Professional Documents

Culture Documents

HSB HPBoilerLog

HSB HPBoilerLog

Uploaded by

eborresonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSB HPBoilerLog

HSB HPBoilerLog

Uploaded by

eborresonCopyright:

Available Formats

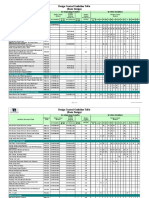

HIGH PRESSURE POWER BOILER LOG

ADDITIONAL LOG(S) REQUEST TO:

Engineering Department, The Hartford Steam Boiler Inspection and Insurance Company,

One State Street, P.O. Box 5024, Hartford, CT 06102-5024.

Please specify which log and how many copies per log.

MANUFACTURER

MONDAY

TUESDAY

A.M.

FRIDAY

THURSDAY

WEDNESDAY

A.M.

BOILER NUMBER

Level

Low

Water

Cut-Off

WATER

Level

Control

Column

Gage

Glass

Fired

Pump

Condensate

Tank

PRESSURE

Steam

Feed

Pump

TEMPERATURE

Feed

Water

Condensate

Flue

Gas

LOCATION

BURNER/

STOKER

OPERATIONS

FUEL

SUPPLY

WATER

TREATMENT

WEEK BEGINNING

BOILER

BLOW

DOWN

FEED

WATER

MAKE-UP

OPERATOR

ON DUTY

REMARKS

P.M.

P.M.

A.M.

P.M.

A.M.

P.M.

A.M.

P.M.

A.M.

P.M.

A.M.

INSTRUCTIONS

P.M.

Continued safe operation of a boiler depends on regular maintenance

and testing of the boiler and its operating and protective controls. The

tests and checks outlined above are designed to determine whether or

not the boiler and controls are in good operating condition.

Should any check or test include that the device being tested or

observed is not in good operating condition it should be repaired

immediately. Record repairs or changes under Remarks so that a

complete record will be available for review at any time.

TESTING

SUNDAY

SATURDAY

CHECK OR TEST RECORD TWICE DAILY

DAY

AND

TIME

NOTE: In addition to the checks and tests listed

here, the Check List for High Pressure Boilers

(on reverse side) must be completed as well.

WATER COLUMN AND GAGE GLASS open drain valve quickly and

flush water from glass and column. When drain is closed water level

should recover promptly.

LOW WATER FUEL CUT-OFF AND WATER LEVEL CONTROL

drain float chamber when firing equipment is operating. Proper

operation of the control should shut off the firing equipment and start

1467 REV 6/08 (ENG)

LOG REVIEWED BY

DATE

COMMENTS

feed pump. If controls are of probe or other type that require lowering

of water level in boiler to test, DO NOT lower level to point below

bottom of gage glass.

CHECKLIST FOR HIGH PRESSURE BOILERS

ADDITIONAL LOG(S) REQUEST TO:

Engineering Department, The Hartford Steam Boiler Inspection and Insurance Company,

One State Street, P.O. Box 5024, Hartford, CT 06102-5024.

Please specify which log and how many copies per log.

MANUFACTURER

DATE

PROCEDURE

COMPLETED

BOILER NUMBER

DESCRIPTION OF PROCEDURE

SAFETY VALVE (monthly)

To check the safety valve, pull try lever to open position with

steam at full pressure. Release to allow valve to snap closed.

DISMANTLE LOW WATER

FUEL CUT-OFF (at least annually)

The low water fuel cut-off should be dismantled for complete

overhaul at regular intervals, and all the internal and external

mechanism (including linkage, contacts, mercury bulbs, floats,

and wiring) should be carefully checked for defects. See

manufacturers instructions and recommendations.

CLEAN FIRE SIDE OF BOILER (annually)

The fire side of the boiler should be cleaned at least annually.

At the time of this cleaning, all brick work and refactory should

be checked and repaired as needed.

WASH OUT BOILER (annually)

COMMENTS

The internal surfaces of the boiler should be checked at

regular intervals to determine if scale or corrosion is present.

Contact your boiler inspector if any unusual condition is noted.

Length of time between washouts should be varied in

accordance with conditions noted at time of washout.

1469 REV 6/08 (ENG)

INSTRUCTIONS:

1. In addition to the checks and tests listed on the daily (form

1467) or hourly (form 2055) log sheets, the following

checks should be made on a periodic basis. More frequent

checks and tests may be required according to the

particular conditions noted.

