Professional Documents

Culture Documents

Asm A2024-O PDF

Asm A2024-O PDF

Uploaded by

jbaldenebroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asm A2024-O PDF

Asm A2024-O PDF

Uploaded by

jbaldenebroCopyright:

Available Formats

24/6/2014 ASM Material Data Sheet

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024O 1/2

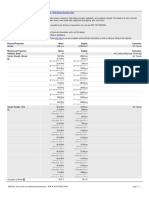

Aluminum 2024-O

Subcategory: 2000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal

Close Analogs:

Composition Notes:

A Zr + Ti limit of 0.20 percent maximum may be used with this alloy designation for extruded and forged

products only, but only when the supplier or producer and the purchaser have mutually so agreed. Agreement

may be indicated, for example, by reference to a standard, by letter, by order note, or other means which

allow the Zr + Ti limit.

Aluminum content reported is calculated as remainder.

Composition information provided by the Aluminum Association and is not for design.

Key Words: Aluminium 2024-O; UNS A92024; ISO AlCu4Mg1; NF A-U4G1 (France); DIN AlCuMg2;

AA2024-O, ASME SB211; CSA CG42 (Canada)

Component Wt. %

Al 90.7 - 94.7

Cr Max 0.1

Cu 3.8 - 4.9

Fe Max 0.5

Component Wt. %

Mg 1.2 - 1.8

Mn 0.3 - 0.9

Other, each Max 0.05

Other, total Max 0.15

Component Wt. %

Si Max 0.5

Ti Max 0.15

Zn Max 0.25

Material Notes:

General 2024 characteristics and uses (from Alcoa): Good machinability and surface finish capabilities. A high strength material of

adequate workability. Has largely superceded 2017 for structural applications. Use of 2024-O not recommended unless

subsequently heat treated.

Uses: Aircraft fittings, gears and shafts, bolts, clock parts, computer parts, couplings, fuse parts, hydraulic valve bodies, missile

parts, munitions, nuts, pistons, rectifier parts, worm gears, fastening devices, veterinary and orthopedic equipment, structures.

Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN.

Physical Properties Metric English Comments

Density 2.78 g/cc 0.1 lb/in

AA; Typical

Mechanical Properties

Hardness, Brinell 47 47

AA; Typical; 500 g load; 10 mm ball

Ultimate Tensile Strength 186 MPa 27000 psi

AA; Typical

24/6/2014 ASM Material Data Sheet

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024O 2/2

Tensile Yield Strength 75.8 MPa 11000 psi

AA; Typical

Elongation at Break 20 % 20 %

AA; Typical; 1/16 in. (1.6 mm) Thickness

Elongation at Break 22 % 22 %

AA; Typical; 1/2 in. (12.7 mm) Diameter

Modulus of Elasticity 73.1 GPa 10600 ksi

AA; Typical; Average of tension and compression.

Compression modulus is about 2% greater than tensile

modulus.

Ultimate Bearing Strength 345 MPa 50000 psi

Edge distance/pin diameter = 2.0

Bearing Yield Strength 131 MPa 19000 psi

Edge distance/pin diameter = 2.0

Poisson's Ratio 0.33 0.33

Fatigue Strength 89.6 MPa 13000 psi

AA; 500,000,000 cycles completely reversed stress; RR

Moore machine/specimen

Machinability 30 % 30 %

0-100 Scale of Aluminum Alloys

Shear Modulus 28 GPa 4060 ksi

Shear Strength 124 MPa 18000 psi

AA; Typical

Electrical Properties

Electrical Resistivity 3.49e-006 ohm-cm 3.49e-006 ohm-cm

AA; Typical at 68F

Thermal Properties

CTE, linear 68F 23.2 m/m-C 12.9 in/in-F

AA; Typical; Average over 68-212F range.

CTE, linear 250C 24.7 m/m-C 13.7 in/in-F

Average over the range 20-300C

Specific Heat Capacity 0.875 J/g-C 0.209 BTU/lb-F

Thermal Conductivity 193 W/m-K 1340 BTU-in/hr-ft-F

AA; Typical at 77F

Melting Point 502 - 638 C 935 - 1180 F

AA; Typical range based on typical composition for wrought

products 1/4 inch thickness or greater. Eutectic melting is

not eliminated by homogenization.

Solidus 502 C 935 F

AA; Typical

Liquidus 638 C 1180 F

AA; Typical

Processing Properties

Annealing Temperature 413 C 775 F

Solution Temperature 256 C 493 F

References for this datasheet.

