Professional Documents

Culture Documents

Evaporation Pond at SLBP

Evaporation Pond at SLBP

Uploaded by

HaleemUrRashidBangashOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaporation Pond at SLBP

Evaporation Pond at SLBP

Uploaded by

HaleemUrRashidBangashCopyright:

Available Formats

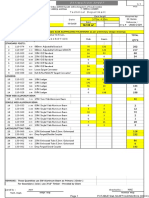

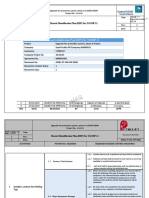

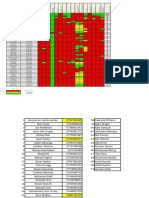

JOB SAFETY ANALYSIS RECORD SHEET

PLANT / EQUIPMENT #

SLBP

DEPARTMENT: CRDD DATE: JANUARY, 08, 2012

DIVISION\Unit: SRBP JSA NO.:

ROUTINE JSA NON ROUTINE JSA

Description of job / task:

Installation of SIX Isolation valves @ NRTU

Prepared By Reviewed By Approved By

Haleem Ur Rashid Bangash

(Safety Engineer)

Hadi Hammad Al- Hammam Group)

Dhafar S. Aldossary

References:

GI 2.100 Work Permit System, SA Safety Handbook, GI 6.021, Saudi Aramco Construction Safety

Manual, Saudi Aramco Excavation Guide, SAES-A-114 Excavation and Backfill, SAES-Q-006 Asphalt

Concrete Paving, SAES-S-020 Industrial Drainage Sewers,

Safety Equipment Required:

Employee is required to wear PPE, Including helmet, safety glasses, hearing protection, Dust mask, Proper

gloves, Safety shoes and FRC,Sand blasting helmet Testing equipment.

Job

Step

#

Sequence of Basic Job

Steps

Potential Hazards Required Hazard Control

1

Site preparation and

Obtain work permit.

- Unsafe work place

might pose danger

- Work permit

procedure violation

- Certified work permit issuer and receiver

will conduct joint site inspection, find out

the hazards and build proper precautions

for it.

- Utilize Fire Watch and fire extinguishers at

site.

- Isolate the job area, install barricades and

warning sings.

- Use proper and good condition hand tools.

- Use certified and valid pipe and metal

detector and check for underground

structures/hazards after every one feet (1)

or (30cm) depression.

- Obtain pre-excavation dully signed by the

concerned departments as mentioned on.

- Obtain daily excavation checklist before

commencing the job.

- Keep the job site clean

2

Excavation

- Falling into excavation

and traffic hazard

- Spoils and mud.

- Hazardous

atmosphere and

materials.

- Barricade the excavation area and install

warning signs and traffic/blinking lights on

the edges of excavation to prevent falling

of vehicles, personnel and others at night.

- Use pully and buckets to take out the

spoils from the excavation when the

excavation exceeds 4 feet.

- Keep the spoils atleast 2 feet away from te

edges of the excavation

- Conduct gas tests each day (more

frequent, if required) for the existence of

Flammble, combustibles and Toxic gases

and also for the oxygen deficiency before

the work shift starts.

- Access means / Exit

and Entry.

- Cave-in / Excavation

collapse.

- Underground

structures

- Nearby structures

- If excavation is deeper than 4 feet ,Provide

proper ladder extending 1m high from the

edges of the excavation.

- If the excavation wider than 25 feet,

provide Egress route on each 25 feet

distance.

- All the ladder components should be free

of defect

- Competent person shall inspect the

excavation on daily basis and after rain,

heavy wind, storm and spills from outside

or inside before the job starts.

- When the excavation reaches 1.2 m or 4

feet deep, install firm shoring system as

per soil classification.

- Dont allow heavy equipment/machinery

within 10 feet of the edges of excavation

- The shoring system should be firm and

jacks/braces supported.

- The shoring system/planks/plyboards shall

extend atleast 1 feet high than the edges.

- Update the shoring (push it down) after

each 1 feet increase in the dept.

- Remove the spills/water from the

excavation before starting work.

- Use certified and valid metal/cable and

pipe detector before starting the work

- Check for underground structures/hazards

after every one feet (1) or (30cm)

depression.

