Professional Documents

Culture Documents

In Mold Decorating of Injection Molded Parts

In Mold Decorating of Injection Molded Parts

Uploaded by

Enrique SantiagoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

In Mold Decorating of Injection Molded Parts

In Mold Decorating of Injection Molded Parts

Uploaded by

Enrique SantiagoCopyright:

Available Formats

Featuring ADVANCED INPUT, MEMTRON, and LRE MEDICAL Products

In Mold Decorating

of Injection Molded Parts

In Mold Decorating of Injection Molded Parts

IMD offers many design flexibility

and productivity advantages versus

other decoration methods done after

molding. These benefits include

design flexibility, multiple colors

and effects, textures with a single

operation, long lasting graphics,

manufacturing productivity, and

systems cost reductions.

Steps in the IMD Process

In-mold Decoration (IMD), also known as

Film Insert Molding (FIM), is a versatile and

cost effective method of decorating and

manufacturing durable plastic parts.

The process of in-mold decorating a plastic

component consists essentially of 4 stages:

Printing, Forming, Cutting and Molding

Printing:

The printing operation is used to create the

decorative appearance of the product. While a

variety of standard technologies can be used for

this stage, silk screen printing is most commonly

used.

Forming:

Film is screen printed

(decorated) on first

and/or second surface.

Film is then formed to

shape and cut to final

size.

The forming process converts the flat 2D-printed

image into a 3D part which is sometimes

referred to as a formed appliqu. This process is

sometimes referred to as thermo-forming which

is a catchall term to include vacuum forming,

hydro forming and high pressure forming. In all

three of these techniques, the flat printed image

is shaped over or into a tool using negative or

positive pressure. The tool can be either male or

female, and each type has its own advantages

and disadvantages.

Cutting: Cutting of the 3D film may be

performed before or after the molding operation

depending on a number of factors and usually

specified by the IMD supplier.

Molding:

Film is inserted into special mold

tool and part is injection molded,

permanently bonding decorated film.

The IMD foil(s) is then placed in the cavity of

the mold tool and the required resin is injected

behind it. The foil can be manually or robotically

placed into the tool depending on the volume

required and the need for a fast cycle time. The

molding process itself will almost certainly have

to be optimized to suit the foil. Since all IMD

techniques are intended to create cosmetically

attractive parts, it will be clear that care in

handling of the product is a key issue.

Advantages - Disadvantages - Applications

One of the most efficient and cost-effective ways of decorating a part is to

do it during the molding cycle. In Mold Decoration (IMD) can provide several

important advantages over other decoration methods.

Advantages:

Design Flexibility allows customers to express

their personalities while the products are

easily manufactured.

Multiple colors, effects and textures with a

single operation that are complete when the

part comes out of the mold.

Legend/graphics wear is almost

indestructible with second surface printing.

A cost effective solution over alternative

decorating techniques.

Changing legends / languages / graphics is

very easy by simply changing the printing.

Disadvantages:

Time to market issues with necessary

developmental iterations.

Some graphics such as concentric circles,

long lines and parallel lines should be

avoided because of the unavoidable

distortion induced by the IMD process.

Keytops, Buttons and Key Pads

Some shape limitations.

For multi-color legends and graphics.

Materials are limited to non V-0 rated Polycarbonate and ABS resins.

For art graphics/decoration

For scratch/abrasion resistance legends and

graphics.

Translucent legends for back lighting.

Panels

For scratch/abrasion resistance legends and

graphics.

For art graphics/decoration.

For multi-color legends and graphics.

Integrating components such as a lens /

window & a panel.

Common Terms

Abrasion Resistance - Ability of a printed image

to withstand wear and tear during handling and

general product usage.

Artwork - Name given to the image to be

transferred to the plastic component during the

decoration process.

Carrier Film - Film material used to temporarily

carry a printed image. The carrier film does

not become part of the finished product and is

discarded during the cutting process.

Cavity side - Term used to describe one half of an

injection mold tool. Generally this side will form

the external surface of the product and is most

often the fixed half of the tool.

Core side - Term used to describe one half of an

injection mold tool. Generally this side will form

the internal

surface of the product and is most

often the moving half of the tool.

Draft Angle - Slight angle introduced on

nominally vertical walls of a molded component to

ease the process of ejection from the mold tool.