Some of the val ues di spl ayed above may have been converted from thei r ori gi nal uni ts and/or rounded i n order to di spl ay the i nformati on i n a consi stant

format. Users requi ri ng more preci se data for sci enti fi c or engi neeri ng cal cul ati ons can cl i ck on the property val ue to see the ori gi nal val ue as wel l as raw

conversi ons to equi val ent uni ts. We advi se that you onl y use the ori gi nal val ue or one of i ts raw conversi ons i n your cal cul ati ons to mi ni mi ze roundi ng error. We

al so ask that you refer to MatWeb's di scl ai mer and terms of use regardi ng thi s i nformati on. MatWeb data and tool s provi ded by MatWeb, LLC.

You might also like

- 7178-T6511 Property - ASM Material Data SheetDocument2 pages7178-T6511 Property - ASM Material Data SheetptrfmNo ratings yet

- Sae As81934c 2019Document18 pagesSae As81934c 2019liuyx866100% (1)

- Anatomy and Physiology TestDocument5 pagesAnatomy and Physiology TestPao Parel100% (1)

- ASM Material Data SheetDocument3 pagesASM Material Data SheetrenjithaeroNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetShankar PranavNo ratings yet

- Aluminum 2024-T4-2024-T351Document3 pagesAluminum 2024-T4-2024-T351Raj EklureNo ratings yet

- ASM Material Data SheetDocument3 pagesASM Material Data SheetMadhu MithaNo ratings yet

- Alumínio Cold ASM Material Data SheetDocument2 pagesAlumínio Cold ASM Material Data Sheetmarcelogf74No ratings yet

- Aluminum 6061 Data SheetDocument2 pagesAluminum 6061 Data SheetASHOK100% (1)

- Aluminio 2024-T3Document2 pagesAluminio 2024-T3IbsonhNo ratings yet

- ASM Material Data Sheet (Aluminium Beam)Document2 pagesASM Material Data Sheet (Aluminium Beam)Mohammed AdnanNo ratings yet

- Al 7075 T651Document2 pagesAl 7075 T651Michael HarrellNo ratings yet

- Aluminio 6061-T6 6061-T651Document2 pagesAluminio 6061-T6 6061-T651leroniusNo ratings yet

- Aluminum 5052 H38Document2 pagesAluminum 5052 H38Vishal VaishnavNo ratings yet

- Astm A351 A351m 18Document4 pagesAstm A351 A351m 18Milady OyuelaNo ratings yet

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- Aluminum 2014-T6 2014-T651: Metal Nonferrous Metal Aluminum Alloy 2000 Series Aluminum AlloyDocument3 pagesAluminum 2014-T6 2014-T651: Metal Nonferrous Metal Aluminum Alloy 2000 Series Aluminum Alloyvishwanadh kNo ratings yet

- Aluminum 6061-O: To View All Available Suppliers For This MaterialDocument2 pagesAluminum 6061-O: To View All Available Suppliers For This MaterialAlonso ReynaNo ratings yet

- Aluminium 2024 t4 2024 t351Document3 pagesAluminium 2024 t4 2024 t351botan_mihaiNo ratings yet

- Special Metals NIMONIC® Alloy 90: Categories: Material NotesDocument3 pagesSpecial Metals NIMONIC® Alloy 90: Categories: Material NotesDragomirescu AlinaNo ratings yet

- Aluminum 2024 T6Document4 pagesAluminum 2024 T6Thiru Kumaran0% (1)

- Data Sheet Res PDFDocument5 pagesData Sheet Res PDFToufani Rizal AlfarisiNo ratings yet

- Aluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument3 pagesAluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum Alloyrezaeibehrouz100% (1)

- Aco AISI 1020 PDFDocument1 pageAco AISI 1020 PDFIbsonhNo ratings yet

- Al7075t6 PDFDocument3 pagesAl7075t6 PDFrenjithaeroNo ratings yet

- AISI 8620 SteelDocument2 pagesAISI 8620 SteelVinit AhluwaliaNo ratings yet

- ASTM-A240-2009. Standard Specification For Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsDocument13 pagesASTM-A240-2009. Standard Specification For Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsSandra Viviana Esquivel BenavidesNo ratings yet

- A 488A 488M - 01 Welding, Qualifications of Procedures and PersonnelDocument16 pagesA 488A 488M - 01 Welding, Qualifications of Procedures and Personnelamitanshu01482100% (1)

