Professional Documents

Culture Documents

Nozzle FEA Calculation

Nozzle FEA Calculation

Uploaded by

berylqzCopyright:

Available Formats

You might also like

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- Solution: WE1 12 Nov 2008Document9 pagesSolution: WE1 12 Nov 2008aauppalNo ratings yet

- Crossover Area Calc For Floating HeadDocument2 pagesCrossover Area Calc For Floating HeadRitesh VishambhariNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Lug On SkidDocument8 pagesLug On Skidmiteshpatel191No ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh Patel100% (1)

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocument6 pagesSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarNo ratings yet

- Skirt Design - For Small VesselsDocument7 pagesSkirt Design - For Small VesselsSakthi VelNo ratings yet

- Pressure VesselDocument46 pagesPressure VesselHaftamu HilufNo ratings yet

- Dennis R Moss 4th EditionDocument5 pagesDennis R Moss 4th Editionsenthil kumarNo ratings yet

- Help For P-V Elite PDFDocument39 pagesHelp For P-V Elite PDFTushar MangratiNo ratings yet

- Design Calculation: Fuel Gas Scrubber TAG NO: V-6011Document239 pagesDesign Calculation: Fuel Gas Scrubber TAG NO: V-6011Peja Jusoh100% (1)

- H H Optimum 0,2: Instructions For Using NomogramDocument4 pagesH H Optimum 0,2: Instructions For Using NomogrammithunjobsNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Nozzle Check Top Head: Input ParametersDocument2 pagesNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Final Weld Strength CalnsDocument5 pagesFinal Weld Strength CalnsamachmouchiNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

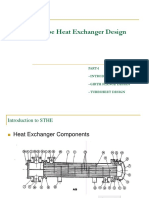

- STHE Design (Training Material)Document37 pagesSTHE Design (Training Material)Herman_ms2000100% (2)

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Wind Seismic Calculation DataDocument8 pagesWind Seismic Calculation Dataaknauriyal2013No ratings yet

- SHELL THICKNESS CHECK-ASME Section VIIIDocument2 pagesSHELL THICKNESS CHECK-ASME Section VIIIskocogluNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Cover Pages For PV Elite VenvelDocument14 pagesCover Pages For PV Elite VenvelSakthi VelNo ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Allowable Nozzle LoadsDocument7 pagesAllowable Nozzle LoadsSiva baalanNo ratings yet

- 003-Heat ExchangerDocument299 pages003-Heat ExchangerVijayshanker GuptaNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On Lugsandry4jc100% (1)

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNo ratings yet

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocument9 pagesCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNo ratings yet

- Saddle Reaction Summary - For Empty CaseDocument12 pagesSaddle Reaction Summary - For Empty CasesridharNo ratings yet

- TUBESHEETDocument5 pagesTUBESHEETMehta MehulNo ratings yet

- Tailing LugDocument12 pagesTailing LuguvarajmecheriNo ratings yet

- 06745JS2 (7) - Strength Calculations of Module4 (IBR)Document23 pages06745JS2 (7) - Strength Calculations of Module4 (IBR)Pratik Ray Chaudhury100% (3)

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- Design of Partition PlateDocument5 pagesDesign of Partition Platepippo2378793No ratings yet

- WRC 107 TipsDocument4 pagesWRC 107 Tipsyatin888No ratings yet

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDocument1 pageExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- FEA Check List For Expansion BellowDocument3 pagesFEA Check List For Expansion BellowRyan FisherNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- 10.1 Asme Viii A-13 Rectangular VesselDocument2 pages10.1 Asme Viii A-13 Rectangular Vesselpastyl100% (1)

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- Top Pipe MomentDocument2 pagesTop Pipe Momentrsubramani100% (1)

- Nozzle TestDocument9 pagesNozzle TestDarshan PanchalNo ratings yet

- Graphical ResultsDocument11 pagesGraphical Resultshgag selimNo ratings yet

- Test ReportDocument18 pagesTest ReportBilel MahjoubNo ratings yet

- Quick PrintDocument2 pagesQuick PrintSimeon ArabovNo ratings yet

- Nozzle Loads AnalysisDocument110 pagesNozzle Loads Analysishgag selimNo ratings yet

- Quick PrintDocument2 pagesQuick PrintSimeon ArabovNo ratings yet

- Aaaa XXX BBB XXX CCC XXX DDD XXX FFF XXXDocument3 pagesAaaa XXX BBB XXX CCC XXX DDD XXX FFF XXXberylqzNo ratings yet

- Calculation of Tir-Rod StiffnessDocument1 pageCalculation of Tir-Rod StiffnessberylqzNo ratings yet

- As-NZS1170.5 Seismic CoefficientDocument2 pagesAs-NZS1170.5 Seismic CoefficientberylqzNo ratings yet

- Flat Rectangular Plate With Four Sides Fixed Under Uniform PressureDocument4 pagesFlat Rectangular Plate With Four Sides Fixed Under Uniform PressureberylqzNo ratings yet

- My Own Tips For Using Solidworks SimulationDocument2 pagesMy Own Tips For Using Solidworks SimulationberylqzNo ratings yet

- Perforated Plate PDFDocument6 pagesPerforated Plate PDFberylqzNo ratings yet

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzNo ratings yet

- O RingsDocument211 pagesO Ringsberylqz100% (2)

- AnswersDocument5 pagesAnswers22 shantanu kapadnisNo ratings yet

- Transport Mechanisms in CellsDocument4 pagesTransport Mechanisms in Cellsd_94No ratings yet

- CH 21 Bridge Works - Super Structure - SteelDocument21 pagesCH 21 Bridge Works - Super Structure - SteelSubhash SinhaNo ratings yet

- Plastic Properties HandbookDocument15 pagesPlastic Properties HandbookguilloteARGNo ratings yet

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Document46 pagesPower Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Lösky D. PinnockNo ratings yet

- 2002 AriDocument53 pages2002 AriMbarouk Shaame MbaroukNo ratings yet

- Semi-Centrifugal Casting: An Extensive Analysis: Technical ReportDocument10 pagesSemi-Centrifugal Casting: An Extensive Analysis: Technical ReportS. R. OvhalNo ratings yet

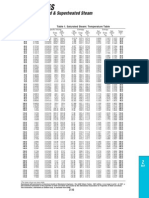

- Steam TablesDocument11 pagesSteam TablesARNOUXNo ratings yet

- Excel BasedDocument24 pagesExcel Basedelha e. maruquinNo ratings yet

- A Study On Some Durability Properties of Coconut Shell Aggregate ConcreteDocument13 pagesA Study On Some Durability Properties of Coconut Shell Aggregate ConcreteMa Victoria CaneteNo ratings yet

- Iqwq-Cpp-Grinv-00-0001 - 0Document24 pagesIqwq-Cpp-Grinv-00-0001 - 0வி.சுரேஷ் குமார்100% (1)

- Background of Titrino 702 Automatic TitratorDocument4 pagesBackground of Titrino 702 Automatic TitratorbuttamanatNo ratings yet

- Vol1i7x ECCC RecommandationsDocument21 pagesVol1i7x ECCC RecommandationsRami GhorbelNo ratings yet

- Mining: Supercritical Flow Critical Flow Subcritical FlowDocument3 pagesMining: Supercritical Flow Critical Flow Subcritical FlowBoonsita NammanaNo ratings yet

