Professional Documents

Culture Documents

Guidelines For Storage and Temperature Monitoring PDF

Guidelines For Storage and Temperature Monitoring PDF

Uploaded by

Hassan HoudoudCopyright:

Available Formats

You might also like

- BIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual 202008Document14 pagesBIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual 202008vmpazvNo ratings yet

- D-288-BIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual AC220V 60Hz 202203Document12 pagesD-288-BIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual AC220V 60Hz 202203Vanessa Margaret Palomino Rodriguez100% (1)

- BIOBASE Laboratory Refrigerator BPR-5V588,1000 User Manual 202012Document13 pagesBIOBASE Laboratory Refrigerator BPR-5V588,1000 User Manual 202012Ferdinand Coo0% (2)

- Gamp Good Practice Guide: GXP Compliant Laboratory Computerized Systems (2 Edition)Document18 pagesGamp Good Practice Guide: GXP Compliant Laboratory Computerized Systems (2 Edition)spalt745867% (3)

- Operations Management 6th Edition Test Bank Nigel SlackDocument8 pagesOperations Management 6th Edition Test Bank Nigel SlackEunice Cheslock100% (44)

- NEC FR-358 Instruction ManualDocument12 pagesNEC FR-358 Instruction Manualekim444666No ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- GGM Gastro SFF746NR UsMan (EN)Document112 pagesGGM Gastro SFF746NR UsMan (EN)Gisell ZapataNo ratings yet

- Mhra Temp MappingDocument11 pagesMhra Temp MappingvijayNo ratings yet

- Manual Bosch KSU 33 y 36 PDFDocument10 pagesManual Bosch KSU 33 y 36 PDFgauchorebelde100% (1)

- Operating Instructions: FreezerDocument5 pagesOperating Instructions: FreezerLacus Bognar100% (1)

- Gorenje K 337 2 MelaDocument18 pagesGorenje K 337 2 Meladjdr1No ratings yet

- c1079 USP36 PDFDocument8 pagesc1079 USP36 PDFHassan HoudoudNo ratings yet

- Technical Document Review: Gamp Good Practice Guide: Calibration ManagementDocument6 pagesTechnical Document Review: Gamp Good Practice Guide: Calibration ManagementHassan HoudoudNo ratings yet

- Technical Document Review: Gamp Good Practice Guide: Calibration ManagementDocument6 pagesTechnical Document Review: Gamp Good Practice Guide: Calibration ManagementHassan HoudoudNo ratings yet

- FDA's Draft Process Validation Guidance PDFDocument44 pagesFDA's Draft Process Validation Guidance PDFHassan HoudoudNo ratings yet

- Final Report of SIPDocument56 pagesFinal Report of SIPRahul Parashar100% (1)

- Cold ChainDocument40 pagesCold ChainJSeasharkNo ratings yet

- Transport of VaccinesDocument16 pagesTransport of Vaccinesvõ thị lệNo ratings yet

- Cold Chain Handling: Department of Pharmaceutical Services Ministry of HealthDocument31 pagesCold Chain Handling: Department of Pharmaceutical Services Ministry of HealthYan ShiangNo ratings yet

- Norma SABMILLERDocument18 pagesNorma SABMILLERpipegallegoNo ratings yet

- GVAV72 HVF72A Service ManualDocument14 pagesGVAV72 HVF72A Service ManualUEENo ratings yet

- Caremed Pharmac1.Docx Cold Chain SopDocument9 pagesCaremed Pharmac1.Docx Cold Chain SopchoncosandisiweNo ratings yet

- Frostig BC Integrerat Kylskap AA 511614 3Document48 pagesFrostig BC Integrerat Kylskap AA 511614 3Michele BiondiNo ratings yet

- Temperature & Temperature/Humidity Mapping: Planning Your StepsDocument4 pagesTemperature & Temperature/Humidity Mapping: Planning Your Stepsltrevino100100% (1)

- Power Failure Contingency PlanDocument2 pagesPower Failure Contingency PlanDaniel Yves IV PaezNo ratings yet

- 741 Ksu405206wDocument19 pages741 Ksu405206wyldosrelNo ratings yet

- Assignment#4 Bernardo, Sophia Mae B. HRMC101Document2 pagesAssignment#4 Bernardo, Sophia Mae B. HRMC101Sophia BernardoNo ratings yet

- AM 782. Instrument and Measurement Techniques: Laboratory Exercise No. 3 Temperature Measurement and Data AcquisitionDocument8 pagesAM 782. Instrument and Measurement Techniques: Laboratory Exercise No. 3 Temperature Measurement and Data AcquisitionryeueNo ratings yet

- navod-WH2310A EDocument34 pagesnavod-WH2310A EPeter FilloNo ratings yet

- Freeze Testing - PQS E003 RF03-VP - 20150916Document10 pagesFreeze Testing - PQS E003 RF03-VP - 20150916DiplomadoEnTecnicasCromatograficasNo ratings yet

- Samsung Freshtech ManualDocument20 pagesSamsung Freshtech ManualKarthik Rajan0% (1)

- Pharmaceutical - Cold ChainDocument5 pagesPharmaceutical - Cold ChainAfnanParker100% (1)

