Professional Documents

Culture Documents

A Brief History of LED Photopolymerization

A Brief History of LED Photopolymerization

Uploaded by

Al-Kawthari As-SunniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Brief History of LED Photopolymerization

A Brief History of LED Photopolymerization

Uploaded by

Al-Kawthari As-SunniCopyright:

Available Formats

dental materi als 2 9 ( 2 0 1 3 ) 605617

Available online at www.sciencedirect.com

j our nal homepage: www. i nt l . el sevi er heal t h. com/ j our nal s/ dema

Review

A brief history of LED photopolymerization

Klaus D. Jandt

a,b,

, Robin W. Mills

c,

a

Faculty of Physics and Astronomy, Friedrich-Schiller-University Jena, Lbdergraben 32, D-07751 Jena, Germany

b

Jena Center for Soft Matter, Friedrich-Schiller-University Jena, Germany

c

School of Oral and Dental Sciences, University of Bristol, Lower Maudlin Street, Bristol BS1 2LY, United Kingdom

a r t i c l e i n f o

Article history:

Received 26 October 2012

Received in revised form

12 February 2013

Accepted 12 February 2013

Keywords:

LED

Photopolymerization

Light curing

Photocuring

Quartz-tungsten-halogen

Materials science

Clinical aspects

a b s t r a c t

Objectives. The majority of modern resin-based oral restorative biomaterials are cured via

photopolymerization processes. A variety of light sources are available for this light curing

of dental materials, such as composites or ssure sealants. Quartz-tungsten-halogen (QTH)

light curing units (LCUs) have dominated light curing of dental materials for decades and

are now almost entirely replaced by modern light emitting diode light curing units (LED

LCUs). Exactly 50 years ago, visible LEDs were invented. Nevertheless, it was not before the

1990s that LEDs were seriously considered by scientists or manufactures of commercial

LCUs as light sources to photopolymerize dental composites and other dental materials.

The objective of this review paper is to give an overview of the scientic development and

state-of-the-art of LED photopolymerization of oral biomaterials.

Methods. The materials science of LED LCU devices and dental materials photopolymerized

with LEDLCU, as well as advantages and limits of LEDphotopolymerization of oral biomate-

rials, are discussed. This is mainly based on a review of the most frequently cited scientic

papers in international peer reviewed journals. The developments of commercial LED LCUs

as well as aspects of their clinical use are considered in this review.

Results. The development of LED LCUs has progressed in steps and was made possible by

(i) the invention of visible light emitting diodes 50 years ago; (ii) the introduction of high

brightness blue light emitting GaN LEDs in 1994; and (iii) the creation of the rst blue LED

LCUs for the photopolymerization of oral biomaterials. The proof of concept of LED LCUs

had to be demonstrated by the satisfactory performance of resin based restorative dental

materials photopolymerized by these devices, before LED photopolymerization was gener-

ally accepted. Hallmarks of LEDLCUs include a unique light emission spectrum, high curing

efciency, long life, low energy consumption and compact device formfactor.

Signicance. By understanding the physical principles of LEDs, the development of LEDLCUs,

their strengths and limitations and the specic benets of LED photopolymerization will be

better appreciated.

2013 Academy of Dental Materials. Published by Elsevier Ltd. All rights reserved.

Corresponding author at: Faculty of Physics and Astronomy, Friedrich-Schiller-University Jena, Lbdergraben 32, D-07751 Jena, Germany.

Tel.: +49 3641 947730; fax: +49 3641 94 77 32.

Corresponding author.

E-mail addresses: k.Jandt@uni-jena.de (K.D. Jandt), R.W.Mills@bristol.ac.uk (R.W. Mills).

0109-5641/$ see front matter 2013 Academy of Dental Materials. Published by Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.dental.2013.02.003

606 dental materi als 2 9 ( 2 0 1 3 ) 605617

Contents

1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 605

2. Basic physics and technology of LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 605

3. Materials science of dental materials photopolymerized with LED LCUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

4. Evolution of commercial LED LCUs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 611

5. Clinical aspects of LED LCUs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 613

6. Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 614

Acknowledgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 614

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 614

All truth passes through three stages. First, it is ridiculed.

Second, it is violently opposed. Third, it is accepted as being

self-evident.

Arthur Schopenhauer

1. Introduction

The introduction of resin-based dental materials near the

middle of the last century was a revolution in restorative den-

tistry. Dental composites are esthetically pleasing since they

possess a tooth-like appearance, are stable within the oral

environment, are relatively easy to handle and set on com-

mand via self curing or light curing.

Today, almost all commercial dental composites utilize

photopolymerization reactions initiated by blue visible light.

Light curing units (LCUs) based on different physical prin-

ciples, such as quartz-tungsten-halogen (QTH) bulbs, laser,

plasma arc lights, and light emitting diodes (LEDs) are avail-

able. Nevertheless, LED LCUs are currently the standard

devices in most modern dental practices.

In many cases, clinicians using LED LCUs on a daily basis

are unaware of the physics and/or history of their develop-

ment. This knowledge, however, is essential so that LED LCUs

can be used to their full potential and are applied appropri-

ately in any particular clinical situation.

In addition, there is currently no scientic review paper

focusing on the LED photopolymerization of available dental

materials. This review, therefore, addresses this need and is

based mainly on peer-reviewed and frequently cited research

articles in international journals available through the Web

of Science. This current paper reviews the history of LED

photopolymerization in the area of oral biomaterials/dental

materials. Withinthis framework, the basic principles of LEDs,

the history and evolution of commercial LED LCUs, the mate-

rials science of dental materials photopolymerized with LED

LCUs, aspects of commercial LED LCUs as well as their clinical

applications are discussed.

2. Basic physics and technology of LEDs

LEDs are a part of our daily lives. LED technology is applied

in modern light sources for room lighting, car headlights

and dashboards, trafc lights, state-of-the-art television at

screens or as LASER LEDs in CD or blue-ray DVD data/video

storage equipment [1]. Compared to conventional light

sources, LEDs are small and energy efcient. Hence, dental

light curing units (LCUs) basedonLEDs are relatively small and

can be battery powered, using high performance nickelmetal

hydride (NiMH) or lithium-ion (Li-ion) batteries [2].

Users of dental LCUs are oftennot fully aware of the physics

of these devices. Because light emission of LED LCUs differs

greatly fromthat of other, more traditional types of LCUs, it is

worth having a closer look at the physical principles of LEDs.

This knowledge may not only help to better understand how

LEDs work, but it may also contribute to the appropriate use

of LED LCUs in clinical practice and to recognize the strengths

and limitations of these devices in daily use.

LEDs are semiconductor-based photonic devices in which

the elementary particles of light (photons) play the key role.

LEDs convert electrical energy into optical radiation [3]. It

has been known for more than one hundred years that light

can be generated if an electric current passes through a

material under bias [3]. This phenomenon is called elec-

troluminescence and was discovered in 1907 in the natural

semiconductor silicon carbide [4].

LEDs emit light under forward biased conditions. To under-

standthis, one has to consider the energy states of electrons in

the semiconductor. Through the quantum mechanical inter-

action of large numbers of atoms (

=10

25

) and electrons in the

solid state, the electronic states may spilt into very closely

spaced electron states called electron energy bands [5]. The

valence energy band is associated with the highest energy,

occupied with electrons at 0K. The band with the next higher

electron energy is called the conduction band and also con-

tains no electrons at 0K. The valence and conduction bands

are separatedby a bandgapinwhichthe Schrdinger equation

has no solution, i.e., no electrons are allowed in this band gap

under normal circumstances. For semiconductors, the typical

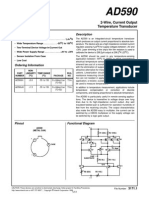

band gap energies are generally less than 2eV [5]. Fig. 1 shows

the band structure of an intrinsic semiconductor.