- Asme Section II A Sa-181 Sa-181mDocument4 pagesAsme Section II A Sa-181 Sa-181mAnonymous GhPzn1xNo ratings yet

- Appendix A: API SpecificationDocument2 pagesAppendix A: API SpecificationNaufal Rizqur RahmanNo ratings yet

- 6061 Vs 6063Document9 pages6061 Vs 6063SrRonNo ratings yet

- Aluminum 6063Document2 pagesAluminum 6063Laurence SarmientoNo ratings yet

- Astm A105 A105m 21Document5 pagesAstm A105 A105m 21miraclemj35No ratings yet

- Zamak 5Document1 pageZamak 5san moedanoNo ratings yet

- Astm A487 A487m 21Document7 pagesAstm A487 A487m 21Milady OyuelaNo ratings yet

- Mini Hermet Pressure SwitchesDocument24 pagesMini Hermet Pressure SwitchesMilosglNo ratings yet

- Astm A744 A744m 21Document5 pagesAstm A744 A744m 21Milady OyuelaNo ratings yet

- Flanged Joints, Gaskets, and Bolting: ScopeDocument20 pagesFlanged Joints, Gaskets, and Bolting: Scopebenedicto soto mestanzaNo ratings yet

- A181A181MDocument3 pagesA181A181Mrgi178No ratings yet

- Astm A193 A193m 23Document7 pagesAstm A193 A193m 23huicholeNo ratings yet

- Sae J51-2004Document11 pagesSae J51-2004khhoseNo ratings yet

- Astm A792 PDFDocument6 pagesAstm A792 PDFOswaldo Enrique Adame67% (3)

- A216a216m 38465 PDFDocument4 pagesA216a216m 38465 PDFraulNo ratings yet

- A878A878M-05 (2011) Standard Specification For Steel Wire, Modified Chromium Vanadium Valve Spring QualityDocument4 pagesA878A878M-05 (2011) Standard Specification For Steel Wire, Modified Chromium Vanadium Valve Spring Qualitytjt4779No ratings yet

- A230A230M-05 (2011) E1 Standard Specification For Steel Wire, Oil-Tempered Carbon Valve Spring QualityDocument4 pagesA230A230M-05 (2011) E1 Standard Specification For Steel Wire, Oil-Tempered Carbon Valve Spring Qualitytjt4779No ratings yet

- Astm A965x 2021aDocument7 pagesAstm A965x 2021aamitNo ratings yet

- Astm A706 A706m 22Document4 pagesAstm A706 A706m 22alvaradolu85No ratings yet

- Astm A216 PDFDocument4 pagesAstm A216 PDFNelson Alves Ferreira JuniorNo ratings yet

- Garlock Gasket Tech Manual GSK3 1 EmpaquetaduraDocument57 pagesGarlock Gasket Tech Manual GSK3 1 EmpaquetaduraJavier AndrésNo ratings yet

- Astm A659-18Document3 pagesAstm A659-18Ryan ZhangNo ratings yet

- Aluminum 413 FDocument2 pagesAluminum 413 Ftanto_deep_15No ratings yet

- A181 - A181M - Standard Specification - 2005Document3 pagesA181 - A181M - Standard Specification - 2005Gerson Foster JuniorNo ratings yet

- 1018Document1 page1018Alonso ReynaNo ratings yet

- Cylindrical RollerDocument25 pagesCylindrical Rollersatish kumar reddyNo ratings yet

- S-8018 B2RDocument5 pagesS-8018 B2ROmid BeygiNo ratings yet

- Sae As1650b-2010Document23 pagesSae As1650b-2010EchoZhang100% (1)

- Aluminum 1100 InformationDocument1 pageAluminum 1100 InformationaxatpgmeNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- A Report On The Internship Training Undergone at "Madhura Fire Works, Sivakasi"Document44 pagesA Report On The Internship Training Undergone at "Madhura Fire Works, Sivakasi"Naresh Kumar100% (4)

- CH U3 A1 Atomic History WorksheetDocument2 pagesCH U3 A1 Atomic History WorksheetАбдурахман Псикс0% (1)

- Maxillofacial Anatomy: Rachmanda Haryo Wibisono Hendra Benyamin Joana de FatimaDocument47 pagesMaxillofacial Anatomy: Rachmanda Haryo Wibisono Hendra Benyamin Joana de FatimaDipo Mas SuyudiNo ratings yet