- ST Handout 3Document23 pagesST Handout 3SwagBeast SKJJNo ratings yet

- En Comparision TableDocument3 pagesEn Comparision TablenikhilnsbNo ratings yet

- Cosmoplast Upvc Drainage Pipes FittingsDocument34 pagesCosmoplast Upvc Drainage Pipes FittingsBahar AbdulqadirNo ratings yet

- Ppt-Sugarcane Bagasse AshDocument27 pagesPpt-Sugarcane Bagasse AshHegdeVenugopalNo ratings yet

- The Real Trick To Drying Ceramic Ware Is To Use A Method That Removes The Water From The Inside of The Ceramic As Fast As The Surface Water Is EvaporatedDocument55 pagesThe Real Trick To Drying Ceramic Ware Is To Use A Method That Removes The Water From The Inside of The Ceramic As Fast As The Surface Water Is EvaporatedMiguel OcampoNo ratings yet

- H2SDocument2 pagesH2Snsivasankar14No ratings yet

- Jurnal InternasionalDocument9 pagesJurnal InternasionalalninditaNo ratings yet

- 15 - Amines (New) PDFDocument25 pages15 - Amines (New) PDFthinkiitNo ratings yet

- Rotacoat 330 Q-CTSDocument2 pagesRotacoat 330 Q-CTSkkkkrolikNo ratings yet

- FCD 450-10Document2 pagesFCD 450-10MohammedFaisalGirachNo ratings yet

- Class X Half Yearly Exam Syllabus 2019 20Document6 pagesClass X Half Yearly Exam Syllabus 2019 20RahulNo ratings yet

- National Fire Protection Association-GoogleDocument2 pagesNational Fire Protection Association-GooglesandeepNo ratings yet

- INDOKOTE Company Profile-4Document8 pagesINDOKOTE Company Profile-4AvijitSinghNo ratings yet

- Time Date I. Objectives: A. Content StandardsDocument5 pagesTime Date I. Objectives: A. Content StandardsRod ReyesNo ratings yet

- Product Catalog PDFDocument979 pagesProduct Catalog PDFa7mos0% (1)

Nozzle FEA Calculation

Nozzle FEA Calculation

Uploaded by

berylqzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nozzle FEA Calculation

Nozzle FEA Calculation

Uploaded by

berylqzCopyright:

Available Formats

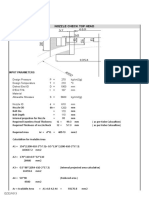

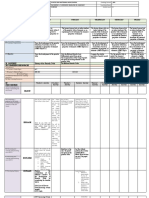

Model Notes (80 NB Shell, 32NB Nozzle)

Input Echo:

Model Type : Cylindrical Shell

Parent Outside Diameter : 88.900 mm.

Thickness : 5.490 mm.

Fillet Along Shell : 5.000 mm.

Parent Properties:

Material DB # 1068318.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1707E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm.(NOT USED)

Nozzle Outside Diameter : 42.100 mm.

Thickness : 3.680 mm.

Length : 150.000 mm.

Nozzle Weld Length : 5.000 mm.

Nozzle Tilt Angle : 0.000 deg.

Distance from Top : 0.000 mm.

Distance from Bottom : 500.000 mm.

Nozzle Properties

Material DB # 1064818.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1707E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm. (NOT USED)

Design Operating Cycles : 7000.

Ambient Temperature (Deg.) : 21.10

The following temperatures have been specified for the analysis:

Nozzle Inside Temperature : 200.00 deg.

Nozzle Outside Temperature : 200.00 deg.

Vessel Inside Temperature : 200.00 deg.

Vessel Outside Temperature : 200.00 deg.

Nozzle Pressure : 2.800 MPa

Vessel Pressure : 2.800 MPa

User Defined Load Input Echo:

Loads are given at the Nozzle/Header Junction

Loads are defined in Local Coordinatesc

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 1200.0 1200.0 1200.0 350.0 350.0 350.0

FEA Model Loads:

These are the actual loads applied to the FEA model.

These are the User Defined Loads translated to the

end of the nozzle and reported in global coordinates.

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 1200.0 1200.0 1200.0 350.0 530.0 170.0

The "top" or "positive" end of this model is "free" in

the axial and translational directions.

Stresses ARE nodally AVERAGED.

Vessel Centerline Vector : 0.000 1.000 0.000

Nozzle Orientation Vector : 1.000 0.000 0.000

Table of Contents

Load Case Report

Inner and outer element temperatures are the same

throughout the model. No thermal ratcheting

calculations will be performed.

THE 8 LOAD CASES ANALYZED ARE:

1 SUSTAINED (Pr Only)

Sustained case run to satisfy local primary

membrane and bending stress limits.

/-------- Loads in Case 1

Pressure Case 1

2 Thermal ONLY

Thermal ONLY case run in the event expansion

stresses exceed the secondary stress allowable.

/-------- Loads in Case 2

Temperature Case 1

3 OPERATING (Fatigue Calc Performed)

Case run to compute the operating stresses used in

secondary, peak and range calculations as needed.

/-------- Loads in Case 3

Pressure Case 1

Temperature Case 1

Loads from (Operating)

4 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 4

Loads from (Axial)

5 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 5

Loads from (Inplane)

6 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 6

Loads from (Outplane)

7 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 7

Loads from (Torsion)

8 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 8

Pressure Case 1

Table of Contents

Solution Data

Maximum Solution Row Size = 870

Number of Nodes = 2112

Number of Elements = 696

Number of Solution Cases = 8

Summation of Loads per Case

Case # FX FY FZ

1 -528. 15309. 0.

2 0. 0. 0.

3 672. 16509. 1200.

4 353202. 0. 0.

5 0. 0. 0.

6 0. 0. 0.

7 0. 0. 0.

8 -528. 15309. 0.

Table of Contents

ASME Code Stress Output Plots

1) Pl < (1.5)(S) (SUS,Membrane) Case 1

2) Qb < SPS (SUS,Bending) Case 1

3) S1+S2+S3 < 4S (SUS,S1+S2+S3) Case 1

4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

8) Membrane < User (OPE,Membrane) Case 3

9) Bending < User (OPE,Bending) Case 3

10) Pl+Pb+Q+F < Sa (SIF,Outside) Case 4

11) Pl+Pb+Q+F < Sa (SIF,Outside) Case 5

12) Pl+Pb+Q+F < Sa (SIF,Outside) Case 6

13) Pl+Pb+Q+F < Sa (SIF,Outside) Case 7

14) Pl+Pb+Q+F < Sa (SIF,Outside) Case 8

Table of Contents

Region Data

Header Next to Nozzle Weld

Cold Allowable ........... 138. MPa

Hot Allowable @ 200 deg .. 133. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 237. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 795. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.680 mm.

Stress Concentration ..... 1.350

Branch Next to Header Weld

Cold Allowable ........... 115. MPa

Hot Allowable @ 200 deg .. 109. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 237. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 795. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.680 mm.

Stress Concentration ..... 1.350

Branch Transition

Cold Allowable ........... 115. MPa

Hot Allowable @ 200 deg .. 109. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 237. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 795. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.680 mm.

Stress Concentration ..... 1.350

Header away from Junction

Cold Allowable ........... 138. MPa

Hot Allowable @ 200 deg .. 133. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 237. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 795. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.680 mm.

