Professional Documents

Culture Documents

15.energy Audits of Fishing Vessels Lessons Learned and The Way Forward

15.energy Audits of Fishing Vessels Lessons Learned and The Way Forward

Uploaded by

Hugo SilvaCopyright:

Available Formats

You might also like

- Raft TT FT FT FT FT AFT AF RAFDocument31 pagesRaft TT FT FT FT FT AFT AF RAFHugo Silva100% (1)

- FMO Training Programme Manual - Stage 1 - ForwarderDocument63 pagesFMO Training Programme Manual - Stage 1 - ForwarderHugo SilvaNo ratings yet

- Simulation of Flow Around KCS HullDocument11 pagesSimulation of Flow Around KCS HullMilovan PericNo ratings yet

- Ridgely-Nevitt C.resistance of A High.1967.TRANSDocument28 pagesRidgely-Nevitt C.resistance of A High.1967.TRANSTi AnnelNo ratings yet

- Shallow Water Resistance Charts For Preliminary Vessel DesignDocument18 pagesShallow Water Resistance Charts For Preliminary Vessel DesignshahjadaNo ratings yet

- Mosaad 86 PDFDocument294 pagesMosaad 86 PDFdoğancan uzunNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Optimization of Fishing VesselDocument11 pagesOptimization of Fishing VesselLucas GuesseNo ratings yet

- Part 3 - 5.mooring FacilitiesDocument49 pagesPart 3 - 5.mooring FacilitiesIlham Hussein RasyidNo ratings yet

- Sistema RSW-CSWDocument8 pagesSistema RSW-CSWDiego Trinidad100% (1)

- Volume IIDocument246 pagesVolume IIathanasios niotisNo ratings yet

- 04 NAC Initial Transverse Stability (160213)Document21 pages04 NAC Initial Transverse Stability (160213)Gilles MathieuNo ratings yet

- STA Article 30jan2013 PDFDocument11 pagesSTA Article 30jan2013 PDFpriyoNo ratings yet

- Intact StabilityDocument1 pageIntact StabilityislimaNo ratings yet

- Predicting The Slamming Force On The HullDocument52 pagesPredicting The Slamming Force On The HullEgwuatu UchennaNo ratings yet

- The First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)Document5 pagesThe First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)pal_malayNo ratings yet

- 59m Ahts Addendum For Final Intact Stability Booklet - 91751918Document18 pages59m Ahts Addendum For Final Intact Stability Booklet - 91751918NHÓM 2 GTSNo ratings yet

- Numerical Simulation of Ship Motion Due To Waves and ManoeuvringDocument48 pagesNumerical Simulation of Ship Motion Due To Waves and ManoeuvringHung NguyenNo ratings yet

- An Overview of The Prediction Methods For Roll Damping of ShipsDocument22 pagesAn Overview of The Prediction Methods For Roll Damping of ShipsВасил ЙордановNo ratings yet

- Resistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) WhereDocument11 pagesResistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) Wheresupriadi90315No ratings yet

- GZ CurvesDocument30 pagesGZ CurvesAhtashamuddin Nizamudin100% (1)

- Visualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelDocument13 pagesVisualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelAnthonyNo ratings yet

- 3rd Paper Shallow Water Effect On Turning Motion of A Pusher Barge System Aphydro 2008Document8 pages3rd Paper Shallow Water Effect On Turning Motion of A Pusher Barge System Aphydro 2008kostas.michaNo ratings yet

- Naval Architecture DigestDocument19 pagesNaval Architecture DigestShivananda PatraNo ratings yet

- 1 s2.0 S0029801817301646 Main PDFDocument15 pages1 s2.0 S0029801817301646 Main PDFOdumoduChigozieUzomaNo ratings yet

- New IMO Requirements - 10th Edition - May 2004Document71 pagesNew IMO Requirements - 10th Edition - May 2004LucianNo ratings yet

- Seakeeping 19301en2 PDFDocument2 pagesSeakeeping 19301en2 PDFTullio OpattiNo ratings yet

- Thesis RGdeJongDocument108 pagesThesis RGdeJongNaval2014DNNo ratings yet

- Grain CodeDocument21 pagesGrain CodeNMHa100% (1)

- ENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Document5 pagesENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Luis De GraciaNo ratings yet

- TribonDocument16 pagesTribonSebastian100% (2)

- Hande - A Computer-Aided Design Approach For Hydrofoil ShipsDocument11 pagesHande - A Computer-Aided Design Approach For Hydrofoil Shipsjwpaprk1No ratings yet

- NAPA Session1Document21 pagesNAPA Session1amialokNo ratings yet

- PHD Wicaksono 2019 PDFDocument145 pagesPHD Wicaksono 2019 PDFEric KulbiejNo ratings yet

- Motor Yacht Hull Form DesignDocument16 pagesMotor Yacht Hull Form Designale barbNo ratings yet

- Design Optimization of The Lines of The Bulbous BowDocument12 pagesDesign Optimization of The Lines of The Bulbous BowFernando Raúl LADINONo ratings yet

- A Practical System For Hydrodynamic Optimization of Ship Hull FormsDocument7 pagesA Practical System For Hydrodynamic Optimization of Ship Hull FormsSalma SherbazNo ratings yet

- Metacentre & Metacentric Height of A Ship (02042020)Document3 pagesMetacentre & Metacentric Height of A Ship (02042020)Xahid HasanNo ratings yet

- Ultramarine Moses CrackDocument3 pagesUltramarine Moses CrackpothirajkalyanNo ratings yet

- Automated Marine Propeller Design Combining Hydrodynamics Models and Neural NetworksDocument10 pagesAutomated Marine Propeller Design Combining Hydrodynamics Models and Neural NetworksPoowadol NiyomkaNo ratings yet

- Slamming Experiments On A Ship Model: Rousset J.-M., Pettinotti B., Quillard O., Toularastel J.-L., Ferrant PDocument4 pagesSlamming Experiments On A Ship Model: Rousset J.-M., Pettinotti B., Quillard O., Toularastel J.-L., Ferrant PmroghaniNo ratings yet

- Abyc H4Document12 pagesAbyc H4NavalcatNo ratings yet

- 03 The Ship Design ProcessDocument10 pages03 The Ship Design Processw12n_sbyNo ratings yet

- Energy Saving Basics - EsdsDocument40 pagesEnergy Saving Basics - Esdsapi-238581599No ratings yet

- Rudders: Semi Balanced Rudder Semi Balanced Rudder With Rudder HornDocument10 pagesRudders: Semi Balanced Rudder Semi Balanced Rudder With Rudder Hornsunil1237No ratings yet

- Test Ii: WPA Volume Mid Area LWLDocument9 pagesTest Ii: WPA Volume Mid Area LWLMark Lester AndayaNo ratings yet

- U-Botten RevDocument10 pagesU-Botten RevJunaid JavaidNo ratings yet

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDDocument10 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDcataiceNo ratings yet

- Assignment 1 (Ship Resistance)Document1 pageAssignment 1 (Ship Resistance)KikiNo ratings yet