Inintrinsic semiconductors, the electrical behavior is based

on the electronic structure inherent in the pure material,

such as silicon [5]. If impurity atoms are introduced to dic-

tate the electrical behavior of the semiconductor, it is called

anextrinsic (doped) semiconductor. LEDs use both, n-type and

p-type doped extrinsic semiconductors, indicating the major-

ity charge carriers are electrons or holes, respectively. Doping

a semiconductor with atoms of the group VA of the peri-

odic table creates n-type extrinsic semiconductors, whereas

doping with atoms from the group IIIA of the periodic table

creates p-type extrinsic semiconductors [5]. The former leads

to new, so-called electron donor states in the band gap just

belowthe conduction band, whereas the latter leads to accep-

tor states in the band gap just above the valence band.

dental materi als 2 9 ( 2 0 1 3 ) 605617 607

Energy

0

Valence Band

(Filled)

Conducon Band

(Empty)

Band Gap E

g

Fig. 1 Band energy structure of a typical intrinsic

semiconductor at 0K. The valence band is lled with

electrons and the conduction band is empty. Both bands

are separated by a band energy gap (typically <2eV). For

extrinsic (doped) semiconductors there are donor states

just below the bottomof the conduction band (n-type

extrinsic semiconductors) or acceptor states just above the

top of the valence band (p-type extrinsic semiconductors).

As a result, the conductivity of extrinsic semiconductors is

greater than the conductivity of intrinsic semiconductors.

Fifty years ago in 1962, Holonyak and Bevacqua reported

the emission of coherent visible light from GaAsP junctions

[6]. This event can be considered to be the birth of LEDs emit-

ting visible light [7]. The rst visible light LEDs were expensive

(approximately 200 USD per unit) and had very few practi-

cal applications [7]. The rst visible light GaAsP LED emitted

red light and had a luminous efcacy of 1.5 lumens per Watt

of electrical power consumption (lmW

1

) [3]. In the early to

mid-1980s, these types of LEDs were supplemented by green

(GaP:N) and yellow (GaAsP:N) types, respectively.

For materials in which electron and hole conduction exists,

the electrical conductivity is strongly dependent on the num-

ber of electrons and holes [5]. For practical purposes, only

these doped semiconductors are suitable as materials for

LEDs. The LED is a diode having p- and n-doped semi-

conductors that are connected by a junction (pn-junction).

This arrangement ideally allows, under a forward biased con-

dition, an electric current owing from the p-doped side

(anode) to the n-doped side (cathode), whereas no current

(ideally innite resistance) is observed under reverse biased

conditions. This effect is based on interactions of the electri-

cal eld and the different electron and hole concentrations,

respectively, at the pn-junction [3].

In doped semiconductor devices, such as LEDs (Fig. 2), elec-

trons and holes (also called defect electrons) contribute to the

electric current. Under a forward biased condition (electrons

entering the p-doped semiconductor side and exiting through

the n-doped layer), electrons and holes recombine near the

pn-junction of the diode and emit photons: an electron in

the conduction band can spontaneously return to an empty

state in the valence band [3], during which a photon is pro-

duced as well as heat. The frequency of photon emission is

controlled by the chemistry of composition of both the p- and

n-doped materials.

The width of the band gap is xed for a particular semicon-

ductor and determines the emitted photon wavelength and,

thus, the color of light generated, leading to the characteristic

narrow light emission spectrumof LEDs. For example, a rela-

tivelywide bandgapelectrontransitionresults inthe emission

of blue light, whereas a narrow band gap electron transition

results in emission of red light from LEDs. The band gaps in

semiconductors can be either direct or indirect. For LEDs, the

direct band gap is most important, because this value inu-

ences the ability to emit photons through direct conduction

bandvalence band transitions. This ability means that pho-

ton absorption or emission through band transitions is based

on the k-selection rule, where k is the crystal-momentum(k-

vector) [3]. The wave vectors of the valence bandwave function

(k

1

) and of the conduction band wave function (k

2

) must differ

by the amount of the emitted photon wave vector, considering

the physical conservation of momentum[3].

In the early 1990s, the standard LCUs in dental practices

and clinics used incandescent QTH light sources in combina-

tion with a blue light (band-pass) lter to generate blue visible

light. Blue light is necessary to initiate the setting reaction

(photopolymerization) in most light cured dental materials.

For the realization of the radically new approach of LED LCUs

[8,9], at least two prerequisites had to be fullled. The rst

prerequisite was the availability of blue LEDs of proper emis-

sion wavelength, the second was that blue LEDs needed to

have sufcient emitted power to cure dental materials within

a reasonable time (2040s). Although blue LEDs with a suit-

able wavelength emission were available from 1971 [7], their

power emission was much too small to be used for clinically

relevant exposure times. This situation changed in 1994 when

Nakamura at the Nichia Corporation developed high bright-

ness GaN LEDs [10]. Fromthat point in time, the development

and scientic exploration of LED photopolymerization of oral

biomaterials began.

LEDs have a number of intrinsic advantages which make

them ideally suited for the photopolymerization of oral bio-

materials. The typical spectral line width of light for LEDs is

520nm[3]. Compared to the emission spectra fromall other

LCUs, with the exception of narrowband argon-ion lasers, this

is extremely narrow(Fig. 3). This narrowemission range is the

major advantage of LED LCUs compared to light emitted from

LCUs based on different principles, because photo initiators

present in oral biomaterials have light absorption spectra with

distinct maxima. If the wavelength of the LED LCU is chosen

in this range, effective and rapid photopolymerization is the

result.

For oral biomaterials containing more than one photo

initiator with different light absorption spectra, LED LCUs

emitting multiple wavelengths can be employed [11]. These

LED LCUs are sometimes called broad band LED LCUs. This

term, however, is not correct because the LEDemissioncharac-

teristics (see above) apply. Rather than a broad light spectrum,

two or more distinct narrow wavelengths bands are emitted

fromthis collection of different wavelength LEDs, each with a

distinct maximum. Thus, these types of LCUs are more appro-

priately referred to as poly-wave LED LCUs.

Conventional QTH LCUs cannot compete in this respect

with LED LCUs because the emission spectrum of the QTH

lamp emits a relatively broad visible light spectrum[9], much

608 dental materi als 2 9 ( 2 0 1 3 ) 605617

Fig. 2 (a) The energy band diagramof a pn

+

(heavily n-type doped) junction without any bias. Built-in potential V

0

prevents electrons fromdiffusing fromthe n

+

to the p side. (b) The applied bias reduces V

0

and thereby allows electrons to

diffuse or be injected into the p-side. Recombination around the junction and within the diffusion length of the electrons in

the p-side leads to photon emission.

Courtesy of Professor S. Kasap, University of Saskatchewan, Canada.

Fig. 3 Flux and irradiance of a typical QTH LCU and a LED

LCU. The narrow maximumof the light emission of the LED

LCU coincides with the maximumabsorption spectrumthe

camphorquinone photoinitiator present in oral

biomaterials. Much of the light of the QTH LCU is emitted

outside the maximumabsorption spectrumof the

camphorquinone photoinitiator.

Reprinted from[22] with permission fromElsevier.

of which is useless for photopolymerization and is dissipated

as heat. In addition, these lamps require infrared-blocking

blue bandpass lters. These lters can deteriorate over time

due to the substantial heat the lamp produces.

The second major advantage of LEDs for photopolymer-

ization is their efciency. The external quantum efciency is

dened as the number of photons emitted externally divided

by the number of charge carriers passing through the pn-

junction [3]. Due to the internal properties of the pn-junction

and to the differences in refractive indices at interfaces of

the semiconductor and the ambient air, there are losses of

photons (i.e., they are not emitted from the semiconductor).

Three mechanisms reduce the quantity of photons emitted

from the LED: (1) internal absorption, (2) Fresnel loss and (3)

critical angle loss [3]. The Lambertian emission pattern, i.e.,

the angular dependence of light emission is controlled by pla-

nar, hemispherical or parabolic epoxy encapsulates onthe LED

semiconductor [7].

An important measure of a LEDis its luminous efcacy (the

ratio of luminous ux emitted to electrical power consumed)

and is a measure of how well a light source produces visible

light [12]. For LEDs, the luminous efcacy is typically in the

order of 60lmW

1

. LEDluminous efcacies of 150lmW

1

have

been attained [13] for white LEDs whereas typical QTH lamps

present in LCUs, have a luminous efcacy of only 25lmW

1

[14].

