Professional Documents

Culture Documents

Fischer FIS V Load TAbles

Fischer FIS V Load TAbles

Uploaded by

ikirby77Copyright:

Available Formats

You might also like

- Metsec JoistsDocument40 pagesMetsec Joistsikirby7750% (2)

- Tables - Bending Moment and Reaction Tables For Continuous BeamsDocument3 pagesTables - Bending Moment and Reaction Tables For Continuous Beamsikirby77100% (1)

- Puddle FlangeDocument12 pagesPuddle FlangeShameel PtNo ratings yet

- Berges Acm STDDocument64 pagesBerges Acm STDAdan Solano50% (4)

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 pagesHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNo ratings yet

- Hilti HVZ 1Document13 pagesHilti HVZ 1Mihnea-Bogdan NicolaescuNo ratings yet

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoNo ratings yet

- Hilti HIT HY 150 MAX With RebarDocument14 pagesHilti HIT HY 150 MAX With RebarNelly BuquironNo ratings yet

- 2011 HSC-I Safety AnchorDocument3 pages2011 HSC-I Safety AnchorDifa LiuNo ratings yet

- Hilti HIT-HY 150 With HIT-V or HAS PDFDocument19 pagesHilti HIT-HY 150 With HIT-V or HAS PDFfkh3dNo ratings yet

- HSL-3 Heavy Duty AnchorDocument12 pagesHSL-3 Heavy Duty AnchorMihnea-Bogdan NicolaescuNo ratings yet

- Hollo BoltDocument1 pageHollo Boltmr_hazzardNo ratings yet

- Press-Fit Technology: The New VaripinDocument3 pagesPress-Fit Technology: The New VaripinonafetsNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- 2014 HKD Push-In Anchor - Single Anchor ApplicationDocument3 pages2014 HKD Push-In Anchor - Single Anchor ApplicationDifa LiuNo ratings yet

- Montavimo Technika Armaturos StrypamsDocument5 pagesMontavimo Technika Armaturos StrypamsHafidh BaequnieNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- Rothoblaas - Ab7.technical Data Sheets - enDocument1 pageRothoblaas - Ab7.technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Hilti - Calculo Manual de Re500Document41 pagesHilti - Calculo Manual de Re500James ClaytonNo ratings yet

- TENSACCIAI - PostTensioningDocument28 pagesTENSACCIAI - PostTensioningnovakno1No ratings yet

- AEGNEP Compressed AirDocument42 pagesAEGNEP Compressed AirDavid HayesNo ratings yet

- RC Beam Design CCAA - Revised 1.2 JWWDocument12 pagesRC Beam Design CCAA - Revised 1.2 JWWFerdie TolosaNo ratings yet

- Rothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enDocument6 pagesRothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocument20 pagesHilti Hit Hy 150 Max Con Barra Corrugadalandsv01No ratings yet

- Hilti Hit-Hy 200 With Hit-V RodDocument20 pagesHilti Hit-Hy 200 With Hit-V RodFodor ZoltanNo ratings yet

- Hilti Hvu HasDocument12 pagesHilti Hvu HasAMCRUZ77No ratings yet

- 4safebarriera ENG H2 W4 A BP - 3n32122Document6 pages4safebarriera ENG H2 W4 A BP - 3n32122TBPNo ratings yet

- Stainless StudsDocument4 pagesStainless StudsNestramiNo ratings yet

- Catalogue Ipsi EpDocument70 pagesCatalogue Ipsi EprachedscribNo ratings yet

- Upvc SWR Pipes PDFDocument7 pagesUpvc SWR Pipes PDFalmig200No ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDocument10 pagesRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNo ratings yet

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Document9 pages2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNo ratings yet

- High Strength Hexagon Bolts (JIS B1186)Document4 pagesHigh Strength Hexagon Bolts (JIS B1186)Mario HanamiciNo ratings yet

- Crom Plated BarsDocument24 pagesCrom Plated BarschonubobbyNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Bridge Design To EurocodesDocument21 pagesBridge Design To EurocodesMahmood MuftiNo ratings yet

- Hilti Hy 150 Rebar Design Guide 1Document11 pagesHilti Hy 150 Rebar Design Guide 1chrtromNo ratings yet