- Contingency Plans Vaccinestorageandhandling Jan 5 2021Document2 pagesContingency Plans Vaccinestorageandhandling Jan 5 2021pharmacy.nemhNo ratings yet

- Title: Thermostat Control of Heater Power: ME43 Experiment No. 1Document3 pagesTitle: Thermostat Control of Heater Power: ME43 Experiment No. 1Mike Rowen BanaresNo ratings yet

- Refrigerator-Only Unit Freezer-Only UnitDocument2 pagesRefrigerator-Only Unit Freezer-Only Unitsupanee kittitanyaponNo ratings yet

- Refrigerator Temp SopDocument8 pagesRefrigerator Temp SopdeshankarunarathneNo ratings yet

- TEMPTECH User Manual MB17WDocument7 pagesTEMPTECH User Manual MB17WFernando Hernández OrtizNo ratings yet

- ApproachPerformance 01 PDFDocument6 pagesApproachPerformance 01 PDFAdam MazurekNo ratings yet

- Experiment 6 (Calibration of Temperature Measuring Devices - A4)Document16 pagesExperiment 6 (Calibration of Temperature Measuring Devices - A4)Jamiel CatapangNo ratings yet

- Frigid A Ire 297079200 en Use and Care ManualDocument11 pagesFrigid A Ire 297079200 en Use and Care Manualsherlock_smallNo ratings yet

- Flow of Food IntroductionDocument15 pagesFlow of Food IntroductionKashien Arianna Reglos100% (3)

- USA Lab HXC-L420 Blood Bank Refrigerator ManualDocument14 pagesUSA Lab HXC-L420 Blood Bank Refrigerator ManualKarol AndradeNo ratings yet

- Microbiology Incubator 1657011940Document5 pagesMicrobiology Incubator 1657011940Huỳnh Ngọc SángNo ratings yet

- GY-NE250RF Instruction ManualDocument15 pagesGY-NE250RF Instruction ManualpinaNo ratings yet

- CEN LSC AMER GMP Warehouse Mapping White Paper B211170EN ADocument12 pagesCEN LSC AMER GMP Warehouse Mapping White Paper B211170EN AcpkakopeNo ratings yet

- Oregon Scientific RMR606HGPADocument16 pagesOregon Scientific RMR606HGPACreed JonesNo ratings yet

- M FL 30138153Document80 pagesM FL 30138153amit1234No ratings yet

- Temperature Mapping and Monitoring - A SummaryDocument3 pagesTemperature Mapping and Monitoring - A SummaryEduardNo ratings yet

- Frigidaire Use and Care Compact Refrigerator Users Guide and Owners ManualDocument9 pagesFrigidaire Use and Care Compact Refrigerator Users Guide and Owners ManualGreg JohnsonNo ratings yet

- Cold Chain SystemDocument52 pagesCold Chain SystemyusraNo ratings yet

- AM 782 Lab 3Document3 pagesAM 782 Lab 3ryeueNo ratings yet

- CFU Tolerance EuropeanDocument8 pagesCFU Tolerance EuropeanRamyNo ratings yet

- GC l207wvqDocument80 pagesGC l207wvqcaracas293345100% (1)

- Balay 3FE2430B EsDocument71 pagesBalay 3FE2430B EseagleeyezNo ratings yet

- Biology Planning and Designing Lab SampleDocument3 pagesBiology Planning and Designing Lab SampleSonia OmapersaudNo ratings yet

- Pharma Cold Chain ProcessDocument3 pagesPharma Cold Chain ProcessakaiunepNo ratings yet

- Instructions Top Hatch With Humidity PumpDocument17 pagesInstructions Top Hatch With Humidity Pumppaul jezreel bondadNo ratings yet

- Refrigeration ExperimentDocument60 pagesRefrigeration ExperimentQQR8 /trollNo ratings yet

- File-1340882782 Elin ZamrzivacDocument8 pagesFile-1340882782 Elin ZamrzivacNandor KermeciNo ratings yet

- User'S Operation Manual: Read and Save These InstructionsDocument5 pagesUser'S Operation Manual: Read and Save These InstructionsAdam PutraNo ratings yet

- Sop of DF KavyaDocument5 pagesSop of DF Kavyakavya nainitaNo ratings yet

- Managing Cold Chian & MaintenanceDocument18 pagesManaging Cold Chian & MaintenanceStephen NzimaNo ratings yet

- Sop Not FinalDocument6 pagesSop Not FinalLyadelou FortuNo ratings yet

- Samsung RL33BDocument9 pagesSamsung RL33BmawunyoNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Refrigerator Revelations: A User's Guide to Operation and MaintenanceFrom EverandRefrigerator Revelations: A User's Guide to Operation and MaintenanceNo ratings yet

- Fiche D Identite Processus AchatDocument16 pagesFiche D Identite Processus AchatHassan HoudoudNo ratings yet

- TS-qualification-controlled Road Vehicles PDFDocument18 pagesTS-qualification-controlled Road Vehicles PDFHassan Houdoud100% (1)