Stress Concentration ..... 1.000

Branch away from Junction

Cold Allowable ........... 115. MPa

Hot Allowable @ 200 deg .. 109. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 237. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 795. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 90. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.680 mm.

Stress Concentration ..... 1.000

Table of Contents

Stress Results - Notes

- Results in this analysis were generated using the finite

element solution method.

- Using post 07 ASME Section VIII Division 2

- Use Polished Bar fatigue curve.

- Ratio between Operating and Design Pressure = 0.9000000

Assume pressure increases all other stresses.

Use operating pressure for occasional load cases.

- Assume free end displacements of attached pipe are

secondary loads within limits of nozzle reinforcement.

- Use Equivalent Stress (Von Mises).

- S1+S2+S3 evaluation omitted from operating stress.

Include S1+S2+S3 evaluation in primary case evaluation.

Assume bending stress not local primary for S1+S2+S3.

Table of Contents

ASME Overstressed Areas

*** NO OVERSTRESSED NODES IN THIS MODEL ***

Table of Contents

Highest Primary Stress Ratios

Header Next to Nozzle Weld

Pl (1.5)(S) Primary Membrane Load Case 1

24 200 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

12%

Branch Next to Header Weld

Pl (1.5)(S) Primary Membrane Load Case 1

15 163 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

9%

Branch Transition

Pl (1.5)(S) Primary Membrane Load Case 1

14 163 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

8%

Header away from Junction

Pl (1.5)(S) Primary Membrane Load Case 1

22 200 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

10%

Branch away from Junction

Pl (1.5)(S) Primary Membrane Load Case 1

14 163 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

8%

Table of Contents

Highest Secondary Stress Ratios

Header Next to Nozzle Weld

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

290 407 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

71%

Branch Next to Header Weld

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

312 336 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

92%

Branch Transition

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

193 336 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

57%

Header away from Junction

Pl+Pb+Q SPS Primary+Secondary (Inner) Load Case 3

106 407 Plot Reference:

MPa MPa 4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

26%

Branch away from Junction

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

147 336 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

43%

Table of Contents

Highest Fatigue Stress Ratios

Header Next to Nozzle Weld

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

196 0.007 Life Stress Concentration Factor = 1.350

MPa 0.406 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 944,526.

Allowable "B31" Fatigue Stress Allowable = 339.2

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 317,661.

WRC 474 99% Probability Cycles = 73,796.

40% WRC 474 95% Probability Cycles = 102,456.

BS5500 Allowed Cycles(Curve F) = 31,790.

Membrane-to-Bending Ratio = 0.602

Bending-to-PL+PB+Q Ratio = 0.624

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Branch Next to Header Weld

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

211 0.013 Life Stress Concentration Factor = 1.350

MPa 0.437 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 552,854.

Allowable "B31" Fatigue Stress Allowable = 279.9

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 319,984.

WRC 474 99% Probability Cycles = 74,335.

43% WRC 474 95% Probability Cycles = 103,205.

BS5500 Allowed Cycles(Curve F) = 18,610.

Membrane-to-Bending Ratio = 0.783

Bending-to-PL+PB+Q Ratio = 0.561

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Branch Transition

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

130 0.002 Life Stress Concentration Factor = 1.350

MPa 0.270 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 4,505,958.

Allowable "B31" Fatigue Stress Allowable = 279.9

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 1,368,181.

WRC 474 99% Probability Cycles = 317,841.

26% WRC 474 95% Probability Cycles = 441,282.

BS5500 Allowed Cycles(Curve F) = 108,897.

Membrane-to-Bending Ratio = 2.063

Bending-to-PL+PB+Q Ratio = 0.327

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Header away from Junction

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Inner) Load Case 3

53 0.000 Life Stress Concentration Factor = 1.000

MPa 0.110 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1.0000E11

Allowable "B31" Fatigue Stress Allowable = 339.2

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 7,399,607.

WRC 474 99% Probability Cycles = 1,718,996.

11% WRC 474 95% Probability Cycles = 2,386,610.

BS5500 Allowed Cycles(Curve F) = 644,618.

Membrane-to-Bending Ratio = 0.330

Bending-to-PL+PB+Q Ratio = 0.752

Plot Reference:

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

Branch away from Junction

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

73 0.000 Life Stress Concentration Factor = 1.000

MPa 0.152 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1.0000E11

Allowable "B31" Fatigue Stress Allowable = 279.9

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 3,121,431.

WRC 474 99% Probability Cycles = 725,137.

15% WRC 474 95% Probability Cycles = 1,006,761.

BS5500 Allowed Cycles(Curve F) = 245,942.

Membrane-to-Bending Ratio = 22.788

Bending-to-PL+PB+Q Ratio = 0.042

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Table of Contents

Stress Intensification Factors

Branch/Nozzle Sif Summary

Peak Primary Secondary

Axial : 3.289 1.835 4.873

Inplane : 1.144 0.926 1.695

Outplane: 1.934 1.097 2.866

Torsion : 0.816 0.985 1.209

Pressure: 0.879 1.069 1.303

The above stress intensification factors are to be used

in a beam-type analysis of the piping system. Inplane,

Outplane and Torsional sif's should be used with the

matching branch pipe whose diameter and thickness is given

below. The axial sif should be used to intensify the

axial stress in the branch pipe calculated by F/A. The

pressure sif should be used to intensify the nominal

pressure stress in the PARENT or HEADER, calculated

from PD/2T.

Pipe OD : 42.100 mm.

Pipe Thk: 3.680 mm.

Z approx: 4266.306 cu.mm.

Z exact : 3929.104 cu.mm.

B31.3 Branch Pressure i-factor = 2.490

Header Pressure i-factor = 1.759

The B31.3 pressure i-factors should be used with with

F/A, where F is the axial force due to pressure, and

A is the area of the pipe wall. This is equivalent to

finding the pressure stress from (ip)(PD/4T).

B31.3

Peak Stress Sif .... 0.000 Axial

1.916 Inplane

2.331 Outplane

1.000 Torsional

B31.1

Peak Stress Sif .... 0.000 Axial

2.407 Inplane

2.407 Outplane

2.407 Torsional

WRC 330

Peak Stress Sif .... 0.000 Axial

1.488 Inplane

1.624 Outplane

1.000 Torsional

Table of Contents

Allowable Loads

SECONDARY Maximum Conservative Realistic

Load Type (Range): Individual Simultaneous Simultaneous

Occuring Occuring Occuring

Axial Force ( N ) 30620. 9666. 14499.

Inplane Moment (mm. N ) 778910. 173873. 368839.

Outplane Moment (mm. N ) 460549. 102806. 218085.

Torsional Moment (mm. N ) 1091422. 344549. 516824.

Pressure (MPa ) 36.82 2.80 2.80

PRIMARY Maximum Conservative Realistic

Load Type: Individual Simultaneous Simultaneous

Occuring Occuring Occuring

Axial Force ( N ) 39515. 11979. 17969.

Inplane Moment (mm. N ) 692745. 149258. 316625.

Outplane Moment (mm. N ) 584368. 125267. 265732.

Torsional Moment (mm. N ) 651047. 197369. 296054.

Pressure (MPa ) 23.13 2.80 2.80

NOTES:

1) Maximum Individual Occuring Loads are the maximum

allowed values of the respective loads if all other

load components are zero, i.e. the listed axial force

may be applied if the inplane, outplane and torsional

moments, and the pressure are zero.

