3

D 543 Practice for Evaluating Resistance of Plastics to

Chemical Reagents

4

D 573 Test Method for RubberDeterioration in an Air

Oven

3

D 638 Test Method for Tensile Properties of Plastics

4

D 1149 Test Method for Rubber Deterioration Surface

Ozone Cracking in a Chamber

3

D 2240 Test Method for Rubber PropertyDurometer

Hardness

3

D 3045 Practice for Heat Aging of Plastics Without Load

5

3. Terminology

3.1 DenitionsFor denitions of terms used in this stan-

dard, see Terminology C 717.

3.2 Denitions of Terms Specic to This Standard:

3.2.1 center stopan integral part of the gasket centered on

its axial length intended to limit the insertion depth of the pipe

to be coupled.

3.2.2 ttingparts of a pipeline other than the straight pipe

couplings, or valves.

3.2.3 exible transition couplingsdevices used to form a

leakproof joint between sections of plain end pipe or ttings of

the same or different materials, of the same or different size, or

any combination of materials or pipe sizes.

3.2.4 free torquethe torque value expressed in lbfin./Nm

when the clamp is tightened four revolutions of the screw nut;

while in the free state, this value does not include any

breakaway effects due to staking or passage of the band ends

beyond the screw heads.

3.2.5 insertsa bushing or ring placed into the coupling

socket to accommodate pipe materials of differing outside

diameters.

3.2.6 jointthe completed assembly of parts consisting of

the exible transition coupling and the joined pipes, or ttings,

or both.

3.2.7 lota specic quantity of similar material or collec-

tion of similar units from a common source; the quantity

offered for inspection and acceptance at any one time. A lot

might comprise a shipment, batch, or similar quantity.

3.2.8 plain end pipeany pipe that does not include any

bell, hub, threaded area, or other means of joining.

3.2.9 shear ringan interior or exterior element which is

used to span the distance between the pipe ends within a

coupling so as to provide increased resistance to axial displace-

ment.

4. Classication

4.1 The couplings shall be permitted to have a center stop.

The components shall be designed so that the elastomeric

material is compressed to form a hydrostatic seal when the

joint is assembled. The couplings shall be of the types

described in 4.1.1-4.1.3.

4.1.1 Type AA coupling consisting of an elastomeric

sleeve incorporating corrosion resistance tension bands and a

tightening mechanism. Couplings shall be fabricated with or

without shear rings, and with or without a center stop.

4.1.2 Type BA coupling consisting of an elastomeric or

1

These specications are under the jurisdiction of ASTM Committee C-24 on

Building Seals and Sealants and are the direct responsibility of Subcommittee

C24.75on Gaskets and Couplings for Plumbing and Sewer Piping.

Current edition approved Dec. 10, 1997. Published April 1998. Originally

published as C 1173 91. Last previous edition C 1173 95.

2

Annual Book of ASTM Standards, Vol 04.07.

3

Annual Book of ASTM Standards, Vol 09.01.

4

Annual Book of ASTM Standards, Vol 08.01.

5

Annual Book of ASTM Standards, Vol 08.02.

1

Copyright ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

rubber sleeve incorporating a corrosion resistant outer sleeve

and tension bands, or tightening mechanism, or both (Note 1).

4.1.3 Type CA coupling fabricated with elastomeric com-

pression seals.

NOTE 1The provisions of this standard are not intended to prevent the

use of any alternate material or method of construction, provided any such

alternate meets the requirements of this standard.

5. Materials and Manufacture

5.1 Elastomeric materials used in the manufacturing of

couplings and inserts shall comply with the requirements set

forth in Table 1.

5.2 Stainless steel tension bands shall be of the 300 series

stainless steel.

5.3 Couplings or bushings/inserts, or both, of multi-piece

construction or with splices shall show no separation, peeling,

or other defects when tested in accordance with Section 9.

5.4 The coupling shall be free from porosity and air pockets.

Its surface shall be smooth and free from pitting, cracks,

blisters, air marks, or any other imperfections that affect its

performance in service. The ash extension shall not exceed 1

mm at any point where the presence of ash affects perfor-

mance.

6. Requirements

6.1 The physical and chemical properties of the coupling

materials shall conform to the requirements specied in Table

1.

7. Dimensions

7.1 Couplings and bushing dimensions shall be compatible

with the dimensions and tolerances of the specic material to

which it is designed to join.