- Iso 22716Document1 pageIso 22716Hassan HoudoudNo ratings yet

- FT Kistock KH210 RFDocument4 pagesFT Kistock KH210 RFHassan HoudoudNo ratings yet

- Boite Pour TubeDocument1 pageBoite Pour TubeHassan HoudoudNo ratings yet

- Technical and Qualification Issues: Alain KupfermanDocument65 pagesTechnical and Qualification Issues: Alain KupfermanHassan HoudoudNo ratings yet

- Met One ISO 21501 Certified Air Particle Counter CalibrationDocument2 pagesMet One ISO 21501 Certified Air Particle Counter CalibrationHassan HoudoudNo ratings yet

- Trace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFDocument22 pagesTrace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFHassan Houdoud100% (1)

- MET ONE 3400 Particle Counter User ManualDocument118 pagesMET ONE 3400 Particle Counter User ManualLupu VasileNo ratings yet

- Food Safety: Research PaperDocument6 pagesFood Safety: Research PaperJon Slavin100% (1)

- Wooden Windows: Cape CultureDocument44 pagesWooden Windows: Cape CultureSerge SalnikoffNo ratings yet

- Draft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleDocument2 pagesDraft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleRica Carmel Lanzaderas100% (3)

- SP22 BseDocument3 pagesSP22 Bsebazm-e- wafaNo ratings yet

- Iac Advanced Financial Accounting and ReDocument4 pagesIac Advanced Financial Accounting and ReIshi AbainzaNo ratings yet

- Design and BuildDocument16 pagesDesign and BuildBernard DavidNo ratings yet

- Succeeding at WorkDocument11 pagesSucceeding at WorkLai RaymundoNo ratings yet

- How A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Document87 pagesHow A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Michaele ErmiasNo ratings yet

- Surface WarfareDocument65 pagesSurface WarfareLobbyist_Myo100% (5)

- Buenacosa, Astrid Hatton Case Study # 1: An Island FirestormDocument12 pagesBuenacosa, Astrid Hatton Case Study # 1: An Island FirestormAstrid BuenacosaNo ratings yet

- Norway Joint Venture Audit GuidelinesDocument31 pagesNorway Joint Venture Audit GuidelinesPatekJoaquinNo ratings yet

- Government Led Joint Assessment in Conflict Affected Districts of Xarardheere & Ceel DheerDocument9 pagesGovernment Led Joint Assessment in Conflict Affected Districts of Xarardheere & Ceel DheerBarre Moulid ShuqulNo ratings yet

- Data Cleansing Process For Master DataDocument4 pagesData Cleansing Process For Master DataAjay Kumar KhattarNo ratings yet

- Display CAT PDFDocument2 pagesDisplay CAT PDFAndres130No ratings yet

- Content Marketing Workflow EbookDocument39 pagesContent Marketing Workflow Ebookjuan gutierrez100% (1)

- Whats New With Smarts and Watch4net - PostDocument21 pagesWhats New With Smarts and Watch4net - PostJesse Dias100% (1)

- M01e1-Introduction of Optometrists & Opticians Act 2007 PresentationDocument45 pagesM01e1-Introduction of Optometrists & Opticians Act 2007 Presentationsytwins100% (1)

- Saudi Indian Embassy ContactDocument4 pagesSaudi Indian Embassy ContactjagateesanNo ratings yet

- Wireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010Document21 pagesWireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010ahmed alshamliNo ratings yet

- Athul AjiDocument5 pagesAthul AjiAsif SNo ratings yet

- Introduction To Surface EngineeringDocument31 pagesIntroduction To Surface Engineeringlogeshboy007No ratings yet

- 9 Polyethylene Piping SystemDocument4 pages9 Polyethylene Piping SystemPrashant PatilNo ratings yet

- Reading Assignment I: Intro To Swift: ObjectiveDocument10 pagesReading Assignment I: Intro To Swift: ObjectiveAlbert JordanNo ratings yet

- Sinumerik - 828D - Machine Commissioning - 2009 PDFDocument476 pagesSinumerik - 828D - Machine Commissioning - 2009 PDFpavlestepanic9932No ratings yet

- Quiz 1 Internet ShoppingDocument1 pageQuiz 1 Internet ShoppingEloy RicouzNo ratings yet

- AmbaniDocument14 pagesAmbaniShimoni ShahNo ratings yet

- 4 Differently Able Persons ActDocument7 pages4 Differently Able Persons Actumer plays gameNo ratings yet

- SM ART-CUT@ Techno Logy S 0 1 A New High Volume Application For Ion ImplantationDocument4 pagesSM ART-CUT@ Techno Logy S 0 1 A New High Volume Application For Ion ImplantationMarco Aurélio DonatoNo ratings yet

Guidelines For Storage and Temperature Monitoring PDF

Guidelines For Storage and Temperature Monitoring PDF

Uploaded by

Hassan HoudoudOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidelines For Storage and Temperature Monitoring PDF

Guidelines For Storage and Temperature Monitoring PDF

Uploaded by

Hassan HoudoudCopyright:

Available Formats

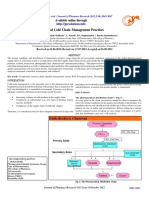

Guidelines for Storage and Temperature

Monitoring of Refrigerated Vaccines

Project funded by the Centers for Disease Control and Prevention

CDC Contact: Patricia Beckenhaupt, Public Health Analyst

What kind of refrigerator should I use?