When comparing commercially available blue LEDs with

conventional QTH lamps in terms of efciency, the lumi-

nous intensity efciency is the measure that is most easily

obtained from technical data sheets and this is more useful

than the external quantum efciency. The luminous inten-

sity is a photometric measure of the optical radiant intensity

which is weighted by the sensitivity of the human eye, with

the peak at 555nm. The luminous intensity I

v

of a commercial

blue LED with an apex angle of 10

which consumes 6.4mW

electrical power is about 9.3cd [15]. Thus, the luminous inten-

sity efciency for a LED is

LED

=9.3cd/6.4mW=145cdW

1

of

blue light. A 75WQTH lamp with the same apex angle of 10

yields 7500cd [16]. The luminous intensity efciency of a QTH

lamp is, therefore,

QTH

=7500cd/75W=100cdW

1

across the

whole of the visible spectrum.

Another important advantage of LED LCUs is their over-

all energy efciency in terms of energy required for a cure

cycle. A contemporary LED LCU that has one 5WLED chip will

dental materi als 2 9 ( 2 0 1 3 ) 605617 609

operate approximately 25min from a fully charged battery,

which may require 10h at 2.5W to recharge [17]. Assum-

ing a light curing cycle of 20s, 75 curing cycles are possible

froma charged battery and the energy required for this use is

25Wh

1

, corresponding to 0.34Wh

1

per curing cycle.

In contrast, operating a typical 150W QTH lamp based

LCU, equipped with a 75W (12V) QTH source, for the same

time (25min), the energy required would be approximately

62.5Wh

1

. This value corresponds to 0.84Wh

1

per 20s cur-

ing cycle: approximately 2.5 times the energy a LEDLCUneeds

to performthe same task as can be easily calculated.

LEDs can have a typical lifetime of 100,000h or more and

undergo little degradation of light output over this time, if not

over-driven [18]. This level of durability is a distinct advantage

when compared to the characteristics of QTH lamps [9] which

have an effective lifetime of approximately 50h [19].

3. Materials science of dental materials

photopolymerized with LED LCUs

There are several well-known examples in the history of sci-

ence that show that change and new ideas are not always

welcomed enthusiastically [20] and can be even opposed. This

situation can be particularly the case if this change hap-

pens quickly and has the character of a paradigm shift. To

some extent, this circumstance was also the case with the

introduction of LED LCUs to photopolymerization of oral bio-

materials. The authors recall submitting one of their rst

scientic papers reporting the novel concept of LEDs used for

the photopolymerization of oral biomaterials to a renowned

international journal. This manuscript was rejected, based on

a referees comment essentially stating that one cannot cure

dental materials with LEDs.

Inthe early1990s, the most commonLCUs indentistrywere

QTH units. Degradation of the QTH lamp, lter aging, con-

tamination of the light-guide tips, and several other factors,

potentially reduced the light output of these devices over time.

Nevertheless, users of LCUs didgenerally not monitor the light

output of these devices over time and the radiometers needed

to do so were not available in most dental practices.

Against this background, in 1995 Mills wrote a letter to the

British Dental Journal wondering if LEDs could be used as an

alternative light source for the photopolymerization of den-

tal composites [8]. Shortly before this letter was published,

the Nichia CorporationinJapanintroduced highintensity blue

GaN LEDs [10] having an emission peak around 465nm. The

former letter mentioned further a simple photopolymeriza-

tion test of one composite sample [8].

The rst scientic peer-reviewed article published in an

international journal presenting data on photopolymeriza-

tion of three contemporary dental composites with a LED

LCUs was published a few years later [9]. In this paper, the

hypothesis was tested, that a blue LED LCU can produce an

equal composite depth of cure as a QTH LCU adjusted to

give the minimum effective irradiance accepted at that time:

300mWcm

2

. This paper is a milestone in the history of LED

photopolymerization and to date, is the most cited article on

LED photopolymerization of dental composites [9]. The rea-

sons for this acknowledgment are threefold. First, the article

presented a newtechnological approachfor photopolymeriza-

tion of oral biomaterials and for the rst time a new powerful

LED LCU was introduced in a peer reviewed scientic article

[21]. At that time, single blue LED emitters were not strong

enough to emit enough light to polymerize dental compos-

ites satisfactorily andwithina reasonable time. Therefore, this

rst LED LCU used 25 blue LEDs in an array. Second, the paper

presented the rst graph showing simultaneously, the spec-

tral ux and spectral irradiance of a conventional QTH LCU

and a LED array based LCU. In addition, it was also shown

that the light emitted from the LED LCU correlated well with

the peak of the absorption of the camphorquinone photoini-

tiator. Much of the light emitted by the QTH LCU, however,

was not effective for photopolymerizationincomposites using

the camphorquinone photoinitiator. Third, the paper demon-

strated that a LED LCU with an irradiance of 290mWcm

2

was able to cure three popular commercial dental composites

to statistically signicantly greater depths of cure than was a

QTHLCUwhich had a 60%greater irradiance of 455mWcm

2

.

Although the light emission characteristics of QTH LCUs and

the light absorption characteristics of the photoinitiator cam-

phorquinone were already known, this article again raised

awareness of the characteristics of the light emitted from

different LCUs and their effects on the properties of the pho-

topolymerized materials. In addition, this work triggered a

new dynamic of research in the area as is evident from the

highnumber of citations of this paper insubsequent published

research.

In a further study, the depths of cure and compressive

strengths of a dental composite of two different shades,

each polymerized with a QTH LCU or a LED LCU, respec-

tively, were compared [22]. The QTH LCU had an irradiance

of 755mWcm

2

whereas the LEDLCUdelivered 350mWcm

2

emitted from 27 blue LEDs (Fig. 4). In addition, an advanced

characterization of the light of both LCUs was performed.

Both LCUs were able to produce a depth of cure exceeding the

requirements of ISO 4049 and the compressive strength of the

composites did not statistically signicantly differ between

the LCUs, despite that fact the LED LCU had less than half

the irradiance of the QTH LCU. This result was explained

by the light emission spectrum of the LED LCU providing

more radiant energy within the peak spectral range of cam-

phorquinone than that measured from the QTH device. A

later study conrmed that camphorquinone has practically

the highest photopolymerization efciency when irradiated

with blue LEDs compared to other photoinitiators, despite

its rather low polymerization quantum yield [23]. This nd-

ing showed clearly that LED LCUs were more effective in the

photopolymerization of dental composites than were QTH

lights.

Asubsequent larger study using three composites fromdif-

ferent manufacturers and three different shades, conrmed

the ability of LED LCUs for effective composite polymerization

[24]. This study also presented a rst simple physical model

for the curing effectiveness of the dental LED LCU based on

the convolution of the absorption spectrumof the photoinitia-

tor camphorquinone present in composites and the emission

spectra of LCUs. This work also showed that a comparison

of the LCUs total irradiance is not sufcient to anticipate

the performance of LCU in photopolymerization but instead

610 dental materi als 2 9 ( 2 0 1 3 ) 605617

Fig. 4 (Top) An LED LCU research prototype by the authors.

It contains 27 LEDs and uses a tapered optical light guide

with a tip diameter of 6mm(total length of the LED LCU is

27cm). (Bottom) LED array used as light source for the LED

LCU shown containing 27 shaped blue LEDs arranged in

concentric rings. The diameter of the LED array is 15mm.

Reprinted from[22] with permission fromElsevier.

a comparison of the mechanical properties of composites

resulting fromeach type LCUs is more appropriate.

One year later, in 2001, the hardness of a dental composite

photopolymerized with an LED LCU based on six LEDs (irradi-

ance 79mWcm

2

) and a QTH LCU (irradiance 475mWcm

2

)

conrmed the greater curing potential of LEDLCUs [25]. Never-

theless, all samples photopolymerized by the LEDLCUshowed

smaller hardness values compared to the sample cured with

the QTH LCU.

The degree of double bond conversion of composites was

then found to be signicantly inuenced by the light source

type and by the energy level (energy density), in addition to

the parameters of material and depth [26]. This study used

an LED, a QTH and a plasma arc LCU. When the same light

energy was applied, the degree of double bond conversion of

the composites was not different among the different LCUs up

to a depth of 2mm. The differences in degree of double bond

conversion, however, were only signicant at depths >3mm.

