Professional Documents

Culture Documents

Traffic Signage - Scope of Works and Technical Specifications - PDF

Traffic Signage - Scope of Works and Technical Specifications - PDF

Uploaded by

nuttyhappyCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ola Chennai PDFDocument3 pagesOla Chennai PDFsrini8558No ratings yet

- Useful Information On Customs MattersDocument726 pagesUseful Information On Customs MattersAditi SharmaNo ratings yet

- Espressuino v1.2 SCHDocument1 pageEspressuino v1.2 SCHbobguv100% (1)

- Mmmxmmto PDF 1645153038Document19 pagesMmmxmmto PDF 1645153038jorge elqueterompeNo ratings yet

- QUESTIONS IN DRAUGHT SURVEY CHAPTER 1 To 3Document2 pagesQUESTIONS IN DRAUGHT SURVEY CHAPTER 1 To 3Davi SousaNo ratings yet

- 441 - 738790 - Module 12Document2 pages441 - 738790 - Module 12Wena Mae CristobalNo ratings yet

- Horarios Transporte 2021Document5 pagesHorarios Transporte 2021PICHONNo ratings yet

- Naufal Tugas B. InggrisDocument2 pagesNaufal Tugas B. InggrisSahtoni SahtoniNo ratings yet

- Technical Book: MI-X Medium Tonnage Range 4 To 5 Tons IC TrucksDocument8 pagesTechnical Book: MI-X Medium Tonnage Range 4 To 5 Tons IC TrucksNurul AlamNo ratings yet

- Recycling and Waste (Practical Data)Document8 pagesRecycling and Waste (Practical Data)PoojaSharmaNo ratings yet

- DTC p1374Document3 pagesDTC p1374David RosadoNo ratings yet

- Sen0650607 SM 114e-6Document416 pagesSen0650607 SM 114e-6Valter Leiriao100% (3)

- CVDocument5 pagesCVadinNo ratings yet

- Certificate 1970797Document1 pageCertificate 1970797Michael SoucyNo ratings yet

- The Village Reporter - September 17th, 2014Document24 pagesThe Village Reporter - September 17th, 2014thevillagereporterNo ratings yet

- How To Assemble B250Document5 pagesHow To Assemble B250Muhammad Imran AftabNo ratings yet

- Flyover Construction Ecotecnic Road System PDFDocument7 pagesFlyover Construction Ecotecnic Road System PDFGalen McbrideNo ratings yet

- Volvo Accessories 2 1981Document20 pagesVolvo Accessories 2 1981vanapeer100% (2)

- Cat 326DDocument28 pagesCat 326DPauloValdivieso50% (2)

- CVT To Manual Ecu Programming - Way Motor WorksDocument2 pagesCVT To Manual Ecu Programming - Way Motor Worksjohn larsonNo ratings yet

- Project Report Power PlantDocument65 pagesProject Report Power PlantAbhishek Mishra100% (1)

- MTK NMEA Packet User ManualDocument24 pagesMTK NMEA Packet User ManualDani IbrahimNo ratings yet

- Materials Pallet ListDocument4 pagesMaterials Pallet ListHumza MazharNo ratings yet

- PCRAU1451A Daikin Super Multi NX Brochure LRDocument27 pagesPCRAU1451A Daikin Super Multi NX Brochure LRammar naeemNo ratings yet

- Bharat MalaDocument36 pagesBharat MalaHitesh PandeyNo ratings yet

- Carreg - Cdm835e1 Parts BookDocument155 pagesCarreg - Cdm835e1 Parts BookLuzioNeto100% (5)

- Potsdam Village Police Dept. Blotter April 4, 2015Document6 pagesPotsdam Village Police Dept. Blotter April 4, 2015NewzjunkyNo ratings yet

- OFRP For SNA Public Version Final - 15janDocument40 pagesOFRP For SNA Public Version Final - 15jansamlagrone100% (1)

- Week 12 Announcements Lead in Unit 7 - Cities Nature + Past ContinuousDocument87 pagesWeek 12 Announcements Lead in Unit 7 - Cities Nature + Past ContinuousHuyền Nguyễn MinhNo ratings yet

- EB204 - Subgrades and Subbases For Concrete Pavements - ACPA WikiDocument80 pagesEB204 - Subgrades and Subbases For Concrete Pavements - ACPA WikiClarice Agor100% (1)

Traffic Signage - Scope of Works and Technical Specifications - PDF

Traffic Signage - Scope of Works and Technical Specifications - PDF

Uploaded by

nuttyhappyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Traffic Signage - Scope of Works and Technical Specifications - PDF

Traffic Signage - Scope of Works and Technical Specifications - PDF

Uploaded by

nuttyhappyCopyright:

Available Formats

82

Technical Specifications

Technical Specifications for Materials

(2009 DPWH Road Signs and Pavement Markings Manual)

A. 10. Materials for Sign Face

Any materials used for the sign face, and not otherwise described in this specification, shall be

in accordance with the approved standard specifications as described in the following sub-

sections:

A. 10.1. Retro-Reflective Materials

Where reflectorization is required the retro-reflecting materials shall comply with the

established standards for retro-reflective materials and devices for road traffic

control purposes.