Pharmaceutical-grade units Household, consumer-grade units

Freezerless Dual-zone Under-the-counter Full-sized

Dual-zone unit is acceptable for refrigerated vaccine

storage only do not use freezer compartment

Dormitory-style units should NEVER be

used for vaccine storage

In the NIST vaccine refrigerator study, the dormitory-style unit exhibited severe temperature

control and stability issues. Within 2 weeks of use, the refrigerator set point had drifted

approximately 5 C colder, freezing the vaccines contained inside.

The unit also exhibits large spatial temperature gradients. There is no good vaccine storage

area inside a dorm-style unit.

Dorm-style refrigerators should NOT be used for vaccine storage under any

circumstance!

Minimum Refrigerator Requirements

Maintain temperature between 2 C and 8 C

Set point temperature = 5 C

Set point drift must not exceed 2 C in the span of one year

Verify temperature stability using a digital data logger

thermometer (min. accuracy = 0.5 C)

Size: large enough to hold 1 years vaccine inventory

Vaccine stock kept in acceptable storage areas ONLY, without

excessive crowding or obstruction of air flow

Necessary design features

Frost-free / automatic defrost

Forced air convection / circulation fan to promote air flow

Temperature Monitoring

How do you know if stored vaccines are safe and effective?

Track temperature history

Refrigerator temperature is NOT a single point measurement

Refrigeration cycle compressor timing

Air circulation patterns spatial temperature variations

Use patterns door opening, loading density, temperature set point

Environmental conditions room temperature variation, power failures

Defrost cycle

Thermometer location what are you measuring?

0

1

2

3

4

5

6

7

8

9

10

11

0:00 0:15 0:30 0:45 1:00 1:15 1:30 1:45 2:00

Duration of measurement, h:min

T

e

m

p

e

r

a

t

u

r

e

,

C

1 (top wall)

2 (mid wall)

3 (lower wall)

4 (top back wall)

5 (air)

6 (vial - floor)

7 (air)

8 (air)

9 (air - top)

10 (in box)

11 (in box)

12 (vial - mid)

13 (syringe in box - top)

14 (inside tray)

15 (back of tray)

17 (glycol - low)

18 (glycol - mid)

19 (glycol - top)

20 (vial - low)

A refrigerator is ONLY as good as the

temperature monitoring system inside

High-tech, pharmaceutical-grade units are

still affected by variable conditions

Accurate temperature history that reflects

actual vaccine temperatures is imperative

to effective vaccine management

Selecting a Digital Data Logger Thermometer

for Vaccine Temperature Monitoring

Main readout unit

(temperature display)

External, detachable temperature probe

Minimum Data Logger Features and Specifications for

Temperature Monitoring of Refrigerated Vaccines

Detachable temperature probe

To be kept in liquid-filled bottle

Cable length > 1 m preferred

Continuous temp monitoring

At least one reading/15 min

Memory storage : 4000 readings

~ 39 days recording at one rdg/15 mins

Device stops recording when memory

is full, reset after data download

Operating range: 20 C to 40 C

(for refrigerated vaccine monitoring)

Uncertainty: 0.5 C

In the range of 1 C to 15 C

Often listed as device accuracy

Resolution: 0.1 C

Battery life: 6 months minimum

Integrated Liquid Crystal Display

(LCD) with minimum:

Last measured temp displayed

in C or F

Hi/Lo alarm status indicator

Alarm capabilities

Factory set, end-user adjustable

Alarm activation at 2 C (low) and 8 C

(high)

Download/ archival software

Download data via standard computer

ports (e.g., USB)

Graphical presentation of

date/time/temperature data

Display alarm configuration details and

total time outside high/low thresholds

Data export capability

(e.g., csv, Excel, txt)

Data Logger Setup

Select a glass or plastic bottle

Minimum diameter = 4 x probe diameter (PD)

Bottle height chosen so that

Immersion depth 10 x probe diameter,

Probe tip to bottom 1 to 2 cm

Sealable lid preferred (e.g. pierceable, rubber

septum cap)

Note: If manufacturer supplies a fluid-filled

bottle/ vial with data logger, this may be

used instead

Completely fill bottle with fluid (e.g., glycol)

Insert logger probe through center of cap

Position probe tip to achieve depth 10 x PD

Make sure tip doesnt touch bottom of bottle

Make sure entire length of probe is centered

within the bottle

To keep the probe from shifting, fix the cable to

the outside of the bottle with tape or cable tie

probe diameter

(PD)

immersion depth

10 x PD

bottle width

4 x PD

1 to 2 cm

Data Logger Installation

Attach logger display to

outside of refrigerator

Place logger probe and bottle setup in a tray in

the center of the refrigerator. Fix bottle in place

with tape or Velcro.

