Professional Documents

Culture Documents

Filtros Ftaur (Eng) PDF

Filtros Ftaur (Eng) PDF

Uploaded by

saber66Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filtros Ftaur (Eng) PDF

Filtros Ftaur (Eng) PDF

Uploaded by

saber66Copyright:

Available Formats

filtration technologies

FTAUR SERIES

FILTERS

(AUTOMATIC

BACKWASH

FILTERS)

The ideal complement for

Ultrafiltration as RO Pretreatment

ftaur series filters (automatic backwash)

Introduction

Fluytec Automatic Backwash filters

allow continuous filtering together with

a backwash process. This equipment is

especially appropriate for applications in

which filtering continuity is a key parameter.

They are specially designed to work with sea

water and ultrafiltration plants.

General Description

The GRP (other materials under request) bodies

are designed according to the Ad-Merkblat

code and manufactured in compliance with the

European 97/23 CE, S.3.3 standard for pressure

vessels.

Stainless Steel filter elements (from AISI316

up to 254SMO -PREn:43-, depending on raw

water salinity) are designed according to the

flow values and filtration rate.

The addition of auxiliary elements (electrical

panel, PLC, differential pressure gauge,

geared motor and solenoid valve) allow the

configuration of compact and completely

automatic

equipment

which

reduces

maintenance operations to the minimum.

Advantages

Completely automatic operation.

Continuous filtering flow, even during the

backwashing process.

Vacuum backwashing.

Compact equipment, ready for use.

Customisable operating parameters for each

specific case.

Standard Materials

Body: GRP*

FF plate: Stainless Steel / Plastic

Legs: Stainless Steel

External bolts: Stainless Steel

Internal parts: Stainless Steel

O-ring: EPDM*

*Other materials available.

General review of Automatic Backwash filter.

filtration technologies

ftaur series filters (automatic backwash)

AIR DRAIN

The operating basis of the Fluytec Automatic

Backwash filter (FTAUR) is the pressure

difference between the untreated water

chamber and the drain pipe outlet. This pressure

difference is an operating parameter that

must be defined and rated in the differential

pressure gauge. Once the pressure difference

has reached this value, the solenoid valve is

operated to start the backwashing process.

Filtered liquid

FILTERED

LIQUID CHAMBER

When the solenoid valve opens, a vacuum

pressure is caused inside the filtering element

being washed, dragging out the solids that

block it and thus cleaning it. The washing flow

to be subtracted from the total flow produced

by the FTAUR is defined according to the time

and flow needed to obtain clean purge water.

Wash / Back-flushing

Unfiltered liquid

OUTLET

Once one filter element has been washed, the

operation is repeated with the rest of the filter

elements until a complete washing cycle has

been completed.

The processes for starting and ending the

washing process, opening and closing valves,

rotating the purge arm, etc, are controlled by

the PLC in the electrical cabinet.

INLET

Flow rate

Up to 2,600 m3/h*

Filtration rate

50 microns - 2 mm*

Design pressure

Up to 10 bar*

Design

temperature

82C - 90C

Electrical

115 VAC or 230 VAC

50/60 Hz

Backwashing

control

Timer and/or

differential pressure*

UNFILTERED

LIQUID CHAMBER

* Other values on request

BACKWASH

Filtration

Back-flushing

filtration technologies

Subject to change without notice.

Other products in this range:

FTI series cartridge filters (SS, CS)

FTPV series cartridge filters (PVC)

See our Website for other design criteria

Fluytec solutions worldwide

Camino de Sakoni, 18 48950 Erandio - Vizcaya (Spain) T: (+34) 94 467 61 50 F: (+34) 94 467 61 53

info@fluytec.com www.fluytec.com

v.2

You might also like

- LGU Libungan-4PHDocument41 pagesLGU Libungan-4PHJERRY LICAYAN100% (2)

- Erma First Ballast Water Treatment SystemDocument5 pagesErma First Ballast Water Treatment SystemKatsaras Sotiris0% (1)

- Instruction Manual 1 (41) : Auramarine LTDDocument41 pagesInstruction Manual 1 (41) : Auramarine LTDMd. Sadman Sakib100% (5)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- ASHRAE 62.2 Ventilation and Acceptable Indoor Air QualitDocument37 pagesASHRAE 62.2 Ventilation and Acceptable Indoor Air QualitmansidevNo ratings yet

