Professional Documents

Culture Documents

LTW MK15 Operation Manual - Vol 2 Rev C

LTW MK15 Operation Manual - Vol 2 Rev C

Uploaded by

molecule112Copyright:

Available Formats

You might also like

- 2013 PipocDocument69 pages2013 Pipocgeri.karimNo ratings yet

- Raising Children in IslamDocument40 pagesRaising Children in IslamFaheem Lea100% (1)

- Flyer TL-FADocument20 pagesFlyer TL-FAmingo622No ratings yet

- NT777Document2 pagesNT777Saltojito100% (1)

- Radius 700 - Long Range Battery Operated TransponderDocument2 pagesRadius 700 - Long Range Battery Operated TransponderNishant PandyaNo ratings yet

- Palfinger DavitDocument1 pagePalfinger DavitbratkpNo ratings yet

- 99 132633 CDocument1 page99 132633 Ccst89No ratings yet

- System Description LP3-CS4000 NHP2&4Document9 pagesSystem Description LP3-CS4000 NHP2&4AlexDorNo ratings yet

- Ffe Lsa 30 July 09Document1 pageFfe Lsa 30 July 09Drago DragicNo ratings yet

- Spare Part KitDocument1 pageSpare Part Kitpacoman7No ratings yet

- Cpos Operator ManualDocument316 pagesCpos Operator ManualJuliana Borges0% (1)

- CMX 007 Adjustable Frequency DriveDocument9 pagesCMX 007 Adjustable Frequency DriveJESUSCALVILLONo ratings yet

- Safe Operating Procedure Ice MakerDocument1 pageSafe Operating Procedure Ice Makermolecule112No ratings yet

- Taut Wire Bandak MK 15 B PDFDocument26 pagesTaut Wire Bandak MK 15 B PDFGonzalo Villalobos Sanchez100% (1)

- Taut Wire Operate ManualDocument27 pagesTaut Wire Operate ManualGonzalo Villalobos SanchezNo ratings yet

- Smith Berger Shark JawsDocument2 pagesSmith Berger Shark JawsmanjuNo ratings yet

- DP Operator Manual: Section 8 Light Weight Taut Wire SystemsDocument5 pagesDP Operator Manual: Section 8 Light Weight Taut Wire SystemsKunal SinghNo ratings yet

- Furuno SSB Operator's Manual PDFDocument222 pagesFuruno SSB Operator's Manual PDFandersonpauser100% (1)

- Gyrocompass Navigat X MK 2Document4 pagesGyrocompass Navigat X MK 2tariktunadNo ratings yet

- Quotation: Radius Transponders For Petroleum Marine Service CoDocument14 pagesQuotation: Radius Transponders For Petroleum Marine Service CoMohamed MohamedNo ratings yet

- SAILOR FBB 500 Installation GuideDocument153 pagesSAILOR FBB 500 Installation GuidekeshtiraniNo ratings yet

- Chapter 4 Tunnel Thruster As Built DrawingsDocument47 pagesChapter 4 Tunnel Thruster As Built DrawingsSergei KurpishNo ratings yet

- ISO - IsO Standards - TC 8 - SC 1 - Lifesaving and Fire ProtectionDocument4 pagesISO - IsO Standards - TC 8 - SC 1 - Lifesaving and Fire Protectionviahul100% (1)

- EPIRB Emergency Radio BeaconDocument32 pagesEPIRB Emergency Radio BeaconAdriano José MenezesNo ratings yet

- DP NotationsDocument5 pagesDP NotationssandeepNo ratings yet

- Sailor 6110 Mini C Gmdss User ManualDocument134 pagesSailor 6110 Mini C Gmdss User ManualborisgolodenkoNo ratings yet

- 3510LR User ManualDocument50 pages3510LR User ManualRoberto Castro ValdesNo ratings yet

- Fugro 9205 User ManualDocument125 pagesFugro 9205 User ManualsfsdffdsdfsdfsdfNo ratings yet

- Aconis 2000 PDFDocument13 pagesAconis 2000 PDFvishnu vardhan0% (1)

- 02 - Operation Instructions - Stern RollerDocument15 pages02 - Operation Instructions - Stern Rollermiguel100% (1)

- Quick Reference Guide For Furuno ProductsDocument25 pagesQuick Reference Guide For Furuno ProductsMahfooz AliNo ratings yet

- List of Life Saving AppliancesDocument2 pagesList of Life Saving Appliances5t3r3No ratings yet

- SEP-500 Instruction ManualDocument76 pagesSEP-500 Instruction ManualIn liong0% (1)

- 1 - Brochure Speedlog SAL-R1Document2 pages1 - Brochure Speedlog SAL-R1thsalimNo ratings yet

- Ship Hull Calculation - Calculations - Paint Inspector Com PDFDocument3 pagesShip Hull Calculation - Calculations - Paint Inspector Com PDFНиколай СтешенкоNo ratings yet

- Odme WorkingDocument23 pagesOdme WorkingSantosh Yellappa Sulebhavikar100% (2)

- What Is Azipod Propulsion System On Ship Marine InsightDocument4 pagesWhat Is Azipod Propulsion System On Ship Marine InsightAffan KhalifNo ratings yet

- JLN-550 Instruction Manual E2Document48 pagesJLN-550 Instruction Manual E2services HL100% (1)

- OwsDocument10 pagesOwsAnte BudimirNo ratings yet

- DGS Gudelines For 2nd Mate FGDocument9 pagesDGS Gudelines For 2nd Mate FGSAKSHI INSTITUTE OF MARITIME FOUNDATIONNo ratings yet

- Taut Wire Manual MK8 InstallationDocument254 pagesTaut Wire Manual MK8 InstallationPurposeful Kentavr100% (1)

- Comissionamento Do Sistema de Pull in PDFDocument65 pagesComissionamento Do Sistema de Pull in PDFrfelippe8733No ratings yet

