Professional Documents

Culture Documents

Atlas Lathe Operations Manual

Atlas Lathe Operations Manual

Uploaded by

ursind80%(5)80% found this document useful (5 votes)

4K views5 pagesThis document provides specifications for the MSO-13 6-inch backgeared screw-cutting lathe. Key details include:

- It has a 6-inch swing and 18-inch capacity between centers. The headstock spindle uses Timken tapered roller bearings.

- It has 16 spindle speeds and back gears for heavy cuts. It also has a reversible automatic longitudinal power feed.

- Accessories included are a graduated compound rest, tool post, ring and rocker, tool bit, change gears, threading chart/dial, and more.

- It can cut threads from 8 to 96 threads per inch and has a wide range of attachments available like chucks, collets, and

Original Description:

A manual on the operations and maintenance of the Atlas M50 metal lathe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for the MSO-13 6-inch backgeared screw-cutting lathe. Key details include:

- It has a 6-inch swing and 18-inch capacity between centers. The headstock spindle uses Timken tapered roller bearings.

- It has 16 spindle speeds and back gears for heavy cuts. It also has a reversible automatic longitudinal power feed.

- Accessories included are a graduated compound rest, tool post, ring and rocker, tool bit, change gears, threading chart/dial, and more.

- It can cut threads from 8 to 96 threads per inch and has a wide range of attachments available like chucks, collets, and

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

80%(5)80% found this document useful (5 votes)

4K views5 pagesAtlas Lathe Operations Manual

Atlas Lathe Operations Manual

Uploaded by

ursindThis document provides specifications for the MSO-13 6-inch backgeared screw-cutting lathe. Key details include:

- It has a 6-inch swing and 18-inch capacity between centers. The headstock spindle uses Timken tapered roller bearings.

- It has 16 spindle speeds and back gears for heavy cuts. It also has a reversible automatic longitudinal power feed.

- Accessories included are a graduated compound rest, tool post, ring and rocker, tool bit, change gears, threading chart/dial, and more.

- It can cut threads from 8 to 96 threads per inch and has a wide range of attachments available like chucks, collets, and

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

MSO-13

0tIa4-. 6" Backgeared Screwcutting LAT E

* 6" swing, 18" capacity between centers

* Headstock spindle is equipped with Timken

tapered roller bearings for accuracy, service

and versatility

* Bed ways are massive, precision ground

grey-iron for accuracy and rugged strength

* The 16 spindle speeds equip you to handle

a wide work range

* Back gears provide extra power for heavy

cuts

* Reversible automatic longitudinal power

feed cuts operating time

* Complete V-belt drive

* Wide thread cutting range - 8 to 96

Standard, right or left hand - Metric, .S

to 3 mm., Standard.

* Operates from a 1f4 or 113 HP motor.

No. 618 6" BACKGEARED SCREW-CUTTING

LATHE. Complete as shown, less motor, with equip-

ment listed below. Code YEDUF, shipping weight

100 lbs.

EQUIPMENT FURNISHED

Reversible Automatic Power Longitudinal Feed; Graduated

Compound Rest; Tool Post, Ring and Rocker, S" Tool Bit;

Complete Set of Change Gears to cut standard threads

between 8 and 96 per inch; Threading Chart, Threading

Dial; Quick-Change Counrershaft; Complete V-Belt Drive;

Motor Pulley furnished is for %" diameter motor shaft-

dealer can supply bushings for 1/

2

" dia. motor shafts; 60-Hole

Indexing Mechanism; 5

1

//' Combination Metal and Wood-

working Face Plate; Two 60

0

Lathe Centers - No.2 Morse

Taper for Headstock, No. 1 Morse Taper for Tailstock;

3 Wrenches; Instruction Manual.

WIDE THREADING RANGE

Atlas 6-inch lathes are equipped

with change gears and thread

ing dial for cutting all threads

from 8 to 95 per inch, right or

left band, in the following

standards: National Coarse

(U5S), National Fine (SAE),

Acme, Square, and Whitworth.

Gear train is completely en-

closed - threading chart

mounted on inside of guard

shows gear train set-ups.

SPECIFICATIONS

CAPACITY

Swing Over Bed 6"

Swing Over Carriage -.. - 3Vz"

Capacity between Centers _ 18"

Threading Range 8 to 96 Standard,

Right or Left Hand - Metric, .5 to 3

mm. Standard

Collet Capacity 9-/32" (see page 14)

Overall Dimensions _ .

33Vz" x 27" x 12" high

SPEEDS AND FEEDS

Sixteen Speeds..... _.... 54, 82, 122, 140, 187,

287, 317, 365, 481, 550, 820, 940, 1250,

1925,2125,3225 RPM.

