Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

7 viewsHeat Pipe Technology: Medium Voltage Adjustable Frequency Drive

Heat Pipe Technology: Medium Voltage Adjustable Frequency Drive

Uploaded by

chahbounnabileaton AFD cooling

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Australian/New Zealand StandardDocument29 pagesAustralian/New Zealand StandardKayleigh Maynard100% (1)

- Material Safety Data Sheet CPO CARGILLDocument3 pagesMaterial Safety Data Sheet CPO CARGILLCarlos MontanoNo ratings yet

- Global Job Structure Job Profile Manual PDFDocument813 pagesGlobal Job Structure Job Profile Manual PDFchahbounnabil100% (3)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyDocument6 pagesThe Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyBrandon CoxNo ratings yet

- Pestle Analysis United Arab EmiratesDocument16 pagesPestle Analysis United Arab EmiratesSamer Abu Rashed0% (2)

- 1 RFP - Gabon Project 04.20-REV1 PDFDocument16 pages1 RFP - Gabon Project 04.20-REV1 PDFVikram SinghNo ratings yet

- Study of A Loop Thermosyphon For Thermal Control of AircraftsDocument20 pagesStudy of A Loop Thermosyphon For Thermal Control of Aircraftsaktk1234No ratings yet

- RDA Induction Heating 4 PageDocument4 pagesRDA Induction Heating 4 Pageนภดล สินธุแปงNo ratings yet

- Art 6Document5 pagesArt 6manjubd1No ratings yet

- Air Conditioning Thesis StatementDocument7 pagesAir Conditioning Thesis Statementewdgbnief100% (2)

- He165 (A4) PDFDocument4 pagesHe165 (A4) PDFLina ShakirNo ratings yet

- Heat Recovery From Exhaust GasesDocument6 pagesHeat Recovery From Exhaust GasesnaveenNo ratings yet

- Xenon Lamp Aging Test ChamberDocument6 pagesXenon Lamp Aging Test ChamberLisun GroupNo ratings yet

- O M Manual W818 PDFDocument71 pagesO M Manual W818 PDFmujeebmehar100% (1)

- RF10 (A4)Document4 pagesRF10 (A4)Dewa Made Astika YathaNo ratings yet

- Caldera de Fluido Térmico - Ce - InglesDocument14 pagesCaldera de Fluido Térmico - Ce - InglespikethNo ratings yet

- SR en 442 RadiatoareDocument3 pagesSR en 442 RadiatoareprodanNo ratings yet

- Thermosyphon EffectDocument10 pagesThermosyphon EffectPit_mkluNo ratings yet

- Encon MVC Brochure 2015Document4 pagesEncon MVC Brochure 2015Pragathees Waran100% (1)

- Distillation ExpDocument10 pagesDistillation Expmehmet hassanNo ratings yet

- Application of HEat PipeDocument29 pagesApplication of HEat PipeNikhil ShahNo ratings yet

- Carte Tehnică NOUĂ OctopusDocument53 pagesCarte Tehnică NOUĂ OctopuscosmynnsNo ratings yet

- ht10xc Os 3Document7 pagesht10xc Os 3Sheikh ShoaibNo ratings yet

- Experiment 1: Refrigeration and Mechanical Heat Pump ExperimentDocument12 pagesExperiment 1: Refrigeration and Mechanical Heat Pump ExperimentMohamad FaizNo ratings yet

- Common Questions Heat Pipes PDFDocument2 pagesCommon Questions Heat Pipes PDFTeo Pei San100% (1)

- June Report For Dennis Tavonga MuzilaDocument17 pagesJune Report For Dennis Tavonga MuzilaDennis MuzilaNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Oschatz Non-Ferrous Metallurgy enDocument12 pagesOschatz Non-Ferrous Metallurgy enSelene Acosta MauricciNo ratings yet

- Spe 137208 Monitoring Pcps in 500F Steam Flood ApplicationsDocument4 pagesSpe 137208 Monitoring Pcps in 500F Steam Flood ApplicationsClyde San VicenteNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Triple Point CellsDocument48 pagesTriple Point CellsGustavo SánchezNo ratings yet

- Heat Sink Considerations - ThermoelectricDocument2 pagesHeat Sink Considerations - ThermoelectricNaranLoganNo ratings yet