- Dywidag High Strength BarsDocument4 pagesDywidag High Strength Barsnishchint100% (1)

- Rothoblaas - Abs Red - Technical Data Sheets - enDocument1 pageRothoblaas - Abs Red - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- Fisa Tehnica Ancore Mecanice Cu InelDocument3 pagesFisa Tehnica Ancore Mecanice Cu InelCristian RezNo ratings yet

- ESA CNDocument2 pagesESA CNblble82No ratings yet

- Post TensionDocument56 pagesPost TensionanoopsurendranNo ratings yet

- Hilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodDocument16 pagesHilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodsandeepsharmafjNo ratings yet

- HSA Stud AnchorDocument11 pagesHSA Stud AnchorWin ThanNo ratings yet

- Hilti Manual For BoltDocument11 pagesHilti Manual For Boltcsengineer20% (1)

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- DSI ALWAG-Systems Pantex Lattice Girders EDocument8 pagesDSI ALWAG-Systems Pantex Lattice Girders Epramods_8No ratings yet

- Declaratie de Conformitate Ancore MTH PDFDocument3 pagesDeclaratie de Conformitate Ancore MTH PDFFerencz ZsoltNo ratings yet

- d05 - r04 Shi & EstimationDocument27 pagesd05 - r04 Shi & EstimationJames McguireNo ratings yet

- Blacks Structural Bolts: Fasteners Your Guarantee of Quality Industrial FastenersDocument4 pagesBlacks Structural Bolts: Fasteners Your Guarantee of Quality Industrial FastenersBhartendu PatniNo ratings yet

- Hilti HIT MM Plus 1Document14 pagesHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuNo ratings yet

- TD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)Document5 pagesTD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)phamducquangNo ratings yet

- AD 001: Guidance On Compactness: Sci Advisory DeskDocument4 pagesAD 001: Guidance On Compactness: Sci Advisory Deskikirby77No ratings yet

- FastenalTechnicalReferenceGuide PDFDocument62 pagesFastenalTechnicalReferenceGuide PDFikirby77No ratings yet

- Bridge Deck PDFDocument2 pagesBridge Deck PDFikirby77100% (1)

- AD171 Partial Penetration Butt WeldsDocument3 pagesAD171 Partial Penetration Butt Weldsikirby77100% (1)

- AD302 Tightening of Ordinary BoltsDocument2 pagesAD302 Tightening of Ordinary Boltsikirby77No ratings yet

- Hollo BoltDocument5 pagesHollo Boltikirby77No ratings yet

- SchockDocument236 pagesSchockikirby77No ratings yet

- Lintel Product SelectorDocument88 pagesLintel Product Selectorikirby77No ratings yet

- Hilti Hit Hy70 System DS GBDocument9 pagesHilti Hit Hy70 System DS GBikirby77No ratings yet

- Recipe For Mince PiesDocument1 pageRecipe For Mince Piesikirby77No ratings yet

- Redman Fisher GuideDocument16 pagesRedman Fisher Guideikirby77No ratings yet

- Stressline Beam and BlockDocument10 pagesStressline Beam and Blockikirby77100% (1)

- Capacitive Touch SensorDocument20 pagesCapacitive Touch SensorSarah Joy ManimtimNo ratings yet

- TI TMP513 Thermocouple CircuitDocument4 pagesTI TMP513 Thermocouple CircuitimbentoscribNo ratings yet

- Frram RelaDocument56 pagesFrram RelaOscar BayardNo ratings yet

- MS-100BT Operationmanual English PDFDocument40 pagesMS-100BT Operationmanual English PDFbNo ratings yet

- Rugged, Lightweight, Wireless and Convertible: Panasonic Recommends Windows Vista BusinessDocument1 pageRugged, Lightweight, Wireless and Convertible: Panasonic Recommends Windows Vista BusinessPana SonicNo ratings yet

- Group Members: Farah Deana Binti Norazhar Syed Fakhrur Radzy Bin Syed Rusli Harrven Kumar A/L Selvaraju Aidilfitri Bin AwaluddinDocument25 pagesGroup Members: Farah Deana Binti Norazhar Syed Fakhrur Radzy Bin Syed Rusli Harrven Kumar A/L Selvaraju Aidilfitri Bin AwaluddinAidil FitriNo ratings yet