Feeds (Left or Right) per Revolution of

Spindle. ..0078", .0048", .0039" or .0024"

Lead Screw _ _ __ .1/ " Diam.,

z

16 Acme Threads per inch

DRIVE UNIT

Motor Recommended 1 ~ or V3 HP, 1725 RPM

Motor Mounting _ _ Bench

Countershaft Spindle Bearings Oilite Bronze

HEADSTOCK

Spindle Bearings _._ _..Timken Tapered

Roller Bearings with Thrust Take-up Collar and

Nut

Spindle Nose 1" Diameter, 10 Pitch NS Threads

Spindle Nose Taper.. No. 2 Morse Taper

Hole through Spindle 17/32"

Back Gears _ 20 Pitch, %" Wide

Backgear Shaft Bearings _ Oilite Bronze

Spindle Gear.. 24 Pitch, 32 Teeth, 7/16" Wide

CARRIAGE

Cross Feed TraveL __ _. __ _. __ __ .. _ _._ __ 4%"

Cross Feed Screw- _.. o/s" Diameter, Acme Thread

Tool Post Slide TraveL. _ _ _l3,4"

Tool Post _ _._ .. 13/32" x %" slot to take O/S" bits

or tool holder for 3/16" bits

TAILSTOCK

Tailstock Ram _._ _ _%" Diam. Bored for

No.1 Morse Taper

Tailstock Ram TraveL __ .__ _. __ _ _ 1 1 ~

Tailstock Set-Over, Forward or Back._ _._._ 9/16"

www.flywheelmachinetools.com

M50-14

LATHE ATTACHMENTS

FLOOR STAND

No. M6-800A FLOOR

STAND. Provides a per-

manently rigid suPPOrt

for your lathe. Legs are

heavy grey-iron castings,

lhickly ribbed and cross

braced. Table board is

IYs" lhick, lhoroughly

seasoned, shellacked, var-

nished, and ready-drilled

for quick lalhe moul1ling.

Large b 0 (( 0 m board is

convenienl for holding

lools and accessories.

Complete as shown in-

cluding mOlor mounling

bracket and coumershaft

support.YELYN. 1401bs.

AlIas mOlors are

wilh ball bearings. 60 Cycle,

1725 RPM-have Ys" single-

end shaft. Don0 I h a v e

switch, cord or plug.

MOTORS

No. HP Voltage Phase,Type Weigh. Code

2120 '/4 110-220 Single Phase, 5ta[[ 261bs. YIERT

2730 I/, 110-220 Single Phase, Capacitor Starr 281bs. YIOFA

2831 I/, 220-440 Three 26 Ibs. YIHEK

No. 2710 MOTOR CORD for single phase motors above. IV4 Ibs.

YIDEG

REVERSlNG SWITCH

Essential for grinding. tapping, nut-selling,

finishing. Operates on single phase,capacitor

and 3-lead repulsion-induction motors (not

4-lead)- also both shunt-wound and com-

pound-wound DC.

No. 6813 REVERSING SWITCH complete

with cable connections and instaIJation dia-

gram. YOKTO. 1l/2 Ibs.

4" INDEPENDENT CHUCK

No. M6-844B 4-JAW INDEPEN

DENT CHUCK, 4" DIAMETER,

threaded for 1"_10 lalhe spindle.

Holds work of all shapes in head

stock. Body is highstrength semi

steel casting. 4 jaws- operated

independenlIy- are special steel,

hand-fitted. Jaws may be reversed

for holding large stock. Wrench

furnished. YIALM. 6 Ibs.

4" UNIVERSAL CHUCK

No. M6-8458 3-JAW UNIVERSAL

CHUCK, 4" DIAMETER, threaded

for 1"_10 lathe spindle. For quickly

centering and holding round and

hexagonal work. Jaws are self-

centering, controlled by a single

screw. Handles rods up to l/z"

through headstock. Complete with

inside and outside jawsandwrench.

YIAJK. 5 Ibs.

HEADSTOCK CHUCK

No. M6-37S JACOBS HEADSTOCK

CHUCK, complele wilh keyrype wrench.

An accurate and convenient chuck for

ing small diameter work. Hollow conStrue

lion for handling long rods from No. 70

drill up to 17/32" rhru headslOck spindle.

YEEBY. 3 lb>.

DRILL CHUCK

No. 40-60 JACOBS DRILL CHUCK with key type wrench.

Holds driIJs for extreme accuracy in drilling and counter-

sinking. Ruggedly built, precisely machined. Requires arbor

No. 378 for headstock, No. L2'378 for tailstock. Capacit)'

No. 70 driJi 1O 1/

2

". YAHIB. 2 Ibs.

CENTER REST

CHUCK

No. 445 JACOBS CENTER REST CHUCK. Has bronze

jaws for holding centerless shafts and armatures in lathe

tail stock. Requires arbor No. M6-377, listed below. Capacity

J/l'to %". Code YAHOC. WI. 3 lbs.

CHUCK ARBORS

No. M6-377 CHUCK ARBOR 10 adapt No. 445 Cenler ReS!