- Ballast Free Ship DesignDocument3 pagesBallast Free Ship DesignAnonymous UCveMQNo ratings yet

- Seakeeping CommitteeDocument56 pagesSeakeeping CommitteeTullio OpattiNo ratings yet

- Shipboard Mooring Equipment: Course No. 12Document39 pagesShipboard Mooring Equipment: Course No. 12Dan CobeliNo ratings yet

- Stability of CatamaransDocument8 pagesStability of CatamaransVinayak29No ratings yet

- 09-NAC-Numerical Integration Method (171229) - Student PDFDocument41 pages09-NAC-Numerical Integration Method (171229) - Student PDFMehedi Hossain MithilNo ratings yet

- An Experimental and Theoritical Study of Planning Surfaces With Trim Flaps PDFDocument63 pagesAn Experimental and Theoritical Study of Planning Surfaces With Trim Flaps PDFGhalih Rasyid Prayogo100% (1)

- A Methodology For A Hydrodynamic Analysis of A Moonpool Structure With Mooring Lines Using The ANSYS AQWA ProductDocument25 pagesA Methodology For A Hydrodynamic Analysis of A Moonpool Structure With Mooring Lines Using The ANSYS AQWA ProductRuly IrawanNo ratings yet

- Dimensional Constraints in Ship DesignDocument6 pagesDimensional Constraints in Ship DesignTat-Hien LeNo ratings yet

- ITTC - Recommended Procedures and GuidelinesDocument20 pagesITTC - Recommended Procedures and Guidelinesaun7328No ratings yet

- Windship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985From EverandWindship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985C SatchwellNo ratings yet

- Training Simulator: Heads Above The CompetitionDocument4 pagesTraining Simulator: Heads Above The CompetitionHugo SilvaNo ratings yet

- Cmu Hiab 190TM-6Document2 pagesCmu Hiab 190TM-6Hugo SilvaNo ratings yet

- Formec Proceedings 2015 Web PDFDocument530 pagesFormec Proceedings 2015 Web PDFHugo SilvaNo ratings yet

- Hansson - Servin - Semi-Autonomous Shared Control For Redundant Forwarder CranesDocument107 pagesHansson - Servin - Semi-Autonomous Shared Control For Redundant Forwarder CranesHugo SilvaNo ratings yet

- Declaration of Honour PTDocument3 pagesDeclaration of Honour PTHugo SilvaNo ratings yet

- Lista de Clasificación Energética de TractoresDocument18 pagesLista de Clasificación Energética de TractoresHugo Silva100% (1)

- MED 2015 EnglishDocument15 pagesMED 2015 EnglishHugo SilvaNo ratings yet

- Murrel Farming PDFDocument10 pagesMurrel Farming PDFshridhanNo ratings yet

- What Is AquacultureDocument10 pagesWhat Is AquacultureGoos HanNo ratings yet

- Argumentative EssayDocument2 pagesArgumentative EssaykaylaNo ratings yet

- TCE TackleDocument1 pageTCE TacklewapamaNo ratings yet

- ROR Flashcard Quiz 3 - Captain DamleyDocument26 pagesROR Flashcard Quiz 3 - Captain DamleyReyNo ratings yet

- Module 4 CompilationDocument16 pagesModule 4 CompilationErine ContranoNo ratings yet

- Lizard Island MapDocument1 pageLizard Island MapEric HoNo ratings yet

- Reducing Gill-Net Mortality of Incidentally Caught Coho SalmonDocument6 pagesReducing Gill-Net Mortality of Incidentally Caught Coho SalmonTri LaelaNo ratings yet

- Vestrics SAP SeaFood India 15th May 2018Document63 pagesVestrics SAP SeaFood India 15th May 2018Yakshit JainNo ratings yet

- What Is in A TangabDocument16 pagesWhat Is in A TangabOrange LemonNo ratings yet

- Employment Contract of Commercial Vessel's FishermanDocument6 pagesEmployment Contract of Commercial Vessel's FishermanCarlota TejeroNo ratings yet

- Ultegra 14000Document1 pageUltegra 14000wizunuNo ratings yet

- Inca Product BrochuresDocument60 pagesInca Product BrochuresGerryNo ratings yet

- Calculating & Cutting TapersDocument26 pagesCalculating & Cutting TapersTiago Catuxo100% (2)

- E5 01A ThemeContentsDocument24 pagesE5 01A ThemeContentsmohammadNo ratings yet

- Fishing IndustryDocument4 pagesFishing IndustryMinahil Fatima ShahNo ratings yet

- TSF - May 2016Document100 pagesTSF - May 2016Dennis ShongiNo ratings yet

- Factsheet On Sea LiceDocument2 pagesFactsheet On Sea LiceJon Arne GrøttumNo ratings yet

- Manitoba Aquatic Invasive Species Summer ChecklistDocument2 pagesManitoba Aquatic Invasive Species Summer Checklistizabella melendezNo ratings yet

- Full Download Test Bank For Political Science An Introduction 12 e Michael G Roskin Robert L Cord James A Medeiros Walter S Jones PDF Full ChapterDocument35 pagesFull Download Test Bank For Political Science An Introduction 12 e Michael G Roskin Robert L Cord James A Medeiros Walter S Jones PDF Full Chaptershaps.tortillayf3th100% (22)

- Light Fishing ReviewDocument21 pagesLight Fishing Reviewfadhilah wahdahNo ratings yet

- 2016 Canary Yelloweye ID FlyerDocument2 pages2016 Canary Yelloweye ID FlyeraninnaNo ratings yet

- Analisa Kebijakan Agro IndustriDocument18 pagesAnalisa Kebijakan Agro IndustriMei Edi PrayitnoNo ratings yet

- Fish Harvest Town Wiki FandomDocument1 pageFish Harvest Town Wiki FandomraenoseNo ratings yet

- RhethDocument77 pagesRhethIndAqua Information PortalNo ratings yet

- Fishing Geography NotesDocument16 pagesFishing Geography NotesHamza Yousuf86% (7)

- Report On Student'S Industrial Work Experience Scheme (Siwes)Document5 pagesReport On Student'S Industrial Work Experience Scheme (Siwes)BroadsageNo ratings yet

- Proposed Rule: Fishery Conservation and Management: Alaska Fisheries of Exclusive Economic Zone— Pacific Halibut and SablefishDocument19 pagesProposed Rule: Fishery Conservation and Management: Alaska Fisheries of Exclusive Economic Zone— Pacific Halibut and SablefishJustia.comNo ratings yet

- Rune Factory 3Document234 pagesRune Factory 3Sinbad Alfin PelautNo ratings yet

- Xii CGDocument59 pagesXii CGSyed Mairaj Ul HaqNo ratings yet

15.energy Audits of Fishing Vessels Lessons Learned and The Way Forward

15.energy Audits of Fishing Vessels Lessons Learned and The Way Forward

Uploaded by

Hugo SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15.energy Audits of Fishing Vessels Lessons Learned and The Way Forward

15.energy Audits of Fishing Vessels Lessons Learned and The Way Forward

Uploaded by

Hugo SilvaCopyright:

Available Formats

Second International Symposium on Fishing Vessel Energy Efficiency

E-Fishing, Vigo, Spain, May 2012

Energy audits of fishing vessels: lessons learned and the way

forward

Oihane C. Basurko, Gorka Gabia, Zigor Uriondo

Marine Research Division, AZTI-Tecnalia, Sukarrieta, Spain.

