Professional Documents

Culture Documents

Material 1: Straw Working

Material 1: Straw Working

Uploaded by

gautamsethi999994Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material 1: Straw Working

Material 1: Straw Working

Uploaded by

gautamsethi999994Copyright:

Available Formats

MATERIAL 1: STRAW

WORKING:

It produces its own heat through agricultural fermentation. During the cold months, dried straw is

composted in acrylic cases within the house using the low-odor Japanese bokashi method. The

fermentation naturally heats up the house by generating 30 celsius heat for up to four weeks.

During the hot summer months, the natural shelter dries straw inside transparent window shelves. These

shelves serve as heat shield panels, and they release cool moisture as the straw dries. In the winter

months, the straw is composted indoors to produce a source of heat through microbial fermentation.

DURATION:

The houses grass walls need to be changed a few times throughout the year, but they provide a natural

system of heating and cooling that requires zero energy.

MATERIAL 2:

CLAY BRICKS

Clay bricks are moulded or cut to shape from selected clays and then red at high temperature. The

ring process transforms the clay into a building component with high compressive strength and excellent

weathering qualities. Bricks are a heavy, readily available, mass produced cladding manufactured in ef

cient factories. Bricks are regularly tested for quality. Brick veneer cladding is perceived as being safe in

terms of the weather tightness risk of the cladding.

EXTRACTION AND MANUFACTURE:

Impact of extraction:

1) Removal of clay creates a visual impact.

2) Industrial waste products such as y ash, glass, plastics, and even hazardous waste can be

incorporated in the mix to make clay bricks.

Energy use:

1) Embodied energy of clay bricks is quoted as 6.7 MJ/kg (7.2 MJ/kg for a glazed brick).

By-products/emissions:

1) Clay bricks are inert once red.

SOURCING:

Material sources:

Clay bricks are made locally.

Availability:

Clay bricks are readily available.

Cost:

Clay bricks are a low to medium cost building material. Installation costs are relatively high. Maintenance

costs are low.

Transport to site:

Clay bricks are heavy and bulky to transport.

Construction/installation:

Health and safety during construction/installation:

1) Safety equipment is required when handling cement for mortar (gloves, overalls) or cutting

brickwork with a masonry saw (ear muffs, safety glasses, mask and overalls) to eliminate risk of

skin irritation and lung damage.

Ease of construction

1) Clay bricks as a veneer cladding have a signi cant history of satisfactory use. Bricks can easily

be handled by site labour.

Adaptability:

1) Once installed, bricks arent easy to replace.

Performance:

Health and safety during life of building:

1) Clay bricks are inert, non-toxic, and not prone to off-gassing of volatile materials.

Expected durability (assuming correct installation and maintenance):

80+ years

Waste disposal/recycling/re-use:

Re-use:

Bricks can be re-used if they are able to be removed in good condition and the mortar removed.

Recycling :

Crushed bricks can be used as basecourse or hardll.

Waste disposal :

Brick demolition material is inert and non-toxic. Its heavy to transport.

You might also like

- Shipping Container Homes: A complete guide to designing and building a container homeFrom EverandShipping Container Homes: A complete guide to designing and building a container homeRating: 5 out of 5 stars5/5 (1)

- Constructing A Low Energy House From Natural MaterialsDocument7 pagesConstructing A Low Energy House From Natural Materialsrijuzaki0% (1)

- M 2008 Ceet 28 Zirimwabagabo Leodomir Gs20020131Document52 pagesM 2008 Ceet 28 Zirimwabagabo Leodomir Gs20020131Katie SandersNo ratings yet

- Junkers Monobloc Planning Guide English PDFDocument184 pagesJunkers Monobloc Planning Guide English PDFReInvieNo ratings yet

- Cleaning in Place (CIP) in Food Processing: December 2013Document55 pagesCleaning in Place (CIP) in Food Processing: December 2013Đivềphía Mặt TrờiNo ratings yet