The reflective sheeting shall be weather resistant and show no appreciable, cracking,

blistering, crazing or dimensional change after two (2) years of unprotected outdoor

exposure.

The reflective sheeting shall have high reflectivity normal to vehicle headlight

dependent on the angle of incidence. The reflective material shall be sharp, no glare

and directed towards the light source of approved angle of incidence.

The reflective sheeting shall perform effectively for a minimum of seven (7) years

from date of fabrication.

The reflective sheeting must retain at least 70% (Type 1) & 50% (Type 2) of its

original brightness for regular and fluorescent sheeting respectively at the end of

seven (7) years. All signs used for road projects should be warranted by the sheeting

manufacturer for above- stated performance.

Signs must be dated at the time of delivery in order to initiate the 7-year

performance warranty. A sign dating sticker that indicates the manufacturers name,

material type/brand name with the month and year of delivery should be placed at

the back of the sign face.

83

The reflective sheeting to be used maybe of two (2) types:

Type 1- High Performance Reflective Sheeting

Type 1 materials to be used for all overhead signs, signs related to movement of

pedestrians, chevron alignment signs and signs identified as black spot areas. The

reflective sheeting shall consist of full cube micro-prismatic lens sheeting with an

interlocking diamond seal pattern with pre-coated adhesive backing protected by a

removable liner. The minimum reflective brightness value of reflective sheeting

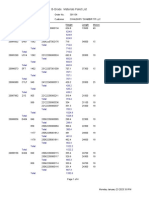

shall be in accordance with the following table:

84

Type 2 Medium Performance Reflective Sheeting

Type 2 materials to be used as minimum standards for all other types of signs not

qualified for use under Type 1. The reflective sheeting shall consist of non-

metalized micro-prismatic lens in an interlocking diamond pattern encapsulated by

a flexible transparent plastic film that has a smooth outer surface. The sheeting

shall have a pre-coated adhesive protected by an easily removable liner. The

adhesive shall have a pressure-sensitive adhesive of the aggressive tack type

requiring no heat , solvent or other preparation for adhesion to surfaces.

The minimum reflective brightness of reflective sheeting shall be in accordance with

the following table:

85

A. 10.2. Fluorescent Reflective Sheeting

The fluorescent reflective sheeting shall consist of a visible-activated fluorescent

materials and full cube micro-prismatic lens sheeting with an interlocking diamond seal

pattern with pre-coated adhesive backing protected by a removable liner. The minimum

reflective brightness shall be in accordance with the following table:

A. 11. Materials for Construction

Standard Road signs shall be constructed with metal. The signs may have a dished,

rolled or beaded edge for additional rigidity. In order to stiffen larger signs and prevent damage

by bending, horizontal battens or bars should be fixed to the rear of the signs as supports, and

may be utilized to provide mounting to posts.

Metal Signs

Metal signs shall be of 2.00 mm thick aluminum substrate materials with stiffening as

provided.

86

A. 12. Post and Attachments

Post required for the erection of signs shall be made of galvanized steel pipes not less

than 48.8 mm (outside diameter) x 3.25 mm thick, or other section of equivalent strength.

Wide flange posts and frames shall be fabricated from structural steel conforming to

ASTM A 283 Grade D. In lieu of wide flange steel posts, the Contractor may use tubular steel

posts conforming to ASTM A 501. All posts shall be thoroughly cleaned, free from grease, scale,

rusts and shall be given one coat of rust-inhibiting priming paint and two (2) coats of gray paint

in accordance with Item 411, Paint DPWH Standard Specification.

Selection of non-frangible signpost lengths based on sign panel sizes and post diameters

is given in Figure A.6. of the latest edition of the DPWH Road Signs and Pavement Markings

Manual.

Attachments shall provide for the positive and robust connection of signs to their

mounting posts. Consideration shall be given to distributing attachment loads, e.g., by the

provision of a suitably shaped saddles and clamps or brackets for a round post. Detailed shop

drawings for the said illustrations shall be provided by the Supplier for approval of CDC.

For the larger signs, the design of the sign support system as a whole shall take into

account possible wind loadings and the criteria specified in appropriate Philippine Code for

Structural Designs. A typical mounting sign is shown in Figure A.7.

87

88

89

A. 13. Protective Treatment

All materials used for signs and sign supports shall be either resistant to, or protected

against deterioration under exposed paint system.