Chuck to 6" lathe tailstock. YEELJ. 8 oz.

No. L2-378 CHUCK ARBOR to adapt

No. 40-60 Jacobs Drill Chuck to 6"

lathe tailstock. YECOC. 8 oz.

No. 378 CHUCK ARBOR to adapt

No. 40-60 Jacobs Drill Chuck to (,"

lathe headstock. YAHYA. 8 oz.

DRAW-IN

COLLET CHUCK ATTACHMENT

The most accurate method of chucking work between 1/32"

and 9/32". Hollow construction permits rods to be passed

through lathe spindle. Handwheel control releases and

tightens collet on work. Closing sleeve is ground inside and

outside to assure maximum accuracy. Atlas split collets are

collet tool steel. One end threads on draw-in spindle. Other

end is ground to fit tapered sleeve.

No. M6-750 DRAW-IN COLLET CHUCK ATTACHMENT

with draw-in spindle, tape)'ed closing sleeve, less split hoJd-

ing collet. YEHYK. 2 lb.

No. M6-7S 1 SPLIT HOLDING COLLETS - Specify d,ametel. SIZeS,

1/32", 1/16", 3/32", VB', 5/32", 3/16", 7/32", 9/3Y. YEIBZ.

4 07.. each.

No. M6-S48 SPINDLE NOSE CAP to protect lathe spindle threods.

Code YELLO. 8 oz.

LATHE LAMP

No. M6-74S LATHE LAMP.

Throws plenly of light on your

work. Has 14" Rexible cable and

ball joint at shade. Mounting

bracke< clamps to base of bed.

Durable, aucaccive. 6-foot rubber

cord, plug furnished. YEERP.

2 lbs.

www.flywheelmachinetools.com

M5015

6" LATHE ATTACHMENTS

3/16" CUTTER BITS

Six high-speed cutters, ready ground to shapes shown: R.H.

turning and L.H. turning, R.H. facing, L.H. facing, round

nose, 60 V-threading.

No. M6-386 SET OF 6 FORMED CUTTER BITS, .3116".

YEGCA. 1 lb.

UNGROUND CUTTER BITS

No. Description Wt. Code

M6-3865

M6-386T

3855

Six 3/16"

Twelve .3116"

Six %" (for tool post)

1 lb.

tl/2 lb.

1

1

/2 lb.

YEZAV

YEZIX

YARPY

TOOL-POST TOOL SET

Seven high-speed boring and turn-

ing tools ground as shown: %"

external 60 Vthreading, o/s" ex-

ternal turning, 3/16" boring, l/l'

internal threading, %" boring,

5/16" boring, :l/s" boring, spacer 1111

an:! V-bbclc

No. M6-380 TOOL-POST TOOL SET complete. 5 internal

tools, 2 he'lvy-duty tools. V-block, hei[:ht spacer.

Code word YEFYH. we. 2 lb.

BORING TOOL HOLDER

No. M6-990 BORING TOOL

HOLDER with clamp ring,

V-black. plaen bkck, and Ill"

high speed borin[: tool. Clamp

ring fits over nol post. Slots

hold boring tools of 3/16", \1/',

5116", %"diam. YIBUH. 1 lb.

BORING TOOLS

No. 6601 'Is" LB. Tool YOKWY 7 oz.

No. 6602 5/16" L.H. Bo,ing Tool YOLAR 6 oz.

No. 6603 1/

4

" L.B. Boring Tool YOUT 5 oz.

No. 6604 3/16" L.H. Boring Tool YOLOV 5 oz.

No. 6605 11," InternaJ Threading Tool YOLRA 5 oz.

TOOL HOLDERS

Shank fits LOol post, head broached for 3/16" cutter bits

shown above. Wt. 4 oz. eacb.

No. Description Code

M6-139L Left Hand YEFAB

M6-139R Right Hand YEFBA

M6-139S Straight YEEWT

KNURLING TOOL

Self-centering floating construction

- heavy steel shank.

No. M6-340 KNURLlNG TOOL with medium diamond-

shaped knurls. Code YEFEC, wt. 8 oz.

No. 343 Extra Knurls, medium diamond. Code word

YEGYJ, wt. 2 oz. Per pair.

CUT-OFF TOOL

Drop-forged holder with

.3

1

11" high speed replaceable

blade for quick, clean cut

offs.

No. M6-590 CUT-OFF TOOL WIth blade. Code word

YEFCE, wt. 8 oz.

No. M6-592 Extra Blade. Code word YEHDA, wt. 4 oz.

THREADING TOOL

Drop-forged L.H. holder with blade ground to cut 60

threads. Resharpen top edge only.

No. M6.430 THREADING TOOL. Code word YEFFO,

wt. 8 oz.

DRILL PAD

No. L2-360 DRILL PAD. Mounts in

tailstock ram as support for drilling flat

or square work with drill in headstock.

Ground steel shank is No. 1 Morse Taper. 3\18" diam. face.