Cable is not thick

enough to affect

refrigerator temperature

Data Logger Settings and Startup

Adjust logger settings

Leave the probe in glycol setup undisturbed inside the refrigerator

Disconnect logger readout unit from probe cable

Connect readout unit to computer via USB cable or cradle

Open logger software and select option to edit logger settings

Verify correct alarm setting: Low = 2 C / High = 8 C

Minimum read rate = 1 rdg/ 15 min

Delayed start (optional): may be chosen to allow enough time to reconnect logger

readout unit to probe in glycol before recording starts. Do not select an

excessively long start delay; 5 or 10 min will be sufficient for most cases.

Device startup

Select start logger or initialize logger in the software program

Disconnect readout unit from computer and reconnect it to the probe cable.

Remember to leave the readout unit outside of the refrigerator for easy viewing.

A small magnetic hook can be used to hang the unit on the outside of the

refrigerator.

If the logger requires a magnetic key or button push start, activate the logger as soon

as it is reconnected to the probe. If the device features a computer-only start, no

further action is required.

The logger should now be recording temperature data at the specified reading rate.

Most loggers feature a recording indicator on the display check to make sure that

this is activated.

Downloading Logger Data

When should I download logger data?

At least once per week, at the same time each week (e.g., Monday morning)

Any time a high or low temperature alarm is activated, download data

immediately, even if it is not the scheduled download time

Downloading procedure

Leave the probe in glycol setup

undisturbed inside the refrigerator

Disconnect logger readout unit from

probe cable

Connect readout unit to computer via

USB cable or cradle

Open logger software and select option

to stop logger and download data

Save the data file with an appropriate,

standardized name which indicates the

data collection date range (e.g. Fridge1

Aug 14-20 2010.xls)

Restart logger and reconnect to probe

DUAL ZONE FREEZERLESS PHARMACEUTICAL

No storage in crisper drawers:

thermally isolated + floor level

runs cold. Remove drawers,

fill space with water bottles

Manufacturer recommends

no floor storage, but vial

thermocouple maintained at

2 to 8 C throughout testing

1 to 2 C colder

than main

fridge space

NO vials touching glass shelf or directly

under cooling vent = 2 to 5 C colder

Best storage practice place vaccines in center fridge space, contained in original

packaging, inside designated storage trays positioned 2 to 3 in from refrigerator walls

Avoid storage on top shelf near cooling vent. First location to

exceed max allowed temp during outages.

Vaccine Storage Methods and Locations in the Refrigerator

Step 1: Refrigerator Installation

Unit location

Guidelines 4 to 6 inches of clearance around outside of unit

Check manufacturer manual to verify minimum spacing

Well-ventilated room for maintaining ambient conditions within mfc specifications

Startup

Remove any vegetable/ dairy bins (not suitable for vaccine storage)

Place filled water bottles in areas where vaccine storage is prohibited

floor level

under/ adjacent to cooling vent

refrigerator door

Step 2: Fridge Setup and Set Point Adjustment

Place plastic trays for vaccine storage inside

refrigerator

Keep trays 2 to 3 inches from walls

No trays on floor level

Identify cooling vent location

No storage directly under vent, add water

bottles if necessary

Do not to block the vent or hinder air

circulation

Ensure that data logger probe in glycol-filled bottle is

properly positioned in center of refrigerator

Set logger to start recording temperature

Power on refrigerator

New refrigerator units are often factory-set to 4 C

or 5 C and may not require adjustment

After 24 hrs, download logger data to determine if

refrigerator temperature has stabilized

If stabilized temp is NOT between 4 C and 6 C,

make small adjustments to refrigerator

thermostat, restart logger and continue monitoring

for another 24 hrs

once correct refrigerator set point is achieved,

continue monitoring logger for 3-5 days to verify

set point stability BEFORE proceeding with

vaccine loading

Continue using data logger to verify target

set point temperature (4 to 6 C) during

weekly data download and make

adjustments when needed

Step 3: Loading Vaccines

Keep vaccines in original

manufacturer packaging

Don t remove individual vials

from cardboard boxes

Place vaccine boxes in plastic

trays

Organize vaccines by type,

VFC/private, etc. to facilitate quick

retrieval and minimize time with

refrigerator door open

Avoid over-filling refrigerator and

hindering air circulation

Keep vaccines in designated

storage trays only

Step 4: Weekly Vaccine Temperature Monitoring

Download logger data at the same time every week

Decide on a schedule and stick to it. Ideally, the same person should be responsible

for downloading data each week.

In the event of a high/low temperature alarm, download logger data immediately even

if it is not the scheduled download time

Resume weekly data download as before (do not change download schedule

following an alarm)

Leave probe-in-glycol setup undisturbed inside the refrigerator at all times

Detach logger readout unit (kept outside the refrigerator) from probe cable to initiate

data download

Maintain electronic archive of weekly download files for at least 3 years

Files should be saved and organized with appropriately descriptive names to indicate

date and specify refrigerator name (if the office operates more than one unit)

Maintain data backup on an external hard-drive, CD, alternate computer, or if no other

option is available, print and file hard copy records

Always restart and re-attach data logger unit to probe cable IMMEDIATELY

after download

Step 6: Interpreting Logger Data

After data download, review logger reports/graphs to determine if any thermal

excursions (temperatures outside the 2 C to 8 C range) have occurred

Green arrows show temperature spikes caused

by defrost cycle (~36 h intervals), but logger

temperature has remained within 2 C to 8 C

If an excursion has occurred

Determine when it started, its duration,

and the maximum or minimum

temperature reached

Try to determine the cause (e.g. power

outage, door left open too long,

problem with refrigerator set point

stability, defrost cycle)