- Calderas ElectrodosDocument39 pagesCalderas ElectrodoscarloscerneyNo ratings yet

- Batam Furnace Manual (English Version)Document14 pagesBatam Furnace Manual (English Version)Tiurmaida DamanikNo ratings yet

- Ewyq FDocument54 pagesEwyq FRicardo Molina SánchezNo ratings yet

- Experimental Investigation of A Vapor Absorption Refrigeration SystemDocument7 pagesExperimental Investigation of A Vapor Absorption Refrigeration Systemakibmahmud392No ratings yet

- Manual ECG - en - v2.1Document25 pagesManual ECG - en - v2.1JeremyYmerehNo ratings yet

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Exploring Pulsating Heat Pipe Efficiency Across Different Sizes and Heat LevelsDocument6 pagesExploring Pulsating Heat Pipe Efficiency Across Different Sizes and Heat Levelsdeepan101969No ratings yet

- Applications of Heat PipeDocument17 pagesApplications of Heat PipeManikantaNaupadaNo ratings yet

- Technical SeminarDocument19 pagesTechnical SeminarLibinNo ratings yet

- M - Electric Heater PIROBLOC EngDocument11 pagesM - Electric Heater PIROBLOC EngpikethNo ratings yet

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Zhongshan Shuangping Electronic Technology Co., LTD: OntactDocument25 pagesZhongshan Shuangping Electronic Technology Co., LTD: OntactNixonGarciaNo ratings yet

- Thermoelectric Cooling For Industrial EnclosuresDocument6 pagesThermoelectric Cooling For Industrial EnclosuresErdinc KlimaNo ratings yet

- RTP AsOne 150Document6 pagesRTP AsOne 150Hitesh KambleNo ratings yet

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Rac 7th Sem ManualDocument26 pagesRac 7th Sem Manualmanishsingla88No ratings yet

- Efficiency of Heat ExchangersDocument27 pagesEfficiency of Heat ExchangersAbdul GhafoorNo ratings yet

- Technical Brochures AW HT 0031 0071 enDocument50 pagesTechnical Brochures AW HT 0031 0071 endouslasNo ratings yet

- Experimental Investigation of Thermal Performance of A Radiant Cooling SystemDocument7 pagesExperimental Investigation of Thermal Performance of A Radiant Cooling Systemrajesh0145No ratings yet

- Automatic Pneumatic Vulcanizing MachineDocument3 pagesAutomatic Pneumatic Vulcanizing MachineBALAJINo ratings yet

- Chapter - 1 1.1 BackgroundDocument83 pagesChapter - 1 1.1 BackgroundRojithNo ratings yet

- ProHeat 35 - MillerDocument8 pagesProHeat 35 - MillerMario Paniagua QuinteroNo ratings yet

- Kendro 3000 Series Service ManualDocument54 pagesKendro 3000 Series Service ManualCarlos Alberto Ramirez GarciaNo ratings yet

- Heat PipeDocument27 pagesHeat Pipesaurabh maneNo ratings yet

- ED - AF GB Ccu Upto37cDocument3 pagesED - AF GB Ccu Upto37cRaja AntonyNo ratings yet

- The ExperimentDocument13 pagesThe ExperimentUsɱâñ MåâñNo ratings yet

- Heat Pipes in Electronics (1) : 15.1 Components of A Heat PipeDocument10 pagesHeat Pipes in Electronics (1) : 15.1 Components of A Heat Pipekeerti06No ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- 4000 Essential English Words 3Document195 pages4000 Essential English Words 3jupiter805393% (28)

- 4000ese6 PDFDocument192 pages4000ese6 PDFamitukumarNo ratings yet

- Deals Blindspot Ebook PDFDocument16 pagesDeals Blindspot Ebook PDFchahbounnabilNo ratings yet

- 1SDA068661R1 Ekip Com X Lsi Lsig M Lriu Xt2 Xt4 F PDocument2 pages1SDA068661R1 Ekip Com X Lsi Lsig M Lriu Xt2 Xt4 F Pchahbounnabil0% (1)

- Catalogue Interrupteur Fusible PDFDocument116 pagesCatalogue Interrupteur Fusible PDFchahbounnabilNo ratings yet

- 2gcs210011a0040 - Apcq ManualDocument35 pages2gcs210011a0040 - Apcq ManualchahbounnabilNo ratings yet