Draw Depth/Draw Height - Depth/Height to

which a decorated foil is formed (drawn) prior to

cutting and molding.

Dual Layer construction - See laminated film

construction.

Ejection - The process of pushing a molded

component off of the core side of a mold tool.

Female Tool - Negative impression forming tool

into which a decorated film is pushed to create an

FIM foil.

Film - Raw material onto which the decorative

image is printed in the FIM process. Generally this

will be a polycarbonate type material.

FIM (Film Insert Molding) - IMD process in which

a pre-decorated, pre-formed foil is placed in the

cavity of a molding tool prior to resin injection.

During the molding cycle, the resin and the foil

fuse together.

First Surface Decoration - Components in which

the decorative image is on the outer surface.

Generally such components will be liable to

abrasion and may have additional lacquers

applied to protect them from this.

Flow Direction - The direction of travel of

molding resin during the injection molding

process.

Flow line - Visible defects on molded

components caused by the flow pattern of the

resin during the injection process. In many cases

this feature can be masked by the presence of an

IMD foil.

Foil - Name given to the printed film in the IMD

(FIM) process once it has been decorated, formed

and cut.

Form Tool - Male or female tool used to shape

the flat, decorated film into a 3D foil.

Forming - The process of shaping a flat decorated

film into a three-dimensional format. Often this

process is referred to as thermo-forming since

heat is generally used.

Gate/Gating - The location on a mold tool where

the resin is injected into the cavity to create the

component.

Hardcoat - Lacquer applied to a film or foil to

increase the abrasion resistance. This can be

applied either as a sprayed coating on a 3D

component or as a pre-coating of the film used in

the decoration process. Generally, hard coating

will be an essential requirement with first surface

decorated parts.

Height to Space Ratio - Ratio used to specify the

required distance between adjacent raised areas

on a formed foil. Particularly important in the

design of IMD keypads where it governs the pitch

between adjacent keys depending on the height

of the key.

Common Terms

HPF (High Pressure Forming) - Forming

technology in which flat films are converted into

3D foils using a combination of heat and high

pressure air in a sealed chamber.

Post-Molding - Operation carried out on

completed moldings to complete the production

process. Can include, de-gating, de-flashing and

several decoration techniques.

Hydro forming - Forming technology in which

flat films are converted into 3D foils using a liquid

in a sealed bladder.

Profile Tool - 3D cutting tool used to stamp out

3D formed films into foils suitable for insertion

into the injection mold tool.

Injection Molding - The process of injection

molten plastic resin into the cavity of a mold tool

to create 3D plastic components.

Registration - The process of controlling the

position of the printed image (decoration) on the

completed plastic component.

Insert Molding - The inclusion of additional

components during the plastic injection molding

process. Typically used to produce moldings with

mechanical components such as threaded metal

bosses. Film Insert Molding is a variant of this

process.

Second Surface Decoration - Components

in which the decorative image is on the inner

surface of a layer of plastic material. Such

components are more difficult to manufacture

than first surface types but have far superior

abrasion resistance.

Image - Term used to describe the decoration,

graphics or legend to be applied to a plastic

component. See also artwork.

Solvent based ink - Thermally curing (drying) ink

used in the decoration process.

IMD (InMold Decoration) - Catchall term used to

describe any one of a number of processes used

to decorate plastic products during the injection

molding cycle.

Substrate - Term used by the printing industry to

describe the material onto which the images are

printed.

Surface Finish - The level of texture, or polish, on

the surface of a plastic component. This can be

controlled by the texture on the mold tool, and/or

the texture on any foil used in the IMD process.

IML (InMold Labeling) - IMD process in which

a flat (2D) decorated foil is placed in the cavity

of a molding tool prior to resin injection.

Generally this process is used where the finished

component is flat or only slighted shaped. It can

also be used to decorate flat localized areas on a

product.

UV Cured Ink - Ink used in the decoration

process which is cured (dried) using UV light.

Ink Blow/Ink Wash - Defect in IMD components

in which a portion of the image is distorted or

displaced during the injection molding process.

Vacuum Forming - Well established

thermoforming technique in which a heated film

is drawn down onto a forming tool.

Male Tool - Positive impression forming tool over

which a decorated film is shaped to create an FIM

foil.