- Green Buildings and InfrastructureDocument9 pagesGreen Buildings and InfrastructureRushika KothuruNo ratings yet

- Rockwool Vs GlasswoolDocument8 pagesRockwool Vs Glasswooly2karein100% (1)

- 7 Best Environmentally Friendly Materials For Buildings RioTy 61200543Document5 pages7 Best Environmentally Friendly Materials For Buildings RioTy 61200543Rio TampatyNo ratings yet

- The 7 Best Eco-Friendly Materials For Building: Taken From: WWW - Broadsword-Group - Co.ukDocument5 pagesThe 7 Best Eco-Friendly Materials For Building: Taken From: WWW - Broadsword-Group - Co.ukFigo Catur PalusaNo ratings yet

- VijayDocument67 pagesVijayvijay kumarNo ratings yet

- Innovative Building Material: Shrihari K. BhuskadeDocument15 pagesInnovative Building Material: Shrihari K. Bhuskademla.santoshNo ratings yet

- Faculty of Engineering & TechnologyDocument12 pagesFaculty of Engineering & TechnologySachin HarriramNo ratings yet

- Building With BiofibresDocument27 pagesBuilding With BiofibresKeith Nicholson100% (1)

- LCA On Building MaterialsDocument3 pagesLCA On Building Materialsvidhya lakshmiNo ratings yet

- Eco-Friendly MaterialsDocument48 pagesEco-Friendly MaterialsShyamv333100% (1)

- Eco Blac BricksDocument21 pagesEco Blac BricksShashankSharma0% (1)

- Material Study: Architectural DesignDocument56 pagesMaterial Study: Architectural DesignShraddha Shenoy100% (1)

- 3672 Part 2Document31 pages3672 Part 2Mukhtiar Ali Jamali100% (1)

- Innovative Building Materials: Presented byDocument19 pagesInnovative Building Materials: Presented byMuhamet AhmetiNo ratings yet

- M6 Eco Friendly MaterialsDocument4 pagesM6 Eco Friendly MaterialsRiksan SueNo ratings yet

- 3672 Assignment 2Document19 pages3672 Assignment 2adeel raziNo ratings yet

- Building With Hemp and LimeDocument26 pagesBuilding With Hemp and LimeAdri DiazNo ratings yet

- Modern Construction Materials: Amir Nazir ParayDocument19 pagesModern Construction Materials: Amir Nazir ParaySahana asmiNo ratings yet

- BRICKS1Document18 pagesBRICKS1Mdtnvr AhmdNo ratings yet

- Rice Straw Bale Construction in Modern ArchitectureDocument36 pagesRice Straw Bale Construction in Modern ArchitectureTmt TarekNo ratings yet

- Green MaterialsDocument12 pagesGreen MaterialsNancy BansalNo ratings yet

- Hemcrete, Biobric & Poroton: Sustainable & Solidwall Systems With Ecological MaterialsDocument18 pagesHemcrete, Biobric & Poroton: Sustainable & Solidwall Systems With Ecological MaterialsLucien SteilNo ratings yet

- Building With Hemp and LimeDocument25 pagesBuilding With Hemp and Lime23krneki100% (3)

- Construction MaterialsDocument4 pagesConstruction MaterialsanmolNo ratings yet

- Agricultural Residues AnasDocument12 pagesAgricultural Residues AnasHazim MohammedNo ratings yet

- Module 3 - Industrial and Agricultural WasteDocument21 pagesModule 3 - Industrial and Agricultural WastemUSINo ratings yet

- Advance Construction Technology and MaterialsDocument10 pagesAdvance Construction Technology and MaterialsIqRa JaVedNo ratings yet

- Ecofriendly MaterialsDocument8 pagesEcofriendly MaterialsGénie Civil2122No ratings yet

- 18221a0119 Innovative Materials PDFDocument19 pages18221a0119 Innovative Materials PDFVenky RajuNo ratings yet