YATPO. 12 oz.

CROTCH CENTER

No. L2356 CROTCH CENTER. Auto

matically centers round work in tail

stock ram for accurate cross-drilling.

Ground Steel shank is No. 1Morse Taper. 2" diam., 1" slot.

YATYR. 12 oz.

BALL BEARING

TAILSTOCK CENTER

No. M6-348 BALL BEARING TAIL

STOCK CENTER. Center rotates on

enclosed ball bearing. Recommended

for high-speed operations. No. 1 Morse

Taper. YEJJO. 8 oz.

No. 2 Morse Taper for headstock, No.

60

0

LATHE

1 Morse Taper for tailstock. Wt. 8 oz.

CENTERS

each.

No. Morse Toper Code

L2-80 No.1 YAVEN

9-88 No.2 YAVAM

M6-138 No.2to 1Sleeve YEHHO

CENTER EJECTOR BAR

Removes center from spindle without burring. Steel shaft

1\12 lb.

has knurled ball grip- brass head cannot damage center or

spindle.

No. M6-790 CENTER EJECTOR BAR. Length 10". Code

word YETWY, wt.

www.flywheelmachinetools.com

M5016

6"

LAY

DOGS

No. 142A SET O.F 4 DOGS for diam-

eters up to p/z'i. Drop-forged steel.

Hold work firmly. Code YAPAG. 2lbs.

No. Opening W. Code

142 liz" 4 oZ. YAOPK

143

%"

5 oZ. YAORM

144 1" 7 oZ. YAOWR

145 IIj2" 10 oz. YAOZT

CLAMP DOG

No. 741 CLAMP TYPE DOG. Handles

square, rectangular, hexagonal, or round

work. Clamp bars are steel forgings,

carefully machined and hardened-screws

are heat treated. Jaws open to

YAPGA. 1 lb.

STEADY REST

No. M6-325 STEADY REST.

Clamps to bed ways to support

long pieces and insur<l accuracy in

turning, b 0 ring and threading.

Bronze jaws prevent scoring work.

Capacity 2%" diameter. YEFHY.

3 lb.

FOLLOWER REST

No. M6-395 FOLLOWER REST.

Insures accurate work on long

slender rods. Mounts on back of

carriage dovetail slide, follows the

cUlling 1001, holds work in rigid

position. YEFID. 2 Ibs.

TAPER

ATTACHMENT

No. M6-700 TA-

PER ATTACH-

MENT. Quickly

installed, easy to

operate. Rectan-

gular slide bar has

rigid grey- iron

bracket

A slolled draw bar connects to carriage cross slide and feeds

tool at desired taper. Easy-tO-read index plate is graduated

7 and 3" both sides of center line. Maximum travel, one

selling-7%". Range, right or left- 7 (2-15/16" per ft.)

YElTS. Wt. 4

1

/

2

Ibs.

CROSS SLIDE STOP

No. M6-725 CROSS SLIDE

StoP. Clamps to cross slide

dovetail to set depths of dupli-

cate cuts. YEMKE. 8 oz.

CARRIAGE STOP

No. 6810 CARRIAGE STOP. Clamps

to bed way to indicate accurate car-

riage SlOpping point. Code YIDAF.

1 lb.

E A A HMEN

MILLING ATTACHMENT

This allachment equips the

Atlas 6-inch lathe for face

milling, CUlling keyways and

slots, milling dovetails, squar-

ing shafts, making dies and

moulds and many other im-

ponant operations. Installed

quickly and easily by removing

the rest and clamp-

ing base of allachment in its

place.

The Atlas milli ng attach-

ment is built extra- heavy to

minimize vibration. Can be

swiveled completely to hold

work at any angle. Vise posi-

tion is controlled by a feed

screw with micrometer grad.

uated collar- a gib take-up

assures permanent accuracy.

Vise slide is graduated and

can also be swiveled to any

desired angle.

SPECIFICATIONS: Vertical Feed

13;4". Overall Height 11Yz", Jaw

Depth -y-'''. Cross Feed Vise

Capacity 2", Jaw \Xlidth 2".

No. M6-500 MILLING AT-

TACHMENT complete as

shown with flat block, and V-

block. YEILK. 10 Jbs.

CUTTER HOLDING SET

No. M6-945 CUTTER HOLD-

ING SET. Holds milling CUller

in headstock spindle. Includes

draw bar, sleeve, arbor for Vz"

shank CUllers. YEYBD, 2 lb.

R.H. SPIRAL END MILLS

For general milling. Straight shank-adaptcd to holding set

with collet bushings below. Wt. 4 oz. ea.

No. 19th.Flute Diam. Code

S76A 'Vs" 1/

4

" YAKCE

5768 11/16" 5/16" YAKEC

576C %" %" YAKFO

576D %" 7/16" YAKID

576E 15/16" liz" YAKOF

WOODRUFF KEYWAY CUTTERS

For Woodruff keyways, slots, grooves, T-slou:. Yz" scraight

shank - held in arbor of M6-945 set. Wt. 6 oz. each.