- Obtain pre-excavation checklist dully

signed by the concerned departments as

mentioned on it.

- Use the tools mentioned on the pre-

excavation checklist only.

- Never use hand tools with metal handles it

can cause shock and heavy vibration.

- Read the pre-excavatiion checklist for

more details.

- Take care for the nearby structures and if

need give proper support to avoid any

damage.

- If power-operated nearby structures exists,

barricade and isolate it.

3

Backfilling and compaction

- Excavation walls

collapse / Cave-In

- Shoring should not be removed all at once.

- Backfilling and removal of shoring is to be

accomplished first by backfilling up to a

level allowing for the removal of the lower

braces or lift up the shoring upto 30cm or 1

- Another layer of backfill is to be positioned

in the excavation up to the next layer of

braces to be removed or lift up the shoring

upto another 30cm and feet hight or more if

safe and allowed.

- Water used for compaction of fill material

shall be reasonably free of salts, oil, acid,

alkalis, organic matter, or other deleterious

substances.

- Compaction shall be done and the

compaction test for soil integrity is to be

carried.

- All the compaction shall be done as per

SAES-M-100.

4

Installing concrete slabs

- Personal Injury

- Use proper PPEs and tools

- Avoid shortcuts and work safely

- Avoid contact with skin and eyes.

Connecting the POND with

old drain/sump/sewere line

- Fire hazard

- Asphyxication

- Isolate the drain line if possible otherwise

provide vaccum tanker to suck the inside

spill

- Conduct gas tests periodically during work

- Remove all the sources of ignitions from the

site

- No hot work is allowed while the work is in

progress and the sewere is mouth open

- Use proper PPEs i.e. respirators

- Take lot of water while working

5

Close the permit and clean

the area.

- Work permit

procedure violation

- If the area is not

cleaned properly

some hazard may

exist to harm.

- Check the area thoroughly and do the

housekeeping, remove all the tools and

equipments to the yard.

- Both WPI and WPR must sign the permit to

close it when the shift comes to end.

- Permit can be extended, by the next shift

WPI after Joint site inspection with WPR

only afeter the new WPI is agree with the

existing precautions on the permit,

otherwise he will issue a new Permit.

You might also like

- General MS For Chemical CrackingDocument12 pagesGeneral MS For Chemical CrackingAs-Syaff ResourcesNo ratings yet

- JSA For Evaporation PondDocument7 pagesJSA For Evaporation PondSheri Diĺl100% (1)

- Method Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)Document4 pagesMethod Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)poovazhaganNo ratings yet

- NAWPPL-BIMS-NPPL-000-HS-PRO-00015 - C01 - Trenching-Excavation Safety ProcedureDocument7 pagesNAWPPL-BIMS-NPPL-000-HS-PRO-00015 - C01 - Trenching-Excavation Safety ProcedureMoaatazz NouisriNo ratings yet

- Scaffolding Inspector ReviewDocument11 pagesScaffolding Inspector ReviewmyklNo ratings yet

- Quiz1 - Defensive Driving HOJNARDocument2 pagesQuiz1 - Defensive Driving HOJNARMr_Yoshi_123No ratings yet

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Document31 pages14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- Building Resilience in Preschool ChildrenDocument65 pagesBuilding Resilience in Preschool ChildrenAnamari SlavicNo ratings yet

- Trenching Excavation PosterDocument1 pageTrenching Excavation PosterBarnum Pebble DarrelNo ratings yet

- Method Statement of PipelineDocument11 pagesMethod Statement of PipelineJethin SurendranNo ratings yet

- H&S, Environment Inspection Report - KILN BRIDGE Checklist - SafetyCultureDocument8 pagesH&S, Environment Inspection Report - KILN BRIDGE Checklist - SafetyCultureNaveen ChaudharyNo ratings yet

- Method Statement For Hume Pipe CulvertDocument6 pagesMethod Statement For Hume Pipe CulvertRabnawaz Imam0% (1)

- Jha ExampleDocument3 pagesJha ExampleDaizy HazelNo ratings yet

- Method Statement For Installation of Underground Checmical Waste TanksDocument8 pagesMethod Statement For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- Site Safety & Health Plan of The Contractor - Prescribed ContentsDocument8 pagesSite Safety & Health Plan of The Contractor - Prescribed ContentsSufiyan KhedekarNo ratings yet