By the early 2000s, the rst commercial LED LCUs became

available. Hence, a published report compared the Barcol

hardness and the compressive strength of composites pho-

topolymerized for 20s or 40s with two different LED LCU

prototypes (27 and 54 LEDs), a rst commercial LED LCU (7

LEDs) and a QTH LCU [27]. While composites photopolymer-

ized by the two LED LCU prototypes and the QTH LCU showed

similar hardness and compressive strengths, the correspond-

ing values of composites exposed using the rst commercial

LED LCU were statistically signicantly smaller. The commer-

cial LED LCU lacked the power reserves of the other LCUs,

Fig. 5 Spectral irradiance of the LCUs (lines) used in this

study and the spectral extinction of the photoinitiators

camphorquinone and Lucirin TPO (lines and symbol). The

absorption spectrumof camphorquinone (according to

manufacturer, Rahn Zurich, Switzerland (0.1% in

methanol)) shows the good match with the LED emission

spectra whereas the co-initiator Lucirin TPO (according to

manufacturer, BASF Ludwigshafen, Germany (0.1% in

ethanol)) does not coincide with the emission of the LED

units. The broad emission spectrumof the halogen unit

shows an overlap with the extinction spectrumof the

co-initiator at approximately 375410nm.

Reprinted from[34] with permission fromElsevier.

especially for shorter curing times (20s). At this time (2002),

commercial LED LCUs were obviously still no match for QTH

LCUs in terms of performance. On the other hand, prototype

LED LCUs having larger numbers of LEDs performed as well as

QTH LCUs.

Similar results were found in a later study in 2002, which

compared composite depths of cure withmaterials having dif-

ferent shades, when photopolymerized using commercial LED

LCU (7 LEDs) and an LED LCU prototype (63 LEDs) [28]. This

study also revealed that the commercial LED LCU was pulsed

at 12Hz. In addition, rened spectral power data of the LCUs

were presented.

In the same year, a study was published that investi-

gated the Knoop hardness and depth of cure proles of

four different dental composites photopolymerized using a

QTH LCU adjusted to the same irradiance as a LED LCU

prototype (approximately 570mWcm

2

) a QTH LCU and a

commercial LED LCU, having irradiance values of (1144 and

122mWcm

2

, respectively) [29]. Two of the composites con-

tained co-initiators in addition to camphorquinone (Fig. 5).

Composites photopolymerized with the commercial LED LCU

showed a statistically signicantly lower hardness for all

materials and exposure times, whereas the LEDLCUprototype

performed as well as the QTH LCUs up to a composite depth

of 1.9mm. For greater composite depths of 3.1mm, the QTH

LCUs performed better than the LED LCU prototype in terms

of composite hardness. There were, however, no statistically

signicant differences in compressive strengths of compos-

ites between the QTH LCUs and the LED LCU prototype. This

dental materi als 2 9 ( 2 0 1 3 ) 605617 611

study demonstrated three essentials of the state-of-the-art in

photopolymerization at that time: (i) commercial LED LCUs

were not quite there yet, i.e., the curing potential of com-

mercial LEDLCUs was less thanthat of conventional QTHLCU;

(ii) a laboratory LED LCU prototype performed as well as high

irradiance QTH LCUs for certain composites; (iii) in order to

perform as well as QTH LCUs, the LED LCUs needed several

LEDs, because the irradiance produced by one single LED was

not sufcient for practical use.

Shrinkage strain kinetics, temperature rise and hardness

values were compared among different composites pho-

topolymerized using two LED LCUs (160 and 320mWcm

2

,

respectively) or a QTHLCU(800mWcm

2

) [30]. The LCUs were

operated in continuous or ramped mode. Composite temper-

ature rise during photopolymerization was lower for the LED

LCU compared to the QTH LCU, whereas the latter LCU pro-

duced the fastest increase in polymerization contraction and

the largest shrinkage strains. Ramp curing decreased the con-

traction speed.

The mechanical property data of dental composites cured

using LED LCUs had made it clear that the LEDs were indeed

suitable for photopolymerization of dental composites. Atten-

tion was then focused on other effects of LED LCUs on these

materials, such as the temperature rise of composites during

photopolymerization. This aspect was also of special inter-

est, because from the late 1990s high irradiance plasma arc

LCUs became available that had a signicant potential to

cause high temperature increases during curing. Excessive

heat applied to teeth can cause irreversible pulpal trauma,

when the pulp temperature exceeds 42.4

C [31,32]. In addi-

tion, soft start QTH LCUs entered the market near the year

2000. Therefore, a key milestone study investigated temper-

ature rise and propagation in three different composites of

two different shades that were photocured using two dif-

ferent LEDs or two QTH LCUs [33]. The results showed that

composites shade inuenced temperature increase and that

composites exposed to QTHLCUs reached signicantly higher

temperatures compared to those cured using LED LCUs. An

exception was a composite cured using the soft start mode

of a QTH LCU. Composites of lighter shades reached higher

temperature than those of darker shades when cured with

LED LCUs. For QTH LCUs, the situation was reversed. Further-

more, this study introduced a high-resolution infrared (HRIR)

camera to document heat propagation in composites. These

ndings demonstrated not only that temperatures of compos-

ite cured using LEDs were generally signicantly lower than

in the same composites exposed to QTH LCUs. In addition,

the heat propagation was slower and the heat penetration

lower in composites exposed using LED LCUs, compared to

those cured with QTH LCUs. Because the temperature gra-

dient (T/x) is signicantly smaller in composites exposed

using LED LCUs, the resulting heat ux is smaller when com-

pared with composites cured with QTH LCUs. The more pulp

friendly temperature properties of LED LCU curing, without

having to compromise in the resulting composite mechanical

properties, emphasized the superiority of LED technology and

was attributed to the different light emission characteristics

of LEDs compared to the QTH light.

In addition to the standard photoinitiator cam-

phorquinone, some dental composites contain co-initiators

that absorb light at shorter wavelengths than cam-

phorquinone. To investigate what effect this condition

has on the mechanical properties of composites cured using

QTH or LED LCUs, the photoinitiator-dependent composite

depth of cure and Knoop hardness using these LCUs was

investigated [34] in a milestone study. The depths of cure

did not discriminate between LCUs used for photopolymer-

ization of composites containing photoinitiators in addition

to camphorquinone, but the Knoop hardness tests did. The

study concluded that LED LCUs should be used with caution

when considered for composites containing co-initiators

that absorb light at shorter wavelengths than the LEDs emit.

Furthermore, this study showed that a LED LCU prototype

did cure composites to greater depths than a commercial

LED LCU, indicating that commercial LED LCUs did not have

the power required for challenging clinical situations at that

point in time, whereas the LED LCU prototype did. For the

latter, the LED LCU prototype required 63 blue LEDs arranged

in a sophisticated and compact array. Although this LED

LCU performed well, simpler LED LCU designs seemed more

desirable at that time.

This goal for a simpler LEDunit design need was addressed

through the introduction of second generation LED LCUs [35].

This classication of LEDLCUs is based on a single high power

LED and allows simpler LED LCU form factors. The perfor-

mance of a single LED LCU with an irradiance of 901Wcm

2

was evaluated by measuring the Knoop hardness and depth

of cure of two different dental composites and one ormocer

composite [35]. The single LED LCU achieved a signicantly

greater depth of cure for all materials than did the QTH LCU

which had an irradiance of 860mWcm

2

. There was no dif-

ference in Knoop hardness observed for one composite or

for the ormocer composite, when cured with either LCU. The

other composite showed a signicantly lower Knoop hardness

when polymerized with the LED LCU compared to the QTH

LCU. Two lessons were learned fromthis study: second gener-

ation LED LCUs have the potential to replace QTH LCUs, if the

composite is chosen carefully and the depth of cure does not

discriminate between the LCU performances, whereas Knoop

hardness testing does. The development of single LED LCUs

was, thus, another major milestone inthe advancement of this

technology for dental applications. Althougharrays of discrete

LEDs are no longer normally used in dental LED LCUs, such

arrays may be utilized in the future in LED-based high power

roomlightening systems [36].