No. Diameter Thick Code

:;-57=-5=-A=------oc

I/2

"'"-----,y,'8''''----.. Y,-;''ALUH

5758 %" 3/16" YALYJ

575C 1" ,/.," YAMAD

575D 1

1

/8' 5/16" YAMDA

575E IV.' 'Is" YAMEF

ANGULAR CUTTERS

For face-miJling, dove-tailing. and curring angles

less than 90. Threaded hole - adapted to M6-945

set with arbors listed below. Wt. 6 oz. each.

No. Thick Diam. Hole Thread Code

574A 7/16" 1

1

;4"

.va"

24 YAUF

5748 9/16" I'YB' Yz"

20 YALJE

ADAPTER ARBORS required

No. For No. W Code

572 574A 8 oZ. YEWTE

567 574B 8 oz. YEWUX

COLLET BUSHINGS

No. 563E FOUR COLLET BUSHINGS. Required to adapt 576 end

mills to M6-945 holding set. Not required for 576E end mill.

YALED, 6 oz.

www.flywheelmachinetools.com

M50-11

6/1

THE ATTACHM TS

COMPLETE ~ ARMATURE OUTFITS

An Atlas outfit puts the full armature profit in your own

pocket. In less than 10 minutes it finishes the complete job

- trueing, undercutting, and polishing. It is always ready

10 run, and JUSt one set-up handles any armature, centered or

cenrerless ...quickly, easily, and accurately.

Only on a rigid accurate lathe is it possible 10 turn out

accurate armature work. The Atlas outfits are buiIc around

the 618 lathe- a rugged, precision-built machine 1001. The

armature, held in Jacobs chucks, is trued on its bearings-

the motor-driven undercutter cuts clean, square parallel

grooves of uniform depth. Result- a perfect contact for the

brushes.

Equipmenr includes everything you need co start work at

once-lathe, undercutter, chucks, tools, and motors-

nOthing else to buy.

No. 15A ARMATURE OUTFIT. Includes Atlas 618 lathe

with No. 2730 Y3 HP 1725 RPM motor and No. 2710 motor

cord, No. M6-510A mica undercutter and 5 high-speed saws,

No. !vf6-441 armature chuck kit, No. M6-139L LH tool

holder, No. M6-386G )/16" armature bit, No. 144 1" lathe

dog. YEJUK. 138 lbs.

No. 16A ARMATURE OUTFIT. Same as above without

motor and motor cord. YEJYL, 117 Ibs.

No. 11 A ARMATURE OUTFIT. Same as 15A except that

No. M6-845B 4" universal chuck is substituted for No.

M6-,75 Jacobs headstock chuck. YEIZY, 140 Ibs.

No. 12A ARMATURE OUTFIT. Same as llA without

motor and motor cord. YEJEG, 1191bs.

MICA UNDERCUTTER

Unsurpassed for quick, easy, profitable

~ ~ ~ ~ precision workmanship on recondition-

ing armatures. Mounts on carriage cross

slide- out of the way while you use

regular lathe tools to true and polish

the armature, moved into position in-

stantly for undercutting. Five nws fur-

nished give you correct width cuts for

various size armatures.

No. M6510A MICA UNDERCUTTER in-

cludes motor, 115 or 230 volt A.C., 25-60

cycle, or D.C. (speci(y voltage deSired), 5 hir,h

speed saws (.015", .020", .025".030"..035'),

extension cord, switch, plug. YOBIK, 9 lbs.

No. 523A SET OF 10 HIGH SPEED SAWS

- 2 each o( above thickness. YETUV. 2 oz.

No. M6-7ao COIL WINDING ATTACHMENT.

Simplifies accur3CC coil winding. Replaces tool

POSt - has fibre wire guide and spring adjuSt

ment on spool for correee tcnsion. Quickly

mounted and removed. Code YEMIL. we. IV2Ibs.

ARMATURE CHUCK KIT

No. M6-441 ARMATURE CHUCK KIT.

Holds centcrless arma[ures in lache. Complete

in mecal case. Includes headscock chuck with

No. 2 MT arbor, cenCer resc chuck wich No. 1

MT arbor. YEJLY. a Ibs.

WOODTURNING CHISELS

No. W13A SET OF8 CHISELS. All have forged steel blades,

long maple handles with strong brass ferrules. Approximate

length, 17 inches. Set consists of one each of the following:

3/

a

" gouge, o/a" gouge, I" gouge, 1//' skew, I" skew, I/

Z

"

round nose, Y2" spear point, %" parting. YAZWY. 6 lb.

No. L33 SET OF 5 CHISELS consisting of one each of the

following: o/a" gouge, Vs" gouge, Yz" skew, Yz" spear point,

%" parting. Code YJKYR. 3 lb.