2) The Conservative Allowable Simultaneous loads are

the maximum loads that can be applied simultaneously.

A conservative stress combination equation is used

that typically produces stresses within 50-70% of the

allowable stress.

3) The Realistic Allowable Simultaneous loads are the

maximum loads that can be applied simultaneously. A

more realistic stress combination equation is used

based on experience at Paulin Research. Stresses are

typically produced within 80-105% of the allowable.

4) Secondary allowable loads are limits for expansion

and operating piping loads.

5) Primary allowable loads are limits for weight,

primary and sustained type piping loads.

Table of Contents

Flexibilities

The following stiffnesses should be used in a piping,

"beam-type" analysis of the intersection. The stiff-

nesses should be inserted at the surface of the

branch/header or nozzle/vessel junction. The general

characteristics used for the branch pipe should be:

Outside Diameter = 42.100 mm.

Wall Thickness = 3.680 mm.

Axial Translational Stiffness = 328869. N /mm.

Inplane Rotational Stiffness = 5227770. mm. N /deg

Outplane Rotational Stiffness = 2134740. mm. N /deg

Torsional Rotational Stiffness = 17393708. mm. N /deg

Intersection Flexibility Factors for

Branch/Nozzle :

Find axial stiffness: K = 3EI/(kd)^3 N /mm.

Find bending and torsional stiffnesses: K = EI/(kd) mm. N per radian.

The EI product is 0.16128E+11 N mm.^2

The value of (d) to use is: 38.420 mm..

The resulting bending stiffness is in units of force x length per radian.

Axial Flexibility Factor (k) = 1.374

Inplane Flexibility Factor (k) = 1.401

Outplane Flexibility Factor (k) = 3.432

Torsional Flexibility Factor (k) = 0.421

Model Notes (80NB Shell, 25NB nozzle)

Input Echo:

Model Type : Cylindrical Shell

Parent Outside Diameter : 88.900 mm.

Thickness : 5.490 mm.

Fillet Along Shell : 5.000 mm.

Parent Properties:

Material DB # 1068318.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1707E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm.(NOT USED)

Nozzle Outside Diameter : 33.500 mm.

Thickness : 3.380 mm.

Length : 150.000 mm.

Nozzle Weld Length : 5.000 mm.

Nozzle Tilt Angle : 0.000 deg.

Distance from Top : 0.000 mm.

Distance from Bottom : 500.000 mm.

Nozzle Properties

Material DB # 1064818.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1707E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm. (NOT USED)

Design Operating Cycles : 7000.

Ambient Temperature (Deg.) : 21.10

The following temperatures have been specified for the analysis:

Nozzle Inside Temperature : 200.00 deg.

Nozzle Outside Temperature : 200.00 deg.

Vessel Inside Temperature : 200.00 deg.

Vessel Outside Temperature : 200.00 deg.

Nozzle Pressure : 2.800 MPa

Vessel Pressure : 2.800 MPa

User Defined Load Input Echo:

Loads are given at the Nozzle/Header Junction

Loads are defined in Local Coordinatesc

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 1100.0 1100.0 1100.0 250.0 250.0 250.0

FEA Model Loads:

These are the actual loads applied to the FEA model.

These are the User Defined Loads translated to the

end of the nozzle and reported in global coordinates.

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 1100.0 1100.0 1100.0 250.0 415.0 85.0

The "top" or "positive" end of this model is "free" in

the axial and translational directions.

Stresses ARE nodally AVERAGED.

Vessel Centerline Vector : 0.000 1.000 0.000

Nozzle Orientation Vector : 1.000 0.000 0.000

Table of Contents

Load Case Report

Inner and outer element temperatures are the same

throughout the model. No thermal ratcheting

calculations will be performed.

THE 8 LOAD CASES ANALYZED ARE:

1 SUSTAINED (Pr Only)

Sustained case run to satisfy local primary

membrane and bending stress limits.

/-------- Loads in Case 1

Pressure Case 1

2 Thermal ONLY

Thermal ONLY case run in the event expansion

stresses exceed the secondary stress allowable.

/-------- Loads in Case 2

Temperature Case 1

3 OPERATING (Fatigue Calc Performed)

Case run to compute the operating stresses used in

secondary, peak and range calculations as needed.

/-------- Loads in Case 3

Pressure Case 1

Temperature Case 1

Loads from (Operating)

4 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 4

Loads from (Axial)

5 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 5

Loads from (Inplane)

6 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 6

Loads from (Outplane)

7 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 7

Loads from (Torsion)

8 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 8

Pressure Case 1

Table of Contents

Solution Data

Maximum Solution Row Size = 870

Number of Nodes = 2256

Number of Elements = 744

Number of Solution Cases = 8

Summation of Loads per Case

Case # FX FY FZ

1 -455. 15299. 0.

2 0. 0. 0.

3 645. 16399. 1100.

4 205408. 0. 0.

5 0. 0. 0.

6 0. 0. 0.

7 0. 0. 0.

8 -455. 15299. 0.

Table of Contents

ASME Code Stress Output Plots

1) Pl < (1.5)(S) (SUS,Membrane) Case 1

2) Qb < SPS (SUS,Bending) Case 1

3) S1+S2+S3 < 4S (SUS,S1+S2+S3) Case 1

4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

8) Membrane < User (OPE,Membrane) Case 3

9) Bending < User (OPE,Bending) Case 3

10) Pl+Pb+Q+F < Sa (SIF,Outside) Case 4

11) Pl+Pb+Q+F < Sa (SIF,Outside) Case 5

12) Pl+Pb+Q+F < Sa (SIF,Outside) Case 6

13) Pl+Pb+Q+F < Sa (SIF,Outside) Case 7

14) Pl+Pb+Q+F < Sa (SIF,Outside) Case 8

Table of Contents

Region Data

Header Next to Nozzle Weld

Cold Allowable ........... 138. MPa

Hot Allowable @ 200 deg .. 133. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 337. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 642. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.380 mm.

Stress Concentration ..... 1.350

Branch Next to Header Weld

Cold Allowable ........... 115. MPa

Hot Allowable @ 200 deg .. 109. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 337. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 642. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.380 mm.

Stress Concentration ..... 1.350

Branch Transition

Cold Allowable ........... 115. MPa

Hot Allowable @ 200 deg .. 109. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 337. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 642. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.380 mm.

Stress Concentration ..... 1.350

Header away from Junction

Cold Allowable ........... 138. MPa

Hot Allowable @ 200 deg .. 133. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 337. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 642. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.380 mm.

Stress Concentration ..... 1.000

Branch away from Junction

Cold Allowable ........... 115. MPa

Hot Allowable @ 200 deg .. 109. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 3

Nominal Stress (M/Z) ... 337. MPa

Pressure Stress (Pd/2t) .. 23. MPa

Case 4

Nominal Stress (M/Z) ... 642. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 94. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 23. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 3.380 mm.

Stress Concentration ..... 1.000

Table of Contents

Stress Results - Notes

- Results in this analysis were generated using the finite

element solution method.

- Using post 07 ASME Section VIII Division 2

- Use Polished Bar fatigue curve.

- Ratio between Operating and Design Pressure = 0.9000000

Assume pressure increases all other stresses.

Use operating pressure for occasional load cases.

- Assume free end displacements of attached pipe are

secondary loads within limits of nozzle reinforcement.

- Use Equivalent Stress (Von Mises).

- S1+S2+S3 evaluation omitted from operating stress.