- CM2859 Cryostat MicrotomeDocument32 pagesCM2859 Cryostat MicrotomeluroguitaNo ratings yet

- KX-FT987 983 981CXDocument2 pagesKX-FT987 983 981CXArsilious ArsiNo ratings yet

- Exceptions: Dr. E. Papanasam Ap-Iii SocDocument16 pagesExceptions: Dr. E. Papanasam Ap-Iii SocThomas NivethaNo ratings yet

- Jual D-LINK DPR-1061 - Print Server - Harga, Spesifikasi, Dan ReviewDocument4 pagesJual D-LINK DPR-1061 - Print Server - Harga, Spesifikasi, Dan ReviewRudhi SaputraNo ratings yet

- EZ Base Assembly InstructionsDocument19 pagesEZ Base Assembly InstructionsAlain GoupNo ratings yet

- Flash BIOS by UEFI BIOS Setup Utility enDocument8 pagesFlash BIOS by UEFI BIOS Setup Utility enrechtman1289No ratings yet

- Database Manager or Technology Manager or CTODocument3 pagesDatabase Manager or Technology Manager or CTOapi-79249551No ratings yet

- Port Unification in GlassFish 3 - Part 2Document2 pagesPort Unification in GlassFish 3 - Part 2MehmetNo ratings yet

- Unit-3: 8085 Microprocessor: (MPI) GTU # 3160712Document107 pagesUnit-3: 8085 Microprocessor: (MPI) GTU # 3160712GajjuNo ratings yet

- P 615 SN 4147526Document52 pagesP 615 SN 4147526Dan Alin MirceaNo ratings yet

- Iris PDFDocument4 pagesIris PDFdinhvuNo ratings yet

- Configuration Steps For Automatic PackagingDocument4 pagesConfiguration Steps For Automatic PackagingcolosoderadaNo ratings yet

- 684 978-1-4577-1664-5/11/$26.00 ©2011 IeeeDocument5 pages684 978-1-4577-1664-5/11/$26.00 ©2011 IeeePradeep AryaNo ratings yet

- CH-2 MethodologyDocument19 pagesCH-2 MethodologyHendri Arief SetyawanNo ratings yet

- Basic PPP ConfigurationDocument16 pagesBasic PPP ConfigurationEngku PuteraNo ratings yet

- Pricelist Connectors 2019Document5 pagesPricelist Connectors 2019Ej AquinoNo ratings yet

- Linux SeminarDocument26 pagesLinux SeminarPiyuSh JainNo ratings yet

- Ripley 2015 CatalogDocument184 pagesRipley 2015 CatalogDivNo ratings yet

- X DSLDocument8 pagesX DSLTushar SaxenaNo ratings yet

- Gilbarco Encore Dispenser FamilyDocument6 pagesGilbarco Encore Dispenser FamilyRick AlingalanNo ratings yet

- Hardware CzoneDocument2 pagesHardware CzoneAbdulhadi WahidNo ratings yet

- Service Manual: TM-H6000/H6000PDocument232 pagesService Manual: TM-H6000/H6000PLeonardo Rufino da Costa100% (1)

- x86 DisassemblyDocument81 pagesx86 DisassemblyAyush PateriaNo ratings yet

Fischer FIS V Load TAbles

Fischer FIS V Load TAbles

Uploaded by

ikirby77Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fischer FIS V Load TAbles

Fischer FIS V Load TAbles

Uploaded by

ikirby77Copyright:

Available Formats

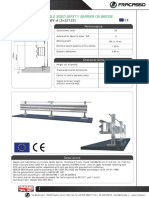

Chemical xings

68

CHEMICAL FIXINGS

Injection technique for concrete

TECHNICAL DATA

Cleaning brush for concrete

Type

Art.-No.

Compressed-air cleaning gun ABP

ID

for thread

qty. per box

M

pcs.

BS 8

BS 10

BS 12

BS 14

BS 18

BS 24

BS 28

BS 35

ABP

78177

78178

78179

78180

78181

78182

78183

78184

59456

7

4

1

7

4

1

8

5

8

M6

M8

M 10

M 12

M 16

M 20

M 24

M 30

-

1

1

1

1

1

1

1

1

1

LOADS - INJECTION MORTAR FIS V AND FIS VS

Mean ultimate loads, design resistant and recommended loads for single anchors of scher Injection system FIS V and

FIS VS used with threaded rods FIS A with large axial spacing and edge distance.