2. Enter date when the test or maintenance procedure

detailed below, has been completed.

DATE

PROCEDURE

COMPLETED

LOCATION

DESCRIPTION OF PROCEDURE

CHECK BOILER and SYSTEM

for LEAKAGE or DEFECTS (semiannually)

The boiler and its entire system should be given a careful and

complete check at regular intervals for leakage or other

defects at pipe connections, flanges, traps, and valves. In the

interest of safe and reliable service, any unsatisfactory

condition should be noted and corrected.

SERVICE STOKER, OIL or GAS BURNER

OPERATING CONTROLS

The stoker, oil or gas burner controls should be thoroughly

checked at least annually. High limit controls should also be

checked annually. Safety controls such as flame failure should

be checked weekly. In general this service should be obtained

from a reliable outside service organization. If service by the

operator, a complete record of work done should be entered

on the log. See manufacturers instructions and

recommendations.

CHECK LOW WATER FUEL

CUT-OFF (weekly)

The low water fuel cut-off should be checked at least weekly

by actually lowering the water level in the boiler slowly to

simulate a developing low water condition. Caution! Do not

lower water level below bottom of Water gage glass.

Should cut-off not function properly under this test, it must be

immediately overhauled and placed in operating condition.

You might also like

- Dep32.36.01.18 - 2014Document59 pagesDep32.36.01.18 - 2014Maffone Numerouno50% (2)

- Chiller Maintenance ChecklistDocument2 pagesChiller Maintenance ChecklistAssem Elhajj100% (17)

- Hydraulic Power Pack 60 B29ADocument3 pagesHydraulic Power Pack 60 B29Agpcd1210No ratings yet

- Rotex A1 BGDocument36 pagesRotex A1 BGjacek_janikowsk4374No ratings yet

- Fulton 40eDocument44 pagesFulton 40eDimas Bagasworo100% (2)

- SIP and Inter Working With PSTNDocument13 pagesSIP and Inter Working With PSTNmehmetcaNo ratings yet

- Boiler Maintanance and Checked ListDocument2 pagesBoiler Maintanance and Checked ListAbdillah Fauzan AriefNo ratings yet

- Boiler Safety ProgramDocument8 pagesBoiler Safety ProgramHussain KhanNo ratings yet

- NEE Boiler-Inspection GuidelineDocument70 pagesNEE Boiler-Inspection GuidelinepiyushagaNo ratings yet

- Vertical Tubeless Gas Fired IOMDocument102 pagesVertical Tubeless Gas Fired IOMElvis RivadeneiraNo ratings yet

- RBC Iom 04 2011Document114 pagesRBC Iom 04 2011Flores CesarNo ratings yet

- Boiler Safety Program Boiler ProgramDocument8 pagesBoiler Safety Program Boiler Programsalman akbarNo ratings yet

- FS HpuDocument11 pagesFS Hpuscribd_thakurNo ratings yet

- Maint IPENDocument13 pagesMaint IPENosmaidaNo ratings yet

- State of Oregon Minimum Boiler Operational Standards: All Persons Assigned Responsibility For Boiler Operations ShallDocument4 pagesState of Oregon Minimum Boiler Operational Standards: All Persons Assigned Responsibility For Boiler Operations ShallzeeshanNo ratings yet

- Appendix-3.0 Scope of Chiller Maintenance WorksDocument3 pagesAppendix-3.0 Scope of Chiller Maintenance Worksnoormuddassirkhan100% (1)

- Isolation & Maintenance of Power Transformers.Document4 pagesIsolation & Maintenance of Power Transformers.अभिषेक कुमार उपाध्यायNo ratings yet

- Boiler Inspection267142Document31 pagesBoiler Inspection267142raj.clarence7No ratings yet

- Boiler Inspection Guidance PDFDocument5 pagesBoiler Inspection Guidance PDFAnonymous yCpjZF1rFNo ratings yet

- Heat Exchanger InspectionDocument6 pagesHeat Exchanger Inspectionjamaljamal20No ratings yet

- Boiler Hydrotest Procedure Boiler BDFB 350-1004Document10 pagesBoiler Hydrotest Procedure Boiler BDFB 350-1004Gunung A E SinamnbelaNo ratings yet

- Quoting and Proposals: Carrier Compressor Inspection OfferDocument12 pagesQuoting and Proposals: Carrier Compressor Inspection OfferIwan HusaeniNo ratings yet