HAND REST

No. 6910 HAND REST. Clamps to

bed and provides a rigid tool support.

Trest can be swiveled to any position

and locked securely. Furnished with tWO T-rests, 4" and 8".

YOJSO. 3 lb.

SPUR CENTER

For driving work mounted between

centers. Replaceable center point.

Morse Taper shank.

No. Shank WI. Code

350 No. z MT 1 lb. YAWTY

L2-16 No. I MT s oz. YEADZ

No. M6-13a SLEEVE No.2 to l MT. YEHHO, 6 oz.

No. L3-147 EXTRA POINT (or No. \50. YEWrV, 2 oz.

No. 147 EXTRA POINT (or No_ L2t6. YEWSA. 2 oz.

CUP CENTER

Supports work in tailstock. Replace-

able center point. Morse Taper shank.

No. L2-17 CUP CENTER with No.1 Morse Taper shank.

Code YEACY, wt. 8 oz.

No. 147 EXTRA POINT for No. L2-17. Code YEWSA

wt. 2 oz. '

SCREW CENTER

For facing and hollowing operations.

Alloy steel with replaceable center.

Morse Taper shank. Diameter 2".

No. Shank WI. Code

352 No.2 MT I lb. YAWYT

L2-352 No. I MT s oZ. YEAHD

M6-13a No. Z to 1 Sleeve 6 oZ. YEHHO

355 Extra Point Z oz. YEYEV

EXTENSION BED

No. M61 E EXTENSION

BED. For handling extra long

wood work. Machined and

finished to same specifications

as lathe bed_ Length I6Y/'.

YEMEK. 24 Ibs.

www.flywheelmachinetools.com

You might also like

- Woodwork Technology MotivateDocument244 pagesWoodwork Technology MotivateTeddy Muleya Sikabanga100% (4)

- The Earthbuilders' Encyclopedia (Second Edition, 2001) Joseph M. TibbetsDocument319 pagesThe Earthbuilders' Encyclopedia (Second Edition, 2001) Joseph M. TibbetsKarela Geiger100% (1)

- 2862 Machine Tool Reconditioning and OverhaulingDocument5 pages2862 Machine Tool Reconditioning and OverhaulingChockalingam Athilingam33% (3)

- Manual of Lathe Operations and Machinists Tables, Atlas Press Co.Document138 pagesManual of Lathe Operations and Machinists Tables, Atlas Press Co.Kevin Haworth98% (41)

- Hercus TextBook of TurningDocument56 pagesHercus TextBook of TurningFrancois Marais100% (2)

- Atlas 618 Lathe ManualDocument15 pagesAtlas 618 Lathe Manualmrmomo99100% (3)

- Boxford Know Your LatheDocument108 pagesBoxford Know Your LatheRoy Masters75% (4)

- Craftsman 101.21400 Metal LatheDocument8 pagesCraftsman 101.21400 Metal Lathejay308100% (2)

- Atlas 10FDocument12 pagesAtlas 10Ffalkirk24100% (1)

- HUTS ADU Catalog 2022 Small.02Document48 pagesHUTS ADU Catalog 2022 Small.02marijaNo ratings yet

- How To Grind Lathe ToolsDocument16 pagesHow To Grind Lathe Toolscharlie20377240100% (11)

- Atlas 12-36 Lathe CatalogDocument6 pagesAtlas 12-36 Lathe CatalogJohn Oeffner50% (2)

- Workshop Practice Series 38 - Tool Cutter SharpeningDocument68 pagesWorkshop Practice Series 38 - Tool Cutter SharpeningWillian Maza100% (6)

- South Bend How To Run A Metal LatheDocument35 pagesSouth Bend How To Run A Metal Lathemasterviking100% (6)

- Logan Lathe Parts PDFDocument0 pagesLogan Lathe Parts PDFCid Schmelzer0% (1)

- 12 Atlas Master Parts ListDocument33 pages12 Atlas Master Parts ListlokiNo ratings yet

- Tricking Out Asian 9x20 LatheDocument48 pagesTricking Out Asian 9x20 Lathearanicki8587No ratings yet

- Craftsman 6-Inch Lathe ManualDocument8 pagesCraftsman 6-Inch Lathe ManualfarfromfreedNo ratings yet

- How To Run A Lathe 1966 Pt1 PDF1 PDFDocument22 pagesHow To Run A Lathe 1966 Pt1 PDF1 PDFSergio Gon100% (1)

- The Art of Hand Scraping - Robert WadeDocument47 pagesThe Art of Hand Scraping - Robert WadeSimon Uwtvuur100% (1)

- Projects For The Unimat Part 1Document85 pagesProjects For The Unimat Part 16KILLER83% (6)

- Small Shaping MachineDocument4 pagesSmall Shaping Machineomikami73% (11)

- 34 - Lathework A Complete CourseDocument83 pages34 - Lathework A Complete Coursemartanarno100% (1)