- Primary Offering 2010 10 - MoroccoDocument127 pagesPrimary Offering 2010 10 - MoroccochahbounnabilNo ratings yet

- Zelio EMR Product SelectorDocument365 pagesZelio EMR Product SelectorchahbounnabilNo ratings yet

- Sales Memo ATV71Document2 pagesSales Memo ATV71chahbounnabilNo ratings yet

- Weaverville Community Forest Becomes A Reality: Summer 2006Document8 pagesWeaverville Community Forest Becomes A Reality: Summer 2006Trinity County Resource Conservation DistrictNo ratings yet

- The Future o Water Availability and Demand in The Metropolitan Area of Monterrey Mexico (2009)Document19 pagesThe Future o Water Availability and Demand in The Metropolitan Area of Monterrey Mexico (2009)REALIDAD EXPUESTANo ratings yet

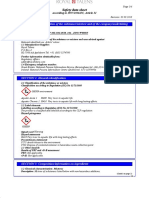

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument6 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingMisterrriotNo ratings yet

- Class 9 ExamDocument3 pagesClass 9 ExamsongsfresherNo ratings yet

- BS Iso 05667-4-2016Document46 pagesBS Iso 05667-4-2016mohamed senoussiNo ratings yet

- EXTERNAL WORKS V 1-0 Apr 10 - ACC - WE - DF6000Document22 pagesEXTERNAL WORKS V 1-0 Apr 10 - ACC - WE - DF6000vin ssNo ratings yet

- Chapter 28 ProtistsDocument48 pagesChapter 28 Protistsbrguzz50% (2)

- Raw Sugar ProcessingDocument6 pagesRaw Sugar ProcessingJan April MahinayNo ratings yet

- THE USES AND ABUSES OF THE ANCIENT MAYA by David WebsterDocument38 pagesTHE USES AND ABUSES OF THE ANCIENT MAYA by David WebstermalizverkoNo ratings yet

- Drainage GCDocument7 pagesDrainage GCVgkBharadwajNo ratings yet

- (PHWR) Technology PDFDocument40 pages(PHWR) Technology PDFJUAN4201No ratings yet

- Remote SensingDocument3 pagesRemote SensingsriniNo ratings yet

- 3. 50 Đề Thi HSG Lớp 12 - Otto ChannelDocument309 pages3. 50 Đề Thi HSG Lớp 12 - Otto ChannelHan YingNo ratings yet

- English 2Document548 pagesEnglish 2Can EryilmazNo ratings yet

- Options For High Temperature Well StimulationDocument11 pagesOptions For High Temperature Well StimulationFra FraNo ratings yet

- FBPB - I-B - 2008 Introduction & SyllabusDocument22 pagesFBPB - I-B - 2008 Introduction & SyllabusMarko ObrknezevNo ratings yet

- Aquaculture Negative - NAUDL 2014Document45 pagesAquaculture Negative - NAUDL 2014divizioniNo ratings yet

- Zambia The Community School Based Urban Agriculture Project of Project Concern International - LusakaDocument6 pagesZambia The Community School Based Urban Agriculture Project of Project Concern International - LusakaFree Rain Garden ManualsNo ratings yet

- One Rarely Falls in Love Without Being As Much Attracted To What Is Interestingly Wrong With Someone As What Is Objectively Healthy Says Philosopher Alain de Botton 1Document5 pagesOne Rarely Falls in Love Without Being As Much Attracted To What Is Interestingly Wrong With Someone As What Is Objectively Healthy Says Philosopher Alain de Botton 1api-308174583No ratings yet

- Apple Spray Schedule 2024 SKUAST KashmirDocument20 pagesApple Spray Schedule 2024 SKUAST Kashmirshakoor.ab.phd.cseNo ratings yet

- NTPC Heat Rate PDFDocument395 pagesNTPC Heat Rate PDFcynaidu67% (6)

- Scenario G - Project Brief - 2020Document8 pagesScenario G - Project Brief - 2020abdul5721No ratings yet

- Jenell Strachan - ResumeDocument2 pagesJenell Strachan - ResumejjastrachanNo ratings yet

- Method For Preparing Anhydrous Iron ChloridesDocument4 pagesMethod For Preparing Anhydrous Iron ChloridesVioleta GrigorasNo ratings yet