As shown previously, some composites that contain co-

initiators in addition to camphorquinone showed lower

hardness when photopolymerized with LED LCU than the

same composites photopolymerized with QTHLCU[34]. Thus,

a test was performed to determine if progressive crosslinking

of the resin phase of such composites after photopolymeriza-

tion (post cure hardening) would eliminate this effect [37]. The

measured increase in post-cure hardening, however, was not

sufcient to compensate for the difference in hardness of the

composites. An interesting additional result of this study was

that the composite Knoop hardness depends on the indenter

load and has the potential to falsify such measurements if not

chosen carefully. These results demonstrated that LED LCUs

had matured and could more than match the performance

provided by QTH LCU technology at that time, however, with

612 dental materi als 2 9 ( 2 0 1 3 ) 605617

a slight restriction of application to certain composites con-

taining co-initiators. The performance of LED LCUs became

clinically satisfactory [38].

Because most manufacturers of direct resin based restor-

ative materials donot provide details about the photoinitiators

contained in their products, it is challenging to choose an

optimal combination of restorative resin and light-curing unit

[39]. Narrow blue LED light spectra emission is ideal for pho-

topolymerization of camphorquinone containing materials,

but when other photoinitiators, such as 1-phenyl-1,2-

propanedione (PPD) are present invery light composite shades

(high color value) used for repair of bleached teeth [40], this

may not be the case. This situation was addressed by manu-

facturing dual-wave (or poly-wave) LEDLCUs, emitting inthe

violet (410nm) and blue (470nm) of the light spectrum [40].

Third generation, poly-wave LEDs are used in these LED LCUs

(see section Evolution of Commercial LED LCUs).

This progress demonstrating the performance of high

power single LED LCUs paved the way for the clinical mass

application of LED LCUs. Nevertheless, more data from com-

posites photopolymerized with LED LCUs were needed to

convince the remaining skeptical minds clinging to the use

of conventional QTH technology LCUs. Thus, distinctions of

the time dependence of composite shrinkage between use of

QTH and LED LCUs was tested [41]. In addition, the reliability

of the light output was tested up to 360min of duty time, for a

prototype LEDLCU, a commercial LEDLCUand a QTHLCU. Dif-

ferent composites showed similar shrinkage behavior when

cured using the LED or QTH LCUs, with one exception [41]. In

the course of this study, the irradiance of the commercial LED

LCU decreased signicantly, whereas the emission spectrum

wavelength characteristics of the QTH LCU changed dramati-

cally. The prototype LEDLCUshowedalmost no change of light

emission spectrumor irradiance over time.

In addition to the power of an LED LCU, further parame-

ters are important for its photopolymerization potential. An

important aspect affecting the LED LCUs irradiance is the

diameter of the light guide tip. At a composites depth of

2mm, a 4mm diameter light guide tip produced a signi-

cantly greater composite hardness than did a 8 or a 10mm

tip [42]. When irradiation times were doubled or tripled for

8mmand 10mmtips, hardness values eventually rose to the

levels of those when using a 4mmtip. In other words, extend-

ing exposure time may compensate for the lower irradiance

found when using larger diameter light guide tips.

It was found later with LED LCUs, that exposing dental

adhesives to a longer time than recommended by the manu-

factures of the adhesives led to a decrease of permeability of

the bonded interfaces [43]. On the other hand, a study inves-

tigating the minimal exposure time of different LED LCUs,

demonstrated that many composites, when incrementally

exposed to LED light, were polymerized sufciently at a maxi-

mumof 20s [44]. This nding underlines that LED LCUs of the

latest generation are not only efcient but are also devices

capable of fast photopolymerization.

At the beginning of the second decade of this current cen-

tury, scientic investigation of LED photopolymerization of

oral biomaterials is still very active. Topics of this research

area include investigations of the inuence of LED LCUs on

the cytotoxicity of dental adhesives [45], evaluation of the

mechanical properties of composites polymerized using LEDs

and with other LCUs [46], curing efciency of high-intensity

LED LCUs [47], depths of cure and gel state-to-glass transition

of composites [48], polymerization efciency of modern LED

LCUs [49], the never-ending quest for the shortest exposure

time possible with LED LCUs [50]. Beyond this, LED lights are

becoming popular in photodynamic therapy in the oral cavity

[51].

4. Evolution of commercial LED LCUs

It was not until 2000 that the rst commercial LEDLCUbecame

available: the LuxOMax LED LCU [46] was a large pen-like

cordless battery-powered design using 7 discrete LEDs. The

device had a tapered fused glass ber light guide to concen-

trate the light output at the tip. The units irradiance measured

116mWcm

2

[8]. The delay in bringing a commercial LEDLCU

into productionwas due to two mainfactors: the power output

of the blue LEDs and their cost. The discrete blue LEDs used

in these early experiments in the 1990s were so-called sin-

gle chip, epoxy-resin encapsulated, through-hole devices of

either the standard T-1 (3mmdiameter LED) or T-1 3/4 (5mm

diameter LED) versions.

In 1995, the 5mm blue LED available from Nichia, had

an optical power output of 1.2mW and cost approximately

50USD [52]. In 2012, Nichia [53] offered 5mm blue LEDs with

a power output of 123mWat an approximate cost of 0.50USD

[54]. This comparison shows how over a period of seventeen

years in one type of LED, its power increased by two orders

of magnitude, while its cost has decreased by two orders of

magnitude. This data translates to approximately a cost of

40USDmW

1

of blue light output in 1995 to 0.004USDmW

1

in 2012. The increase in the external quantum efciency of

LEDs has an advantage for commercial LED LCU designers.

As a greater proportion of the electrical energy driving the

LED is converted into emitted light energy, the heat sinking

requirements of the LEDs become less demanding. This aspect

is important, as smaller heat sinking requirements mean a

potential reduction in the size, weight and cost of commercial

LED LCUs.

The rst generation of LED LCUs on the market in 2000,

such as the previously mentioned LuxOMax LED LCU, was

thus relatively low-powered, compared to their conventional

QTH LCU competitors. This difference led to some disap-

pointing early results, when commercial LED LCUs were

compared with commercial QTH LCUs [28]. In 2002, these

early comparisons of commercial LED LCUs with QTH LCU

sources produced some premature negative predictions for

the future of LED LCUs [55]. Later in 2002, however, it was

demonstrated that an experimental LED LCU could exceed

the performance of a QTH LCU [2].

First generation commercial LED LCUs improved rapidly

and mirrored the advances and efciency achieved in blue

LED semiconductor research and development. In 2001, the

Elipar

TM

FreeLight having 19 discrete LEDs became available,

with an irradiance of 400mWcm

2

[56]. The manufacturer

claimed this output level was equivalent to a conventional

800mWcm

2

QTHLCU, and studies were quoted in their tech-

nical product prole [57]. This more powerful rst generation

dental materi als 2 9 ( 2 0 1 3 ) 605617 613

LED LCU still used a tapered fused glass ber light guide to

further boost the irradiance.