- Deck OfficerDocument39 pagesDeck OfficerYudistira Aurum StoreNo ratings yet

- Shuaiba DetailsDocument7 pagesShuaiba DetailsGrațian ȘtefanNo ratings yet

- Steering Control SystemsDocument23 pagesSteering Control Systemsdonato del rosarioNo ratings yet

- MGPSDocument9 pagesMGPSMikhail BagliukNo ratings yet

- TT98-127659-A TT3000LRIT Installation ManualDocument35 pagesTT98-127659-A TT3000LRIT Installation ManualBeneDict Ben D100% (2)

- PUSNES Deck Machinery Installation ProcedureDocument18 pagesPUSNES Deck Machinery Installation ProcedurexatzaraNo ratings yet

- Apos For Hipap Complete ManualDocument131 pagesApos For Hipap Complete ManualAlaa Eldin MohamedNo ratings yet

- Sea Horizon SpecificationDocument2 pagesSea Horizon SpecificationSyafiq HalimNo ratings yet

- OperationManual NavDP4000 v1600.$ - Release-15A b6651 PDFDocument315 pagesOperationManual NavDP4000 v1600.$ - Release-15A b6651 PDFPeterJBloomNo ratings yet

- Cy ScanDocument32 pagesCy ScanLi Ann ChungNo ratings yet

- 94-0094-4-H CyScan A4 4pp AW 2015 (singles-HR) PDFDocument4 pages94-0094-4-H CyScan A4 4pp AW 2015 (singles-HR) PDFEnrique Hernández VázquezNo ratings yet

- SIRE 2.0 Question Library - Part 2 - Chapters 8 To 12 - Version 1.0 (January 2022) - 301-581Document281 pagesSIRE 2.0 Question Library - Part 2 - Chapters 8 To 12 - Version 1.0 (January 2022) - 301-581SteliosNo ratings yet

- Procedure To Discharge Clean Bilge Training - enDocument3 pagesProcedure To Discharge Clean Bilge Training - enclaudioNo ratings yet

- HDFN35T - Spec - HyundayDocument4 pagesHDFN35T - Spec - HyundayCleverson SchmidtNo ratings yet

- A1021 (26) Code On Alerts AlarmsDocument37 pagesA1021 (26) Code On Alerts AlarmsmarinedgeNo ratings yet

- Accommodation Ladder NewDocument9 pagesAccommodation Ladder NewBrian Voyd Rebito100% (1)

- DP Brochure Navis NavDP4000Document12 pagesDP Brochure Navis NavDP4000dimitriapNo ratings yet

- Dynamic positioning The Ultimate Step-By-Step GuideFrom EverandDynamic positioning The Ultimate Step-By-Step GuideRating: 5 out of 5 stars5/5 (1)

- Avr 100s IngleseDocument65 pagesAvr 100s IngleseVedran GaćeNo ratings yet

- Write Up On EHC - REV-01Document11 pagesWrite Up On EHC - REV-01jp mishra100% (2)

- Automatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsDocument65 pagesAutomatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsYassine.G ChipLabNo ratings yet

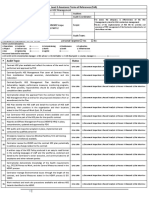

- Petroleum CSG: Hsec Management System ProcedureDocument18 pagesPetroleum CSG: Hsec Management System Proceduremolecule112No ratings yet

- Contractor Hse Management: Level 2 Assurance: Terms of References (Tor)Document3 pagesContractor Hse Management: Level 2 Assurance: Terms of References (Tor)molecule112100% (1)

- Safety Moment: The Seasick SSEDocument3 pagesSafety Moment: The Seasick SSEmolecule112No ratings yet

- Nor Captain - DLB Support VesselDocument1 pageNor Captain - DLB Support Vesselmolecule112No ratings yet

- 'General' Effective Existing Safeguards 'Lifting' Effective Existing SafeguardsDocument2 pages'General' Effective Existing Safeguards 'Lifting' Effective Existing Safeguardsmolecule112No ratings yet

- ChronOS InjecDocument24 pagesChronOS Injecmolecule112No ratings yet

- Safety Alert - ElectrocutionDocument2 pagesSafety Alert - Electrocutionmolecule112No ratings yet

- How To Create and Play Kahoot!Document15 pagesHow To Create and Play Kahoot!Sri Raman NairNo ratings yet

- Sample Test 1Document3 pagesSample Test 1Bình Phạm ThịNo ratings yet

- Power-Linker Training Centre: GroupDocument1 pagePower-Linker Training Centre: GroupSunil SinghNo ratings yet

- Ngo Assignment Meryem Barhdadi MSC IbDocument9 pagesNgo Assignment Meryem Barhdadi MSC IbMeryem BarhdadiNo ratings yet

- Troubleshooting For Rb433R3, Rb433Ur2: No Power, Blue Led Isn'T LitDocument7 pagesTroubleshooting For Rb433R3, Rb433Ur2: No Power, Blue Led Isn'T LitJoseAugustoOsteicoechea100% (1)

- How To Impress Someone at First MeetingDocument1 pageHow To Impress Someone at First MeetingMohammad Fahim HossainNo ratings yet

- An Assessment of The InternshipDocument1 pageAn Assessment of The InternshipRaj GuruNo ratings yet

- Assignment#2 Submitted To: Dr. Aliya Submitted By: Issma Munir Abbasi MS-SP-19-REL-013Document3 pagesAssignment#2 Submitted To: Dr. Aliya Submitted By: Issma Munir Abbasi MS-SP-19-REL-013issma abbasiNo ratings yet

- Abap Code PracticeDocument35 pagesAbap Code PracticeAkhilaNo ratings yet

- Appendix G Elastic and Inelastic Response SpectraDocument11 pagesAppendix G Elastic and Inelastic Response SpectracedaserdnaNo ratings yet

- Current Status, Research Trends, and ChallengesDocument23 pagesCurrent Status, Research Trends, and Challengesqgi-tanyaNo ratings yet