- Waste Management Handbook PDFDocument90 pagesWaste Management Handbook PDFAkulSenapati100% (1)

- Application Form For Infrastructure-Integrated FinalDocument5 pagesApplication Form For Infrastructure-Integrated FinalSamer KhaledNo ratings yet

Heat Pipe Technology: Medium Voltage Adjustable Frequency Drive

Heat Pipe Technology: Medium Voltage Adjustable Frequency Drive

Uploaded by

chahbounnabil0 ratings0% found this document useful (0 votes)

7 views2 pageseaton AFD cooling

Original Title

SA02000001E_150

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenteaton AFD cooling

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views2 pagesHeat Pipe Technology: Medium Voltage Adjustable Frequency Drive

Heat Pipe Technology: Medium Voltage Adjustable Frequency Drive

Uploaded by

chahbounnabileaton AFD cooling

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

SC9000 EP

Medium voltage adjustable frequency drive

Heat pipe technology

The SC9000 EP technology

Heat exits the heat pipe

at the condenser (fin stack)

where the working fluid

condenses through and

releases its latent heat

through vaporization.

Heat pipe technology used

to cool power components

Encapsulated medium voltage

components, creating a harshenvironment inverter

Roll-in/roll-out inverter design

minimizes downtime

Condenser Area

Epoxy coated pipes

for protection in

harsh environments.

HEAT

OUT

Heat enters the pipe at the

evaporator (block) through

the semiconductor devices

where it causes working

fluid to vaporize. The

vaporized fluid creates a

pressure gradient, which

forces the vapor toward

the condenser (fin stack).

HEAT

OUT

Fluid

Return

Vapor

Sealed Copper Heat Pipe

(uncoated)

The capillary lining serves

as a pump using capillary

pressure to return the fluid

from the condenser (fin

stack) to the evaporator

(block). The capillary lining

also acts as an extended

surface to allow higher

heat fluxes.

HEAT

IN

HEAT

IN

Evaporator Area

About heat pipe technology

Q: What is heat pipe

technology and how

does it work?

A: Heat pipe technology allows

for efficient and fast transfer

of heat from active heatgenerating elements to

condenser elements in an

electrical system. The heat

pipe uses a self-contained,

constant flow of fluid from

the heat-generating elements

to the condenser elements.

Fluid in the heat pipe

vaporizes due to the heat

in the active elements, and

capillary pressure returns the

cooled fluid toward the part

of the heat pipe that contains

the active element.

Q: Why would I need

this technology?

A: The heat pipe cooling

method is the most

efficient air-cooled thermal

management system

available today. It is up to

10 times more efficient

than conventional air-cooled

methods. Consequently, less

airflow is necessary, reducing

audible noise and levels of

contaminants pulled into

electrical cabinets.

Q: Is heat pipe technology

safe in cold climates?

A: Yes. A third-party testing

lab performed temperature

testing on the heat pipe

exchangers at 50 C

for 24hours, in order to

simulate harsh transportation

temperatures. The lab reports

that: Cold storage at 50C

has no influence on the

structure of the [heat pipe]

unit. No defects were found.

Q: If a heat pipe gets

damaged, will

performance be

affected?

A: It is nearly impossible

to damage a heat pipe

during normal handling

and operation. If one does

leak, performance will not

be affected in most cases.

However, contact your

Eaton service center if

a leak is noticed.

For more information on Eaton medium

voltage adjustable frequency drives, visit

Eaton.com/SC9000 or call

1-877-ETN-CARE, option 2, then option 7

Q: How does heat pipe

technology integrate

into products?

A: The heat pipe connects

the active elements of a

system to the condenser

elements. Heat enters pipes

at the evaporator block

(through semiconductor

devices), where it causes

working fluid to vaporize.

The vaporized fluid creates

a pressure gradient and

forces the vapor toward the

condenser (fin stack). Heat

exits the heat pipe at the

condenser (fin stack) where

the working fluid condenses

and releases its latent

heat of vaporization. The

condensed working fluid is

drawn down into the pores

of the capillary lining and

returns to the evaporator.

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

2014 Eaton

All Rights Reserved

Printed in USA

Publication No. SA02000001E / Z15346

June 2014

Eaton is a registered trademark.