Include S1+S2+S3 evaluation in primary case evaluation.

Assume bending stress not local primary for S1+S2+S3.

Table of Contents

ASME Overstressed Areas

*** NO OVERSTRESSED NODES IN THIS MODEL ***

Table of Contents

Highest Primary Stress Ratios

Header Next to Nozzle Weld

Pl (1.5)(S) Primary Membrane Load Case 1

22 200 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

11%

Branch Next to Header Weld

Pl (1.5)(S) Primary Membrane Load Case 1

11 163 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

6%

Branch Transition

Pl (1.5)(S) Primary Membrane Load Case 1

12 163 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

7%

Header away from Junction

Pl (1.5)(S) Primary Membrane Load Case 1

20 200 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

10%

Branch away from Junction

Pl (1.5)(S) Primary Membrane Load Case 1

12 163 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

7%

Table of Contents

Highest Secondary Stress Ratios

Header Next to Nozzle Weld

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

286 407 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

70%

Branch Next to Header Weld

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

322 336 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

95%

Branch Transition

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

254 336 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

75%

Header away from Junction

Pl+Pb+Q SPS Primary+Secondary (Inner) Load Case 3

100 407 Plot Reference:

MPa MPa 4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

24%

Branch away from Junction

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

182 336 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

54%

Table of Contents

Highest Fatigue Stress Ratios

Header Next to Nozzle Weld

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

193 0.007 Life Stress Concentration Factor = 1.350

MPa 0.400 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1,026,306.

Allowable "B31" Fatigue Stress Allowable = 339.2

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 335,511.

WRC 474 99% Probability Cycles = 77,942.

40% WRC 474 95% Probability Cycles = 108,213.

BS5500 Allowed Cycles(Curve F) = 33,329.

Membrane-to-Bending Ratio = 0.561

Bending-to-PL+PB+Q Ratio = 0.640

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Branch Next to Header Weld

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

218 0.016 Life Stress Concentration Factor = 1.350

MPa 0.452 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 446,366.

Allowable "B31" Fatigue Stress Allowable = 279.9

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 302,511.

WRC 474 99% Probability Cycles = 70,276.

45% WRC 474 95% Probability Cycles = 97,570.

BS5500 Allowed Cycles(Curve F) = 15,731.

Membrane-to-Bending Ratio = 0.920

Bending-to-PL+PB+Q Ratio = 0.521

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Branch Transition

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

172 0.005 Life Stress Concentration Factor = 1.350

MPa 0.356 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1,503,594.

Allowable "B31" Fatigue Stress Allowable = 279.9

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 609,573.

WRC 474 99% Probability Cycles = 141,609.

35% WRC 474 95% Probability Cycles = 196,607.

BS5500 Allowed Cycles(Curve F) = 47,359.

Membrane-to-Bending Ratio = 2.060

Bending-to-PL+PB+Q Ratio = 0.327

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Header away from Junction

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Inner) Load Case 3

50 0.000 Life Stress Concentration Factor = 1.000

MPa 0.103 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1.0000E11

Allowable "B31" Fatigue Stress Allowable = 339.2

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 9,028,427.

WRC 474 99% Probability Cycles = 2,097,386.

10% WRC 474 95% Probability Cycles = 2,911,956.

BS5500 Allowed Cycles(Curve F) = 783,499.

Membrane-to-Bending Ratio = 0.349

Bending-to-PL+PB+Q Ratio = 0.741

Plot Reference:

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

Branch away from Junction

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

91 0.000 Life Stress Concentration Factor = 1.000

MPa 0.189 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1.0000E11

Allowable "B31" Fatigue Stress Allowable = 279.9

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 1,680,991.

WRC 474 99% Probability Cycles = 390,510.

18% WRC 474 95% Probability Cycles = 542,173.

BS5500 Allowed Cycles(Curve F) = 128,176.

Membrane-to-Bending Ratio = 15.094

Bending-to-PL+PB+Q Ratio = 0.062

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Table of Contents

Stress Intensification Factors

Branch/Nozzle Sif Summary

Peak Primary Secondary

Axial : 2.772 1.656 4.107

Inplane : 1.048 0.911 1.553

Outplane: 1.480 0.921 2.192

Torsion : 0.764 0.919 1.131

Pressure: 0.799 0.980 1.184

The above stress intensification factors are to be used

in a beam-type analysis of the piping system. Inplane,

Outplane and Torsional sif's should be used with the

matching branch pipe whose diameter and thickness is given

below. The axial sif should be used to intensify the

axial stress in the branch pipe calculated by F/A. The

pressure sif should be used to intensify the nominal

pressure stress in the PARENT or HEADER, calculated

from PD/2T.

Pipe OD : 33.500 mm.

Pipe Thk: 3.380 mm.

Z approx: 2408.331 cu.mm.

Z exact : 2192.609 cu.mm.

B31.3 Branch Pressure i-factor = 2.611

Header Pressure i-factor = 1.598

The B31.3 pressure i-factors should be used with with

F/A, where F is the axial force due to pressure, and

A is the area of the pipe wall. This is equivalent to

finding the pressure stress from (ip)(PD/4T).

B31.3

Peak Stress Sif .... 0.000 Axial

1.760 Inplane

2.141 Outplane

1.000 Torsional

B31.1

Peak Stress Sif .... 0.000 Axial

1.928 Inplane

1.928 Outplane

1.928 Torsional

WRC 330

Peak Stress Sif .... 0.000 Axial

1.314 Inplane

1.500 Outplane

1.000 Torsional

Table of Contents

Allowable Loads

SECONDARY Maximum Conservative Realistic

Load Type (Range): Individual Simultaneous Simultaneous

Occuring Occuring Occuring

Axial Force ( N ) 26161. 8332. 12498.

Inplane Moment (mm. N ) 474306. 106818. 226594.

Outplane Moment (mm. N ) 336002. 75670. 160521.

Torsional Moment (mm. N ) 651026. 207347. 311020.

Pressure (MPa ) 42.47 2.80 2.80

PRIMARY Maximum Conservative Realistic

Load Type: Individual Simultaneous Simultaneous

Occuring Occuring Occuring

Axial Force ( N ) 31517. 9772. 14659.

Inplane Moment (mm. N ) 392661. 85818. 182047.

Outplane Moment (mm. N ) 388545. 84939. 180183.

Torsional Moment (mm. N ) 389298. 120709. 181064.

Pressure (MPa ) 25.22 2.80 2.80

NOTES:

1) Maximum Individual Occuring Loads are the maximum

allowed values of the respective loads if all other

load components are zero, i.e. the listed axial force

may be applied if the inplane, outplane and torsional

moments, and the pressure are zero.

2) The Conservative Allowable Simultaneous loads are

the maximum loads that can be applied simultaneously.

A conservative stress combination equation is used

that typically produces stresses within 50-70% of the

allowable stress.

3) The Realistic Allowable Simultaneous loads are the

maximum loads that can be applied simultaneously. A

more realistic stress combination equation is used

based on experience at Paulin Research. Stresses are

typically produced within 80-105% of the allowable.

4) Secondary allowable loads are limits for expansion

and operating piping loads.

5) Primary allowable loads are limits for weight,

primary and sustained type piping loads.

Table of Contents

Flexibilities

The following stiffnesses should be used in a piping,

"beam-type" analysis of the intersection. The stiff-

nesses should be inserted at the surface of the

branch/header or nozzle/vessel junction. The general

characteristics used for the branch pipe should be:

Outside Diameter = 33.500 mm.