- Durastor Tank Brochure PDFDocument8 pagesDurastor Tank Brochure PDFhamadaniNo ratings yet

- ESP Standard SizingDocument131 pagesESP Standard Sizingmohamed gamal100% (2)

- BC KMBN107 Unit 3Document26 pagesBC KMBN107 Unit 3Rizwan SaifiNo ratings yet

- Neurological Development From Birth To Six YearsDocument143 pagesNeurological Development From Birth To Six YearsWaleska SakibNo ratings yet

- Plusco325 Coatings External Pipe CoatingDocument1 pagePlusco325 Coatings External Pipe Coatinga.hasan670No ratings yet

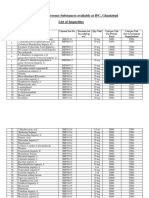

- List of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesDocument4 pagesList of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesUrva VasavadaNo ratings yet

- Ipad - Apple Technician Guide (2011)Document116 pagesIpad - Apple Technician Guide (2011)Jonathan Long100% (1)

- EMT 7103 Computer Applications in Engineering Kris KegoDocument28 pagesEMT 7103 Computer Applications in Engineering Kris KegoMugisa PeterNo ratings yet

- Conclusion ParagraphDocument7 pagesConclusion Paragraphapi-334926654No ratings yet

- NE20E-S V800R022C00SPC600 Configuration Guide 01 Basic ConfigurationDocument422 pagesNE20E-S V800R022C00SPC600 Configuration Guide 01 Basic ConfigurationMoises HenriqueNo ratings yet

- Chronic LeukemiaDocument38 pagesChronic LeukemiaV Lee 'Nozhat'100% (1)

- 50420231021331792nav.2 Module 5Document2 pages50420231021331792nav.2 Module 5joeNo ratings yet

- Cluster SamplingDocument3 pagesCluster Samplingken1919191100% (1)

- FRP Parameter Optimization Settings: Wilfried Baumgartner / Hans Georg Kloep, SAP July 6, 2016Document36 pagesFRP Parameter Optimization Settings: Wilfried Baumgartner / Hans Georg Kloep, SAP July 6, 2016atungmuNo ratings yet

- MK17C01-Group 3-MKT328m-Final Report DIFFERENTDocument14 pagesMK17C01-Group 3-MKT328m-Final Report DIFFERENTTran Minh Quy (K17 QN)No ratings yet

- Welded Steel Fabric: Natsteel Holdings Pte LTDDocument8 pagesWelded Steel Fabric: Natsteel Holdings Pte LTDSantosoNo ratings yet

LTW MK15 Operation Manual - Vol 2 Rev C

LTW MK15 Operation Manual - Vol 2 Rev C

Uploaded by

molecule112Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LTW MK15 Operation Manual - Vol 2 Rev C

LTW MK15 Operation Manual - Vol 2 Rev C

Uploaded by

molecule112Copyright:

Available Formats

Bandak

Light Weight Taut Wire Mk 15B

Volume 2 Operation Manual

Sagamoen, N-3825 Lunde, Norway

Phone +47 35 94 66 00 Fax +47 35 94 66 01

www. bandak.no

Light Weight Taut Wire Mk 15B Operation Manual

Document revisions

Rev.

A

B

C

D

Written by

Date

Sign.

21/9-04

SL

14/5-08

SL

29/10-08

SL

Checked by

Date

Sign.

25/9-04

HT

15/5-08

HT

30/10-08

HT

Approved by

Date

Sign.

30/9-04

SL

26/5-08

SL

31/10-08

SL

Light Weight Taut Wire Mk 14B Operation Manual

Table of contents

1

INTRODUCTION.......................................................................................................... 5

ABBREVIATIONS ........................................................................................................ 6

TECHNICAL DATA ..................................................................................................... 7

3.1 Operational Specifications ........................................................................................ 7

3.2 System Accuracy....................................................................................................... 7

TECHNICAL DESCRIPTION..................................................................................... 9

4.1 Principle of Operation ............................................................................................. 23

4.2 Hydraulic System .................................................................................................... 12

4.3 Winch System.......................................................................................................... 13

4.4 Tension Compensating System ............................................................................... 13

4.5 Control System ........................................................................................................ 13

4.6 Heating System........................................................................................................ 14

OPERATION................................................................................................................ 15

5.1 Setting in Operation................................................................................................. 17

5.2 Parking..................................................................................................................... 21

5.3 Adjusting Wire ........................................................................................................ 23

Light Weight Taut Wire Mk 15B Operation Manual

Document History

Rev A

Initial Issue

Rev B

Revised fig. 5.2 Optional Remote Control Panel and table 5.2 Remote

Control Panel Button Functions both available from SN BAN-090.

Rev C

Revised chapter 5, Operation; due to change of operation terminal.

Light Weight Taut Wire Mk 14B Operation Manual

1 INTRODUCTION

The Taut Wire is a position reference system intended for a

deck-mounted, starboard or portside position, on most surface vessels.

The purpose of the Taut Wire is to give accurate input data, related to

vessel movement, to the vessel's data processing system to calculate

vessel position corrections.

The purpose of this manual is to provide the user a general

understanding of the principles, and instructions for operation of the

MK15 Taut Wire System.

Note

All technical description, information and specification given in this

manual are subject to change without further notice.