- Standard Specification of Roads Works - Section 3 - Drainage Works PDFDocument25 pagesStandard Specification of Roads Works - Section 3 - Drainage Works PDFShyue Leong LeeNo ratings yet

- E7709 3 06 12 - RF3 - WebDocument8 pagesE7709 3 06 12 - RF3 - WebNicolas Alvarez GomezNo ratings yet

- Eaton Tubular Backwashing AFC AFR & F-Series FiltersDocument14 pagesEaton Tubular Backwashing AFC AFR & F-Series FiltersJuan CarvajalNo ratings yet

- Bernoulli UK PDFDocument4 pagesBernoulli UK PDFjose03No ratings yet

- Operation & Maintenance Manual Integra-Mate: Water Purification SystemsDocument22 pagesOperation & Maintenance Manual Integra-Mate: Water Purification Systemsanandhra2010No ratings yet

- PR BW600Document8 pagesPR BW600tata_77No ratings yet

- Manual de Filtro AutolimpianteDocument29 pagesManual de Filtro AutolimpianteMegan PierceNo ratings yet

- Mini Water: If You Have Any Questions, Please Do Not Hesitate To Contact Us!Document1 pageMini Water: If You Have Any Questions, Please Do Not Hesitate To Contact Us!Eduardo CramerNo ratings yet

- Eaton - Internormen Fluid Purifier SystemsDocument4 pagesEaton - Internormen Fluid Purifier SystemsEaton FiltrationNo ratings yet

- Reliance 400Document8 pagesReliance 400Mathieu ArseneauNo ratings yet

- Filtomat M100-6800 - GRPDocument17 pagesFiltomat M100-6800 - GRPJose Angel Malpica PNo ratings yet

- Multipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deDocument2 pagesMultipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deJoshua PhillipsNo ratings yet

- Trans Cond EDocument6 pagesTrans Cond EM_ABDOLRAHMANINo ratings yet

- 52 Filtrex BrochureDocument6 pages52 Filtrex BrochureCvitaCvitićNo ratings yet

- Operation and Maintenance ManualDocument22 pagesOperation and Maintenance ManualKiki HendraNo ratings yet

- Om004 Om008 Integral ManualDocument9 pagesOm004 Om008 Integral ManualistopiNo ratings yet

- WT.025.055.000.IE - ps.0714 Evoqua ChlorinatorDocument8 pagesWT.025.055.000.IE - ps.0714 Evoqua ChlorinatorNguyễn Đăng QuýNo ratings yet

- Water Maze Delta-3000a 1Document2 pagesWater Maze Delta-3000a 1Marcelita AraujoNo ratings yet

- Vantage UFI Feb2011 SiemensDocument4 pagesVantage UFI Feb2011 SiemenssirtrungNo ratings yet

- Flash MixerDocument2 pagesFlash MixerKhaldoon AlnashiNo ratings yet

- Pentair Rotary Valve Whole House Carbon Filter ManualDocument28 pagesPentair Rotary Valve Whole House Carbon Filter Manualsquadron2k19No ratings yet

- Safematic Seal Support - ENGDocument8 pagesSafematic Seal Support - ENGManojkumar ThilagamNo ratings yet

- Fleck 2850s Spec SheetDocument2 pagesFleck 2850s Spec SheetMạnh Tuấn VũNo ratings yet

- ZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFDocument4 pagesZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFJohn PaulNo ratings yet

- Self Cleaning Filters CatalogDocument6 pagesSelf Cleaning Filters CatalogSinergroup Water Filters Water Purifiers Water SoftenersNo ratings yet

- Standard Specification: 2.10.3 Pressure FiltersDocument8 pagesStandard Specification: 2.10.3 Pressure FiltersmakcodetechNo ratings yet

- Alfa Laval Brew 301Document4 pagesAlfa Laval Brew 301Andor MolitoriszNo ratings yet

- Capital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityDocument8 pagesCapital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityLoan NguyênNo ratings yet

- A075 Valve Operation Guide PDFDocument130 pagesA075 Valve Operation Guide PDFedhy_03No ratings yet

- Vitra Faucets and AccessoriesDocument272 pagesVitra Faucets and AccessoriescothacoNo ratings yet

- Ocean Whisper - Technical SpecificationsDocument8 pagesOcean Whisper - Technical SpecificationsAtanasio PerezNo ratings yet