Wall Thickness = 3.380 mm.

Axial Translational Stiffness = 252619. N /mm.

Inplane Rotational Stiffness = 3489170. mm. N /deg

Outplane Rotational Stiffness = 1513391. mm. N /deg

Torsional Rotational Stiffness = 15530895. mm. N /deg

Intersection Flexibility Factors for

Branch/Nozzle :

Find axial stiffness: K = 3EI/(kd)^3 N /mm.

Find bending and torsional stiffnesses: K = EI/(kd) mm. N per radian.

The EI product is 0.71616E+10 N mm.^2

The value of (d) to use is: 30.120 mm..

The resulting bending stiffness is in units of force x length per radian.

Axial Flexibility Factor (k) = 1.460

Inplane Flexibility Factor (k) = 1.189

Outplane Flexibility Factor (k) = 2.742

Torsional Flexibility Factor (k) = 0.267

Model Notes

Input Echo:

Model Type : Cylindrical Shell

Parent Outside Diameter : 114.300 mm.

Thickness : 6.020 mm.

Fillet Along Shell : 5.000 mm.

Parent Properties:

Material DB # 1085918.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1740E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm.(NOT USED)

Nozzle Outside Diameter : 60.300 mm.

Thickness : 5.540 mm.

Length : 150.000 mm.

Nozzle Weld Length : 5.000 mm.

Nozzle Tilt Angle : 0.000 deg.

Distance from Top : 0.000 mm.

Distance from Bottom : 500.000 mm.

Nozzle Properties

Material DB # 1068318.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1740E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm. (NOT USED)

Design Operating Cycles : 7000.

Ambient Temperature (Deg.) : 21.10

The following temperatures have been specified for the analysis:

Nozzle Inside Temperature : 250.00 deg.

Nozzle Outside Temperature : 250.00 deg.

Vessel Inside Temperature : 250.00 deg.

Vessel Outside Temperature : 250.00 deg.

Nozzle Pressure : 2.800 MPa

Vessel Pressure : 2.800 MPa

User Defined Load Input Echo:

Loads are given at the Nozzle/Header Junction

Loads are defined in Local Coordinatesc

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 1700.0 1700.0 1700.0 650.0 650.0 650.0

FEA Model Loads:

These are the actual loads applied to the FEA model.

These are the User Defined Loads translated to the

end of the nozzle and reported in global coordinates.

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 1700.0 1700.0 1700.0 650.0 905.0 395.0

The "top" or "positive" end of this model is "free" in

the axial and translational directions.

Stresses ARE nodally AVERAGED.

Vessel Centerline Vector : 0.000 1.000 0.000

Nozzle Orientation Vector : 1.000 0.000 0.000

Table of Contents

Load Case Report

Inner and outer element temperatures are the same

throughout the model. No thermal ratcheting

calculations will be performed.

THE 8 LOAD CASES ANALYZED ARE:

1 SUSTAINED (Pr Only)

Sustained case run to satisfy local primary

membrane and bending stress limits.

/-------- Loads in Case 1

Pressure Case 1

2 Thermal ONLY

Thermal ONLY case run in the event expansion

stresses exceed the secondary stress allowable.

/-------- Loads in Case 2

Temperature Case 1

3 OPERATING (Fatigue Calc Performed)

Case run to compute the operating stresses used in

secondary, peak and range calculations as needed.

/-------- Loads in Case 3

Pressure Case 1

Temperature Case 1

Loads from (Operating)

4 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 4

Loads from (Axial)

5 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 5

Loads from (Inplane)

6 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 6

Loads from (Outplane)

7 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 7

Loads from (Torsion)

8 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 8

Pressure Case 1

Table of Contents

Solution Data

Maximum Solution Row Size = 1296

Number of Nodes = 3076

Number of Elements = 1012

Number of Solution Cases = 8

Summation of Loads per Case

Case # FX FY FZ

1 -1294. 25806. 0.

2 0. 0. 0.

3 406. 27507. 1700.

4 1090827. 0. 0.

5 0. 0. 0.

6 0. 0. 0.

7 0. 0. 0.

8 -1294. 25806. 0.

Table of Contents

ASME Code Stress Output Plots

1) Pl < (1.5)(S) (SUS,Membrane) Case 1

2) Qb < SPS (SUS,Bending) Case 1

3) S1+S2+S3 < 4S (SUS,S1+S2+S3) Case 1

4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

8) Membrane < User (OPE,Membrane) Case 3

9) Bending < User (OPE,Bending) Case 3

10) Pl+Pb+Q+F < Sa (SIF,Outside) Case 4

11) Pl+Pb+Q+F < Sa (SIF,Outside) Case 5

12) Pl+Pb+Q+F < Sa (SIF,Outside) Case 6

13) Pl+Pb+Q+F < Sa (SIF,Outside) Case 7

14) Pl+Pb+Q+F < Sa (SIF,Outside) Case 8

Table of Contents

Region Data

Header Next to Nozzle Weld

Cold Allowable ........... 138. MPa

Hot Allowable @ 250 deg .. 122. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 3

Nominal Stress (M/Z) ... 134. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 4

Nominal Stress (M/Z) ... 1145. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 27. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 5.540 mm.

Stress Concentration ..... 1.350

Branch Next to Header Weld

Cold Allowable ........... 138. MPa

Hot Allowable @ 250 deg .. 126. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 3

Nominal Stress (M/Z) ... 134. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 4

Nominal Stress (M/Z) ... 1145. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 27. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 5.540 mm.

Stress Concentration ..... 1.350

Branch Transition

Cold Allowable ........... 138. MPa

Hot Allowable @ 250 deg .. 126. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 3

Nominal Stress (M/Z) ... 134. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 4

Nominal Stress (M/Z) ... 1145. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 27. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 5.540 mm.

Stress Concentration ..... 1.350

Header away from Junction

Cold Allowable ........... 138. MPa

Hot Allowable @ 250 deg .. 122. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 3

Nominal Stress (M/Z) ... 134. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 4

Nominal Stress (M/Z) ... 1145. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 27. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 5.540 mm.

Stress Concentration ..... 1.000

Branch away from Junction

Cold Allowable ........... 138. MPa

Hot Allowable @ 250 deg .. 126. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 3

Nominal Stress (M/Z) ... 134. MPa

Pressure Stress (Pd/2t) .. 27. MPa

Case 4

Nominal Stress (M/Z) ... 1145. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 27. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 5.540 mm.

Stress Concentration ..... 1.000

Table of Contents

Stress Results - Notes

- Results in this analysis were generated using the finite

element solution method.

- Using post 07 ASME Section VIII Division 2

- Use Polished Bar fatigue curve.

- Ratio between Operating and Design Pressure = 0.9000000

Assume pressure increases all other stresses.

Use operating pressure for occasional load cases.

- Assume free end displacements of attached pipe are

secondary loads within limits of nozzle reinforcement.

- Use Equivalent Stress (Von Mises).

- S1+S2+S3 evaluation omitted from operating stress.

Include S1+S2+S3 evaluation in primary case evaluation.

Assume bending stress not local primary for S1+S2+S3.