Provide this information to VFC

coordinator/ vaccine manufacturer for

guidance on how to proceed

Yellow arrow shows a thermal excursion lasting

2 h 20 min, with max. temperature = 16 C

This excursion was caused by a staff member

accidentally leaving the fridge door open for 1 h

You might also like

- BIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual 202008Document14 pagesBIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual 202008vmpazvNo ratings yet

- D-288-BIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual AC220V 60Hz 202203Document12 pagesD-288-BIOBASE Laboratory Refrigerator BPR-5V160'250'310 User Manual AC220V 60Hz 202203Vanessa Margaret Palomino Rodriguez100% (1)

- BIOBASE Laboratory Refrigerator BPR-5V588,1000 User Manual 202012Document13 pagesBIOBASE Laboratory Refrigerator BPR-5V588,1000 User Manual 202012Ferdinand Coo0% (2)

- Gamp Good Practice Guide: GXP Compliant Laboratory Computerized Systems (2 Edition)Document18 pagesGamp Good Practice Guide: GXP Compliant Laboratory Computerized Systems (2 Edition)spalt745867% (3)

- Operations Management 6th Edition Test Bank Nigel SlackDocument8 pagesOperations Management 6th Edition Test Bank Nigel SlackEunice Cheslock100% (44)

- NEC FR-358 Instruction ManualDocument12 pagesNEC FR-358 Instruction Manualekim444666No ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- GGM Gastro SFF746NR UsMan (EN)Document112 pagesGGM Gastro SFF746NR UsMan (EN)Gisell ZapataNo ratings yet

- Mhra Temp MappingDocument11 pagesMhra Temp MappingvijayNo ratings yet

- Manual Bosch KSU 33 y 36 PDFDocument10 pagesManual Bosch KSU 33 y 36 PDFgauchorebelde100% (1)

- Operating Instructions: FreezerDocument5 pagesOperating Instructions: FreezerLacus Bognar100% (1)

- Gorenje K 337 2 MelaDocument18 pagesGorenje K 337 2 Meladjdr1No ratings yet

- c1079 USP36 PDFDocument8 pagesc1079 USP36 PDFHassan HoudoudNo ratings yet

- Technical Document Review: Gamp Good Practice Guide: Calibration ManagementDocument6 pagesTechnical Document Review: Gamp Good Practice Guide: Calibration ManagementHassan HoudoudNo ratings yet

- Technical Document Review: Gamp Good Practice Guide: Calibration ManagementDocument6 pagesTechnical Document Review: Gamp Good Practice Guide: Calibration ManagementHassan HoudoudNo ratings yet

- FDA's Draft Process Validation Guidance PDFDocument44 pagesFDA's Draft Process Validation Guidance PDFHassan HoudoudNo ratings yet

- Final Report of SIPDocument56 pagesFinal Report of SIPRahul Parashar100% (1)

- Cold ChainDocument40 pagesCold ChainJSeasharkNo ratings yet

- Transport of VaccinesDocument16 pagesTransport of Vaccinesvõ thị lệNo ratings yet

- Cold Chain Handling: Department of Pharmaceutical Services Ministry of HealthDocument31 pagesCold Chain Handling: Department of Pharmaceutical Services Ministry of HealthYan ShiangNo ratings yet

- Norma SABMILLERDocument18 pagesNorma SABMILLERpipegallegoNo ratings yet

- GVAV72 HVF72A Service ManualDocument14 pagesGVAV72 HVF72A Service ManualUEENo ratings yet

- Caremed Pharmac1.Docx Cold Chain SopDocument9 pagesCaremed Pharmac1.Docx Cold Chain SopchoncosandisiweNo ratings yet

- Frostig BC Integrerat Kylskap AA 511614 3Document48 pagesFrostig BC Integrerat Kylskap AA 511614 3Michele BiondiNo ratings yet

- Temperature & Temperature/Humidity Mapping: Planning Your StepsDocument4 pagesTemperature & Temperature/Humidity Mapping: Planning Your Stepsltrevino100100% (1)

- Power Failure Contingency PlanDocument2 pagesPower Failure Contingency PlanDaniel Yves IV PaezNo ratings yet

- 741 Ksu405206wDocument19 pages741 Ksu405206wyldosrelNo ratings yet

- Assignment#4 Bernardo, Sophia Mae B. HRMC101Document2 pagesAssignment#4 Bernardo, Sophia Mae B. HRMC101Sophia BernardoNo ratings yet

- AM 782. Instrument and Measurement Techniques: Laboratory Exercise No. 3 Temperature Measurement and Data AcquisitionDocument8 pagesAM 782. Instrument and Measurement Techniques: Laboratory Exercise No. 3 Temperature Measurement and Data AcquisitionryeueNo ratings yet