Anchor size

h01 =

h02 =

h03 =

Effektive anchorage depth =

Drill hole depth

Drill hole diameter

hef1

hef2

hef3

d0

M6

M8

M 10

Non-cracked concrete

M 12

M 16

M 20

M 24

M30

50

60

75

8

65

80

95

10

80

90

110

12

95

110

120

14

160

170

210

24

190

240

285

28

240

280

340

35

[mm]

[mm]

[mm]

[mm]

125

140

170

18

Mean ultimate loads Nu and Vu [kN]

A4

14.1*

14.1*

14.1*

8.4*

gvz

19.0*

19.0*

19.0*

11.4*

A4

25.6*

25.6*

25.6*

15.4*

gvz

30.2*

30.2*

30.2*

18.1*

A4

40.6*

40.6*

40.6*

24.4*

gvz

43.8*

43.8*

43.8*

26.3*

A4

58.4

59.0*

59.0*

35.4*

gvz

A4

gvz

81.6* 93.2 127.4

81.6* 104.4 127.4*

81.6* 109.9* 127.4*

49.0* 65.9* 76.4*

gvz

4.7

5.7

7.1

4.2

A4

4.7

5.7

7.1

4.5

gvz

8.2

10.1

11.9

7.6

A4

8.2

10.1

11.9

8.2

gvz

12.6

14.1

17.3

12.1

A4

12.6

14.1

17.3

13.0

gvz

17.9

20.7

22.6

17.5

A4

17.9

20.7

22.6

18.9

gvz

31.4

35.2

42.7

32.6

gvz

A4

gvz

A4

gvz

A4

gvz

A4

gvz

A4

gvz

A4

gvz

A4

gvz

A4

3.4

4.1

5.1

3.0

3.4

4.1

5.1

3.2

5.9

7.2

8.5

5.4

5.9

7.2

8.5

5.9

9.0

10.1

12.4

8.6

9.0

10.1

12.4

9.3

12.8

14.8

16.1

12.5

12.8

14.8

16.1

13.5

22.4

25.1

30.5

23.3

22.4

25.1

30.5

25.2

28.7

30.5

37.7

36.4

28.7

30.5

37.7

39.3

40.9

51.7

61.4

52.4

40.9

51.7

61.4

56.6

48.4

56.6

68.6

83.4

48.4

56.6

68.6

89.9

gvz

Mrec [Nm]

4.5

Component dimensions, minimum axial spacings and edge distances

A4

4.9

gvz

114

A4

11.9

gvz

22.3

A4

23.8

gvz

38.9

A4

42.1

gvz

98.9

A4

gvz

A4

gvz

A4

gvz

A4

106.7 193.1 207.9 333.1 359.4 668.0 720.7

Tensile

Nu

Shear

90

Vu

gvz

[kN] hef1 10.5*

[kN] hef2 10.5*

[kN] hef3 10.5*

[kN]

6.3*

A4

127.4

135.4

167.2

102.9*

gvz

176.9

183.6*

183.6*

110.1*

A4

176.9

223.5

247.1*

148.3*

A4

40.2

42.7

52.8

55.0

gvz

57.3

72.4

85.9

73.4

A4

57.3

72.4

85.9

79.2

gvz

248.1

289.5

291.7*

175.0*

A4

248.1

289.5

351.5

235.6*

Design resistant loads NRd and VRd [kN]

Tensile

NRd

Shear

90

VRd

[kN] hef1

[kN] hef2

[kN] hef3

[kN]

A4

31.4

35.2

42.7

35.3

gvz

40.2

42.7

52.8

51.0

gvz

A4

67.8 67.8

79.2 79.2

96.1 96.1

116.7 125.9

Recommended loads Nrec and Vrec [kN]

Tensile

Nrec

Shear

90

Vrec

[kN] hef1

[kN] hef2

[kN] hef3

[kN]

Recommended bending moment Mrec [Nm]

Min. axial spacing 1)

Min. edge distance 1)

Min. structural component thickness

Required torque

smin

cmin

hmin1

hmin2

hmin3

T inst

[mm]

[mm]

[mm]

[mm]

[mm]

[Nm]

40

40

100

100

115

5

40

40

100

110

125

10

45

45

110

120

140

20

55

55

125

140

150

40

65

65

165

180

210

60

85

85

210

220

260

120

105

105

250

300

345

150

140

140

310

350

410

300

Steel failure decisive.