Table of Contents

ASME Overstressed Areas

*** NO OVERSTRESSED NODES IN THIS MODEL ***

Table of Contents

Highest Primary Stress Ratios

Header Next to Nozzle Weld

Pl (1.5)(S) Primary Membrane Load Case 1

31 182 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

17%

Branch Next to Header Weld

Pl (1.5)(S) Primary Membrane Load Case 1

20 189 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

10%

Branch Transition

Pl (1.5)(S) Primary Membrane Load Case 1

14 189 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

7%

Header away from Junction

Pl (1.5)(S) Primary Membrane Load Case 1

24 182 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

13%

Branch away from Junction

Pl (1.5)(S) Primary Membrane Load Case 1

14 189 Plot Reference:

MPa MPa 1) Pl < (1.5)(S) (SUS,Membrane) Case 1

7%

Table of Contents

Highest Secondary Stress Ratios

Header Next to Nozzle Weld

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

313 389 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

80%

Branch Next to Header Weld

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

258 395 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

65%

Branch Transition

Pl+Pb+Q SPS Primary+Secondary (Outer) Load Case 3

115 395 Plot Reference:

MPa MPa 5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

29%

Header away from Junction

Pl+Pb+Q SPS Primary+Secondary (Inner) Load Case 3

107 389 Plot Reference:

MPa MPa 4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

27%

Branch away from Junction

Pl+Pb+Q SPS Primary+Secondary (Inner) Load Case 3

94 395 Plot Reference:

MPa MPa 4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

23%

Table of Contents

Highest Fatigue Stress Ratios

Header Next to Nozzle Weld

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

211 0.013 Life Stress Concentration Factor = 1.350

MPa 0.438 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 542,806.

Allowable "B31" Fatigue Stress Allowable = 324.4

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 237,731.

WRC 474 99% Probability Cycles = 55,227.

43% WRC 474 95% Probability Cycles = 76,676.

BS5500 Allowed Cycles(Curve F) = 25,335.

Membrane-to-Bending Ratio = 0.544

Bending-to-PL+PB+Q Ratio = 0.648

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Branch Next to Header Weld

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

174 0.005 Life Stress Concentration Factor = 1.350

MPa 0.361 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1,433,146.

Allowable "B31" Fatigue Stress Allowable = 329.5

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 446,978.

WRC 474 99% Probability Cycles = 103,837.

36% WRC 474 95% Probability Cycles = 144,165.

BS5500 Allowed Cycles(Curve F) = 45,313.

Membrane-to-Bending Ratio = 0.674

Bending-to-PL+PB+Q Ratio = 0.597

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Branch Transition

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Outer) Load Case 3

78 0.000 Life Stress Concentration Factor = 1.350

MPa 0.161 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1.0000E11

Allowable "B31" Fatigue Stress Allowable = 329.5

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 5,160,248.

WRC 474 99% Probability Cycles = 1,198,772.

16% WRC 474 95% Probability Cycles = 1,664,344.

BS5500 Allowed Cycles(Curve F) = 510,190.

Membrane-to-Bending Ratio = 1.897

Bending-to-PL+PB+Q Ratio = 0.345

Plot Reference:

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

Header away from Junction

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Inner) Load Case 3

53 0.000 Life Stress Concentration Factor = 1.000

MPa 0.111 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1.0000E11

Allowable "B31" Fatigue Stress Allowable = 324.4

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 6,838,555.

WRC 474 99% Probability Cycles = 1,588,658.

11% WRC 474 95% Probability Cycles = 2,205,652.

BS5500 Allowed Cycles(Curve F) = 640,861.

Membrane-to-Bending Ratio = 0.362

Bending-to-PL+PB+Q Ratio = 0.734

Plot Reference:

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

Branch away from Junction

Pl+Pb+Q+F Damage Ratio Primary+Secondary+Peak (Inner) Load Case 3

47 0.000 Life Stress Concentration Factor = 1.000

MPa 0.098 Stress Strain Concentration Factor = 1.000

Cycles Allowed for this Stress = 1.0000E11

Allowable "B31" Fatigue Stress Allowable = 329.5

482.0 Markl Fatigue Stress Allowable = 329.8

MPa WRC 474 Mean Cycles to Failure = 9,393,385.

WRC 474 99% Probability Cycles = 2,182,169.

9% WRC 474 95% Probability Cycles = 3,029,666.

BS5500 Allowed Cycles(Curve F) = 929,255.

Membrane-to-Bending Ratio = 14.331

Bending-to-PL+PB+Q Ratio = 0.065

Plot Reference:

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

Table of Contents

Stress Intensification Factors

Branch/Nozzle Sif Summary

Peak Primary Secondary

Axial : 4.530 2.243 6.711

Inplane : 1.383 1.316 2.049

Outplane: 3.047 1.370 4.513

Torsion : 0.901 0.982 1.334

Pressure: 0.951 1.171 1.409

The above stress intensification factors are to be used

in a beam-type analysis of the piping system. Inplane,

Outplane and Torsional sif's should be used with the

matching branch pipe whose diameter and thickness is given

below. The axial sif should be used to intensify the

axial stress in the branch pipe calculated by F/A. The

pressure sif should be used to intensify the nominal

pressure stress in the PARENT or HEADER, calculated

from PD/2T.

Pipe OD : 60.300 mm.

Pipe Thk: 5.540 mm.

Z approx: 13047.465 cu.mm.

Z exact : 11970.017 cu.mm.

B31.3 Branch Pressure i-factor = 3.318

Header Pressure i-factor = 1.902

The B31.3 pressure i-factors should be used with with

F/A, where F is the axial force due to pressure, and

A is the area of the pipe wall. This is equivalent to

finding the pressure stress from (ip)(PD/4T).

B31.3

Peak Stress Sif .... 0.000 Axial

2.916 Inplane

3.582 Outplane

1.000 Torsional

B31.1

Peak Stress Sif .... 0.000 Axial

3.582 Inplane

3.582 Outplane

3.582 Torsional

WRC 330

Peak Stress Sif .... 0.000 Axial

2.309 Inplane

2.602 Outplane

1.316 Torsional

Table of Contents

Allowable Loads

SECONDARY Maximum Conservative Realistic

Load Type (Range): Individual Simultaneous Simultaneous

Occuring Occuring Occuring

Axial Force ( N ) 56160. 17639. 26459.

Inplane Moment (mm. N ) 2310468. 508404. 1078488.

Outplane Moment (mm. N ) 1032534. 224472. 476178.

Torsional Moment (mm. N ) 3547619. 1114283. 1671424.

Pressure (MPa ) 29.11 2.80 2.80

PRIMARY Maximum Conservative Realistic

Load Type: Individual Simultaneous Simultaneous

Occuring Occuring Occuring

Axial Force ( N ) 80128. 23038. 34557.

Inplane Moment (mm. N ) 1659555. 324434. 688228.

Outplane Moment (mm. N ) 1647272. 346564. 735173.

Torsional Moment (mm. N ) 2259663. 624731. 937096.

Pressure (MPa ) 16.41 2.80 2.80

NOTES:

1) Maximum Individual Occuring Loads are the maximum

allowed values of the respective loads if all other

load components are zero, i.e. the listed axial force

may be applied if the inplane, outplane and torsional

moments, and the pressure are zero.

2) The Conservative Allowable Simultaneous loads are

the maximum loads that can be applied simultaneously.

A conservative stress combination equation is used

that typically produces stresses within 50-70% of the

allowable stress.