- Types of PVA Glue and How To Use ItDocument2 pagesTypes of PVA Glue and How To Use ItSaleem FarhanNo ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Right Angle HeadDocument13 pagesRight Angle Headkwayneolson6081100% (3)

- South Bend Lathe TrainingDocument68 pagesSouth Bend Lathe TrainingSMWilson100% (2)

- Home Shop Machinist's Gears GuideDocument8 pagesHome Shop Machinist's Gears Guidegaragepunkfan100% (1)

- Emco Unimat Lathe AccessoriesDocument1 pageEmco Unimat Lathe Accessoriesjose garofanoNo ratings yet

- How To Run A Lathe 1928Document148 pagesHow To Run A Lathe 1928John Watson50% (2)

- Parts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.ADocument16 pagesParts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.Ataxmac100% (2)

- AA109, Craftsman 80& Dunlap LathesDocument30 pagesAA109, Craftsman 80& Dunlap Lathesbogesz68No ratings yet

- Atlas Lathe AccessoriesDocument8 pagesAtlas Lathe Accessoriesfix100% (1)

- 8454 PDFDocument72 pages8454 PDFjon@libertyintegrationcom100% (2)

- Mini-Lathe Cross Slide Extension and Thrust Bearing Mod PDFDocument7 pagesMini-Lathe Cross Slide Extension and Thrust Bearing Mod PDFCody McCormackNo ratings yet

- Lathe TutorialDocument56 pagesLathe TutorialMichel Rigaud88% (8)

- Why Are They Scraped BookletDocument5 pagesWhy Are They Scraped BookletKyle Starr100% (4)

- Making It Dead Flat and SquareDocument9 pagesMaking It Dead Flat and SquareSimon Uwtvuur100% (2)

- Screwcutting Lathe Workshop Practice Series 0852428383 BookDocument4 pagesScrewcutting Lathe Workshop Practice Series 0852428383 BookrefaeNo ratings yet

- South Bend How To Make BushingsDocument12 pagesSouth Bend How To Make Bushingsjuliansimon100% (2)

- Shop - Metal - Gingery's Pipe Bending MachineDocument1 pageShop - Metal - Gingery's Pipe Bending MachinePutra Pratama100% (6)

- How To Run A Lathe1930Document164 pagesHow To Run A Lathe1930smithdoor83% (6)

- Micro Machine Shop Mods EtcDocument488 pagesMicro Machine Shop Mods EtcUmair MypusakaNo ratings yet

- Bridgeport Rebuid 2Document15 pagesBridgeport Rebuid 2wolviak100% (1)

- Clayton Steam Truck-Ocr PDFDocument76 pagesClayton Steam Truck-Ocr PDFbackyardcnc100% (1)

- Metal Turning, Short Course inDocument13 pagesMetal Turning, Short Course inJim100% (15)

- Projects For The Unimat Part 2Document95 pagesProjects For The Unimat Part 26KILLER100% (2)

- Workshop Practice Series 35 - Milling, A Complete CourseDocument71 pagesWorkshop Practice Series 35 - Milling, A Complete CourseCosmin Ionut100% (6)

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopFrom EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedNo ratings yet

- Metalworking for Home Machinists: 53 Practical Projects to Build YourselfFrom EverandMetalworking for Home Machinists: 53 Practical Projects to Build YourselfNo ratings yet

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsFrom EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo ratings yet

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Shop Theory (Henry Ford Trade School)From EverandShop Theory (Henry Ford Trade School)No ratings yet

- Workholding MethodDocument37 pagesWorkholding MethodAinii KunNo ratings yet

- ACE - Brochure Coil WindingDocument6 pagesACE - Brochure Coil WindingSikasep TeaNo ratings yet

- Plans For Building A Forest Service Radio Lab TowerDocument2 pagesPlans For Building A Forest Service Radio Lab TowerursindNo ratings yet

- 8 Rod Portatble DryerDocument4 pages8 Rod Portatble DryerursindNo ratings yet

- Oregon Chain ManualDocument102 pagesOregon Chain ManualursindNo ratings yet

- How To Make Wooden Props Part 2Document44 pagesHow To Make Wooden Props Part 2ursindNo ratings yet

- Text Book of TurningDocument57 pagesText Book of Turningursind100% (1)

- Di-Arco Hand Operated Benders GuideDocument2 pagesDi-Arco Hand Operated Benders GuideursindNo ratings yet

- How To Make Wooden Props Part 2Document44 pagesHow To Make Wooden Props Part 2ursindNo ratings yet

- Gold Mining - M. Corral, J. Earle (Nova, 2009) BBS PDFDocument241 pagesGold Mining - M. Corral, J. Earle (Nova, 2009) BBS PDFshanehatfieldNo ratings yet

- International Log Builders Association Technical Tip No 11Document1 pageInternational Log Builders Association Technical Tip No 11ursindNo ratings yet