AbstractCommercial fishing activities are strongly fueldependent. Consequently, the dramatic increase in the price of

diesel fuel has impacted negatively on the economic incomes of

fishing. Moreover, the overexploitation of north-Atlantic

fisheries, over many decades, has caused international regulatory

bodies to establish more restrictive catch quotas, on certain

commercial fisheries. Both the fuel dependency and the

restrictive catch limitation have brought the Basque commercial

fishing industry to its survival limit. To examine the situation,

an energy audit methodology for fishing vessels has been

developed, with two objectives: a) to make shipowners aware of

the way fuel is consumed in their activities; b) help shipowners to

reduce their fuel bill. This contribution provides an overview of

the methodology, together with the steps undertaken for energy

audits. Three fishing vessels (a stern trawler, a live bait purse

seiner, and a troller have been studied, for developing this

methodology. The methodology uses a combination of

commercial tools, such as GESTOIL (an onboard fuel

consumption management system) to collect and assess data. The

energy audit has served to highlight the areas of major

consumption and potential savings; it provides also a list of

recommendations to shipowners, for changes in the operational

patterns of a ship. Likewise, structural changes to increase the

fuel efficiency of a vessel. In order to improve the efficiency of

future energy audits, the experience gained and the difficulties

undergone are presented.

Keywords: Energy audits, fishing vessels, energy consumption,

best practice, experience learned.

I.

INTRODUCTION

Traditional fishing has been the economic driver for many

coastal communities in the Basque Country. The increase in the

fuel price, the stock decline, occupational risks of fishing,

together with the possibilities of establishing a different future

for newer generations, are some of the reasons that have made

fishing arrive to its survival limits, in many parts of Europe.

Fishing gears have evolved throughout recorded history;

ships, nowadays, are more technological than ever before.

Examples are the mechanisation of gear handling, improved

performances of vessels and motorization, computer processing

for gear design, navigation aids, and fish detection technologies

[1]. Shipowners have invested greatly in updating their ships

with new technology; this has helped to fish more efficiently

and increase the comfort and safety onboard. Despite fishing

more efficiently, more technology usually implies a major fueldependency. This pattern has evolved in the fishing sector to

account for about 1.2% of the global oil consumption; which

entails approximately 134 million tonnes of CO2 emission into

the atmosphere [2]. Whilst no mention has been made in policy

or international agreements, such as in the Kyoto protocol, with

regards to Greenhouse Gas emission from fishing, the

quantities consumed and emitted by the sector are considerable.

This conclusion may make policy-makers consider fishing in

their future policies, as one of the strategies to combat

atmospheric pollution.

The fishing sector needs to cope with all of these

challenges, present a solid behaviour and become proactive in

response to the rise in the fuel price. This objective requires

good energy management, including monitoring the engines

and the energy consumption, redesigning ships, and

reinvention of the way fuel is consumed onboard [3]. However

presently, the bunker purchased is usually the only registry a

fishing vessel maintains of their fuel consumption. Therefore,

energy audits may play an important role in this approach,

since they can detail how energy is consumed within a vessel.

Likewise, an audit may highlight the areas of major

consumption and potential savings, including structural

changes and operational practices.

Research and experiences are growing within the published

literature in this regard [4-10]. Nonetheless, more work is

required since few have implemented energy efficient

measures onboard. The present contribution provides: the main

results of an energy audit of three vessels (stern trawler, purse

seiner, and a troller); likewise, the methodology developed in

AZTI-Tecnalia to undertake energy audits on fishing vessels

and guide auditors on the process; and the experience gained

and the difficulties undergone. The contribution ends with a list

of recommendations for undertaking efficient energy audits.

II.

ENERGY AUDIT OF THREE FISHING VESSELS

Three

Basque

fishing

vessels

were

audited,

comprehensively, during a year. The main details of the vessels

analysed are listed in Table 1. The fishing gears analysed are

representative of the main fishing gears used in the Basque

fishing fleet: a stern trawler, a troller, and a purse seiner

(operating with two fishing modalities: the purse seine and the

life bait purse seine).

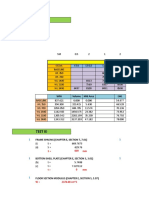

TABLE 1. DETAILS OF THE VESSELS

Vessel 1

Fishing gear

Length

overall (m)

Length at

waterline

Displacement

(dwt)

Displacement

(GT)

Construction

year

Hull material

Trawling nets

Vessel 2

Purse seine and life

bait purse seine

Vessel 3

Trolling line*

39

37

25.9

33.4

30

20

239.1

149

66.4

432

231

84.2

2008

2004

1995

Steel

Steel

Steel

Base port

Ondarroa

Orio

Bermeo

Main engine

1030kW 8cyl.

800rpm

1060kW 16cyl.

1600rpm

3 of 1500 rpm:

3 of 1500rpm:

493 kW 12cyl.

1800rpm

2 of 1500rpm:

Auxiliary

engines

2 of 515kW,

1 of 59 kW,

a shaft generator

420kW,

170kW,

112kW

Crew size

11

Target

species

Mixed fisheries

15

Anchovy, mackerel,

horse-mackerel,

sardine (purse

seiner); Tuna (Life

bait p.s.)

Fishery

The Atlantic, VIVII-AVIIIabd

zones

The Atlantic, A1

and A2 zones

The Atlantic,

VII-VIII zones

Fishing

period

Mid-Sept. until

mid-July

Spring and winter

(purse seine),

Summer and autumn

(life bait p.s.)

Summer and

autumn

Downtime

period

Beginning of

July until midSeptember

Mid-December until

mid-February

Mid-March

until beginning

of June

32kW,

20kW,

a shaft

generator

5

Tuna

*Vessel 3 combines three fishing modalities during a year: trolling line, gillnet

and vertical lines. In this contribution, only the results of the trolling line are

presented.

For the data collection, flow-meters, a portable electric

power logger, energy meters and the GESTOIL system (an

onboard fuel consumption management system) were used. All

of the equipment was installed and fixed onboard, with the

exception of the portable electric power logger that was used

sporadically. The electrical power logger was used for three

outputs: (1) to measure the power consumption of a particular

piece of equipment or machinery; (2) to register the energy

patterns of a particular piece of equipment or machinery, for

that it was left onboard for the duration of a particular fishing

voyage; (3) to check the quality of the electrical load and

network (including the rate of harmonics and unbalance).