3) The Realistic Allowable Simultaneous loads are the

maximum loads that can be applied simultaneously. A

more realistic stress combination equation is used

based on experience at Paulin Research. Stresses are

typically produced within 80-105% of the allowable.

4) Secondary allowable loads are limits for expansion

and operating piping loads.

5) Primary allowable loads are limits for weight,

primary and sustained type piping loads.

Table of Contents

Flexibilities

The following stiffnesses should be used in a piping,

"beam-type" analysis of the intersection. The stiff-

nesses should be inserted at the surface of the

branch/header or nozzle/vessel junction. The general

characteristics used for the branch pipe should be:

Outside Diameter = 60.300 mm.

Wall Thickness = 5.540 mm.

Axial Translational Stiffness = 332999. N /mm.

Inplane Rotational Stiffness = 9792365. mm. N /deg

Outplane Rotational Stiffness = 3616443. mm. N /deg

Torsional Rotational Stiffness = 30174178. mm. N /deg

Intersection Flexibility Factors for

Branch/Nozzle :

Find axial stiffness: K = 3EI/(kd)^3 N /mm.

Find bending and torsional stiffnesses: K = EI/(kd) mm. N per radian.

The EI product is 0.70375E+11 N mm.^2

The value of (d) to use is: 54.760 mm..

The resulting bending stiffness is in units of force x length per radian.

Axial Flexibility Factor (k) = 1.569

Inplane Flexibility Factor (k) = 2.291

Outplane Flexibility Factor (k) = 6.202

Torsional Flexibility Factor (k) = 0.743

Model Notes

Input Echo:

Model Type : Cylindrical Shell

Parent Outside Diameter : 168.300 mm.

Thickness : 7.110 mm.

Fillet Along Shell : 5.000 mm.

Parent Properties:

Material DB # 1064818.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1730E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm.(NOT USED)

Nozzle Outside Diameter : 88.900 mm.

Thickness : 5.490 mm.

Length : 150.000 mm.

Nozzle Weld Length : 5.000 mm.

Nozzle Tilt Angle : 0.000 deg.

Distance from Top : 0.000 mm.

Distance from Bottom : 500.000 mm.

Nozzle Properties

Material DB # 1064818.

(See Output Reports for Allowables.)

Elastic Modulus (Amb) : 195100.0 MPa

Poissons Ratio : 0.300

Expansion Coefficient : 0.1730E-04 mm./mm./deg.

Weight Density : 0.0000E+00 N /cu.mm. (NOT USED)

Design Operating Cycles : 7000.

Ambient Temperature (Deg.) : 21.10

The following temperatures have been specified for the analysis:

Nozzle Inside Temperature : 235.00 deg.

Nozzle Outside Temperature : 235.00 deg.

Vessel Inside Temperature : 235.00 deg.

Vessel Outside Temperature : 235.00 deg.

Nozzle Pressure : 2.800 MPa

Vessel Pressure : 2.800 MPa

User Defined Load Input Echo:

Loads are given at the Nozzle/Header Junction

Loads are defined in Local Coordinatesc

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 2700.0 2700.0 2700.0 1000.0 1000.0 1000.0

FEA Model Loads:

These are the actual loads applied to the FEA model.

These are the User Defined Loads translated to the

end of the nozzle and reported in global coordinates.

Forces( N ) Moments (N-m)

Load Case FX FY FZ MX MY MZ

---------------------------------------------------------------------------

OPER: 2700.0 2700.0 2700.0 1000.0 1405.0 595.0

The "top" or "positive" end of this model is "free" in

the axial and translational directions.

Stresses ARE nodally AVERAGED.

Vessel Centerline Vector : 0.000 1.000 0.000

Nozzle Orientation Vector : 1.000 0.000 0.000

Table of Contents

Load Case Report

Inner and outer element temperatures are the same

throughout the model. No thermal ratcheting

calculations will be performed.

THE 8 LOAD CASES ANALYZED ARE:

1 SUSTAINED (Pr Only)

Sustained case run to satisfy local primary

membrane and bending stress limits.

/-------- Loads in Case 1

Pressure Case 1

2 Thermal ONLY

Thermal ONLY case run in the event expansion

stresses exceed the secondary stress allowable.

/-------- Loads in Case 2

Temperature Case 1

3 OPERATING (Fatigue Calc Performed)

Case run to compute the operating stresses used in

secondary, peak and range calculations as needed.

/-------- Loads in Case 3

Pressure Case 1

Temperature Case 1

Loads from (Operating)

4 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 4

Loads from (Axial)

5 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 5

Loads from (Inplane)

6 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 6

Loads from (Outplane)

7 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 7

Loads from (Torsion)

8 Program Generated -- Force Only

Case run to compute sif's and flexibilities.

/-------- Loads in Case 8

Pressure Case 1

Table of Contents

Solution Data

Maximum Solution Row Size = 1164

Number of Nodes = 2764

Number of Elements = 908

Number of Solution Cases = 8

Summation of Loads per Case

Case # FX FY FZ

1 -2027. 57168. 0.

2 0. 0. 0.

3 673. 59868. 2700.

4 2349565. 0. 0.

5 0. 0. 0.

6 0. 0. 0.

7 0. 0. 0.

8 -2027. 57168. 0.

Table of Contents

ASME Code Stress Output Plots

1) Pl < (1.5)(S) (SUS,Membrane) Case 1

2) Qb < SPS (SUS,Bending) Case 1

3) S1+S2+S3 < 4S (SUS,S1+S2+S3) Case 1

4) Pl+Pb+Q < SPS (OPE,Inside) Case 3

5) Pl+Pb+Q < SPS (OPE,Outside) Case 3

6) Pl+Pb+Q+F < Sa (EXP,Inside) Case 3

7) Pl+Pb+Q+F < Sa (EXP,Outside) Case 3

8) Membrane < User (OPE,Membrane) Case 3

9) Bending < User (OPE,Bending) Case 3

10) Pl+Pb+Q+F < Sa (SIF,Outside) Case 4

11) Pl+Pb+Q+F < Sa (SIF,Outside) Case 5

12) Pl+Pb+Q+F < Sa (SIF,Outside) Case 6

13) Pl+Pb+Q+F < Sa (SIF,Outside) Case 7

14) Pl+Pb+Q+F < Sa (SIF,Outside) Case 8

Table of Contents

Region Data

Header Next to Nozzle Weld

Cold Allowable ........... 115. MPa

Hot Allowable @ 235 deg .. 105. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 33. MPa

Case 3

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 33. MPa

Case 4

Nominal Stress (M/Z) ... 1633. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 83. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 83. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 83. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 8

Nominal Stress (M/Z) ... 33. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Smallest Thickness ....... 5.490 mm.

Stress Concentration ..... 1.350

Branch Next to Header Weld

Cold Allowable ........... 115. MPa

Hot Allowable @ 235 deg .. 105. MPa

Case 1

Nominal Stress (M/Z) ... 0. MPa

Pressure Stress (Pd/2t) .. 33. MPa

Case 3

Nominal Stress (M/Z) ... 91. MPa

Pressure Stress (Pd/2t) .. 33. MPa

Case 4

Nominal Stress (M/Z) ... 1633. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 5

Nominal Stress (M/Z) ... 83. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 6

Nominal Stress (M/Z) ... 83. MPa

Pressure Stress (Pd/2t) .. 0. MPa

Case 7

Nominal Stress (M/Z) ... 83. MPa