Wall Thickness - The nominal wall thickness of a

molded plastic component.

Parting Line - The point on a molding tool at

which the core and cavity halves of the tool meet.

Weld line - Cosmetic defect on a molded plastic

component caused by the coming together of

different mold flow fronts.

Thermoforming - The process used to convert

flat 2D decorated films, into 3D foils.

Featuring ADVANCED INPUT, MEMTRON, and LRE MEDICAL Products

Americas

Headquarters

600 W. Wilbur Avenue

Coeur dAlene, ID 83815

208-765-8000

530 N. Franklin Street

Frankenmuth, MI 48734

989-652-2656

Europe

Asia

Hofer Strae 5

D-86720 Nrdlingen, Germany

+49 (0) 9081 800-1

Caoheijing High Tech Park

6th Floor, Block 87,

No. 1199 Quin Zhou Bei Road

Shanghai, China

eit.sales@esterline.com

www.esterline.com/interfacetechnologies

You might also like

- Chemical Analysis of Limestone, Quicklime, and Hydrated LimeDocument39 pagesChemical Analysis of Limestone, Quicklime, and Hydrated LimeHồng Nguyễn100% (1)

- Injection Mold Standards 80 Eng D 20Document21 pagesInjection Mold Standards 80 Eng D 20Deep ShahNo ratings yet

- Injection Mold Design Engineering Complete Self-Assessment GuideFrom EverandInjection Mold Design Engineering Complete Self-Assessment GuideNo ratings yet

- P Doct Nov 10 in Mold DecoratingDocument4 pagesP Doct Nov 10 in Mold Decoratingpavel59No ratings yet

- Vectrabr eDocument80 pagesVectrabr enseminar100% (1)

- Part and Mold Design Guide (2005)Document174 pagesPart and Mold Design Guide (2005)dlstoneNo ratings yet

- PIM 101 Ebook-1Document33 pagesPIM 101 Ebook-1agniflameNo ratings yet

- TPU Drying GuideDocument16 pagesTPU Drying GuideBang QuachNo ratings yet

- Mould Design Part OneDocument15 pagesMould Design Part Oneazizmaarof100% (3)

- InTech-Modelling and Simulation For Micro Injection Molding ProcessDocument16 pagesInTech-Modelling and Simulation For Micro Injection Molding ProcessPankaj SattawatNo ratings yet

- Bayer Material Science Thermoplastic Joining TechniquesDocument38 pagesBayer Material Science Thermoplastic Joining TechniquesdlstoneNo ratings yet

- Overmolding GuidelinesDocument18 pagesOvermolding GuidelinesRJCIIINo ratings yet

- Fit Tolerance For Plastic PartsDocument16 pagesFit Tolerance For Plastic PartsA_JANNESNo ratings yet

- Moulding ProblemDocument52 pagesMoulding ProblemSree RajNo ratings yet

- Mold Flow AnalysisDocument30 pagesMold Flow AnalysisArun PrasadNo ratings yet

- CastingDocument74 pagesCastingParth Maldhure100% (1)

- Design Guide (Bayer)Document174 pagesDesign Guide (Bayer)Hari Suthan100% (1)

- Injection Molding - Design Guidelines - Solid Concepts IncDocument12 pagesInjection Molding - Design Guidelines - Solid Concepts InckaranNo ratings yet

- Moldflow: A Tool To Predict Post-Molding ProblemsDocument47 pagesMoldflow: A Tool To Predict Post-Molding ProblemspraveenmanturNo ratings yet

- Explain Basic Injection Molding Machine ProcessDocument9 pagesExplain Basic Injection Molding Machine ProcessNazriNo ratings yet

- Layout and Design: Hot Runner GuideDocument15 pagesLayout and Design: Hot Runner Guidenam0% (1)

- Mold Flow Analysis GuideDocument7 pagesMold Flow Analysis Guidesaurav0000999100% (1)

- Moldflow PDFDocument80 pagesMoldflow PDFsandokan_85100% (1)

- Design For Mouldability-UK092010Document16 pagesDesign For Mouldability-UK092010mjobson100% (1)

- Deep Drawing: Benefits and Industrial ApplicationsDocument3 pagesDeep Drawing: Benefits and Industrial ApplicationsChandru NatarajanNo ratings yet