Energy consumption of the main engine and the operational

profiles of the vessel were collected with the GESTOIL

system. The operational profiles of the auxiliary engines were

estimated from the data collected with the portable power

logger and the fixed energy meter. The analysis included also

the identification of the activity patterns, engine loads, engine

usage patterns, and their associated energy consumption for

each of the activities onboard. Such activities include: energy

consumed while sailing; finding fish; fishing (e.g. for trawling

it meant energy consumed during letting the net out, trawling,

tacking the net), and whilst in port.

Data

regarding

the

energy-consuming

equipment/machinery onboard were provided by skippers and

chief engineers. These data were completed with onboard

measurement of selected equipment/machinery, such as the

refrigeration and freezing system, water pumps and the lighting

by the electrical power logger.

III.

RESULTS

A. Performance indicators

Performance indicators are listed in Table 2. The detailed

report and results are available in [11]. An interesting indicator

in energy efficiency is the fuel use coefficient which provides

results in terms of litres of fuel consumed, per tonne of fish

landed [10, 12]. Vessel 3 is the smallest in dimension, capacity

and crew size amongst the three vessels. Purse seine is the most

efficient of all the fishing gear studied, since it presents the best

indicator in relation to the litres of fuel consumed, for the fish

landed, i.e. 98 L/t. Considering tuna as a target species, the

results indicate that trolling line and the life bait purse seine

present a similar energy performance indicator (1080L/t and

1136 L/t, respectively). Further whilst, purse seining for

pelagic species is the least energy-intensive of the three, the

trawling is the most energy-intensive. The most realistic

comparison would arise, however, when two vessels operating

in the same fisheries and using the same fishing gear are

compared. The results obtained are similar with the ones

presented in [10] for the same target species and gear used.

Regarding the fuel costs compared with the total costs of

the vessel, trolling is the one presenting the lowest ratio (15.3%

in comparison to the 30-40% for the other gears).

TABLE 2. PERFORMANCE INDICATOR OF THE VESSELS AUDITED (1 YEAR PERIOD)

Vessel 1

Gear

Purse seine

Life bait purse seine

Trolling line

224

89

91

100

Mon-Sat (6 d/voyage)

0.8 day/voyage

15 days/voyage

20 day/voyage

841896

L/yr

Fuel

consumption

L/h

Vessel 3

Stern trawl nets

Days at sea (days/yr)

Average voyage pattern

Vessel 2

Main

66600

Aux.

Sail.

Fish.

Elec.

22.4 %

65.5%

178.4

162.2

L fuel/tn fish

landed

Main

135150

Aux.

Main

49751

Aux.

Main

Aux.

Sail.

Fish.

Elec.

Sail.

Fish.

Elec.

Sail.

Fish.

Elec.

9.3 %

68.9%

15.1%

16.0%

81.8%

5.3%

12.9%

58.4%

30.6%

11 %

87.46*

6.3*

102.5

5.5

35.89

21.70

1646 L/t

146 L/t

1080 L/t

1136 L/t

Average RPM

789

686

1083*

600*

1150

600

1000

1200

Average speed (kn)

10.4

4.01

9.5*

0.9*

> 6.5

Engine usage (h/voyage)

26.1

93.3

12.0*

1.7*

190

45

117

258

Income (/yr)

Fish landed (tonnes)

1550717

320830

429333

198268

511.5

455.8

125. 2

43.8

% fuel consumption regarding

39.3%

33.7%

38.4%

annual costs

Main: Main engine

Aux.: Auxiliary engines

Sail. : % of energy consumed for sailing to, from or in between fishing grounds

Fish: % of energy consumed during fishing activities (such as letting out and tacking the net, trawling, trolling)

Elec.: % of energy consumed to power the machinery onboard

*target species: anchovy. Manoeuvring time has been omitted

All of the fishing gears, with the exception of the trawling,

consume the most fuel while sailing (Table 2): the purse seine

and the life bait purse seine more than the 80% of the total fuel

consumption by the vessel, and the trolling lines approximately

the 60% of the total. In contrast, in trawling more than the 60%

is consumed whilst fishing. These percentages present a strong

impact on the energy efficient measures that will be

formulated, to reduce the energy consumption. Thus, it is clear,

that energy efficient measures should be formulated

considering the vessel, fishing pattern and the fishing gear

used.

B. Energy-consuming equipment/machinery

The variety of onboard equipment and machinery onboard

is wide-range. Different equipment classifications can be found

in the literature [4, 9, 13]. Nevertheless, a more systematic

classification is proposed herein (see below).

GROUP 1. Navigation equipment/machinery. Essential

equipment for navigation, such as fuel pumps, water pumps for

engine refrigeration, lubricating oil pumps, air compressor, and

fans.

GROUP 2. Refrigeration and freezing system. Essential

machinery for the cooling and freezing systems onboard, such

as water pumps for the condenser for cooling the hatchery of

15.3%

fish in life bait purse seiners, and water pumps for the

condenser of refrigerators.

GROUP 3. Equipment/machinery for fishing. Equipment

onboard used for and during fishing and the management of the

catch, such as suction pumps, and the net winch.

GROUP 4.

Lighting. Interior and exterior lighting.

GROUP 5. Accommodation. Machinery related to living

onboard the vessel, such as the kitchen tops, TV, washing

machine, and oven.

GROUP 6. Additional

equipment/machinery.

The

remaining machinery, such as desalination plant, freshwater

plant, and water pumps.

The energy-consuming equipment and the machinery used

in the vessels studied accounted only for 9-13% of the total fuel

consumption for each vessel. The navigation machinery and

the cooling system accounted, together, for 40% of the

electricity consumption in the trawler, i.e. the same consumed

by the machinery for fishing along. On the other hand, the

navigation and the cooling system of the troller accounted for

70% of the total energy demand. Regarding the purse seiner

and the life bait purse seine modalities, the demand varied with

the modality, with lighting being the most demanding one, and

with the machinery for fishing and additional machinery

onboard being second. The energy consumption related to each

group is shown in Table 3.

TABLE 3. THE DISTRIBUTION OF ENERGY-CONSUMING

EQUIPMENT/MACHINERY

Trawler

(%)

Purse

seiner

(%)

Life

bait

Purse

seiner

(%)

Trolling

line (%)

Navigation equipment/machinery

20,2

3,4

2,2

41,9

Refrigeration and freezing system

20,0

5,2

6,6

28,3

Equipment/machinery for fishing

36,9

4,6

38,6

0,6

Accommodation

6,58

7,2

4,7

2,3

Lighting

5,07

16.3

16.9

3,9

Additional equipment/machinery

11,3

63.2

30.9

22,9

In Vessel 3, a shat generator is used to power the hydraulic

pump for boarding the tuna from the sea. This requirement

makes the percentage of the machinery and equipment used for

fishing in trolling being very low. With a different

configuration, this value is expected to be higher.

Hence, it can be concluded that the energy demand is

fishing gear-specific and no generalisations can be made in

this regard, i.e. unless two vessels operating in the same

fisheries and using the same fishing gear are compared.