All other trademarks are property

of their respective owners.

You might also like

- Australian/New Zealand StandardDocument29 pagesAustralian/New Zealand StandardKayleigh Maynard100% (1)

- Material Safety Data Sheet CPO CARGILLDocument3 pagesMaterial Safety Data Sheet CPO CARGILLCarlos MontanoNo ratings yet

- Global Job Structure Job Profile Manual PDFDocument813 pagesGlobal Job Structure Job Profile Manual PDFchahbounnabil100% (3)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyDocument6 pagesThe Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyBrandon CoxNo ratings yet

- Pestle Analysis United Arab EmiratesDocument16 pagesPestle Analysis United Arab EmiratesSamer Abu Rashed0% (2)

- 1 RFP - Gabon Project 04.20-REV1 PDFDocument16 pages1 RFP - Gabon Project 04.20-REV1 PDFVikram SinghNo ratings yet

- Study of A Loop Thermosyphon For Thermal Control of AircraftsDocument20 pagesStudy of A Loop Thermosyphon For Thermal Control of Aircraftsaktk1234No ratings yet

- RDA Induction Heating 4 PageDocument4 pagesRDA Induction Heating 4 Pageนภดล สินธุแปงNo ratings yet

- Art 6Document5 pagesArt 6manjubd1No ratings yet

- Air Conditioning Thesis StatementDocument7 pagesAir Conditioning Thesis Statementewdgbnief100% (2)

- He165 (A4) PDFDocument4 pagesHe165 (A4) PDFLina ShakirNo ratings yet

- Heat Recovery From Exhaust GasesDocument6 pagesHeat Recovery From Exhaust GasesnaveenNo ratings yet

- Xenon Lamp Aging Test ChamberDocument6 pagesXenon Lamp Aging Test ChamberLisun GroupNo ratings yet

- O M Manual W818 PDFDocument71 pagesO M Manual W818 PDFmujeebmehar100% (1)

- RF10 (A4)Document4 pagesRF10 (A4)Dewa Made Astika YathaNo ratings yet

- Caldera de Fluido Térmico - Ce - InglesDocument14 pagesCaldera de Fluido Térmico - Ce - InglespikethNo ratings yet

- SR en 442 RadiatoareDocument3 pagesSR en 442 RadiatoareprodanNo ratings yet

- Thermosyphon EffectDocument10 pagesThermosyphon EffectPit_mkluNo ratings yet

- Encon MVC Brochure 2015Document4 pagesEncon MVC Brochure 2015Pragathees Waran100% (1)

- Distillation ExpDocument10 pagesDistillation Expmehmet hassanNo ratings yet

- Application of HEat PipeDocument29 pagesApplication of HEat PipeNikhil ShahNo ratings yet

- Carte Tehnică NOUĂ OctopusDocument53 pagesCarte Tehnică NOUĂ OctopuscosmynnsNo ratings yet

- ht10xc Os 3Document7 pagesht10xc Os 3Sheikh ShoaibNo ratings yet

- Experiment 1: Refrigeration and Mechanical Heat Pump ExperimentDocument12 pagesExperiment 1: Refrigeration and Mechanical Heat Pump ExperimentMohamad FaizNo ratings yet

- Common Questions Heat Pipes PDFDocument2 pagesCommon Questions Heat Pipes PDFTeo Pei San100% (1)

- June Report For Dennis Tavonga MuzilaDocument17 pagesJune Report For Dennis Tavonga MuzilaDennis MuzilaNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Oschatz Non-Ferrous Metallurgy enDocument12 pagesOschatz Non-Ferrous Metallurgy enSelene Acosta MauricciNo ratings yet

- Spe 137208 Monitoring Pcps in 500F Steam Flood ApplicationsDocument4 pagesSpe 137208 Monitoring Pcps in 500F Steam Flood ApplicationsClyde San VicenteNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Triple Point CellsDocument48 pagesTriple Point CellsGustavo SánchezNo ratings yet

- Heat Sink Considerations - ThermoelectricDocument2 pagesHeat Sink Considerations - ThermoelectricNaranLoganNo ratings yet

- Calderas ElectrodosDocument39 pagesCalderas ElectrodoscarloscerneyNo ratings yet

- Batam Furnace Manual (English Version)Document14 pagesBatam Furnace Manual (English Version)Tiurmaida DamanikNo ratings yet