- ILBA Log Building News - 70Document20 pagesILBA Log Building News - 70ursindNo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- Log Building News Issue No 62Document24 pagesLog Building News Issue No 62ursindNo ratings yet

- Log Building News Issue No 67Document24 pagesLog Building News Issue No 67ursindNo ratings yet

- Log Building News Issue No 58Document28 pagesLog Building News Issue No 58ursindNo ratings yet

- Logbuilding News Issue No 48Document28 pagesLogbuilding News Issue No 48ursindNo ratings yet

- Log Building News Issue No 55Document28 pagesLog Building News Issue No 55ursindNo ratings yet

- Log Building News Issue No 53Document32 pagesLog Building News Issue No 53ursindNo ratings yet

- Test 25: Machine Shop PracticeDocument51 pagesTest 25: Machine Shop PracticeNiaz KilamNo ratings yet

- Air Grinders: GP-260 / RA-600 (Precision Type)Document1 pageAir Grinders: GP-260 / RA-600 (Precision Type)Yanuar AndriyantoNo ratings yet

- Chief Architect: Feature ComparisonDocument17 pagesChief Architect: Feature ComparisonABOU DabiNo ratings yet

- American Girl Dollhouse - Fits 18 Dolls Ana WhiteDocument1 pageAmerican Girl Dollhouse - Fits 18 Dolls Ana WhiteSchindler JoanieNo ratings yet

- Division of Lanao Del Norte: Republic of The Philippines Department of Education Region X - Northern MindanaoDocument3 pagesDivision of Lanao Del Norte: Republic of The Philippines Department of Education Region X - Northern MindanaoVaness Flor Cabug PuyatNo ratings yet

- Specifications Digest: Proposed 3-Bedroom ResidenceDocument6 pagesSpecifications Digest: Proposed 3-Bedroom ResidencePamelaMariePatawaran100% (1)

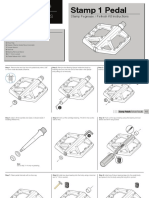

- Stamp 1 OverhaulDocument3 pagesStamp 1 OverhaulsecamachoiNo ratings yet

- 21st Century Houses 150 of The World's BestDocument457 pages21st Century Houses 150 of The World's BestzrufkoNo ratings yet

- Complete Construction Cost of An A+ Category 1 Kanal House in Pakistan - Zameen BlogDocument26 pagesComplete Construction Cost of An A+ Category 1 Kanal House in Pakistan - Zameen BlogMalik BilalNo ratings yet

- StockSceneryPart 2Document121 pagesStockSceneryPart 2Tau Omicron Sixty D90No ratings yet

- Montoria Grand 49 Brochure PlanDocument2 pagesMontoria Grand 49 Brochure PlanindyanexpressNo ratings yet

- Types of RaftersDocument3 pagesTypes of RaftersJeriza AquinoNo ratings yet

- Sandvik 64552322 Block, Manifold, Dump/Brake 64552322 7: 6.000" X 7.00" X 7.25", PLATEDocument1 pageSandvik 64552322 Block, Manifold, Dump/Brake 64552322 7: 6.000" X 7.00" X 7.25", PLATEEthan StoneNo ratings yet

- Basic Hand Tools.: Produced By, Joe Wintermute ASE Certified Master Automobile TechnicianDocument54 pagesBasic Hand Tools.: Produced By, Joe Wintermute ASE Certified Master Automobile TechnicianJad MacintoshNo ratings yet

- Self Study On Recycling Materials (RECYCLABLE MATERIALS)Document16 pagesSelf Study On Recycling Materials (RECYCLABLE MATERIALS)SinchanaNo ratings yet

- New YorkDocument1 pageNew YorkMRUNALNo ratings yet

- Wood Processes: Product DesignDocument26 pagesWood Processes: Product Design809945No ratings yet

- Stairway Installation InstructionsDocument5 pagesStairway Installation InstructionsRuben GarciaNo ratings yet

- Bosch Professional Power Tools Range Catalogue Final LRDocument244 pagesBosch Professional Power Tools Range Catalogue Final LRtcNo ratings yet

- Live Edge River TableDocument4 pagesLive Edge River TableGülbaharNo ratings yet

- R9 PLUS 952568 - Manual PDFDocument40 pagesR9 PLUS 952568 - Manual PDFRicardo Bodelon FernandezNo ratings yet

- DIY Adjustable DeskDocument28 pagesDIY Adjustable DeskWorker0% (1)

- Civil BOQ FinalDocument11 pagesCivil BOQ Finaleed kurigramNo ratings yet

- General Note SampleDocument13 pagesGeneral Note SampleShyam AwalNo ratings yet

- Myanmar National Building Code 2012: MaterialDocument35 pagesMyanmar National Building Code 2012: MaterialHeinMinn AungNo ratings yet

- Floor SupportDocument3 pagesFloor SupportFrancis PrudenciadoNo ratings yet