C. Energy-efficient measures

Several energy efficient measures are available for these

vessels; some relate to improvements whilst the vessel sails;

others relate to the technological improvement of the energyconsuming equipment/machinery. The most popular measures

are the following [4, 9, 14, 15]:

a) Improving the energy consumption while sailing:

-

reducing the cruising speed to an economic level;

changing the propeller for a more efficient one;

painting with more efficient antifouling paint;

adding a bulbous bow to the hull structure;

selecting the best route; and

the use of sails

b) Improving the energy consumption of auxiliary machinery:

-

introducing frequency converters for electric motors and

parts;

changing the cooker to an induction cooktop;

changing some of the lights to LED;

switching off the unnecessary lights, in port;

cold ironing to reduce emissions and energy consumption

while in port

The most common published in literature, for their impact

on fuel efficiency, are, as listed in Table 4, being the ones

influencing the energy performance whilst sailing or fishing

(such as adding a bulbous bow, downsizing the engines, or

changing the propeller for a more efficient one). These actions

imply, usually, a structural change. Although their investment

may be returned within a 5 year limit [4], the investment is

frequently outside of the economic possibilities and/or too

risky for many shipowners. Hence, those with a lower

investment are considered herein (see below).

a)

Adding energy management software onboard such as the

GESTOIL system.

b) Improving the energy consumption whilst sailing (see

below).

Reducing the cruising speed to an economic speed

(15% saving). It must be noted, however, that a

reduction in speed entails less time for fishing.

Hence, the amount of fish landed would be

reduced. In the trawler, for example, it was

estimated that a reduction of a 1kn implied one

less fishing set. The shipowner would need to

consider the benefit of reducing the fuel

consumption, in comparison to a reduction in

income, due to the fish caught, if the voyage

pattern needs to be maintained.

TABLE 4. ENERGY-EFFICIENT MEASURES (WITHIN A 5 YEAR RETURN) FOR

THE THREE VESSELS ASSESSED

Energy efficient

measures

From

10kn to

9kn

Reducing

Always

sailing

<

speed

9.5kn

Always

< 8kn

Adding frequency

converters

Use of LEDs

Induction cooktop

Total investment

In 5

Possible

years

economic

In 10

saving

years

Vessel 1

L/yr

Return

saved

(yr)

Vessel 2

L/yr

Return

saved

(yr)

Vessel 3^

L/yr

Return

saved

(yr)

45.322

13954

337

3812

1.2

1647

1.9

3861

3.3

841

4,2

400

5.3

3242

1.5

792

3.1

16291

5660

1296

162653*

54974*

951*

360287*

115034*

3198*

Fuel price: 0.61/L

*Without considering the amount of time reduced for fishing and its economic

implication.

^ Results are estimated for the case that the vessels use only the trolling line

during an entire year.

c)

Improving

machinery

IV.

the

energy

consumption

of

auxiliary

Introducing a frequency converter for electric

motors and parts (Vessel 1 - in ice-making

machine compressor and water pump, and the

water pump for the refrigeration of the main

engine; Vessel 2 - ventilation system and water

pump for the refrigeration of the main engine): a

25% saving in each case.

Changing the cooker to an induction cooktop:

50% saving

Changing some of the lights to LED (Vessel 1 only all the 18W fluorescent lamps located in the

engine room; Vessel 2 and 3 - all interior 18W

fluorescent lamps): 55% saving.

RECOMMENDATION TO EFFICIENTLY AUDIT

FISHING VESSELS

A. Auditing process

The comprehensive analysis of the vessels, together with

the interactions with shipowners, skippers, chief engineers and

the particulars of the fishing seasons, have led to the

development of an energy audit methodology. This

methodology presents the steps of an energy audit in, a

structured manner. Likewise, it may assist auditors in reducing

the time to collect quality data and decrease the disturbance to

the crew and shipowner, during the audit.

The methodology is based upon the Spanish norm for

energy audits [16]; on published literature [4]; and on the

experience gained doing comprehensive energy audits. The

methodology is:

1.

GOAL AND SCOPE. Select the vessel to audit and

define the goal and the scope of the audit, together with

the shipowner.

2.

ESTABLISH CONTACT. Get in contact with the

interested parties (shipowners, skippers, etc.)

3.

1st VISIT ONBOARD. The first visit permits observing

the general state of the vessel, the detection of health and

safety risks, and obtaining an idea of the working

conditions onboard, as well as the required technical

equipment (appropriate measurement tools) and safety

equipment to audit the vessel (whilst onboard).

4.

QUESTIONNAIRE. Before meeting the shipowner

prepare a questionnaire with the data required. Send this

questionnaire to the shipowner, to be filled up.

5.

SHIPOWNERS APPROVAL. The energy audit will

require periodical visits to the vessel, interviews and

equipment installation onboard. Before any of these takes

place, the shipowner needs to give approval to all the

aforementioned. The number of visits onboard should

also be defined.

6.

RETURN THE QUESTIONNAIRE. Once the

questionnaire is filled in, it will need to be returned to the

auditors, to process the information.

7.

INTERVIEWS AND VISITS ONBOARD. The

shipowner and the Chief Engineer should be interviewed

and, if necessary, the oilers too. Engines and onboard

equipment/machinery-related data will be collected

during the onboard visits, through the aforementioned

portable and fixed instruments. Collect data whilst the

vessel is in port.

8.

INSTALLATION OF THE GESTOIL (or similar)

SYSTEM AND ENERGY METERS ONBOARD. The

GESTOIL systems may be installed onboard to assist in

collecting reliable data regarding the energy profile of the

vessel.

9.

ANALYSIS OF DATA. The data collected (measured

onboard and provided during interviews) will be assessed

statistically.

10. ENERGY EFFICIENT MEASURES. Several energyefficient measures will be formulated, to help to reduce

the energy demand of the vessel. The physical and

economic feasibility of each measure will be assessed

also from the data assessed.

11. FINAL REPORT. The Final Report will detail the energy

diagnosis of the vessel. The report will include: the goal

and scope of the audit; the methodology followed; and the

proposed energy efficient measures, for that particular

vessel and working conditions.

B. Additional recommendations

Several recommendations are proposed that can help in the

auditing process and the implementation of the energy-efficient

measures.

Talk to shipowners and try to convince them of the

benefit of undertaking an energy audit.

Define the procedure of the audit with the shipowner, to

make him/her aware of the steps that will be followed and

the implications of each step.

The readiness of the ship is the priority. Most of the time,

the auditor is the last on the lists of priority after the

service engineers, electricians, etc. Make sure that the

facilities needed are provided on time for the audit.

Be organised and have all documentations ready, before

the visit onboard.

Undertake a visit onboard guided by the Chief Engineer,

but carry out the interview in a place without any noise.

Talk to the skipper and find a way to get him/her involved

in the energy-efficient measures (perhaps providing an

extra for reducing the energy consumption of the vessel).

Small impact energy efficient measures are good too! Be

realistic. Shipowners have gone through a huge

technological change to improve onboard technologies.

