Professional Documents

Culture Documents

Brickwork Faqs

Brickwork Faqs

Uploaded by

Ruans080 ratings0% found this document useful (0 votes)

75 views3 pagesThe document contains answers to common questions about working with clay bricks. It addresses how to remove white deposits from new brickwork caused by efflorescence, the importance of blending bricks to avoid uneven coloring, reasons why brick walls may leak not related to the bricks themselves, how strong brick buildings are, cleaning brickwork, the cost effectiveness of clay bricks, quantities of materials needed for bricklaying projects, and explanations of different mortar classes.

Original Description:

FAQ of brickwork structures

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document contains answers to common questions about working with clay bricks. It addresses how to remove white deposits from new brickwork caused by efflorescence, the importance of blending bricks to avoid uneven coloring, reasons why brick walls may leak not related to the bricks themselves, how strong brick buildings are, cleaning brickwork, the cost effectiveness of clay bricks, quantities of materials needed for bricklaying projects, and explanations of different mortar classes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

75 views3 pagesBrickwork Faqs

Brickwork Faqs

Uploaded by

Ruans08The document contains answers to common questions about working with clay bricks. It addresses how to remove white deposits from new brickwork caused by efflorescence, the importance of blending bricks to avoid uneven coloring, reasons why brick walls may leak not related to the bricks themselves, how strong brick buildings are, cleaning brickwork, the cost effectiveness of clay bricks, quantities of materials needed for bricklaying projects, and explanations of different mortar classes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

QUESTION 1 : I have just finished building and my clay brickwork is covered with a white

deposit. What is it and how can I get rid of it?

ANSWER : Your brickwork is showing signs of efflorescence. This is a deposit of crystallized

salts which may appear on the brickwork as it dries out. There is no cause for alarm. The deposit

will probably wash off in the first shower of rain. If not, it can be removed with a firm bristle

brush. There is absolutely no need to use chemicals, acids or any other proprietary treatment to

solve this problem.

QUESTION 2 : I am going to use clay face bricks for the first time. Ive seen walls on face

brick buildings that look patchy because the bricks are slightly different colours. How can I

avoid this?

ANSWER : Clay face bricks are a natural product so slight colour variations are to be expected. It

is however not desirable to have a few dark bricks on an otherwise light shaded wall. This gives the

patchy effect that you mention. The solution is simple. Always have at least two packs of bricks on

site and draw from each pack as you work. This is known as on-site blending and will ensure that

you achieve an overall evenness of shade and tone. Never build from one pack of bricks at a time.

QUESTION 3 : I built my house with clay face bricks and the walls have started to leak.

Whats wrong with the bricks?

ANSWER : It is extremely rare to find brick walls that leak due to a fault in the brick. Damp is

usually the result of poor construction techniques, inadequate window and sill detailing, lack of

proper damp proof coursing and /or cracked walls. Buildings must be properly constructed with

appropriate damp coursing, cavity walls where appropriate and suitable roof overhangs in order to

avoid water ingress. NB: A cracked exterior face brick wall will not lead to water penetration if

correct waterproofing techniques have been followed.

QUESTION 4 : How strong will my clay brick building be?

ANSWER : Generally speaking, loads imposed on brickwork are very small in comparison with

the load which the brickwork carries. Brickwork is strong under compression, so the greater the

load imposed on the brickwork, the more stable it becomes. When building boundary walls and

other free-standing brick structure make sure that you provide appropriate foundations and

reinforcing.

QUESTION 5 : How can I clean brickwork?

ANSWER : During construction, protect the brickwork from cement smear, paint and other

substances. Once finished, buildings constructed from clay bricks, clay face bricks, and clay

roofing tiles require little or no maintenance. We do not recommend the application of unnecessary

and costly sealants on our products. Click here for more information (how to care for clay brick)

QUESTION 6 : I would like to use clay bricks (or specifically, clay face bricks) but I think

they may be too expensive.

Page 1of 3 Corobrik

2010/04/29 file://C:\Documents and Settings\Deon\Desktop\Brickwork%20faqs.htm

ANSWER : Because brickwork is the largest visible component of a building, the perception exists

that the major cost of a building must be the brickwork. However, this is not the case. They are in

fact extremely cost effective. The cost of clay plaster bricks and clay face bricks for an average

house is between 6% and 8% of the total building costs. The cost of clay face bricks and plaster

bricks for a non-residential building (factory or office block) is approx 2% - 3% of the total

building costs. In the case of clay face brick building, once the plaster and paint component is

added to the building process and the long term maintenance cost of repainting and replastering is

added to the life of the building, clay face brick is a clear cost winner.

QUESTION 7 : How many bricks, how much cement, and how much sand will I need for my

project?