- Cable Percussion Rig ChecksDocument2 pagesCable Percussion Rig Checksargon39No ratings yet

- CA-4079 - Hand Book - 02062018Document49 pagesCA-4079 - Hand Book - 02062018Mohamed RizwanNo ratings yet

- Fuel Tank Lifting REV01Document7 pagesFuel Tank Lifting REV01armagan55No ratings yet

- BOQ For Civil-BhatindaDocument19 pagesBOQ For Civil-BhatindaRajesh ChowhanNo ratings yet

- WMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1Document8 pagesWMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1tanaNo ratings yet

- Sop Magnesium Anode Installation - ThiessDocument10 pagesSop Magnesium Anode Installation - ThiessbonnicoNo ratings yet

- Crushing Concrete Cylinders at 28 Days of Precast 111 Nos.Document1 pageCrushing Concrete Cylinders at 28 Days of Precast 111 Nos.AlbyNo ratings yet

- SECTION 16270 Transformers Rev 0Document26 pagesSECTION 16270 Transformers Rev 0syedanwerNo ratings yet

- Work Method StatementDocument2 pagesWork Method StatementYasirNo ratings yet

- Standards or NorMS With COST BREakdown AnalysisDocument65 pagesStandards or NorMS With COST BREakdown AnalysisRiyaad MandisaNo ratings yet

- Welcome: Created By: D.S.PAWAR Hse Officer. Mep-In Noted By: A.DASH. Qhse Manger IndiaDocument10 pagesWelcome: Created By: D.S.PAWAR Hse Officer. Mep-In Noted By: A.DASH. Qhse Manger IndiaIrvan HidanNo ratings yet

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Document1 pagePOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelNo ratings yet

- Work Method Statement For Structure ErectionDocument12 pagesWork Method Statement For Structure ErectionMuhammad TeguhNo ratings yet

- Planning Handbook: F:/Field Controls/HANDDocument24 pagesPlanning Handbook: F:/Field Controls/HANDespinozcristianNo ratings yet

- DPR - Product Storage Tank 07.06.2023Document6 pagesDPR - Product Storage Tank 07.06.2023ashfaque khanNo ratings yet

- Step Description Controls: HazardDocument3 pagesStep Description Controls: HazardMainak KhanraNo ratings yet

- Quotation SupplyDocument6 pagesQuotation SupplyShaikhMazharAhmedNo ratings yet

- ANCC ProfileDocument35 pagesANCC ProfileMohammad RawoofNo ratings yet

- Method For Installation of NMFOC & OPGW at GOSP 10Document10 pagesMethod For Installation of NMFOC & OPGW at GOSP 10Subhash Chekka SEC 115KV ProjectNo ratings yet

- Jagan Steam Power PlantDocument101 pagesJagan Steam Power PlantMahender VangalaNo ratings yet

- Work Method Statement For Column InternalDocument13 pagesWork Method Statement For Column Internalgururaj100% (1)

- Risk Assessment ExcavationDocument16 pagesRisk Assessment ExcavationJaseelKanhirathinkal100% (1)

- PRAKASAM Irrigation ProfileDocument32 pagesPRAKASAM Irrigation ProfilePrabhakara Rao ThanikondaNo ratings yet

- C0329C-SOW-00-M-0005 - Scope of Work For Scaffolding RentDocument9 pagesC0329C-SOW-00-M-0005 - Scope of Work For Scaffolding RentReza Furqon100% (1)

- Denso Brochure 3Document10 pagesDenso Brochure 3mohdNo ratings yet

- Warning Tape SpecsDocument3 pagesWarning Tape SpecsAnees OlasserilNo ratings yet

- PTW RemovedDocument71 pagesPTW RemovedSYED AHMEDNo ratings yet

- Appendix 1 WPCG Activity MatrixDocument7 pagesAppendix 1 WPCG Activity MatrixDulanjaya NayanajithNo ratings yet

- Working at HeightDocument3 pagesWorking at HeightMelanie CortezNo ratings yet

- JSA For Confined Space 20 12 2019 - TS3Document5 pagesJSA For Confined Space 20 12 2019 - TS3narasimhamurthy414No ratings yet

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDocument10 pagesSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanNo ratings yet