For minimum axial spacing and minimum edge distance the above described loads have to be reduced (see fischer Technical Handbook or design software CC-Compufix)!

Values given above are valid under the following assumptions: - Sufficient mechanical cleaning of the drill hole using stainless steel brushes.

- Dry concrete, temperature range 50C long term temperature and 80C short term temperature.

All values apply for concrete C 20/25 without edge or spacing influence.

Design resistant loads: material safety factor M is included. Material safety factor M depends on the type of anchor.

Recommended loads: material safety factor M and safety factor for load L = 1.4 are included.

1)

The condition of application dier from those given in the European Technical Approval (ETA). For further detailed information about the ETA please contact the scher technical service department.

RG M threaded rods can be used as an alternative. Please refer to page 47 for suitable threaded rods.

You might also like

- Metsec JoistsDocument40 pagesMetsec Joistsikirby7750% (2)

- Tables - Bending Moment and Reaction Tables For Continuous BeamsDocument3 pagesTables - Bending Moment and Reaction Tables For Continuous Beamsikirby77100% (1)

- Puddle FlangeDocument12 pagesPuddle FlangeShameel PtNo ratings yet

- Berges Acm STDDocument64 pagesBerges Acm STDAdan Solano50% (4)

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 pagesHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNo ratings yet

- Hilti HVZ 1Document13 pagesHilti HVZ 1Mihnea-Bogdan NicolaescuNo ratings yet

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoNo ratings yet

- Hilti HIT HY 150 MAX With RebarDocument14 pagesHilti HIT HY 150 MAX With RebarNelly BuquironNo ratings yet

- 2011 HSC-I Safety AnchorDocument3 pages2011 HSC-I Safety AnchorDifa LiuNo ratings yet

- Hilti HIT-HY 150 With HIT-V or HAS PDFDocument19 pagesHilti HIT-HY 150 With HIT-V or HAS PDFfkh3dNo ratings yet

- HSL-3 Heavy Duty AnchorDocument12 pagesHSL-3 Heavy Duty AnchorMihnea-Bogdan NicolaescuNo ratings yet

- Hollo BoltDocument1 pageHollo Boltmr_hazzardNo ratings yet

- Press-Fit Technology: The New VaripinDocument3 pagesPress-Fit Technology: The New VaripinonafetsNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- 2014 HKD Push-In Anchor - Single Anchor ApplicationDocument3 pages2014 HKD Push-In Anchor - Single Anchor ApplicationDifa LiuNo ratings yet

- Montavimo Technika Armaturos StrypamsDocument5 pagesMontavimo Technika Armaturos StrypamsHafidh BaequnieNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- Rothoblaas - Ab7.technical Data Sheets - enDocument1 pageRothoblaas - Ab7.technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Hilti - Calculo Manual de Re500Document41 pagesHilti - Calculo Manual de Re500James ClaytonNo ratings yet

- TENSACCIAI - PostTensioningDocument28 pagesTENSACCIAI - PostTensioningnovakno1No ratings yet

- AEGNEP Compressed AirDocument42 pagesAEGNEP Compressed AirDavid HayesNo ratings yet

- RC Beam Design CCAA - Revised 1.2 JWWDocument12 pagesRC Beam Design CCAA - Revised 1.2 JWWFerdie TolosaNo ratings yet

- Rothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enDocument6 pagesRothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocument20 pagesHilti Hit Hy 150 Max Con Barra Corrugadalandsv01No ratings yet

- Hilti Hit-Hy 200 With Hit-V RodDocument20 pagesHilti Hit-Hy 200 With Hit-V RodFodor ZoltanNo ratings yet

- Hilti Hvu HasDocument12 pagesHilti Hvu HasAMCRUZ77No ratings yet

- 4safebarriera ENG H2 W4 A BP - 3n32122Document6 pages4safebarriera ENG H2 W4 A BP - 3n32122TBPNo ratings yet