Light Weight Taut Wire Mk 15B Operation Manual

2 ABBREVIATIONS

Abbreviation Explanation

DC

Direct Current

DP

Dynamic Positioning

KM

Kongsberg Maritime

LTW

Light Weight Taut Wire

PLC

Programmable Logic Controller

TB

Terminal Board

TW

Taut Wire

UPS

Uninterruptible Power Supply

Light Weight Taut Wire Mk 14B Operation Manual

3 TECHNICAL DATA

3.1 Operational Specifications

LTW MK15-300 / 500

700 m

4,9 mm +/- 0,1 mm

18 kN

22 kN

360 kg / 465 kg

50 litres / 65 litres

300m / 500 m (with ATWC installed)

2,5 m/s2

2,5 m/s

150-300 (adjustable)

+/- 10 %

Available wire length

Mechanical stop at 25o

Adjustable 0-1.5 m/s

Wire length

Wire diameter

Min. wire breaking load

Calculated breaking load

Depressor weight

Depressor weight volume

Max. operational depth

Max. wire acceleration

Max. wirespeed

Mooring tension

Tension variation

Max.heave compensation

Max. wire angle

Hoist / Lower speed

3.2 System Accuracy

CURRENT AT SEA SURFACE

CURRENT AT SEABED

WIRE ANGLE

200 Kp

MOORING

TENSION

300 Kp

MOORING

TENSION

0o

DEVIATION IN METERS

0 m/s

0,5 m/s

0 m/s

0,5 m/s

o

o

o

10

20

0

10o

20o

WATER DEPTH

100

200

300

0

0

0

0,6

1,8

3,5

1,2

3,5

7,6

2,4

9,3

20,2

2,9

11,2

23,3

3,5

13,0

28,0

WATER DEPTH

100

200

300

400

0

0

0

0

0,5

1,5

3,0

5,0

1,0

3,0

6,6

11,0

2,0

8,0

18,0

31,0

2,5

9,5

20,0

35,0

3,0

11,0

24,0

41,0

Light Weight Taut Wire Mk 15B Operation Manual

Figure 3.1 Overall Dimensions

Total weight

LTW MK15

2150 kg not incl. Depr. weight

Light Weight Taut Wire Mk 14B Operation Manual

4 TECHNICAL DESCRIPTION

4.1 Principle of Operation

The purpose of the Taut Wire is to give accurate input data, related to

vessel movement, to the vessel data processing system to calculate

vessel position corrections.

The Taut Wire system is fundamentally electro-hydraulic-pneumatic

and requires electrical and air supply from the vessel.

The wire rope, although thin to reduce the "offsets" caused by

underwater current disturbance, is strong enough to heave the weight

with a safety factor of 400 percent. Control of the system is effected

from either of two control panels; main control panel (local) or optional

bridge control panel (remote).

The wire rope is tightened against the depressor weight (on the seabed)

with a constant tension by means of a pneumatically and servo electric

"mooring" control system. Any movement of the vessel in either or

both of the X (alongship) or Y (beam) co-ordinates, will cause a

deviation of the tensioned wire rope from the vertical. This deviation

activates potentiometers mounted in the gimbal (sensor) head and

produce changes of analogue data directly proportional to the X-Y

inclination of the gimbal head.

The analogue wire length measurement is obtained from a measuring

device driven by the moving wire.

The DP system contains an accurate model of the dynamics of the

vessel which simulates the vessel's response to various forces e.g. wind,

wave and current disturbance.

Deviations in the specified position of the vessel (detected by changes

above analogue input parameters) will be processed by the software

model to generate appropriate corrective commands to the vessel's

propeller and rudder system.

Light Weight Taut Wire Mk 15B Operation Manual

Wave and Current

Disturbance

Wind

Taut Wire

Feed

Forward

Measured

State

Propeller/

Rudder

Command

+

Depressor

Weight

Optimum

Gain

Figure 4.1 Principle of DP System Operation

10

Light Weight Taut Wire Mk 14B Operation Manual

Figure 4.2 Taut Wire Main Parts

11

Light Weight Taut Wire Mk 15B Operation Manual

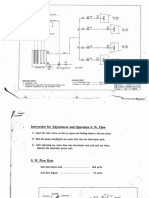

4.2 Hydraulic System

The Hydraulic System operates the boom between the parked and the

operating position.

The system is powered by a small hydraulic power unit, and is

automatically controlled and operated by the PLC system.

The hydraulic system gear pump is driven by a 3-phase, 440 V, 60 Hz,

1.5 kW AC motor IP class 56.

Hydraulic oil tank has a capacity of 10 litres Mobile DTE 13 M or

equivalent

Figure 4.2 Cabinet Door Removed

12

Light Weight Taut Wire Mk 14B Operation Manual

4.3 Winch System

The winch lower and hoist the depressor weight to and from the seabed.

The winch is powered by a electrical powered servomotor, and the

servo system is equipped with a fail-safe magnetic brake located

between the servomotor and the gear.

The system is automatically controlled and is operated by the amplifier

and the PLC.

Electrical power are from the vessels own supply.

A MDFRARS 132 Mx4 IP 66 Special Asynchron Servomotor, giving

84Nm at 2030 rpm/18 kW powers the winch drum. Max. moment is

168 Nm.

The SEW gear system (gear ratio 1:12) is bringing the maximum torque

up to 1200 Nm.

4.4 Tension Compensating System

The system activates the electrical powered servomotor whenever the

wire tension is deviating from the set-point in mooring mode.

Compensating cylinders air pressure is manually set and automatically

controlled by the pressure regulator. Actual pressure is indicated on the

manometer. Wire tension is directly related to the cylinder air pressure

i.e. increased pressure gives increased tension and visa versa.

Pressurised air is from the vessels own supply.

Wire tension is recorded by the load cells (2) located under the wire

angle compensator and visualized on a gauge located on the local

operating panel.

4.5 Control System

The hydraulic and winch drive systems are automatically controlled

and operated by a Telemecanique TSX Micro PLC system.

The local control panel, is situated on the taut wire cabinet R/H side

and has the following equipment

Main power switch

PLC terminal

Mooring indicator lamp

Mooring tension indicator (optional)

Joystick for manual hoisting and lowering

13

Light Weight Taut Wire Mk 15B Operation Manual

A pressure manometer, located on hydraulic cabinet is, when pump is

running, indicating max. hydraulic working pressure. The pressure is

manually set and automatically controlled by the hydraulic pressure

regulator valve.

Air pressure manometer for air cylinder pressure (tension) control and

adjustment is located on the air pressure regulator inside the cabinet.

The air dumping valve is set to dump the tension compensating

cylinder air pressure whenever the taut wire is outside mooring mode.