- Determination of Molecular Weight Through Boiling Point ElevationDocument1 pageDetermination of Molecular Weight Through Boiling Point ElevationremNo ratings yet

- CYSTOSTOMYDocument60 pagesCYSTOSTOMYOepil KirickNo ratings yet

- DSAA Midterm Quiz 1Document34 pagesDSAA Midterm Quiz 1charles raffy talisaysayNo ratings yet

- DVT Case StudyDocument3 pagesDVT Case StudyCrystal B Costa78No ratings yet

- Handbook of Practical Electrical Design, 3rd Edition: IEEE Electrical Insulation Magazine December 1999Document2 pagesHandbook of Practical Electrical Design, 3rd Edition: IEEE Electrical Insulation Magazine December 1999James FitzGeraldNo ratings yet

- Branches of Forensic ScienceDocument19 pagesBranches of Forensic ScienceSriram ShirkeNo ratings yet

- Blood Type Diet Chart 26Document2 pagesBlood Type Diet Chart 26shafali bediNo ratings yet

- Jihyd-11846 YemkejDocument92 pagesJihyd-11846 YemkejhaNo ratings yet

- Ernest John Dobbert, Jr. v. Louie L. Wainwright, Secretary, Florida Department of Corrections, 468 U.S. 1231 (1984)Document16 pagesErnest John Dobbert, Jr. v. Louie L. Wainwright, Secretary, Florida Department of Corrections, 468 U.S. 1231 (1984)Scribd Government DocsNo ratings yet

- DOC-01-031 - AFP-3030 Installation Manual (AUS) Rev ADocument52 pagesDOC-01-031 - AFP-3030 Installation Manual (AUS) Rev AMohamed RafihNo ratings yet

- Mil STD 461eDocument288 pagesMil STD 461ech.navnNo ratings yet

- Practical Guide To Affinity Designer Learn Affinity Designer Through Practical Projects by Dawid TuminskiDocument99 pagesPractical Guide To Affinity Designer Learn Affinity Designer Through Practical Projects by Dawid Tuminskimp3elv1428No ratings yet

- Cambridge IGCSE: Global Perspectives 0457/11Document12 pagesCambridge IGCSE: Global Perspectives 0457/11Vinayak KapoorNo ratings yet

- Artikel 13 Hak Dan Kewajiban Anak Terhadap Orang TuaDocument12 pagesArtikel 13 Hak Dan Kewajiban Anak Terhadap Orang TuaMuhammad Irfan SaputraNo ratings yet

- Motion in One DimentionDocument4 pagesMotion in One DimentionYashNo ratings yet

- Xylo Repair ManualDocument2 pagesXylo Repair ManualHARI VISHNU KRISHNAMURTHYNo ratings yet

- An Overview of The Research of Psychological Entitlement. Definitions and Conceptual CharacteristicsDocument13 pagesAn Overview of The Research of Psychological Entitlement. Definitions and Conceptual CharacteristicsFarah AniaNo ratings yet

- Tesol End Term AssignmentDocument7 pagesTesol End Term Assignmentakshita ramdasNo ratings yet

- The Case Study of OliviaDocument2 pagesThe Case Study of Oliviabilly bongNo ratings yet

- Pilippine Short StoriesDocument75 pagesPilippine Short StoriesRaymond Bill Bela-o Patacsil50% (2)

- A Progressive Christology and The MotifDocument43 pagesA Progressive Christology and The Motifmemra.travelNo ratings yet

- Fundamentals of Nursing: (BATCH 2021 Bachelor of Science in Nursing 1 - Adeventist Medical Center College - IliganDocument5 pagesFundamentals of Nursing: (BATCH 2021 Bachelor of Science in Nursing 1 - Adeventist Medical Center College - Iliganriann leigh TrangiaNo ratings yet

- Botanical Inks Plant-to-Print DyesDocument276 pagesBotanical Inks Plant-to-Print DyesNoémi Gyimóthy100% (3)

- Construction and Working Principle of Transformers, ItsDocument12 pagesConstruction and Working Principle of Transformers, ItsSandeep Joshi100% (1)

- Pan Release AgentDocument5 pagesPan Release AgentCharaf ZAHIRINo ratings yet

- Learn-Html. - Various Jobs AvailableDocument19 pagesLearn-Html. - Various Jobs AvailableMichael GloverNo ratings yet