- Maintenance Schedule For SubstationDocument21 pagesMaintenance Schedule For SubstationSajid Shaikh100% (1)

- High-Pressure Boiler Inspection Procedures: A Complete ChecklistDocument6 pagesHigh-Pressure Boiler Inspection Procedures: A Complete ChecklistROHITNo ratings yet

- Maintenance Inspections: Standby Inspections Running InspectionsDocument35 pagesMaintenance Inspections: Standby Inspections Running Inspectionsrafiee100% (2)

- Boiler InspectionsDocument6 pagesBoiler InspectionsAndre YosiNo ratings yet

- HVAC-Final CleanedDocument14 pagesHVAC-Final Cleanedbastin louisNo ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument2 pagesTesting & Commissioning of Fan Coil Units FCU'sDong VanraNo ratings yet

- Sample Preventive Maintenance Manual For A Packaged FireDocument16 pagesSample Preventive Maintenance Manual For A Packaged FireKevin PersadNo ratings yet

- Rohit Dave: Wednesday, February 17, 2010Document78 pagesRohit Dave: Wednesday, February 17, 2010Ryan JohnNo ratings yet

- Steam System Best Practices 14 Best Practices For Guide Lines For Boiler Plant Log BooksDocument12 pagesSteam System Best Practices 14 Best Practices For Guide Lines For Boiler Plant Log BooksAjay Kumar GiriNo ratings yet

- Rohit Dave: Wednesday, February 17, 2010Document78 pagesRohit Dave: Wednesday, February 17, 2010Sérgio CruzNo ratings yet

- Cartridge Valves CT 198974Document312 pagesCartridge Valves CT 198974oleg-spb100% (2)

- Appendix G - All FTPDocument81 pagesAppendix G - All FTPRaja AntonyNo ratings yet

- Ammonia Plant Maint.Document11 pagesAmmonia Plant Maint.mahmadwasiNo ratings yet

- Inspection of BoilersDocument13 pagesInspection of BoilersLuis MenaNo ratings yet

- 154 KV CIRCUIT BREAKER PDFDocument9 pages154 KV CIRCUIT BREAKER PDFCelil GOZELNo ratings yet

- متابعة صيانة التكييف المركزيDocument52 pagesمتابعة صيانة التكييف المركزيRomou Alsaaq100% (1)

- Boiler Hydrostatic Testing ProcedureDocument5 pagesBoiler Hydrostatic Testing ProcedureMico CampoNo ratings yet

- HPAC - Evaluating Deaerator OperationDocument5 pagesHPAC - Evaluating Deaerator Operationghostamir100% (1)

- Boiler MtceDocument3 pagesBoiler MtceJustin Raj0% (1)

- Boilers: - Asit MondalDocument29 pagesBoilers: - Asit MondalAJITSPATILNo ratings yet

- Boiler SpecificationsDocument34 pagesBoiler SpecificationsHenry CoronadoNo ratings yet

- Guide Spec Summary: Option ListDocument20 pagesGuide Spec Summary: Option ListRamachandra Reddy ChinthamreddyNo ratings yet

- Operating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterDocument27 pagesOperating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterAmir EbrahimNo ratings yet

- CraneDocument32 pagesCranesabes26100% (1)

- Boiler InspectionDocument6 pagesBoiler Inspectiondaimahesh100% (1)

- List of HVAC SpecificationsDocument46 pagesList of HVAC Specificationsnguyenquoc1988100% (1)

- Asco Today v7375r5Document34 pagesAsco Today v7375r5Jesus N RodriguezNo ratings yet

- BR 1701 PDFDocument7 pagesBR 1701 PDFdestiny2bnNo ratings yet

- HP Dosing - AgecDocument12 pagesHP Dosing - AgecShameer MajeedNo ratings yet

- Pressure Relief Device InspectionDocument14 pagesPressure Relief Device InspectionM.Hamdy A.ElNabyNo ratings yet

- BR 170 1Document7 pagesBR 170 1Himanshu ChaturvediNo ratings yet

- LP Dosing AgecDocument12 pagesLP Dosing AgecShameer MajeedNo ratings yet

- 32 Saip 11Document9 pages32 Saip 11malika_00No ratings yet

- Over 2000 of Today's Most Popular ProductsDocument34 pagesOver 2000 of Today's Most Popular ProductsRaul Guevara TorresNo ratings yet