Introducing energy-efficient technologies do not always

mean the incorporation of expensive technologies. There

has to always be a solution, for all levels of budgets.

Discuss the results with the shipowner. The best measure

may not be attractive for its implementation, as it may

affect the fishing (e.g. the trawling door: whilst one door

resulted in being the most efficient, the other one fished

the best and had a slightly worse energy-efficiency. The

latter one was selected as best). As such, the best option is

that which considers all of the aspects together.

Be aware that many factors affect the registered data.

Registering a comprehensive amount of data is very timeconsuming. In contrast, registering few data can provide

you with an estimation of the energy consumption.

However, results might be biased by: the weather and sea

conditions at the time of the registration; the amount of

bunker onboard; the position of the full fuel tanks; the

tidal conditions (low, high), etc. Hence, 3 data samples

are recommended as the minimum size for the main and

auxiliary engines.

Measures on board provide a more realistic result, than

approximation by the Chief Engineer. Human factor plays

an important role in reducing the energy consumption on

the vessel.

Some shipowners work onboard as skippers, Chief

Engineers and crew. In these cases, implementing

operational energy-efficient measures will be easier.

The fishing voyages of purse seiners, life bait purse

seiners and trolling are irregular (in terms of length of

fishing voyages). Extrapolating from a small sample may

introduce a large error in the results. Therefore, fixed

energy measuring tools are more recommendable than the

mobile logger to collect data from the main and auxiliary

engines.

V.

CONCLUSIONS

Fishing is fuel dependent. The increase in the fuel price

has made the future of this sector insecure. A proactive attitude

and measures are needed to overcome the present difficulties.

Energy audits may play an important role in this approach, to

establish the energetic condition of the vessel and its activity.

Whereas energy audits in fishing are limited, in shipping, they

are common. Shipowners and shipping associations have

become proactive and have started collective actions, research

and implementations, which help combating the effects of

climate change on shipping [17]. The fishing industry needs to

be established at the same level. Besides having the problems

with the price of the fuel, additional problems may affect

fishing in the future, e.g. the IMOs regulation on greenhouse

gas emission (Annex VI of MARPOL which is regulated by the

Annex VI of MARPOL 73/78). Energy audits will permit an

improvement in the pollution of vessels, to be in a better

position to overcome additional legislation in the future.

A methodology to undertake energy audits has been

presented. Likewise, the main results of an energy audit along

with the potential energy efficient measures have been showed

also. These measures have been formulated for the three

audited vessels; nonetheless, they can be considered for

possible inclusion in all energy audits. However, it must be

noted, that each vessel behaves differently, despite operating

with the same fishing gear. Therefore, an energy efficient

solution for one may not be adequate for another vessel. None

of these technical recommendations is possible, without

undertaking an energy audit of the vessel. Furthermore, purse

seiners and trollers have very irregular fishing journeys. Hence,

data collection would need to accommodate these irregularities.

The minimum data required will not necessarily be the same

for all cases. Sampling a minimum of three voyages is

recommended, to achieve a realistic result. Likewise, installing

energy meters and an energy management system, such as the

GESTOIL system, is recommended strongly for all vessels,

but especially for purse seiners and trollers due to their

irregularities (in terms of length of voyage).

ACKNOWLEDGMENTS

The work presented in this contribution has been supported

by the European Fisheries Fund (ref. 351BI20090040). We

would like to express our sincere gratitude to: the shipowners,

skippers and crew of the three audited vessels for their helpful

support in this project; to Iigo Krug and Jose Mari Ferarios

(AZTI-Tecnalia), for their knowledge and help during the data

collection in the fieldwork; and to Prof Michael Collins

(IKERBASQUE, Basque Foundation for Science, Fellow (PIE,

UPV/EHU)) for his helpful comments.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

FAO, "Fishing gear and methods. 2012 20/02/2012]; Available from:

http://www.fao.org/fishery/topic/1617/en.

P.H. Tyedmers, R. Watson, and D. Pauly, "Fueling global fishing fleet",

Ambio, 2005, 34(8):635-638.

Lloyd's Register, "Ship Energy Services. 2010"; Available from:

www.lr.org/sectors/marine/Services/Consultancy/ES/.

G. Thomas, D. O'Doherty, D. Sterling, C. Chin, "Energy audit of fishing

vessels", Proceedings of the Institution of Mechanical Engineers, Part

M: Journal of Engineering for the Maritime Environment, 2010.

224(2):87-101.

S. Villarroya, M.J. Otero, L. Romero, J.C. Cotos, V. Pita, "Modular and

Scalable Multi-interface Data Acquisition Architecture Design for

Energy Monitoring in Fishing Vessels", Proceedings of the 10th

International Work-Conference on Artificial Neural Networks: Part II:

Distributed Computing, Artificial Intelligence, Bioinformatics, Soft

Computing, and Ambient Assisted Living 2009, Springer-Verlag:

Salamanca, Spain. pp. 531-538.

M. Thrane, "Energy Consumption in the Danish Fishery: Identification

of Key Factors", Journal of Industrial Ecology, 2004, 8(1-2): 223-239.

[7]

J. Parente, P. Fonseca, V. Henriques, A. Campos, "Strategies for

improving fuel efficiency in the Portuguese trawl fishery", Fisheries

Research, 2008, 93(1-2):117-124.

[8] K.E. Abernethy, P. Trebilcock, B. Kebede, E.H. Allison, N.K. Dulvy,

"Fuelling the decline in UK fishing communities?" ICES Journal of

Marine Science: Journal du Conseil, 2010, 67(5):1076-1085.

[9] J.D.K. Wilson, "Fuel and financial savings for operators of small fishing

vessels", Fisheries Technical Paper N 383, Food and Agricultural

Organization of the United Nations, FAO, Editor 1999: Rome, Italy.

[10] E.M. Schau, H. Ellingsen, A. Endal, S.A. Aanondsen, "Energy

consumption in the Norwegian fisheries", Journal of Cleaner Production,

2009, 17(3):325-334.

[11] O. Cabezas, J.M. Ferarios, J. Franco, G. Gabia, Z. Uriondo, "Desarrollo

e implantacin de auditoras energticas y actuaciones tcnicas para

optimizar la eficiencia energtica en buques de pesca" Report prepared

for the Deptarment of Agriculture, Fisheries and Food, Basque

Government, 2012, AZTI-Tecnalia: AZTI-Tecnalia, pp. 425.

[12] P. Tyedmers, "Fisheries and Energy Use", C.J. Cleveland (ED), The

encyclopedia of energy, Academic Press/Elsevier Science, San Diego,

2004, pp. 683-693.

[13] IEA, "World Energy Outlook 2008", World Energy Outlook 20082008,

OECD/IEA: Paris. p. 578.

[14] R. Latorre, "Reducing fishing vessel fuel consumption and NOX

emissions", Ocean Engineering, 2001, 28(6):723-733.