- Ewyq FDocument54 pagesEwyq FRicardo Molina SánchezNo ratings yet

- Experimental Investigation of A Vapor Absorption Refrigeration SystemDocument7 pagesExperimental Investigation of A Vapor Absorption Refrigeration Systemakibmahmud392No ratings yet

- Manual ECG - en - v2.1Document25 pagesManual ECG - en - v2.1JeremyYmerehNo ratings yet

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Exploring Pulsating Heat Pipe Efficiency Across Different Sizes and Heat LevelsDocument6 pagesExploring Pulsating Heat Pipe Efficiency Across Different Sizes and Heat Levelsdeepan101969No ratings yet

- Applications of Heat PipeDocument17 pagesApplications of Heat PipeManikantaNaupadaNo ratings yet

- Technical SeminarDocument19 pagesTechnical SeminarLibinNo ratings yet

- M - Electric Heater PIROBLOC EngDocument11 pagesM - Electric Heater PIROBLOC EngpikethNo ratings yet

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Zhongshan Shuangping Electronic Technology Co., LTD: OntactDocument25 pagesZhongshan Shuangping Electronic Technology Co., LTD: OntactNixonGarciaNo ratings yet

- Thermoelectric Cooling For Industrial EnclosuresDocument6 pagesThermoelectric Cooling For Industrial EnclosuresErdinc KlimaNo ratings yet

- RTP AsOne 150Document6 pagesRTP AsOne 150Hitesh KambleNo ratings yet

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Rac 7th Sem ManualDocument26 pagesRac 7th Sem Manualmanishsingla88No ratings yet

- Efficiency of Heat ExchangersDocument27 pagesEfficiency of Heat ExchangersAbdul GhafoorNo ratings yet

- Technical Brochures AW HT 0031 0071 enDocument50 pagesTechnical Brochures AW HT 0031 0071 endouslasNo ratings yet

- Experimental Investigation of Thermal Performance of A Radiant Cooling SystemDocument7 pagesExperimental Investigation of Thermal Performance of A Radiant Cooling Systemrajesh0145No ratings yet

- Automatic Pneumatic Vulcanizing MachineDocument3 pagesAutomatic Pneumatic Vulcanizing MachineBALAJINo ratings yet

- Chapter - 1 1.1 BackgroundDocument83 pagesChapter - 1 1.1 BackgroundRojithNo ratings yet

- ProHeat 35 - MillerDocument8 pagesProHeat 35 - MillerMario Paniagua QuinteroNo ratings yet

- Kendro 3000 Series Service ManualDocument54 pagesKendro 3000 Series Service ManualCarlos Alberto Ramirez GarciaNo ratings yet

- Heat PipeDocument27 pagesHeat Pipesaurabh maneNo ratings yet

- ED - AF GB Ccu Upto37cDocument3 pagesED - AF GB Ccu Upto37cRaja AntonyNo ratings yet

- The ExperimentDocument13 pagesThe ExperimentUsɱâñ MåâñNo ratings yet

- Heat Pipes in Electronics (1) : 15.1 Components of A Heat PipeDocument10 pagesHeat Pipes in Electronics (1) : 15.1 Components of A Heat Pipekeerti06No ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- 4000 Essential English Words 3Document195 pages4000 Essential English Words 3jupiter805393% (28)

- 4000ese6 PDFDocument192 pages4000ese6 PDFamitukumarNo ratings yet

- Deals Blindspot Ebook PDFDocument16 pagesDeals Blindspot Ebook PDFchahbounnabilNo ratings yet

- 1SDA068661R1 Ekip Com X Lsi Lsig M Lriu Xt2 Xt4 F PDocument2 pages1SDA068661R1 Ekip Com X Lsi Lsig M Lriu Xt2 Xt4 F Pchahbounnabil0% (1)

- Catalogue Interrupteur Fusible PDFDocument116 pagesCatalogue Interrupteur Fusible PDFchahbounnabilNo ratings yet

- 2gcs210011a0040 - Apcq ManualDocument35 pages2gcs210011a0040 - Apcq ManualchahbounnabilNo ratings yet

- Primary Offering 2010 10 - MoroccoDocument127 pagesPrimary Offering 2010 10 - MoroccochahbounnabilNo ratings yet