The set point is adjusted at the bottom of the valve and should give an

air pressure corresponding to 150 kp tension.

4.6 Heating System

Heating elements in electrical motors and outdoor cabinet provides

heating while the main power switch at the local control panel is

switched OFF to prevent condensation.

14

Light Weight Taut Wire Mk 14B Operation Manual

5 OPERATION

Date

Bandak

Wirelenght Out (m)

Hoist

Alarm

Page

Stop

Time

Reset

Alarm

TW READY

Bridge

Control

Lower

Boom In

Boom

Out

Wire

Adjust

Local

Control

Alarm/Warning

Figure 5.1 Local Operator Panel

Button

Hoist

Display

Wirelength:

TW Control

Wirelength:

Stop

TW Control

Wirelength:

Lower

TW Control

Wirelength:

Boom In

TW Control

Boom Out Wirelength:

TW Control

Codeword:

Wire

Adjust

New Wire :

TW Control

Local

Control

Bridge Control

Bridge

Control

Reset

Alarm

Alarm

Page

Action

0

m

Hoist

0

m

TW Stopped

0

m

Lower

0

m

Boom In

0

m

Boom Out

0

0

m

TW Ready

TW ready

Hoisting weight.

Activating brake.

Lower weight.

Boom to parked position.

Boom to operating position.

Adjusting wirelenght after cutting and new

wire installation.

LTW manually controlled from local panel

LTW manually controlled from bridge

Resetting alarms

Alarm history

Table 5.1 Local Control Panel Button Functions

15

Light Weight Taut Wire Mk 15B Operation Manual

Figure 5.2 Optional Remote Operator Panel

Button

Display

Action

F1

Wirelength:

TW Control

0

Hoist

F2

Wirelength:

TW Control

0

m

TW Ready

Activating brake.

Controlled braking

F3

Wirelength:

TW Control

0

m

Lower

Lower weight.

F4

Bridge Control

TW Ready

Bridge Control Selected

ENTER

N/A

N/A

ESC

N/A

N/A

Hoisting depressor weight.

Table 5.2 Remote Control Panel Button Functions

16

Light Weight Taut Wire Mk 14B Operation Manual

The operation of the Taut Wire System is divided into three modes:

Setting in Operation - This procedure puts the system into the

operational mode, i.e. providing position-reference data.

Parking - This procedure puts the system back to the parked

position, i.e. boom and depressor weight inboard, with the boom in

its stowage position and the weight resting in its cradle.

Winding Wire - Whenever it is necessary to wind off or on wire

from the drum.

5.1 Setting in Operation

Note

This operation should be carried out with the vessel as stationary as

possible, particularly when placing the depressor weight on the seabed.

Four factors are vital to the correct function of the Taut Wire System,

particularly when operating in shallow water:

Seabed Condition.

Select whenever possible a sea bed condition that will give good

adherence to the weight - a hard surface may allow dragging.

Working Angle.

Angle between the depressor weight and the gimbal head. Keep wire

operating-angle from the vertical to a minimum - as the horizontal

forces acting upon the weight, and chances of dragging, increases

with the angle.

Wire Mooring Tension.

Verify that the correct mooring tension is maintained by checking

the mooring tension metre on the main control panel (option) or by

checking the air pressure in the tension compensating system.

Pitch and Roll of the vessel.

Avoid using the Taut Wire if the rate of the vessel's pitch and roll

exceeds the maximum speed and acceleration capability of the

mooring system.

17

Light Weight Taut Wire Mk 15B Operation Manual

Figure 5.3 Operational Mode

The starting procedure is for safety reasons solely effected from the

Taut Wire Control Panel, but the Taut Wire Control may be transferred

to the Bridge Control Panel (option) where it remains throughout the

positioning operation.

Note

18

Hydraulic power will only be available when BOOM OUT, or BOOM

IN mode is activated, and 10 seconds after

Light Weight Taut Wire Mk 14B Operation Manual

STEP PROCEDURE

COMMENT

Check air lubricating system

Fill up with Mecman oil if necessary

Drain and pressurise tension

compensating system.

3 bar is theoretically corresponding to 200 kp

tension (appox. 4.2 bar = 300 kp)

NOTE!

Do not exceed recommended pressure limits as

this may result in damaged gimbal head and

loss of depressor weight.

Check wire rope for proper alignment

with regard to wire guide wheels etc.

Set MAIN SWITCH to "ON"

CONNECTING is displayed throughout the PLC

self test program.

WARNING!

Do not operate buttons or joystick before TW

READY is displayed.

Press

HOIST

Check that weight is stabilised in weight catcher.

WARNING!

Never activate Stop prior to operating the boom. If

doing so, the brake will be activated and the boom

in/out movement will most likely cut the wire.

NOTE!

With reference to the warning above, its vital that

taut wire is still in HOIST mode during boom in/out

operation to allow wire to be paid off the drum.

Check that WIRELENGTH 0 m is displayed before

proceeding to next step. Please see table 5.3.3.

19

Light Weight Taut Wire Mk 15B Operation Manual

STEP PROCEDURE

COMMENT

BOOM OUT is displayed.

Press

BOOM OUT

Hydraulic system is activated and pressure gage

indicates max. 200 bar.

Boom moves as long as button is pressed. Ensure

that boom has reached its operating position.

Press WINCH STOP

The winch brake will engage and relieve the

servomotor from the load of the depressor weight.

The taut wire should never be left in HOIST mode

for more than a few minutes as the servo system

might trip due to overtemperature.

Press WINCH LOWER

WINCH LOWER is displayed.

Weight will descend at a speed of 1 m/s.

Wire length paid out will be displayed.

NOTE!

The joystick may override WINCH LOWER.

Mooring light comes on as soon as weight has

reached seabed.

10

Check that mooring tension is as

required.

Adjust air pressure if necessary.

11

Press BRIDGE CONTROL

If BRIDGE REMOTE CONTROL is installed

(option).