8. Sampling, Tests, and Retests

8.1 Test specimens representative of the couplings to be

used shall be randomly selected from the manufactured lot for

testing.

8.2 No less than two couplings for each size or type shall be

tested, unless otherwise specied or waived by the purchaser.

8.3 Where there is a failure in the original test, the entire test

shall be rerun with twice the number of samples and any failure

shall be cause for rejection.

9. Test Methods

9.1 Elastomeric Materials:

9.1.1 HardnessHardness shall be measured on either a

nished surface, a squarely cut end, or a at sliced or buffed

surface, depending on the size and shape of the specimen. See

Test Method D 2240.

9.1.2 Tensile Strength and Elongation The dumbbells

shall be prepared from sections of the nished material. See

Test Methods D 412.

9.1.3 Heat Aging, for hardness, tensile and elongation shall

be performed in accordance with Test Method D 573. Speci-

mens shall be oven-aged for 96 h at 158 6 3.6F (70 6 2C).

9.1.4 Ozone ResistanceTest specimens shall be used as

described in Test Method D 518, Procedure A, stretched 20 %

and exposed to an ozone concentration of 50 parts per 100

million for 100 h at 104 6 3.6F (40 6 2C). See Test Method

D 1149.

9.1.5 Water AbsorptionSize and time determinations shall

be set in accordance with Test Method D 471. A specimen

0.075 by 1 by 2 in. (1.9 by 25 by 50 mm) shall be immersed in

distilled water at 158 6 3.6F (70 6 2C) for 7 days. After

seven days the specimen shall be removed, the surface mois-

ture blotted and the specimen weighed. The percent gain shall

be determined by the following equation:

~WF 2 WO!

WO

100

where:

WF 5 weight of specimen after immersion for 7 days, and

WO 5 dry weight of specimen before immersion.

9.1.6 Chemical ResistanceSamples shall be aged for 48 h

at 74 6 3.6F (23 6 2C) using solutions of 1N sulfuric acid

and 1N hydrochloric acid. See Test Method D 543.

9.2 Tension Band Performance:

9.2.1 Torque ResistanceStainless steel tension bands shall

be tested to withstand the manufacturers required torque or a

minimum of 60 in.-lb (8.5 Nm) of applied torque without

visible signs of failure. The band shall be tested over a steel

mandrel of the appropriate coupling diameter and torqued as

required.

9.2.2 The maximum free running torque shall be 4 in.-lb

(0.45 Nm).

9.2.2.1 Stainless steel tension bands with torque resistance

in excess of 100 in.-lb shall have a maximum free running

torque of 8 in.-lb.

9.2.3 Test Procedure for Free Running Torque:

9.2.3.1 With the nonstressed clamp hand held and the

TABLE 1 Test Requirements

Properties

Physical

Requirements

ASTM Test

Method

Elastomeric Materials

Hardness, Nominal Shore A Durometer

as specied by the coupling manufacturer

5075 D 2240

Hardness, Nominal Shore D Durometer

as specied by the coupling manufacturer

3545 D 2240

Tensile strength, min psi (KPa) 1000 (6894) D 412, Die C,

Fig. 2 or D638

Elongation at rupture, min, % 200 D 412, Die C,

Fig. 2 or D638

Heat aging, 70 h, 158 6 3.6F (70 6 2C) D 573 or D3045

Hardness increase, maximum Durometer

points

10

Change in tensile strength, max, % 25

Change in elongation, max, % 35

Ozone resistance No cracks D 1149

At 20 % elongation

For 100 h at 1046 3.6F (40 6 2C)

With 50 parts per 100 million

Water absorption, weight gain, %, max 20 D 471

Chemical resistance, 48 h, 746 3.6F (23

6 2C)

no weight loss D 543

Stainless Steel Materials

Torque resistance, 60 in.-lb (6.8 Nm) no failure 9.2 of C1173

Manufacturers required torque resistance no failure 9.2 of C1173

Joint Assemblies

Deection resistance 4.3 psi (30 kPa) as given in Table

2

9.3.1 of C1173

Shear loading resistance (optional) as given in Table

3

9.3.2 of C1173

C 1173

2

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

slotted band fully engaged, the screw shall be rotated clock-

wise 10 revolutions with the maximum value of the torque

meter recorded.

9.2.3.2 The equipment required shall be a hand held torque

meter with a 0 to 15 in.-lb range.