The second generation of LED LCUs is regarded as a move

from devices that employed multiple discrete LEDs to those

that contained the more powerful single LEDs, often specially

designedfor dental curing applications. Examples of these sin-

gle more powerful LED emitters are the Luxeon LXHL-BRD1

in 2004 [58] with an electrical consumption of 1400mW to

provide 140mW of blue light, to the more recent LED Engin

Inc., LZ4-00B200 in 2012 with an electric consumption of

1160mWto give 3800mWof blue light [59]. Thus, in the rst

case 10% of the electrical power is converted into blue light,

while in the second case 30%conversion was attained, a 3-fold

increase in efciency within only a time span of 8 years. An

example of a single LED, second generation LED LCU using

1 LED was the Elipar

TM

FreeLight 2 [60]. The irradiance of

this LED LCU was approximately 1000mWcm

2

and repre-

sented an increase of 2.5 times that of its predecessor: the

Elipar

TM

FreeLight that used 19 discrete LEDs. It should be

noted that a tapered waveguide (the so-called turbo-tip) was

still employed to boost emitted irradiance and nickel metal

hydride batteries were used to supply the operating power

[61]. Even in 2005, another second generation LED LCU, hav-

ing a conventional pistol grip design, the Kerr L. E. Demetron

II, still incorporated a fan, which, considering the efciency

of LEDs, may have indicated a design compromise with the

heat sinking component [62]. The L. E. Demetron II LED LCU,

like others of this era, used the technique of a tapered light

guide to boost irradiance. Other designs of second generation

LED LCUs, such as the Dentsply SmartLite PS did not utilize a

conventional light guide. This unit was a slim, pen-style unit

like the LuxOMax, but had the LED source at the tip of the

unit, adjacent to the tooth [63]. Dentsply also announced in

2012, the imminent launch of a newer version, the SmartLite

Focus having a lens system designed to allow effective cur-

ing for up to 8mm from the composite [64]. This technique

has the advantage of less light loss as there is no light guide

betweenthe light source and the composite. This advantage in

turnresults ina reductioninelectrical power and heat genera-

tion if all other parameters remain the same. This design also

sets out to overcome the two main disadvantages of tapered

light guides: rst the light beam is more divergent. This is

caused by a progressive increase in the angle of total inter-

nal reection as the light propagates through a tapered ber,

resulted in an exaggerated loss of irradiance compared with

a more parallel beam as the LCU tip is moved further away

fromthe tooth. The second is the smaller light tip area which

requires repeated overlapping exposures to adequately cover

the composite area. More recently, a second generation LED

LCU the Elipar

TM

S10 (manufactured by 3M ESPE) having a

10mmdiameter parallel glass ber light guide capable of pro-

ducing an irradiance of 1200mWcm

2

has become available

[65]. This tip delivers not only four times the minimumirradi-

ance of 300mWcm

2

[66,67] required for a conventional QTH

LCU, but it is known that the spectral output froman LED LCU

is more effective than the equivalent QTH LCU of the same

irradiance [68]. This 1200mWcm

2

irradiance over a 10mm

diameter parallel light guide is a remarkable advance made

possible by the increase in power and reduction of cost of

LEDs. An optical power increase of over 50% is required to

achieve the same irradiance over a 10mmdiameter light guide

compared with the standard 8 mmversion.

As mentioned above, these rst and second generation

commercial LED LCUs both consist of blue LEDs designed to

peak in the absorption spectrum of camphorquinone (CQ),

which is the sole photoinitiator in the majority of commercial

composites. The incorporation of other photoinitiators has

led to the development of third generation commercial poly-

wave LED LCUs. The rst of these was the pen-like Ultralume

5 (Ultradent Products Inc., South Jordan, UT, US) in 2003 [69].

This comprised two different LED wavelengths, a central blue

LED surrounded by 4 violet LEDs at the end of the curing tip.

A more sophisticated dual wavelength LED LCU version called

the bluephase 20i (Ivoclar Vivadent AG, Schaan, Principality of

Liechtenstein) has a maximum irradiance of 2200mWcm

2

[70,71]. This LED LCU has 3 blue LED emitter elements and

a shorter violet LED wavelength emitter mounted on a sub-

strate in a square conguration: 1 emitter in each quadrant.

The bluephase 20i has a more traditional gun-shape with a

pistol grip, conventional fused glass ber light guide, and a

cooling fan. Another LED LCU, the VALO (Ultradent Products

Inc., South Jordan, UT, US) sought to improve on this still

further in 2011 by using 4 emitters in a similar square con-

guration to the bluephase 20i. However, in the VALO, there

are two blue emitters (439nm) diagonally opposite to each

other and also two different shorter wavelengthemitters diag-

onally opposite toeachother inthe other quadrants: one violet

(405nm) and another, longer-wavelength blue (460nm) [72].

The VALO, thus, has 3 emitters of different wavelengths incor-

porated. The heat dissipationaspect of this unit is a metal case

machined fromsolid aluminumrather than having a fan. This

design appears to apply the innovative principle of using one

component for two purposes, i.e., the case and the heat sink.

The VALO eliminates the light loss of a light guide by hav-

ing the emitters at the curing tip. This unit has a maximum

claimed irradiance of a remarkable 3200mWcm

2

. Another

third generation LED LCU, the ScanWave (ACTEON Germany

GmbH, Mettmann), uses 4 LED emitters like the bluephase 20i

and the VALO. In this case, however, all 4 emitters have dif-

ferent wavelengths from each other and can be switched in

sequence. The maximumirradiance is 2200mWcm

2

[73]. The

sophisticated programming options of the ScanWave claimto

helpoptimize curing while minimizing heat generationwithin

the target. Some preliminary results fromthis unit have been

described [74]. In this previous study, it is suggested that the

ScanWave couldbe regardedas arst versionof afourthgener-

ationLEDLCUbecause of the sophisticatedcontrol algorithms.

Both the VALO and ScanWave appear to be good examples of

the state-of-the-art of LED LCU evolution at the time of writ-

ing. Fig. 6 shows two examples of contemporary commercial

LED LCUs.

The further evolution of commercial LED LCUs is likely

to be conned to ne tuning the devices to ensure consis-

tent reliable spectral outputs over the lifetime of the device

and uniform irradiances over the whole of the emitting

tip area. Previous work [75] has demonstrated the lack of

homogeneity at the end of the light guide and multiple com-

mercial chip LED sources are imaged at the other end of

the coherent light guide tip resulting in a differential curing

over the target. One possible solution here to achieve more

614 dental materi als 2 9 ( 2 0 1 3 ) 605617

Fig. 6 Two contemporary commercial LED LCUs: (a) is the

SmartLite PS (courtesy of DENTSPLY Ltd., UK) and (b) is the

Elipar

TM

S10 (courtesy of 3M Espe Dental Products). Two

main approaches in LED LCU design are shown here: the

SmartLite PS in which the LED is located at the end of the

LCU which is placed near the tooth and the Elipar

TM

S10 in

which a conventional fused glass ber light guide

transmits the light to the tip that is placed near the tooth.

homogeneity would be to try a non-imaging incoherent light

guide. The higher energy density of lithium-based battery

technologies compared with earlier nickel metal hydride

has allowed commercial portable LED LCUs with enhanced

endurance. Further advances in battery technology would

improve on this aspect. It remains to be seen whether the

third generation of commercial LED LCUs will be sustained

with their more hazardous wavelengths [76]. This factor

together with the more limited penetration of light toward the

UVviolet region [77] resulted in curing wavelengths evolving

into the blue region of the spectrum. It may be that alternative

strategies achieve composites having high color value occur

in the future, without having to accept the disadvantages of

shorter wavelengths of light.

5. Clinical aspects of LED LCUs

When commercial LED LCUs became available to dental prac-

titioners after 2000, they slowly evolved and became serious

contenders to challenge the dominance of QTH LCUs in clini-

cal dentistry. It is natural for clinicians to want more powerful

light-curing devices to reduce the time taken for a given pro-

cedure for patient comfort. LED LCUs can currently achieve

irradiance values in excess of 3200mWcm

2

[72]. This irra-

diance value in isolation is only an approximate guide of the

clinical composites depth of cure. By achieving higher irra-

diance values, the depth of cure can be increased slightly, but

the work by Nomoto et al. reminds clinicians that a doubling of

the irradiance, if all other parameters stay the same, equates

to only an approximate 20% increase in depth of cure [78].

Doubling the irradiance, will however, double the energy deliv-

ered to the tooth of the patient. Higher power means higher

amounts of heat generatedwithinthe toothandpotential pulp

damage [79,80]. It is not only the energy absorbed fromthe LED

LCU that is important but also the exothermic reaction of the

polymerization [33].

Teeth are sensitive to the rate of change of temperature [81]

and can be cooled and warmed slowly within reason without

causing pain. Rapidtemperature changes cancause pain, such

as drinking hot beverages followed immediately by biting into

ice cream. If energy is fed into the dental pulp at a greater

rate than it can be dissipated during curing in a clinical situa-

tion, thena rise intemperature will occur and irreversible pulp

damage is possible [70]. In clinical situations, where a local

anesthetic is used, the protective warning mechanismof pain

is maskedandsothe patient cannot indicate whenthis occurs.

Thus, thermal safety shouldbe of primary considerationwhen

photopolymerizing composites.

The gains obtainedby increasing irradiance tothe very high

levels found in the plasma arc LCUs of the 1990s are often

questioned. To the clinician, the composite may appear hard

when tested with a probe but premature vitrication of the

composite can occur giving the impression that adequate cur-

ing has occurred.