- Polypropylene PDFDocument296 pagesPolypropylene PDFdavid francoNo ratings yet

- MoldFlow Glossary 1Document83 pagesMoldFlow Glossary 1Aleksandar MarkovicNo ratings yet

- Plastic Material SelectionDocument62 pagesPlastic Material SelectiondarshanmrNo ratings yet

- How To Calculate The Torsional Stiffness of Rubber Shock MountsDocument4 pagesHow To Calculate The Torsional Stiffness of Rubber Shock MountsspibluNo ratings yet

- Ford Motor Company Instrument Panel Scrap Reduction TeamDocument66 pagesFord Motor Company Instrument Panel Scrap Reduction TeamMisrael Benitez SibajasNo ratings yet

- Casting TolerancesDocument1 pageCasting TolerancesKumaraswamy ViswanathanNo ratings yet

- Guide To Polyolefin Injection Molding 5979Document50 pagesGuide To Polyolefin Injection Molding 5979brijeshmaurya2100% (1)

- Plastics Snapfit Design Guide 5771Document24 pagesPlastics Snapfit Design Guide 5771gr8swap100% (1)

- PM DesignTip EssentialsDocument20 pagesPM DesignTip EssentialsPurece EugenNo ratings yet

- Engineered PlasticsDocument61 pagesEngineered Plastics고병석No ratings yet

- Mold CoatingDocument36 pagesMold Coatingsandeep100% (1)

- Designing With Plastics - TiconaDocument84 pagesDesigning With Plastics - Ticonacavid78No ratings yet

- Introduction To Plastics 8 11 09Document147 pagesIntroduction To Plastics 8 11 09orlandoinsaneNo ratings yet

- Pricing The Plastic MoldDocument4 pagesPricing The Plastic MoldSteven ChengNo ratings yet

- Metal Injection MouldingDocument1 pageMetal Injection Mouldingkranthi1992No ratings yet

- LCP-027 VectraLCPDesignGuideTG AM 0613Document80 pagesLCP-027 VectraLCPDesignGuideTG AM 0613Evert100% (1)

- Formosa Ldpe Data SheetDocument5 pagesFormosa Ldpe Data SheetBasant AGarwalNo ratings yet

- Injection MouldingDocument18 pagesInjection MouldingKishore Steve AustinNo ratings yet

- Joining Methods: Tolerances: Fit Between PartsDocument11 pagesJoining Methods: Tolerances: Fit Between PartsChiara RipaltiNo ratings yet

- C Polybridge Calculator V25 Feb 09 Office 2003Document58 pagesC Polybridge Calculator V25 Feb 09 Office 2003KodhansNo ratings yet

- Plastic Processing ResourcesDocument9 pagesPlastic Processing ResourcesRatul MohsinNo ratings yet

- Ultrasonic Welding: Search Products Markets Innovations Library Certificates SalesDocument2 pagesUltrasonic Welding: Search Products Markets Innovations Library Certificates SalessyuepiNo ratings yet

- Rynite Pet DupontDocument28 pagesRynite Pet Dupontpirom_popirom500No ratings yet

- Proto Labs Whitepaper PDFDocument15 pagesProto Labs Whitepaper PDFSugarboy3 SurNo ratings yet

- Injection Molded Part Problems & Solutions With: SkillbuilderDocument2 pagesInjection Molded Part Problems & Solutions With: SkillbuilderradzNo ratings yet

- Design for additive manufacturing A Clear and Concise ReferenceFrom EverandDesign for additive manufacturing A Clear and Concise ReferenceNo ratings yet

- Computer Modeling for Injection Molding: Simulation, Optimization, and ControlFrom EverandComputer Modeling for Injection Molding: Simulation, Optimization, and ControlHuamin ZhouNo ratings yet

- Design For Manufacturability A Complete Guide - 2021 EditionFrom EverandDesign For Manufacturability A Complete Guide - 2021 EditionNo ratings yet

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionFrom EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionNo ratings yet

- New Heat Exchaner Design - 5mwDocument20 pagesNew Heat Exchaner Design - 5mwDaniel Perez0% (1)

- MSDS Coladol 91-6Document5 pagesMSDS Coladol 91-6mndmatt100% (2)