- Stainless StudsDocument4 pagesStainless StudsNestramiNo ratings yet

- Catalogue Ipsi EpDocument70 pagesCatalogue Ipsi EprachedscribNo ratings yet

- Upvc SWR Pipes PDFDocument7 pagesUpvc SWR Pipes PDFalmig200No ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDocument10 pagesRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNo ratings yet

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Document9 pages2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNo ratings yet

- High Strength Hexagon Bolts (JIS B1186)Document4 pagesHigh Strength Hexagon Bolts (JIS B1186)Mario HanamiciNo ratings yet

- Crom Plated BarsDocument24 pagesCrom Plated BarschonubobbyNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Bridge Design To EurocodesDocument21 pagesBridge Design To EurocodesMahmood MuftiNo ratings yet

- Hilti Hy 150 Rebar Design Guide 1Document11 pagesHilti Hy 150 Rebar Design Guide 1chrtromNo ratings yet

- Dywidag High Strength BarsDocument4 pagesDywidag High Strength Barsnishchint100% (1)

- Rothoblaas - Abs Red - Technical Data Sheets - enDocument1 pageRothoblaas - Abs Red - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- Fisa Tehnica Ancore Mecanice Cu InelDocument3 pagesFisa Tehnica Ancore Mecanice Cu InelCristian RezNo ratings yet

- ESA CNDocument2 pagesESA CNblble82No ratings yet

- Post TensionDocument56 pagesPost TensionanoopsurendranNo ratings yet

- Hilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodDocument16 pagesHilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodsandeepsharmafjNo ratings yet

- HSA Stud AnchorDocument11 pagesHSA Stud AnchorWin ThanNo ratings yet

- Hilti Manual For BoltDocument11 pagesHilti Manual For Boltcsengineer20% (1)

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- DSI ALWAG-Systems Pantex Lattice Girders EDocument8 pagesDSI ALWAG-Systems Pantex Lattice Girders Epramods_8No ratings yet

- Declaratie de Conformitate Ancore MTH PDFDocument3 pagesDeclaratie de Conformitate Ancore MTH PDFFerencz ZsoltNo ratings yet

- d05 - r04 Shi & EstimationDocument27 pagesd05 - r04 Shi & EstimationJames McguireNo ratings yet

- Blacks Structural Bolts: Fasteners Your Guarantee of Quality Industrial FastenersDocument4 pagesBlacks Structural Bolts: Fasteners Your Guarantee of Quality Industrial FastenersBhartendu PatniNo ratings yet

- Hilti HIT MM Plus 1Document14 pagesHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuNo ratings yet

- TD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)Document5 pagesTD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)phamducquangNo ratings yet

- AD 001: Guidance On Compactness: Sci Advisory DeskDocument4 pagesAD 001: Guidance On Compactness: Sci Advisory Deskikirby77No ratings yet

- FastenalTechnicalReferenceGuide PDFDocument62 pagesFastenalTechnicalReferenceGuide PDFikirby77No ratings yet

- Bridge Deck PDFDocument2 pagesBridge Deck PDFikirby77100% (1)

- AD171 Partial Penetration Butt WeldsDocument3 pagesAD171 Partial Penetration Butt Weldsikirby77100% (1)

- AD302 Tightening of Ordinary BoltsDocument2 pagesAD302 Tightening of Ordinary Boltsikirby77No ratings yet

- Hollo BoltDocument5 pagesHollo Boltikirby77No ratings yet

- SchockDocument236 pagesSchockikirby77No ratings yet

- Lintel Product SelectorDocument88 pagesLintel Product Selectorikirby77No ratings yet

- Hilti Hit Hy70 System DS GBDocument9 pagesHilti Hit Hy70 System DS GBikirby77No ratings yet

- Recipe For Mince PiesDocument1 pageRecipe For Mince Piesikirby77No ratings yet

- Redman Fisher GuideDocument16 pagesRedman Fisher Guideikirby77No ratings yet

- Stressline Beam and BlockDocument10 pagesStressline Beam and Blockikirby77100% (1)

- Capacitive Touch SensorDocument20 pagesCapacitive Touch SensorSarah Joy ManimtimNo ratings yet