ANSWER : To lay 1 000 bricks in a Class II mortar (1:6 mix) will require 0,5m sand and 2,5 x

50kg bags of cement.

BRICK QUANTITIES

BRICK

FORMAT

WORK SIZE BRICKS PER M BASED ON

SINGLE-SKIN CONSTRUCTION

WITH 12MM JOINTS

SQUARE METRES

PER 1000 BRICKS

Imperial

(Standard)

222 x 106 x

73mm

52 19.23

CoroMaxi 90*

222 x 90 x

114mm

34 29.40

CoroMaxi

140**

290 x 140 x

114mm

27 37.00

* Only available in KwaZulu-Natal and Western Cape ** Only available in KwaZulu-Natal.

MORTAR MIX PROPORTIONS

Good brickwork is

impossible without good

mortar!

Mortar plasticizer (eg. Lime) should not be used with

masonry cement. A plasticizer may only be used with the

approval of the designer.

1000litres =1m

1 Bag Cement =33 litres

2 Bagx =1 Builders Barrow

(65 litres)

Mortar sand should comply with the requirements of SABS

1090 Sand for Plaster & Mortar.

If masonry cement is used,

reduce volume of sand by

10%.

Use only enough water to produce a workable mix that

spreads easily.

PROPORTION OF MORTAR

CLASS CEMENT:SAND COMMON

CEMENT

SAND BRICKS LAID IN

230MM WALL

(APPROX.)

I 1:4

1 bag =50kg =

33litres

130 litres 300

Page 2of 3 Corobrik

2010/04/29 file://C:\Documents and Settings\Deon\Desktop\Brickwork%20faqs.htm

II 1:6

1 bag =50kg =

33litres

200 litres 410

III 1:9

1 bag =50kg =

33litres

300 litres 590

NB: No allowance has been made for waste. Where poor workmanship and / or poor supervision are

encountered the number of bricks laid can easily be reduced by 25% - 30%.

The applications of the different classes of mortar are as follows:

Class I

Highly stressed masonry, incorporating high strength structural units such as might be used in multi-

storey load bearing building

Class II

Normal load bearing applications, as well as parapets, balustrades, free-standing and garden walls

and other walls exposed to possible severe dampness.

Class III

Lightly stressed (e.g. single-storey) walls where exposure to dampness is not severe.

Note

Increasing mortar strength reduces the ability of the structure to accommodate movement due to

settlement, temperature and moisture changes

<<back

Page 3of 3 Corobrik

2010/04/29 file://C:\Documents and Settings\Deon\Desktop\Brickwork%20faqs.htm

You might also like

- Concrete Blocks NotesDocument16 pagesConcrete Blocks NotesDharshan KNo ratings yet

- A Seminar Report OnDocument14 pagesA Seminar Report OnDevesh SharmaNo ratings yet

- Tae Evo 015 - 351 EnglDocument39 pagesTae Evo 015 - 351 EnglMantenimientoValdezGutierrezNo ratings yet

- Brick PresentationDocument34 pagesBrick PresentationPrakriti GoelNo ratings yet

- Unfired Clay Masonry: Information Paper IP 16/11Document6 pagesUnfired Clay Masonry: Information Paper IP 16/11Amanpreet singhNo ratings yet

- Bricks: Properties and Classifications: G.C.J. LynchDocument6 pagesBricks: Properties and Classifications: G.C.J. LynchMyra Chemyra LuvabyNo ratings yet

- Exterior Finishes: Jaspreet Kaur Aulakh B.Arch 2nd Year 4th Semester K.R.Mangalam S.A.PDocument29 pagesExterior Finishes: Jaspreet Kaur Aulakh B.Arch 2nd Year 4th Semester K.R.Mangalam S.A.PJaspreet AulakhNo ratings yet

- Inter Locking Bricks PresentationDocument19 pagesInter Locking Bricks PresentationSiddesh Naik100% (6)

- History of Bricks: Free Powerpoint TemplatesDocument11 pagesHistory of Bricks: Free Powerpoint TemplatesRanaNo ratings yet

- Construction Material TermsDocument6 pagesConstruction Material TermsMuddassar FayyazNo ratings yet

- Types of Bricks PDFDocument12 pagesTypes of Bricks PDFBhumi Batra100% (1)

- Lecture 5 - Modular Units PDFDocument21 pagesLecture 5 - Modular Units PDFVaishnav SathishNo ratings yet

- Technical Brochure Gruntec BlocksDocument5 pagesTechnical Brochure Gruntec BlockspatnipranayNo ratings yet

- 3-Clay BrickDocument22 pages3-Clay BrickZhiwar oramariNo ratings yet

- Final 333Document45 pagesFinal 333Mekala BharathNo ratings yet

- Week 5 To 6 Tutorial - Walls and PartitionsDocument11 pagesWeek 5 To 6 Tutorial - Walls and PartitionsPeng XunNo ratings yet