- Electrospray Mass Spectrometry of Human Hair Wax Esters. - 2007 - Fitzgerald, MurphyDocument16 pagesElectrospray Mass Spectrometry of Human Hair Wax Esters. - 2007 - Fitzgerald, MurphymasurNo ratings yet

- Supercritical Fluid Extraction From Vegetable MaterialsDocument78 pagesSupercritical Fluid Extraction From Vegetable MaterialsJonatas LopesNo ratings yet

- Review Solvatochromically Based Solvent-Selectivity TriangleDocument11 pagesReview Solvatochromically Based Solvent-Selectivity TriangleMarcos SilvaNo ratings yet

- Form 4 - Salts (+experiment)Document4 pagesForm 4 - Salts (+experiment)kanryu_zonasNo ratings yet

- Characterization of Silver/Glass/Silicon Front Contact Interface in A Silicon Solar CellDocument4 pagesCharacterization of Silver/Glass/Silicon Front Contact Interface in A Silicon Solar Cellmrn_irNo ratings yet

- Captex 300 TDS I-10Document2 pagesCaptex 300 TDS I-10Erik SteinbergNo ratings yet

- Skema Latihan HabaDocument10 pagesSkema Latihan HabafizikkopuNo ratings yet

- 1 s2.0 S001623612101752X MainDocument12 pages1 s2.0 S001623612101752X MainAulia Sukma HutamaNo ratings yet

- Chapter 7 - Electricity (Teacher's Guide)Document61 pagesChapter 7 - Electricity (Teacher's Guide)Izawati AmatNo ratings yet

- CTPDocument2 pagesCTPRobert HutapeaNo ratings yet

- Lembar Kerja Percobaan 1 No. Gambar Struktur 2D Dan Nama IUPAC Parameter Fisika Kimia Struktur 3D Yang Telah DiminisasiDocument3 pagesLembar Kerja Percobaan 1 No. Gambar Struktur 2D Dan Nama IUPAC Parameter Fisika Kimia Struktur 3D Yang Telah DiminisasiNur AmaliaNo ratings yet

- Chemistry of The Ironmaking by Blast Furnace Process - IspatguruDocument7 pagesChemistry of The Ironmaking by Blast Furnace Process - IspatguruSanjeev Sahu100% (1)

- Aluminum IngotDocument12 pagesAluminum Ingothrishi.gaonkarNo ratings yet

- 18F46-DOMI of Compressors Blowers Level 2Document2 pages18F46-DOMI of Compressors Blowers Level 2ehabwardaNo ratings yet

- Chemistry Investigatory Project - Study of Constituent of AlloysDocument19 pagesChemistry Investigatory Project - Study of Constituent of AlloyscaptainclockNo ratings yet

- 7557 - Lubricants Brochure PDFDocument6 pages7557 - Lubricants Brochure PDFrachitmailNo ratings yet

- Chapter 3: Oxidation and Reduction Form 5 Chemistry Title: Rusting As A Redox ReactionDocument3 pagesChapter 3: Oxidation and Reduction Form 5 Chemistry Title: Rusting As A Redox Reactionryder1man6433No ratings yet

- Review Synthesis Properties and Practical ApplicationDocument23 pagesReview Synthesis Properties and Practical ApplicationRasha El-GhazawyNo ratings yet

- Sunday Afternoon, October 27, 2013: TechnologyDocument283 pagesSunday Afternoon, October 27, 2013: TechnologyNatasha MyersNo ratings yet

- Chapter Active and Passive TransportDocument26 pagesChapter Active and Passive TransportHafizuddin KamarudinNo ratings yet

- Iacuc FormDocument8 pagesIacuc FormKate Montenegro0% (1)

- ATOMDocument68 pagesATOMFrench Joana PaboritoNo ratings yet

- Simple Atmospheric Electrical Instrument For Educational UseDocument10 pagesSimple Atmospheric Electrical Instrument For Educational UseMarcos Lima100% (1)

- Resource 20240531183309 Class X, Holidays HW, 2024-2025Document8 pagesResource 20240531183309 Class X, Holidays HW, 2024-2025kirna516No ratings yet

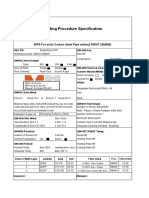

- Welding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Lipika Gayen100% (1)