- "SAF" Automatic Filters: For Flow Rates Up To 400 M /HDocument5 pages"SAF" Automatic Filters: For Flow Rates Up To 400 M /Hharry_chemNo ratings yet

- TC02 DigitalDocument17 pagesTC02 DigitalNebojsa CekicNo ratings yet

- Diesel Exhaust Fluid Plant For Automotive Er800Document3 pagesDiesel Exhaust Fluid Plant For Automotive Er800indianepal420No ratings yet

- TFIA Series High Volume Air SamplersDocument4 pagesTFIA Series High Volume Air SamplersM Wahyuddin SaputraNo ratings yet

- Modular, Simple, Intelligent: SMART Digital Dosing Pumps From 0.0025 To 30 L/HDocument2 pagesModular, Simple, Intelligent: SMART Digital Dosing Pumps From 0.0025 To 30 L/HHeri SulasionoNo ratings yet

- Va69d 17 B 0958 005Document12 pagesVa69d 17 B 0958 005Mathieu ArseneauNo ratings yet

- Diaphragm Pump CharacteristicsDocument9 pagesDiaphragm Pump CharacteristicslamiaNo ratings yet

- M/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDocument16 pagesM/S. Airro Engineering Co.: Operation & Instructions Manual FOR Oxygen PlantDr Gajanan ShirkeNo ratings yet

- Manual 65S Eng.V6Document35 pagesManual 65S Eng.V6gugiNo ratings yet

- High Pure Water Machine Producing Water Specialized For LaboratoryDocument30 pagesHigh Pure Water Machine Producing Water Specialized For LaboratoryFaizNo ratings yet

- Manual ReadySoftDocument36 pagesManual ReadySoftGreg ReynekeNo ratings yet

- Stero U31 DishwasherDocument4 pagesStero U31 Dishwasherwsfc-ebayNo ratings yet

- FT Ultrasonic Repr IngDocument5 pagesFT Ultrasonic Repr IngYana LesmanaNo ratings yet

- Comp AirDocument6 pagesComp AirOliver CambelNo ratings yet

- 1-1-6 en Frese Optima Aug 10Document12 pages1-1-6 en Frese Optima Aug 10mymikeymikesNo ratings yet

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersDocument26 pagesProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenNo ratings yet

- Lowara Grupuri de Pompare - Ghvseries-Td-En PDFDocument120 pagesLowara Grupuri de Pompare - Ghvseries-Td-En PDFmariuspiNo ratings yet

- 001-232500-0 2.7 Filtration EquipmentDocument34 pages001-232500-0 2.7 Filtration Equipmentmolinach100% (1)

- Unidad de FiltradoDocument4 pagesUnidad de FiltradoNestor SalasNo ratings yet

- Model TFIA Series High Volume Air Samplers: Best Seller!Document3 pagesModel TFIA Series High Volume Air Samplers: Best Seller!Iman FerisendyNo ratings yet

- Invalco Brochure PDFDocument20 pagesInvalco Brochure PDFMargaret DaughertyNo ratings yet

- Hobart ft1000 PDFDocument12 pagesHobart ft1000 PDFhernan espitiaNo ratings yet

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 pagesReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- Inner Scraper Self-Cleaning FiltersDocument1 pageInner Scraper Self-Cleaning FiltersCarlos BarriosNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- NORD Geared MotorsDocument12 pagesNORD Geared Motorssaber66No ratings yet

- BSS Steel Guide CataloguesDocument52 pagesBSS Steel Guide Cataloguessaber66No ratings yet

- Sika Solutions For Waste Water Treatment Plants - Low PDFDocument48 pagesSika Solutions For Waste Water Treatment Plants - Low PDFsaber66No ratings yet

- Grundfos Data Booklet PDFDocument292 pagesGrundfos Data Booklet PDFsaber66100% (1)

- Suspended Growth Biological - 43 PDFDocument356 pagesSuspended Growth Biological - 43 PDFsaber66No ratings yet

- Prominent Equipment Catalogue 2011Document751 pagesProminent Equipment Catalogue 2011saber66No ratings yet

- Tanks Simona Pe 100Document44 pagesTanks Simona Pe 100saber66100% (1)