[15] J.M. Torres Palenzuela, L. Gonzales Vilas, E. Spyrakos, L. Rodriguez

Dominguez, "Routing optimization using neural networks and

oceanographic models from remote sensing data", 1st International

Symposium on Fishing Vessel Energy Efficiency, 2010, Vigo, Spain.

[16] UNE, UNE 216501:2009 Auditoras Energticas, 2009, AENOR.

[17] R. Asariotis, "Climate change impatcs on international transportation

and adptation", Oral presentation at RiMER (Research in Marine

Environment and Resources), Donostia-San Sebastin, Spain, 31

January-10 February 2012.

You might also like

- Raft TT FT FT FT FT AFT AF RAFDocument31 pagesRaft TT FT FT FT FT AFT AF RAFHugo Silva100% (1)

- FMO Training Programme Manual - Stage 1 - ForwarderDocument63 pagesFMO Training Programme Manual - Stage 1 - ForwarderHugo SilvaNo ratings yet

- Simulation of Flow Around KCS HullDocument11 pagesSimulation of Flow Around KCS HullMilovan PericNo ratings yet

- Ridgely-Nevitt C.resistance of A High.1967.TRANSDocument28 pagesRidgely-Nevitt C.resistance of A High.1967.TRANSTi AnnelNo ratings yet

- Shallow Water Resistance Charts For Preliminary Vessel DesignDocument18 pagesShallow Water Resistance Charts For Preliminary Vessel DesignshahjadaNo ratings yet

- Mosaad 86 PDFDocument294 pagesMosaad 86 PDFdoğancan uzunNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Optimization of Fishing VesselDocument11 pagesOptimization of Fishing VesselLucas GuesseNo ratings yet

- Part 3 - 5.mooring FacilitiesDocument49 pagesPart 3 - 5.mooring FacilitiesIlham Hussein RasyidNo ratings yet

- Sistema RSW-CSWDocument8 pagesSistema RSW-CSWDiego Trinidad100% (1)

- Volume IIDocument246 pagesVolume IIathanasios niotisNo ratings yet

- 04 NAC Initial Transverse Stability (160213)Document21 pages04 NAC Initial Transverse Stability (160213)Gilles MathieuNo ratings yet

- STA Article 30jan2013 PDFDocument11 pagesSTA Article 30jan2013 PDFpriyoNo ratings yet

- Intact StabilityDocument1 pageIntact StabilityislimaNo ratings yet

- Predicting The Slamming Force On The HullDocument52 pagesPredicting The Slamming Force On The HullEgwuatu UchennaNo ratings yet

- The First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)Document5 pagesThe First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)pal_malayNo ratings yet

- 59m Ahts Addendum For Final Intact Stability Booklet - 91751918Document18 pages59m Ahts Addendum For Final Intact Stability Booklet - 91751918NHÓM 2 GTSNo ratings yet

- Numerical Simulation of Ship Motion Due To Waves and ManoeuvringDocument48 pagesNumerical Simulation of Ship Motion Due To Waves and ManoeuvringHung NguyenNo ratings yet

- An Overview of The Prediction Methods For Roll Damping of ShipsDocument22 pagesAn Overview of The Prediction Methods For Roll Damping of ShipsВасил ЙордановNo ratings yet

- Resistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) WhereDocument11 pagesResistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) Wheresupriadi90315No ratings yet

- GZ CurvesDocument30 pagesGZ CurvesAhtashamuddin Nizamudin100% (1)

- Visualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelDocument13 pagesVisualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelAnthonyNo ratings yet

- 3rd Paper Shallow Water Effect On Turning Motion of A Pusher Barge System Aphydro 2008Document8 pages3rd Paper Shallow Water Effect On Turning Motion of A Pusher Barge System Aphydro 2008kostas.michaNo ratings yet

- Naval Architecture DigestDocument19 pagesNaval Architecture DigestShivananda PatraNo ratings yet

- 1 s2.0 S0029801817301646 Main PDFDocument15 pages1 s2.0 S0029801817301646 Main PDFOdumoduChigozieUzomaNo ratings yet

- New IMO Requirements - 10th Edition - May 2004Document71 pagesNew IMO Requirements - 10th Edition - May 2004LucianNo ratings yet

- Seakeeping 19301en2 PDFDocument2 pagesSeakeeping 19301en2 PDFTullio OpattiNo ratings yet

- Thesis RGdeJongDocument108 pagesThesis RGdeJongNaval2014DNNo ratings yet

- Grain CodeDocument21 pagesGrain CodeNMHa100% (1)

- ENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Document5 pagesENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Luis De GraciaNo ratings yet

- TribonDocument16 pagesTribonSebastian100% (2)

- Hande - A Computer-Aided Design Approach For Hydrofoil ShipsDocument11 pagesHande - A Computer-Aided Design Approach For Hydrofoil Shipsjwpaprk1No ratings yet

- NAPA Session1Document21 pagesNAPA Session1amialokNo ratings yet

- PHD Wicaksono 2019 PDFDocument145 pagesPHD Wicaksono 2019 PDFEric KulbiejNo ratings yet

- Motor Yacht Hull Form DesignDocument16 pagesMotor Yacht Hull Form Designale barbNo ratings yet

- Design Optimization of The Lines of The Bulbous BowDocument12 pagesDesign Optimization of The Lines of The Bulbous BowFernando Raúl LADINONo ratings yet

- A Practical System For Hydrodynamic Optimization of Ship Hull FormsDocument7 pagesA Practical System For Hydrodynamic Optimization of Ship Hull FormsSalma SherbazNo ratings yet

- Metacentre & Metacentric Height of A Ship (02042020)Document3 pagesMetacentre & Metacentric Height of A Ship (02042020)Xahid HasanNo ratings yet

- Ultramarine Moses CrackDocument3 pagesUltramarine Moses CrackpothirajkalyanNo ratings yet

- Automated Marine Propeller Design Combining Hydrodynamics Models and Neural NetworksDocument10 pagesAutomated Marine Propeller Design Combining Hydrodynamics Models and Neural NetworksPoowadol NiyomkaNo ratings yet

- Slamming Experiments On A Ship Model: Rousset J.-M., Pettinotti B., Quillard O., Toularastel J.-L., Ferrant PDocument4 pagesSlamming Experiments On A Ship Model: Rousset J.-M., Pettinotti B., Quillard O., Toularastel J.-L., Ferrant PmroghaniNo ratings yet

- Abyc H4Document12 pagesAbyc H4NavalcatNo ratings yet

- 03 The Ship Design ProcessDocument10 pages03 The Ship Design Processw12n_sbyNo ratings yet

- Energy Saving Basics - EsdsDocument40 pagesEnergy Saving Basics - Esdsapi-238581599No ratings yet

- Rudders: Semi Balanced Rudder Semi Balanced Rudder With Rudder HornDocument10 pagesRudders: Semi Balanced Rudder Semi Balanced Rudder With Rudder Hornsunil1237No ratings yet

- Test Ii: WPA Volume Mid Area LWLDocument9 pagesTest Ii: WPA Volume Mid Area LWLMark Lester AndayaNo ratings yet