- navod-WH2310A EDocument34 pagesnavod-WH2310A EPeter FilloNo ratings yet

- Freeze Testing - PQS E003 RF03-VP - 20150916Document10 pagesFreeze Testing - PQS E003 RF03-VP - 20150916DiplomadoEnTecnicasCromatograficasNo ratings yet

- Samsung Freshtech ManualDocument20 pagesSamsung Freshtech ManualKarthik Rajan0% (1)

- Pharmaceutical - Cold ChainDocument5 pagesPharmaceutical - Cold ChainAfnanParker100% (1)

- Contingency Plans Vaccinestorageandhandling Jan 5 2021Document2 pagesContingency Plans Vaccinestorageandhandling Jan 5 2021pharmacy.nemhNo ratings yet

- Title: Thermostat Control of Heater Power: ME43 Experiment No. 1Document3 pagesTitle: Thermostat Control of Heater Power: ME43 Experiment No. 1Mike Rowen BanaresNo ratings yet

- Refrigerator-Only Unit Freezer-Only UnitDocument2 pagesRefrigerator-Only Unit Freezer-Only Unitsupanee kittitanyaponNo ratings yet

- Refrigerator Temp SopDocument8 pagesRefrigerator Temp SopdeshankarunarathneNo ratings yet

- TEMPTECH User Manual MB17WDocument7 pagesTEMPTECH User Manual MB17WFernando Hernández OrtizNo ratings yet

- ApproachPerformance 01 PDFDocument6 pagesApproachPerformance 01 PDFAdam MazurekNo ratings yet

- Experiment 6 (Calibration of Temperature Measuring Devices - A4)Document16 pagesExperiment 6 (Calibration of Temperature Measuring Devices - A4)Jamiel CatapangNo ratings yet

- Frigid A Ire 297079200 en Use and Care ManualDocument11 pagesFrigid A Ire 297079200 en Use and Care Manualsherlock_smallNo ratings yet

- Flow of Food IntroductionDocument15 pagesFlow of Food IntroductionKashien Arianna Reglos100% (3)

- USA Lab HXC-L420 Blood Bank Refrigerator ManualDocument14 pagesUSA Lab HXC-L420 Blood Bank Refrigerator ManualKarol AndradeNo ratings yet

- Microbiology Incubator 1657011940Document5 pagesMicrobiology Incubator 1657011940Huỳnh Ngọc SángNo ratings yet

- GY-NE250RF Instruction ManualDocument15 pagesGY-NE250RF Instruction ManualpinaNo ratings yet

- CEN LSC AMER GMP Warehouse Mapping White Paper B211170EN ADocument12 pagesCEN LSC AMER GMP Warehouse Mapping White Paper B211170EN AcpkakopeNo ratings yet

- Oregon Scientific RMR606HGPADocument16 pagesOregon Scientific RMR606HGPACreed JonesNo ratings yet

- M FL 30138153Document80 pagesM FL 30138153amit1234No ratings yet

- Temperature Mapping and Monitoring - A SummaryDocument3 pagesTemperature Mapping and Monitoring - A SummaryEduardNo ratings yet

- Frigidaire Use and Care Compact Refrigerator Users Guide and Owners ManualDocument9 pagesFrigidaire Use and Care Compact Refrigerator Users Guide and Owners ManualGreg JohnsonNo ratings yet

- Cold Chain SystemDocument52 pagesCold Chain SystemyusraNo ratings yet

- AM 782 Lab 3Document3 pagesAM 782 Lab 3ryeueNo ratings yet

- CFU Tolerance EuropeanDocument8 pagesCFU Tolerance EuropeanRamyNo ratings yet

- GC l207wvqDocument80 pagesGC l207wvqcaracas293345100% (1)

- Balay 3FE2430B EsDocument71 pagesBalay 3FE2430B EseagleeyezNo ratings yet

- Biology Planning and Designing Lab SampleDocument3 pagesBiology Planning and Designing Lab SampleSonia OmapersaudNo ratings yet

- Pharma Cold Chain ProcessDocument3 pagesPharma Cold Chain ProcessakaiunepNo ratings yet

- Instructions Top Hatch With Humidity PumpDocument17 pagesInstructions Top Hatch With Humidity Pumppaul jezreel bondadNo ratings yet

- Refrigeration ExperimentDocument60 pagesRefrigeration ExperimentQQR8 /trollNo ratings yet

- File-1340882782 Elin ZamrzivacDocument8 pagesFile-1340882782 Elin ZamrzivacNandor KermeciNo ratings yet

- User'S Operation Manual: Read and Save These InstructionsDocument5 pagesUser'S Operation Manual: Read and Save These InstructionsAdam PutraNo ratings yet

- Sop of DF KavyaDocument5 pagesSop of DF Kavyakavya nainitaNo ratings yet

- Managing Cold Chian & MaintenanceDocument18 pagesManaging Cold Chian & MaintenanceStephen NzimaNo ratings yet

- Sop Not FinalDocument6 pagesSop Not FinalLyadelou FortuNo ratings yet

- Samsung RL33BDocument9 pagesSamsung RL33BmawunyoNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Refrigerator Revelations: A User's Guide to Operation and MaintenanceFrom EverandRefrigerator Revelations: A User's Guide to Operation and MaintenanceNo ratings yet