Bridge Control is displayed.

To regain TW Control, press Local Control button.

12

20

Close and secure the Taut Wire Control

Panel door.

Light Weight Taut Wire Mk 14B Operation Manual

5.2 Parking

For both practical and safety reasons this procedure is effected

solely from the local panel.

Note

This procedure should always be carried out at completion of

every operation before attempting to move the vessel to a new

operational area.

WARNING

Due to the boom over-centre position when parked, the

Depressor Weight is part of the boom locking system and

must not be removed unless the boom is mechanically

secured.

Figure 5.4 Parked Mode

21

Light Weight Taut Wire Mk 15B Operation Manual

STEP PROCEDURE

1

Press Local Control

COMMENT

TW CONTROL is displayed.

Winch starts hoisting.

Press "WINCH HOIST"

Hoisting speed reduces to 0,3 m/s the last 3 metre.

NOTE!

"WINCH HOIST" can be overridden by the joystick.

For safer hoisting and better weight control it is

recommended to stop weight a few meters below

the water surface and manually hoist the weight up

to the weight catcher. Note also that the last

meters of hoisting have reduced speed.

Check that weight is secured in catcher before

proceeding to next step.

If joystick is used to override the hoist function,

stop mode is activated when joystick is released.

(Zero position)

WARNING!

Before BOOM IN, ensure that taut wire is in

HOIST mode.

Press "BOOM IN"

NOTE!

The boom can be stopped in any position

Operate the joystick and manually

lower the weight into the basket.

WARNING!

For safety reasons, use manual lowering only.

Turn MAIN SWITCH to "OFF" position

Close and secure panel door

Drain water from air reservoir and air

pressure regulators

22

NOTE!

In case of long operation stops, depressurise air

system.

Light Weight Taut Wire Mk 14B Operation Manual

5.3 Adjusting Wire

NOTE!

This procedures are used for resetting wirelength whenever new wire is

installed/cut or if the wirelength displayed differ from the actual situation.

5.3.1 Installing new wire

STEP

PROCEDURE

COMMENT

Turn MAIN SWITCH to "ON"

Wait till "T W READY" is displayed.

Using joystick unwind old wire

Disconnect wire both from depressor weight and

wiredrum.

Keep a tension of 100-150 kp when spooling on

wire to prevent the wire from penetrating the layers

on the wiredrum.

Spool on new wire using Joystick

Connect wire to the depressor weight

Pull in the slack and hoist the weight

into the weightcatcher and then lower it

back to the cradle.

It might be an usefull safety action to lower the

weight into the sea till the last layer is visible on the

wiredrum and then pull it up again.

Press Wire Adjust

Keep pressed till new menu is displayed.

Insert code 7533 and enter

Press New Wire

Keep pressed till new menu is displayed

Insert new wirelength

500 alternatively 700 meters

10

Press Main

Returning to main menu.

23

Light Weight Taut Wire Mk 15B Operation Manual

5.3.2 Cutting wire

Note

This procedure is calculating remaining wire on the drum after cutting.

STEP

PROCEDURE

COMMENT

Turn MAIN SWITCH to "ON"

Wait till "T W READY" is displayed.

Using joystick, unwind wire

Cut off necessary length of wire and reattach wire to weight

Using joystick, pull in wire slack.

Press Wire Adjust

Insert actual m cut and press enter

Press Main

Keep pressed until new menu is displayed.

Returning to main menu

5.3.3 Wirelength 0-point reset

STEP

PROCEDURE

COMMENT

Press Wire Adjust

Keep pressed till new menu appears

Press Reset Wirelength

24

Light Weight Taut Wire Mk 14B Operation Manual

STEP

PROCEDURE

COMMENT

Press Main

Returning to main menu

Note

It is not possible to reset wire length when more than 20 metres

are displayed. To get the reading below 20 metres, turn wire

counter wheel backwards.

25

You might also like

- 2013 PipocDocument69 pages2013 Pipocgeri.karimNo ratings yet

- Raising Children in IslamDocument40 pagesRaising Children in IslamFaheem Lea100% (1)

- Flyer TL-FADocument20 pagesFlyer TL-FAmingo622No ratings yet

- NT777Document2 pagesNT777Saltojito100% (1)

- Radius 700 - Long Range Battery Operated TransponderDocument2 pagesRadius 700 - Long Range Battery Operated TransponderNishant PandyaNo ratings yet

- Palfinger DavitDocument1 pagePalfinger DavitbratkpNo ratings yet

- 99 132633 CDocument1 page99 132633 Ccst89No ratings yet

- System Description LP3-CS4000 NHP2&4Document9 pagesSystem Description LP3-CS4000 NHP2&4AlexDorNo ratings yet

- Ffe Lsa 30 July 09Document1 pageFfe Lsa 30 July 09Drago DragicNo ratings yet

- Spare Part KitDocument1 pageSpare Part Kitpacoman7No ratings yet

- Cpos Operator ManualDocument316 pagesCpos Operator ManualJuliana Borges0% (1)

- CMX 007 Adjustable Frequency DriveDocument9 pagesCMX 007 Adjustable Frequency DriveJESUSCALVILLONo ratings yet

- Safe Operating Procedure Ice MakerDocument1 pageSafe Operating Procedure Ice Makermolecule112No ratings yet

- Taut Wire Bandak MK 15 B PDFDocument26 pagesTaut Wire Bandak MK 15 B PDFGonzalo Villalobos Sanchez100% (1)

- Taut Wire Operate ManualDocument27 pagesTaut Wire Operate ManualGonzalo Villalobos SanchezNo ratings yet

- Smith Berger Shark JawsDocument2 pagesSmith Berger Shark JawsmanjuNo ratings yet

- DP Operator Manual: Section 8 Light Weight Taut Wire SystemsDocument5 pagesDP Operator Manual: Section 8 Light Weight Taut Wire SystemsKunal SinghNo ratings yet