- U-Botten RevDocument10 pagesU-Botten RevJunaid JavaidNo ratings yet

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDDocument10 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDcataiceNo ratings yet

- Assignment 1 (Ship Resistance)Document1 pageAssignment 1 (Ship Resistance)KikiNo ratings yet

- Ballast Free Ship DesignDocument3 pagesBallast Free Ship DesignAnonymous UCveMQNo ratings yet

- Seakeeping CommitteeDocument56 pagesSeakeeping CommitteeTullio OpattiNo ratings yet

- Shipboard Mooring Equipment: Course No. 12Document39 pagesShipboard Mooring Equipment: Course No. 12Dan CobeliNo ratings yet

- Stability of CatamaransDocument8 pagesStability of CatamaransVinayak29No ratings yet

- 09-NAC-Numerical Integration Method (171229) - Student PDFDocument41 pages09-NAC-Numerical Integration Method (171229) - Student PDFMehedi Hossain MithilNo ratings yet

- An Experimental and Theoritical Study of Planning Surfaces With Trim Flaps PDFDocument63 pagesAn Experimental and Theoritical Study of Planning Surfaces With Trim Flaps PDFGhalih Rasyid Prayogo100% (1)

- A Methodology For A Hydrodynamic Analysis of A Moonpool Structure With Mooring Lines Using The ANSYS AQWA ProductDocument25 pagesA Methodology For A Hydrodynamic Analysis of A Moonpool Structure With Mooring Lines Using The ANSYS AQWA ProductRuly IrawanNo ratings yet

- Dimensional Constraints in Ship DesignDocument6 pagesDimensional Constraints in Ship DesignTat-Hien LeNo ratings yet

- ITTC - Recommended Procedures and GuidelinesDocument20 pagesITTC - Recommended Procedures and Guidelinesaun7328No ratings yet

- Windship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985From EverandWindship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985C SatchwellNo ratings yet

- Training Simulator: Heads Above The CompetitionDocument4 pagesTraining Simulator: Heads Above The CompetitionHugo SilvaNo ratings yet

- Cmu Hiab 190TM-6Document2 pagesCmu Hiab 190TM-6Hugo SilvaNo ratings yet

- Formec Proceedings 2015 Web PDFDocument530 pagesFormec Proceedings 2015 Web PDFHugo SilvaNo ratings yet

- Hansson - Servin - Semi-Autonomous Shared Control For Redundant Forwarder CranesDocument107 pagesHansson - Servin - Semi-Autonomous Shared Control For Redundant Forwarder CranesHugo SilvaNo ratings yet

- Declaration of Honour PTDocument3 pagesDeclaration of Honour PTHugo SilvaNo ratings yet

- Lista de Clasificación Energética de TractoresDocument18 pagesLista de Clasificación Energética de TractoresHugo Silva100% (1)

- MED 2015 EnglishDocument15 pagesMED 2015 EnglishHugo SilvaNo ratings yet

- Murrel Farming PDFDocument10 pagesMurrel Farming PDFshridhanNo ratings yet

- What Is AquacultureDocument10 pagesWhat Is AquacultureGoos HanNo ratings yet

- Argumentative EssayDocument2 pagesArgumentative EssaykaylaNo ratings yet

- TCE TackleDocument1 pageTCE TacklewapamaNo ratings yet

- ROR Flashcard Quiz 3 - Captain DamleyDocument26 pagesROR Flashcard Quiz 3 - Captain DamleyReyNo ratings yet

- Module 4 CompilationDocument16 pagesModule 4 CompilationErine ContranoNo ratings yet

- Lizard Island MapDocument1 pageLizard Island MapEric HoNo ratings yet

- Reducing Gill-Net Mortality of Incidentally Caught Coho SalmonDocument6 pagesReducing Gill-Net Mortality of Incidentally Caught Coho SalmonTri LaelaNo ratings yet

- Vestrics SAP SeaFood India 15th May 2018Document63 pagesVestrics SAP SeaFood India 15th May 2018Yakshit JainNo ratings yet

- What Is in A TangabDocument16 pagesWhat Is in A TangabOrange LemonNo ratings yet

- Employment Contract of Commercial Vessel's FishermanDocument6 pagesEmployment Contract of Commercial Vessel's FishermanCarlota TejeroNo ratings yet

- Ultegra 14000Document1 pageUltegra 14000wizunuNo ratings yet

- Inca Product BrochuresDocument60 pagesInca Product BrochuresGerryNo ratings yet

- Calculating & Cutting TapersDocument26 pagesCalculating & Cutting TapersTiago Catuxo100% (2)

- E5 01A ThemeContentsDocument24 pagesE5 01A ThemeContentsmohammadNo ratings yet

- Fishing IndustryDocument4 pagesFishing IndustryMinahil Fatima ShahNo ratings yet

- TSF - May 2016Document100 pagesTSF - May 2016Dennis ShongiNo ratings yet

- Factsheet On Sea LiceDocument2 pagesFactsheet On Sea LiceJon Arne GrøttumNo ratings yet

- Manitoba Aquatic Invasive Species Summer ChecklistDocument2 pagesManitoba Aquatic Invasive Species Summer Checklistizabella melendezNo ratings yet

- Full Download Test Bank For Political Science An Introduction 12 e Michael G Roskin Robert L Cord James A Medeiros Walter S Jones PDF Full ChapterDocument35 pagesFull Download Test Bank For Political Science An Introduction 12 e Michael G Roskin Robert L Cord James A Medeiros Walter S Jones PDF Full Chaptershaps.tortillayf3th100% (22)

- Light Fishing ReviewDocument21 pagesLight Fishing Reviewfadhilah wahdahNo ratings yet

- 2016 Canary Yelloweye ID FlyerDocument2 pages2016 Canary Yelloweye ID FlyeraninnaNo ratings yet

- Analisa Kebijakan Agro IndustriDocument18 pagesAnalisa Kebijakan Agro IndustriMei Edi PrayitnoNo ratings yet

- Fish Harvest Town Wiki FandomDocument1 pageFish Harvest Town Wiki FandomraenoseNo ratings yet

- RhethDocument77 pagesRhethIndAqua Information PortalNo ratings yet

- Fishing Geography NotesDocument16 pagesFishing Geography NotesHamza Yousuf86% (7)

- Report On Student'S Industrial Work Experience Scheme (Siwes)Document5 pagesReport On Student'S Industrial Work Experience Scheme (Siwes)BroadsageNo ratings yet

- Proposed Rule: Fishery Conservation and Management: Alaska Fisheries of Exclusive Economic Zone— Pacific Halibut and SablefishDocument19 pagesProposed Rule: Fishery Conservation and Management: Alaska Fisheries of Exclusive Economic Zone— Pacific Halibut and SablefishJustia.comNo ratings yet

- Rune Factory 3Document234 pagesRune Factory 3Sinbad Alfin PelautNo ratings yet

- Xii CGDocument59 pagesXii CGSyed Mairaj Ul HaqNo ratings yet