- HSE Alert - Pipe Roll Over TBT PDFDocument19 pagesHSE Alert - Pipe Roll Over TBT PDFrodman823No ratings yet

- MTO Pipeline Mazalij Civil SubconDocument20 pagesMTO Pipeline Mazalij Civil SubconJonald DagsaNo ratings yet

- CC Road A-B-C-D-E WARD - 111CR (12-2-2020 LD) BOQ PDFDocument15 pagesCC Road A-B-C-D-E WARD - 111CR (12-2-2020 LD) BOQ PDFSwapnil PalavNo ratings yet

- Hanging Scaffolding Rev B-Layout1Document1 pageHanging Scaffolding Rev B-Layout1grantNo ratings yet

- 02013-RFQ-036-REV00 Chemical Storage Building DesignDocument7 pages02013-RFQ-036-REV00 Chemical Storage Building DesignOusmane DiengNo ratings yet

- F09 - QC Monthly Report - JanuaryDocument10 pagesF09 - QC Monthly Report - Januaryrazi khanNo ratings yet

- JSA Pile Concrete Works OkDocument9 pagesJSA Pile Concrete Works OkMon Trang NguyễnNo ratings yet

- EOT Crane PermitDocument1 pageEOT Crane PermitHimanshu KumarNo ratings yet

- Project Safety OrientationDocument3 pagesProject Safety OrientationJuan Camilo RomeroNo ratings yet

- Scaffolding Rental - One Oasis Cdo BLDG 2Document3 pagesScaffolding Rental - One Oasis Cdo BLDG 2Ronell SolijonNo ratings yet

- Kure Kote 75Document1 pageKure Kote 75pravi3434100% (2)

- Safety BookDocument18 pagesSafety BookSohag MiahNo ratings yet

- Shoring ProcedureDocument7 pagesShoring Procedurechebok manNo ratings yet

- Smart Glass ProcedureDocument117 pagesSmart Glass ProcedureFrancis DhanarajNo ratings yet

- 01 Rigging and Lifting Plan GTG-2 GeneratorDocument2 pages01 Rigging and Lifting Plan GTG-2 GeneratorHamzaNoumanNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 pageBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNo ratings yet

- BI 10-02133, March 23 2020, SAFETY STATISTICSDocument2 pagesBI 10-02133, March 23 2020, SAFETY STATISTICSHaleemUrRashidBangashNo ratings yet

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 pagesBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Document31 pages13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashNo ratings yet

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 pagesBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 pageBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNo ratings yet

- BI 10-02133, WEEK 06, Safety Statistics Reoport NDocument1 pageBI 10-02133, WEEK 06, Safety Statistics Reoport NHaleemUrRashidBangash100% (1)

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 pagesHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNo ratings yet

- 01 Safety Statistics by Haleem Ur Rashid, BI 10-02185Document3 pages01 Safety Statistics by Haleem Ur Rashid, BI 10-02185HaleemUrRashidBangashNo ratings yet

- Hazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Document27 pages20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- Hse Organization Chart: Industrial Projections Contracting EstablishmentDocument1 pageHse Organization Chart: Industrial Projections Contracting EstablishmentHaleemUrRashidBangash100% (2)

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 pagesHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNo ratings yet

- 11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020Document36 pages11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pages9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNo ratings yet

- Branch of Egyptian Projects Co.: Hse Organization ChartDocument1 pageBranch of Egyptian Projects Co.: Hse Organization ChartHaleemUrRashidBangashNo ratings yet

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pages5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNo ratings yet

- Haleem Ur Rashid - Lac - QMS - IrcaDocument1 pageHaleem Ur Rashid - Lac - QMS - IrcaHaleemUrRashidBangashNo ratings yet

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pages4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNo ratings yet

- FA BleedingDocument1 pageFA BleedingHaleemUrRashidBangashNo ratings yet

- 60 Training MatrixDocument4 pages60 Training MatrixHaleemUrRashidBangashNo ratings yet

- Hse Organization Chart: Industrial Projections Contracting EstablishmentDocument1 pageHse Organization Chart: Industrial Projections Contracting EstablishmentHaleemUrRashidBangash100% (1)

- SAOO Safety Orientation Registration Form - PETROJET 03-Mar-20Document1 pageSAOO Safety Orientation Registration Form - PETROJET 03-Mar-20HaleemUrRashidBangashNo ratings yet