- Group Members: White StoneDocument38 pagesGroup Members: White StoneAshiqNo ratings yet

- Bricks Presentation (By G Dhar)Document81 pagesBricks Presentation (By G Dhar)Glistering Dhar100% (1)

- BrickDocument9 pagesBrickArinah SanatNo ratings yet

- BCM Notes Unit No. IIDocument14 pagesBCM Notes Unit No. IIMahesh RamtekeNo ratings yet

- Lecture 11 MasonryDocument26 pagesLecture 11 MasonrySunny LeungNo ratings yet

- Mud As A MortarDocument6 pagesMud As A MortarKumaresan T Kaniyur100% (1)

- Summer 1 Project ReportDocument16 pagesSummer 1 Project ReportPrashant singh100% (1)

- 3ce7: Civil Engineering Material Lab: Experiment No.:-12Document6 pages3ce7: Civil Engineering Material Lab: Experiment No.:-12sita ram JatNo ratings yet

- Mansory 1Document5 pagesMansory 1John Isaac BanaagNo ratings yet

- Present By: Mohd Naim Bin Mohtar 5KA1Document13 pagesPresent By: Mohd Naim Bin Mohtar 5KA1Mohd Naiemz Ozaka100% (1)

- Blocklaying Bricklaying Concreting 2008 UnprotectedDocument7 pagesBlocklaying Bricklaying Concreting 2008 Unprotectedgabrieloduro318No ratings yet

- Interlocking Bricks ReportDocument13 pagesInterlocking Bricks ReportSandeep Sampth RamNo ratings yet

- Brickwork: Practical Restoration HandbookDocument26 pagesBrickwork: Practical Restoration HandbookJailaneeNo ratings yet

- Walled HouseDocument3 pagesWalled HousePriyanka RajaniNo ratings yet

- LoveDocument11 pagesLoveRas ZeruNo ratings yet

- Lecture #01: BY Engineer Asghar Hussain ShahDocument8 pagesLecture #01: BY Engineer Asghar Hussain ShahAsghar Hussain ShahNo ratings yet

- Lec-3 - CE 201 - Bricks@CE-22 - 2021Document33 pagesLec-3 - CE 201 - Bricks@CE-22 - 2021Rj 30No ratings yet

- 2-Concrete Blocks and TestingDocument8 pages2-Concrete Blocks and TestingZhiwar oramariNo ratings yet

- Intoduction Mini ProjectDocument47 pagesIntoduction Mini Projectsurveying of civilNo ratings yet

- Most Common Concrete Problems and FixesDocument20 pagesMost Common Concrete Problems and FixesSo3daa Cr7No ratings yet

- Abdulrahman's Project1Document58 pagesAbdulrahman's Project1Abubakar MusaNo ratings yet

- 4-3 - Brick LayingDocument83 pages4-3 - Brick LayingFahmi NazriNo ratings yet

- Bricks PDFDocument30 pagesBricks PDFTaranpreet Singh100% (1)

- Artificial Construction Materials NotesDocument18 pagesArtificial Construction Materials NotesHARISH DASNo ratings yet

- Hollow Block ConstructionDocument2 pagesHollow Block Constructionpilapil_jNo ratings yet

- Brick For LicenceDocument8 pagesBrick For LicenceAbinashNo ratings yet

- Structural MR M L I AbeysingheDocument10 pagesStructural MR M L I AbeysingheErica S EricaNo ratings yet

- Report BataDocument17 pagesReport BataLutadias InawafaysNo ratings yet

- TRAINING REPORT - Rate AnalysisDocument28 pagesTRAINING REPORT - Rate AnalysisvarshaNo ratings yet

- Interlock Block Mold IntroductionDocument17 pagesInterlock Block Mold Introductionandreia6397No ratings yet

- Plastering, Pointing & Interior FinishingDocument20 pagesPlastering, Pointing & Interior FinishingSANZIDA ZAMANNo ratings yet

- Construction MaterialDocument9 pagesConstruction Materialamitkap00rNo ratings yet

- Fly Ash Brick ThesisDocument4 pagesFly Ash Brick Thesisafksaplhfowdff100% (2)

- Exposed Brickwork PDFDocument2 pagesExposed Brickwork PDFEdwardNo ratings yet

- Bricks 1Document38 pagesBricks 1Rahul KaushikNo ratings yet

- Assignment QuestionsDocument13 pagesAssignment Questionskritika soodNo ratings yet

- RCC Chaukath Making MachineDocument9 pagesRCC Chaukath Making MachineShibinMohammedIqbalNo ratings yet

- Lecture #01: BY Engineer Asghar Hussain ShahDocument9 pagesLecture #01: BY Engineer Asghar Hussain ShahAsghar Hussain ShahNo ratings yet