- CompanyListG LDocument198 pagesCompanyListG LMahasar SiddiquiNo ratings yet

- Method of Statement and JSA For 13.8kV and 69kV Live Line Crosssing Between Loc 125 To 126 of PX-BDocument16 pagesMethod of Statement and JSA For 13.8kV and 69kV Live Line Crosssing Between Loc 125 To 126 of PX-BTwin BullsNo ratings yet

- American Beauty CatalogDocument28 pagesAmerican Beauty CatalogPravin Mevada100% (1)

- Spring Loaded RTDDocument36 pagesSpring Loaded RTDpumpisrbNo ratings yet

- Claims in Construction Projects A Comprehensive LiDocument8 pagesClaims in Construction Projects A Comprehensive LiMwaNo ratings yet

- Information On SchemesDocument3 pagesInformation On SchemesBiki DuttaNo ratings yet

- 04.0. Seepage Through Earth DamsDocument26 pages04.0. Seepage Through Earth DamsEbrahim AskerNo ratings yet

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- IKO Ball Needle BRGDocument5 pagesIKO Ball Needle BRGjohnsonregoNo ratings yet

- Assessment of Key Performance Indicators in Project Quality Plan For Construction ProjectDocument6 pagesAssessment of Key Performance Indicators in Project Quality Plan For Construction ProjectGRD JournalsNo ratings yet

- Compendium of Ground Modification FDOT - BC354 - 64 - RPTDocument371 pagesCompendium of Ground Modification FDOT - BC354 - 64 - RPTBluebelgianNo ratings yet

- Stability Analysis of A Concrete Gravity Dam Tongue Wall PDFDocument11 pagesStability Analysis of A Concrete Gravity Dam Tongue Wall PDFRyan CassellsNo ratings yet

- CV311 - Final Assignment#2Document11 pagesCV311 - Final Assignment#2Inoke LiutoloNo ratings yet

- V4044C, V4044F Motorized Zone ValvesDocument4 pagesV4044C, V4044F Motorized Zone Valvesconstantin.iacomi3837No ratings yet

- Hot Work Permit To Work Template Checklist - SafetyCulture PDFDocument5 pagesHot Work Permit To Work Template Checklist - SafetyCulture PDFEdmilsoni Arlin-Nk José NyokaNo ratings yet

- Fire Rating DoorDocument9 pagesFire Rating Doormilind_meherNo ratings yet

- Acers ME - MDSP R2 Jun 16 2021 With AnswersDocument1 pageAcers ME - MDSP R2 Jun 16 2021 With AnswersTatsNo ratings yet

- Harga Wiremesh Standard: RemeshDocument3 pagesHarga Wiremesh Standard: RemeshSyNo ratings yet

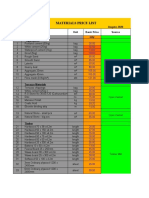

- Materials Price List: August, 2020 Item Material Unit Basic Price Source GH T e L e P H o N e AggregatesDocument19 pagesMaterials Price List: August, 2020 Item Material Unit Basic Price Source GH T e L e P H o N e Aggregatesmissowusu100% (1)

- Details For R.C Floor Slabs, Beam, Lintel, Columns and Stair Details See Structural DrawingsDocument1 pageDetails For R.C Floor Slabs, Beam, Lintel, Columns and Stair Details See Structural DrawingsNana BarimaNo ratings yet

- Assignment I PDFDocument4 pagesAssignment I PDFRefisa JiruNo ratings yet

- Final Draft Letter - Flexible Pavement Design - NKC - RD2Document3 pagesFinal Draft Letter - Flexible Pavement Design - NKC - RD2Purshottam SharmaNo ratings yet

- Lecture 4 - Water Supply FittingsDocument38 pagesLecture 4 - Water Supply Fittingsswapnil aggarwal�No ratings yet

- CE 524 Preliminary - Formula Sheet 1Document2 pagesCE 524 Preliminary - Formula Sheet 1Ed Adrian Navarro ParanganNo ratings yet

- 8044 3 Technical Specification of HT AB Cable 11KVDocument9 pages8044 3 Technical Specification of HT AB Cable 11KVdkshtdkNo ratings yet

- Lhoist - Lime and Dolime ProducerDocument1 pageLhoist - Lime and Dolime ProducerDefriNo ratings yet

- Hydril Mac IIDocument4 pagesHydril Mac IIFabian Romero BecerraNo ratings yet