Clinical studies have demonstrated that LED LCUs are as

effective as QTH LCUs when curing composites [82]. This

was also demonstrated in the area of orthodontics [83]. The

drawback for single wavelength LED LCUs is that they cannot

adequately cure composites withphotoinitiators lying outside

the absorption curve of CQ. This issue has been discussed

above and has now been addressed by poly-wave third gen-

eration LED LCUs [84]: units having two or more different

wavelength semiconductor chips [70]. There is a fundamen-

tal exponential correlation between the wavelength of light

and the penetration of the material to be cured. Scattering of

light S is inversely proportional to its wavelength [85]

S

and a signicant factor governing light penetration of a com-

posite [86].

A recent study examined 210 LCUs in government clini-

cal health establishments [87]. One hundred and twenty of

these units were QTH lights and 90 were LED LCUs. Nearly

68% of the QTH LCUs and 15.6% of the LED LCUs were judged

to have failed to reach the minimumacceptable irradiance of

300mWcm

2

for clinical success. This same value was used

for both types of LCU even though it has been demonstrated

that LED LCUs are more effective at the same irradiance when

all other parameters remain equal. It has been suggested

how the clinician can help offset the deterioration in LCUs

in the early stages of declining output by compensating for

this decline [88]. To record the reduction in output of an LED

LCUcontaining more than one wavelength of LEDover time, it

may be necessary to have a more sophisticated radiometer in

a clinical situation in which more than one detector indicates

the reduction of the different wavelength LEDs that comprise

the LCU. Such a radiometer could be constructed by using the

LEDs that comprise the LED LCU used in reverse function as

wavelength-specic detectors [28].

For clinical applications, LED LCUs are the current gold

standard for photopolymerization of resin based dental mate-

rials. Before using LED LCUs clinically, it can be seen that the

dental materi als 2 9 ( 2 0 1 3 ) 605617 615

main tasks are to check the wavelength compatibility with the

composite to be cured and to monitor the output in line with

the manufacturers guidance in combination with the advice

above.

Currently, studies evaluating the clinical performance of

light polymerized dental composites focus almost exclusively

LEDLCUs. The inherent characteristics of LEDs meanthat both

clinicians and patients should be able to rely on the poten-

tial of a consistent and long-lasting light output. This result

will only be true if the LEDs within the LED LCU are heat-

sinked correctly and powered at the recommended voltage

and current ratings of the LED manufacturers datasheets. If

the clinician measures a signicant deterioration in light out-

put over a relatively short period of time in an LED LCU, it

could be an indication that these manufacturing rules have

not been adhered to in the design and construction of the

device. Two main requirements for LCUs in the treatment

of patients are reliability and consistency of performance.

LED LCUs offer clinicians the potential to achieve both of

these.

6. Conclusions

The introduction of LED LCUs has revolutionized the pho-

topolymerization of oral biomaterials. Until the introduction

of LED LCUs, QTH lamp based LCUs were the standard curing

devices in most dental practices. Due to the physical charac-

teristics of the solid-state light emitting diodes, LEDLCUs have

almost entirely replaced QTH LCUs whose inherent problems

include a decay of light output over time, blue light lter degra-

dation, relatively limited time of life of the QTH source, high

energy consumption, bulky construction, a requirement for

a mains electricity supply, and relatively high heat transfer

to the pulp chamber of the tooth during photopolymeriza-

tion. It is, therefore, not surprising that hand-heldpencil-style,

battery powered, compact LED LCUs are now the standard

photopolymerization devices in most dental practices world-

wide.

This paradigm change in photopolymerization develop-

ment was made possible mainly by three factors: (i) the

invention of visible light emitting diodes exactly 50 years

ago; (ii) the introduction of high brightness blue light emit-

ting GaN LEDs in 1994; and (iii) the creation of the rst

blue LED LCUs for photopolymerization of oral biomateri-

als. The physical characterization of these LCUs as well

dental composites photopolymerized with these LCUs and

elucidation of particularities of the LED photopolymeriza-

tion process from 1995 to date have been addressed in this

review.

The LED-based photopolymerization process has become

the gold standard of curing dental composites at the begin-

ning of the 21st century. With efcient high power, single LED

LCUs commercially available, it is likely that this trend will

not change for quite some time, especially if one considers

the energy efciency of LEDs, which are the green way to

produce light. The history of LED photopolymerization of bio-

materials is also a good example of how science works and

progresses.

Acknowledgement

We thank Dipl.-Phys. Matthias M.L. Arras, FSU Jena, for calcu-

lating the luminous intensity values of the LED and the QTH

lamp.

r e f e r e n c e s

[1] http://en.wikipedia.org/wiki/Light-emitting diode

[2] http://en.wikipedia.org/wiki/Dental curing light

[3] Sze SM, Ng KK. Physics of semiconductor devices. 3rd ed.

Hoboken: John Wiley & Sons; 2007. p. 601 ff. 608620.

[4] Round HJ. A note on carborundum. Electrical World

1907;49:309.

[5] Callister WD. Fundamentals of materials science and

engineering. An integrated approach. Hoboken: John Wiley

& Sons; 2005. p. 478ff.

[6] Holonyak Jr N, Bevacqua SF. Coherent (visible) light emission

fromGa(As

1x

P

x

) junctions. Applied Physics Letters

1962;1:823.

[7] Schubert EF. Light-emitting diodes. Cambridge: Cambridge

University Press; 2003. p. 7.

[8] Mills RW. Blue light emitting diodes another method of

light curing? British Dental Journal 1995;178:169.

[9] Mills RW, Jandt KD, Ashworth SH. Dental composite depth of

cure with halogen and blue light emitting diode technology.

British Dental Journal 1999;186:38891.

[10] Nakamura S, Mukai T, Senoh M. Candela-class

high-brightness InGaN/AlGaN double-heterostructure

blue-light-emitting-diodes. Applied Physics Letters

1994;64:1687.

[11] Cao D. Light for use in activating light-activated materials,

the light having a plurality of light emitting semiconductor

chips emitting light of differing peak wavelengths to provide

a wide light spectrumprole. United States Patent US

2002/0190659 A1 (2002), to Cao Group, Inc.

[12] http://en.wikipedia.org/wiki/Luminous efcacy

[13] http://phys.org/news202453100.html

[14] http://techon.nikkeibp.co.jp/english/NEWS EN/20061221/

125713/

[15] Technical data sheet Specications for Nichia Blue LED

Model: NSPB500AS, Nichia Corporation, http://www.nichia.

co.jp/specication/en/product/led/NSPB500AS-E.pdf

[16] Family data sheet OSRAM HALOPAR 30, OsramGmbH;

2013. http://www.osram.com/appsinfo/pdc/pdf.do?cid=

GPS01 1027714&vid=EU ALL eCat&lid=EN

[17] http://www.dentsply.de/

[18] Haitz RH, Craford MG, Weissmann RH. Light emitting diodes.

In: Bass M, editor. Handbook of optics. 2nd ed. New York:

McGraw Hill Inc.; 1995. p. 12.112.39.

[19] Cayless MA, Marsden AM. Tungsten halogen lamps. In:

Lamps and lighting. 3rd ed. London: Edward Arnold Ltd.;

1983. p. 169182.

[20] Gribbin J. Science: a history 15432001. London: Penguin;

2003.

[21] Ferracane JL. A new approach for curing light activated oral

biomaterials. British Dental Journal 1999;186:384.

[22] Jandt KD, Mills RW, Blackwell GB, Ashworth SH. Depth of

cure and compressive strength of composites cured with

blue light emitting diodes (LEDs). Dental Materials

2000;16:417.

[23] Neumann MG, Schmitt CC, Ferreira GC, Correa IC. The

initiating radical yields and the efciency of polymerization

for various dental photoinitiators excited by different light

curing units. Dental Materials 2006;22:57684.

616 dental materi als 2 9 ( 2 0 1 3 ) 605617

[24] Stahl F, Ashworth S, Jandt KD, Mills RW. Light emitting diode

(LED) polymerisation of composites: exural properties and

polymerisation potential. Biomaterials 2000;2:137985.

[25] Kurachi C, Tuboy AM, Magalhaes DV, Bagnato VS. Hardness

evaluation of a dental composite polymerized with

experimental LED-based devices. Dental Materials

2001;17:30915.

[26] Yoon TH, Lee YK, LimBS, KimCW. Degree of polymerization

of resin composites by different light sources. Journal of Oral

Rehabilitation 2002;29:116573.