- Bricks: Deval Shah Aditya Singhania Shailesh Kumar Maheep SanerDocument25 pagesBricks: Deval Shah Aditya Singhania Shailesh Kumar Maheep SanerYash Dhabalia100% (1)

- Feild Visit Report Srijana Goja ShresthaDocument2 pagesFeild Visit Report Srijana Goja ShresthaSrijana ShresthaNo ratings yet

- 2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionDocument20 pages2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionBlessy FrancisNo ratings yet

- 2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionDocument20 pages2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionBlessy FrancisNo ratings yet

- Lecture 4Document18 pagesLecture 4Awwal EdrisNo ratings yet

- Building Materials Assemblies HandoutDocument16 pagesBuilding Materials Assemblies HandoutChristian EspinolaNo ratings yet

- MATERIAL STUDY and AUROVILLE CASE STUDYDocument18 pagesMATERIAL STUDY and AUROVILLE CASE STUDYMinni ImmanuelNo ratings yet

- Sustainable MaterialsDocument9 pagesSustainable Materialsdani.angovNo ratings yet

- Innovative Design KomalshahazimDocument23 pagesInnovative Design Komalshahazimkomal shahazimNo ratings yet

- KTC BricksDocument55 pagesKTC BricksKiran KumarNo ratings yet

- Alternative Materials: Prepared By: Agcaoili, Louella Bs-Architeture 4A Orence, Fhirsky Junhe Salvilla, Ma. YlleanoreDocument14 pagesAlternative Materials: Prepared By: Agcaoili, Louella Bs-Architeture 4A Orence, Fhirsky Junhe Salvilla, Ma. YlleanoreRoque CapaqueNo ratings yet

- Autoclaved Aerated Concrete BricksDocument24 pagesAutoclaved Aerated Concrete BricksRazil RomNo ratings yet

- Study On Fly Ash BricksDocument66 pagesStudy On Fly Ash BricksKiran Kumar100% (2)

- Matthew IssaDocument9 pagesMatthew Issarh.rassan.connectNo ratings yet

- Sustainable Planning & Architecture (Unit - 3)Document51 pagesSustainable Planning & Architecture (Unit - 3)Minni ImmanuelNo ratings yet

- Green BuildingDocument5 pagesGreen BuildingDennis DaltonNo ratings yet

- Straw Bale Is Future House Building MaterialDocument14 pagesStraw Bale Is Future House Building MaterialJcdenaesNo ratings yet

- Top 12 Future Construction MaterialsDocument5 pagesTop 12 Future Construction MaterialsMauson HSNo ratings yet

- 37 Sustainable Construction and Building MaterialsDocument9 pages37 Sustainable Construction and Building Materials薇神No ratings yet

- Contruction Materials Around The GlobeDocument5 pagesContruction Materials Around The GlobeYimkum OzzyNo ratings yet

- Present & Future of Lightweight ConcreteDocument7 pagesPresent & Future of Lightweight ConcreteGlobal_FriendshipNo ratings yet

- Organic Building and Building MaterialsDocument3 pagesOrganic Building and Building MaterialsMalak BenattiaNo ratings yet

- Samruddhi RESEARCH SamruddhiDocument12 pagesSamruddhi RESEARCH SamruddhiAtharva PadwalNo ratings yet

- Export DocumentDocument8 pagesExport Documentakshatkdm1112No ratings yet

- Troubled Times Shelter 2012Document477 pagesTroubled Times Shelter 2012AveksaNo ratings yet

- Sustainable Building Material ArchDocument15 pagesSustainable Building Material ArchJeyamaniNo ratings yet

- The House That Hemp BuiltDocument4 pagesThe House That Hemp Builtmludwig8888No ratings yet

- Chapter 9 Steam Power CycleDocument29 pagesChapter 9 Steam Power CycleAmanRaghaniNo ratings yet

- Chapt 1 3 4 5 DoneDocument75 pagesChapt 1 3 4 5 DoneShaira Abigail AutorNo ratings yet