Where corrosion protection is destroyed or damaged in the manufacturing or fixing

process, steps shall be taken to restore protection by appropriate after-treatment.

Where different metals are in contact, appropriate action shall be taken to prevent

galvanic action and resultant corrosion.

Approval of Prototype

The supplier shall submit within Fifteen (15) calendar days upon effectivity of contract a sample

prototype of the said signage for approval of CDC for each type of typical signage (Sign Face

only). No fabrication of the said signage would be undertaken unless said sample signage had

been approved for fabrication. The said prototype should be included in the bid cost.

90

Priority Signs (R1)

91

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ola Chennai PDFDocument3 pagesOla Chennai PDFsrini8558No ratings yet

- Useful Information On Customs MattersDocument726 pagesUseful Information On Customs MattersAditi SharmaNo ratings yet

- Espressuino v1.2 SCHDocument1 pageEspressuino v1.2 SCHbobguv100% (1)

- Mmmxmmto PDF 1645153038Document19 pagesMmmxmmto PDF 1645153038jorge elqueterompeNo ratings yet

- QUESTIONS IN DRAUGHT SURVEY CHAPTER 1 To 3Document2 pagesQUESTIONS IN DRAUGHT SURVEY CHAPTER 1 To 3Davi SousaNo ratings yet

- 441 - 738790 - Module 12Document2 pages441 - 738790 - Module 12Wena Mae CristobalNo ratings yet

- Horarios Transporte 2021Document5 pagesHorarios Transporte 2021PICHONNo ratings yet

- Naufal Tugas B. InggrisDocument2 pagesNaufal Tugas B. InggrisSahtoni SahtoniNo ratings yet

- Technical Book: MI-X Medium Tonnage Range 4 To 5 Tons IC TrucksDocument8 pagesTechnical Book: MI-X Medium Tonnage Range 4 To 5 Tons IC TrucksNurul AlamNo ratings yet

- Recycling and Waste (Practical Data)Document8 pagesRecycling and Waste (Practical Data)PoojaSharmaNo ratings yet

- DTC p1374Document3 pagesDTC p1374David RosadoNo ratings yet

- Sen0650607 SM 114e-6Document416 pagesSen0650607 SM 114e-6Valter Leiriao100% (3)

- CVDocument5 pagesCVadinNo ratings yet

- Certificate 1970797Document1 pageCertificate 1970797Michael SoucyNo ratings yet

- The Village Reporter - September 17th, 2014Document24 pagesThe Village Reporter - September 17th, 2014thevillagereporterNo ratings yet

- How To Assemble B250Document5 pagesHow To Assemble B250Muhammad Imran AftabNo ratings yet

- Flyover Construction Ecotecnic Road System PDFDocument7 pagesFlyover Construction Ecotecnic Road System PDFGalen McbrideNo ratings yet

- Volvo Accessories 2 1981Document20 pagesVolvo Accessories 2 1981vanapeer100% (2)

- Cat 326DDocument28 pagesCat 326DPauloValdivieso50% (2)

- CVT To Manual Ecu Programming - Way Motor WorksDocument2 pagesCVT To Manual Ecu Programming - Way Motor Worksjohn larsonNo ratings yet

- Project Report Power PlantDocument65 pagesProject Report Power PlantAbhishek Mishra100% (1)

- MTK NMEA Packet User ManualDocument24 pagesMTK NMEA Packet User ManualDani IbrahimNo ratings yet

- Materials Pallet ListDocument4 pagesMaterials Pallet ListHumza MazharNo ratings yet

- PCRAU1451A Daikin Super Multi NX Brochure LRDocument27 pagesPCRAU1451A Daikin Super Multi NX Brochure LRammar naeemNo ratings yet

- Bharat MalaDocument36 pagesBharat MalaHitesh PandeyNo ratings yet

- Carreg - Cdm835e1 Parts BookDocument155 pagesCarreg - Cdm835e1 Parts BookLuzioNeto100% (5)

- Potsdam Village Police Dept. Blotter April 4, 2015Document6 pagesPotsdam Village Police Dept. Blotter April 4, 2015NewzjunkyNo ratings yet

- OFRP For SNA Public Version Final - 15janDocument40 pagesOFRP For SNA Public Version Final - 15jansamlagrone100% (1)

- Week 12 Announcements Lead in Unit 7 - Cities Nature + Past ContinuousDocument87 pagesWeek 12 Announcements Lead in Unit 7 - Cities Nature + Past ContinuousHuyền Nguyễn MinhNo ratings yet

- EB204 - Subgrades and Subbases For Concrete Pavements - ACPA WikiDocument80 pagesEB204 - Subgrades and Subbases For Concrete Pavements - ACPA WikiClarice Agor100% (1)