- Furuno SSB Operator's Manual PDFDocument222 pagesFuruno SSB Operator's Manual PDFandersonpauser100% (1)

- Gyrocompass Navigat X MK 2Document4 pagesGyrocompass Navigat X MK 2tariktunadNo ratings yet

- Quotation: Radius Transponders For Petroleum Marine Service CoDocument14 pagesQuotation: Radius Transponders For Petroleum Marine Service CoMohamed MohamedNo ratings yet

- SAILOR FBB 500 Installation GuideDocument153 pagesSAILOR FBB 500 Installation GuidekeshtiraniNo ratings yet

- Chapter 4 Tunnel Thruster As Built DrawingsDocument47 pagesChapter 4 Tunnel Thruster As Built DrawingsSergei KurpishNo ratings yet

- ISO - IsO Standards - TC 8 - SC 1 - Lifesaving and Fire ProtectionDocument4 pagesISO - IsO Standards - TC 8 - SC 1 - Lifesaving and Fire Protectionviahul100% (1)

- EPIRB Emergency Radio BeaconDocument32 pagesEPIRB Emergency Radio BeaconAdriano José MenezesNo ratings yet

- DP NotationsDocument5 pagesDP NotationssandeepNo ratings yet

- Sailor 6110 Mini C Gmdss User ManualDocument134 pagesSailor 6110 Mini C Gmdss User ManualborisgolodenkoNo ratings yet

- 3510LR User ManualDocument50 pages3510LR User ManualRoberto Castro ValdesNo ratings yet

- Fugro 9205 User ManualDocument125 pagesFugro 9205 User ManualsfsdffdsdfsdfsdfNo ratings yet

- Aconis 2000 PDFDocument13 pagesAconis 2000 PDFvishnu vardhan0% (1)

- 02 - Operation Instructions - Stern RollerDocument15 pages02 - Operation Instructions - Stern Rollermiguel100% (1)

- Quick Reference Guide For Furuno ProductsDocument25 pagesQuick Reference Guide For Furuno ProductsMahfooz AliNo ratings yet

- List of Life Saving AppliancesDocument2 pagesList of Life Saving Appliances5t3r3No ratings yet

- SEP-500 Instruction ManualDocument76 pagesSEP-500 Instruction ManualIn liong0% (1)

- 1 - Brochure Speedlog SAL-R1Document2 pages1 - Brochure Speedlog SAL-R1thsalimNo ratings yet

- Ship Hull Calculation - Calculations - Paint Inspector Com PDFDocument3 pagesShip Hull Calculation - Calculations - Paint Inspector Com PDFНиколай СтешенкоNo ratings yet

- Odme WorkingDocument23 pagesOdme WorkingSantosh Yellappa Sulebhavikar100% (2)

- What Is Azipod Propulsion System On Ship Marine InsightDocument4 pagesWhat Is Azipod Propulsion System On Ship Marine InsightAffan KhalifNo ratings yet

- JLN-550 Instruction Manual E2Document48 pagesJLN-550 Instruction Manual E2services HL100% (1)

- OwsDocument10 pagesOwsAnte BudimirNo ratings yet

- DGS Gudelines For 2nd Mate FGDocument9 pagesDGS Gudelines For 2nd Mate FGSAKSHI INSTITUTE OF MARITIME FOUNDATIONNo ratings yet

- Taut Wire Manual MK8 InstallationDocument254 pagesTaut Wire Manual MK8 InstallationPurposeful Kentavr100% (1)

- Comissionamento Do Sistema de Pull in PDFDocument65 pagesComissionamento Do Sistema de Pull in PDFrfelippe8733No ratings yet

- Deck OfficerDocument39 pagesDeck OfficerYudistira Aurum StoreNo ratings yet

- Shuaiba DetailsDocument7 pagesShuaiba DetailsGrațian ȘtefanNo ratings yet

- Steering Control SystemsDocument23 pagesSteering Control Systemsdonato del rosarioNo ratings yet

- MGPSDocument9 pagesMGPSMikhail BagliukNo ratings yet

- TT98-127659-A TT3000LRIT Installation ManualDocument35 pagesTT98-127659-A TT3000LRIT Installation ManualBeneDict Ben D100% (2)

- PUSNES Deck Machinery Installation ProcedureDocument18 pagesPUSNES Deck Machinery Installation ProcedurexatzaraNo ratings yet

- Apos For Hipap Complete ManualDocument131 pagesApos For Hipap Complete ManualAlaa Eldin MohamedNo ratings yet

- Sea Horizon SpecificationDocument2 pagesSea Horizon SpecificationSyafiq HalimNo ratings yet

- OperationManual NavDP4000 v1600.$ - Release-15A b6651 PDFDocument315 pagesOperationManual NavDP4000 v1600.$ - Release-15A b6651 PDFPeterJBloomNo ratings yet

- Cy ScanDocument32 pagesCy ScanLi Ann ChungNo ratings yet

- 94-0094-4-H CyScan A4 4pp AW 2015 (singles-HR) PDFDocument4 pages94-0094-4-H CyScan A4 4pp AW 2015 (singles-HR) PDFEnrique Hernández VázquezNo ratings yet

- SIRE 2.0 Question Library - Part 2 - Chapters 8 To 12 - Version 1.0 (January 2022) - 301-581Document281 pagesSIRE 2.0 Question Library - Part 2 - Chapters 8 To 12 - Version 1.0 (January 2022) - 301-581SteliosNo ratings yet

- Procedure To Discharge Clean Bilge Training - enDocument3 pagesProcedure To Discharge Clean Bilge Training - enclaudioNo ratings yet

- HDFN35T - Spec - HyundayDocument4 pagesHDFN35T - Spec - HyundayCleverson SchmidtNo ratings yet

- A1021 (26) Code On Alerts AlarmsDocument37 pagesA1021 (26) Code On Alerts AlarmsmarinedgeNo ratings yet

- Accommodation Ladder NewDocument9 pagesAccommodation Ladder NewBrian Voyd Rebito100% (1)