- Zelio EMR Product SelectorDocument365 pagesZelio EMR Product SelectorchahbounnabilNo ratings yet

- Sales Memo ATV71Document2 pagesSales Memo ATV71chahbounnabilNo ratings yet

- Weaverville Community Forest Becomes A Reality: Summer 2006Document8 pagesWeaverville Community Forest Becomes A Reality: Summer 2006Trinity County Resource Conservation DistrictNo ratings yet

- The Future o Water Availability and Demand in The Metropolitan Area of Monterrey Mexico (2009)Document19 pagesThe Future o Water Availability and Demand in The Metropolitan Area of Monterrey Mexico (2009)REALIDAD EXPUESTANo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument6 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingMisterrriotNo ratings yet

- Class 9 ExamDocument3 pagesClass 9 ExamsongsfresherNo ratings yet

- BS Iso 05667-4-2016Document46 pagesBS Iso 05667-4-2016mohamed senoussiNo ratings yet

- EXTERNAL WORKS V 1-0 Apr 10 - ACC - WE - DF6000Document22 pagesEXTERNAL WORKS V 1-0 Apr 10 - ACC - WE - DF6000vin ssNo ratings yet

- Chapter 28 ProtistsDocument48 pagesChapter 28 Protistsbrguzz50% (2)

- Raw Sugar ProcessingDocument6 pagesRaw Sugar ProcessingJan April MahinayNo ratings yet

- THE USES AND ABUSES OF THE ANCIENT MAYA by David WebsterDocument38 pagesTHE USES AND ABUSES OF THE ANCIENT MAYA by David WebstermalizverkoNo ratings yet

- Drainage GCDocument7 pagesDrainage GCVgkBharadwajNo ratings yet

- (PHWR) Technology PDFDocument40 pages(PHWR) Technology PDFJUAN4201No ratings yet

- Remote SensingDocument3 pagesRemote SensingsriniNo ratings yet

- 3. 50 Đề Thi HSG Lớp 12 - Otto ChannelDocument309 pages3. 50 Đề Thi HSG Lớp 12 - Otto ChannelHan YingNo ratings yet

- English 2Document548 pagesEnglish 2Can EryilmazNo ratings yet

- Options For High Temperature Well StimulationDocument11 pagesOptions For High Temperature Well StimulationFra FraNo ratings yet

- FBPB - I-B - 2008 Introduction & SyllabusDocument22 pagesFBPB - I-B - 2008 Introduction & SyllabusMarko ObrknezevNo ratings yet

- Aquaculture Negative - NAUDL 2014Document45 pagesAquaculture Negative - NAUDL 2014divizioniNo ratings yet

- Zambia The Community School Based Urban Agriculture Project of Project Concern International - LusakaDocument6 pagesZambia The Community School Based Urban Agriculture Project of Project Concern International - LusakaFree Rain Garden ManualsNo ratings yet

- One Rarely Falls in Love Without Being As Much Attracted To What Is Interestingly Wrong With Someone As What Is Objectively Healthy Says Philosopher Alain de Botton 1Document5 pagesOne Rarely Falls in Love Without Being As Much Attracted To What Is Interestingly Wrong With Someone As What Is Objectively Healthy Says Philosopher Alain de Botton 1api-308174583No ratings yet

- Apple Spray Schedule 2024 SKUAST KashmirDocument20 pagesApple Spray Schedule 2024 SKUAST Kashmirshakoor.ab.phd.cseNo ratings yet

- NTPC Heat Rate PDFDocument395 pagesNTPC Heat Rate PDFcynaidu67% (6)

- Scenario G - Project Brief - 2020Document8 pagesScenario G - Project Brief - 2020abdul5721No ratings yet

- Jenell Strachan - ResumeDocument2 pagesJenell Strachan - ResumejjastrachanNo ratings yet

- Method For Preparing Anhydrous Iron ChloridesDocument4 pagesMethod For Preparing Anhydrous Iron ChloridesVioleta GrigorasNo ratings yet

- Waste Management Handbook PDFDocument90 pagesWaste Management Handbook PDFAkulSenapati100% (1)

- Application Form For Infrastructure-Integrated FinalDocument5 pagesApplication Form For Infrastructure-Integrated FinalSamer KhaledNo ratings yet