9.3 Joint Assemblies:

9.3.1 Deection Sealing Resistance The joint shall have

sufficient exibility to permit deection in any direction as

dened by Table 2 and shall show no visible leakage when so

deected while under an internal hydrostatic pressure of 4.3 psi

(30 KPa). The ends of the test pipe shall be restrained only by

an amount necessary to prevent longitudinal movement. The

deection shall be measured as the distance the free end of the

one pipe has moved away from the center line of the xed pipe.

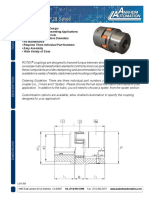

See Fig. 1.

9.3.2 Shear Loading ResistanceThe joint shall have suf-

cient resistance to shear loading to meet the requirements of

the following test. Two lengths of pipe shall be joined by a

coupling with the two joined lengths of pipe supported on

blocks at three locations. One length of pipe shall be supported

on two blocks, one near the unjoined end, and the other

immediately adjacent to the joint. This length shall then be

rmly restrained in position. The other length of pipe shall be

supported by a single block located 36 in. (0.9 m) from the

centerline of the joint. A load of 50 lb/in. (220N/25 mm) of

nominal pipe diameter adjusted by the weight of pipe extend-

ing beyond the support times its moment arm divided by the

moment arm to the test load, shall be uniformly applied over an

arc of 120 and along a longitudinal length of 24 in. (0.6 m)

immediately adjacent to the joint of the pipe having one

support (see Fig. 2). While thus loaded, an internal hydrostatic

pressure of 4.3 psi (30 KPa) shall be maintained for a period of

1 h with the temperature of water, pipe, and atmosphere within

the range between 60 and 75F (15.5 and 23.8C) (Note 2).

NOTE 2Fig. 2 and Table 3 in 9.3.1 are not mandatory at this time

because Subcommittee C24.75 is attempting to verify the procedure and

values.

10. Product Marking

10.1 Each coupling shall be marked with the manufacturers

name or trademark, or both.

10.2 The type and size of pipe for which the coupling is

intended or the manufacturers product shall be marked on or

attached to each coupling.

10.3 All couplings shall be marked with the designation

ASTM C 1173 showing compliance to this standard.

11. Keywords

11.1 couplings; drainage; elastomeric; exible; sewer;

transition; underground piping

TABLE 2 RequirementsDeection per Foot of Pipe Length

A

Nominal ID,

in. (mm), incl.

Offset in./linear ft

(mm/linear m)

212 (50300)

1

2(42)

1524 (375600)

3

8(31)

2736 (675900)

1

4(21)

3942 (9751050)

3

16(15)

A

See 9.3.1.

NOTE 1Deection (in.(mm)) 5 L(ft(m)) 3 offset (in./linear ft (mm/

linear m)). See Table 2.

FIG. 1 Deection Test (Plan View)

NOTE 1For maximum axial deviation values, see Table 3.

FIG. 2 Shear Test

TABLE 3 Maximum Axial Deviation

A

Nominal ID,

in. (mm), incl.

Axial Deection,

in. (mm)

26 (50150)

3

8 (9)

812 (200300)

7

8 (22)

1524 (375600) 1

1

8 (28)

2736 (675900)

3

4 (19)

3942 (9751050)

9

16 (14)

A

See 9.3.2.

C 1173

3

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

C 1173

4

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

You might also like

- Toro 518XI, 520XI, 522XI Service ManualDocument93 pagesToro 518XI, 520XI, 522XI Service ManualKevins Small Engine and Tractor Service80% (5)

- Vibration Analysis For Improving ReliabilityDocument67 pagesVibration Analysis For Improving ReliabilityDevasyruc100% (2)

- C1140 PDFDocument3 pagesC1140 PDFMyriam Carrera100% (2)

- C645 Nonstructural Steel Framing PDFDocument6 pagesC645 Nonstructural Steel Framing PDFkatubelitos100% (1)

- Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete Under Restrained ShrinkageDocument7 pagesDetermining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete Under Restrained ShrinkageSatya kaliprasad vangaraNo ratings yet

- ASTM D 6396 - 99 - Pipe Thread SealantsDocument5 pagesASTM D 6396 - 99 - Pipe Thread SealantsJoão Pedro MoreiraNo ratings yet