- Fa 1 PDFDocument1 pageFa 1 PDFHaleemUrRashidBangashNo ratings yet

- The Psychometric Properties of The Gilliam AutismDocument14 pagesThe Psychometric Properties of The Gilliam AutismJuan Alberto Veras VelozNo ratings yet

- 03 Positive Behaviour Support Planning Part 3 Web 2014Document15 pages03 Positive Behaviour Support Planning Part 3 Web 2014Mirela Cojocaru StetcoNo ratings yet

- Presented Before The Annual Meeting of The American Association of Orthodontists, Dal-Las, Texas, April, 1953Document13 pagesPresented Before The Annual Meeting of The American Association of Orthodontists, Dal-Las, Texas, April, 1953Paola LoloNo ratings yet

- Self Sufficient Herbalism A Guide To Growing, Gat Z Lib OrgDocument339 pagesSelf Sufficient Herbalism A Guide To Growing, Gat Z Lib OrgMatheus Ferreira100% (2)

- Generalized Body Pain and Weakness: 1. Encourage The PatientDocument4 pagesGeneralized Body Pain and Weakness: 1. Encourage The PatientVhiance Czaramae LahuranNo ratings yet

- DLPDocument7 pagesDLPVINUYA, Kurl JoshuaNo ratings yet

- Coding BPJS KesehatanDocument3 pagesCoding BPJS Kesehatananang tri joe100% (1)

- Jsa Removal Fixing InsulationDocument2 pagesJsa Removal Fixing InsulationAprilia Rizki Ardila63% (8)

- DLP 3 P.E 1Document3 pagesDLP 3 P.E 1Ej MisolaNo ratings yet

- Food Chain Self-Evaluation Rubric - FinalDocument1 pageFood Chain Self-Evaluation Rubric - Finalapi-365348813No ratings yet

- Suspended SolidDocument7 pagesSuspended Solidiena razakNo ratings yet

- Aditya Birla - Claim - FormDocument9 pagesAditya Birla - Claim - FormSaransh KumarNo ratings yet

- Articaine Vs LidocaineDocument25 pagesArticaine Vs LidocainecjoybensondmdNo ratings yet

- Speech & Language Therapy in Practice, Autumn 2006Document32 pagesSpeech & Language Therapy in Practice, Autumn 2006Speech & Language Therapy in PracticeNo ratings yet

- Q4 English 10 - Module 3Document22 pagesQ4 English 10 - Module 3Ljoy Vlog Survived100% (1)

- Doli RaunakDocument32 pagesDoli RaunakDivya Raunak100% (1)

- Ultraviolet Water Disinfection Systems: From VIQUADocument2 pagesUltraviolet Water Disinfection Systems: From VIQUAWendy LopezNo ratings yet

- Amylin Analogue As An Antidiabetic AgentDocument5 pagesAmylin Analogue As An Antidiabetic AgentPsicología del SerNo ratings yet

- AAE ProtocolsDocument7 pagesAAE ProtocolsPriyanka SehgalNo ratings yet

- Head and Neck SarcomasDocument30 pagesHead and Neck SarcomasEka Sulistyowati PNo ratings yet

- 2023 Proposed Fauquier Budget SummaryDocument24 pages2023 Proposed Fauquier Budget SummaryFauquier NowNo ratings yet

- Bon Secours Memorial College of NursingDocument2 pagesBon Secours Memorial College of Nursingapi-422763411No ratings yet

- Anesthesia Side EffectsDocument10 pagesAnesthesia Side EffectsPADAYON MEDISINANo ratings yet

- Policies and Programmes For Women AdvancementDocument13 pagesPolicies and Programmes For Women AdvancementrheaNo ratings yet

- Jaha 120 017275Document150 pagesJaha 120 017275Leonardo LiswojoNo ratings yet

- AAF Product CatalogDocument170 pagesAAF Product CatalogAlan Tan100% (3)

- Daftar Pustaka Makalah ObatDocument2 pagesDaftar Pustaka Makalah Obatnur adiniNo ratings yet

- 1392149762keystone Reliance Reference Guide Feb 2014Document9 pages1392149762keystone Reliance Reference Guide Feb 2014Thiago BerthaudNo ratings yet