- 5.0 Microfine Cement Grout Laboratory Testing and ResultsDocument25 pages5.0 Microfine Cement Grout Laboratory Testing and ResultsTATATAHERNo ratings yet

- Everything You Wanted To Know About SOC MemoryDocument29 pagesEverything You Wanted To Know About SOC MemorySai Srikanth ReddyNo ratings yet

- HEBT2024 BrochureDocument8 pagesHEBT2024 Brochureraj RajputNo ratings yet

- Forming ProcessesDocument8 pagesForming ProcessesKishor PatilNo ratings yet

- ME3400 Characteritics Types ProcessingDocument43 pagesME3400 Characteritics Types ProcessingWish SetsNo ratings yet

- Fluid Bed Drying PDFDocument83 pagesFluid Bed Drying PDFsouhir gritliNo ratings yet

- Oxirane (Ethylene Oxide) PDFDocument134 pagesOxirane (Ethylene Oxide) PDFMuhammad Irfan Malik100% (1)

- RACOR 500FG Turbine SeriesDocument8 pagesRACOR 500FG Turbine Serieswarrimaint2No ratings yet

- Tree-Structure Canopy A Case Study in deDocument18 pagesTree-Structure Canopy A Case Study in deDrGanesh KameNo ratings yet

- Expansion& Construction Joint DetailsDocument2 pagesExpansion& Construction Joint DetailsMostafa SayedNo ratings yet

- Shoepolish CBSE Investigatory ProjectDocument10 pagesShoepolish CBSE Investigatory ProjectYashika Mani TripathiNo ratings yet

- 2012EU ACC ViewerDocument44 pages2012EU ACC ViewerDana LoreNo ratings yet

- MMLB 01 - 02 Manual GB - FR-FR PDFDocument8 pagesMMLB 01 - 02 Manual GB - FR-FR PDFAnonymous xBi2FsBxNo ratings yet

- Performance of Evaporative Cooling System Recirculating Pump in Re-Heating FurnaceDocument63 pagesPerformance of Evaporative Cooling System Recirculating Pump in Re-Heating FurnaceVijay KumarNo ratings yet

- Astm C 219 03Document3 pagesAstm C 219 03FelipeNo ratings yet

- s5113 Mm39 F.O Supply UnitDocument408 pagess5113 Mm39 F.O Supply UnitJorge AguilarNo ratings yet

- MEC531 Chapter 1 - BibiDocument64 pagesMEC531 Chapter 1 - BibiAfizi IzwanNo ratings yet

- Chemistry+Final+Exam+Practice+Problems,+Set+I+ (Dec +2022)Document4 pagesChemistry+Final+Exam+Practice+Problems,+Set+I+ (Dec +2022)srinath parvatine100% (1)

- SteelDocument20 pagesSteelShashank SaxenaNo ratings yet

- Aeromats Aeropress Aeropress 10s Aerovac GeneralDocument2 pagesAeromats Aeropress Aeropress 10s Aerovac Generalsaket2006No ratings yet

- New Household ItemsDocument30 pagesNew Household ItemsAstrael KokebNo ratings yet

- Duo-Chek II - The High Performance Check ValveDocument27 pagesDuo-Chek II - The High Performance Check ValveZak CahuichNo ratings yet

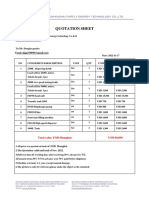

- Quotation Sheet From Farfly 11-17Document15 pagesQuotation Sheet From Farfly 11-17douglas guedez100% (1)

- TDS 805 PT SG NewDocument2 pagesTDS 805 PT SG NewWahyudi Rendiana NyotoNo ratings yet

- Bearing and Sealing Components: For Mechanical EngineeringDocument24 pagesBearing and Sealing Components: For Mechanical EngineeringramakantinamdarNo ratings yet

- Chemistry Quiz Chapter 6 Form 4 @Document5 pagesChemistry Quiz Chapter 6 Form 4 @Mohd Norihwan100% (1)