- Best Practice Guide For Power Transformer Maintenance EEPDocument1 pageBest Practice Guide For Power Transformer Maintenance EEPashutosh ambeyNo ratings yet

- Fulton Steam BoilerDocument46 pagesFulton Steam BoilerDonatas Bertasius100% (1)

- Boiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerDocument9 pagesBoiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerChriscarl De LimaNo ratings yet

- BoilerDocument22 pagesBoilerAngel Silva VicenteNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Database Standard MandatoriDocument31 pagesDatabase Standard MandatorizalzizaNo ratings yet

- Basic Drill String DesignDocument22 pagesBasic Drill String DesignDon Braithwaite100% (3)

- SDH Access Tester Up To STM-16: Key FeaturesDocument13 pagesSDH Access Tester Up To STM-16: Key FeaturesKurama AxNo ratings yet

- Martin SprocketsDocument48 pagesMartin SprocketsMauro TognocchiNo ratings yet

- Petroworks Manual 6Document40 pagesPetroworks Manual 6ahmed_497959294No ratings yet

- PDF Tratado Enciclopedico de Ifa Ojuani - CompressDocument216 pagesPDF Tratado Enciclopedico de Ifa Ojuani - CompressGuillermo Escalona100% (1)

- Generator KPC SpecsDocument70 pagesGenerator KPC SpecsdmugalloyNo ratings yet

- 2.2.3.4 Packet Tracer - Configuring Initial Switch SettingsDocument9 pages2.2.3.4 Packet Tracer - Configuring Initial Switch SettingsParthPatel100% (1)

- Human Resources Assistant JobDocument5 pagesHuman Resources Assistant JobJohn Cleeven Buensuceso GarciaNo ratings yet

- Jetspeed Iad Wp2 (SR)Document59 pagesJetspeed Iad Wp2 (SR)akcija_npstefan0% (2)

- Direct Reduction Technology: Danieli and Energiron A History of Success Supporting The Future ChallengesDocument8 pagesDirect Reduction Technology: Danieli and Energiron A History of Success Supporting The Future ChallengesEli Elke GalindoNo ratings yet

- New Forms For Taking Over Process of Water Supply System by Tuan Haji Sanusi SuliemanDocument20 pagesNew Forms For Taking Over Process of Water Supply System by Tuan Haji Sanusi SuliemansharifahNo ratings yet

- IS Alarm SounderDocument3 pagesIS Alarm SounderHari KrishnanNo ratings yet

- DX DU: Self-Lubricating BearingsDocument33 pagesDX DU: Self-Lubricating Bearingsguruchims100% (1)

- Database Programming: Case and Character ManipulationDocument30 pagesDatabase Programming: Case and Character ManipulationKevin Van MalderenNo ratings yet

- TBHM3 (P) PDFDocument64 pagesTBHM3 (P) PDFSpeckedLecturerNo ratings yet

- PCD ED 451 Attachment 02Document13 pagesPCD ED 451 Attachment 02mNo ratings yet

- KWXR 616Document42 pagesKWXR 616Rajwant KaurNo ratings yet

- Coupling AlignmentDocument14 pagesCoupling Alignmentkutts76No ratings yet

- Astm b209 06Document29 pagesAstm b209 06wanggaNo ratings yet

- BS en Iso 9013 - 2003Document4 pagesBS en Iso 9013 - 2003OteloElMoroNo ratings yet

- Easy Pact Schneider 8Document1 pageEasy Pact Schneider 8MELVINNo ratings yet

- Andorra XiR-P6600 Portable AR3-04-002 0512Document4 pagesAndorra XiR-P6600 Portable AR3-04-002 0512Yusrefli ZulkifliNo ratings yet

- Bicycle Power Generator Design For DC House 52pagesDocument52 pagesBicycle Power Generator Design For DC House 52pagesDeepjyoti Talukdar100% (2)

- Diesel Engine StartingDocument28 pagesDiesel Engine Startingpatrick banisaNo ratings yet

- Bosch Presentation of Diagnostic CommunicationDocument23 pagesBosch Presentation of Diagnostic Communicationbrj100% (2)

- Civil EngineeringDocument3 pagesCivil EngineeringlawNo ratings yet

- S-Felt T300 PDSDocument3 pagesS-Felt T300 PDSRandi RahmanNo ratings yet