[27] Mills RW, Uhl A, Blackwell G, Jandt KD. High power light

emitting diode (LED) arrays versus halogen light

polymerisation of oral biomaterials: Barcol hardness,

compressive strength and radiometric properties.

Biomaterials 2002;23:295563.

[28] Mills RW, Uhl A, Jandt KD. Optical power outputs, spectra

and dental composites depths of cure, obtained with blue

light emitting diode (LED) and halogen light curing units

(LCUs). British Dental Journal 2002;193:45963.

[29] Uhl A, Mills RW, Vowles RW, Jandt KD. Knoop hardness

depth proles and compressive strength of selected dental

composites polymerized with halogen and LED light curing

technologies. Journal of Biomedical Materials Research A

2002;63:72938.

[30] Hofmann N, Hugo B, Klaiber B. Effect of irradiation type (LED

or QTH) on photo-activated composite shrinkage strain

kinetics, temperature rise and hardness. European Journal

of Oral Sciences 2002;110:4719.

[31] Pohto M, Scheinin A. Microscopic observation of living

dental pulp. Acta Odontology Scandinavia 1958;16:30327.

[32] Zach L, Cohen G. Pulp response to externally applied heat.

Oral Surgery 1965;19:51530.

[33] Uhl A, Mills RW, Jandt KD. Polymerisation and light-induced

heat of dental composites cured with LED and halogen

technology. Biomaterials 2003;24:180920.

[34] Uhl A, Mills RW, Jandt KD. Photoinitiator dependent

composite depth of cure and Knoop hardness with halogen

and LED light curing units. Biomaterials 2003;24:

178795.

[35] Uhl A, Sigusch BW, Jandt KD. Second generation LEDs for the

polymerization of oral biomaterials. Dental Materials

2004;20:807.

[36] Mills RW, Jandt KD. United States Patent US 7,645,056 B1

(2010), to Koniniklijke Philips Electronics NV.

[37] Uhl A, Michaelis C, Mills RW, Jandt KD. The inuence of

storage and indenter load on the Knoop hardness of dental

composites polymerized with LED and halogen

technologies. Dental Materials 2004;20:218.

[38] Bennett AW, Watts DC. Performance of two blue

Light-emitting-diode dental curing units with distance and

irradiation time. Dental Materials 2004;20:729.

[39] Kameyama A, Hatayama H, Kato J, Haruyama A, Teraoka H,

Takase Y, et al. Spectral characteristics of light-curing units

and dental adhesives. Journal of Photopolymer Science and

Technology 2011;24:4116.

[40] Watts DC. Witness statement (2012) on resin composites

and light curing. London: Witness seminar British Dental

Association; 2012.

[41] Uhl A, Mills RW, Rzanny AE, Jandt KD. Time dependence of

composite shrinkage using halogen and LED light curing.

Dental Materials 2005;21:27886.

[42] Nitta K. Effect of light guide diameter of LED-light curing

unit on polymerization of light-cured composites. Dental

Materials 2005;21:21723.

[43] Breschi L, Cadenarro M, Antoniolli F, Sauro S, Biasotto M,

Prati C, et al. Polymerization kinetics of dental adhesives

cured with LED: correlation between extent of conversion

and permeability. Dental Materials 2007;23:106672.

[44] Schattenberg A, Lichtenberg D, Stender E, Willershausen B,

Erst CP. Minimal exposure time of different LED-curing

devices. Dental Materials 2008;24:10439.

[45] Sigusch BW, PaumT, Volpel A, Schinkel M, Jandt KD. The

inuence of various light curing units on the cytotoxicity of

dental adhesives. Dental Materials 2009;25:

144656.

[46] Topcu FT, Erdemir U, Sahinkesen G, Yildiz E, Uslan I, Acikel

C. Evaluation of microhardness, surface roughness, and

wear behavior of different types of resin composites

polymerized with two different light sources. Journal of

Biomedical Materials Research Part B-Applied Biomaterials

2010;92B:4708.

[47] Rahiotis C, Patsouri K, Silikas N, Kakaboura A. Curing

efciency of high-intensity light-emitting diode (LED)

devices. Journal of Oral Science 2010;52:18795.

[48] Leprince JG, Leveque P, Nystenv B, Gallez B, Devaux J, Leloup

G. New insight into the depth of cure of

dimethacrylate-based dental composites. Dental Materials

2012;28:51220.

[49] Rencz A, Hickel R, Ilie N. Curing efciency of modern LED

units. Clinical Oral Investigations 2012;16:1739.

[50] Busemann I, Lipke C, Schattenberg A, Willershausen B, Ernst

CP. Shortest exposure time possible with LED curing lights.

American Journal of Dentistry 2011;24:3744.

[51] Rios A, He JN, Glickman GN, Spears R, Schneiderman ED,

Honeyman AL. Evaluation of photodynamic therapy using a

light-emitting diode lamp against Enterococcus faecalis in

extracted human teeth. Journal of Endodontics

2011;37:8569.

[52] DCL Components Ltd., 2 Kennet House, 19 High Street,

Hungerford, Berkshire, RG17 0NL, UK.

[53] Nichia Corporation, 491 Oka, Kaminaka-Cho, Anan-Shi,

Tokushima 774-8601, Japan.

[54] Nichia LED Catalogue 2012: p036. Aka, Kaminaka Cho, Anan

Shi, Tokushima 774 8601, Japan.

[55] Christensen GJ. The curing light dilemma. Journal of the

American Dental Association 2002;133:7613.

[56] Elipar

TM

FreeLight Product leaet GD67 2002. 3M ESPE,

Morley Street, Loughborough, Leicestershire LE1 1EP,

UK.

[57] Elipar

TM

FreeLight Technical Product Prole 2002. 3M ESPE,

3M Center, Building 275 2SE-03, St. Paul, MN 55144 1000, US.

[58] Technical Data DS35 Lumileds Lighting U.S., LLC 370 West

Trimble Road San Jose, CA 95131, US.

[59] Data sheet LZ4-00B200 (5.1-09/19/12), 2012. LED Engin, Inc.,

651 River Oaks Parkway, San Jose, CA 95134, US.

[60] Elipar

TM

FreeLight 2 Product brochure (70-2009-3582-6), 2003.

3M ESPE, 3M Center, Building 275 2SE-03, St. Paul, MN 55144

1000, US.

[61] Elipar

TM

FreeLight 2 Technical Product Prole 2002. 3M ESPE,

3M Center, Building 275 2SE-03, St. Paul, MN 55144 1000,

US.

[62] L.E. Demetron II. Kerr Quarterly Promotions 2005 Kerr UK

Limited, 4 Flag Business Exchange, Vicarage FarmRoad,

Peterborough, PE1 5TX, UK.

[63] SmartLite

TM

PS Brochure (ref K103610-02) 2004. DENTSPLY

DeTrey GmbH, De-Trey-Str. 1, 78467 Konstanz, Germany.

[64] SmartLight

TM

Focus 2012. DENTSPLY Limited, Building 1,

Aviator Park, Station Road, Addlestone KT15 2PG, UK.

[65] Elipar

TM

S10 3M ESPE, Morley Street, Loughborough,

Leicestershire LE1 1EP, UK.

[66] Caughman WF, Rueggeberg FA, Curtis Jr JW. Clinical

guidelines for photocuring restorative resins. Journal of the

American Dental Association 1995;126:12806.

[67] Shortall AC, Harrington E. Guidelines for the selection, use,

and maintenance of visible light activation units. British

Dental Journal 1996;181:3837.

dental materi als 2 9 ( 2 0 1 3 ) 605617 617

[68] Fujibayashi K, Ishimaru K, Takahashi N, Kohno A. Newly

developed light curing unit using blue light-emitting diodes.

Dentistry in Japan 1998;34:4953.

[69] Ultralume 5. Ultradent Products Inc., 505 West 10200 South,

South Jordan, UT 84095, US.

[70] Vlkel T. Bluephase

family scientic documentation April

2009. IvoclarVivadent AG, Bendererstr. 2, FL 9494 Schaan,

Principality of Liechtenstein.

[71] Bluephase

20i brochure 627360/0111/e/W. IvoclarVivadent

AG, Bendererstr.2, FL 9494 Schaan, Principality of

Liechtenstein.

[72] Valo LED LCU, 2011. Ultradent Products Inc., 505 West 10200