- A 74 - 03 Qtc0lvjfraDocument5 pagesA 74 - 03 Qtc0lvjfraMarko's Brazon'No ratings yet

- C 509 - 00 - QzuwoqDocument5 pagesC 509 - 00 - Qzuwoqmercab150% (1)

- D994Document4 pagesD994smanoj354No ratings yet

- C 1173 Coupling StandardDocument4 pagesC 1173 Coupling StandardFernando GonçalvesNo ratings yet

- Flexible Transition Couplings For Underground Piping SystemsDocument4 pagesFlexible Transition Couplings For Underground Piping SystemsPaulo GalvãoNo ratings yet

- Treated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification ForDocument3 pagesTreated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification ForGrato Jr SingcoNo ratings yet

- Astm D3139 (1998)Document3 pagesAstm D3139 (1998)anish_am2005No ratings yet

- C 1541 - 04 Qze1ndeDocument5 pagesC 1541 - 04 Qze1ndecarlosNo ratings yet

- Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsDocument6 pagesTensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsPablo AlcázarNo ratings yet

- Comparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensDocument4 pagesComparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensJosé Ramón Gutierrez100% (1)

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersDocument4 pagesUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersYENCEINo ratings yet

- Astm D2412-2008Document6 pagesAstm D2412-2008hashemNo ratings yet

- C 1497 - 04 Qze0otcDocument4 pagesC 1497 - 04 Qze0otcRufo CascoNo ratings yet

- Norma Astm 2412Document7 pagesNorma Astm 2412Jluis IpnNo ratings yet

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method FordaovandongpktNo ratings yet

- Joints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsDocument3 pagesJoints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsbetopagoadaNo ratings yet

- C 864 - 99 Qzg2naDocument3 pagesC 864 - 99 Qzg2naRufo CascoNo ratings yet

- Astm F477-08Document4 pagesAstm F477-08ALARCONISTANo ratings yet

- C 1461 - 00 - Qze0njetukveDocument4 pagesC 1461 - 00 - Qze0njetukveSamuel EduardoNo ratings yet

- C426 Contraccion Bloques 2010Document6 pagesC426 Contraccion Bloques 2010Javier MendezNo ratings yet

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezNo ratings yet

- Cold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceDocument5 pagesCold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceJosé Ramón GutierrezNo ratings yet

- Treated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification ForDocument3 pagesTreated Core and Nontreated Core Gypsum Sheathing Board: Standard Specification FordorbarelNo ratings yet

- ASTM (Los Angeles Test)Document4 pagesASTM (Los Angeles Test)Efri DwiyantoNo ratings yet

- Astm D-113 PDFDocument3 pagesAstm D-113 PDFjulianovmNo ratings yet

- D 1970 - 00 Rde5nzatukveDocument7 pagesD 1970 - 00 Rde5nzatukvedaovandongpktNo ratings yet

- D628 PDFDocument4 pagesD628 PDFArnold RojasNo ratings yet

- Astm D 897 - 01 - RDG5NWDocument3 pagesAstm D 897 - 01 - RDG5NWphaindikaNo ratings yet

- C 803 - C 803M - 97 Qzgwmy9dodazts1sruqDocument6 pagesC 803 - C 803M - 97 Qzgwmy9dodazts1sruqTemur LomidzeNo ratings yet

- Norma TestDocument3 pagesNorma TestIvan Huilcapaz MoraNo ratings yet

- B 565 - 04 - Qju2nqDocument3 pagesB 565 - 04 - Qju2nqmalika_00No ratings yet

- Determining Dimensions of Thermoplastic Pipe and Fittings: Standard Test Method ForDocument5 pagesDetermining Dimensions of Thermoplastic Pipe and Fittings: Standard Test Method ForhashemNo ratings yet

- D897 617621-1Document3 pagesD897 617621-1Fernando Cardeño LopezNo ratings yet

- C 1135 - 00 QzexmzuDocument4 pagesC 1135 - 00 QzexmzuRufo CascoNo ratings yet

- D 2122 - 98 RdixmjitotgDocument5 pagesD 2122 - 98 RdixmjitotgHumberto GutierrezNo ratings yet

- C 932 - 03 QZKZMGDocument5 pagesC 932 - 03 QZKZMGHumberto GutierrezNo ratings yet

- Astm F 1092 - 04Document9 pagesAstm F 1092 - 04Juan Pablo Garcia100% (1)