- Fiche D Identite Processus AchatDocument16 pagesFiche D Identite Processus AchatHassan HoudoudNo ratings yet

- TS-qualification-controlled Road Vehicles PDFDocument18 pagesTS-qualification-controlled Road Vehicles PDFHassan Houdoud100% (1)

- Iso 22716Document1 pageIso 22716Hassan HoudoudNo ratings yet

- FT Kistock KH210 RFDocument4 pagesFT Kistock KH210 RFHassan HoudoudNo ratings yet

- Boite Pour TubeDocument1 pageBoite Pour TubeHassan HoudoudNo ratings yet

- Technical and Qualification Issues: Alain KupfermanDocument65 pagesTechnical and Qualification Issues: Alain KupfermanHassan HoudoudNo ratings yet

- Met One ISO 21501 Certified Air Particle Counter CalibrationDocument2 pagesMet One ISO 21501 Certified Air Particle Counter CalibrationHassan HoudoudNo ratings yet

- Trace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFDocument22 pagesTrace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFHassan Houdoud100% (1)

- MET ONE 3400 Particle Counter User ManualDocument118 pagesMET ONE 3400 Particle Counter User ManualLupu VasileNo ratings yet

- Food Safety: Research PaperDocument6 pagesFood Safety: Research PaperJon Slavin100% (1)

- Wooden Windows: Cape CultureDocument44 pagesWooden Windows: Cape CultureSerge SalnikoffNo ratings yet

- Draft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleDocument2 pagesDraft Resolution No. 58-2020 - Authorizing Mayor To Sign Deed of Donation With PCSO For Patient Transport VehicleRica Carmel Lanzaderas100% (3)

- SP22 BseDocument3 pagesSP22 Bsebazm-e- wafaNo ratings yet

- Iac Advanced Financial Accounting and ReDocument4 pagesIac Advanced Financial Accounting and ReIshi AbainzaNo ratings yet

- Design and BuildDocument16 pagesDesign and BuildBernard DavidNo ratings yet

- Succeeding at WorkDocument11 pagesSucceeding at WorkLai RaymundoNo ratings yet

- How A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Document87 pagesHow A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Michaele ErmiasNo ratings yet

- Surface WarfareDocument65 pagesSurface WarfareLobbyist_Myo100% (5)

- Buenacosa, Astrid Hatton Case Study # 1: An Island FirestormDocument12 pagesBuenacosa, Astrid Hatton Case Study # 1: An Island FirestormAstrid BuenacosaNo ratings yet

- Norway Joint Venture Audit GuidelinesDocument31 pagesNorway Joint Venture Audit GuidelinesPatekJoaquinNo ratings yet

- Government Led Joint Assessment in Conflict Affected Districts of Xarardheere & Ceel DheerDocument9 pagesGovernment Led Joint Assessment in Conflict Affected Districts of Xarardheere & Ceel DheerBarre Moulid ShuqulNo ratings yet

- Data Cleansing Process For Master DataDocument4 pagesData Cleansing Process For Master DataAjay Kumar KhattarNo ratings yet

- Display CAT PDFDocument2 pagesDisplay CAT PDFAndres130No ratings yet

- Content Marketing Workflow EbookDocument39 pagesContent Marketing Workflow Ebookjuan gutierrez100% (1)

- Whats New With Smarts and Watch4net - PostDocument21 pagesWhats New With Smarts and Watch4net - PostJesse Dias100% (1)

- M01e1-Introduction of Optometrists & Opticians Act 2007 PresentationDocument45 pagesM01e1-Introduction of Optometrists & Opticians Act 2007 Presentationsytwins100% (1)

- Saudi Indian Embassy ContactDocument4 pagesSaudi Indian Embassy ContactjagateesanNo ratings yet

- Wireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010Document21 pagesWireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010ahmed alshamliNo ratings yet

- Athul AjiDocument5 pagesAthul AjiAsif SNo ratings yet

- Introduction To Surface EngineeringDocument31 pagesIntroduction To Surface Engineeringlogeshboy007No ratings yet

- 9 Polyethylene Piping SystemDocument4 pages9 Polyethylene Piping SystemPrashant PatilNo ratings yet

- Reading Assignment I: Intro To Swift: ObjectiveDocument10 pagesReading Assignment I: Intro To Swift: ObjectiveAlbert JordanNo ratings yet

- Sinumerik - 828D - Machine Commissioning - 2009 PDFDocument476 pagesSinumerik - 828D - Machine Commissioning - 2009 PDFpavlestepanic9932No ratings yet

- Quiz 1 Internet ShoppingDocument1 pageQuiz 1 Internet ShoppingEloy RicouzNo ratings yet

- AmbaniDocument14 pagesAmbaniShimoni ShahNo ratings yet

- 4 Differently Able Persons ActDocument7 pages4 Differently Able Persons Actumer plays gameNo ratings yet

- SM ART-CUT@ Techno Logy S 0 1 A New High Volume Application For Ion ImplantationDocument4 pagesSM ART-CUT@ Techno Logy S 0 1 A New High Volume Application For Ion ImplantationMarco Aurélio DonatoNo ratings yet