- Exposed Brickwork ConstructionDocument12 pagesExposed Brickwork ConstructionUzair Ahmed0% (1)

- Mud As Mortar PDFDocument5 pagesMud As Mortar PDFdiesan100No ratings yet

- CEMC Module 5Document52 pagesCEMC Module 5Biswajit SamalNo ratings yet

- Material and Processes: Assignment - 3 BricksDocument15 pagesMaterial and Processes: Assignment - 3 BricksPradnya MoreNo ratings yet

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Circulatory SystemDocument14 pagesCirculatory Systemsmbdy tbhhhNo ratings yet

- Hydraulic Transients: When The Steady-State Design Fails!Document58 pagesHydraulic Transients: When The Steady-State Design Fails!gustavods8990No ratings yet

- Property, Plant and Equipment (IAS 16.Pptx NEW LATESTDocument47 pagesProperty, Plant and Equipment (IAS 16.Pptx NEW LATESTNick254No ratings yet

- JKR Geotechnical SpecificationDocument9 pagesJKR Geotechnical SpecificationSousei No Keroberos100% (1)

- 100G Tuning TechEx2016.TierneyDocument43 pages100G Tuning TechEx2016.Tierneymlazar20009720No ratings yet

- Theories of The UniverseDocument15 pagesTheories of The UniverseindakNo ratings yet

- Listado de Verbos Regulares E Irregulares Más Comunes en InglésDocument8 pagesListado de Verbos Regulares E Irregulares Más Comunes en InglésLogo DesingNo ratings yet

- Tanks DesignDocument8 pagesTanks DesignAhmed EnnehriNo ratings yet

- RP 2002E ManualDocument172 pagesRP 2002E ManualTu Pham Minh75% (16)

- Locatio Map A: Symbols DescriptionDocument1 pageLocatio Map A: Symbols DescriptionAlsean Soriano DetubioNo ratings yet

- Color in FoodDocument4 pagesColor in FoodHaque Bhai0% (1)

- Covid 19 Article - 2Document8 pagesCovid 19 Article - 2Kiruba KaranNo ratings yet

- Msds LicowaxDocument5 pagesMsds LicowaxciswandiNo ratings yet

- Eep19 5Document38 pagesEep19 5Balamurugan ArumugamNo ratings yet

- 429 Wind Actions Steel Sheds 2009Document12 pages429 Wind Actions Steel Sheds 2009eceronitiscaliNo ratings yet

- Section - III, Pipe SupportsDocument2 pagesSection - III, Pipe SupportspalluraviNo ratings yet

- Reddit - PDF For Handbook On PCTDocument43 pagesReddit - PDF For Handbook On PCTGagandeep SinghNo ratings yet

- Heat Transfer Sample ProblemsDocument5 pagesHeat Transfer Sample ProblemsdropgorgeousNo ratings yet

- Structural Design: 780 CMR 16.00 Is Unique To MassachusettsDocument40 pagesStructural Design: 780 CMR 16.00 Is Unique To MassachusettsDLNo ratings yet

- Arch Pipe With Rod TensionDocument4 pagesArch Pipe With Rod Tensionahm_shaabanNo ratings yet

- A6V12101348Document6 pagesA6V12101348Junaid IftekharNo ratings yet

- Flash Mix Gentle Mix Quiescent Condition: CoagulantDocument18 pagesFlash Mix Gentle Mix Quiescent Condition: CoagulantfranciscojesusdasilvNo ratings yet

- Chemistry For Engineers 3Document34 pagesChemistry For Engineers 3Audrey VicenteNo ratings yet

- Summary Safety Data Sheet: 1. Substance NameDocument2 pagesSummary Safety Data Sheet: 1. Substance NameAchraf Ben DhifallahNo ratings yet

- Brochure MK4 Post TensioningDocument36 pagesBrochure MK4 Post Tensioningaev65No ratings yet

- Biochemistry: DR - Radhwan M. Asal Bsc. Pharmacy MSC, PHD Clinical BiochemistryDocument13 pagesBiochemistry: DR - Radhwan M. Asal Bsc. Pharmacy MSC, PHD Clinical BiochemistryAnas SeghayerNo ratings yet

- Yield of Cucumber Varieties To Be ContinuedDocument24 pagesYield of Cucumber Varieties To Be ContinuedMaideluz V. SandagNo ratings yet

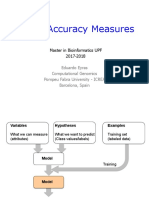

- Lecture - Model Accuracy MeasuresDocument61 pagesLecture - Model Accuracy MeasuresTanmoyNo ratings yet

- X-Cure WB90 PDFDocument2 pagesX-Cure WB90 PDFVirah Sammy ChandraNo ratings yet