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00No ratings yet

- Astm d1871Document5 pagesAstm d1871Edwin RamirezNo ratings yet

- ASTMDocument6 pagesASTMcarmin79100% (2)

- ASTM D 2290Document5 pagesASTM D 2290Pablo AlcázarNo ratings yet

- Astm C143Document4 pagesAstm C143Audrey Schwartz100% (2)

- C 1460 - 04 - Qze0njaDocument4 pagesC 1460 - 04 - Qze0njaSamuel EduardoNo ratings yet

- F2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic PipeDocument8 pagesF2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic Pipemasoud132No ratings yet

- A 822 - 90 r00 Qtgymi9bodiytqDocument3 pagesA 822 - 90 r00 Qtgymi9bodiytqsachinguptachdNo ratings yet

- D3034 16Document12 pagesD3034 16masoudNo ratings yet

- Astm D3212.380331 1Document3 pagesAstm D3212.380331 1anish_am2005No ratings yet

- Self-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectionDocument5 pagesSelf-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectiondaovandongpktNo ratings yet

- F 477 - 02 RJQ3NWDocument4 pagesF 477 - 02 RJQ3NWHumberto GutierrezNo ratings yet

- Astm c131 06 LaavDocument4 pagesAstm c131 06 LaavRasya FiezaNo ratings yet

- Welded Steel Plain Bar or Rod Mats For Concrete ReinforcementDocument2 pagesWelded Steel Plain Bar or Rod Mats For Concrete ReinforcementGustavo SuarezNo ratings yet

- C 1330 - 02 - QzezmzaDocument2 pagesC 1330 - 02 - Qzezmzamercab15No ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- ts619 PDFDocument12 pagests619 PDFMung Duong XuanNo ratings yet

- ts617 PDFDocument34 pagests617 PDFMung Duong XuanNo ratings yet

- ts609 PDFDocument18 pagests609 PDFMung Duong XuanNo ratings yet

- ts510 PDFDocument31 pagests510 PDFMung Duong XuanNo ratings yet

- ts603 PDFDocument35 pagests603 PDFMung Duong XuanNo ratings yet

- ts610 PDFDocument18 pagests610 PDFMung Duong XuanNo ratings yet

- ts606 PDFDocument33 pagests606 PDFMung Duong XuanNo ratings yet

- ts501 PDFDocument162 pagests501 PDFMung Duong XuanNo ratings yet

- ts513 PDFDocument6 pagests513 PDFMung Duong XuanNo ratings yet

- Slop Reception and Processing Facilities: ShipsDocument10 pagesSlop Reception and Processing Facilities: ShipsMung Duong XuanNo ratings yet

- ts613 PDFDocument44 pagests613 PDFMung Duong XuanNo ratings yet

- DNV 100 Above Hull StructuralDocument187 pagesDNV 100 Above Hull StructuralDaniela AleidanNo ratings yet

- ts602 PDFDocument15 pagests602 PDFMung Duong XuanNo ratings yet

- ts511 PDFDocument30 pagests511 PDFMung Duong XuanNo ratings yet

- ts502 PDFDocument152 pagests502 PDFMung Duong XuanNo ratings yet

- Management of Safety and Environmental Protection (SEP) : Ships / High Speed, Light Craft and Naval Surface CraftDocument1 pageManagement of Safety and Environmental Protection (SEP) : Ships / High Speed, Light Craft and Naval Surface CraftMung Duong XuanNo ratings yet

- ts402 PDFDocument12 pagests402 PDFMung Duong XuanNo ratings yet

- Hull Structural Design - Ships With Length Less Than 100 MetresDocument107 pagesHull Structural Design - Ships With Length Less Than 100 MetresMung Duong XuanNo ratings yet

- ts802 PDFDocument1 pagets802 PDFMung Duong XuanNo ratings yet

- ts634 PDFDocument6 pagests634 PDFMung Duong XuanNo ratings yet

- ts633 PDFDocument22 pagests633 PDFMung Duong XuanNo ratings yet

- ts702 PDFDocument34 pagests702 PDFMung Duong XuanNo ratings yet

- Tentative Rules For Gas Ready ShipsDocument10 pagesTentative Rules For Gas Ready ShipsMung Duong XuanNo ratings yet