- TI TMP513 Thermocouple CircuitDocument4 pagesTI TMP513 Thermocouple CircuitimbentoscribNo ratings yet

- Frram RelaDocument56 pagesFrram RelaOscar BayardNo ratings yet

- MS-100BT Operationmanual English PDFDocument40 pagesMS-100BT Operationmanual English PDFbNo ratings yet

- Rugged, Lightweight, Wireless and Convertible: Panasonic Recommends Windows Vista BusinessDocument1 pageRugged, Lightweight, Wireless and Convertible: Panasonic Recommends Windows Vista BusinessPana SonicNo ratings yet

- Group Members: Farah Deana Binti Norazhar Syed Fakhrur Radzy Bin Syed Rusli Harrven Kumar A/L Selvaraju Aidilfitri Bin AwaluddinDocument25 pagesGroup Members: Farah Deana Binti Norazhar Syed Fakhrur Radzy Bin Syed Rusli Harrven Kumar A/L Selvaraju Aidilfitri Bin AwaluddinAidil FitriNo ratings yet

- CM2859 Cryostat MicrotomeDocument32 pagesCM2859 Cryostat MicrotomeluroguitaNo ratings yet

- KX-FT987 983 981CXDocument2 pagesKX-FT987 983 981CXArsilious ArsiNo ratings yet

- Exceptions: Dr. E. Papanasam Ap-Iii SocDocument16 pagesExceptions: Dr. E. Papanasam Ap-Iii SocThomas NivethaNo ratings yet

- Jual D-LINK DPR-1061 - Print Server - Harga, Spesifikasi, Dan ReviewDocument4 pagesJual D-LINK DPR-1061 - Print Server - Harga, Spesifikasi, Dan ReviewRudhi SaputraNo ratings yet

- EZ Base Assembly InstructionsDocument19 pagesEZ Base Assembly InstructionsAlain GoupNo ratings yet

- Flash BIOS by UEFI BIOS Setup Utility enDocument8 pagesFlash BIOS by UEFI BIOS Setup Utility enrechtman1289No ratings yet

- Database Manager or Technology Manager or CTODocument3 pagesDatabase Manager or Technology Manager or CTOapi-79249551No ratings yet

- Port Unification in GlassFish 3 - Part 2Document2 pagesPort Unification in GlassFish 3 - Part 2MehmetNo ratings yet

- Unit-3: 8085 Microprocessor: (MPI) GTU # 3160712Document107 pagesUnit-3: 8085 Microprocessor: (MPI) GTU # 3160712GajjuNo ratings yet

- P 615 SN 4147526Document52 pagesP 615 SN 4147526Dan Alin MirceaNo ratings yet

- Iris PDFDocument4 pagesIris PDFdinhvuNo ratings yet

- Configuration Steps For Automatic PackagingDocument4 pagesConfiguration Steps For Automatic PackagingcolosoderadaNo ratings yet

- 684 978-1-4577-1664-5/11/$26.00 ©2011 IeeeDocument5 pages684 978-1-4577-1664-5/11/$26.00 ©2011 IeeePradeep AryaNo ratings yet

- CH-2 MethodologyDocument19 pagesCH-2 MethodologyHendri Arief SetyawanNo ratings yet

- Basic PPP ConfigurationDocument16 pagesBasic PPP ConfigurationEngku PuteraNo ratings yet

- Pricelist Connectors 2019Document5 pagesPricelist Connectors 2019Ej AquinoNo ratings yet

- Linux SeminarDocument26 pagesLinux SeminarPiyuSh JainNo ratings yet

- Ripley 2015 CatalogDocument184 pagesRipley 2015 CatalogDivNo ratings yet

- X DSLDocument8 pagesX DSLTushar SaxenaNo ratings yet

- Gilbarco Encore Dispenser FamilyDocument6 pagesGilbarco Encore Dispenser FamilyRick AlingalanNo ratings yet

- Hardware CzoneDocument2 pagesHardware CzoneAbdulhadi WahidNo ratings yet

- Service Manual: TM-H6000/H6000PDocument232 pagesService Manual: TM-H6000/H6000PLeonardo Rufino da Costa100% (1)

- x86 DisassemblyDocument81 pagesx86 DisassemblyAyush PateriaNo ratings yet