- DP Brochure Navis NavDP4000Document12 pagesDP Brochure Navis NavDP4000dimitriapNo ratings yet

- Dynamic positioning The Ultimate Step-By-Step GuideFrom EverandDynamic positioning The Ultimate Step-By-Step GuideRating: 5 out of 5 stars5/5 (1)

- Avr 100s IngleseDocument65 pagesAvr 100s IngleseVedran GaćeNo ratings yet

- Write Up On EHC - REV-01Document11 pagesWrite Up On EHC - REV-01jp mishra100% (2)

- Automatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsDocument65 pagesAutomatic Voltage Regulator AVR100S Operation, Use and Maintenance InstructionsYassine.G ChipLabNo ratings yet

- Petroleum CSG: Hsec Management System ProcedureDocument18 pagesPetroleum CSG: Hsec Management System Proceduremolecule112No ratings yet

- Contractor Hse Management: Level 2 Assurance: Terms of References (Tor)Document3 pagesContractor Hse Management: Level 2 Assurance: Terms of References (Tor)molecule112100% (1)

- Safety Moment: The Seasick SSEDocument3 pagesSafety Moment: The Seasick SSEmolecule112No ratings yet

- Nor Captain - DLB Support VesselDocument1 pageNor Captain - DLB Support Vesselmolecule112No ratings yet

- 'General' Effective Existing Safeguards 'Lifting' Effective Existing SafeguardsDocument2 pages'General' Effective Existing Safeguards 'Lifting' Effective Existing Safeguardsmolecule112No ratings yet

- ChronOS InjecDocument24 pagesChronOS Injecmolecule112No ratings yet

- Safety Alert - ElectrocutionDocument2 pagesSafety Alert - Electrocutionmolecule112No ratings yet

- How To Create and Play Kahoot!Document15 pagesHow To Create and Play Kahoot!Sri Raman NairNo ratings yet

- Sample Test 1Document3 pagesSample Test 1Bình Phạm ThịNo ratings yet

- Power-Linker Training Centre: GroupDocument1 pagePower-Linker Training Centre: GroupSunil SinghNo ratings yet

- Ngo Assignment Meryem Barhdadi MSC IbDocument9 pagesNgo Assignment Meryem Barhdadi MSC IbMeryem BarhdadiNo ratings yet

- Troubleshooting For Rb433R3, Rb433Ur2: No Power, Blue Led Isn'T LitDocument7 pagesTroubleshooting For Rb433R3, Rb433Ur2: No Power, Blue Led Isn'T LitJoseAugustoOsteicoechea100% (1)

- How To Impress Someone at First MeetingDocument1 pageHow To Impress Someone at First MeetingMohammad Fahim HossainNo ratings yet

- An Assessment of The InternshipDocument1 pageAn Assessment of The InternshipRaj GuruNo ratings yet

- Assignment#2 Submitted To: Dr. Aliya Submitted By: Issma Munir Abbasi MS-SP-19-REL-013Document3 pagesAssignment#2 Submitted To: Dr. Aliya Submitted By: Issma Munir Abbasi MS-SP-19-REL-013issma abbasiNo ratings yet

- Abap Code PracticeDocument35 pagesAbap Code PracticeAkhilaNo ratings yet

- Appendix G Elastic and Inelastic Response SpectraDocument11 pagesAppendix G Elastic and Inelastic Response SpectracedaserdnaNo ratings yet

- Current Status, Research Trends, and ChallengesDocument23 pagesCurrent Status, Research Trends, and Challengesqgi-tanyaNo ratings yet

- Durastor Tank Brochure PDFDocument8 pagesDurastor Tank Brochure PDFhamadaniNo ratings yet

- ESP Standard SizingDocument131 pagesESP Standard Sizingmohamed gamal100% (2)

- BC KMBN107 Unit 3Document26 pagesBC KMBN107 Unit 3Rizwan SaifiNo ratings yet

- Neurological Development From Birth To Six YearsDocument143 pagesNeurological Development From Birth To Six YearsWaleska SakibNo ratings yet

- Plusco325 Coatings External Pipe CoatingDocument1 pagePlusco325 Coatings External Pipe Coatinga.hasan670No ratings yet

- List of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesDocument4 pagesList of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesUrva VasavadaNo ratings yet

- Ipad - Apple Technician Guide (2011)Document116 pagesIpad - Apple Technician Guide (2011)Jonathan Long100% (1)

- EMT 7103 Computer Applications in Engineering Kris KegoDocument28 pagesEMT 7103 Computer Applications in Engineering Kris KegoMugisa PeterNo ratings yet

- Conclusion ParagraphDocument7 pagesConclusion Paragraphapi-334926654No ratings yet

- NE20E-S V800R022C00SPC600 Configuration Guide 01 Basic ConfigurationDocument422 pagesNE20E-S V800R022C00SPC600 Configuration Guide 01 Basic ConfigurationMoises HenriqueNo ratings yet

- Chronic LeukemiaDocument38 pagesChronic LeukemiaV Lee 'Nozhat'100% (1)

- 50420231021331792nav.2 Module 5Document2 pages50420231021331792nav.2 Module 5joeNo ratings yet

- Cluster SamplingDocument3 pagesCluster Samplingken1919191100% (1)

- FRP Parameter Optimization Settings: Wilfried Baumgartner / Hans Georg Kloep, SAP July 6, 2016Document36 pagesFRP Parameter Optimization Settings: Wilfried Baumgartner / Hans Georg Kloep, SAP July 6, 2016atungmuNo ratings yet

- MK17C01-Group 3-MKT328m-Final Report DIFFERENTDocument14 pagesMK17C01-Group 3-MKT328m-Final Report DIFFERENTTran Minh Quy (K17 QN)No ratings yet

- Welded Steel Fabric: Natsteel Holdings Pte LTDDocument8 pagesWelded Steel Fabric: Natsteel Holdings Pte LTDSantosoNo ratings yet