- ts630 PDFDocument15 pagests630 PDFMung Duong XuanNo ratings yet

- ts632 PDFDocument37 pagests632 PDFMung Duong XuanNo ratings yet

- SILENT Class Notation: ShipsDocument21 pagesSILENT Class Notation: ShipsMung Duong XuanNo ratings yet

- BarSplice BarGrip DataSheet Metric RevJ PDFDocument2 pagesBarSplice BarGrip DataSheet Metric RevJ PDFBárbara Constanza Valenzuela ValdiviaNo ratings yet

- 102 80 - DE - 4322 4372 - Withpermanent Magnet - IO PDFDocument56 pages102 80 - DE - 4322 4372 - Withpermanent Magnet - IO PDFandersson benito herreraNo ratings yet

- BR Cat Cafs STD Eng R02 0 PDFDocument572 pagesBR Cat Cafs STD Eng R02 0 PDFRafael HenriquesNo ratings yet

- Technical Spec & BOQ Screw ConveyorDocument7 pagesTechnical Spec & BOQ Screw ConveyorjhsudhsdhwuNo ratings yet

- Modelling and Vibration Analysis of Misaligned Rotor-Ball Bearing SystemsDocument16 pagesModelling and Vibration Analysis of Misaligned Rotor-Ball Bearing Systemsmanjunath k sNo ratings yet

- Conveyor System ReportDocument14 pagesConveyor System ReportTawanda NyambiyaNo ratings yet

- Escorts EC2420 Parts CatalogDocument202 pagesEscorts EC2420 Parts CatalogPrakash Niroula0% (1)

- Valve StatusDocument18 pagesValve Statussinghrakes@gmail.comNo ratings yet

- L011393 - Rotex Standard 28 SeriesDocument4 pagesL011393 - Rotex Standard 28 SeriesCAT MINING SHOVELNo ratings yet

- Puranmal Lahoti Government Polytechnic Latur: Name of The StudentsDocument11 pagesPuranmal Lahoti Government Polytechnic Latur: Name of The Studentsshankar biradarNo ratings yet

- Diaphragm Coupling - P-7491-AcDocument4 pagesDiaphragm Coupling - P-7491-AcAndrea GentileNo ratings yet

- TESCO MLT Torque Ring Field Make-Up Handbook PDFDocument44 pagesTESCO MLT Torque Ring Field Make-Up Handbook PDFRene Torres HinojosaNo ratings yet

- ANSI AGMA 6113-B16 Factor de ServicioDocument84 pagesANSI AGMA 6113-B16 Factor de ServiciovortegabNo ratings yet

- Aurora Pump MaintenanceDocument35 pagesAurora Pump MaintenancemetropumpsNo ratings yet

- En Omk TD 50HZDocument78 pagesEn Omk TD 50HZMatsumura SokonNo ratings yet

- EjesDocument32 pagesEjesbexehenNo ratings yet

- 5837 15542 1 SM PDFDocument5 pages5837 15542 1 SM PDFDaiNguyenNo ratings yet

- Driveline: SectionDocument263 pagesDriveline: SectionАндрей НадточийNo ratings yet

- Wartsila Water Lubricated Brochure v4 2Document7 pagesWartsila Water Lubricated Brochure v4 2Marlon Alejandro Arboleda TapiaNo ratings yet

- Tolerances DimensionsDocument2 pagesTolerances Dimensionsagox194No ratings yet

- Cat IcsDocument31 pagesCat IcsSrinivas RegulavalasaNo ratings yet

- ICC ES Report: Barsplice Products, IncDocument6 pagesICC ES Report: Barsplice Products, IncXiomara Muñoz MendozaNo ratings yet

- Metaflex Coupling - RSV IndustriesDocument43 pagesMetaflex Coupling - RSV IndustriesInamMuradNo ratings yet

- Axle and Bogie Wheel AssemblyDocument10 pagesAxle and Bogie Wheel AssemblyHarish KumarNo ratings yet

- Design of Machine Elements SyllabusDocument2 pagesDesign of Machine Elements SyllabusGirish HanumaiahNo ratings yet

- 135MW CFBC Operation Manual 1 20080306Document148 pages135MW CFBC Operation Manual 1 20080306Sakthi Sekar CbiNo ratings yet

- SRB CatalogDocument236 pagesSRB CatalogpbsrivinayNo ratings yet

- P 1819 AcDocument52 pagesP 1819 AcUdayan BasuNo ratings yet